Abstract

In this paper, through a similar simulation experiment, the roof rock breaking situation of horizontal sublevel caving method in extremely thick and steep inclined coal seam is studied, and the response characteristics of coal and rock mass under different dynamic load strength are analyzed. The mechanical response mechanisms of different mining positions under the influence of dynamic load and the law characteristics of the surrounding rock from elastic deformation to impact failure are revealed. The study shows that with the increase in the horizontal sublevel mining depth, the roof is gradually broken from the suspended state, and the broken block fills the goaf. The thin rock strata form a granular structure, and the thick rock strata form a block splicing and occlusion structure. On the same side of the coal seam floor, the concentrated stress gradually increases, and the closer the distance from the goaf is, the more obvious the stress change in the coal body below is. With the increase in dynamic load energy, the dynamic instability and failure of the dynamic load side of the roadway occur, and the stress of the bottom coal in the intake roadway of the working face increases due to the influence of the lateral abutment pressure of the goaf, while the stress of the bottom coal in the middle of the working face and the return airway decreases due to the mining of the upper section, which reveals that the dynamic load-induced dynamic behavior requires the critical energy. Due to vibration waves, the dynamic load effect is short, and the reflective stretching is generated on the surface of the roadway, resulting in the failure of the roadway. The peak acceleration increases linearly with the increase in source energy, indicating that the stronger the dynamic load energy is, the higher the impact risk is. When the dynamic load intensity is constant, the peak acceleration decreases with the increase in propagation distance, indicating that the vibration wave has the dominant propagation direction, and there are certain directional differences in the effect of coal and rock. When the dynamic load is applied, the impact failure of the coal body has a critical displacement. When the displacement of the roadway surface is less than this critical displacement, the impact failure will not occur.

1. Introduction

A coal seam with a thickness greater than 8 m and a dip angle greater than 45° is defined as an extremely thick steeply inclined coal seam in China. The horizontal sublevel mining technology of steep and extra thick coal seams has formed a unique overburden migration law. Many scholars have conducted a lot of research on the horizontal sublevel mining technology of steep and extra thick coal seams. Ju Wenjun et al. [,] analyzed the causes of rock burst through in situ measurement and mechanical derivation of multi-layer steep coal seam mining, and pointed out that the mechanical causes of rock burst are mining superimposed stress and the unstable impact load of overburden cantilever beam structures; Lai Xingping [,,,] pointed out through theoretical analysis and in situ monitoring that the mining stress of multi-seam mining is transmitted to the interlayer coal and rock pillars, causing the coal and rock pillars to bend and squeeze the coal seam to induce the rock burst. Secondly, the dynamic disaster in shallow to deep fully mechanized open mining of steep coal seams is essentially the cyclic dynamic impact caused by the instability of the overburden structure under the repeated disturbance of horizontal segmented and multi-stage mining; Dou Linming [,,,] pointed out that the cause of rock bursts caused by mining of steep coal seam is the clamping and squeezing effect of the roof and floor on the coal body on both sides; Wang Ningbo et al. [] pointed out that the surrounding rock of roadway in steeply inclined and extra thick coal seam has zoning fracture characteristics by analyzing the fracture morphology of roadways surrounding the rock and the structural characteristics of coal and rock mass in horizontal sublevel mining of steeply inclined coal seams; Zhang Jiwei et al. [] put forward the method of directional release of elastic energy of an overhanging roof structure in a large dip and extra thick coal seam, which can effectively prevent and control the impact disaster of mining roadway. Jiang Fuxing et al. [] believe that the bottom coal will be plastically damaged under the influence of horizontal stress, and that the slip impact will be due to vertical stress. They have established an estimation model of the sliding limit bearing capacity of the bottom coal in the mining of extra thick coal seams and an estimation model of the advance bearing pressure of the accident working face, and studied the occurrence mechanism of the overall sliding instability type rock burst of the bottom coal in the mining of extra thick coal seams; Du Taotao, Yu Guiliang [,] and others believe that the mutual disturbance of upper mining and lower mining in steep coal seams is the main inducement for the formation of rock bursts. Miao Shengjun et al. [,] pointed out through theoretical analysis and field in situ monitoring that the mining stress of multi-seam mining is transmitted to the interlayer coal and rock pillars, causing the coal and rock pillars to bend and squeeze the coal seam to induce the rock burst behavior; and secondly, the cyclic dynamic impact caused by the instability of the overburden structure under the repeated disturbance of horizontal segmented multi-stage mining. Cai, M.; Jeoungseok, Y. [,] and others pointed out that the hard roof slate has obvious elastic–brittle plastic failure characteristics by analyzing the mechanical characteristics, roof collapse law, and sudden collapse characteristics of the coal rock mass with a steep and hard roof. The elastic–brittle plastic strain softening constitutive model is used to calculate the failure process of a coal rock contact surface, which can reasonably reflect the failure characteristics of a coal rock roof with a steep and hard roof.

The above researchers have conducted research on the production of rock bursts and the fracture of surrounding rock in the mining of steeply inclined coal seams. On this basis, this paper takes the mining of steeply inclined coal seams in the Yaojie No. 3 coal mine as the background, and uses dynamic and static superposition similarity simulation to study the temporal and spatial evolution law of overburden structure fracture and the response characteristics of coal and rock mass.

2. Mine Overview

The third mine of the Yaojie Coal Power Group is located in Yaojie Town, Honggu District, Lanzhou city. The production capacity of the mine is 1.8 million tons annually, and the main mining is at the 2# coal seam. The average dip angle of the coal seam is 53°, the average thickness is 24.6 m, and the burial depth is +1760~+1100 m. It is an extremely thick and steep coal seam. The coal seams in the fifth mining area in this study are basically complete, but they are partially characterized by compression and distortion dislocation. Within 30 m near the f604 reverse fault, the coal body is severely crumpled, joint fissures are developed, and the coal seam structure is complex. There are 2–4 layers of intercalated rocks with a thickness of 0.2–1 m.

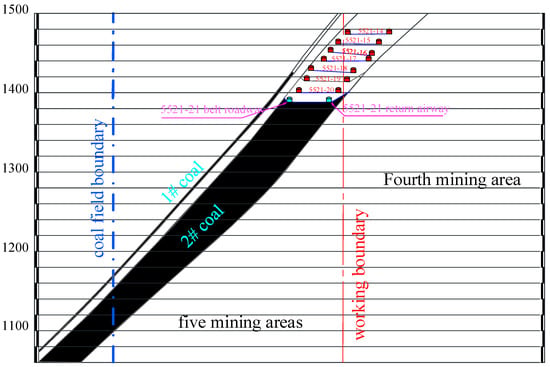

The roadway layout profile of the working face 5521-21 is shown in Figure 1. The false roof of coal seam 2# is carbonaceous mudstone with a thickness of 1–1.6 m. The immediate roof is gray (white) quartz fine sandstone with a thickness of 2–3 m, siliceous cementation, dense, and hard. The baseplate is composed of grayish black carbonaceous mudstone, grayish brown thin-layer fine sandstone, and pebbly sandstone, with developed fractures, loose and easily broken, soft in water, 2–6 m thick, and proctor’s coefficient f = 2–5. See Table 1 for the roof and floor of the coal seam.

Figure 1.

Roadway layout section of 5521-21 working face.

Table 1.

Roof and floor of the coal seam.

3. Design of Similar Simulation Experiment Scheme for Dynamic Loading

In this paper, the response characteristics of roadway coal and rock due to roof breaking and different dynamic load intensities after layered mining are studied through similar tests, and the mechanical response mechanism of different positions of the roadway under the influence of vibration waves when the dynamic load is loaded on roadway coal and rock mass is revealed. Then, the regularity and characteristics of how the dynamic load changes the roadway surrounding the rock, from elastic deformation to impact damage, are determined.

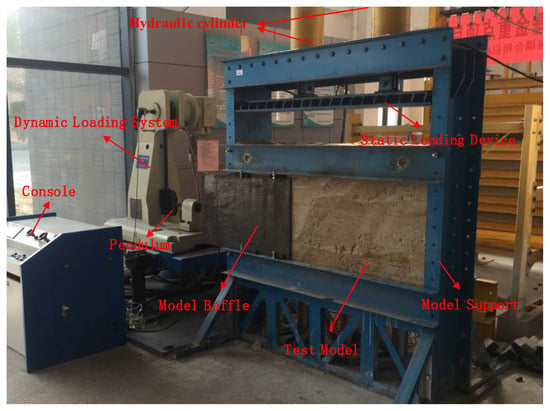

3.1. Test Set

As shown in Figure 2, the test device is divided into four parts: 1. Control table; 2. Dynamic loading device (pendulum); 3. Static loading device (hydraulic cylinder); 4. Model framework. The model frame size is 1.6 m × 0.4 m × 1.2 m (length × width × height). The control table can adjust the pendulum to different heights, control the static load stress, and loading and unloading. The dynamic loading device uses a pendulum to swing to different heights and angles and then freely drop and knock to transfer the rod to form the dynamic load energy, and passes the rod to the plate embedded in the model. The dynamic load is applied to the set position, and the dynamic load propagates in the model in the form of vibration waves and causes coal rock vibration. The static loading device is mainly controlled by the hydraulic cylinder. Two hydraulics are linked to the loading plate that is not on the model. When the loading plate contacts the model, the hydraulic cylinder pressure rises to the preset static loading stress, which is uniformly applied to the upper part of the model, so as to simulate the self-weight stress of coal rock on the upper part of the model.

Figure 2.

Similarity simulation test system.

3.2. Test Monitoring System

As shown in Figure 3, the displacement and acceleration of coal and rock on the roadway can be measured by DH5960 ultra-dynamic signal test and analysis system, and the mechanical parameters such as displacement and acceleration of the roadway sidewall and floor under dynamic load can be measured. The range of the acceleration sensor is set to 3700 m/s, which is enough to meet the measurement requirements of roadway instantaneous deformation under dynamic load. Displacement sensor range is 4 mm, non-contact arrangement on the roadway surface; roadway small vibration deformation can also be measured.

Figure 3.

Ultra-dynamic signal analysis system.

As shown in Figure 4, a PAC acoustic emission system is used to monitor the generation and development of cracks in the model during dynamic loading. The crack propagation in the model will lead to the release and transmission of energy. Using an acoustic emission device to monitor the temporal and spatial characteristics of energy accumulation and release can accurately analyze the damage degree of roadway surrounding rock and reflect the failure process of the surrounding rock. The probe is arranged on the surface of the model, and the acoustic emission signal in the model is received by the porcelain of the probe. The acoustic emission signal includes ringing count, amplitude, and signal waveform. When four or more probes monitor the energy signal, the energy event will be located and the event location will be determined.

Figure 4.

Acoustic emission and high-speed camera acquisition system.

After dynamic loading, the deformation and failure process of the roadway coal rock is short (within 1 s). With ordinary image acquisition equipment, it is difficult to capture the process of dynamic deformation and failure. Memrecam GX-3 high-speed dynamic acquisition system is used in the experiment. The acquisition frequency is set to 1000 frames/s; that is, 1000 images can be taken in 1 s, and the displacement changes caused by the dynamic load can be completely collected.

3.3. Test Dynamic Load Stress Wave Simulation

Dynamic stress waves with different intensities are simulated by adjusting the height of the pendulum. After design, the weight of the pendulum used is 20 kg, and the length of the pendulum rod is 1 m; that is, the maximum height of the pendulum can be set to 2 m; after calculation, the actual maximum gravitational potential energy that can be input is 20 × 9.8 × 2 J = 392.0 J, which is determined by the energy similarity ratio CE, which can simulate the actual mine earthquake energy of 6.53 × 105 J, which is equivalent to the larger energy mine earthquake energy level in the actual mine, so this test can meet the requirements of simulating the actual site. The swing height of the pendulum and the simulated energy are shown in Table 2.

Table 2.

Pendulum position and simulated energy.

4. Analysis of Simulation Results of Dynamic Loading in Horizontal Sublevel Mining

4.1. Analysis of Shock Manifestation Characteristics

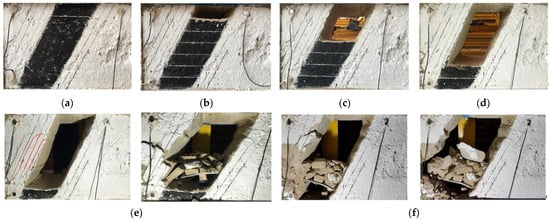

Figure 5 shows the model mining test process and the test phenomenon after the dynamic load is applied, and Figure 6 shows the breaking characteristics of the roof.

Figure 5.

Model excavation process and phenomenon. (a) Not excavated; (b) Tier 1; (c) Tier 3; (d) Tier 5; (e) Tier 6 and Dynamic load applied to the 6th layer; (f) Tier 7 and Dynamic load applied to the 7th layer.

Figure 6.

Roof breaking characteristics. (a) Tier 6 and Local magnification. (b) Dynamic load applied on the sixth layer and Local magnification.

Analysis of Figure 5 and Figure 6 shows that the roof fracture is not obvious after the four horizontal layers at the top of the model are mined and dynamic loads are applied. The maximum swing height of the pendulum in the first 2-layer tests is 0.4 m, and the maximum swing height of the pendulum in the 3–4-layer tests is 0.5 m; that is, the input dynamic load energy is 3.27 × 105 J, the goaf range is limited and the dynamic load is relatively small, and the model is not irreversibly damaged. Because 200 mm of top coal is left on the top of the model, the top coal and the top and bottom plates act to form a mechanical bearing structure, and the roof of the goaf is transformed into a plate with fixed supports at both ends, and the bearing capacity is strong, so the caving step distance is relatively large.

Figure 7 shows the high-speed camera image of the coal rock mass impact in the roadway. When the impact appeared in the seventh layer test, the height of the pendulum was 0.6 m; that is, the dynamic load energy was 4.57 × 105 J.

Figure 7.

High-speed camera image of coal rock impact appearance.

It can be seen from Figure 7 that when the impact appears, the coal and rock around the roadway are partially protruded and damaged, and the impact is relatively violent, the dust rises rapidly and fills the entire goaf area, and the deformation and damage scale of the roof on the left side of the roadway is relatively serious. The caving coal rock at the top of the layer also sank. When the coal rock is elastically deformed and the roof collapses, the damage intensity is not severe. If the roadway coal rock has supporting conditions, the coal rock mass is broken within a controllable range; the impact caused by the dynamic load appears, the coal rock damage range, and the extent of damage and the form of damage are significantly more serious. If the impact occurs during the mining process of the working face, the instantaneous displacement of the coal and rock in the roadway, and the extrusion and deformation of the roadway space will cause serious disaster consequences.

4.2. Analysis of Stress Evolution Law

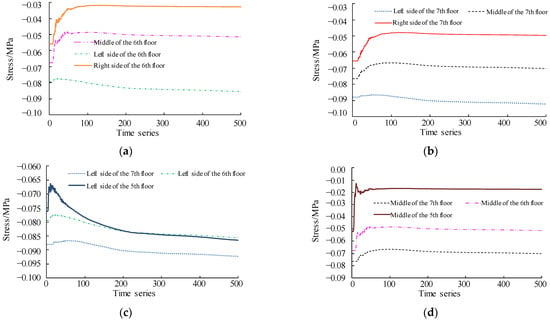

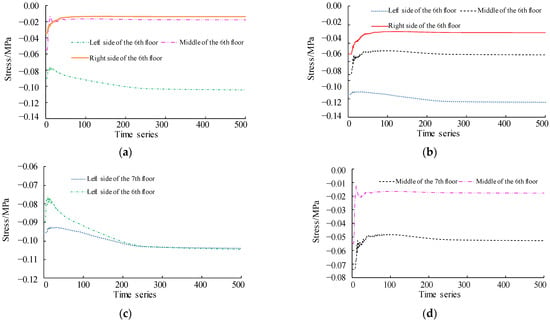

Figure 8 shows the vertical stress distribution law of the 5th, 6th, and 7th horizontally layered bottom plates after the fifth layer is excavated.

Figure 8.

Stress evolution law after excavation in different layers. (a) 6th layer base plate stress; (b) 7th layer base plate stress; (c) Left stress of roadway floor; (d) The middle stress of roadway floor.

From Figure 8a,b, it can be seen that the stress state of the left, middle, and right sides of the same horizontal coal seam floor are not the same; the stress on the left side of the coal seam floor is the largest, followed by the middle of the floor, and the stress on the right side of the floor is at the lowest state. After the excavation of the fifth stratum, the stress in the middle of the bottom plate of the sixth stratum decreases rapidly from −0.068 to −0.05 MPa, and then gradually stabilizes; the stress on the right side of the bottom plate decreases rapidly from −0.056 to −0.033 MPa, and the trend is the same as that in the middle; while the stress on the left side of the bottom plate decreases first from −0.08 to −0.077 MPa and then rises slowly to −0.083 MPa, and finally stabilizes gradually; and unlike the middle and right sides, the stress on the left side of the bottom plate increases rather than decreases. After the coal seam was mined, the top plate did not collapse but the extent of the mining void increased, and the overhanging area of the top plate on the left side was larger; thus, the bending moment was larger. This makes the stress concentration more obvious on the left side of the top plate below, while the central and right side of the bottom plate area also decreases its stress concentration due to the increase in gravity parting moment and the transfer of force. The stress distribution and trend of the bottom plate of the seventh stratum are the same as those of the bottom plate of the sixth stratum, with an increase in the stress on the left side and a decrease in the stress on the middle and right side. From Figure 8c,d, it can be seen that on the same side of the coal seam floor, the stress increases with the increase in mining depth. The magnitude of stress change at the bottom of the fifth stratified coal seam is greater, and the rate of stress rise is faster, so the closer the distance to the mining area, the more obvious the stress change in the coal body below it.

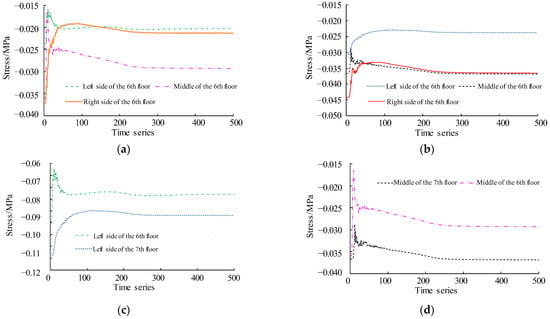

As shown in Figure 9, Figure 10 and Figure 11, the vertical and horizontal stresses of the coal seam floor after the excavation of the sixth and seventh stratum, respectively.

Figure 9.

Static load vertical stress of bottom plate after excavation of the sixth layer. (a) 6th layer; (b) 7th layer; (c) Left side of roadway floor; (d) Middle of roadway floor.

Figure 10.

Static load horizontal stress of bottom plate after excavation of the sixth layer. (a) 6th layer; (b) 7th layer; (c) Left side of roadway floor; (d) Middle of roadway floor.

Figure 11.

Static load stress of bottom plate after excavation of the seventh layer.

Analysis of Figure 9, Figure 10 and Figure 11 shows that: the vertical stress in the coal seam floor is similar to the stress distribution and change trend in Figure 8, while the horizontal stress and vertical stress distribution are not the same. After the sixth stratum was mined, the horizontal stress on the left side of the coal seam floor was relatively small, and the stress on the left side of the bottom of the sixth stratum first decreased and then increased, from −0.025 to −0.016 MPa and then increased to −0.020 MPa and then stabilized; the stress on the left side of the base plate of sublevel 7 then decreases from −0.031 to −0.023 MPa and then gradually stabilizes. The trend of stress changes in the middle and the right side is similar, both decrease first and then increase, and finally, the stress decreases overall. The stress trend on the right side of the 6-layer bottom slab is the largest, with a stress drop of about 0.016 MPa. after the 7th stratification mining, the vertical stress on the left side of the bottom slab first decreases and then increases, and the overall stress is basically the same as before the change after stabilization. In contrast, the vertical stresses in the middle and the right side of the bottom plate decreased rapidly, from −0.06 MPa and −0.03 to −0.01 MPa, respectively, and the vertical stresses in the middle and the right side were almost the same after stabilization. For the horizontal stress, the left, middle, and right-side horizontal stresses are all decreasing before rising, and the stresses are in decreasing state after stabilization, and the stress drops are 0.004 MPa, 0.015 MPa, and 0.018 MPa, respectively, and the right-side horizontal stress decreases and changes the most, while the middle stress is at the highest level after stabilization.

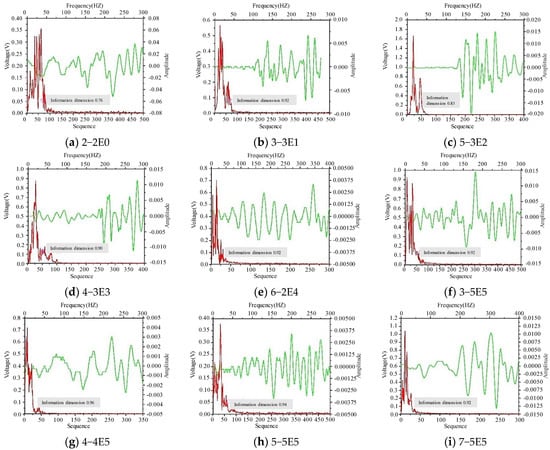

4.3. Acceleration and Displacement Response Characteristics of Coal and Rock

4.3.1. Acceleration Response Characteristics at the Same Position with Different Energies

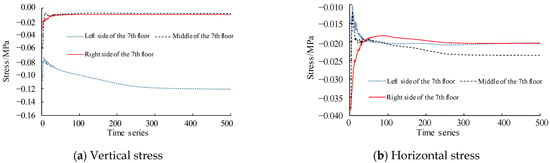

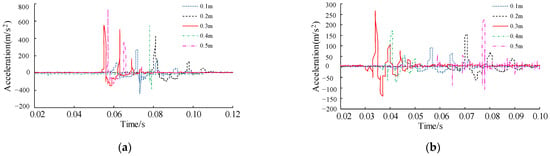

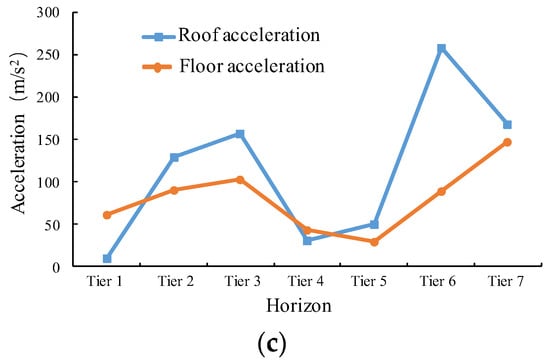

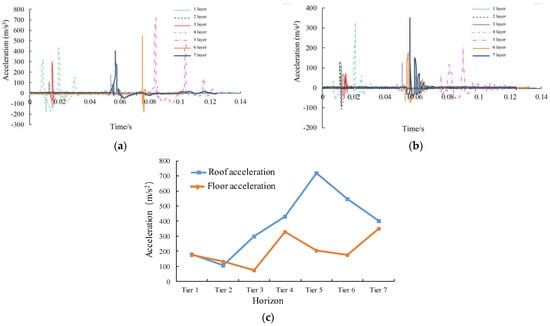

The acceleration of the roadway coal rock under dynamic load is one of the key parameters reflecting the dynamic response of the roadway, and the deformation and damage mode and degree of the roadway coal rock are often related to the peak acceleration. The acceleration response characteristics for different intensity dynamic loads in 5, 6, and 7 strata are shown in Figure 12, Figure 13 and Figure 14.

Figure 12.

Acceleration response characteristics of coal and rock in the fifth layered test. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the bottom of the roadway; (c) Peak acceleration at different energies.

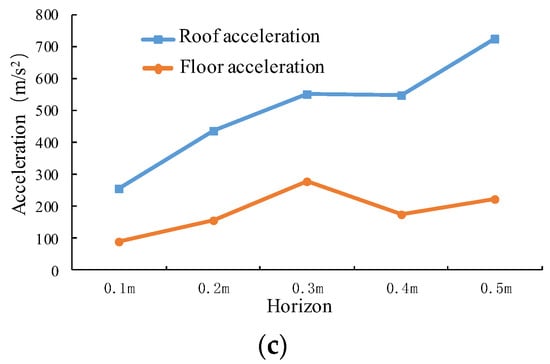

Figure 13.

Acceleration response characteristics of coal and rock in the sixth layered test. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the floor of the roadway; (c) Peak acceleration at different energies.

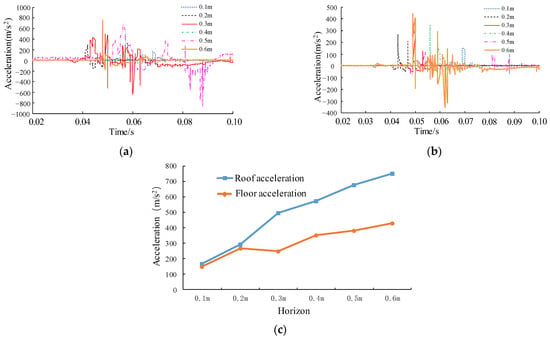

Figure 14.

Acceleration response characteristics of coal and rock in the seventh layered test. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the floor of the roadway; (c) Peak acceleration at different energies.

From the site monitoring, the working face has been at a high level of stress in the roadway on the roof side during the mining process, and the impact hazard is relatively high. Therefore, the acceleration sensor is arranged at the top plate of the coal seam and the bottom plate of the roadway. First of all, from the acceleration time curve, the acceleration at the top and bottom plate oscillates instantaneously and then gradually returns to stability, and the whole vibration process does not exceed 0.05 s, which indicates that the dynamic load is instantaneous. During the vibration process, the acceleration first increases to the positive peak, then decreases to zero and continues to increase to the negative peak, and then continues to reverse vibration. The negative acceleration peak is much smaller than the positive peak, and the negative acceleration recovery time is shorter. This is closely related to the form of vibration wave action, the test loading vibration wave is half-sine wave forward loading, and negative acceleration is mainly caused by the reflected wave.

It can be seen from Figure 13c that with the increase in the source energy, the acceleration peak value also increases gradually, and presents a linear increase process. As shown in Table 3, the slope of the trend line of the peak velocity of layers 5, 6, and 7 under different intensities of dynamic loads. It is not difficult to find that when the source energy increases, the acceleration increase slope is at a high level, resulting in more obvious deformation and damage to the model.

Table 3.

Peak acceleration increasing trend.

For the seventh stratification, the peak acceleration increases continuously when the pendulum is cyclically loaded. When a certain spatial structure is formed at the top of the working face, the increase in mining range will lead to a rapid rise in coal rock stress. When the pendulum height was 0.1–0.5 m, the impact appeared in the roadway, but the response characteristics were more obvious, and the maximum acceleration of the top and bottom plates was 675.8 m/s2 and 381.18 m/s2, respectively, while when the pendulum height was 0.6 m, the impact appeared at the top plate, and the peak acceleration was 752.1 m/s2 and 431.2 m/s2, which increased only 11.3% and 13.1%, respectively. Therefore, when the dynamic load energy and static load stress are superimposed, the coal rock stress reaches a certain level and is in sub-equilibrium; at this time, if the dynamic load energy continues to increase and exceeds the critical load of the coal rock to bear the stress, the impact will be induced. According to the test data, it is known that the critical acceleration peak of the impact of the 5521-21 working face in this simulation test is about 700 m/s2, and it is very easy to occur when this critical value is exceeded.

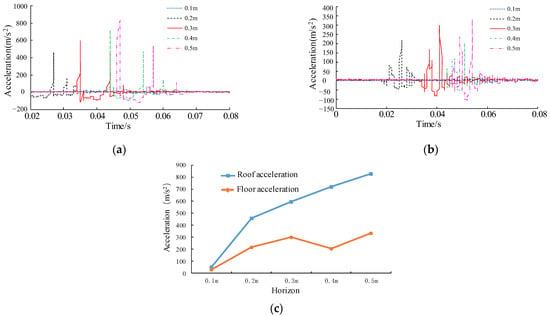

4.3.2. Acceleration Response Characteristics at Different Positions with the Same Energy

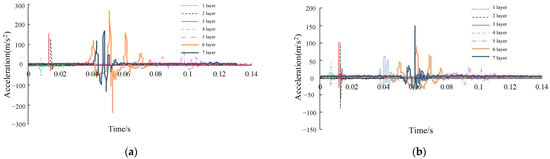

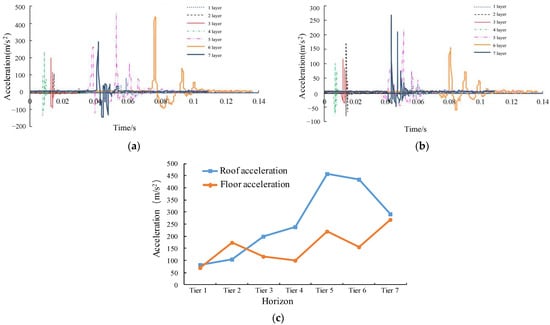

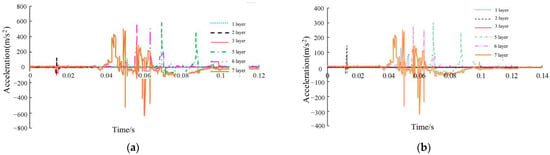

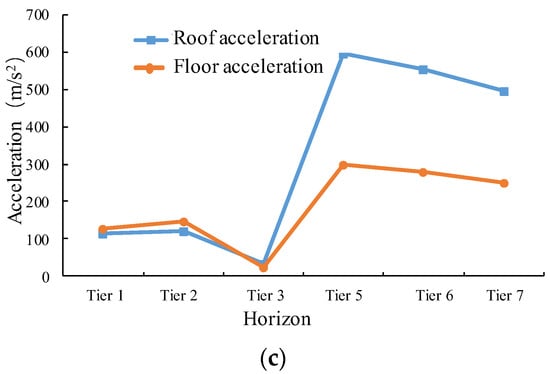

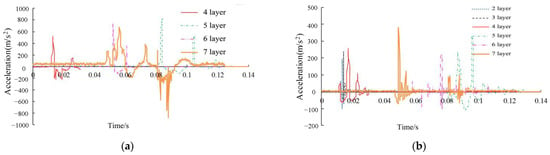

In order to study the relationship between acceleration response characteristics and source propagation distance, the acceleration time history curves of each layer under the same energy condition are compared and analyzed, so as to reveal the influence of propagation distance on the deformation and failure of coal rock. The acceleration response characteristics of each layer under the same dynamic load are shown in Figure 15, Figure 16, Figure 17, Figure 18 and Figure 19.

Figure 15.

Acceleration response characteristics of each layer when the pendulum height is 0.1 m. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the floor of the roadway; (c) Peak acceleration at each level.

Figure 16.

Acceleration response characteristics of each layer when the pendulum height is 0.2 m. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the floor of the roadway; (c) Peak acceleration at each level.

Figure 17.

Acceleration response characteristics of each layer when the pendulum height is 0.3 m. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the floor of the roadway; (c) Peak acceleration at each level.

Figure 18.

Acceleration response characteristics of each layer when the pendulum height is 0.4 m. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the floor of the roadway; (c) Peak acceleration at each level.

Figure 19.

Acceleration response characteristics of each layer when the pendulum height is 0.5 m. (a) Acceleration at the roof of surrounding rock; (b) Acceleration at the floor of the roadway; (c) Peak acceleration at each level.

The baffle for applying dynamic load is buried at 400 mm from the bottom and 500 mm from the left side of the model, and the distance between each stratum and the seismic source is as follows: stratum 5 < stratum 4 < stratum 6 < stratum 7 < stratum 3 < stratum 2 < stratum 1. Analysis of Figure 15, Figure 16, Figure 17, Figure 18 and Figure 19 shows that:

- (1)

- Except for the pendulum height of 0.1 m, the peak acceleration at the top plate of each stratum is basically linear with the propagation distance. Take the pendulum height of 0.4 m as an example, the peak acceleration at the top plate of the fifth stratum is the largest, reaching 718.72 m/s2, while the peak accelerations at the other strata 1–7 are 25.03%, 14.55%, 41.74%, 59.77%, 76.12%, and 55.61%, respectively, the larger the propagation distance, the smaller the peak acceleration value, and the coupling is good.

- (2)

- Although the peak acceleration at the bottom of the roadway and the top of the roadway have similar trends, the differences between individual layers are larger, especially when the dynamic load energy is larger. In addition, taking the pendulum height of 0.4 m as an example, the acceleration peak at the bottom plate of the seventh stratum is the largest, reaching 350.62 m/s2, and the acceleration peaks of the other strata 1–6 are 49.89%, 37.15%, 20.86%, 93.82%, 58.35%, and 49.98%, respectively. The change pattern is obviously different from that at the top plate, but there is a certain correlation with the distance of the seismic source in the vertical direction, which indicates that there is a dominant propagation direction of the vibration wave longitudinal and transverse waves, and there is a certain variability in the direction of action on the form of coal rock action; not only that, when the vibration wave passes through the propagation and action in the medium of the coal body, it makes the form of action of the seismic source on the coal rock body become more complicated.

- (3)

- The propagation distance between stratum 4 and the earthquake source is smaller than that between stratum 6 and 7, but the peak acceleration velocities in stratum 6 and 7 are generally larger than that in stratum 4. By monitoring the model stress, it is found that the pressure in stratum 6 and 7 is significantly higher than that in stratum 4, the stress concentration is higher, and the stress is greater after the superposition of dynamic and static loads. It indicates that the stress has a certain influence on the acceleration response characteristics in the bearing range of the coal body. In addition, when the pendulum height is 0.4 and 0.5 m, the acceleration peak in the fifth stratum is greater than that in the seventh stratum when the impact appears, but no impact occurs, and the stress level in the seventh stratum is higher than that in the fifth stratum, so the dynamic load-induced impact appears as a result of the joint action of multiple factors.

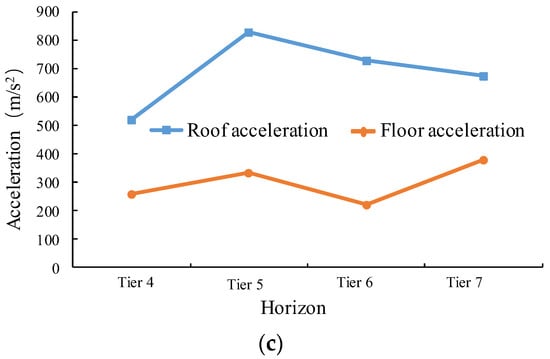

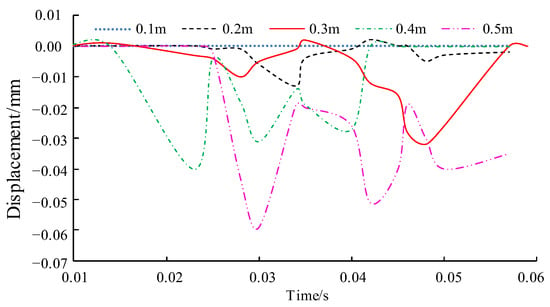

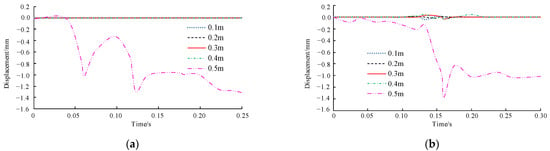

The displacement response characteristics have a certain linear relationship with the acceleration response characteristics, and the change law is similar to that of acceleration. The displacement–deformation characteristics of coal rock under the action of dynamic load were analyzed, but due to the limitation of monitoring equipment, the collection of effective test data was limited, so some displacement data were analyzed to explore the displacement–deformation law of coal rock body after the action of dynamic load. The displacement time curves of stratum 5–7 are shown in Figure 20, Figure 21 and Figure 22, respectively.

Figure 20.

Displacement time history curve at the 5th layer.

Figure 21.

Displacement time history curve of the 6th layer. (a) Displacement at the top plate; (b) Displacement at the base.

Figure 22.

Displacement time history curve of the 7th layer. (a) Displacement at the top plate; (b) Displacement at the base.

Analysis of Figure 20, Figure 21 and Figure 22 shows that: the fifth stratum only monitors the displacement at the bottom plate of the roadway, the sixth stratum is the test pendulum height of 0.5 m, the top and bottom plate displacement is valid data, and the seventh stratum monitoring data are relatively more complete. In Figure 21, the peak displacements of the bottom plate are 0, 0.013 mm, 0.032 mm, 0.04 mm, and 0.059 mm when the pendulum height is 0.1–0.5 m, respectively, and the displacement deformation increases with the increase in dynamic load energy. In Figure 22b, the pendulum height is 0.1–0.6 m, and the peak displacements of the bottom plate are 0.005 mm, 0.092 mm, 0.021 mm, 0.152 mm, 0.273 mm, and 0.733 mm, respectively, compared with stratum 5, the displacement deformation increases more for the same energy dynamic load, similar to the acceleration response characteristics, and the displacement deformation is also related to the dynamic and static load stresses. Closely related to the mining range, a free space increase to a certain extent will also make the coal rock displacement deformation more obvious.

4.4. Response Characteristics of Coal and Rock Acoustic Emission

4.4.1. Acoustic Emission Localization Results

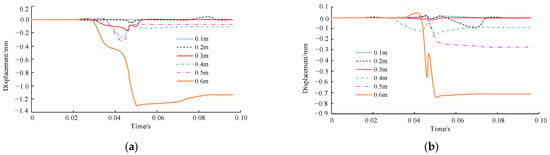

The results of acoustic emission event localization during the test are shown in Figure 23. The rock rupture releases energy and forms a seismic source, and the acoustic emission system reflects the coal rock rupture location by monitoring the source.

Figure 23.

Location results of acoustic emission events in each layer.

From Figure 23, it can be seen that the acoustic emission events are mostly concentrated in the left plate and the bottom plate of the coal seam. In the 1–4 stratum tests, the dynamic load source is located in the lower left position; in the 6 and 7 stratum tests, the dynamic load source is located in the upper left position, and the acoustic emission positioning results accurately reflect the appearance of coal rock rupture after the dynamic load is applied, and the coupling is good. The first and sixth stratification tests did not show events larger than 60 dB, while all other stratifications did. In the first stratum test, the excavation area was limited and the distance from the source of the dynamic load was far, so the rupture of coal rock caused by the dynamic load was not obvious. In the sixth stratification test, the roof was broken and the coal rock stress was released, so the stress level was low and the rupture caused by dynamic load was less. Regardless of the relative position of the dynamic load source, the large energy events mostly occurred at the location of the bottom plate of the coal seam, indicating that the location of the bottom plate was affected by the mining structure after the stress was higher, and the response characteristics were more obvious after the dynamic load was loaded, and the degree of coal rock rupture was larger and the danger was higher.

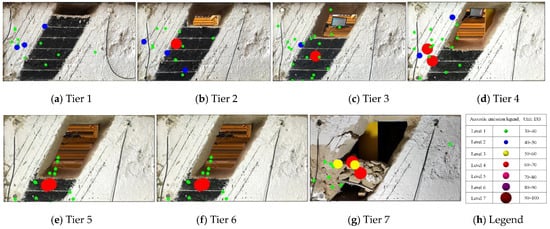

4.4.2. Characteristic Analysis of Coal Rock Fracture Signal

The characteristics of the acoustic emission event signal are shown in Figure 24. The rupture of coal rock is induced after the action of dynamic load to form a seismic source, and the monitoring of the source signal can, to a certain extent, respond to the characteristics of the source, etc.

Figure 24.

Acoustic emission event signal characteristics.

Figure 24a–f show the simulated intensity 100–104 J energy signal waveform and spectrum respectively, and Figure 24g–i shows the signal characteristics above 105 J energy at each stratification test, whereby taking Figure 24f as an example, the 6-2E4 meaning is the 104 J source signal at the sixth stratification pendulum height of 0.2 m. It can be seen from the figure that the signal frequency below 104 J is higher, with a frequency range of 0–100 Hz and with relatively slow decay; the signal main frequency of 104 J and above is more single, with a frequency range of 0–50 Hz; the peak value section of the waveform of large energy signal (above 104 J) has a shorter duration and faster decay.

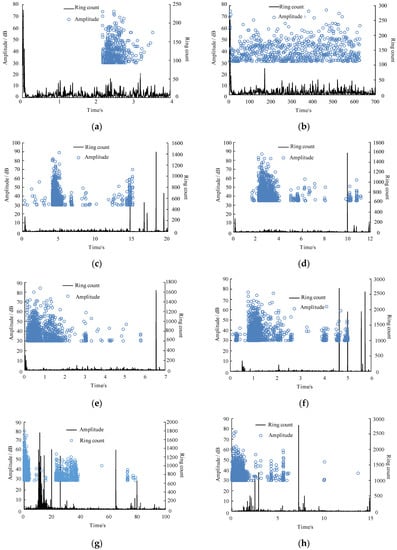

4.4.3. Characteristic Analysis of Acoustic Emission Activity

The characteristics of the acoustic emission ringing counts and amplitude responses of different layers at different intensity dynamic loads are shown in Figure 25.

Figure 25.

Characteristics of acoustic emission activity parameters. (a) The height of the first layer pendulum is 0.3 m; (b) The height of the first layer pendulum is 0.4 m; (c) The third layer pendulum height is 0.3 m; (d) The third layer pendulum height is 0.5 m; (e) The fifth layer pendulum height is 0.3 m; (f) Fifth layer pendulum height is 0.5 m; (g) The seventh layered pendulum height is 0.4 m; (h) The seventh layered pendulum height is 0.6 m.

It can be seen from Figure 25 with the same stratification test, and with the increase in dynamic load energy, that the acoustic emission signal amplitude change is small, but the ringing count increased by 10, 150, 1000, and 900, respectively, showing that the coal rock rupture is more serious; with the same intensity of dynamic load action, 1 and 3 stratification acoustic emission signal had a maximum amplitude of 75 dB and 90 dB, and the ringing count average was 250 and 1500; and 5 and 7. Therefore, the coal rock rupture is more serious in the working face of the lower stratum with higher stress levels.

5. Conclusions

- (1)

- When the mining section of the steeply inclined ultra-thick coal seam is less, the roof of the upper goaf is suspended. With an increase in the mining section, the roof is gradually broken, and the broken block is dumped into the goaf due to gravity.

- (2)

- When the dynamic load energy is small, the model can resist the dynamic load disturbance. With the continuous increase in dynamic load energy, when the dynamic load energy exceeds the critical load of coal and rock under stress, it will cause the dynamic instability and failure of the moving load side of the roadway. It shows that the dynamic load-induced impact dynamic behavior requires critical energy, and the prevention and control of rock bursts are mainly aimed at strong earthquakes with large energy.

- (3)

- After the mining of the segmented working face, the stress of the side bottom coal of the working face is increased due to the influence of the lateral abutment pressure of the goaf, and the stress of the side bottom coal of the return airway is reduced due to the disturbance of the upper section mining. On the same side, the stress concentration phenomenon gradually increases with the increase in sub-mining depth, and the closer to the goaf, the more obvious the stress change in the coal below.

- (4)

- The dynamic load effect is transient. The negative peak value of acceleration is much smaller than the positive peak value, and the recovery time is short. The peak value increases linearly with the increase in the source energy, indicating that the negative acceleration is mainly caused by the reflection wave. Due to the vibration waves, the reflection tensile can be generated on the surface of the roadway, leading to the failure of the roadway. The stronger the dynamic load energy is, the higher the impact risk is.

- (5)

- When the dynamic load intensity is constant, the peak acceleration decreases with the increase in the propagation distance. The vibration wave has the dominant propagation direction, and there are certain differences in the form and direction of the action on the coal rock. Due to the dynamic load, the impact failure of coal has a critical displacement. When the displacement of the roadway surface is less than the critical displacement, no impact failure occurs. Therefore, strengthening roadway support is conducive to preventing rock bursts.

- (6)

- Large energy events often occur in the position of coal seam floor, which indicates that the stress of floor position is greatly affected by the goaf structure; the response characteristics are obvious after dynamic load loading, the degree of coal rock rupture is large, and the risk is high. The acoustic emission location and energy results can reflect the failure law of coal and rock mass. Microseismic monitoring can be used to judge the activity law of mining and excavation, so as to provide an early warning of the impact risk.

Author Contributions

Author Contributions: Conceptualization, Y.W. and C.Y.; methodology, Y.W., Q.C. and X.S.; software, Y.W. and B.Z.; validation, Y.W. and C.Y.; formal analysis, Q.C., B.Z. and X.S.; investi-gation, Y.W. and C.Y.; resources, Y.W., Q.C. and C.Y.; data curation, Y.W.; writing—original draft preparation, Y.W.; writing—review and editing, Y.W. and C.Y.; visualization, Y.W., B.Z. and X.S.; supervision, Y.W., and X.S.; project administration, Y.W., Q.C. and C.Y.; funding acquisition, Q.C. All authors have read and agreed to the published version of the manuscript.

Funding

General Project of National Natural Science Foundation of China, Grant Number: 52174130, General Project of National Natural Science Foundation of China, Grant Number: 52074270.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The Microsoft Excel Worksheet data used to support the findings of this study are available from the corresponding author (17640513318@163.com (C.Y.); 18342833697@163.com (B.Z.)) upon request.

Conflicts of Interest

The authors declare that they have no competing interests.

References

- Ju, W.J.; Zheng, J.W.; Wei, D.; Sun, L.W.; Li, W.Z. Study on the causes and control technology about the coal bump in multi-layered mining roadway in steep-thick coal seams. J. Min. Saf. Eng. 2019, 36, 280–289. [Google Scholar]

- Ju, W.; Li, W. Fracture mechanical model of main roof along inclined for fully mechanized top coal caving in steep and extra thick coal seam. J. China Coal Soc. 2008, 33, 606–608. [Google Scholar]

- Lai, X.P.; Liu, B.; Chen, J.Q.; Zhang, X.Z.; Sun, B.C.; Wang, J. Induced hazardprone prediction to the intermediate rock—Pillar dynamic instability in heavy steep—Thick coal seam. J. Xi’an Univ. Sci. Technol. 2015, 35, 277–283. [Google Scholar]

- Lai, X.P.; Sun, H.; Cai, M.; Chen, J.Q.; Chang, B. Mechanism of dynamic hazards due to coal and rock mass instability in extremely steep coal seams with the deepening mining. J. Xi’an Univ. Sci. Technol. 2017, 37, 305–311. [Google Scholar]

- Lai, X.P.; Yang, Y.R.; Chen, J.Q.; Ge, R.Z.; Cui, F. Control of dynamic hazards induced by mining stress distortion in extremely steep and thick coal seams. J. China Coal Soc. 2016, 41, 1610. [Google Scholar]

- Lai, X.P.; Yang, Y.R.; Shan, P.F.; Lv, Z.H. Comprehensive analysis of disaster-causing characteristics of roof stress superimposed effect in steeply inclined coal seams. J. China Coal Soc. 2018, 43, 70–78. [Google Scholar]

- Wang, Z.; Dou, L.; Wang, G. Coal burst induced by horizontal section mining of a steeply inclined, extra-thick coal seam and its prevention: A case study from Yao jie No.3 Coal Mine, China. Shock Vib. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Li, A.N.; Dou, L.M.; Wang, Z.Y.; Xie, J.H.; Wang, Y.Z. Impact mechanism and prevention of clamped coal in horizontal sublevel mining of near vertical coal seam. J. Coal 2018, 43, 50–56. [Google Scholar]

- Dou, L.M.; He, J.; Cao, A.Y.; Gong, S.Y.; Cai, W. Superposition principle of dynamic and static loads of rockburst in coal mine and its prevention. J. Coal Ind. 2015, 40, 1469. [Google Scholar]

- Wang, N.; Zhang, N.; Cui, F.; Cao, J.; Lai, X. Characteristics of stope migration and roadway surrounding rock fracture for fully mechanized top coal caving face in steeply dipping and extra thick coal seam. J. China Coal Soc. 2013, 38, 1312–1318. [Google Scholar]

- Zhang, J.W.; Wang, J.N. Energy distribution characteristics and rock burst control methods of steeper inclined thick coal seam hanging roof. J. China Coal Soc. 2014, 39, 316. [Google Scholar]

- Jiang, F.X.; Shi, X.F.; Wang, C.W.; Wei, Q.D.; Yao, S.L.; Zhu, S.T.; Geng, C. Mechanical mechanism of rock burst accidents in slice mining face under high pressure. Chin. J. Geotech. Eng. 2015, 37, 1123–1131. [Google Scholar]

- Du, T.T.; Chen, J.Q.; Lan, H.; Sun, B.C.; Yang, L.; Liu, X.D. Risk analysis of rockburst in near vertical extra thick coal seam. Coal Sci. Technol. 2016, 44, 123–127. [Google Scholar]

- Yu, G.L.; Li, Q.; Wang, Y.J. Prevention and control technology of rock burst in layered mining of deep steep and extra thick coal seam. Coal Sci. Technol. 2011, 39, 17–21. [Google Scholar]

- Zhang, B.; Zhou, H.Q.; Chang, Q.L.; Zhao, X.; Sun, Y.T. The Stability Analysis of Roadway near Faults under Complex High Stress. Adv. Civ. Eng. 2020, 2020, 8893842. [Google Scholar] [CrossRef]

- Miao, S.; Lai, X.P.; Cui, F. Top coal flows in an excavation disturbed zone of high section top coal caving of an extremely steep and thick seam. Min. Sci. Technol. 2011, 21, 99–105. [Google Scholar]

- Miao, S.J.; Lai, X.P.; Zhao, X.G.; Ren, F.H. Simulation experiment of AE-based locali zation damage and deformation characteristic on covering rock in mined-out area. Int. J. Miner. Metall. Mater. 2009, 16, 255–260. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Morioka, H. FIAC/PFC coupled numerical simulation of AE in large-scale underground excavations. Int. J. Rock Mech. Min. Sci. 2007, 44, 550–564. [Google Scholar] [CrossRef]

- Jeoungseok, Y. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int. J. Rock Mech. Min. Sci. 2007, 44, 871–889. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).