Abstract

Advanced manufacturing technology (AMT) has the potential to significantly improve manufacturing performance and boost competitiveness in the global market. Investment in AMT remains a promising but potentially risky venture due to the numerous factors that must be considered before the full benefits of implementing a new technology can be realized. To respond to the reported risks and uncertainties, such as those revealed in the recent industrial revolution, it is very important to identify and classify the critical factors that can influence the success of AMT adoption early in the planning stage. Based on an extensive review of relevant literature, 32 critical factors are identified and classified into ten categories in this paper. A new multiple-input single-output (MISO) model is developed by combining the fuzzy Delphi method (FDM) and the fuzzy inference system (FIS) based on the objectives defined. The FDM is used to determine the critical factors, and the FIS addresses the general fuzzy multi-attribute decision-making (MADM) problem in order to evaluate and predict the percentage of AMT adoption success with an existing system. The model is validated using a numerical test bed, and the results show that the model is a proper tool for risk management in AMT implementation.

1. Introduction

Companies have introduced and implemented advanced manufacturing technology (AMT) since the 1980s in order to increase their potential for success in the local market and also expand their businesses’ boundaries to the global market. One of the benefits of AMT is its ability to provide greater processing and product flexibility (amount of adaptability or responsiveness for any future modification in a product design, including new products and derivatives of current products) [1], improve product quality (reduction or elimination of waste, rework, and losses in the production process) [2,3], improve customer service (ensuring customer satisfaction with a product or service) [4,5], and enhance time efficiency (managing the time effectively to produce more results) [6,7]. According to [8], and [9], AMT also offers lower labor costs, reduced dependency on external suppliers, shortened lead time and time-to-market, increased market share, and better management control. Integration of AMTs with new-generation IT technologies such as blockchain and digital twins can produce even better outcomes [10,11]. Using blockchain may increase security and enhance the traceability and sustainability of the AMT systems, and digital twins is an important factor affecting the adoption of AMTs technology in firms. Past studies [12,13] indicate that the fourth industrial revolution was ushered in by modernized technologies, which have resulted in many positive impacts for the manufacturing sector, since the revolution has accelerated the adoption of new technologies. The Industry 5.0, however, with its human focus, sustainability, and resilience is seen as assisting in delivering mass personalized products to customers with high speed and accuracy [14]. After all, investment in advanced technologies, arguably, remains a risky venture [13,15]. As a result, lately, AMT is requiring even more attention than before. To respond to the existing failure risks and uncertainty about success, the key aim of the present research is to submit a model to correctly predict the success of AMT applications prior to their implementation.

Advanced Manufacturing Technology (AMT)

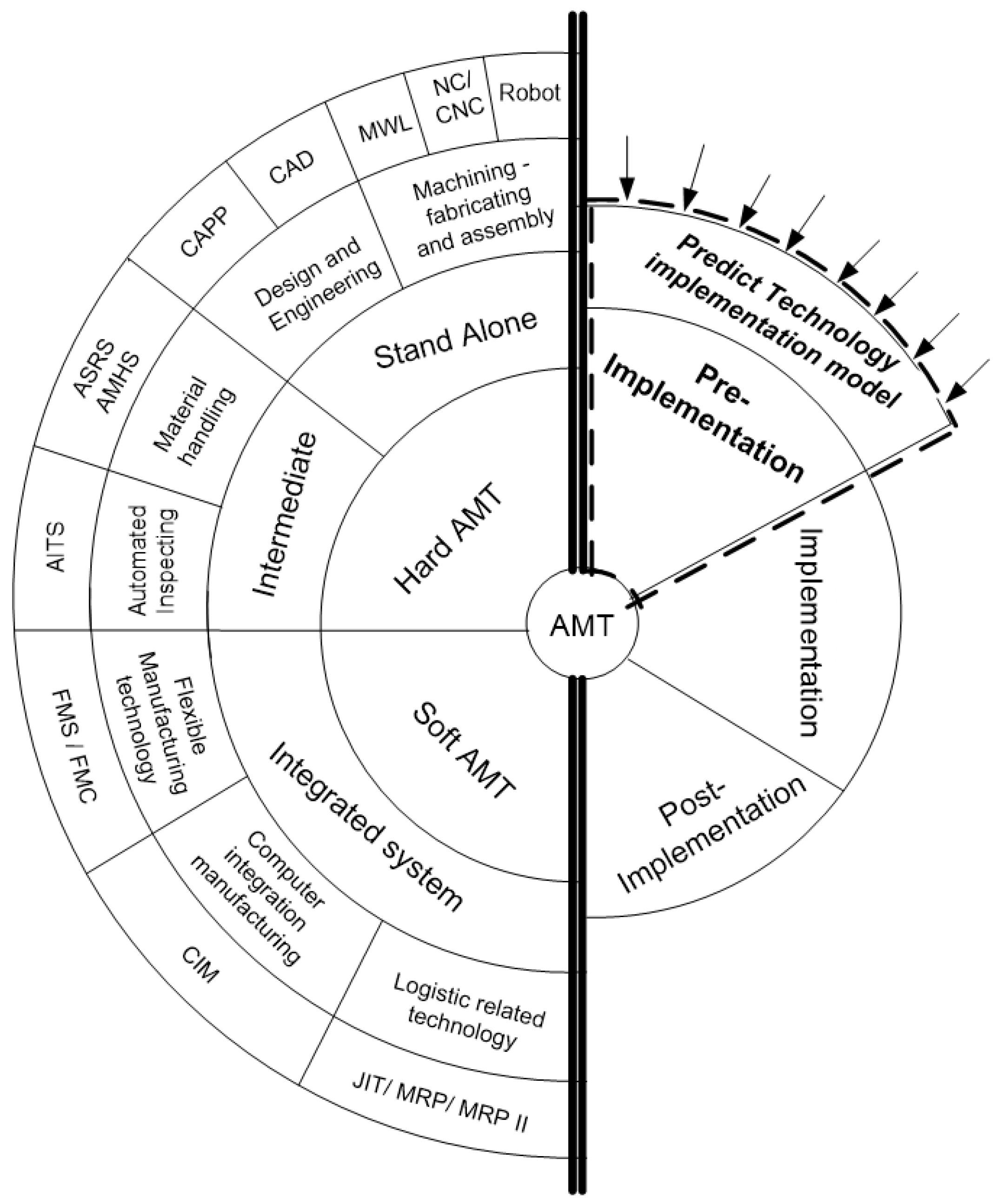

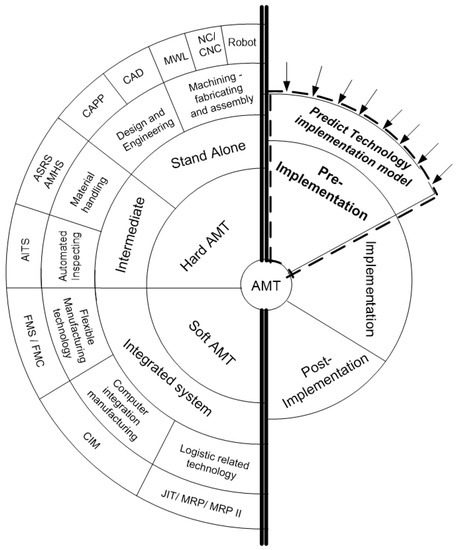

In general, AMT can be classified as divided into hard and soft AMT segments. Soft AMTs consist of integrated systems and this segment is further sub-classified as logistic-related technology, flexible manufacturing technology (FMT), and computer-integrated manufacturing (CIM) [16]. Hard AMTs consist of intermediate and stand-alone AMTs. Intermediate AMTs consist of technologies pertaining to automated inspection and material handling. In contrast, stand-alone AMTs consist of technologies related to design and engineering, machining, fabrication, and assembly [17,18]. More details of AMTs’ classification are shown in Figure 1, which provides an overall view of the technologies currently available in this context. AMTs involve three phases, namely, pre-implementation, implementation, and post-implementation [19,20,21]. Arrows in Figure 1 show the application area of the model developed in this paper.

Figure 1.

Classification of various advanced manufacturing technologies.

In general, the methods used to justify the implementation of AMTs can be classified as economic, strategic, and analytical methods. The primary difference between these methods lies in their treatment of non-monetary factors [22].

- Economic methods. Since financial matters are a crucial aspect in the manufacturing industry, it is vital for manufacturers to scrutinize the methods, which play a key role in achieving the desired target, such as payback methods, return on investment, and discounting cash flow methods. Even though these methods offer ease of data collection as well as intuitive appeal, they do not account for strategic and non-economic benefits, which managers need to address. In addition, these methods only consider a single objective for cash flow and neglect other benefits such as quality and flexibility [23].

- Strategic methods. Several manufacturers advocate the use of strategic methods in order to eradicate the drawbacks associated with conventional financial methods. These strategic methods cover technical importance, business objectives, competitive advantage, as well as research and development (R&D). Although these methods require fewer technical data and priority is given to the general objectives of the firm, there is one important factor which is typically overlooked by manufacturers since only long-term intangible benefits are considered, and it pertains to the use of strategic methods with either economic or analytical ones [24].

- Analytical methods. They can be used to evaluate and improve the promotion of manufactured products in order to gain business success. Analytical methods consist of scoring models (e.g., analytical hierarchy process (AHP)), mathematical programming, goal programming, integer programming, data envelopment analysis (DEA), stochastic methods, fuzzy set theories and multiple-attribute decision-making (MADM) [25].

There are two types of MADM methods; the first method involves selecting an alternative from a set of alternatives, which have been given scores, and the importance of the attributes for each alternative. In contrast, the second method involves ranking the alternatives using a role model or similar models [26], which will help manufacturers to account for future uncertainties associated with multiple objectives as well as incorporate subjective criteria during the modelling phase.

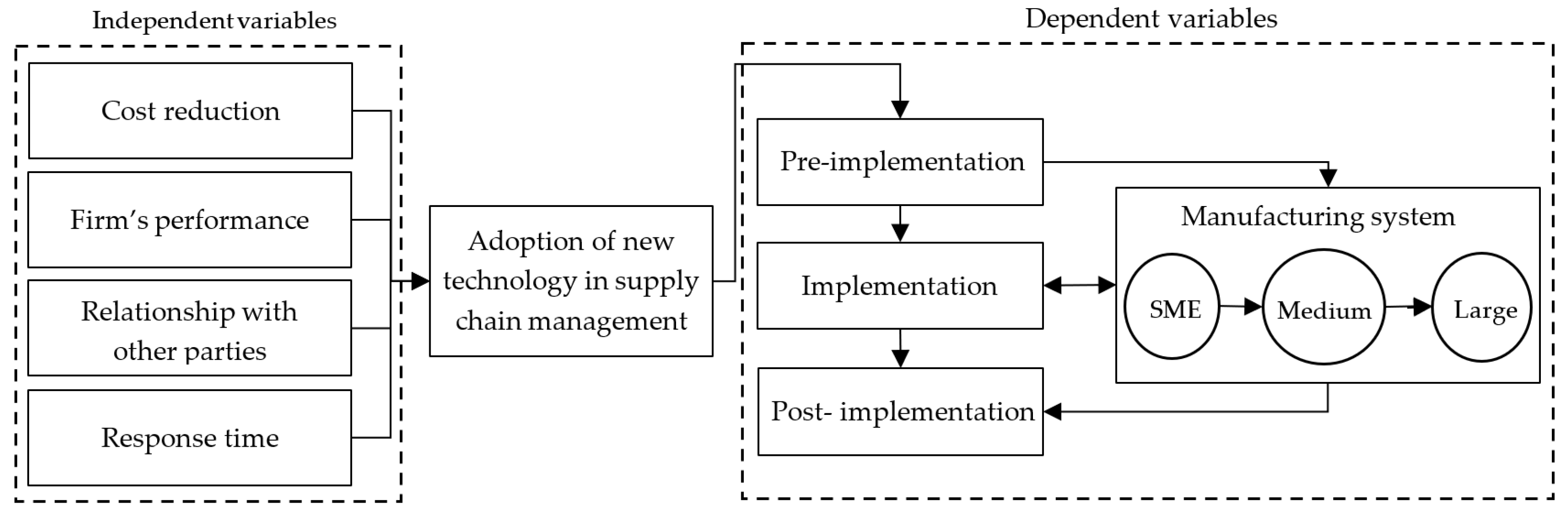

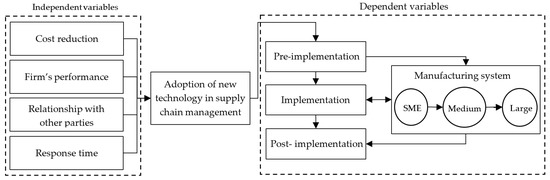

Figure 2 shows the conceptual framework of adopting new technology in supply chain management. This is classified into two main parts: independent and dependent variables. New technology helps factories to reduce cost, increase the firm’s performance, intensify, build relationships with other parties, and increase response time. For adopting new technologies in the manufacturing system, three main stages are important; pre-implementation, implementation, and post-implementation. This adoptive technology can be used in SMEs, medium- and large-size factories.

Figure 2.

Adoption of new technology conceptual framework.

In this study, we first tried to identify the critical factors in AMT’s successful adoption. Then, a fuzzy MADM approach was suggested, where the fuzzy Delphi method (FDM) and fuzzy inference system (FIS) are combined to develop a model to predict the percentage of successful adoption of AMTs. The model is a part of the pre-implementation phase.

2. Identification of Criteria for Advanced Manufacturing Technology

Implementing a new technology is a complicated process as there are numerous important factors which need to be considered to get the full benefits of AMT. This begs the question: ‘what are the most influential factors affecting the successful adoption of AMT?’ In order to address this, 67 articles related to AMT were reviewed and 32 factors were identified, as shown in Table 1. Most of the papers were published in peer-reviewed journals with high quality/h-index. It is therefore presumed that the information provided is reliable. Some of the keywords used to search for the papers were: advanced manufacturing technology, adoption, criteria, decision-making model. The most important factor for adopting AMT successfully is the ‘strategy’. As adoption of AMT needs huge investment for the high cost of manufacturing, it needs special attention in the level of planning stage [27]. The accomplishment of business goals is supported by manufacturing strategy, by providing proper structural items (facilities, plant, equipment, etc.) and infrastructure items (control policies, human resources, economic, organizational structure, etc.) so that the operations can be ascertained as effective [28,29].

Efstathiades et al. divided the organizational structures into two strategic elements: knowledge and policies [30]. In order to implement AMT successfully, it is necessary to process changes in organizational infrastructure and practices, also obtain ‘the worker’s skills and knowledge’. The organization needs to adapt to new technology environments by focusing on the alignment of organizational and business factors [17]. A study on Spanish firms has shown that it is important to have ‘top management support’ for successful technology implementation [31]. In the same vein, [32] ranked ‘top management support’ as a first sub-objective for effective implementation of AMTs. Executives are committed sponsors who have a realistic understanding on the capabilities and limitations of technologies, and value these technologies to spend considerable time and energy in guiding their development. Operating sponsor is also another factor which affects the implementation of AMTs and refers to the case where the tasks are carried out frequently but are not always delegated to a trusted subordinate who becomes the operating sponsor or technology champion [33]. In addition, technology is innovative since it requires access to state-of-the-art knowledge and technology for successful implementation. Many organizations have successfully collaborated with academic institutions and/or used their research facilities to seek guidance and assistance in system development, as well as to seek technical knowledge to improve their technical skills and implementation. The present beliefs concerning the usefulness and integration of AMTs with the existing systems will either be dampened or heightened by personal beliefs on the effectiveness of AMTs [34].

Table 1.

Identification of the critical factors which influence the successful implementation of AMTs.

Table 1.

Identification of the critical factors which influence the successful implementation of AMTs.

| Strategy | Financial | Organization and Business | Support | Technical | Management | Vendor/Supplier | Process/ Planning | Project Champion | Employee | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Operation Strategy | Strategic Management and Planning | Strategic Analysis and Motivation | Financial Evaluation | Economic Justification | Human Resource Management | Organizational Infrastructure and Culture | Alignment of AMT with Organization and Business | Top Management Support | Operating Sponsor | Support Systems before Equipment Installation | Governance and Commitment | Think-Tank Linkage | Knowledge and Perfecting Skills | Technical Infrastructure and its Influence on Successful Adoption | Technology Identification | Production Management and System | Managers experimenting with new Technologies | managers’ Personal Beliefs and Understanding of AMT | Expectations of AMT | Commitment and Relationships with Vendors | Supplier-Related Factors | Selection of the Appropriate Technological Supplier(s) | Planning Process and Requirements | Product-Process Dependency | Integration of AMT with Existing Systems | Project Champions and Market Risk | Manufacturing Performance | Pilot Project | Training | Communication and Coordination | Lack of Knowledge and Skills | |

| [35] | x | x | x | x | ||||||||||||||||||||||||||||

| [36] | x | x | x | |||||||||||||||||||||||||||||

| [37] | x | x | x | x | ||||||||||||||||||||||||||||

| [19] | x | x | x | x | x | |||||||||||||||||||||||||||

| [38] | x | x | x | x | ||||||||||||||||||||||||||||

| [39] | x | x | x | x | ||||||||||||||||||||||||||||

| [40] | x | |||||||||||||||||||||||||||||||

| [41] | x | x | ||||||||||||||||||||||||||||||

| [33] | x | x | ||||||||||||||||||||||||||||||

| [42] | x | x | x | |||||||||||||||||||||||||||||

| [43] | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||

| [31] | x | x | x | |||||||||||||||||||||||||||||

| [44] | x | x | ||||||||||||||||||||||||||||||

| [45] | x | x | x | |||||||||||||||||||||||||||||

| [46] | x | x | ||||||||||||||||||||||||||||||

| [47] | x | x | x | |||||||||||||||||||||||||||||

| [48] | x | x | x | |||||||||||||||||||||||||||||

| [49] | x | |||||||||||||||||||||||||||||||

| [50] | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| [51] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [17] | x | x | x | x | x | x | x | |||||||||||||||||||||||||

| [30] | x | x | x | |||||||||||||||||||||||||||||

| [52] | x | x | x | |||||||||||||||||||||||||||||

| [32] | x | x | x | |||||||||||||||||||||||||||||

| [53] | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||||

| [54] | x | x | x | x | ||||||||||||||||||||||||||||

| [55] | x | x | x | x | ||||||||||||||||||||||||||||

| [56] | x | x | x | x | x | |||||||||||||||||||||||||||

| [57] | x | x | ||||||||||||||||||||||||||||||

| [58] | x | x | x | x | ||||||||||||||||||||||||||||

| [59] | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| [60] | x | x | x | x | x | |||||||||||||||||||||||||||

| [61] | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||

| [21] | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| [62] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [63] | x | |||||||||||||||||||||||||||||||

| [64] | x | x | x | |||||||||||||||||||||||||||||

| [65] | x | x | x | x | ||||||||||||||||||||||||||||

| [66] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [67] | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||

| [68] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [69] | x | x | x | x | x | |||||||||||||||||||||||||||

| [28] | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||

| [70] | x | x | x | x | x | |||||||||||||||||||||||||||

| [71] | x | x | ||||||||||||||||||||||||||||||

| [72] | x | |||||||||||||||||||||||||||||||

| [73] | x | x | x | x | ||||||||||||||||||||||||||||

| [74] | x | x | x | x | x | |||||||||||||||||||||||||||

| [75] | x | |||||||||||||||||||||||||||||||

| [76] | x | x | ||||||||||||||||||||||||||||||

| [3] | x | x | x | |||||||||||||||||||||||||||||

| [77] | x | x | x | x | x | x | x | |||||||||||||||||||||||||

| [78] | x | |||||||||||||||||||||||||||||||

| [79] | x | x | x | |||||||||||||||||||||||||||||

| [80] | x | x | x | x | x | |||||||||||||||||||||||||||

| [81] | x | x | x | |||||||||||||||||||||||||||||

| [82] | x | x | x | |||||||||||||||||||||||||||||

| [83] | x | x | x | x | x | |||||||||||||||||||||||||||

| [84] | x | x | x | x | ||||||||||||||||||||||||||||

| [85] | x | x | x | x | ||||||||||||||||||||||||||||

| [86] | x | x | ||||||||||||||||||||||||||||||

| [87] | x | x | x | |||||||||||||||||||||||||||||

| [88] | x | x | x | x | ||||||||||||||||||||||||||||

| [89] | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||

| [90] | x | x | x | x | x | |||||||||||||||||||||||||||

3. Proposed Model to Predict the Success of AMT Adoption

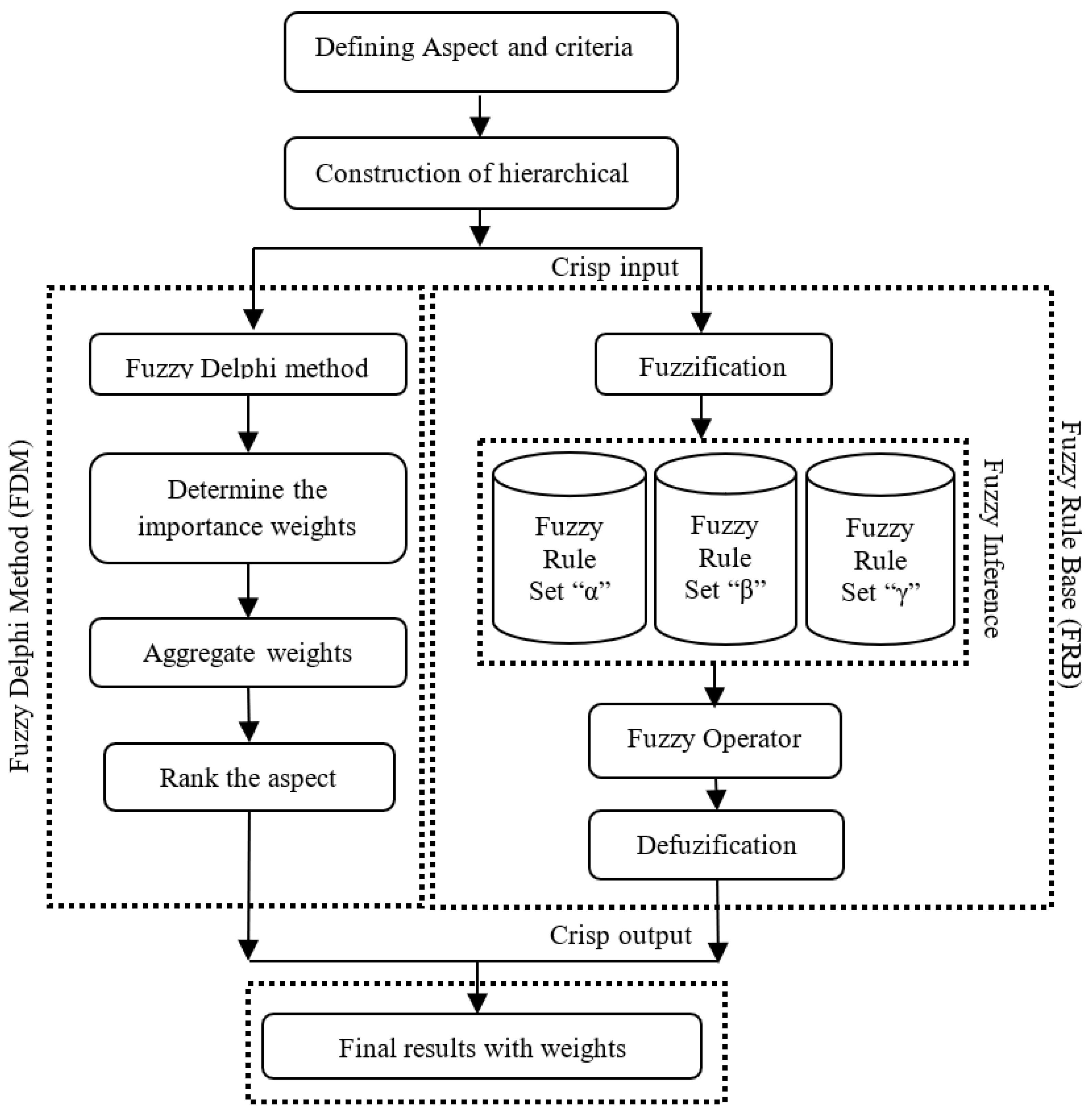

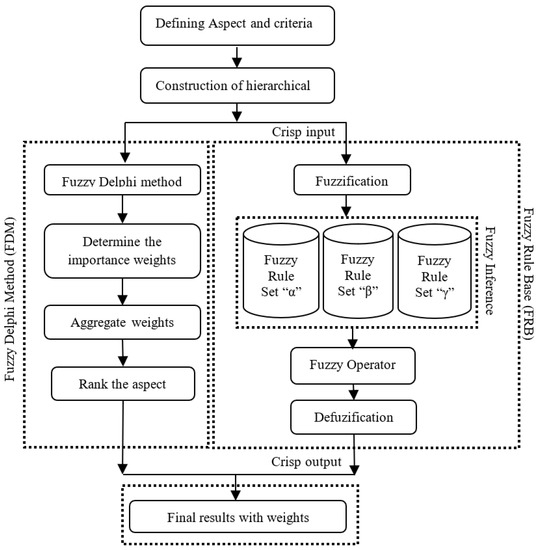

The objective of this study is to develop a model, which predicts the percentage of success of AMT adoption. The methodology in this study consists of two main phases. The first phase involves applying the FDM to determine the critical factors which influence the successful implementation of AMTs. The second phase involves applying FIS to determine the percentage of success of AMT implementation. Figure 3 displays the structure of the fuzzy decision-making system (FDMS). This provides an example of all the qualitative and quantitative criteria used to test and validate the feasibility of the model.

Figure 3.

Process flow of fuzzy decision-making system (FDMS) structure.

The multi-criteria decision-making procedure is used to integrate both quality and quantity criteria in order to evaluate mutually exclusive prediction technologies for successful implementation of AMT [91].

Multi-criteria evaluation problem requires a number of criteria under every k criterion (C1, C2,…, Ck), taking into account the specific requirements of the problem. The criteria classified as (1) subjective criteria (C1, C2,…, Ch) which are defined in linguistic/qualitative terms and (2) objective criteria (Ch+1, Ch+2,…, Ck) which are defined in monetary/quantitative terms. These criteria construct the hierarchical structure of the primary model based on the aspects.

3.1. Fuzzy Delphi Method

Ref. [92] proposed FDM, which is based on the traditional Delphi method and fuzzy theory. Delphi is a method for gathering expert opinion that includes three components: anonymous response, iteration, and controlled feedback, as well as statistical group response. However, the Delphi method needs surveys in order to achieve a convergence of predicted values, making it time-consuming and costly [92,93].

The FDM is used to create a set of weight-pooled criteria. The triangular fuzzy numbers and linguistic variables are used to assess preference ratings in terms of the importance and appropriateness of linguistic variations.

The primary aim of the Delphi method is to achieve a common understanding of the group opinions using a questionnaire. However, this method is somewhat negated by the fact that it requires two-time provision of the questionnaire. Hence, the FDM was developed based on the fuzzy theory and offers the benefits of the Delphi method and eliminates the drawbacks associated with the conventional Delphi method [94,95].

In this study, FDM was used to screen the attribute factors in the first phase to solve the group decision [96] and fuzzy theory applied to solve and evaluate the fuzziness of common understanding among experts on a more flexible scale. The triangular membership function was also used to solve group decision-making. Accordingly, the efficiency and the quality of the questionnaires improved. It led to the increase in the number of objective evaluation factors that could be screened through the statistical results.

The steps of FDM are described briefly as follows:

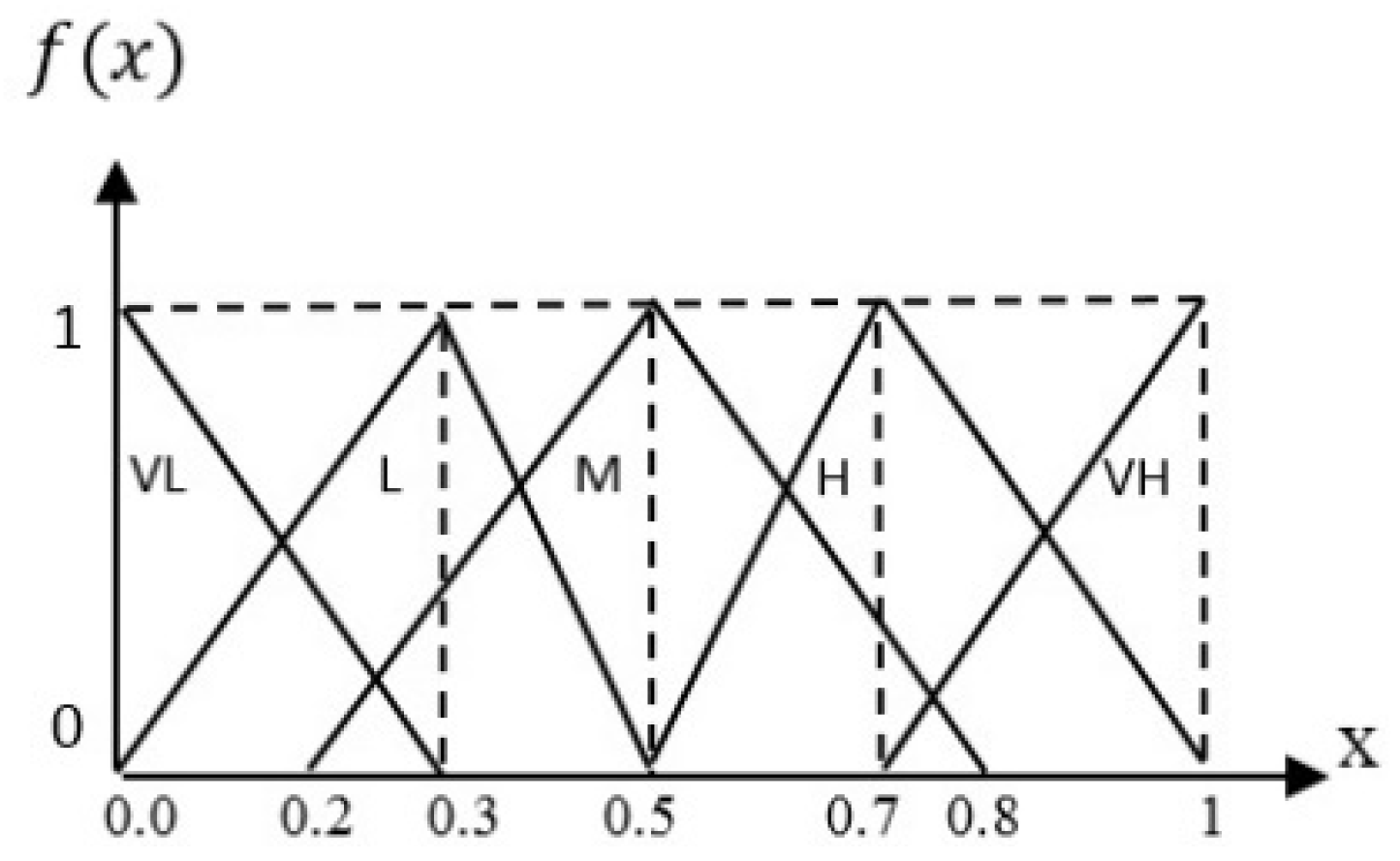

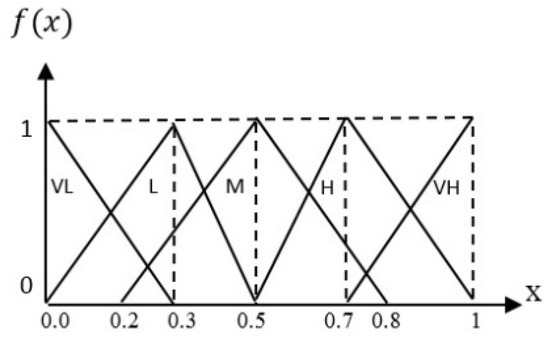

1-Collect opinions of the decision-making group: a group of n decision-makers (D1, D2,…, Dn) choose to assess the importance weights of K quantitative and qualitative criteria (C1, C2,…,Ck) [97] (Figure 4 and Table 2).

Figure 4.

Membership functions for importance weights of criteria.

Table 2.

List of linguistic variables and their corresponding fuzzy numbers for importance weights.

2-Assigning triangular fuzzy numbers: for each factor given by the experts, the evaluation value and the significance of the triangular fuzzy number will be determined.

3-Aggregating expert opinions: mean of weight (Wt) obtained by the operation of fuzzy numbers and the linguistic terms transfer to positive trapezoidal fuzzy numbers. Wt represents the weight given to the subjective criteria C1, C2,…, Ck−s and objective criteria Ck−s+1,…, Ck by expert Ej.

where ⊗ and ⊕ displays the multiplication and the summation of fuzzy numbers, respectively. Ej is a fuzzy number, which stands for the overall average weighting evaluation of alternative i under criterion j over m assessors. Equation (2) describes Ej by a triangular membership function:

where the minimum of experts’ common consensuses is shown as point LEj, and the medium and maximum are shown as point MEj and UEj. The fuzzy weight of element j is given by where t = 1, 2,..., k. Note that:

It should be noted that the fuzzy synthetic decision results, i.e., the weights of each criterion, are fuzzy numbers. As a result, the non-fuzzy ranking method must be used for all fuzzy numbers in each criterion. Non-fuzzy ranking, also known as defuzzification, is a method for converting fuzzy numbers into crisp real numbers. The primary goal of defuzzification is to find the best non-fuzzy performance (BNP) values. The centre-of-area defuzzification method was chosen due to its simplicity, as it does not require the personal judgement of the analyst [91]. The BNP value of a fuzzy number is given by:

3.2. Fuzzy Inference System

For the fuzzy inference system, four steps can be defined: 1. Fuzzifier, 2. Fuzzy rule set, 3. Fuzzy operator, and 4. Defuzzification. The steps are briefly presented here but they were described in detail previously in [91].

3.2.1. Fuzzifier

A fuzzy set in the domain ℝ is called a fuzzy trapezoidal number if its membership function has the shape represented by Equation (5) and has a core [b, c], left width δ = b − a, and right width β = d − c [98]:

where a, b, c, d ∈ ℝ and (x) is between 0 and 1.

Fuzzy set is a class of objects with a continuum of grades of membership. Let X be a non-empty set and a domain of discourse where X= {x1, x2, …, xn}. A fuzzy (sub) set of a domain of discourse X is a set of ordered pairs, which is given by:

where is a membership function or grade of a fuzzy set , whereby the accepted mathematical notation for is : X→ [0, 1]. The membership function (xi) gives the membership degree of a generic element xi to the fuzzy set .

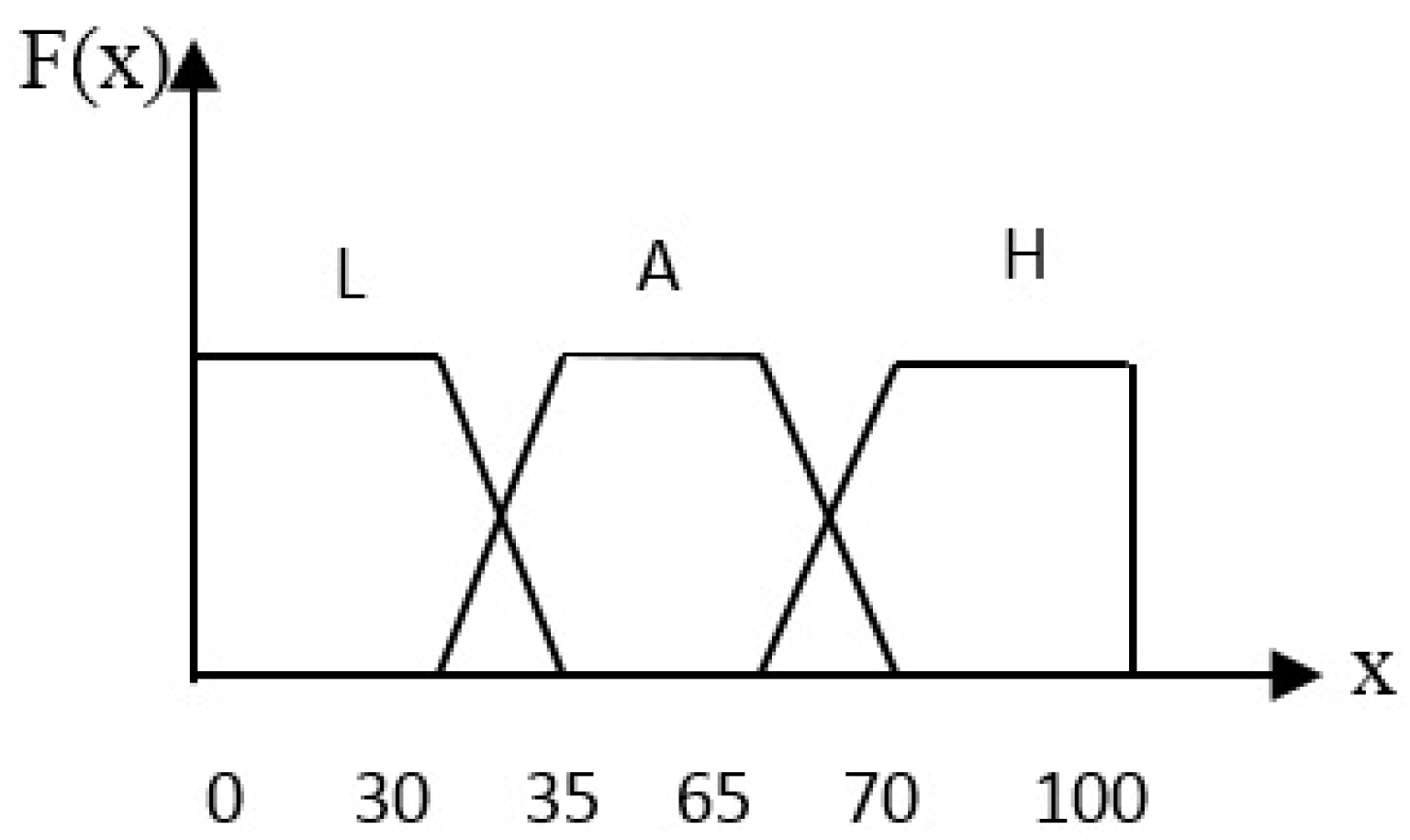

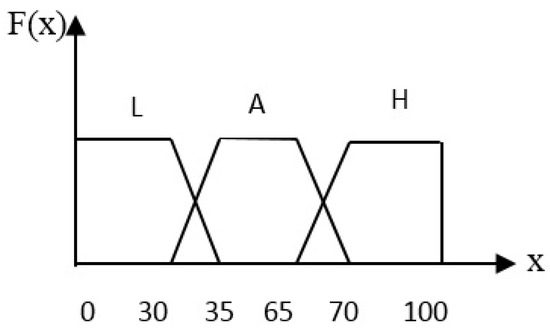

This study uses multiple-input single-output (MISO) and trapezoidal fuzzy numbers. Three fuzzy sets (‘Low’, ‘Average’, and ‘High’) are shown in Figure 5. These linguistic variables are used to evaluate the importance of the input and output variables and are equal to the range of 0–1.

Figure 5.

Three fuzzy sets in terms of ‘Low’, ‘Average’ and ‘High’ linguistic variables.

3.2.2. Fuzzy Rule Set

An essential element of fuzzy rule-based system is a set of IF-THEN linguistic rules, which have the following general form ‘IF A THEN B’. Here, A and B are collections of propositions containing the linguistic variables. If there are i rules (Ri), each with k premises in the system, the ith rule has the following form:

Ri: If Xi1 is Ai1 and Xi2 is Ai2... and Xik is Aik, then Y is Bi

In the above expression, X represents the crisp inputs to the rule and Ai and Bi are linguistic variables. Xi1 to Xik and Y represent the input variables and output variables for regression, respectively. The number of fuzzy rules used to control the system by means of fuzzy control is given by:

where N is the total number of rules needed to control the system, m is the number of sets of rules that use the same set of variables, n is the number of input variables used in a set of rules, and L is the number of fuzzy sets (labels) in an input variable (i).

Based on the number of input variables for each aspect, related FIS engine rules are designed. Table 3, Table 4 and Table 5 show the MISO system rules with two, three, and four input variables, which are called α, β and γ rule respectively. The number of rules for each aspect is calculated independently based on the name of each rule.

Table 3.

Fuzzy IF-THEN α rules.

Table 4.

Fuzzy IF-THEN β rules.

Table 5.

Fuzzy IF-THEN γ rules.

3.2.3. Fuzzy Operator

The addition and multiplication of fuzzy operations are carried out for the proposed model. Let us suppose that Equations (8) and (9) are two trapezoidal fuzzy numbers, i.e.,

R = (r1, r2, r3, r4)

S = (s1, s2, s3, s4)

Hence, the addition of trapezoidal fuzzy numbers is given by:

and the multiplication of the trapezoidal fuzzy numbers is given by:

R + S = (r1 + s1, r2 + s2, r3 + s3, r4 + s4)

R × S = (r1 × s1, r2 × s2, r3 × s3, r4 × s4)

3.2.4. Defuzzification

The input for the defuzzification procedure is a fuzzy set, i.e., aggregate output fuzzy set, whereas the output is only a single number. The centroid defuzzification method is expressed as follows:

where X* is the defuzzified output, µi (x) is the aggregated membership function and x is the output variable.

The final results are determined based on each weight assigned to each aspect and the values assigned to each fuzzy output criterion.

where Wi represents aspect i, and µi(x) is the aggregated membership function and x is the output variable.

Based on the final result, the AMT implementation is successful if the score is 50% or above. Likewise, the AMT implementation is a failure if the value is less than 50%.

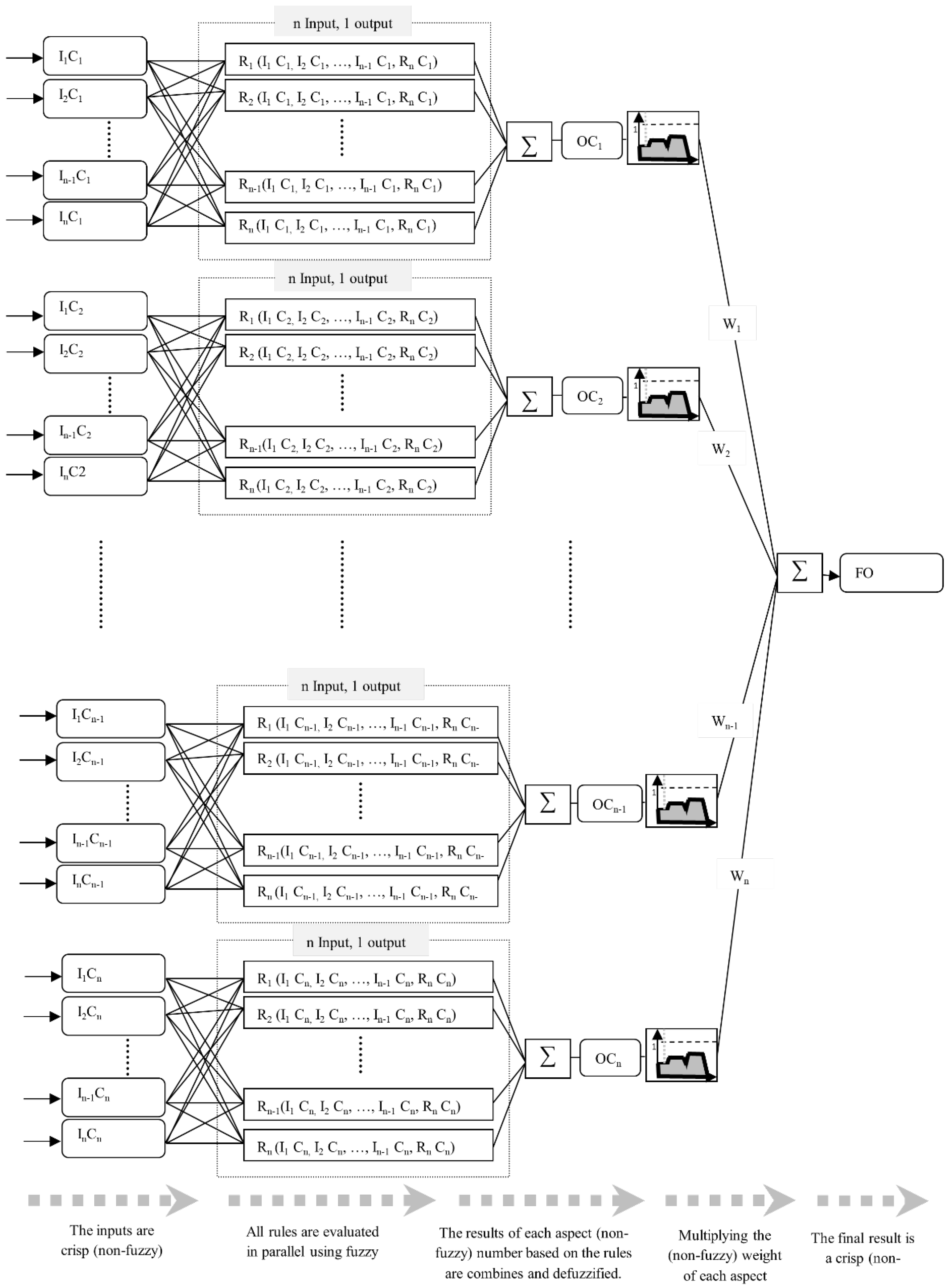

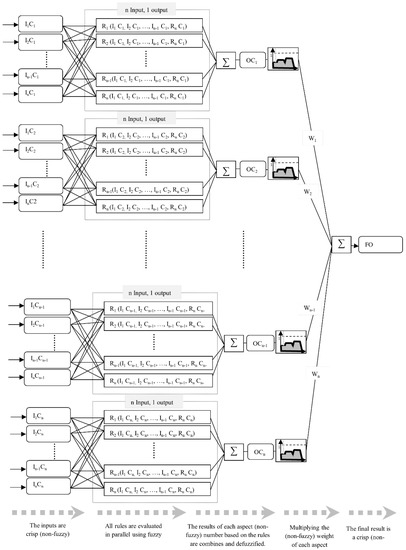

3.3. Description of the Proposed Model

Figure 6 presents the proposed model in hierarchical structure based on the properties of the aspects, as well as input variables in crisp non-fuzzy numbers and output variables. The model is used to forecast AMT implementation success. It should be noted that all the rules are evaluated concurrently using fuzzy reasoning. Based on the rules, the results of each non-fuzzy number aspect are combined and defuzzified. The results are then calculated by multiplying the non-fuzzy weight of each feature by the values assigned to each fuzzy output criterion. The AMT implementation prediction model is evaluated based on 10 aspects and 32 criteria, as shown in Table 6. An overall agreement among experts is needed to form a hierarchical structure based on the FDM model.

Figure 6.

The hierarchical model of success for predicting implementation technology.

Table 6.

List of aspects and corresponding criteria.

Three decision-makers called D1, D2, and D3 use the weights to assess each aspect. A total of ten aspects are considered, namely, strategy (A1), financial (A2), organization/business (A3), support (A4), technical (A5), management (A6), vendor/supplier (A7), process/planning (A8), project champion (A9), and employee (A10). The membership functions and the linguistic variables for the importance weights of criteria are summarized in Figure 4 and Table 2, respectively. FDM is used to adjust the fuzzy weights of each expert in order to reach a consensus condition. The importance weights of all criteria for the three decision-makers are shown in Table 7.

Table 7.

Importance weights for each aspect.

Table 8 shows the answers of experts to the FDM questionnaires which converted into positive triangular fuzzy numbers. The aggregate fuzzy weights for each criterion determined using Equations (1)–(4) and are shown in the fifth column of Table 8. The center-of-area defuzzification method is applied to convert the fuzzy numbers into crisp real numbers and the values are shown in the last column of Table 8.

Table 8.

Average linguistic rating for each aspect in the AMT implementation prediction model.

Several scholars have studied the ranking of multi-aspect fuzzy numbers. In this study, the fuzzy numbers are ranked based on the ten aspects in the following order: A4 < A10 < A2 < A7 < A6 < A5 < A9 = A8 < A3 < A1 and the results are tabulated in Table 9.

Table 9.

Ranking of fuzzy aspects based on the α-cut set.

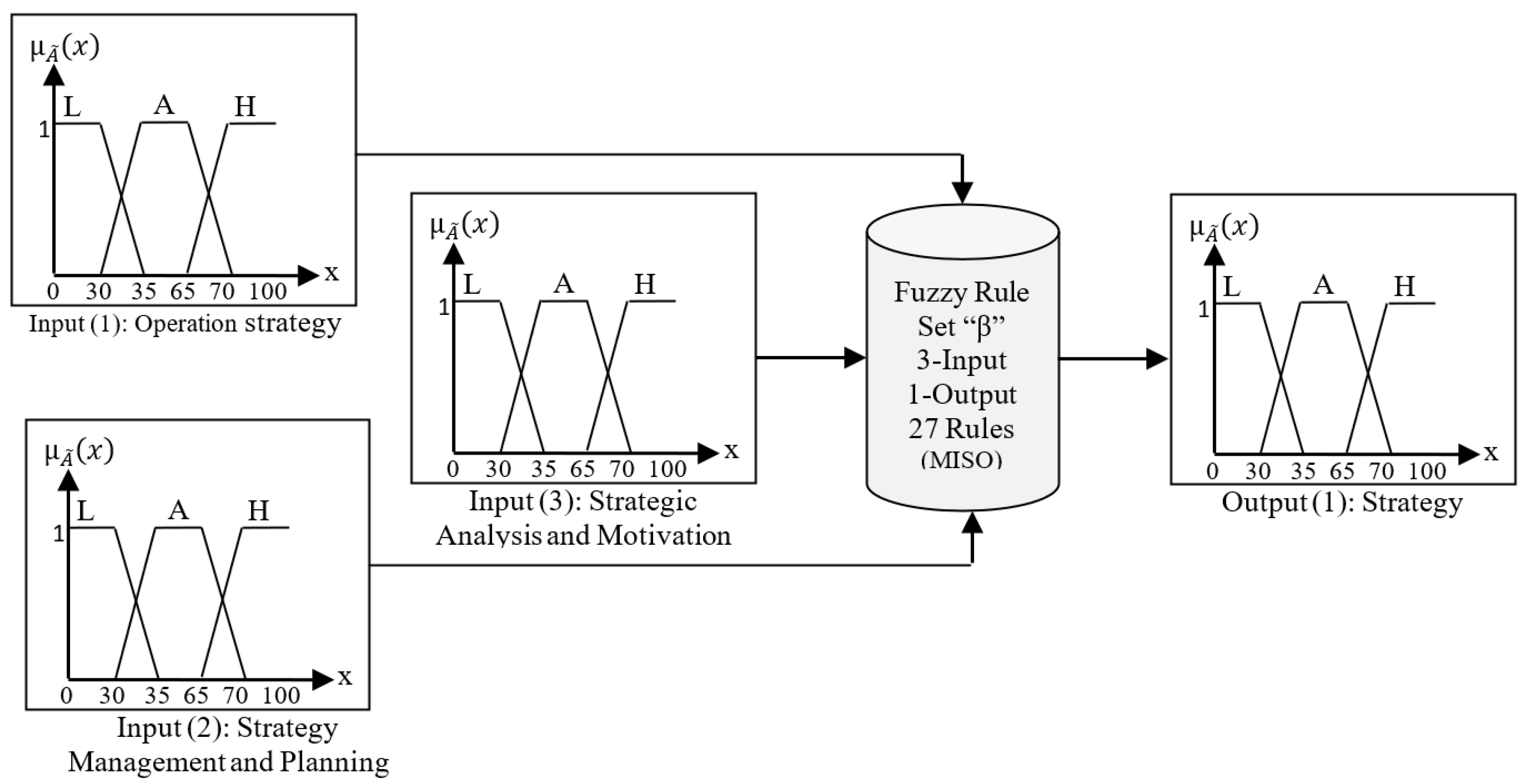

In this study, there are three different fuzzy rule sets for the ten aspects, which depend on the number of input criteria. The α rule is used when there are two input criteria (N2 α = 32), whereas the β rule (N2 β = 33) and γ rule (N2 γ = 34) are used when there are three and four input criteria, respectively.

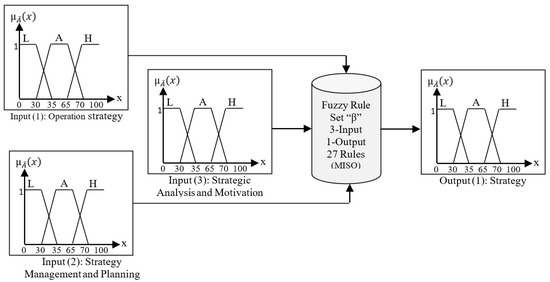

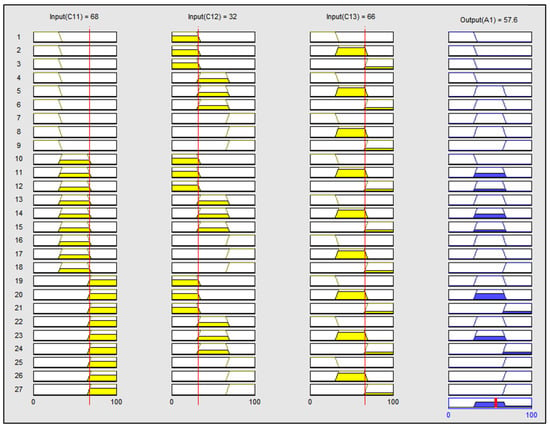

For example, the ‘strategy (A1)’ aspect consists of three input variables, namely, ‘operation strategy (C11)’, ‘strategy management and planning (C12)’ and ‘strategic analysis and motivation (C13)’. These input variables are used as the three trapezoidal membership functions, as shown in Figure 7. Following this, the fuzzy rules are formulated, whereby the collection of fuzzy rules approximately reflects the way humans think during the decision-making process. The fuzzy rules for MISO systems are based on the number of input variables, as shown in Table 3, Table 4 and Table 5. For instance, the β rule set (Table 4) is used to generate 27 fuzzy rules for the ‘strategy’ aspect, given that there are three input variables.

Figure 7.

Multi-factor fuzzy inference system for strategy aspect (output 1).

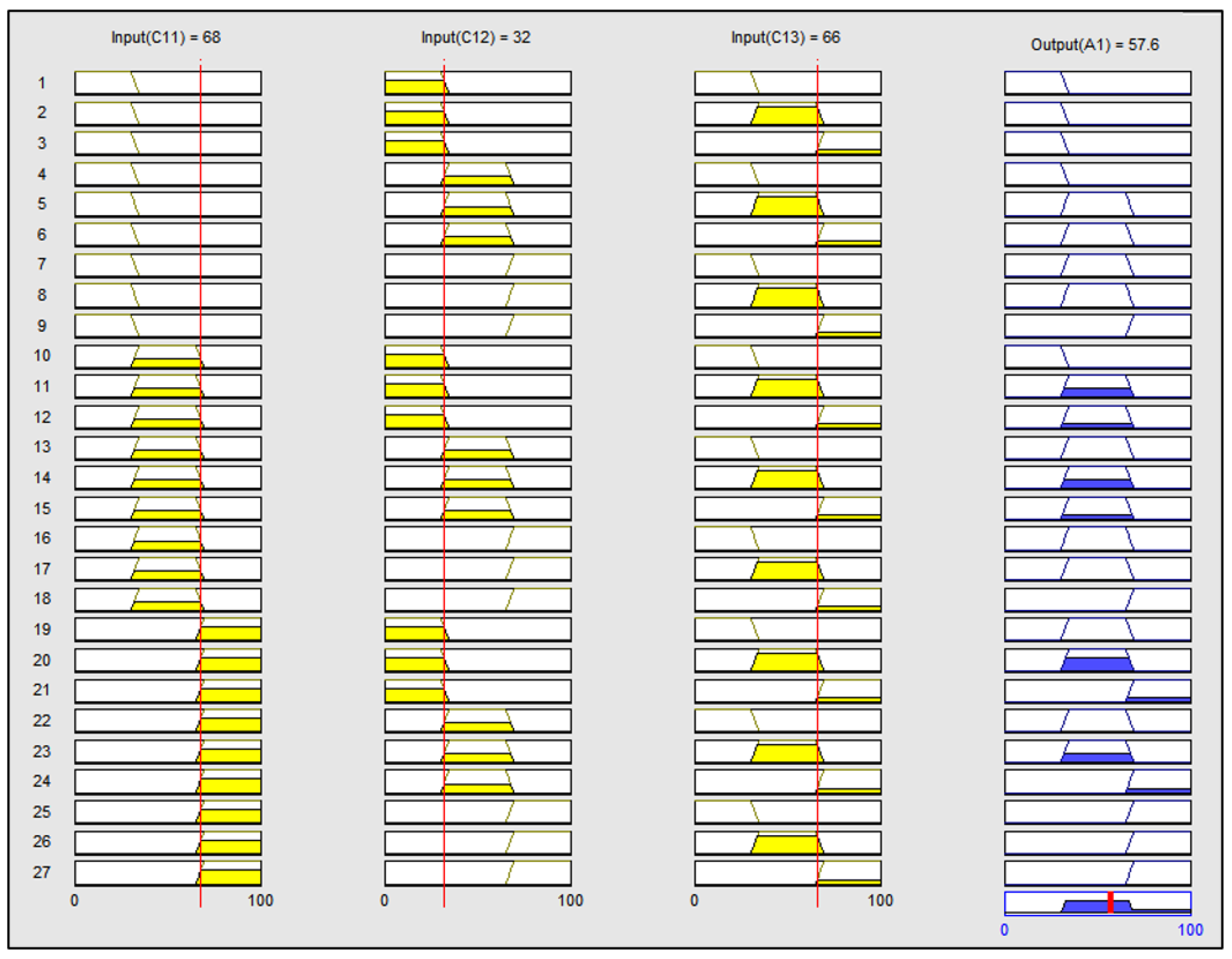

One of the FIS is chosen as an example to demonstrate the structure of the rule viewer in the model. The rule viewer is indicative of the road network in FIS. Figure 8 shows the rule viewer of the FIS for the ‘strategy’ aspect. Each rule is represented by a row of plots whereas each column represents an input variable. In this example, the input variables painted yellow are ‘operation strategy (C11)’, ‘strategic management and planning (C12)’ and ‘strategic analysis and motivation (C13)’, whereas ‘strategy (A1)’ represents the output variable or aspect painted blue. The input values can be varied by moving the red line and the FIS system correspondingly generates the output value. Since three membership functions are considered for the inputs, the number of rules is 27 in order to generate the output value (Table 10). Once the rules have been verified, it is clear that the output value (strategy) increases with an increase in the input values. The three rules are placed together in order to demonstrate how the output of each rule is combined or aggregated into a single fuzzy set value, which yields output (A1) = 57.6 (Equation (12)).

Figure 8.

Rule viewer of the fuzzy inference system for strategy (A1) aspect.

Table 10.

Basic Fuzzy Rule-Based System, a summary.

The overall rate (Equation (13)) is calculated based on the fuzzy Delphi weight values of each aspect and the fuzzy rule-based values of each fuzzy output criterion (Table 11). The overall rate of the predicted AMT implementation (specifically robot technology) is 64.21%, which indicates the probability of successful AMT implementation. Since the overall rate exceeds 50%, the implementation of AMT falls within the successful range.

Table 11.

Final scores of the AMT implementation prediction model.

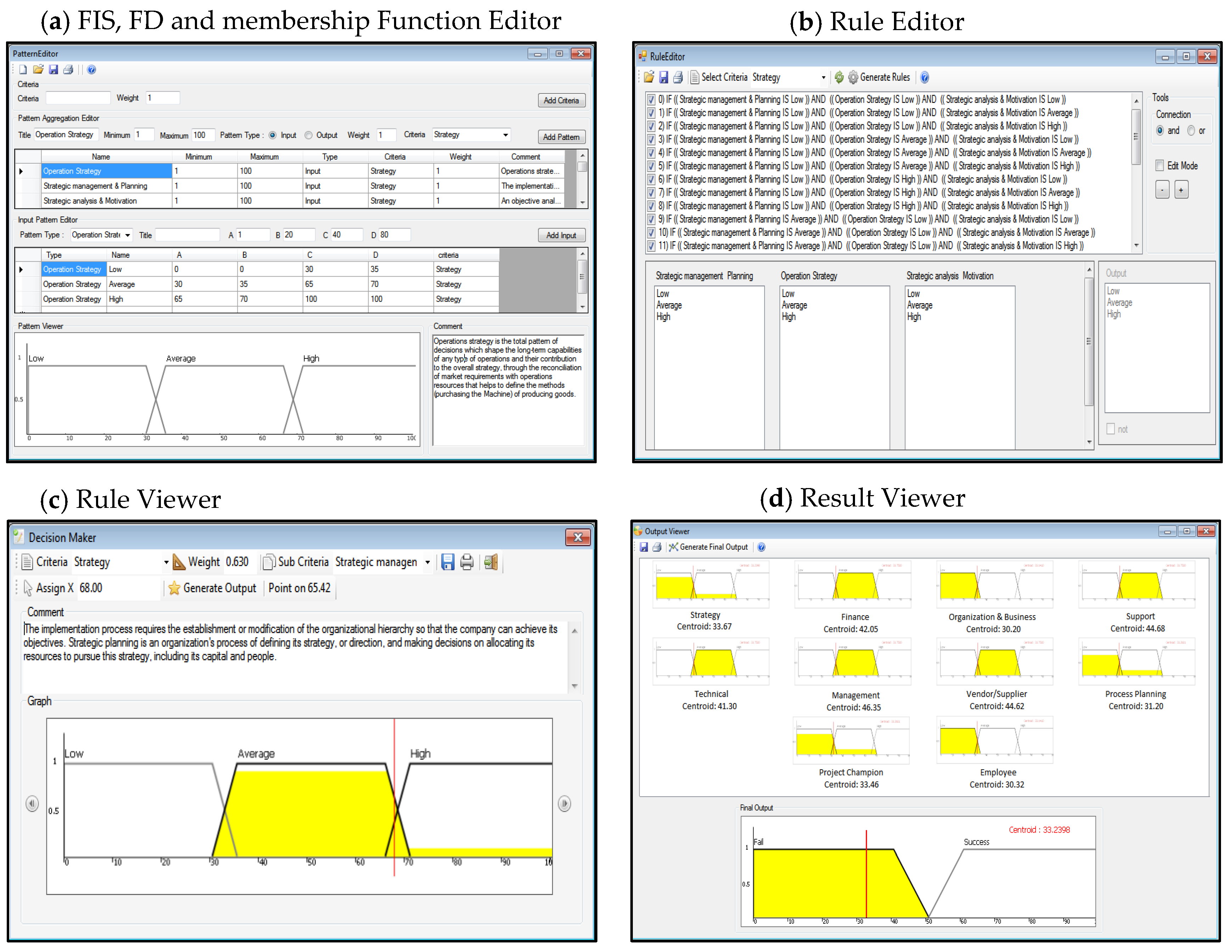

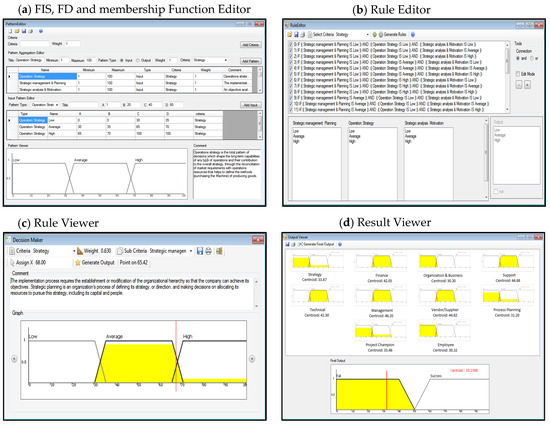

4. Supporting Tool

The model-supporting tool applied in this paper, is a C#-based implementation. This tool is developed to help managers in manufacturing firms to obtain results in a convenient manner. In fact, this tool offers the chance for decision makers to automate the specific steps of the decision-making procedure set out in Figure 3. The tool guides operators to express their judgments between all possible sets of functional and non-functional requirements in a similar way as the AMT decision-making approach does. Sample screenshots of the graphical user interface (GUI) of the software are shown in Figure 9a–d, which shows the ‘rule editor’, fuzzy Delphi, FIS, membership function editor, ‘rule viewer’, and ‘final result viewer’. The GUIs provide users with tools to edit and observe fuzzy inference systems in the AMT prediction model. The ‘rule editor’ lets the user to read and modify the FIS data, whereas the fuzzy rules and final results of the FIS can be viewed in the ‘rule viewer’ and ‘final result viewer’, respectively.

Figure 9.

Screenshots of graphical user interfaces available in the AMT prediction tool.

The main user interface shows the membership and rule function menus. The ‘pattern editor’ is basically a FIS and membership function editor; it is used to define the input, output, and universal range for each variable. The ‘pattern editor’ enables the user to define and edit the FIS for all the membership functions associated with the input and output variables as shown in Figure 9a. The ‘rule editor’ is a feature provided in the tool, which enables the user to edit a list of rules, which are automatically created, based on description of the input and output variables (Figure 9b). The ‘rule viewer’ user interface displays the road network of the whole fuzzy inference process. The FIS is based on the fuzzy inference diagram described in the previous section. The criteria (aspect), sub-criteria (input variable), and its current value are displayed on the top pane of the user interface (Figure 9c). The ‘final result viewer’ user interface is presented in Figure 9d. The decision maker can view the final results based on the input value of each criterion and will be able to make decisions.

5. Conclusions

The first outcome of this work is to identify the critical criteria that affect the successful implementation of AMTs in manufacturing firms. A total of 10 aspects including 32 criteria were identified. The aspects consisted of ‘strategy’, ‘financial’, ‘organization/business’, ‘support’, ‘technical’, ‘management’, ‘vendor/supplier’, ‘process/planning’, ‘project champion’, and ‘employee’. ‘Strategy’, and ‘organization/business’ were ranked as the top two aspects. Another significant outcome of this article was to develop a multi-criteria decision-making model to assess and validate all criteria defined above in order to predict the percentage of AMT success. This prediction model for AMT was established by integrating FDM and FIS. The numbers of input variables for each aspect comprised the design of the rules for the FIS. Considering the name of each rule (α, β and γ), its number was separately calculated. The α fuzzy rule set consisted of 9 rules, whereas the β and γ fuzzy rule set consisted of 27 and 81 rules, respectively, which made a total of 117 rules. Whenever the overall rate of the model exceeded 50%, the implementation of AMT fell within the successful range. The model was tested using a numerical test bed and the result indicated that the AMT implementation with the rate of 64.21% was successful. By comparing various AMTs with the suitable criteria and aspects, the decision makers will be enabled to examine the strengths and weaknesses of technology implementations. The model is deemed beneficial, as it is applicable to various AMT implementation problems. A supporting tool was developed using C# programming software. It greatly facilitates the calculation of the percentage of success for the company, which intends to implement a particular AMT in order to reach consensus in the manufacturing firm, amongst decision-makers.

Author Contributions

Conceptualization, F.T., M.M. and H.G.; methodology, F.T.; validation, F.T. and M.M.; formal analysis, F.T.; data curation, F.T.; writing—original draft preparation, F.T.; writing—review and editing, M.M., H.G. and S.S.; supervision, F.T. and H.G.; project administration, F.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Full data is presented in the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Athey, S.; Schmutzler, A. Product and process flexibility in an innovative environment. RAND J. Econ. 1995, 26, 557–574. [Google Scholar] [CrossRef]

- Swink, M.; Nair, A. Capturing the competitive advantages of AMT: Design–manufacturing integration as a complementary asset. J. Oper. Manag. 2007, 25, 736–754. [Google Scholar] [CrossRef]

- Salaheldin, S.I. The impact of organizational characteristics on AMT adoption: A study of Egyptian manufacturers. J. Manuf. Technol. Manag. 2007, 18, 443–460. [Google Scholar] [CrossRef]

- Burcher, P.G.; Lee, G.L. Competitiveness strategies and AMT investment decisions. Integr. Manuf. Syst. 2000, 11, 340–347. [Google Scholar] [CrossRef]

- Waldeck, N.E.; Leffakis, Z.M. HR perceptions and the provision of workforce training in an AMT environment: An empirical study. Omega 2007, 35, 161–172. [Google Scholar] [CrossRef]

- Rong-fu, Z.; Shu-fen, F. Research on Synergy of Advanced Manufacturing Technology and Production Process. In Proceedings of the 2007 International Conference on Management Science and Engineering, Harbin, China, 20–22 August 2007; pp. 873–878. [Google Scholar]

- Sun, H. Current and future patterns of using advanced manufacturing technologies. Technovation 2000, 20, 631–641. [Google Scholar] [CrossRef]

- Spanos, Y.E.; Voudouris, I. Antecedents and trajectories of AMT adoption: The case of Greek manufacturing SMEs. Res. Policy 2009, 38, 144–155. [Google Scholar] [CrossRef]

- Tansel, Y.; Yurdakul, M. Development of a two-stage advanced manufacturing technology option selection model to use in Turkish manufacturing companies. J. Glob. Bus. Adv. 2015, 8, 176–189. [Google Scholar]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Sorooshian, S.; Panigrahi, S. Impacts of the 4th Industrial Revolution on Industries. Walailak J. Sci. Technol. (WJST) 2020, 17, 903–915. [Google Scholar] [CrossRef]

- Lee, W.Y.; Tan, S.T.; Sorooshian, S. Impacts of Industry 4.0 on Malaysian Manufacturing Industries. WSEAS Trans. Bus. Econ. 2019, 16, 355–359. [Google Scholar]

- Leng, J.; Sha, W.; Lin, Z.; Jing, J.; Liu, Q.; Chen, X. Blockchained smart contract pyramid-driven multi-agent autonomous process control for resilient individualised manufacturing towards Industry 5.0. Int. J. Prod. Res. 2022. Available online: https://www.tandfonline.com/doi/citedby/10.1080/00207543.2022.2089929?scroll=top&needAccess=true (accessed on 25 August 2022). [CrossRef]

- Teck, T.S.; Subramaniam, H.; Sorooshian, S. Exploring challenges of the fourth industrial revolution. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 27–30. [Google Scholar] [CrossRef]

- Chen, I.; Small, M. Implementing advanced manufacturing technology: An integrated planning model. Omega 1994, 22, 91–103. [Google Scholar] [CrossRef]

- Yusuff, R.M.; Yee, K.P.; Hashmi, M. A preliminary study on the potential use of the analytical hierarchical process (AHP) to predict advanced manufacturing technology (AMT) implementation. Robot. Comput. Integr. Manuf. 2001, 17, 421–427. [Google Scholar] [CrossRef]

- Burgess, T.F.; Gules, H.K. Buyer–supplier relationships in firms adopting advanced manufacturing technology: An empirical analysis of the implementation of hard and soft technologies. J. Eng. Technol. Manag. 1998, 15, 127–152. [Google Scholar] [CrossRef]

- Sun, H.; Riis, J.O. Organizational, technical, strategic and managerial issues along the implementation process of advanced manufacturing technology—A general framework of implementation guide. Int. J. Hum. Factors Manuf. 1994, 4, 23–36. [Google Scholar] [CrossRef]

- Frohlich, M. How do you successfully adopt an advanced manufacturing technology? Eur. Manag. J. 1998, 16, 151–159. [Google Scholar] [CrossRef]

- Efstathiades, A.; Tassou, S.; Antoniou, A. Strategic planning, transfer and implementation of Advanced Manufacturing Technologies (AMT). Development of an integrated process plan. Technovation 2002, 22, 201–212. [Google Scholar] [CrossRef]

- Iakymenko, N.; Alfnes, E.; Thomassen, M.K. A differentiated approach for justification of advanced manufacturing technologies. Adv. Manuf. 2016, 4, 257–267. [Google Scholar] [CrossRef]

- Kim, J.S.; Chung, G.H. Implementing innovations within organizations: A systematic review and research agenda. Innovation 2017, 19, 372–399. [Google Scholar] [CrossRef]

- Stornelli, A.; Ozcan, S.; Simms, C. Advanced manufacturing technology adoption and innovation: A systematic literature review on barriers, enablers, and innovation types. Res. Policy 2021, 50, 104229. [Google Scholar] [CrossRef]

- Siaminwe, L.; Malama, T.; Chizyuka, C.; Mwenda, H.; Mwanza, M. Strategic Justification of Advanced Manufacturing Technologies Through Manufacturing Technology Research. Int. J. Eng. Res. Technol. 2016, 5, 837–842. [Google Scholar]

- Ribeiro, R.A. Fuzzy multiple attribute decision making: A review and new preference elicitation techniques. Fuzzy Sets Syst. 1996, 78, 155–181. [Google Scholar] [CrossRef]

- Choudhury, A.; Shankar, R.; Tiwari, M. Consensus-based intelligent group decision-making model for the selection of advanced technology. Decis. Support Syst. 2006, 42, 1776–1799. [Google Scholar] [CrossRef]

- Gouvea Da Costa, S.E.; Platts, K.W.; Fleury, A. Strategic selection of advanced manufacturing technologies (AMT), based on the manufacturing vision. Int. J. Comput. Appl. Technol. 2006, 27, 12–23. [Google Scholar] [CrossRef]

- Singh, H.; Khamba, J. An evaluation of AMTs utilisation in Indian industry for enhanced manufacturing performance: Evidence from large-and medium-scale organisations. Int. J. Indian Cult. Bus. Manag. 2009, 2, 585–601. [Google Scholar] [CrossRef]

- Efstathiades, A.; Tassou, S.A.; Oxinos, G.; Antoniou, A. Advanced manufacturing technology transfer and implementation in developing countries: The case of the Cypriot manufacturing industry. Technovation 2000, 20, 93–102. [Google Scholar] [CrossRef]

- Sanchez, A.M. Adopting advanced manufacturing technologies: Experience from Spain. J. Manuf. Syst. 1996, 15, 133–140. [Google Scholar] [CrossRef]

- Singh, H.; Kumar, R. Hybrid methodology for measuring the utilization of advanced manufacturing technologies using AHP and TOPSIS. Benchmarking Int. J. 2013, 20, 169–185. [Google Scholar] [CrossRef]

- Beatty, C.A. Implementing advanced manufacturing technologies: Rules of the road. MIT Sloan Manag. Rev. 1992, 33, 49. [Google Scholar] [CrossRef]

- Tahriri, F.; Dawal, S.Z.M.; Taha, Z. Fuzzy mixed assembly line sequencing and scheduling optimization model using multiobjective dynamic fuzzy GA. Sci. World J. 2014, 2014, 505207. [Google Scholar] [CrossRef]

- Noori, H. Implementing advanced manufacturing technology: The perspective of a newly industrialized country (Malaysia). J. High Technol. Manag. Res. 1997, 8, 1–20. [Google Scholar] [CrossRef]

- Lei, D.; Hitt, M.A.; Goldhar, J.D. Advanced manufacturing technology: Organizational design and strategic flexibility. Organ. Stud. 1996, 17, 501–523. [Google Scholar] [CrossRef]

- Lefebvre, L.A.; Lefebvre, E.; Harvey, J. Intangible assets as determinants of advanced manufacturing technology adoption in SME’s: Toward an evolutionary model. IEEE Trans. Eng. Manag. 1996, 43, 307–322. [Google Scholar] [CrossRef]

- Ramasesh, R.; Jayakumar, M. Economic justification of advanced manufacturing technology. Omega 1993, 21, 289–306. [Google Scholar] [CrossRef]

- Dimnik, T.; Johnston, D. Manufacturing managers and the adoption of advanced manufacturing technology. Omega 1993, 21, 155–162. [Google Scholar] [CrossRef]

- Sohal, A.; Samson, D.; Weill, P. Manufacturing and technology strategy: A survey of planning for AMT. Comput. Integr. Manuf. Syst. 1991, 4, 71–79. [Google Scholar] [CrossRef]

- Dean, J.W., Jr.; Susman, G.I.; Porter, P.S. Technical, economic and political factors in advanced manufacturing technology implementation. J. Eng. Technol. Manag. 1990, 7, 129–144. [Google Scholar] [CrossRef]

- Tyre, M.J.; Hauptman, O. Effectiveness of organizational responses to technological change in the production process. Organ. Sci. 1992, 3, 301–320. [Google Scholar] [CrossRef]

- Zhao, H.; Co, H.C. Adoption and implementation of advanced manufacturing technology in Singapore. Int. J. Prod. Econ. 1997, 48, 7–19. [Google Scholar] [CrossRef]

- Lowe, J.; Sim, A. The diffusion of a manufacturing innovation: The case of JIT and MRPII. Int. J. Technol. Manag. 1993, 8, 244–258. [Google Scholar] [CrossRef]

- Lewis, M.W. Advanced manufacturing technology: A multiparadigm deconstruction and reconstruction of the literature. In Academy of Management Proceedings; Academy of Management: Briarcliff Manor, NY, USA; pp. C1–C9.

- McDermott, C.M.; Stock, G.N. Organizational culture and advanced manufacturing technology implementation. J. Oper. Manag. 1999, 17, 521–533. [Google Scholar] [CrossRef]

- Parthasarthy, R.; Sethi, S.P. The impact of flexible automation on business strategy and organizational structure. Acad. Manag. Rev. 1992, 17, 86–111. [Google Scholar] [CrossRef]

- Zammuto, R.F.; O’Connor, E.J. Gaining advanced manufacturing technologies’ benefits: The roles of organization design and culture. Acad. Manag. Rev. 1992, 17, 701–728. [Google Scholar] [CrossRef]

- Small, M.H.; Yasin, M.M. Developing a framework for the effective planning and implementation of advanced manufacturing technology. Int. J. Oper. Prod. Manag. 1997, 17, 468–489. [Google Scholar] [CrossRef]

- Udo, G.J.; Ehie, I.C. Critical success factors for advanced manufacturing systems. Comput. Ind. Eng. 1996, 31, 91–94. [Google Scholar] [CrossRef]

- Chan, F.; Chan, M.; Lau, H.; Ip, R. Investment appraisal techniques for advanced manufacturing technology (AMT): A literature review. Integr. Manuf. Syst. 2001, 12, 35–47. [Google Scholar] [CrossRef]

- Das, A.; Narasimhan, R. Process-technology fit and its implications for manufacturing performance. J. Oper. Manag. 2001, 19, 521–540. [Google Scholar] [CrossRef]

- Small, M.H. Planning, justifying and installing advanced manufacturing technology: A managerial framework. J. Manuf. Technol. Manag. 2007, 18, 513–537. [Google Scholar] [CrossRef]

- Saberi, S.; Rosnah, M.Y. Advanced Manufacturing Technology Implementation Performance: Towards A Strategic Framework. In Proceedings of the 2011 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 22–24 January 2011. [Google Scholar]

- Alvarado, A. Problems in the implementation process of advanced manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 64, 123–131. [Google Scholar]

- Baldwin, J.; Lin, Z. Impediments to advanced technology adoption for Canadian manufacturers. Res. Policy 2002, 31, 1–18. [Google Scholar] [CrossRef]

- Canada, J.; Sullivan, W. Persistent pitfalls and applicable approaches for justification of advanced manufacturing systems. Eng. Cost Prod. Econ. 1990, 18, 241–253. [Google Scholar] [CrossRef]

- Hynek, J.; Janecek, V. Advanced Manufacturing Technology Projects Justification. In Proceedings of the 2007 IEEE International Conference on Mechatronics, Kumamoto, Japan, 8–10 May 2007; pp. 1–6. [Google Scholar]

- Sukathong, S.; Suksawang, P.; Naenna, T. Analyzing the importance of critical success factors for the adoption of advanced manufacturing technologies. Int. J. Eng. Bus. Manag. 2021, 13, 18479790211055057. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, H.; Chandel, R. Exploring the key success factors of advanced manufacturing technology implementation in Indian manufacturing industry. J. Manuf. Technol. Manag. 2017, 29, 25–40. [Google Scholar] [CrossRef]

- Bhise, D.V.; Sunnapwar, V.K. Developing framework for the implementation of advanced manufacturing technologies in small and medium-sized enterprises. Int. J. Appl. Manag. Technol. 2019, 18, 10. [Google Scholar] [CrossRef]

- Abdel-Kader, M.G.; Dugdale, D. Evaluating investments in advanced manufacturing technology: A fuzzy set theory approach. Br. Account. Rev. 2001, 33, 455–489. [Google Scholar] [CrossRef]

- Monge, C.A.M.; Rao, S.S.; Gonzalez, M.E.; Sohal, A.S. Performance measurement of AMT: A cross-regional study. Benchmarking Int. J. 2006, 13, 135–146. [Google Scholar] [CrossRef]

- Datta, V.; Sambasivarao, K.; Kodali, R.; Deshmukh, S. Multi-attribute decision model using the analytic hierarchy process for the justification of manufacturing systems. Int. J. Prod. Econ. 1992, 28, 227–234. [Google Scholar] [CrossRef]

- Demmel, J.G.; Askin, R.G. A multiple-objective decision model for the evaluation of advanced manufacturing system technologies. J. Manuf. Syst. 1992, 11, 179–194. [Google Scholar] [CrossRef][Green Version]

- Huang, P.Y.; Sakurai, M. Factor automation: The Japanese experience. IEEE Trans. Eng. Manag. 1990, 37, 102–108. [Google Scholar] [CrossRef]

- Sohal, A.S.; Schroder, R.; Uliana, E.O.; Maguire, W. Adoption of AMT by South African manufacturers. Integr. Manuf. Syst. 2001, 12, 15–34. [Google Scholar] [CrossRef]

- Díaz, M.S.; Gil, M.J.Á.; Machuca, J.A.D. Performance measurement systems, competitive priorities, and advanced manufacturing technology: Some evidence from the aeronautical sector. Int. J. Oper. Prod. Manag. 2005, 25, 781–799. [Google Scholar] [CrossRef][Green Version]

- Mital, A.; Pennathur, A. Advanced technologies and humans in manufacturing workplaces: An interdependent relationship. Int. J. Ind. Ergon. 2004, 33, 295–313. [Google Scholar] [CrossRef]

- Saleh, B.; Hacker, M.; Randhawa, S. Factors in capital decisions involving advanced manufacturing technologies. Int. J. Oper. Prod. Manag. 2001, 21, 1265–1288. [Google Scholar] [CrossRef]

- Sohal, A.S.; Burcher, P.G.; Millen, R.; Lee, G. Comparing American and British practices in AMT adoption. Benchmarking Int. J. 1999, 6, 310–324. [Google Scholar] [CrossRef]

- DeRuntz, B.D.; Turner, R.M. Organizational Considerations for Advanced Manufacturing Technology. J. Technol. Stud. 2003, 29, 4–9. [Google Scholar] [CrossRef]

- Mohanty, R. Analysis of justification problems in CIMS review and projection. Prod. Plan. Control. 1993, 4, 260–272. [Google Scholar] [CrossRef]

- Mohanty, R.; Deshmukh, S. Evaluating manufacturing strategy for a learning organization: A case. Int. J. Oper. Prod. Manag. 1999, 19, 308–328. [Google Scholar] [CrossRef]

- Bolden, R.; Waterson, P.; Warr, P.; Clegg, C.; Wall, T. A new taxonomy of modern manufacturing practices. Int. J. Oper. Prod. Manag. 1997, 17, 1112–1130. [Google Scholar] [CrossRef]

- Rosnah, M.; Ahmad, M.M.; Osman, M. Barriers to advanced manufacturing technologies implementation in the small and medium scales industries of a developing country. Int. J. Eng. Technol. 2004, 1, 39–46. [Google Scholar]

- Rao, K.S.; Deshmukh, S. Strategic framework for implementing flexible manufacturing systems in India. Int. J. Oper. Prod. Manag. 1994, 14, 50–63. [Google Scholar]

- Teng, K.L.L.; Seetharaman, A. The selection and management of cost justification techniques among advanced manufacturing technology companies in Malaysia. Int. J. Manag. 2004, 21, 45. [Google Scholar]

- Kotha, S.; Swamidass, P. Strategy, advanced manufacturing technology and performance: Empirical evidence from U.S. manufacturing firms. J. Oper. Manag. 2000, 18, 257–277. [Google Scholar] [CrossRef]

- Low-Lock, K.; Seetharaman, A. Towards a better manufacturing sector: A perspective on the implementation of advanced manufacturing technology in Malaysia. Int. J. Manag. 2003, 20, 234–239. [Google Scholar]

- Shehabuddeen, N.; Probert, D.; Phaal, R. From theory to practice: Challenges in operationalising a technology selection framework. Technovation 2006, 26, 324–335. [Google Scholar] [CrossRef]

- Shepherd, D.; McDemott, C.; Stock, G. Advanced manufacturing technology: Does more radicalness mean more perceived benefits? J. High Technol. Manag. Resour. 2000, 11, 19–33. [Google Scholar] [CrossRef]

- Ordoobadi, S.M. Application of AHP and Taguchi loss functions in evaluation of advanced manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 2593–2605. [Google Scholar] [CrossRef]

- Thomas, A.; Barton, R. Characterizing SME migration towards advanced manufacturing technologies. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 745–756. [Google Scholar] [CrossRef]

- Kwon, C.-W.; Chun, B.G. The effect of strategic technology adoptions by local firms on technology spillover. Econ. Model. 2015, 51, 13–20. [Google Scholar] [CrossRef]

- Schiopu, I. Technology adoption, human capital formation and income differences. J. Macroecon. 2015, 45, 318–335. [Google Scholar] [CrossRef]

- Muita, K.; Westerlund, M.; Rajala, R. The evolution of rapid production: How to adopt novel manufacturing technology. IFAC-Pap. 2015, 48, 32–37. [Google Scholar] [CrossRef]

- Lewis, M.W.; Boyer, K.K. Factors impacting AMT implementation: An integrative and controlled study. J. Eng. Technol. Manag. 2002, 19, 111–130. [Google Scholar] [CrossRef]

- Bhatt, N. Forecasting the Implementation Success of AMT in SMEs using an Integrated AHP-TOPSIS Approach. Glob. J. Enterp. Inf. Syst. 2016, 8, 18–28. [Google Scholar] [CrossRef]

- Singh, R.; Singh, C.D.; Deepak, D. Analyzing performance indicators of advanced manufacturing technology implementation using MCDM. Mater. Today Proc. 2021, 47, 3750–3753. [Google Scholar] [CrossRef]

- Tahriri, F.; Mousavi, M.; Hozhabri Haghighi, S.; Zawiah Md Dawal, S. The application of fuzzy Delphi and fuzzy inference system in supplier ranking and selection. J. Ind. Eng. Int. 2014, 10, 66. [Google Scholar] [CrossRef]

- Ishikawa, A.; Amagasa, M.; Shiga, T.; Tomizawa, G.; Tatsuta, R.; Mieno, H. The max-min Delphi method and fuzzy Delphi method via fuzzy integration. Fuzzy Sets Syst. 1993, 55, 241–253. [Google Scholar] [CrossRef]

- Wang, M.-L.; Lin, Y.-H. To construct a monitoring mechanism of production loss by using Fuzzy Delphi method and fuzzy regression technique–A case study of IC package testing company. Expert Syst. Appl. 2008, 35, 1156–1165. [Google Scholar] [CrossRef]

- Hsu, Y.-L.; Lee, C.-H.; Kreng, V.B. The application of Fuzzy Delphi Method and Fuzzy AHP in lubricant regenerative technology selection. Expert Syst. Appl. 2010, 37, 419–425. [Google Scholar] [CrossRef]

- Ho, Y.-F.; Wang, H.-L. Applying Fuzzy Delphi Method to Select the Variables of a Sustainable Urban System Dynamics Model. In Proceedings of the 26th International Conference of System Dynamics Societ, Athens, Greece, 20–24 July 2008. [Google Scholar]

- Noorderhaven, N. Strategic Decision Making; Duxbury Press: London, England, 1995. [Google Scholar]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning—I. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Kaufman, A.; Gupta, M.M. Introduction to Fuzzy Arithmetic; Van Nostrand Reinhold Company: New York, NY, USA, 1991. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).