Abstract

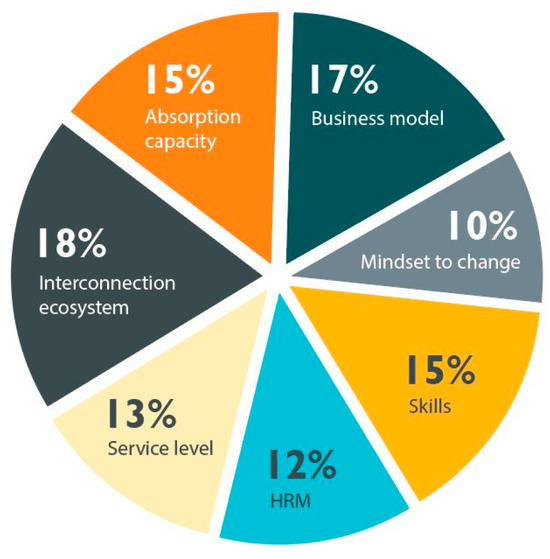

Despite growing interest in smart manufacturing, there is little information on how organizations can approach the alignment of strategic processes with Industry 4.0. This study seeks to fill this knowledge gap by developing a framework for the integration of Industry 4.0 techniques and artificial intelligence systems. This framework will serve as a conceptual guide in the digital transformation processes toward Industry 4.0. This study involved a systematic literature review of the important methodological proposals and identification of thematic axes, research topics, strategic objectives, challenges, drivers, technological trends, models, and design architectures. In total, 160 articles were selected (120 were published between 2017 and 2022). The results provide insights into the prospects for strategic alignment in the adoption of Industry 4.0. The conceptualization of the framework shows that Industry 4.0 needs strategic adjustments mainly in seven objectives (business model, change mindset, skills, human resources, service level, ecosystem, interconnection, and absorption capacity) derived from 10 thematic axes and 28 research topics. Understanding the strategic adoption of Industry 4.0 and artificial intelligence is vital for industrial organizations to stay competitive and relevant in a constantly evolving business landscape.

1. Introduction

Industry 4.0 readiness is how readily organizations can use fourth industrial revolution technologies [1]. Industry 4.0 development changes the management of business operations and leads to new strategic thinking [2]. New business strategies are accompanied by new business models [3]. This strategic adjustment requires new configurations of products and processes [4]. Strategies no longer depend on the traditional competitive model. Instead, they are linked to customer expectations and experiences and focused on emerging consumer ecosystems [5]. Organizations are redefining their strategies for Industry 4.0. According to Ghobakhloo et al. [6], there must be strategic alignment with the new management paradigm. The technological trends of Industry 4.0 must be balanced with new models that integrate sustainable manufacturing [7], smart companies [8], and circular economies [9,10]. This strategic alignment should recognize clients’ needs, generate competitive advantages, and facilitate exploring and exploiting new opportunities [11]. The convergence of Industry 4.0 and artificial intelligence is revolutionizing organizational management by providing real-time information, automating repetitive tasks, and enhancing strategic decision-making. These technologies are increasing the efficiency, effectiveness, and adaptability of management in response to an ever-changing business environment.

For Tang and Veelenturf [12], automation is accompanied by self-management in the fourth industrial revolution, unlike the third industrial revolution, where automation requires programming. Self-management is complex and requires all process information to be available in real time. Real-time process information requires an interconnected ecosystem between all the individuals and objects within Industry 4.0 business models [13]. For Morawski and Ignaciuk [14], machines or processes must process and analyze all data to self-manage. Self-management requires multidisciplinary technologies that clarify the complexity of Industry 4.0 [15]. Interconnecting smart factories requires information and communication technologies (ICT) [16], such as cyber-physical systems (CPS), cloud computing (CC), the internet of things (IoT), and artificial intelligence [17]. Industry 4.0 will impact all human endeavors, including medicine, industrial maintenance, construction processes, agriculture, computer problem-solving, commerce, and society [18]. Industry 4.0 forces individuals to learn new skills and abilities, and technological transitions create new business models, jobs, and opportunities [19]. Industry 4.0 has various major benefits, including real-time integration of operations, cost reduction, energy efficiency, sustainability [20], increased flexibility, increased productivity, higher return on investment, and better performance management systems [21].

For Colli et al. [22], Industry 4.0 business models must adapt to the architecture of the digital world, which poses new challenges for organizational teams (hierarchical, projects, innovation). Additionally, more complex digital architectures require modification of strategic behaviors [23]. Furthermore, market instability forces structural and typological analysis of commercial strategic models and leads to better strategies [24]. Business strategies drive organizational design and dictate information system infrastructure [25]. Innovation strategies in many organizational structures are considered cost centers that are difficult to limit and measure. However, Industry 4.0 business models require separate growth incubators from the other organizational teams because they are essential for generating future value for customers and the company.

Industry 4.0 technologies are creating open innovation strategies. According to Sahi et al. [26], this model grows businesses by facilitating the exploration and exploitation of technological knowledge through corporate collaboration networks and synergy between suppliers, clients, or partners for business growth [27]. Open business models and innovation strategies are the definitive paths toward Industry 4.0 business models [28].

The new digital business models (Google, Instagram, Airbnb, YouTube, Meta, Uber, Spotify, etc.) have high market value. Conversely, traditional supply chains base their sustainability on experience, learning curves, constant investments in infrastructure, equal legal frameworks for all, etc. [29]. These supply chains should not ignore the need to adopt Industry 4.0. For Arromba et al. [30], digital transformation requires a model of critical management competencies, which considers customer relationship strategies, adaptation and collaboration strategies for agile and flexible responses, innovation strategies, and marketing strategies [31]. Digital transformation leads to measurable positive results and facilitates strategic business objectives [32]. Legacy industries must adjust their management strategies to utilize new digital architectures effectively and successfully compete with new digital business models [33].

1.1. Contribution and Limitations

This document systematically reviews the literature on the Industry 4.0 concept, identifies thematic axes and challenges, highlights technological and design trends, and offers a strategic roadmap and simple guide for organizations to align their business strategies toward Industry 4.0.

The framework presented in this study can successfully guide academics and organizations to transition from traditional supply chains to Industry 4.0. However, no universal strategic path will fit all supply chains. Each organization must consider factors such as sequential planning, management of technological resources (technological infrastructures, information systems, and cybersecurity), human resources management [34], customer relationship models, competition, individual value chains, and specific company objectives, priorities, and budgets.

The findings of this study are subject to baseline analysis by country. In addition, our list of Industry 4.0 strategic alignment perspectives, themes, and research topics is not exhaustive. SLR relied on extensive analysis of the literature on strategic adjustments for Industry 4.0 adoption but cannot exclude the presence of other significant perspectives not mentioned in SLR.

1.2. Study Structure

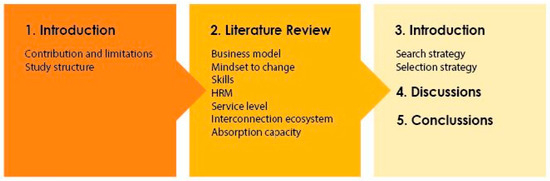

The study structure is outlined in Figure 1. The importance of conceptualizing a strategic framework for Industry 4.0 adoption is highlighted in Section 2 (literature review). This document focuses on identifying the areas of strategic alignment, thematic axes, and current research on innovative digital models for various applications in engineering. Additionally, a descriptive analysis of the studies is included. Section 3 of this document describes our methodology and defines how bibliographic references for this study were searched for and selected. Section 4 presents the discussions of the study. Finally, Section 5 summarizes our conclusions and some future research perspectives.

Figure 1.

Article structure.

2. Literature Review

Traditional supply chains require strategic adjustments for the adoption of Industry 4.0. Through SLR, it was possible to identify authors who have raised important strategic trends for Industry 4.0 [13,35,36]. These trends were grouped into subgroups to classify thematic axes, research topics, and strategic objectives. Then, through an SLR analysis and based on the experience and knowledge of the authors of this study, 7 strategic objectives, 10 thematic axes, and 28 research topics were determined. The seven strategic objectives identified are part of the organizational strategic alignment perspectives necessary for adopting Industry 4.0.

The knowledge and concepts within our seven objectives provide a clear vision and strategy for medium- and long-term Industry 4.0 adoption plans. These plans determine strategically aligned operating and cost projections for Industry 4.0. Table 1 summarizes the references found, classifying them by thematic axis.

Table 1.

Summary of articles by thematic axis.

The framework presented in this document classifies studies by thematic axes, research topics, and prospects for strategic alignment for Industry 4.0. The authors of this study assess and analyze strategic adjustments to identify best practices for adopting Industry 4.0 (Table 2).

Table 2.

Systematic review of the literature.

2.1. Strategic Alignment Perspectives for Industry 4.0

2.1.1. Business Model

New business models for Industry 4.0 must clearly define objectives, prioritize efficiency, and optimize value chains [16]. In digital business, technologies generate unique value propositions and experiences that differentiate companies and give them a competitive advantage. Business model design starts with planning and alignment with a company’s global strategy. Identifying and evaluating obstacles, critical factors, and internal and external barriers related to new digital businesses are part of the initial strategic analysis [2,38,39]. Implementing and managing digital services requires a new organizational structure, cultural change, new responsibilities, and greater emphasis on ICT strategic decisions.

The new business models focused on digital services will be based on customer satisfaction, so the customer experience must be central to the digital strategy. Industry 4.0 requires companies to implement innovative strategies that constantly redesign the portfolio of products and services and improve customer-organization interaction throughout the value chain. The most effective way to formulate digital strategies is to involve corporate leaders (owners, shareholders, managers, boards of directors, or those in charge of digital processes) so the strategy is aligned with business values and objectives.

2.1.2. Change Mindset

Traditional supply chains must constantly innovate to overcome challenges and stay competitive by embracing digital transformation. Industry 4.0 democratizes technology and makes all members an integral part of its operation. The focus of Industry 4.0 is the client and their requirements, which directs the implementation of digital technologies and operating systems.

The COVID-19 pandemic caused market and industry disruptions, forced many companies to look for new ways of doing business to survive, and accelerated the adoption of digital innovation strategies. Many companies and SMEs have had to quickly adapt to this new reality and accelerate their digital transformation. Depending on a company’s size, policy changes should be aimed at product or process innovation. Process innovation is the most appropriate for SMEs. According to Wamba and Queiroz [48], some companies, especially SMEs, hesitate to implement Industry 4.0 technologies because they require large investments in infrastructure and technology, impact their business model, and require specialist knowledge and skills.

The implementation of Industry 4.0 depends on the specific knowledge of each technology and its benefits. All hierarchical levels of the organization are responsible for acquiring this knowledge and skills, especially managers, who must design training policies and invest in technology. The periodic evaluation of digital ecosystems allows us to understand their potential and real benefits. The definition of policies and regulatory frameworks will facilitate knowledge transfer among Industry 4.0 participants, including smart companies, technology providers, and universities. Digital business models generate changes in organizational cultures and must be accompanied by robust knowledge management policies.

2.1.3. Skills

Skills and organizational capacities allow business activity development from the available resources. The strategy dictates the development and assignment of these skills and abilities [13]. Therefore, organizations must define internal and external competencies to optimize their strategic objectives. Supply chains with comprehensive sustainable manufacturing/circular economy/smart manufacturing models generate competitive advantages [95].

Few organizations have defined a transformation strategy for their digital ecosystems to adapt to Industry 4.0. Those organizations that develop digital strategies will gain competitiveness and market share in the future. Smart factories are changing the industrial landscape and require new capabilities for information processing. Data management, visibility, and availability allow faster decision-making. ICT and digitally interconnected ecosystems for real-time data processing are the main basis of Industry 4.0. Industry 4.0 technologies such as IoT, CC, CPS, additive manufacturing, augmented reality, etc., and artificial intelligence with machine learning and deep learning require new skills and human capabilities.

Digital skills facilitate product innovation and customization, value chain digitalization, process optimization, and data-driven decision-making. Together, these factors generate a competitive advantage among supply chains. The new technological skills should help achieve the maximum benefit with the least investment without losing sight of an organization’s needs.

2.1.4. Human Resources Management

According to Vereycken et al. [101] effective HRM implementation requires understanding the impact of Industry 4.0 on the workforce, analyzing workforce requirements, and measuring the impact on organizational effectiveness. Additionally, successful implementation depends on an organization’s ability to attract, retain, and develop its workforce and foster a culture of innovation and lifelong learning [99]. Implementing, operating, and maintaining digital technologies requires training or hiring HRM with novel skills and abilities. These HRMs need to be planned at all organizational levels. Organizational culture change must occur throughout the value chain and focus on digital ecosystems. Managing the Industry 4.0 workforce is complex; training models must be aligned with the workforce’s education, and well-being must be the center of transformation policies. Innovation strategies in the work environment must accompany the connection between the virtual model and the physical environment and workforce skills qualifications. Innovation and qualification ensure the operational digitization of the value chain. Likewise, it is necessary to facilitate a work environment that promotes an open mentality oriented toward learning, change, and experimentation.

2.1.5. Service Level

Fast responses to changes in customer demand require effective use of technological resources [73]. The implementation of Industry 4.0 requires the gradual introduction of new technologies or systems [40]. Optimizing service levels in Industry 4.0 requires new strategies, technologies, and information systems. These strategies must evaluate the digitization of the value chain, assess whether the products/services are sustainable, and facilitate product customization by the client.

Interconnected ecosystems and absorption capacity define the service level in a smart factory. However, despite the multiple advantages of industrial digitization, several challenges remain, such as real-time availability and accessibility of data, data protection, data bias, storage, processing, integrated communication protocols, auditing, transmission speed, information security, and data quality.

Major outstanding concerns in preparation and evolution models include immature industrial digital technologies, integrating multiple pieces of equipment from different vendors with different communication capabilities and network technologies in a single ecosystem, and high cyber security standards. The service level depends on linking the virtual model and the physical environment with variables such as optimization of investment in technology, market and industry disruptions, digitization of the value chain and its ability to analyze big data, customer experience, client-organization integration, product portfolio innovation, digital ecosystem, business opportunities, product design, and human-centered processes, among others.

2.1.6. Interconnected Ecosystems

Few companies have adopted technological innovation strategies that facilitate successful digital process transformation and generate new business models. Most organizations use technological innovation strategies for operational improvements and customer experience.

Industry 4.0 technologies can support production by implementing different capabilities depending on the needs of the production system. The ITC readiness concept defines how companies can exploit and benefit from technologies. According to Mittal et al. [75] a term adjacent to readiness is ripeness. Readiness can be distinguished from maturity; readiness is assessed before maturation, and maturity is assessed following technological implementation [107]. Developing a digitized lean manufacturing system is a viable business strategy for corporate survival in the Industry 4.0 environment [49].

Interconnected ecosystems depend on different internal and external knowledge sources. These collaborative networks promote business innovation and knowledge sharing about technology adoption impact, challenges, and benefits. Industry 4.0 requires open innovation strategies, technological investments, and internal and external ideas. These ideas depend a lot on the ability of everyone to transfer their knowledge to organizations, and this transfer depends a lot on HRM management practices. Idea contribution is essential for the success of technological innovation strategies.

Interconnected ecosystems depend on the type of digital business model and big data management. Digital ecosystems must be evaluated and analyzed using readiness and maturity models to optimize investments in technology. ICT computer security is a critical control point to protect big data from products and processes. Although Industry 4.0 requires vertical and horizontal integration and digitization strategies, it is important to highlight the common benefits of strategic alliances. Consequently, selecting a team of vendors with proven technologies is critical when building a network of partners. Connecting the virtual model and the physical environment must occur with the correct selection and implementation of technologies. Poor decision-making will slow the adoption processes and generate cost overruns. Digitizing each of the activities in the value chain should be the objective of any company. Companies must also focus on customer satisfaction, requirements, and human-centered design. Developing robust ICT digital interconnection ecosystems is essential for the survival of SMEs that aspire to be part of the fourth industrial revolution.

2.1.7. Absorption Capacity

A concept introduced by Cohen and Levinthal [123], absorption capacity measures an organization’s ability to absorb external knowledge over time. A more current concept is an organization’s ability to detect, integrate, and take advantage of internal or external knowledge. Absorption capacity assigns value to an organization’s ability to capture, assimilate, and use knowledge to develop a competitive advantage [6]. Absorption capacity refers to an organization’s acquisition or assimilation of information and its ability to exploit it [124]. Big data analysis improves learning curves by adjusting management decision-making processes. According to Müller et al. [37], absorption capacity is important for organizational innovation. Information and communication technologies in Industry 4.0 (ICT 4.0) are essential in order to increase absorption capacity and facilitate the creation of innovation strategies [72].

Acquiring knowledge and information depends on a company’s ability to generate and manage big data acquired from its products and processes. As a result, the articulation of knowledge in Industry 4.0 is closely linked to the technological innovation strategies adopted by each company. This adaptation relies on various factors, such as the availability and transfer of technology, optimization of technology investments, entrepreneurial capacity, economic needs of the organization, and hiring expert personnel for technology adoption processes. These essential elements enhance absorption capacity, facilitating the development of new products, product customization, and process optimization. Absorption capacity can be measured using the four-dimensional scale suggested in [125] proposed and validated by [126].

The capacity for knowledge assimilation is partly determined by an organization’s structure, specifically its configuration and communication processes. Organizational structures with high levels of complexity typically offer limited opportunities for vertical communication processes. Likewise, horizontal communication processes with other business units may be reduced, often resulting in collaborative processes that are either forced or necessary due to the situation.

The capacity for transformation defines the internalization processes of external knowledge. Absorption capacity drives internal and external dynamics, accumulating knowledge and developing organizational learning processes. This process impacts the organization’s present and future activities, as external knowledge leads to internal knowledge development. An individual’s ability to transfer knowledge to the organization largely depends on developing policies at the HRM level. The implementation of ICT 4.0 drives new teaching and learning mechanisms. However, much literature is still needed to help define the processes required to transform this knowledge into innovation. The relationship between absorption and innovation capacity is partially mediated by organizational learning capacity [127]. The SLR suggests that this ability is complementary to the assimilative ability, and organizational structures aid in articulating and disseminating knowledge. Learning mechanisms serve as channels through which companies assimilate and internalize knowledge. Exploitation capacity measures the application of knowledge once information has been acquired, assimilated, and transformed. These activities allow for decision-making based on data and support the input for innovation strategies. Exploitation is when knowledge produces tangible outcomes such as new products or services. Customer organization and market interactions drive innovation processes and product portfolios. The SLR highlights the importance of R+D+I strategies in absorptive capacity. However, implementing these strategies requires economic investments, development times, and specialized human resources, which are often the main barriers to their development for most companies. Therefore, government policies that offer incentives and support are essential due to companies’ lack of capabilities and economic budgets to invest in these ideas.

3. Methodology

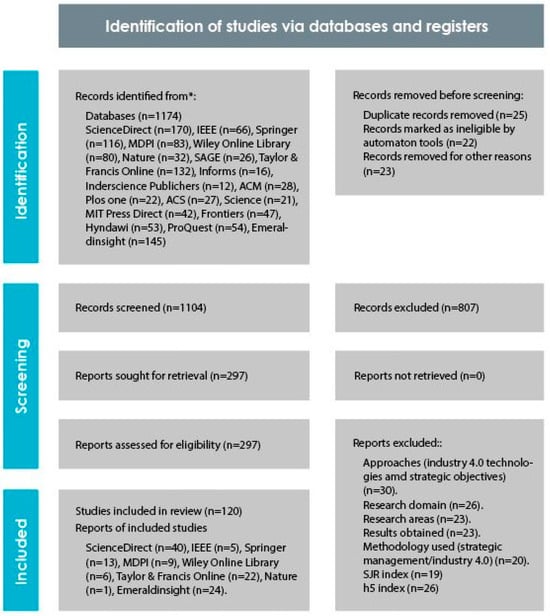

This study conducts a systematic literature review (SLR) to search for relevant Industry 4.0 strategic management research articles comprehensively. SLR aims to identify, evaluate, and synthesize studies meeting predetermined eligibility criteria to answer a research question. Various authors have used this scientific research method [95,128,129,130,131,132,133,134,135,136,137]. This study validates nine perspectives of strategic alignment for adopting Industry 4.0 through a combination of SLR and the authors’ experience and knowledge. The SLR follows the preferred reporting items for systematic reviews and meta-analyses (PRISMA) guidelines [138,139]. The study utilized content analysis to categorize the information, a valid technique for analyzing scientific documents [140]. Figure 2 summarizes the proposed PRISMA methodology.

Figure 2.

Summary PRISMA methodology. * WOS-Scopus databases.

3.1. Search Strategy

The Google Scholar search engine returned 4.1 million articles for the search term “Industry 4.0”. The study combined two different groups of keywords using the “AND” operator to combine the two groups and the “OR” operator to combine keywords within each group to improve accuracy. The study used a comprehensive search strategy with keywords such as “Industry 4.0 and strategic management”, “Industry 4.0 technologies and strategic goals”, and “digital models and business strategies” to synthesize and limit the study area. Other complementary keywords with Industry 4.0 included “strategic roadmap”, “strategy readiness model”, and “digital strategy”. The study considered articles published in 2017 and onward, except for articles published by highly reputable authors with many citations.

The filter with multiple keywords significantly reduced the number of articles to thousands. The study then selected the most relevant titles, read the abstracts, and finally, read the complete articles.

3.2. Selection Strategy

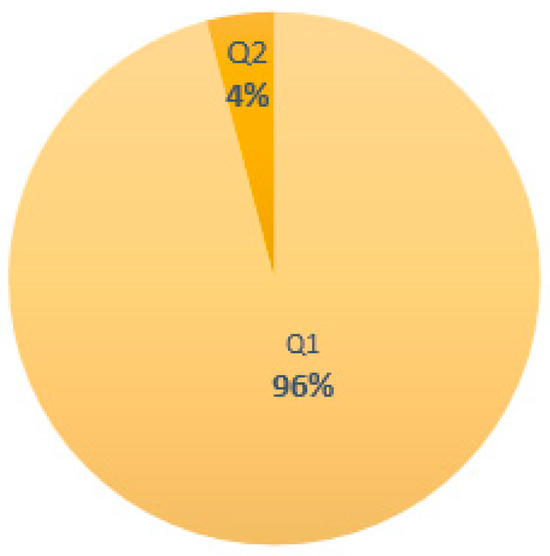

The study’s selection strategy was based on five criteria: (1) the use of the index-median level metric h5 ≤ 40 [141]; (2) a quality index—scientific journal ranking (SJR) ≤ 0,4 [142]; (3) the quartile range (Q) of SJR, preferably the upper quartile Q1, with some exceptions for passing another selection criterion—Q2.

The SJR index is calculated based on the number of citations journals receive over three years, considering the prestige of the journals from which these citations originate. It assigns a classification from Q1 to Q4. Q1 is the highest quartile for the thematic categories in which the journal publishes its articles. The h5-index is the h-index of articles published in the last five full years, where h is the largest number such that h articles published in 2019–2023 have at least h citations each.

Table 3 summarizes the information collected from the selection strategy, including authors, type of study, journal name, h5 index, SJR index, SJR quartile, year of publication, and the number of citations.

Table 3.

Table of references.

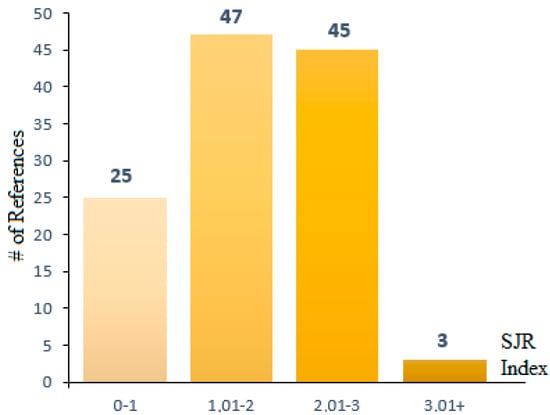

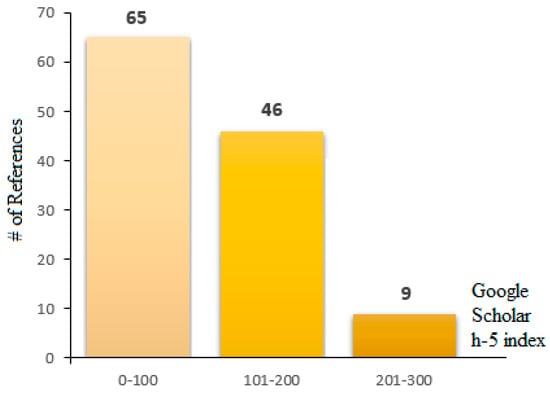

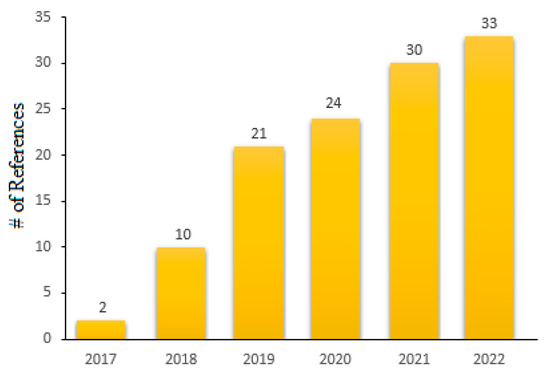

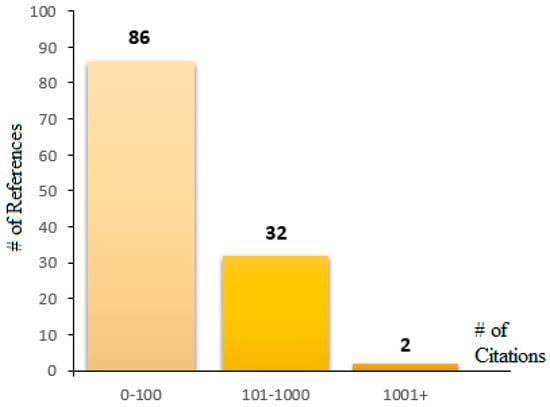

The distribution of the SJR index and the Google Scholar h5-index for the 120 references that are part of the SLR can be seen in Figure 3 and Figure 4. Figure 5 and Figure 6 illustrate the increase in publications and citations per reference from 2017 to 2022, indicating the growing interest in the study subject. Most selected articles are highly cited, ensuring the analysis of widely accepted and influential papers. However, some newly published articles do not follow this trend. Figure 7 shows that 96% of the references in this study are in the first Q1 quartile of the SJR. Only five references are in the second quartile Q2 because they met other selection criteria or were essential for the SLR [13,17,79,80,99].

Figure 3.

Distribution of the SJR index.

Figure 4.

Distribution of the Google Scholar h-5 index.

Figure 5.

Distribution of references by year of publication.

Figure 6.

Distribution of references by the number of citations.

Figure 7.

Quartile distribution of the SJR index.

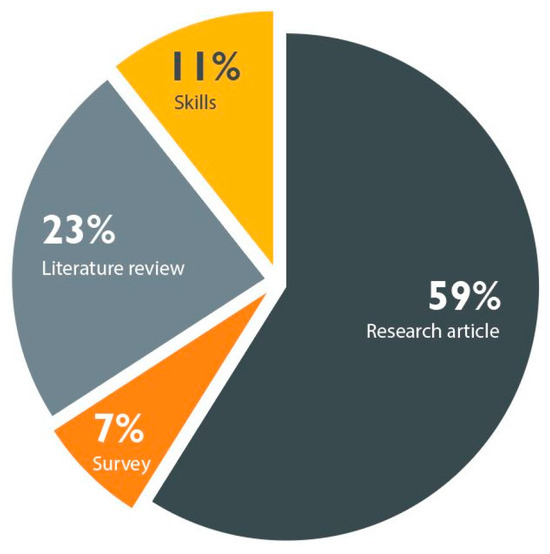

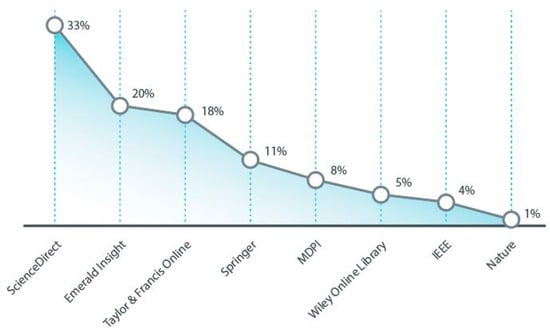

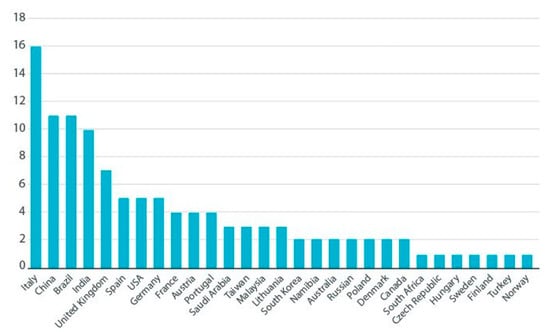

Interconnection ecosystems and business models were the most frequently cited perspectives for strategic alignment for Industry 4.0 adoption, with 22 studies each (Figure 8). We identified 71 research studies proposing new methodologies and 28 literature reviews (Figure 9). ScienceDirect had the highest number of contributions, with 40 studies, followed by Emerald Insight, with 24 publications (Figure 10). Italy contributed the most studies (16), followed by China and Brazil, with 11 studies each (Figure 11).

Figure 8.

Strategic alignment perspectives for Industry 4.0 adoption.

Figure 9.

Distribution of study types.

Figure 10.

Distribution of studies by database.

Figure 11.

Distribution of studies by country where the study was conducted.

4. Discussion

This section discusses the strategic adjustments required for adopting Industry 4.0 by examining the SLR. While numerous studies on Industry 4.0 readiness models exist, strategic alignment perspectives vary. We identified 11 research questions (RQ1–RQ11) that must be answered to facilitate discussion and serve as a support tool.

RQ1 .

Why should the list of Industry 4.0 technologies remain open?

The technological vision of Industry 4.0 is continuously evolving. At the Hannover Messe, nine key pillars were identified, including the Internet of Things, Additive Manufacturing, Cyber-Physical Systems, Cloud Computing, Big Data, Cybersecurity, Augmented Reality, Robotics, and Simulation [95]. As the world continues to explore the concepts of Industry 4.0, some have changed. New digital strategies suggest that the technology list should be open to new methodological proposals. For instance, Blockchain technology is often not included in the original list but is now considered an important aspect of Industry 4.0 evolution. Blockchain is a disruptive and promising technology that provides secure peer-to-peer connectivity by eliminating third-party intervention or central authority. It provides cybersecurity to industrial machines against cyber-attacks and supports efficient supply chain management. The main attractive features of Blockchain technology include distributed databases, peer-to-peer transactions, transaction automation, anonymity and transparency, and irreversibility of records [143].

RQ2 .

How do digital models influence the direction and output of public policies and research methods?

The Fourth Industrial Revolution demands strategic adjustments in various production systems [54]. Context diversity must be considered when discussing the effective implementation of Industry 4.0. Application of the Industry 4.0 concept varies according to each country’s situation and business environment and requires evaluation through academic research. Additionally, public policies play a crucial role in driving the adoption of Industry 4.0. Furthermore, the adoption of Industry 4.0 methodological solutions requires a multidisciplinary approach that addresses issues such as privacy, sustainability, intellectual property, skills, human resource capacity, information system infrastructure, demographics, national and international policy formulation, integration of manufacturing and service competencies, and cybersecurity (including authenticity, confidentiality, integrity, availability, and cyber defense).

RQ3 .

What are the main challenges of integrating new digital models?

Traditional supply chains must evolve toward interconnected service networks through real-time data sharing and exchange (volume, speed, variety, and criticality), which will require effective big data management strategies. Achieving the digitalization of the value chain requires a reassessment of industrial processes based on the heterogeneity of devices and protocols, scalability, flexibility, functional requirements, and the ability to manage latency in complex computer systems.

However, to achieve vertical and horizontal integration and digitalization of the value chain, Industry 4.0 faces several organizational, technological, and environmental challenges, including high financial costs, organizational and process changes, security/privacy, data protection, and the implementation of adaptable solutions. Organizations often lack skilled workers, knowledge management systems, and data understanding. Furthermore, they do not fully appreciate the benefits of IoT, standardization, robust ICT infrastructures, interoperability and integration capabilities, regulatory frameworks, legal and contractual guarantees, user-friendly solutions, and effective digital strategies [46,144,145].

RQ4 .

How up-to-date are strategies for Industry 4.0 preparation and adoption?

The main goal of planning models is to identify the starting point and design a development plan. Proper planning is crucial for the successful implementation of Industry 4.0. Preparation models cover dimensions that must be contextualized and evaluated to understand which key dimensions of preparation must be addressed before the technological implementation of Industry 4.0.

SLR identified several dimensions included in these models, with the most frequent being technology, people, strategy, leadership, process, and innovation, with the technological dimension being the most important. Additionally, SLR discovered numerous readiness models developed by both academia and industry [146]. Preparation models have evolved and become more specialized in their scope and use. These models can also be used as a management tool to reorganize, restructure, and upgrade existing organizational capabilities [94,147]. Preparation models evaluate the vertical and horizontal integration of the organization.

RQ5 .

How up-to-date are maturity models for adopting digital strategies?

Value chains must adopt new business models, invest in R&D and innovation strategies, or transform traditional models to achieve digitization. According to Paulk et al. [148], maturity models, as quantification tools, are necessary for this process. Most Industry-4.0-related maturity models establish connections between technologies [64,149,150], strategy [33,37,151], culture [4,21,58], and resources [41,75,152]. They are based on three key factors: current company diagnosis, readiness models, and corporate strategy. These models provide a clear roadmap for the company’s digital transformation.

According to Lassnig et al. [74], SMEs and large companies must consider several factors when implementing digital strategies. (1) Firstly, digital strategies may highlight deficiencies in established and well-defined processes. (2) Secondly, SMEs seek to acquire new skills and abilities for digitization more actively than larger companies. Management personnel in SMEs also tend to have better guidelines on digitization and developing new skills. (3) Thirdly, the literature states that digital services complement traditional forms of customer acquisition/loyalty and digital marketing. However, automated steps in either SMEs or large companies do not usually accompany the innovation of the product portfolio. (4) Fourthly, (i) the literature on supply chains reports low levels of automation, sensor use, and application of real-time data in production processes. Conversely, (ii) inventory management presents better percentages in everything related to sensor implementation, real-time data applications, and automatic order planning. Finally, large companies use web-based platforms in a higher percentage to share information with their suppliers and customers.

RQ6 .

How does the lean philosophy apply to Industry 4.0 adoption?

The lean management approach involves implementing principles and tools, such as Just-in-time, Jidoka, teamwork, waste reduction, and continuous improvement [153]. Two main visions summarize the links between lean management and Industry 4.0 as described by SLR. (1) The first vision sees lean as a necessary foundation for Industry 4.0, while (2) the second vision asserts that Industry 4.0 improves the effectiveness of lean [98]. The findings suggest that by simplifying products and processes through the lean approach, implementing Industry 4.0 technologies can be both effective and cost-efficient. However, optimizing lean processes and principles through standardization is crucial before adopting Industry 4.0. The initial implementation of a lean production system involves numerous changes, which can prepare HRM for the organizational changes required by Industry 4.0. Furthermore, specific technologies related to Industry 4.0 can enhance the efficiency of certain lean principles or tools.

SLR provides several examples illustrating the relationship between lean management and Industry 4.0. These examples include: (i) the use of electronic identification and real-time product traceability to support just-in-time supply chains [154]; (ii) coupling real-time data acquisition with lean tools to achieve process transparency and product quality [155]; (iii) case analysis to determine which Industry 4.0 technologies provide greater support for lean tools [156]; (iv) the use of lean tools in designing an intelligent factory [157]; and (v) hybrid proposals that combine both approaches to enable vertical/horizontal integration of information systems [158]. Industry 4.0 does not encompass lean tools, but it can improve the efficiency of existing lean tools. Therefore, Industry 4.0 technologies could improve the implementation of lean management strategies. Implementing a digitized lean production system can be expensive and challenging but offers greater long-term business competitiveness [49]. Adopting lean and Industry 4.0 approaches requires a significant upfront investment; however, cost savings from improved efficiency and competitiveness can outweigh this investment in the long term.

RQ7 .

What are the roles of IoT technology, big data, and artificial intelligence?

Integrating artificial intelligence of Industrial Internet of Things (IIoT) technology is required to process information effectively in Industry 4.0. However, significant challenges exist in storing, calculating, and processing big data. IIoT ecosystems leverage IoT communication paradigms specifically designed for industrial automation, connecting devices and machines in smart industries to the internet. This makes IIoT one of the enabling technologies of Industry 4.0, often implemented in conjunction with Edge Computing. IIoT requires 5G communication systems combined with artificial intelligence and big data for faster data analysis and accurate data-driven decision-making. Artificial intelligence applications are particularly useful in Industry 4.0 for quality and predictive performance, predictive maintenance, smart manufacturing, industrial robotics, generative design, and market management. These applications are made possible by integrating IIoT with artificial intelligence and big data, enabling faster and more accurate data analysis to improve decision-making and business outcomes [70].

RQ8 .

What is the effect of adsorption capacity, and how does it influence digital strategies?

Companies that have explored the possible uses of Industry 4.0 technologies to innovate and customize their services have improved their absorption capacity. Previous knowledge decisively influences a company’s ability to absorb new information, positively impacting its innovation strategies. Recent digital business models have developed new competitive capabilities. The experience acquired through failure today improves the possibility of success tomorrow. According to Paiola et al. [90], the technologies of the fourth industrial revolution enable the implementation of servitization strategies, also known as value services. Digital instruments are being used to create product-service systems, which vary in complexity and are currently in the early stages of development [159]. These models have great potential for developing sustainable strategies, strengthening competitiveness, and promoting constant innovation [47,160]. The successful development of innovative digital service solutions depends on the absorption capacity and adoption of new technologies within the service sector. A robust understanding of these issues is essential to overcome challenges posed by new digital strategies and to achieve success in Industry 4.0 projects. Additionally, previous knowledge is crucial for properly conceptualizing and classifying digital service projects and patterns.

RQ9 .

What are the main barriers and HRM drivers for Industry 4.0 adoption?

An effective strategy, employee integration, and the incorporation of manufacturing processes throughout the value chain are required to manage digitalization successfully. Some HRM studies suggest that resistance to change from implementing Industry 4.0 technologies is not a significant barrier. However, a dearth of digital transformation skills and competencies could limit their benefits. Efficiency is considered a crucial factor driving the adoption of Industry 4.0 technologies, and a lack of competencies and financial resources remain the main barriers to their adoption [161]. There is a lack of appropriate skills among upper-level managers and lower-level employees. Many organizations do not utilize digital technology for recruitment and employee selection.

Further research is necessary to cover various topics related to human skills in Industry 4.0, including occupational health risks, process security, and human capital for strategic projects exploring and exploiting innovation [162].

Integrating technological innovation strategies in HRM processes enables organizations to perform recruitment, selection, training, and evaluation tasks more efficiently and quickly. It allows them to concentrate on other activities that generate greater value for the company. Specific technologies could be used for specific tasks, such as online work via CC, robotic process automation (RPA) for HR management, artificial intelligence tools in selection processes, Big Data for the self-development of human resources, virtual reality for training, and virtual platforms for performance evaluation.

RQ10.

What are the implications, both in theory and practice, of the relationship between Industry 4.0 and artificial intelligence?

Understanding and adapting to this convergence has significant theoretical and practical implications across various domains:

- Industrial transformation: this relationship is revolutionizing industrial operations. Theoretical frameworks need to be adapted to comprehend and elucidate these changes, while practical implementation must integrate new technologies and strategies to fully harness this convergence.

- Decision-making: artificial intelligence enables intelligent, data-driven decisions in real time. Theoretically, this requires a reevaluation of decision-making models. In practice, it entails implementing artificial intelligence systems to enhance the efficiency and quality of decisions.

- Personalization and adaptability: Industry 4.0, combined with artificial intelligence, facilitates enhanced personalization in production. This affects both the theoretical and practical aspects of operations management. Companies must realign their processes to efficiently meet evolving customer demands.

- Training and skills: the fusion of Industry 4.0 and artificial intelligence requires a workforce with new skills. In theory, this underscores the need to develop novel training and educational models. In practice, companies must invest in staff training or hire talent specialized in artificial intelligence.

- Security and ethics: artificial intelligence and Industry 4.0 present ethical and security challenges. Theoretical exploration should focus on how to address these concerns and establish clear ethical guidelines. In practice, companies must implement security measures and adhere to ethical practices in the use of artificial intelligence.

- Global competition: successful adoption of Industry 4.0 and artificial intelligence can enhance global competitiveness for companies. Theoretical exploration should focus on how companies can attain sustainable competitive advantages, while practical implementation requires effective integration of these technologies to remain competitive in the market.

RQ11 .

How does Industry 4.0 correlate with artificial intelligence to benefit decision makers and policy formulation in the industrial sector?

Industry 4.0 enhances industrial processes through artificial intelligence, optimizing efficiency, quality, and customization. Artificial intelligence plays a key role in real-time decision-making. This convergence unleashes novel opportunities for both companies and employees.

The correlation between Industry 4.0 and artificial intelligence provides decision-makers and policymakers with powerful tools to address challenges, make more informed decisions, predict trends, optimize resource allocation, assess risks, tailor policies and strategies, execute predictive maintenance, enhance energy efficiency, bolster industrial safety, drive innovation and competitiveness strategies, elevate quality of life, and optimize efficiency across the supply chain.

5. Conclusions

Through the evaluation and analysis of relevant documents, this study summarizes strategic adjustments necessary for adopting Industry 4.0 and its main thematic and topical research axes. We conducted SLR and identified the main methodological contributions published between 2017–2022 that address the seven strategic alignment perspectives necessary for implementing Industry 4.0 in companies. This study conceptualizes a framework that guides the strategic alignment process and identifies 10 thematic axes and 28 research topics. Additionally, it offers a perspective on the challenges, benefits, promoters, and opportunities companies face in the era of smart industries. The study analyzed 160 documents, of which 120 were included in the SLR. Italy leads research in methodological proposals, followed by China, Brazil, and India. The Science Direct databases, Emerald Insight, and Taylor & Francis Group contributed significantly. The scientific journals Production Planning & Control, Journal of Manufacturing Technology Management, and Technological Forecasting and Social Change made the greatest contributions with eight publications each.

Industry 4.0 is still in its early stages, with many technological concepts integrated into a conceptual framework. Creating a comprehensive strategic roadmap that identifies and plans each phase (including Gantt charts, costs, and benefits) is necessary to address the challenges of transitioning to Industry 4.0 and providing a global vision of the value chain. However, each company’s strategic adoption of Industry 4.0 will be unique, depending on corporate values, absorption capacity, motivations, HRM policies, intentions, business models, competition, priorities, service level, and budgets. As a result, each Industry 4.0 framework must be designed and adapted to fit the specific needs of each company.

SLR identified various driving forces of Industry 4.0, with customer satisfaction being the most prominent. Other significant drivers included business profitability, market competitiveness, improvements in efficiency, flexibility, quality, delivery times, lower expenses, error rates, and production stops. Corporate process control and reliable operations were also identified as important factors [45].

An effective digital transformation strategy requires a comprehensive understanding of the organization’s current state and future vision. SLR revealed that, in most cases, digital strategies are supported by upper-level management. Many managers believe that increased use of digitalization and automation would allow companies to enhance their competitiveness and profitability.

Transitioning to Industry 4.0 is a complex and costly process. Small and medium-sized enterprises (SMEs) must possess specific skills for strategic planning, maintain an open mindset toward change, and prioritize the development of a digital commercial strategy that includes a high level of technological, digital, operational, and cybernetic maturity. Industry 4.0 adoption also requires integrated approaches to improve productivity, such as integrating ICT technologies and total digitalization of the supply chain. For SMEs, Industry 4.0 adoption can begin with digitalizing some operational areas. All these changes must align with the organization’s central strategy, improve the customer value proposition, and require operational and technical resources. Manufacturers are responsible for directing their digitalization process in a direction that safeguards the triple bottom line. Furthermore, green agreements’ demands must also be resolved within Industry 4.0 frameworks.

Industry 4.0 offers external knowledge that enables companies to participate in exploratory and exploitative innovation strategies, leading to new business models or restructuring existing ones. A company’s ability to absorb knowledge is essential to achieve these results. Industry 4.0 companies must also interact with other companies to access and transfer knowledge. For SMEs, a useful example of technological innovation is transforming and exploiting external knowledge. SMEs should seek associations with ICT 4.0 specialists, technology suppliers, or expert consultants to find scalable solutions that can adapt Industry 4.0 knowledge to the specific needs of their business model. While SMEs have been using Industry 4.0 to improve efficiency, they should also explore new business opportunities. Conversely, larger companies must adopt a transverse organizational culture to ensure their innovation strategies are effective. This synergy allows for knowledge transfer.

Industry-4.0-related policies must be supported by a constant flow of information and support to disseminate opportunities, decisions, barriers, and challenges in the search for new digital models. These policies should be articulated through the collaborative triple helix work model of innovation and management support essential for exploratory and exploitative innovation. This approach transforms traditional supply chains into innovation ecosystems for Industry 4.0. Government policies should provide access to production technology and information technologies, financing, specific information, display tools, implementation supports, and computer security to overcome the budget limitations of SMEs. Additionally, policies should promote the formation of national and international networks to share knowledge and improve collaboration between SMEs.

Soon, companies will be completely driven by artificial intelligence with the support of Industry 4.0 technologies, such as smart machines, Big Data, IIoT, robots, high-speed communication architectures, and blockchain. However, the path to the successful implementation of Industry 4.0 is long and still in its early stages. Several strategic challenges are hindering the process. Combining the conceptual knowledge of digital transformation with the planning of solid strategies will facilitate effective digital transformations. Therefore, companies must adopt Industry 4.0 as soon as possible to avoid falling behind.

Future research should take a more global approach to evaluate other strategic alignment perspectives for Industry 4.0 and compare regional similarities and differences. Additionally, it is necessary to study the effects of Industry 4.0 technologies on business models and the impact of changes in working conditions and identify challenges and drivers. Finally, future research should evaluate the impact of the disruptive events of the COVID-19 pandemic on the technological adoption of Industry 4.0.

Author Contributions

Conceptualization, J.S. (Joel Serey) and M.V.; methodology, G.F. and J.S. (Joel Serey); software, S.G. and C.D.; validation, M.V. and J.S. (Jorge Sabattin); formal analysis, R.T. and M.A.; investigation, G.F. and J.S. (Joel Serey); resources, S.G.; data curation, M.A. and M.V.; writing—original draft preparation, C.D.; writing—review and editing, S.G.; visualization, R.T.; supervision, J.S. (Joel Serey); project administration, G.F. and M.V.; funding acquisition, J.S. (Jorge Sabattin) and M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by DICYT (Scientific and Technological Research Bureau) of the University of Santiago of Chile (USACH) and the Department of Industrial Engineering. This work was supported in part by Fondecyt (Chile), grant No. 11200993 (M.V.). ANID: SAAS with quantum security and 5g for decision making in agriculture, code SUC220081. Corfo: Agriculture Management System Project 21CVID-171949.

Data Availability Statement

Not applicable.

Acknowledgments

This research was supported by DICYT (Scientific and Technological Research Bureau) of the University of Santiago of Chile (USACH) and the Department of Industrial Engineering. This work was supported in part by Fondecyt (Chile), grant No. 11200993 (M.V.). The authors would like to acknowledge and thank the ANID project: SAAS with quantum security and 5g for decision making in agriculture, code SUC220081. Corfo: Agriculture Management System Project 21CVID-171949 and the Dicyt project: Optimization of coverage and location of water reservoirs to extinction forest fires, code 062217AM.

Conflicts of Interest

The authors declare that there are no conflict of interest regarding the publication of this paper.

References

- Serey, J.; Alfaro, M.; Fuertes, G.; Vargas, M.; Durán, C.; Ternero, R.; Rivera, R.; Sabattin, J. Pattern Recognition and Deep Learning Technologies, Enablers of Industry 4.0, and Their Role in Engineering Research. Symmetry 2023, 15, 535. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical Factors for the Successful Implementation of Industry 4.0: A Review and Future Research Direction. Prod. Plan. Control 2019, 31, 799–815. [Google Scholar] [CrossRef]

- Bonaccorsi, A.; Chiarello, F.; Fantoni, G.; Kammering, H. Emerging Technologies and Industrial Leadership. A Wikipedia-Based Strategic Analysis of Industry 4.0. Expert. Syst. Appl. 2020, 160, 113645. [Google Scholar] [CrossRef]

- Bravi, L.; Murmura, F. Industry 4.0 Enabling Technologies as a Tool for the Development of a Competitive Strategy in Italian Manufacturing Companies. J. Eng. Technol. Manag. 2021, 60, 101629. [Google Scholar] [CrossRef]

- Santos, M.Y.; Oliveira e Sá, J.; Andrade, C.; Vale Lima, F.; Costa, E.; Costa, C.; Martinho, B.; Galvão, J. A Big Data System Supporting Bosch Braga Industry 4.0 Strategy. Int. J. Inf. Manag. 2017, 37, 750–760. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Grybauskas, A.; Vilkas, M.; Petraitė, M. Industry 4.0, Innovation, and Sustainable Development: A Systematic Review and a Roadmap to Sustainable Innovation. Bus. Strategy Environ. 2021, 30, 4237–4257. [Google Scholar] [CrossRef]

- Ching, N.T.; Ghobakhloo, M.; Iranmanesh, M.; Maroufkhani, P.; Asadi, S. Industry 4.0 Applications for Sustainable Manufacturing: A Systematic Literature Review and a Roadmap to Sustainable Development. J. Clean. Prod. 2022, 334, 130133. [Google Scholar] [CrossRef]

- Shi, Z.; Xie, Y.; Xue, W.; Chen, Y.; Fu, L.; Xu, X. Smart Factory in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 607–617. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Razzaq, A.; Yu, Z.; Miller, S. Industry 4.0 and Circular Economy Practices: A New Era Business Strategies for Environmental Sustainability. Bus. Strategy Environ. 2021, 30, 4001–4014. [Google Scholar] [CrossRef]

- Dahmani, N.; Benhida, K.; Belhadi, A.; Kamble, S.; Elfezazi, S.; Jauhar, S.K. Smart Circular Product Design Strategies towards Eco-Effective Production Systems: A Lean Eco-Design Industry 4.0 Framework. J. Clean. Prod. 2021, 320, 128847. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.M.; Lau, H.; Yang, Y. Strategic Response to Industry 4.0: An Empirical Investigation on the Chinese Automotive Industry. Ind. Manag. Data Syst. 2018, 118, 589–605. [Google Scholar] [CrossRef]

- Tang, C.S.; Veelenturf, L.P. The Strategic Role of Logistics in the Industry 4.0 Era. Transp. Res. E Logist. Transp. Rev. 2019, 129, 1–11. [Google Scholar] [CrossRef]

- Kaya, İ.; Erdoğan, M.; Karaşan, A.; Özkan, B. Creating a Road Map for Industry 4.0 by Using an Integrated Fuzzy Multicriteria Decision-Making Methodology. Soft Comput. 2020, 24, 17931–17956. [Google Scholar] [CrossRef]

- Morawski, M.; Ignaciuk, P. Choosing a Proper Control Strategy for Multipath Transmission in Industry 4.0 Applications. IEEE Trans. Ind. Inform. 2022, 18, 3609–3619. [Google Scholar] [CrossRef]

- Ancarani, A.; Di Mauro, C.; Mascali, F. Backshoring Strategy and the Adoption of Industry 4.0: Evidence from Europe. J. World Bus. 2019, 54, 360–371. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the Definition of Industry 4.0: Analysis and Open Questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- da Silva, V.L.; Kovaleski, J.L.; Pagani, R.N. Technology Transfer in the Supply Chain Oriented to Industry 4.0: A Literature Review. Technol. Anal. Strateg. Manag. 2018, 31, 546–562. [Google Scholar] [CrossRef]

- Abidi, M.H.; Alkhalefah, H.; Umer, U. Fuzzy Harmony Search Based Optimal Control Strategy for Wireless Cyber Physical System with Industry 4.0. J. Intell. Manuf. 2021, 33, 1795–1812. [Google Scholar] [CrossRef]

- Reiman, A.; Kaivo-oja, J.; Parviainen, E.; Takala, E.P.; Lauraeus, T. Human Factors and Ergonomics in Manufacturing in the Industry 4.0 Context—A Scoping Review. Technol. Soc. 2021, 65, 101572. [Google Scholar] [CrossRef]

- Yu, Z.; Khan, S.A.R.; Umar, M. Circular Economy Practices and Industry 4.0 Technologies: A Strategic Move of Automobile Industry. Bus. Strategy Environ. 2022, 31, 796–809. [Google Scholar] [CrossRef]

- Robert, M.; Giuliani, P.; Gurau, C. Implementing Industry 4.0 Real-Time Performance Management Systems: The Case of Schneider Electric. Prod. Plan. Control 2022, 33, 244–260. [Google Scholar] [CrossRef]

- Colli, M.; Berger, U.; Bockholt, M.; Madsen, O.; Møller, C.; Wæhrens, B.V. A Maturity Assessment Approach for Conceiving Context-Specific Roadmaps in the Industry 4.0 Era. Annu. Rev. Control 2019, 48, 165–177. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Müller, J.M. Business Model Innovation in Small- and Medium-Sized Enterprises: Strategies for Industry 4.0 Providers and Users. J. Manuf. Technol. Manag. 2019, 30, 1127–1142. [Google Scholar] [CrossRef]

- Cucculelli, M.; Dileo, I.; Pini, M. Filling the Void of Family Leadership: Institutional Support to Business Model Changes in the Italian Industry 4.0 Experience. J. Technol. Transf. 2021, 47, 213–241. [Google Scholar] [CrossRef]

- Sahi, G.K.; Gupta, M.C.; Cheng, T.C.E. The Effects of Strategic Orientation on Operational Ambidexterity: A Study of Indian SMEs in the Industry 4.0 Era. Int. J. Prod. Econ. 2020, 220, 107395. [Google Scholar] [CrossRef]

- Teixeira, J.E.; Tavares-Lehmann, A.T.C.P. Industry 4.0 in the European Union: Policies and National Strategies. Technol. Forecast. Soc. Change 2022, 180, 121664. [Google Scholar] [CrossRef]

- Bonamigo, A.; Frech, C.G. Industry 4.0 in Services: Challenges and Opportunities for Value Co-Creation. J. Serv. Mark. 2020, 35, 412–427. [Google Scholar] [CrossRef]

- Di Maria, E.; De Marchi, V.; Galeazzo, A. Industry 4.0 Technologies and Circular Economy: The Mediating Role of Supply Chain Integration. Bus. Strategy Environ. 2022, 31, 619–632. [Google Scholar] [CrossRef]

- Arromba, I.F.; Martin, P.S.; Cooper Ordoñez, R.; Anholon, R.; Rampasso, I.S.; Santa-Eulalia, L.A.; Martins, V.W.B.; Quelhas, O.L.G. Industry 4.0 in the Product Development Process: Benefits, Difficulties and Its Impact in Marketing Strategies and Operations. J. Bus. Ind. Mark. 2021, 36, 522–534. [Google Scholar] [CrossRef]

- Kucukaltan, B.; Saatcioglu, O.Y.; Irani, Z.; Tuna, O. Gaining Strategic Insights into Logistics 4.0: Expectations and Impacts. Prod. Plan. Control 2020, 33, 211–227. [Google Scholar] [CrossRef]

- Trzaska, R.; Sulich, A.; Organa, M.; Niemczyk, J.; Jasiński, B. Digitalization Business Strategies in Energy Sector: Solving Problems with Uncertainty under Industry 4.0 Conditions. Energies 2021, 14, 7997. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M. Digital Transformation Success under Industry 4.0: A Strategic Guideline for Manufacturing SMEs. J. Manuf. Technol. Manag. 2021, 32, 1533–1556. [Google Scholar] [CrossRef]

- Mukhuty, S.; Upadhyay, A.; Rothwell, H. Strategic Sustainable Development of Industry 4.0 through the Lens of Social Responsibility: The Role of Human Resource Practices. Bus. Strategy Environ. 2022, 31, 2068–2081. [Google Scholar] [CrossRef]

- Chiarini, A.; Belvedere, V.; Grando, A. Industry 4.0 Strategies and Technological Developments. An Exploratory Research from Italian Manufacturing Companies. Prod. Plan. Control 2020, 31, 1385–1398. [Google Scholar] [CrossRef]

- Smuts, S.; van der Merwe, A.; Smuts, H. A Strategic Organisational Perspective of Industry 4.0: A Conceptual Model. In Proceedings of the Responsible Design, Implementation and Use of Information and Communication Technology; Springer: Skukuza, South Africa, 2020; pp. 89–101. [Google Scholar]

- Müller, J.M.; Buliga, O.; Voigt, K.I. The Role of Absorptive Capacity and Innovation Strategy in the Design of Industry 4.0 Business Models—A Comparison between SMEs and Large Enterprises. Eur. Manag. J. 2021, 39, 333–343. [Google Scholar] [CrossRef]

- Chauhan, C.; Singh, A.; Luthra, S. Barriers to Industry 4.0 Adoption and Its Performance Implications: An Empirical Investigation of Emerging Economy. J. Clean. Prod. 2021, 285, 124809. [Google Scholar] [CrossRef]

- Virmani, N.; Salve, U.R.; Kumar, A.; Luthra, S. Analyzing Roadblocks of Industry 4.0 Adoption Using Graph Theory and Matrix Approach. IEEE Trans. Eng. Manag. 2021, 70, 454–463. [Google Scholar] [CrossRef]

- Benešová, A.; Basl, J.; Tupa, J.; Steiner, F. Design of a Business Readiness Model to Realise a Green Industry 4.0 Company. Int. J. Comput. Integr. Manuf. 2021, 34, 920–932. [Google Scholar] [CrossRef]

- Lin, T.C.; Wang, K.J.; Sheng, M.L. To Assess Smart Manufacturing Readiness by Maturity Model: A Case Study on Taiwan Enterprises. Int. J. Comput. Integr. Manuf. 2020, 33, 102–115. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ferreira-Lima, M.; Ayala, N.F.; Frank, A.G. Industry 4.0 Technology Provision: The Moderating Role of Supply Chain Partners to Support Technology Providers. Supply Chain. Manag. 2022, 27, 89–112. [Google Scholar] [CrossRef]

- Mubarak, M.F.; Petraite, M. Industry 4.0 Technologies, Digital Trust and Technological Orientation: What Matters in Open Innovation? Technol. Forecast. Soc. Change 2020, 161, 120332. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Herceg, I.V.; Kuč, V.; Mijušković, V.M.; Herceg, T. Challenges and Driving Forces for Industry 4.0 Implementation. Sustainability 2020, 12, 4208. [Google Scholar] [CrossRef]

- Senna, P.P.; Ferreira, L.M.D.F.; Barros, A.C.; Bonnín Roca, J.; Magalhães, V. Prioritizing Barriers for the Adoption of Industry 4.0 Technologies. Comput. Ind. Eng. 2022, 171, 108428. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Y.; Chen, H.; Chong, D. Industry 4.0 and Its Implementation: A Review. Inf. Syst. Front. 2021, 1–11. [Google Scholar] [CrossRef]

- Wamba, S.F.; Queiroz, M.M. Industry 4.0 and the Supply Chain Digitalisation: A Blockchain Diffusion Perspective. Prod. Plan. Control 2020, 33, 193–210. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M. Corporate Survival in Industry 4.0 Era: The Enabling Role of Lean-Digitized Manufacturing. J. Manuf. Technol. Manag. 2020, 31, 1–30. [Google Scholar] [CrossRef]

- Prause, M. Challenges of Industry 4.0 Technology Adoption for SMEs: The Case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef]

- Liu, B.; De Giovanni, P. Green Process Innovation through Industry 4.0 Technologies and Supply Chain Coordination. Ann. Oper. Res. 2019, 1–36. [Google Scholar] [CrossRef]

- Jabr, W.; Zheng, Z. Exploring Firm Strategy Using Financial Reports: Performance Impact of Inward and Outward Relatedness with Digitisation. Eur. J. Inf. Syst. 2020, 31, 145–165. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, W.; Zhou, G.; Shi, X.; Long, S.; Chen, Z.; Yan, X. Supply Chain Innovation Announcements and Shareholder Value under Industries 4.0 and 5.0: Evidence from China. Ind. Manag. Data Syst. 2022, 122, 1909–1937. [Google Scholar] [CrossRef]

- Bai, C.; Orzes, G.; Sarkis, J. Exploring the Impact of Industry 4.0 Technologies on Social Sustainability through a Circular Economy Approach. Ind. Mark. Manag. 2022, 101, 176–190. [Google Scholar] [CrossRef]

- Kosolapova, N.A.; Matveeva, L.G.; Nikitaeva, A.Y.; Molapisi, L. The Rational Use of Water Resources in the Strategy of Industry 4.0. Water Resour. Manag. 2021, 35, 3023–3041. [Google Scholar] [CrossRef]

- Ramanathan, K.; Samaranayake, P. Assessing Industry 4.0 Readiness in Manufacturing: A Self-Diagnostic Framework and an Illustrative Case Study. J. Manuf. Technol. Manag. 2022, 33, 468–488. [Google Scholar] [CrossRef]

- Asokan, D.R.; Huq, F.A.; Smith, C.M.; Stevenson, M. Socially Responsible Operations in the Industry 4.0 Era: Post-COVID-19 Technology Adoption and Perspectives on Future Research. Int. J. Oper. Prod. Manag. 2022, 42, 185–217. [Google Scholar] [CrossRef]

- Calzavara, M.; Battini, D.; Bogataj, D.; Sgarbossa, F.; Zennaro, I. Ageing Workforce Management in Manufacturing Systems: State of the Art and Future Research Agenda. Int. J. Prod. Res. 2019, 58, 729–747. [Google Scholar] [CrossRef]

- Caputo, F.; Cillo, V.; Candelo, E.; Liu, Y. Innovating through Digital Revolution: The Role of Soft Skills and Big Data in Increasing Firm Performance. Manag. Decis. 2019, 57, 2032–2051. [Google Scholar] [CrossRef]

- James, A.T.; Kumar, G.; Tayal, P.; Chauhan, A.; Wadhawa, C.; Panchal, J. Analysis of Human Resource Management Challenges in Implementation of Industry 4.0 in Indian Automobile Industry. Technol. Forecast. Soc. Change 2022, 176, 121483. [Google Scholar] [CrossRef]

- Ciffolilli, A.; Muscio, A. Industry 4.0: National and Regional Comparative Advantages in Key Enabling Technologies. Eur. Plan. Stud. 2018, 26, 2323–2343. [Google Scholar] [CrossRef]

- Nagy, J.; Oláh, J.; Erdei, E.; Máté, D.; Popp, J. The Role and Impact of Industry 4.0 and the Internet of Things on the Business Strategy of the Value Chain—The Case of Hungary. Sustainability 2018, 10, 3491. [Google Scholar] [CrossRef]

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing Industry 4.0 Readiness in Manufacturing: Evidence for the European Union. Comput. Ind. 2019, 107, 22–32. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Purohit, J.K.; Menon, K.; Romero, D.; Wuest, T. A Smart Manufacturing Adoption Framework for SMEs. Int. J. Prod. Res. 2020, 58, 1555–1573. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Gavião, L.O.; Ivson, P.; de Mattos Nascimento, D.L.; Garza-Reyes, J.A. A Fuzzy Rule-Based Industry 4.0 Maturity Model for Operations and Supply Chain Management. Int. J. Prod. Econ. 2021, 231, 107883. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, A.; Kumar, V.; Garza-Reyes, J.A.A. Machine Learning Applications for Sustainable Manufacturing: A Bibliometric-Based Review for Future Research. J. Enterp. Inf. Manag. 2022, 35, 566–596. [Google Scholar] [CrossRef]

- Xu, X.; Hua, Q. Industrial Big Data Analysis in Smart Factory: Current Status and Research Strategies. IEEE Access 2017, 5, 17543–17551. [Google Scholar] [CrossRef]

- Khayyam, H.; Jamali, A.; Bab-Hadiashar, A.; Esch, T.; Ramakrishna, S.; Jalili, M.; Naebe, M. A Novel Hybrid Machine Learning Algorithm for Limited and Big Data Modeling with Application in Industry 4.0. IEEE Access 2020, 8, 111381–111393. [Google Scholar] [CrossRef]

- López Martínez, P.; Dintén, R.; Drake, J.M.; Zorrilla, M. A Big Data-Centric Architecture Metamodel for Industry 4.0. Future Gener. Comput. Syst. 2021, 125, 263–284. [Google Scholar] [CrossRef]

- Jagatheesaperumal, S.K.; Rahouti, M.; Ahmad, K.; Al-Fuqaha, A.; Guizani, M. The Duo of Artificial Intelligence and Big Data for Industry 4.0: Applications, Techniques, Challenges, and Future Research Directions. IEEE Internet Things J. 2022, 9, 12861–12885. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K. Application of Industry 4.0 Technologies for Effective Coordination in Humanitarian Supply Chains: A Strategic Approach. Ann. Oper. Res. 2021, 319, 379–411. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Yang, G. Smart Supply Chain Management in Industry 4.0: The Review, Research Agenda and Strategies in North America. Ann. Oper. Res. 2022, 322, 1075–1117. [Google Scholar] [CrossRef] [PubMed]

- Raji, I.O.; Shevtshenko, E.; Rossi, T.; Strozzi, F. Industry 4.0 Technologies as Enablers of Lean and Agile Supply Chain Strategies: An Exploratory Investigation. Int. J. Logist. Manag. 2021, 32, 1150–1189. [Google Scholar] [CrossRef]

- Lassnig, M.; Müller, J.M.; Klieber, K.; Zeisler, A.; Schirl, M. A Digital Readiness Check for the Evaluation of Supply Chain Aspects and Company Size for Industry 4.0. J. Manuf. Technol. Manag. 2022, 33, 1–18. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-Sized Enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R.; Jafarnejad, H. The Smart SME Technology Readiness Assessment Methodology in the Context of Industry 4.0. J. Manuf. Technol. Manag. 2021, 32, 1037–1065. [Google Scholar] [CrossRef]

- Lizarralde, D.R.; Ganzarain, E.J.; Lopez, L.C.; Serrano, L.I. An Industry 4.0 Maturity Model for Machine Tool Companies. Technol. Forecast. Soc. Change 2020, 159, 120203. [Google Scholar] [CrossRef]

- Tang, Y.M.; Chau, K.Y.; Fatima, A.; Waqas, M. Industry 4.0 Technology and Circular Economy Practices: Business Management Strategies for Environmental Sustainability. Environ. Sci. Pollut. Res. 2022, 29, 49752–49769. [Google Scholar] [CrossRef]

- Gallego-García, S.; Groten, M.; Halstrick, J. Integration of Improvement Strategies and Industry 4.0 Technologies in a Dynamic Evaluation Model for Target-Oriented Optimization. Appl. Sci. 2022, 12, 1530. [Google Scholar] [CrossRef]

- Chang, S.C.; Chang, H.H.; Lu, M.T. Evaluating Industry 4.0 Technology Application in SMEs: Using a Hybrid MCDM Approach. Mathematics 2021, 9, 414. [Google Scholar] [CrossRef]

- Bruno, G.; Antonelli, D. Dynamic Task Classification and Assignment for the Management of Human-Robot Collaborative Teams in Workcells. Int. J. Adv. Manuf. Technol. 2018, 98, 2415–2427. [Google Scholar] [CrossRef]

- Cimini, C.; Pirola, F.; Pinto, R.; Cavalieri, S. A Human-in-the-Loop Manufacturing Control Architecture for the next Generation of Production Systems. J. Manuf. Syst. 2020, 54, 258–271. [Google Scholar] [CrossRef]

- Somohano-Rodríguez, F.M.; Madrid-Guijarro, A.; López-Fernández, J.M. Does Industry 4.0 Really Matter for SME Innovation? J. Small Bus. Manag. 2020, 60, 1001–1028. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S. Industry 4.0 Adoption and 10R Advance Manufacturing Capabilities for Sustainable Development. Int. J. Prod. Econ. 2021, 231, 107844. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A Supply Chain Innovation Perspective. Int. J. Prod. Res. 2019, 58, 1425–1441. [Google Scholar] [CrossRef]

- Soni, G.; Kumar, S.; Mahto, R.V.; Mangla, S.K.; Mittal, M.L.; Lim, W.M. A Decision-Making Framework for Industry 4.0 Technology Implementation: The Case of FinTech and Sustainable Supply Chain Finance for SMEs. Technol. Forecast. Soc. Change 2022, 180, 121686. [Google Scholar] [CrossRef]

- Kim, J.; Campbell, A.S.; de Ávila, B.E.F.; Wang, J. Wearable Biosensors for Healthcare Monitoring. Nat. Biotechnol. 2019, 37, 389–406. [Google Scholar] [CrossRef] [PubMed]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 Innovation Ecosystems: An Evolutionary Perspective on Value Cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Ertz, M.; Sun, S.; Boily, E.; Kubiat, P.; Quenum, G.G.Y. How Transitioning to Industry 4.0 Promotes Circular Product Lifetimes. Ind. Mark. Manag. 2022, 101, 125–140. [Google Scholar] [CrossRef]

- Paiola, M.; Schiavone, F.; Khvatova, T.; Grandinetti, R. Prior Knowledge, Industry 4.0 and Digital Servitization. An Inductive Framework. Technol. Forecast. Soc. Change 2021, 171, 120963. [Google Scholar] [CrossRef]

- Alkaraan, F.; Albitar, K.; Hussainey, K.; Venkatesh, V.G. Corporate Transformation toward Industry 4.0 and Financial Performance: The Influence of Environmental, Social, and Governance (ESG). Technol. Forecast. Soc. Change 2022, 175, 121423. [Google Scholar] [CrossRef]

- Sung, T.K. Industry 4.0: A Korea Perspective. Technol. Forecast. Soc. Change 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Key Ingredients for Evaluating Industry 4.0 Readiness for Organizations: A Literature Review. Benchmark. Int. J. 2020, 27, 2213–2232. [Google Scholar] [CrossRef]

- Tripathi, S.; Gupta, M. A Holistic Model for Global Industry 4.0 Readiness Assessment. Benchmark. Int. J. 2021, 28, 3006–3039. [Google Scholar] [CrossRef]

- Fuertes, G.; Zamorano, J.; Alfaro, M.; Vargas, M.; Sabattin, J.; Duran, C.; Ternero, R.; Rivera, R. Opportunities of the Technological Trends Linked to Industry 4.0 for Achieve Sustainable Manufacturing Objectives. Sustainability 2022, 14, 11118. [Google Scholar] [CrossRef]

- Yang, F.; Gu, S. Industry 4.0, a Revolution That Requires Technology and National Strategies. Complex. Intell. Syst. 2021, 7, 1311–1325. [Google Scholar] [CrossRef]

- Rocha, C.F.; Quandt, C.O.; Deschamps, F.; Philbin, S. R&D Collaboration Strategies for Industry 4.0 Implementation: A Case Study in Brazil. J. Eng. Technol. Manag. 2022, 63, 101675. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 Technologies on Lean Principles. Int. J. Prod. Res. 2019, 58, 1644–1661. [Google Scholar] [CrossRef]

- Verma, A.; Venkatesan, M. Industry 4.0 Workforce Implications and Strategies for Organisational Effectiveness in Indian Automotive Industry: A Review. Technol. Anal. Strateg. Manag. 2021, 35, 1241–1249. [Google Scholar] [CrossRef]

- Mian, S.H.; Salah, B.; Ameen, W.; Moiduddin, K.; Alkhalefah, H. Adapting Universities for Sustainability Education in Industry 4.0: Channel of Challenges and Opportunities. Sustainability 2020, 12, 6100. [Google Scholar] [CrossRef]

- Vereycken, Y.; Ramioul, M.; Desiere, S.; Bal, M. Human Resource Practices Accompanying Industry 4.0 in European Manufacturing Industry. J. Manuf. Technol. Manag. 2021, 32, 1016–1036. [Google Scholar] [CrossRef]

- da Silva, L.B.P.; Soltovski, R.; Pontes, J.; Treinta, F.T.; Leitão, P.; Mosconi, E.; de Resende, L.M.M.; Yoshino, R.T. Human Resources Management 4.0: Literature Review and Trends. Comput. Ind. Eng. 2022, 168, 108111. [Google Scholar] [CrossRef]

- Ansari, F.; Hold, P.; Khobreh, M. A Knowledge-Based Approach for Representing Jobholder Profile toward Optimal Human–Machine Collaboration in Cyber Physical Production Systems. CIRP J. Manuf. Sci. Technol. 2020, 28, 87–106. [Google Scholar] [CrossRef]

- Bogoviz, A.V. Perspective Directions of State Regulation of Competition between Human and Artificial Intellectual Capital in Industry 4.0. J. Intellect. Cap. 2020, 21, 583–600. [Google Scholar] [CrossRef]

- Brocal, F.; González, C.; Komljenovic, D.; Katina, P.F.; Sebastián, M.A.; Garciá-Alcaraz, J.L. Emerging Risk Management in Industry 4.0: An Approach to Improve Organizational and Human Performance in the Complex Systems. Complexity 2019, 2019, 13. [Google Scholar] [CrossRef]

- Leong, W.D.; Teng, S.Y.; How, B.S.; Ngan, S.L.; Rahman, A.A.; Tan, C.P.; Ponnambalam, S.G.; Lam, H.L. Enhancing the Adaptability: Lean and Green Strategy towards the Industry Revolution 4.0. J. Clean. Prod. 2020, 273, 122870. [Google Scholar] [CrossRef]

- Stentoft, J.; Adsbøll Wickstrøm, K.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: Empirical Evidence from Small and Medium-Sized Manufacturers. Prod. Plan. Control 2020, 32, 811–828. [Google Scholar] [CrossRef]

- Calabrese, A.; Levialdi Ghiron, N.; Tiburzi, L. ‘Evolutions’ and ‘Revolutions’ in Manufacturers’ Implementation of Industry 4.0: A Literature Review, a Multiple Case Study, and a Conceptual Framework. Prod. Plan. Control 2020, 32, 213–227. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The Industrial Management of SMEs in the Era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on Supply Chain Performance. Prod. Plan. Control 2020, 32, 63–81. [Google Scholar] [CrossRef]

- Pacchini, A.P.T.; Lucato, W.C.; Facchini, F.; Mummolo, G. The Degree of Readiness for the Implementation of Industry 4.0. Comput. Ind. 2019, 113, 103125. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Introna, V.; Santolamazza, A.; Cesarotti, V. Maintenance Transformation through Industry 4.0 Technologies: A Systematic Literature Review. Comput. Ind. 2020, 123, 103335. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The Impact of Digital Technology and Industry 4.0 on the Ripple Effect and Supply Chain Risk Analytics. Int. J. Prod. Res. 2018, 57, 829–846. [Google Scholar] [CrossRef]