Abstract

Good practices are among the direct/indirect components that influence agrofood safety knowledge, and occupying quality assurance control facets within the (agrofood) product industry. Cleaner production involves an integrated preventive environmental strategy applied to processes, products, and services, which increases overall efficiency, and reduces risks to humans/environment. However, ‘cleaner food production’ appears neither yet clearly defined nor well established. In this preliminary survey analysis, how good practices would contribute towards achieving cleaner food production in the context of food retail sector was performed. Specifically, Wrocław-Poland served as a case reference targeting managers/supervisors given their expected service, experience, and expertise. The sampling technique used was the judgment/purposive type, and the research instrument took the form of a questionnaire. Managers’/supervisors’ responses revealed significant differences (p < 0.05) across variables, with ‘yes’ emerging greater in most cases. Knowledge, experience, and expertise of good practices enabled the managers/supervisors connect with (some) cleaner production components. A total of 53 statistically significant correlations were found, wherein some showed perfect linear relationships. Specific to the context of (food) retail sector, the term “cleaner food production” could be defined as “the effective and efficient utilization of good practices to deliver high-quality food retail products through environmental-friendly as well as sustainable processes”.

1. Introduction

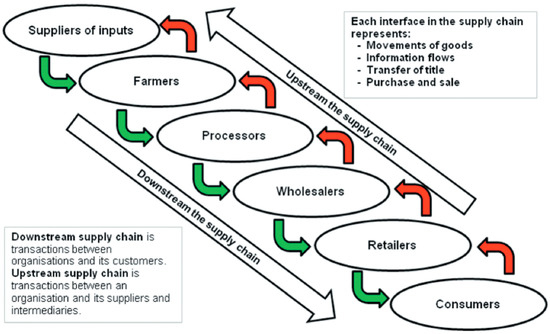

The agrofood product supply chain remains very complex, with produce channels that are either direct or outside given localities [1,2,3]. Given the ever-increasing global population competing for the available agrofood resources, there continues to be increased efforts to sustain (agrofood) systems for the future [4]. A diagrammatic representation of a typical agrofood product supply chain is shown in Figure 1, which reveals how goods and services move from consumers to suppliers. The actual stage of product development depends on (product) type, from simple (for instance, a locally produced meat product) to complex (for instance, ingredients of a final meat product that can be obtained from different parts of the globe) [3]. Whereas the downstream flow involves the development of agrofood products within, the upstream flow involves the information from the end of the supply chain. More so, contracts that emanate from customers would allow the assembly of required inputs from different parts of the upstream chain [3]. In Europe, for instance, countries including France, Germany, Poland, and the UK possess very promising records of high-quality food retail outlets [5]. In Poland specifically, over the past decades, a number of challenges have been encountered by (Polish) enterprises, especially in adapting and adhering to the EU requirements involving agrofood production, from crop to livestock standpoints [6,7]. Despite the fluctuations that persist in the global supply chain, for a given manufactured food product to be realized at the market shelf would require in many cases a wide range of operations [8].

Figure 1.

A diagrammatic representation of a typical agrofood product supply chain. From the consumers to the suppliers, the downstream (green) and upstream (red) direction flow of transactions takes place within the supply chain (Source: Costa-Font & Revoredo-Giha, [4]; Open access platform of London School of Economics Business Review).

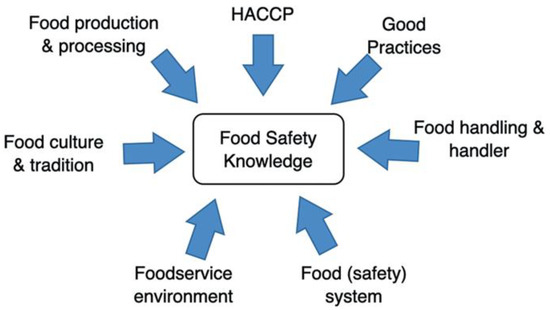

Good practices, among the direct/indirect components that influence product safety knowledge within the agrofood industry, as shown in Figure 2, provide a strong foundation for handling both materials and their associated processes [3,9]. Despite occupying various quality assurance control facets within the food production pathway, good practices are of various types, namely: good agricultural practice (GAP), good catering practice (GCP), good hygiene practice (GHP), good manufacturing practice (GMP), good retail practice (GRP), good storage practice (GSP), and good transport practice (GTP) [3,10,11,12]. If good practices were to be viewed from a typical food operation unit to the broader spectrum of the food industry, three categories would emerge, namely: (a) those directly connected with food technology, e.g., GMP; (b) those directly connected with either food challenges, issues and or problems, e.g., GRP, GTP; and (c) those that deal with all activities concerning food handling, e.g., GHP [10,13]. Understanding the various good practices and their functions is necessary if the integrity of food safety and consumer protection within the agrofood product industry is to be consolidated [3,11]. Notably, the importance of food safety was tested during the global COVID-19 pandemic [14], wherein various aspects of the agrofood product industry, especially the retail sector, had to step up the quality delivery of their good practices. Notwithstanding this, an increased incidence occurrence, as well as an increased severity of foodborne pathogens, would still occur because of various negative operational activities, such as unsafe food sourcing, inadequacies in (food) processing, and cross-contamination [3,15]. That is why the agrofood product industry continually persists in discovering innovative strategies that improve consumer protection/food preservation [16].

Figure 2.

Key direct/indirect components that influence food safety knowledge (Source: Okpala and Korzeniowska [3]; Permission to use given by Taylor and Francis Ltd.).

United Nations Environment Programme (UNEP) defines “cleaner production” as “the continuous application of an integrated preventive environmental strategy to processes, products, and services to increase overall efficiency, and reduce risks to humans and the environment” [17]. In addition, the broad scope of cleaner production involves such areas as energy efficiency, environmental nexus, green sustainable chemistry, building construction, improved material handling, and toxic substances reduction, as well as waste elimination/management [18]. Sustainability change drivers that build cleaner production, according to Deprá et al. [19], strongly associate with the food production chain, which includes: (a) biophysical and environmental aspects; (b) innovation and technology aspects; (c) economic and market aspects; (d) institutional and political aspects; and (e) demographic and socio-cultural aspects. However, the concept of ‘cleaner food production’ in the scientific literature still appears to be not yet fully defined. Before this specific contribution, the author herein could only find three publications that specifically used ‘cleaner food production’ in their titles, which included the works of Xu et al. [20], Hou et al. [21], and Ding et al. [22]. Firstly, Xu et al. [20] presented cleaner food production as an approach in their investigation of three rice production modes in Panjin city, surrounding the Liaohe River in Northeast China. Secondly, Hou et al. [21] posited that rice-crayfish systems would not be a panacea for sustaining cleaner food production, which these workers deduced via economic and emergy analysis, together with nutrient use efficiency analyses of three rice production modes. Thirdly, Ding et al. [22] attempted to sustain cleaner food production via an optimized ratoon rice system in Jianghan Plain-China, regarding which these workers explained using a comprehensive emergy assessment. Contextualizing the three above-mentioned published works, could ‘cleaner food production’ either directly or indirectly address at least some key fundamental (food and its related) quality safety challenges and concerns within the agrofood product industry, and at the same time, promote environmentally friendly as well as sustainable processes? Well-constructed formulated questions could help develop interesting and influential theories [23,24]. Therefore, could formulating appropriate questions, and posing them to key stakeholders within the agrofood industry serve as a way to actualize such meeting points? Therefore, to supplement existing information, this preliminary survey analysis sought to delineate how good practices could contribute to achieving cleaner food production in the context of the food retail sector. Specifically, the food retail shops/stores in Wrocław-Poland served as a case reference for targeting managers/supervisors given their expected service, experience, and expertise.

2. A Short Background Literature Review

In this section, the author herein has performed a short background literature review, which aimed to provide some foundation about how cleaner production connects with the agrofood industry. It also provides a foundation about how good practices occupy a space within the food retail sector. To achieve this, the following subsections are succinctly presented, namely: (a) cleaner production’s relevance to agrofood product industry; (b) good practices germane to food retail sector; and (c) consumer engagement, product stewardship, and waste management.

2.1. Cleaner Production’s Relevance to Agrofood Product Industry

Increasingly, in its broader concept, cleaner production continues to gain a reputation within the agrofood product industry [20,25,26,27,28], the latter being among the world’s largest sectors, occupying both domestic and industrial aspects of various countries. For instance, regarding food processing—part of the agrofood product industry contributes to organic pollution if designed with insufficient attention to the environment, which reiterates the importance of cleaner production [27]. A summary of some cleaner production implementations involving diverse sectors of the agrofood product industry specific to research focus, region of study, and (research) strategy, is shown in Table 1. Moreover, cleaner production research focus and strategy would vary across the agrofood product industry. For instance, cleaner production audit/methodology [29,30,31] and emergy analysis [20], together with case and survey studies [25,26,28], were shown in Table 1 among the research strategies. In addition, the majority of the above-mentioned cleaner production studies demonstrated, from recommendation options, an effective use of (cleaner production) checklist(s), foundations required for developing incentive schemes, and policy reforms and strategies, spreading across various regions of the globe.

Table 1.

Summary of some cleaner production implementation involving diverse sectors of the agrofood product industry specific to research focus, and region of study, as well as (research) strategy.

In addition to Teller et al. [28], as shown in Table 1 determining the root cause of (food) waste occurrence in a food retail store, ‘cleaner food production’ appeared in the title of work conducted by Xu et al. [20] that considered the environmental and economic performance of three rice production modes in Panjin city, surrounding Liaohe River in Northeast China. Indeed, cleaner production has complex interactions with economic and social performance [32]. Despite these, its relevance to the agrofood industry, on one hand, should not be limited to waste elimination, water management, energy efficiency, and so on [33,34], but ought to extend to useful quality safety activities of food production processes. On the other hand, there could be environmental risks associated with the entire agrofood system, and associated with some inefficiencies (e.g., food loss, food waste, contaminations, etc.) [35,36,37]. With respect to the agrofood industry, however, Okpala, Korzeniowska, and Guiné [38] opined that in addition to the food product development pathway entailing major steps, there should be areas where good practices in food product development could help motivate consumers. Moreover, Fresner [39] understood that cleaner production, especially as a management strategy, may well initiate continuous improvement/prevention approaches with the end goal of saving the environment.

2.2. Good Practices Germane to Food Retail Sector

The agrofood product industry has to ensure affordable hazard measures for food (product) safety and (food) safety instruments, which facilitate the progress of local food management strategies [3,40]. Given the Codex Alimentarius Commission’s code of practice for fruits and vegetables (CAC/RCP 53-2003), GAP has codes, standards, and regulations that have helped to curtail farm-level hazards before, during, and or after production [3]. Methodically, GAP identifies risks associated with individual fruits and vegetables based on available scientific data [41]. Within food safety and quality assurance, GCP identifies practical catering essentials/procedures in food processing, ensuring that they are displayed together with prepared items for consumption, remaining wholesome and safe [11,42]. GHP guidelines specify the monitoring of hygiene responsibilities within the food supply chain [43]. Both above-mentioned instances of GCP and GHP are applicable to the meat industry, and such guidelines would specifically constitute practical processes that return the work environment to its original condition and standard [10]. Under the EU hygiene regulation directive, for instance, the GHP makes the consumer directly responsible for food safety, despite the flexibility associated with the agrofood industry stakeholders in meeting their statutory obligations [44].

Applicable to the food retail sector, the agrofood products that require refrigeration would require GMP that involves (food product) development, processing, and marketing phases [45]. On one hand, the quality of GMP is the standard for operating procedures (SOPs) that serves as a guiding principle for agrofood product development [3]. To reduce food hazards and risks, on the other hand, GHP provides adequate specifics about food handling, preparation, and storage procedures [3]. More so, especially within the food retail sector, GRP would incorporate procedures and processes that ensure the delivery of requested (food) product(s) to the correct address within the satisfactory time period and under the required conditions [10]. Specific to the food retail industry, GRP would sustain the required (food) safety level through the following categories: (a) certification/training of managers; (b) cleaning and sanitation practices; (c) food storage conditions; and (d) temperature/time controls [15]. Overall, good practices would interconnect within the various aspects of the food processing industry. For example, GCP sometimes finds itself embedded in GHP [46], whereas GHP and GMP could also be part of GRP.

2.3. Consumer Engagement, Product Stewardship, and Waste Management

Consumer engagement, relevant in achieving cleaner production, is among the useful areas within the food retail sector which link to (consumer) behavior. To encourage behavioral change, Azapagic et al. [47] considered consumer engagement activities as very purposeful. Indeed, before either addressing or initiating any pressing environmental problem, consumer/individual well-being together with societal development is prioritized. To envision consumption as social activity/perceived need, there is a need for the active engagement of consumers so as to better their quality of life [48]. Importantly, across various sectors, consumer engagement platforms would associate with efficiency improvements that bring about (desirable) program successes [49]. Moreover, product stewardship within the agrofood industry would be demonstrated by responsible management, especially in situations where implementing a product lifecycle ranging from discovery, through manufacturing, to disposal stages, requires regulatory frameworks [50,51]. Further, product stewardship would assume the form of shared responsibility between organizations [52], for instance, within a given packaging supply chain. Indeed, product stewardship strategies, as reflected by stakeholders’ perspectives, can integrate external environmental pressures into the product design and developmental processes [50]. Crucially, the success of cleaner production is unrealistic without human involvement and support. Empowering employees together with creating performance evaluation and reward systems should enhance the effectiveness of cleaner production [53]. Preferably at the time of waste disposal, as well as during the product design, (waste) production, and transport, etc., the policies associated with (product) stewardship would encourage built-in incentives/mechanisms that minimize the environmental impact [54].

In addition, when identifying dominant topics appearing in the “Journal of Cleaner Production”, Schober et al. [55] showed food production together with food-service-waste as being among the ten most characteristic topics. The concept of “food” would clearly appear with great importance in both food production and food service waste. Broadly, waste management, despite its complexities, is considered part of the generation, collection, and disposal system. In addition, implementing an effective waste disposal system requires an integrated approach, especially in the context of a sustainable society [56]. Global consumption and population within the past decade have increased with solid wastes, largely generated by the food industry [57]. More so, grocery retail sectors would produce substantial amounts of food waste, very critical to supermarkets given the negative socio-economic and environmental implications. In addition to the characterization and quantification of food waste streams, managerial attitudes and approaches to food waste mitigation are critical [58]. Elsewhere, other workers consider cleaner production as a voluntary approach to reduce waste [59].

3. Survey Methodology

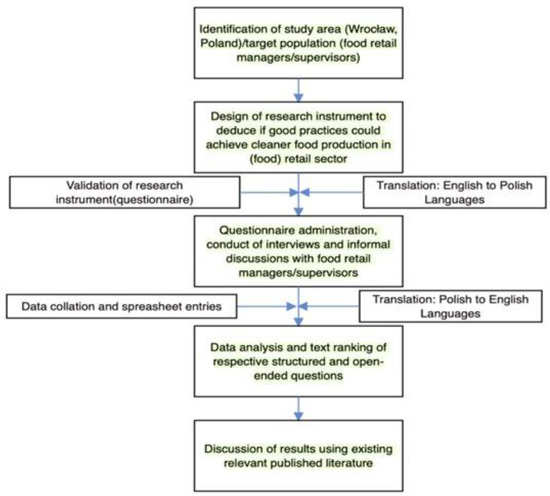

3.1. Schematic Overview of Current Survey

The schematic overview of the current survey, from the identification of the study area/target population and the design of the research instrument, through to the questionnaire administration, data analysis, and discussion of the results using the relevant published information, is shown in Figure 3. This current survey seeks to delineate the degree to which good practices would contribute to cleaner food production specific to the context of the food retail sector. Further, the increasingly thriving food retail shops/stores in Wrocław-Poland [60] served as a case reference, specifically targeting their managers/supervisors given their expected service, experience, and expertise.

Figure 3.

The schematic overview of the current preliminary survey, from the identification of the study area/target population and design of the research instrument, through to the questionnaire administration, data analysis, and discussion of results using relevant published information.

3.2. Ethical Considerations

As this current survey was strictly questionnaire-based, institutional ethics approval was not required. However, informed consent was orally obtained, confirmed by a request for permission to participate as stated on the first page of the questionnaire made available to all participants of this study. Consistent with the code of ethics of the World Medical Association Declaration of Helsinki, participants of this study were voluntary [61].

3.3. Survey Area, Sampling Technique, and Target Population

The area of focus in this current survey was the Wroclaw metropolis, situated in Lower Silesian Voivodeship, Poland. More so, the Wroclaw metropolis occupies the coordinates of latitude 51°06′00″ N, and longitude 17°01′59″ E, with a population of over 600,000 inhabitants [62,63]. The sampling technique used for this preliminary survey was the judgement/purposive type; the managers/supervisors of food retail shops/stores were targeted given their expected service and experience, as well as expertise. More so, the food retail shops (and their respective managers/supervisors) were holistically representative of others found at other places elsewhere in Poland in terms of their size, volume of responsibilities, and workforce.

3.4. Development of Research Instrument

The research instrument took the form of a questionnaire, which incorporated the author’s combined specialist experience, expertise, and knowledge, additionally supplemented with the synthesized relevant literature [64]. To ensure the questions presented in the research instrument (that is, the questionnaire) were authentic and reliable, content validation, as highly recommended by Taherdoost [65], was employed. Specifically, the content validation process was implemented by a food retail sector expert with many years of work experience. The content validation process involved a critical evaluation of the research instrument, which allowed for useful amendments to be made, as deemed most appropriate. This process helped to enhance the relevance of the survey questions, which constructively aligned with the research objective and context [65]. Two native Polish speakers with a strong command of the English language were recruited to expertly perform not only the translation and re-translation of the research instrument from English to Polish, and thereafter from Polish to English, but also the conduction of the interviews and recording of the responses. Throughout the translation process, the content and context of the questions, as well as their corresponding responses, were adequately maintained.

3.5. Survey Questions, Food Retail Workday, and Interview Activity

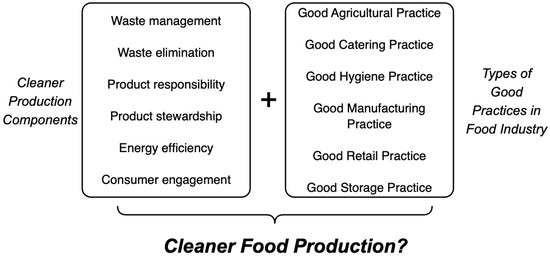

In the questionnaire shown to the managers/supervisors, Figure 4 was presented on the front page, followed by survey questions on the subsequent page. Specifically, there were a total of 11 questions, which included: (a) Do you believe good practices are essential to your food retail shop? (b) Do you believe good practices provide a foundation for agrofood product quality? (c)Are there any cleaner production components (Refer to Figure 4) you identify with?’ (d) Do you apply any of the cleaner production components(Refer to Figure 4) in your food retail shop? (e) Do you engage with customers that come into your food retail shop? (f) Do you think the presence of customers helps improve your overall work efficiency in the food retail shop/store? (g) Are you responsible for customers as well as product safety in your food retail shop? (h) Do you share responsibilities in your food retail shop? (i) Are there any waste disposal challenges that you encounter at your food retail shop/store? (j) Are both the manager and management involved in the waste elimination process at this food retail shop/store? (k) Based on the above-mentioned questions, would you consider the utilization of cleaner production in the food retail shop/store to be useful?

Figure 4.

Could it be possible for cleaner production components and types of good practices in the food industry to either combine or at least meet to form “cleaner food production”?

When Figure 4 was shown to the managers/supervisors, this question was verbally presented to them: “Could it be possible for cleaner production components and types of good practices in the food industry to either combine or at least meet to form “cleaner food production?” As the managers/supervisors reflected on the figure and the question verbally posed to them, they perused the survey questions, of which there were 11 in total. The survey questions required either ‘yes’, ‘no’, or ‘not sure’ responses. An open-ended option was provided to allow for some informal discussions with the managers/supervisors. From the author’s previous survey experience [64], the number of survey questions in this current work was considered appropriate and sufficient so as not to deter the food retailer managers’/supervisors’ participation.

A total of eighty-five (N = 85) food retail managers/supervisors at their respective shops/stores were interviewed during the survey period, and none participated more than once. Chiefly, a typical workday of a food retail store manager/supervisor(alongside their respective co-workers) starts with a security inspection to ensure that the shop whilst closed remained intact. There is also general housekeeping, which involves a quick brushing/mopping of the floor, checking for any kind of spillages and situations that could pose safety hazards at the workplace, and an operational perusal of the shop’s/store’s electronic and electrical appliances. There is also the point of sale (POS) check, which may follow the evaluation of stock, either to place or replace new items, check expiry dates, appropriate price tags of food products on the shelves, etc.

The interview process involved several visits to various food retail shops/stores around Wrocław-Poland, which cumulated the data collection period that lasted a total of 12 weeks. The idea was to interview one manager/supervisor per food retail shop. The criteria for selecting a retail shop/store were that it must have both fresh and packaged food items, which included any form of meat products. During the interview process, the food retail store managers/supervisors, in most of their responses to the questions, engaged effectively via informal discussions when they were either at work or had already accomplished their expected daily tasks. Neither the names, gender, or personal information of the managers/supervisors, nor those of their respective shops, were asked for. This helped to enhance their participation together with the provision of non-biased information as much as possible. The interview times at the food retail stores were varied because they were dependent on the managers’/supervisors’ availability and convenience. There were instances where the food retail managers/supervisors were very occupied and could not attend to all of the questions and requested the interviewers to return on another day. In addition, there were other instances where the managers/supervisors showed some reluctance to provide responses to some questions despite their willingness to participate. When such instances transpired, the interviewers did not pressure the managers/supervisors but gratefully accepted their efforts given their willingness to participate despite their very occupied schedules.

3.6. Statistical Analysis

The emergent data, having fulfilled the assumptions of non-parametric distribution, were subject to the Kruskal-Wallis(K-W) analysis of variance(ANOVA) test, which established the statistical significance between the response variables. The results of the analyzed data were presented via frequencies, percentages, p-values, and K-W statistics. When the correlation was needed, Spearman’s test was implemented and reported via correlation coefficient (r) and probability (p) values. The probability level for statistical significance was set at p < 0.05 (95% confidence). GraphPad Prism version 9.4.1 (458) for macOS (GraphPad Software LLC, San Diego, CA, USA) was used to run the statistical analysis. The open-ended responses were categorized using a word-based technique, previously described by Okpala, Nwobi, and Korzeniowska [64], with slight modifications. This involved the sorting of the actual text responses provided by the food retail managers/supervisors to identify a specific theme, thereafter being tallied to ascertain the frequency of these occurrences, which were subsequently reported in percentages.

4. Results and Discussion

4.1. Managers’/Supervisors’ Responses to Question

Deducing the knowledge base of food retail supervisors/managers specifically related to their good practices, and how this is utilized to achieve cleaner food production, would require the use of appropriate open-ended questions. Table 2 presents the managers’/supervisors’ responses concerning the extent to which their good practices would contribute to achieving cleaner food production in their respective (food) retail sectors/shops. Significant differences were found across response variables (p < 0.05), with ‘Yes’ being greater in most cases. However, the response of ‘no’ seemed greater only regarding waste disposal challenges in the food retail shop. Cleaner production components that the respondents identified more with, as well as engaging with customers that come to the food retail shop/store, both obtained the highest K-W statistic (70.37), whereas the manager and management involvement in the waste elimination process, obtained the least (40.82). This may well suggest the managers/supervisors in this current study considered cleaner production components that they identified more with to be equally as important as engaging with customers that come to their food retail shops/stores. Importantly, the K-W statistic remains among the most robust and valid means of ranking variance differences [66]. Whether differences between given groups occur by chance or are genuine, the K-W statistic would capably provide a way out by comparing the sample with population curves, which forms the basis of the H-test that aims to ascertain the same form of distribution between samples and the population [67].

Table 2.

Managers’/ supervisors’ responses to questions about the extent at which their good practices would contribute to achieving cleaner food production in their respective (food) retail sectors/shops.

With respect to the (food) retail sector, and applicable to other aspects of the food service industry, the integrity of food safety would be compromised if the job roles of those who assure quality were neither clearly defined nor well understood [3,11]. Further, imagine a situation wherein a given meat industry’s retail manager/supervisor underperforming at food safety designated tasks, the outcome could subject such enterprise to become increasingly vulnerable to the emergence of foodborne risks. Thus, there is a need for increased emphasis on good practices within the domain of consumer protection and food quality [3,11]. In the current survey, some respondents who indicated ‘yes’ for good practices being essential to the food retail shop (N = 52; 61.2%) did so because they considered it a mandatory activity to avoid being fired (N = 5; 9.6%); a duty/responsibility (N = 3; 5.8%); a way to keep everything (in the shop) clean and good looking for customers (N = 2; 3.9%); a method of providing (good practices) knowledge as an opportunity to educate other people (N = 1; 1.9%); a contribution to saving the environment/planet (N = 1; 1.9%); and a way to help the shop to grow (N = 1; 1.9%). Some respondents who indicated ‘yes’ regarding whether good practices provided a foundation for the agrofood product quality (N = 47; 55.3%) did so because it was deemed compulsory (N = 2; 4.3%); it was considered useful in ensuring a clean shop (N = 1; 2.1%), and it helped to create environmental awareness (N = 1; 2.1%). Indeed, good practices would cut across all key aspects of the (food) supply chain processes within the agrofood industry [3,9]. More so, both consumer engagement—being purposeful for achieving workplace improvement and product stewardship—that itself empowers employees, can collectively increase the effectiveness of cleaner production [47,49,52,53]

In this current survey, when the respondents were shown the cleaner production components (refer to Figure 4), some were able to identify with all of them (N= 60; 70.6%), which might suggest their managerial efficiency, proactivity, and productivity. From these, some respondents further indicated having applied all of the shown cleaner production components (N = 14; 60.9%), whereas for some others just a few were implemented (N = 9; 39.1%). The shown cleaner production components that some respondents were specifically able to identify with included waste management (N = 5; 8.3%), waste elimination (N = 3; 13.04%), energy efficiency (N = 2; 8.7%), and customer engagement (N = 1; 4.4%). This finding further connects the complex interactions associated with why its relevance to the agrofood industry should not be limited to energy efficiency, waste elimination, etc. [32,33,34]. Probably, the respondents demonstrating a reasonably good practice capacity could identify with some cleaner production components. This is where the concept of product stewardship plays a very important role, especially the involvement of responsible management that aims to implement waste disposal [50,51]. This is also why the food service industry has a significant role to play, especially in addressing the concerns of food waste [55]. In the current survey, a reasonable number of respondents engaged with customers in their food retail shops/stores (N= 66; 77.7%), some of whom attributed this to be among their corporate responsibilities (N = 12; 18.18%) and a component of their personnel work culture (N = 5; 7.58%), which would cumulatively enhance their communication skills (N = 2; 3.0%) and strengthen their customer support system (N = 9; 13.6%). More so, a reasonable proportion of the respondents considered the presence of customers to be a likely contributor to improving the efficiency of food retail shops/stores (N = 51; 60.0%). Through their knowledge of good practices, the respondents’ ability to apply some cleaner production components to their food retail shop/store probably helps to encourage customers to return (N = 5; 9.8%) and recommend the food retail shop to other customers (N = 6; 11.76%). Indeed, cleaner production evidently associates with economic, social, and environmental benefits to an organization’s activities, as well as the culture, especially when the target is to implement a short-to-long-term vision [59].

Quality, whether in terms of concept, content, or context, has to move from people through to the food technological processes, prior to being received by the consumer in a product on the market shelf [3,68,69]. In this current survey, a promising number of respondents demonstrated some responsibility regarding consumer and product safety specific to their food retail shop (N= 39; 45.9%), some of whom further engaged in such activities as cleaning the entire shop and its surroundings (N = 8; 20.5%) alongside checking the quality of food products (N = 8; 20.5%). Additionally, nearly half of the respondents indicated they shared some of their responsibilities (N = 37; 43.5%), wherein some believed it would expedite the daily work and ease the workload (N = 13; 35.1%). A reasonable number of respondents considered waste disposal not to be a challenge (N= 37; 43.5%), even though some others indicated otherwise (N = 14; 16.5%), from whom some specifically indicated the reason as being the inadequacy of disposal bins (N = 9; 64.3%). Further, a reasonable number of respondents indicated both managers’ and management’s involvement in the waste elimination process (N = 31; 36.5%). Moreover, Schober et al. [55] understood that ‘food’ is given very high importance in terms of food service waste, especially those that emanate from (food) retail shops/stores that need to be mitigated [58]. In addition, there were a number of respondents that considered cleaner production in food retail shops to be useful (N = 37; 43.5%), some of whom believed such knowledge would strengthen (food)product quality for the customers (N = 7; 18.9%), as well as demonstrate their corporate responsibility (N = 7; 18.9%). Notably, Stone [70] identified some key elements reflective of cleaner production uptake to actualize organizational change, culture, and key attitudes. With respect to organizational change, there were cleaner production options together with a recognition of the economic benefits. With respect to organizational culture, there were barriers from senior management to improving the environment, and the staff was encouraged to identify areas to improve the environment. With respect to key attitudes, reducing waste would require changing both products and processes.

4.2. Correlation Outcomes to “Yes” Responses

Given the nature of the managers’/supervisors’ ‘yes’ responses about how their good practices would contribute to cleaner food production, it was deemed necessary to find out whether any relationship existed between the various responses, and therefore, a correlation analysis was performed. The correlation outcomes between the ‘yes’ responses to questions from managers/supervisors regard how their good practices would contribute to cleaner food production, as shown in Table 3. There was a total of 53 statistically significant correlations, all of which were positive, from which some showed perfect linear relationships. For instance, in the food retail shop, although the good practices are an essential factor statistically correlated (p < 0.05) with the foundation of agrofood product quality (r = 0.787); the cleaner production components’ application (r = 0.664)/identification (r = 0.609); the presence of customers to improve (food retail) shop’s/store’s overall efficiency (r = 0.917); the responsibility of customers’ product safety (r = 0.604); the shared responsibility (r = 0.586); the challenges encountered during waste disposal (r = 0.249); and the usefulness of utilizing cleaner production (in the food retail shop/store) (r = 0.586), yet good practices being a foundation itself would strongly correlate with all of the above-mentioned elements. As the various good practices would adhere to standards/regulations [41,42,43], with the stakeholders within the agrofood industry having their responsibilities shared, the activities of customer engagement should help address not only the emerging socio-environmental concerns but also the incorporation of efficiency improvements and program successes [47,48,49].

Table 3.

Correlation outcomes between ‘yes’ responses to questions from managers/supervisors regards how their good practices would contribute to cleaner food production.

Another instance, and not surprising, is the fact that identification of cleaner production components were statistically correlated (p < 0.05) with its application (r = 0.918); the presence of customers to improve food retail shop’s/store’s overall work efficiency (r = 0.559); the managers/supervisors’ responsibility to customers/product safety (r = 0.368); and the shared responsibility (for the food retail shop/store) (r = 0.357); as well as the manager/management involvement in waste elimination process (r = 0.298). Largely, the application of cleaner production components would correlate positively with the others as well. Interestingly, engaging with customers in food retail shops/stores would demonstrate a perfect relationship (r = 1.000) with good practices being essential and the latter providing the foundation for agrofood quality and the identification of cleaner production components (p < 0.001). Interestingly also, engaging with customers in food retail shops/stores would demonstrate a perfect relationship (r = 1.000) with improving overall work efficiency, the responsibility of customer/product safety, the sharing of responsibilities, the waste disposal challenges encountered, the manager/management involvement in the waste elimination process, and the usefulness of utilizing cleaner production (p < 0.001). Clearly, the above-mentioned perfect association that involves engaging with customers in food retail shops/stores, specifically within the service delivery of managers/supervisors, further reiterates the interrelatedness of consumer engagement, product stewardship, and waste management. More so, the perfect correlation outcomes of the present work, as shown in Table 3, could cumulatively suggest why product stewardship contributes to shared responsibility, especially in the disposal as well as recycling of products at the end of the life cycle [50,51,52].

5. Conclusions

How good practices would contribute to achieving cleaner food production in the context of the food retail sector has been surveyed. For clarity, Wrocław-Poland served as a reference location, and the managers/supervisors were targeted given their expected service, experience, and expertise. Through their responses, the managers/supervisors demonstrated a capacity for understanding that good practices contribute towards achieving cleaner food production specific to the context of their food retail shops/stores. More so, the utilization of cleaner production in food retail would significantly associate with waste elimination. Despite the promising findings of this preliminary survey analysis, a limitation could be that not all of the survey questions were attempted by the participants. Nonetheless, there were a total of 53 statistically significant correlations, all of which were positive. The perfect correlation outcomes could cumulatively suggest why product stewardship contributes to shared responsibility, especially in the disposal as well as recycling of products at the end of life cycle.

Ultimately, ‘cleaner food production’ would suggest either directly or indirectly addressing at least some key fundamental (food and its related) quality safety challenges within the agrofood product industry, and at the same time, promoting environmentally friendly/sustainable processes. Therefore, considering the entirety of this current preliminary survey analysis, the ‘cleaner food production’ specific to the context of the (food) retail sector and service, could be defined as “the effective and efficient utilization of good practices to deliver high quality food retail products through environmentally friendly, as well as sustainable, processes”. More surveys that incorporate such elements as demography, education, experience, corporate responsibility, retailer classification, and types within the research space (independent shops, grocery, local chains, national chains, international chains, and market shares, etc.) are warranted, which should help to provide a wider context regarding the food retail sector, as well as strengthening the debate about ‘cleaner food production’. Additionally, more studies that bring together various “cleaner production” and “food technological” components are warranted, which should provide insightful knowledge and help increase the understanding that underpins “cleaner food production”.

Funding

This work was supported by Wrocław University of Environmental and Life Sciences (Poland) under the Ph.D. research program ‘Doctoral student grant at the Doctoral School of Wrocław University of Environmental and Life Sciences’ no: N020/0011/20. Publication financed by project UPWR 2.0: international and interdisciplinary programme of development of Wrocław University of Environmental and Life Sciences, co-financed by the European Social Fund under the Operational Program Knowledge Education Development, under contract no. POWR.03.05.00-00-Z062/18 of 4 June 2019.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Verbal consent was obtained from all managers/supervisors prior to their participation in this questionnaire-based study.

Data Availability Statement

Data is contained within the article. Additionally, due to project restrictions, the Polish translation of the survey questionnaire is not shared.

Acknowledgments

Author C.O.R.O. appreciates the funding support from Wrocław University of Environmental and Life Sciences, Poland.

Conflicts of Interest

The author declares no conflict of interest.

References

- Okpala, C.O.R. Towards Sustaining Global Food Systems for the Future. Front. Sustain. Food Syst. 2020, 4, 3. [Google Scholar] [CrossRef]

- Dora, M.; Kumar, M.; Goubergen, D.V.; Molnar, A.; Gellynck, X. Food quality management system: Reviewing assessment strategies and feasibility study for European food small and medium-sized enterprises. Food Control 2013, 31, 607–616. [Google Scholar] [CrossRef]

- Okpala, C.O.R.; Korzeniowska, M. Understanding the relevance of quality management in agro-food product industry: From ethical considerations to assuring food hygiene quality safety standards and its associated processes. Food Rev. Int. 2021, 39, 1–74. [Google Scholar] [CrossRef]

- Costa-Font, M.; Revoredo-Giha, C. COVID-19: The Underlying Issues Affecting the UK’s Food Supply Chains. LSE Business Review. Available online: https://blogs.lse.ac.uk/businessreview/2020/03/25/covid-19-the-underlying-issues-affecting-the-uks-food-supply-chains/ (accessed on 3 March 2023).

- Retail index, Rankings and Profiles of Food Retailers in Europe, America, Asia and Africa. Available online: https://www.retail-index.com/Sectors/FoodRetailersinEuropeandworldwide.aspx?gclid=CjwKCAjwztL2BRATEiwAvnALctKAmLM5vMA7bIRkBn978FBAqgbwlRWjEZUI9flzdxqMZ3gddVYx1BoCUlUQAvD_BwE (accessed on 2 June 2020).

- Buko, J.; Duda, J.; Makowski, A. Food Production Security in Times of a Long-Term Energy Shortage Crisis: The Example of Poland. Energies 2021, 14, 4725. [Google Scholar] [CrossRef]

- Trafialek, J.; Kolozyn-Krajewska, D. Implementation of safety assurance system in food production in Poland. Pol. J. Food Nutr. Sci. 2011, 61, 115–124. [Google Scholar] [CrossRef]

- Wrzesińska-Kowal, J.; Drabarczyk, K. Food production in Poland, compared to selected European Union Member states. Probl. World Agric. Probl. Rol. Swiat. 2014, 14, 205–214. [Google Scholar] [CrossRef]

- Varzakas, T.; Tzia, C. Handbook of Food Processing, Food Safety, Quality and Manufacturing Processes; CRC Press: Boca Raton, FL, USA, 2016; p. 676. ISBN 978-1-4987-2178-3. [Google Scholar]

- Raspor, P. Total food chain safety: How good practices can contribute? Trends Food Sci. Technol. 2008, 19, 405–412. [Google Scholar] [CrossRef]

- Raspor, P.; Jevšnik, M. Good Nutritional Practice from Producer to Consumer. Crit. Rev. Food Sci. Nutr. 2008, 48, 276–292. [Google Scholar] [CrossRef]

- Selmat, J.; Iqbal, S.Z. (Eds.) Food Safety: Basic Concepts; Recent Issues and Future Challenge Springer International Publishing: Cham, Switzerland, 2016; p. 164. ISBN 978-3-319-39253-0. [Google Scholar]

- Nedovic, V.; Raspor, P.; Levic, J.; Saponjac, V.T.; Barbosa-Cánovas, G.V. Emerging and Traditional Technologies for Safe, Healthy and Quality Food; Springer International Publishing: Cham, Switzerland, 2016; p. 487. ISBN 978-3-319-24038-1. [Google Scholar]

- Shahidi, F. Does COVID-19 affect food safety and security? J. Food Bioact. 2020, 9, 1–3. [Google Scholar] [CrossRef]

- Gole, S. Unit 14: Good Retail Practices, Good Transport Practices and Nutrition Labeling. 2018. Available online: https://www.14.139.199/bitstream/123456789/42855/1/Unit-14.pdf/ (accessed on 14 March 2020).

- Voysey, P.A.; Brown, M. Microbiological risk assessment: A new approach to food safety control. Int. J. Food Microbiol. 2000, 58, 173–179. [Google Scholar] [CrossRef]

- Yüksel, H. An empirical evaluation of cleaner production practices in Turkey. J. Clean. Prod. 2008, 16, S50–S57. [Google Scholar] [CrossRef]

- Journal of Cleaner Production. Available online: https://www.journals.elsevier.com/journal-of-cleaner-production (accessed on 2 June 2020).

- Deprá, M.C.; Dias, R.R.; Zepka, L.Q.; Jacob-Lopes, E. Building cleaner production: How to anchor sustainability in the food production chain? Environ. Adv. 2022, 9, 100295. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, X.; Xiao, B.; Hu, K. Rice-crab coculture to sustain cleaner food production in Liaohe River Basin, China: An economic and environmental assessment. J. Clean. Prod. 2019, 208, 188–198. [Google Scholar] [CrossRef]

- Hou, J.; Wang, X.; Xu, Q.; Cao, Y.; Zhang, D.; Zhu, J. Rice-crayfish systems are not a panacea for sustaining cleaner food production. Environ. Sci. Pollut. Res. 2021, 28, 22913–22926. [Google Scholar] [CrossRef]

- Ding, Z.; Hu, R.; Styles, D.; Wang, X.; Tian, Y.; Cao, Y.; Hou, J. Optimized ratoon rice system to sustain cleaner food production in Jianghan Plain, China: A comprehensive emergy assessment. Environ. Sci. Pollut. Res. 2022, 29, 24639–24650. [Google Scholar] [CrossRef] [PubMed]

- Sandberg, J.; Alvesson, M. Ways of constructing research questions: Gap-spotting or problematization? Organization 2011, 18, 23–44. [Google Scholar] [CrossRef]

- Okpala, C.O.R. Reflecting in the Woods: Can it Help to Enhance the Formulation of (our) Research Questions? BioResources 2017, 12, 4490–4494. [Google Scholar] [CrossRef]

- Garrone, P.; Melacini, M.; Perego, A.; Sert, S. Reducing food waste in food manufacturing companies. J. Clean. Prod. 2016, 137, 1076–1085. [Google Scholar] [CrossRef]

- Massoud, M.A.; Fayad, R.; El-Fadel, M.; Kamleh, R. Drivers, barriers and incentives to implementing environmental management systems in the food industry: A case of Lebanon. J. Clean. Prod. 2010, 18, 200–209. [Google Scholar] [CrossRef]

- Ramjeawon, T. Cleaner production in Mauritian cane-sugar factories. J. Clean. Prod. 2000, 8, 503–510. [Google Scholar] [CrossRef]

- Teller, C.; Holweg, C.; Reiner, G.; Kotzab, H. Retail store operations and food waste. J. Clean. Prod. 2018, 185, 981–997. [Google Scholar] [CrossRef]

- Gurbuz, S.; Kiran-Ciliz, N.; Yenigun, O. Cleaner production implementation through process modifications for selected SMEs in Turkish olive oil production. J. Clean. Prod. 2004, 12, 613–621. [Google Scholar] [CrossRef]

- Özbay, A.; Demirer, G.N. Cleaner production opportunity assessment for a milk processing facility. J. Environ. Manag. 2007, 84, 484–493. [Google Scholar] [CrossRef] [PubMed]

- Rahim, R.; Raman, A.A.A. Cleaner production implementation in a fruit juice production plant. J. Clean. Prod. 2015, 101, 215–221. [Google Scholar] [CrossRef]

- Fan, Y.V.; Chin, H.H.; Klemeš, J.J.; Varbanov, P.S.; Liu, X. Optimisation and process design tools for cleaner production. J. Clean. Prod. 2020, 247, 119181. [Google Scholar] [CrossRef]

- Lemaire, A.; Limburg, S. How can food loss and waste management achieve sustainable development goals. J. Clean. Prod. 2019, 234, 1221–1234. [Google Scholar] [CrossRef]

- Zamri, G.B.; Azizal, N.K.A.; Nakamura, S.; Okada, K.; Nordin, N.H.; Othman, N.-A.; Akhir, F.N.M.; Sobian, A.; Kaida, N.; Hara, H. Delivery, impact and approach of household food waste reduction campaigns. J. Clean. Prod. 2020, 246, 118969. [Google Scholar] [CrossRef]

- Amicarelli, V.; Fiore, M.; Bux, C. Hidden flows assessment in the agri-food sector: Evidence from the Italian beef system. Br. Food J. 2020, 123, 384–403. [Google Scholar] [CrossRef]

- Clark, M.; Springmann, M.; Rayner, M.; Harrington, R.A. Estimating the environmental impacts of 57,000 food products. Environ. Sci. 2022, 119, e21205841190. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Castellani, V.; Sala, S. Environmental impacts of food consumption in Europe. J. Clean. Prod. 2017, 140, 753–765. [Google Scholar] [CrossRef]

- Okpala, C.O.R.; Korzeniowska, M.; Guiné, R.P.F. Good practices in food product development processes: Some keys to motivating the consumer. In Proceedings of the Presentation delivered at the International Web Conference on Food Choice & Eating Motivation, Online, 19–20 May 2022. [Google Scholar]

- Fresner, J. Cleaner production as a means for effective environmental management. J. Clean. Prod. 1998, 6, 171–179. [Google Scholar] [CrossRef]

- Aruoma, C.I. The impact of food regulation on the food supply chain. Toxicology 2006, 221, 119–127. [Google Scholar] [CrossRef]

- da Cruz, A.G.; Cenci, S.A.; Maia, M.C.A. Good agricultural practices in a Brazilian produce plant. Food Control 2006, 17, 781–788. [Google Scholar] [CrossRef]

- Raspor, P.; Ambrožič, M.; Jevšnik, M. Food Chain Safety Management Systems: The Impact of Good Practices. In Advances in Food Process Engineering Research and Applications; Yanniotis, S., Taoukis, P.S., Stoforos, N.G., Karathanos, V.T., Eds.; Food Engineering Series: New York, NY, USA, 2013; p. 19. [Google Scholar] [CrossRef]

- Sikora, T.; Strada, A. Safety and quality assurance and management systems in food industry: An overview. In The Food Industry in Europe; Agricultural University of Athens: Ateny, Greece, 2005. [Google Scholar]

- Lelieveld, H.L.M.; Mostert, M.A.; Holah, J.; White, B. Hygiene in Food Processing; Woodhead Publishing Ltd.: Cambridge, UK, 2003; p. 390. ISBN 1855734664. [Google Scholar]

- Moberg, L. Good manufacturing practices for refrigerated foods. J. Food Prot. 1989, 52, 363–367. [Google Scholar] [CrossRef] [PubMed]

- Wallace, C.A.; Sperber, W.H.; Mortimore, S.C. Food Safety for the 21st Century: Managing HACCP and Food Safety throughout the Global Supply Chain, 2nd ed.; John Wiley and Sons, Ltd.: Oxford, UK, 2018; p. 494. ISBN 978-1-11905383. [Google Scholar]

- Azapagic, A.; Bore, J.; Cheserek, B.; Kamunya, S.; Elbehri, A. The global warming potential of production and consumption of Kenyan tea. J. Clean. Prod. 2016, 112, 4031–4040. [Google Scholar] [CrossRef]

- Briceno, T.; Stagl, S. The role of social processes for sustainable consumption. J. Clean. Prod. 2006, 14, 1541–1551. [Google Scholar] [CrossRef]

- Parag, Y. Beyond energy efficiency: A ‘prosumer market’ as an integrated platform for consumer engagement with the energy system. Eur. Counc. Energy Effic. Econ. Summer Study 2015, 1, 15–23. [Google Scholar]

- Braglia, M.; Petroni, A. Stakeholders influence and internal championing of product stewardship in the Italian food packaging industry. J. Ind. Ecol. 2000, 4, 75–92. [Google Scholar] [CrossRef]

- Carlton, R.; Thompson, H. Product Stewardship—Is there a role for better collaboration? Outlooks Pest Manag. 2009, 20, 126–127. [Google Scholar] [CrossRef]

- Lewis, H. Defining product stewardship and sustainability in the Australian packaging industry. Environ. Sci. Policy 2005, 8, 45–55. [Google Scholar] [CrossRef]

- Neto, A.S.; Jabbour, C.J.C. Guidelines for improving the adoption of cleaner production in companies through attention to non-technical factors: A literature review. Afr. J. Bus. Manag. 2010, 4, 4217–4229. [Google Scholar]

- Stitzhal, D. Product Stewardship: Can it drive green design? Environ. Qual. Manag. 2011, 20, 25–41. [Google Scholar] [CrossRef]

- Schober, A.; Kittel, C.; Baumgartner, R.J.; Füllsack, M. Identifying dominant topics appearing in the Journal of Cleaner Production. J. Clean. Prod. 2018, 190, 160–168. [Google Scholar] [CrossRef]

- Seadon, J.K. Sustainable waste management systems. J. Clean. Prod. 2010, 18, 1639–1651. [Google Scholar] [CrossRef]

- Aarnio, T.; Hämäläinen, A. Challenges in packaging waste management in the fast food industry. Resour. Conserv. Recycl. 2008, 52, 612–621. [Google Scholar] [CrossRef]

- Filimonau, V.; Gherbin, A. An exploratory study of food waste management practices in the UK grocery retail sector. J. Clean. Prod. 2017, 167, 1184–1194. [Google Scholar] [CrossRef]

- de Oliveira Santos, H.; Alves, J.L.S.; Coutinho de Melo, F.J.; Dumke de Medeiros, D. An approach to implement cleaner production in services: Integrating quality management process. J. Clean. Prod. 2020, 246, 118985. [Google Scholar] [CrossRef]

- Sojkin, B.; Ankiel, M. Retail networks as a place of purchase-the example of large cities in Poland. Acta Sci. Polonorum. Oeconomia 2019, 18, 101–110. [Google Scholar] [CrossRef]

- WMA. World Medical Association Declaration of Helsinki: Ethical principles for medical research involving human subjects. J. Am. Med. Assoc. 2013, 310, 2191–2194. [Google Scholar]

- Convention Bureau Wroclaw. About the City. 2022. Available online: https://convention.wroclaw.pl/about-the-city/ (accessed on 15 November 2022).

- Fedyk, W.; Sołtysik, M.; Olearnik, J.; Barwicka, K.; Mucha, A. How Overtourism Threatens Large Urban Areas: A Case Study of the City of Wrocław, Poland. Sustainability 2020, 12, 1783. [Google Scholar] [CrossRef]

- Okpala, C.O.R.; Nwobi, O.C.; Korzeniowska, M. Assessing Nigerian Butchers’ Knowledge and Perception of Good Hygiene and Storage Practices: A Cattle Slaughterhouse Case Analysis. Foods 2021, 10, 1165. [Google Scholar] [CrossRef]

- Taherdoost, H. Validity and Reliability of the Research Instrument: How to Test the Validation of a Questionnaire/Survey in a Research. Int. J. Acad. Res. Manag. 2016, 5, 28–36. [Google Scholar] [CrossRef]

- Vargha, A.; Delaney, H.D. The Kruskal-Wallis test and stochastic homogeneity. J. Educ. Behav. Stat. 1998, 23, 170–192. [Google Scholar] [CrossRef]

- Chan, Y.; Walmsley, R.P. Learning and understanding the Kruskal-Wallis one-way analysis-of-variance-by-ranks test for differences among three or more independent groups. Phys. Ther. 1997, 77, 1755–1761. [Google Scholar] [CrossRef] [PubMed]

- Okpala, C.O.R.; Korzeniowska, M. Concept, Content, and Context Perspectives of Quality of Agrofood Products: Reflections on Some Consumer Decision-Making-Purchase Scenarios. Front. Nutr. 2020, 7, 578941. [Google Scholar] [CrossRef]

- Okpala, C.O.R.; Korzeniowska, M.; Guiné, R.P.F. Towards managing quality in agro-food technological processes: From people to products. In Proceedings of the Poster Presented at the 9th Quality and Safety in Food Production Chain Conference, Wroclaw, Poland, 15–16 September 2022. [Google Scholar]

- Stone, L. When case studies are not enough: The influence of corporate culture and employee attitudes on the success of cleaner production initiatives. J. Clean. Prod. 2000, 8, 353–359. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).