A Decision-Making Model for Predicting Technology Adoption Success

Abstract

1. Introduction

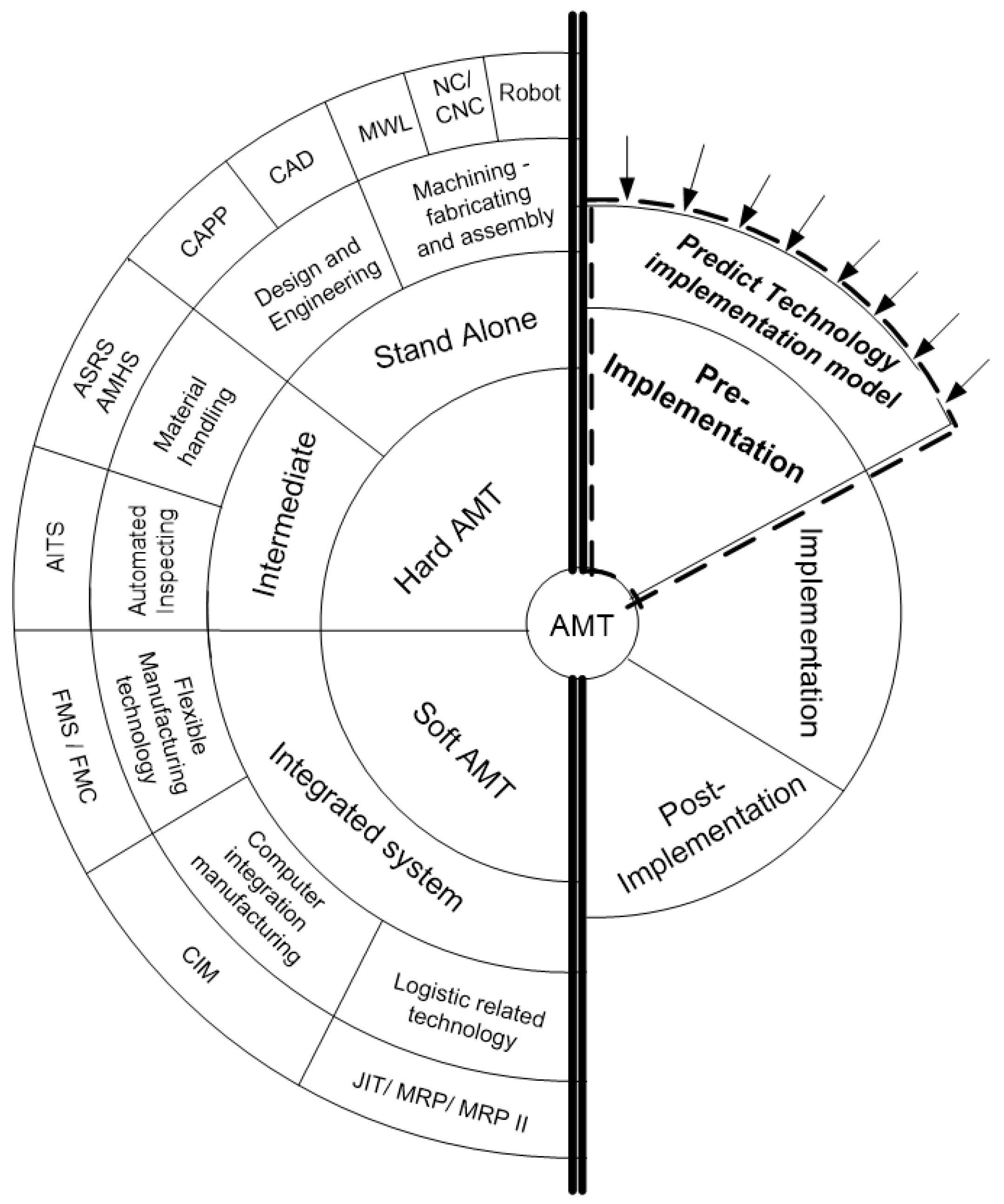

Advanced Manufacturing Technology (AMT)

- Economic methods. Since financial matters are a crucial aspect in the manufacturing industry, it is vital for manufacturers to scrutinize the methods, which play a key role in achieving the desired target, such as payback methods, return on investment, and discounting cash flow methods. Even though these methods offer ease of data collection as well as intuitive appeal, they do not account for strategic and non-economic benefits, which managers need to address. In addition, these methods only consider a single objective for cash flow and neglect other benefits such as quality and flexibility [23].

- Strategic methods. Several manufacturers advocate the use of strategic methods in order to eradicate the drawbacks associated with conventional financial methods. These strategic methods cover technical importance, business objectives, competitive advantage, as well as research and development (R&D). Although these methods require fewer technical data and priority is given to the general objectives of the firm, there is one important factor which is typically overlooked by manufacturers since only long-term intangible benefits are considered, and it pertains to the use of strategic methods with either economic or analytical ones [24].

- Analytical methods. They can be used to evaluate and improve the promotion of manufactured products in order to gain business success. Analytical methods consist of scoring models (e.g., analytical hierarchy process (AHP)), mathematical programming, goal programming, integer programming, data envelopment analysis (DEA), stochastic methods, fuzzy set theories and multiple-attribute decision-making (MADM) [25].

2. Identification of Criteria for Advanced Manufacturing Technology

| Strategy | Financial | Organization and Business | Support | Technical | Management | Vendor/Supplier | Process/ Planning | Project Champion | Employee | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Operation Strategy | Strategic Management and Planning | Strategic Analysis and Motivation | Financial Evaluation | Economic Justification | Human Resource Management | Organizational Infrastructure and Culture | Alignment of AMT with Organization and Business | Top Management Support | Operating Sponsor | Support Systems before Equipment Installation | Governance and Commitment | Think-Tank Linkage | Knowledge and Perfecting Skills | Technical Infrastructure and its Influence on Successful Adoption | Technology Identification | Production Management and System | Managers experimenting with new Technologies | managers’ Personal Beliefs and Understanding of AMT | Expectations of AMT | Commitment and Relationships with Vendors | Supplier-Related Factors | Selection of the Appropriate Technological Supplier(s) | Planning Process and Requirements | Product-Process Dependency | Integration of AMT with Existing Systems | Project Champions and Market Risk | Manufacturing Performance | Pilot Project | Training | Communication and Coordination | Lack of Knowledge and Skills | |

| [35] | x | x | x | x | ||||||||||||||||||||||||||||

| [36] | x | x | x | |||||||||||||||||||||||||||||

| [37] | x | x | x | x | ||||||||||||||||||||||||||||

| [19] | x | x | x | x | x | |||||||||||||||||||||||||||

| [38] | x | x | x | x | ||||||||||||||||||||||||||||

| [39] | x | x | x | x | ||||||||||||||||||||||||||||

| [40] | x | |||||||||||||||||||||||||||||||

| [41] | x | x | ||||||||||||||||||||||||||||||

| [33] | x | x | ||||||||||||||||||||||||||||||

| [42] | x | x | x | |||||||||||||||||||||||||||||

| [43] | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||

| [31] | x | x | x | |||||||||||||||||||||||||||||

| [44] | x | x | ||||||||||||||||||||||||||||||

| [45] | x | x | x | |||||||||||||||||||||||||||||

| [46] | x | x | ||||||||||||||||||||||||||||||

| [47] | x | x | x | |||||||||||||||||||||||||||||

| [48] | x | x | x | |||||||||||||||||||||||||||||

| [49] | x | |||||||||||||||||||||||||||||||

| [50] | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| [51] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [17] | x | x | x | x | x | x | x | |||||||||||||||||||||||||

| [30] | x | x | x | |||||||||||||||||||||||||||||

| [52] | x | x | x | |||||||||||||||||||||||||||||

| [32] | x | x | x | |||||||||||||||||||||||||||||

| [53] | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||||

| [54] | x | x | x | x | ||||||||||||||||||||||||||||

| [55] | x | x | x | x | ||||||||||||||||||||||||||||

| [56] | x | x | x | x | x | |||||||||||||||||||||||||||

| [57] | x | x | ||||||||||||||||||||||||||||||

| [58] | x | x | x | x | ||||||||||||||||||||||||||||

| [59] | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| [60] | x | x | x | x | x | |||||||||||||||||||||||||||

| [61] | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||

| [21] | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||

| [62] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [63] | x | |||||||||||||||||||||||||||||||

| [64] | x | x | x | |||||||||||||||||||||||||||||

| [65] | x | x | x | x | ||||||||||||||||||||||||||||

| [66] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [67] | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||

| [68] | x | x | x | x | x | x | ||||||||||||||||||||||||||

| [69] | x | x | x | x | x | |||||||||||||||||||||||||||

| [28] | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||

| [70] | x | x | x | x | x | |||||||||||||||||||||||||||

| [71] | x | x | ||||||||||||||||||||||||||||||

| [72] | x | |||||||||||||||||||||||||||||||

| [73] | x | x | x | x | ||||||||||||||||||||||||||||

| [74] | x | x | x | x | x | |||||||||||||||||||||||||||

| [75] | x | |||||||||||||||||||||||||||||||

| [76] | x | x | ||||||||||||||||||||||||||||||

| [3] | x | x | x | |||||||||||||||||||||||||||||

| [77] | x | x | x | x | x | x | x | |||||||||||||||||||||||||

| [78] | x | |||||||||||||||||||||||||||||||

| [79] | x | x | x | |||||||||||||||||||||||||||||

| [80] | x | x | x | x | x | |||||||||||||||||||||||||||

| [81] | x | x | x | |||||||||||||||||||||||||||||

| [82] | x | x | x | |||||||||||||||||||||||||||||

| [83] | x | x | x | x | x | |||||||||||||||||||||||||||

| [84] | x | x | x | x | ||||||||||||||||||||||||||||

| [85] | x | x | x | x | ||||||||||||||||||||||||||||

| [86] | x | x | ||||||||||||||||||||||||||||||

| [87] | x | x | x | |||||||||||||||||||||||||||||

| [88] | x | x | x | x | ||||||||||||||||||||||||||||

| [89] | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||

| [90] | x | x | x | x | x | |||||||||||||||||||||||||||

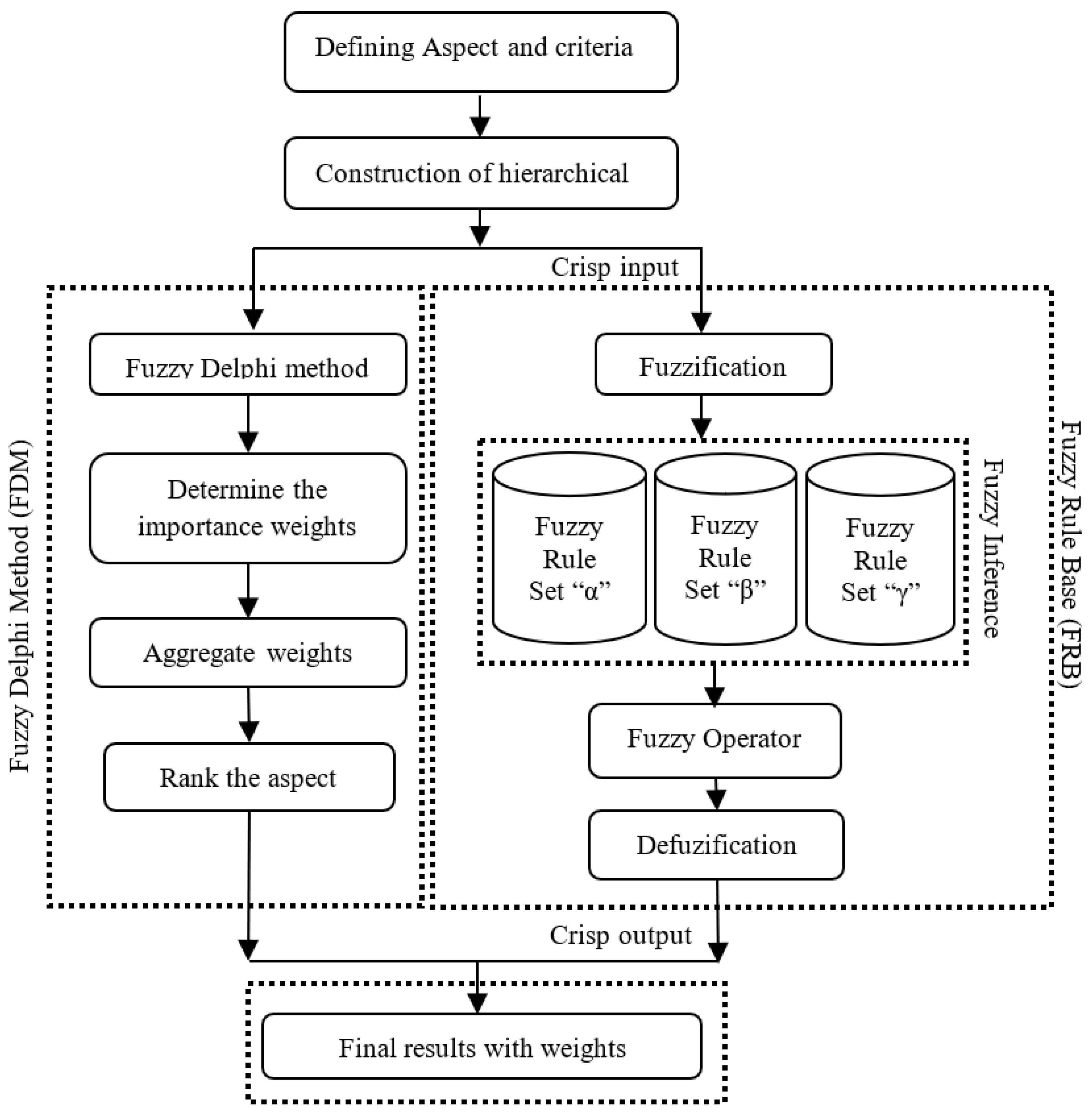

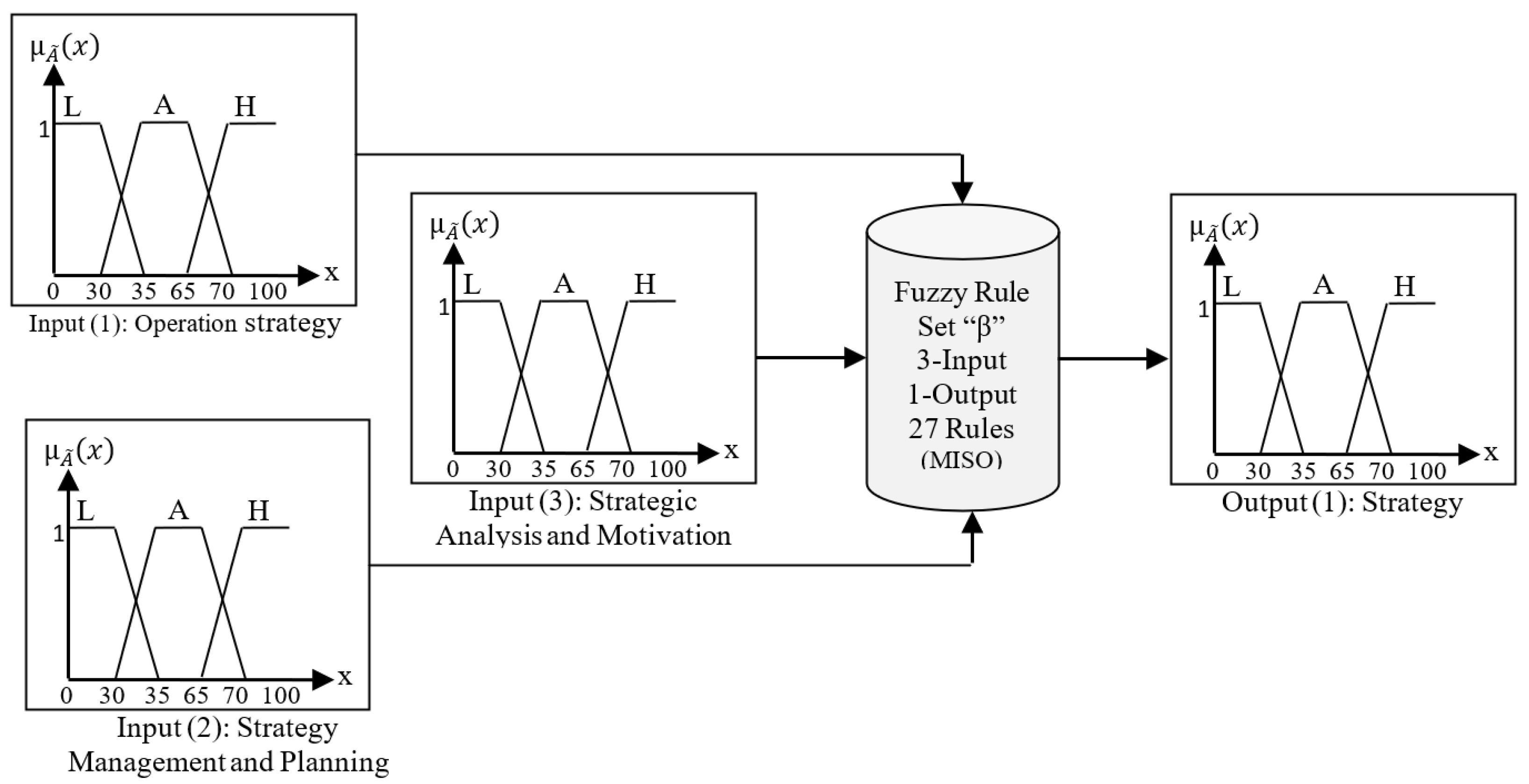

3. Proposed Model to Predict the Success of AMT Adoption

3.1. Fuzzy Delphi Method

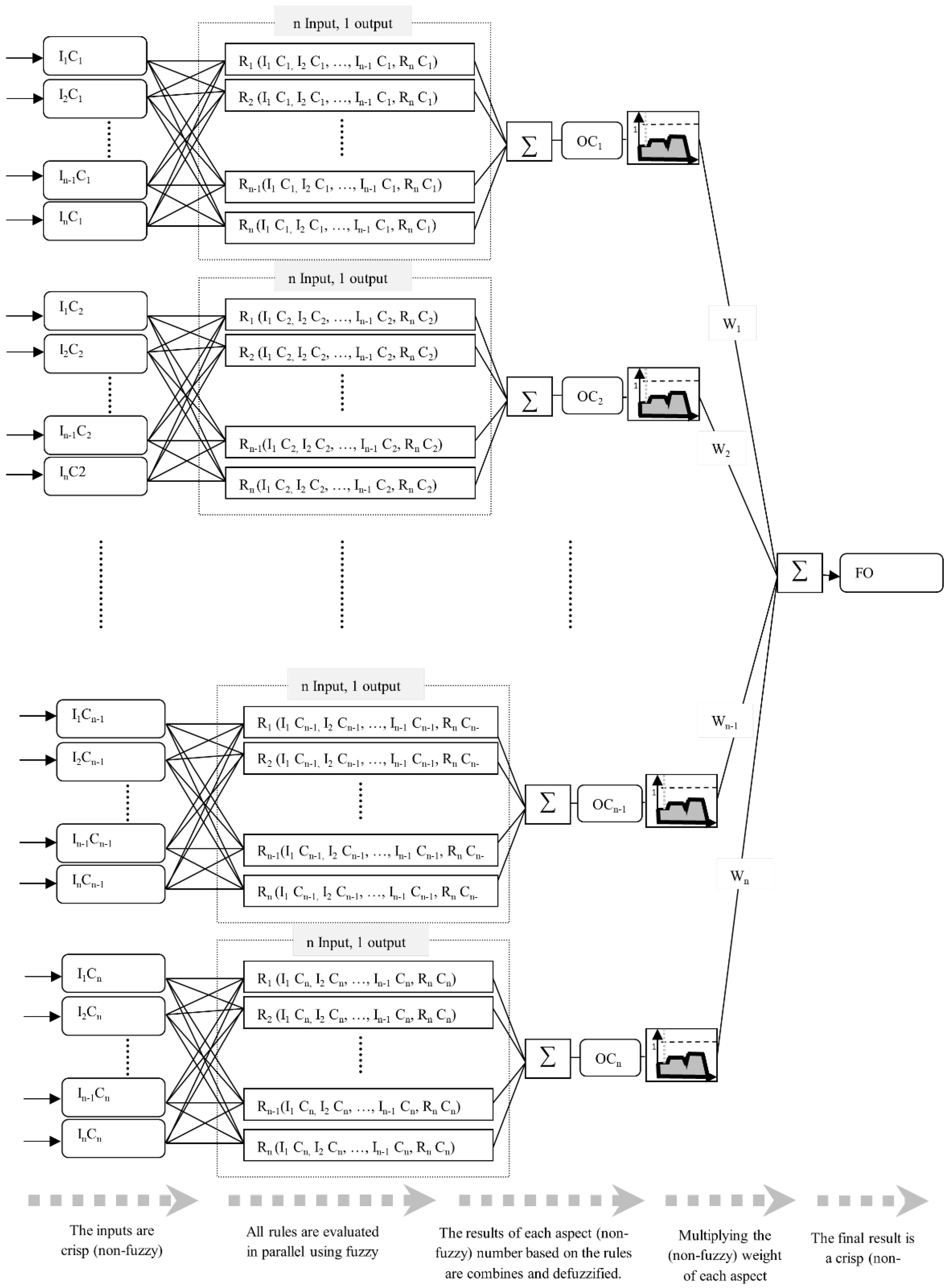

3.2. Fuzzy Inference System

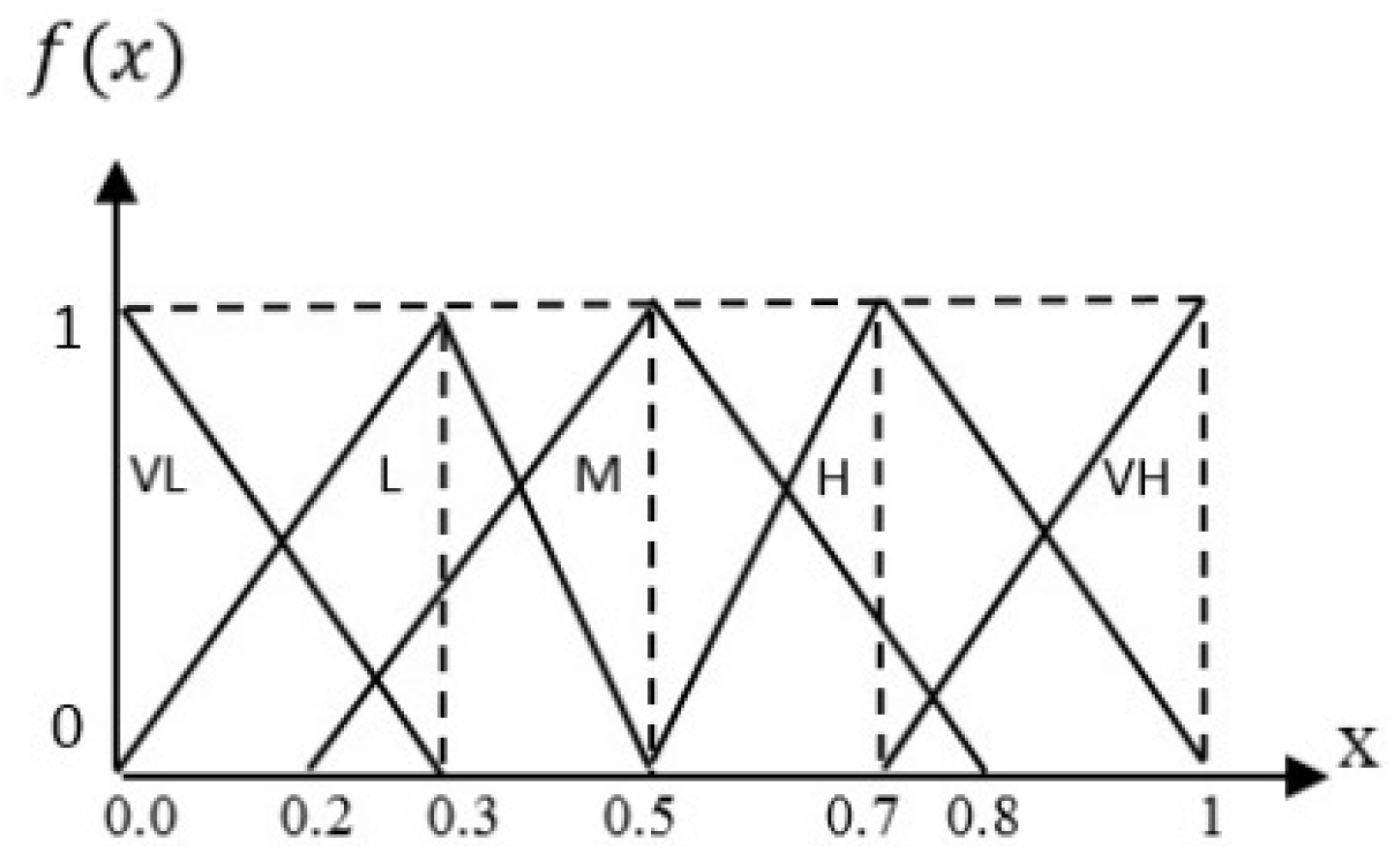

3.2.1. Fuzzifier

3.2.2. Fuzzy Rule Set

3.2.3. Fuzzy Operator

3.2.4. Defuzzification

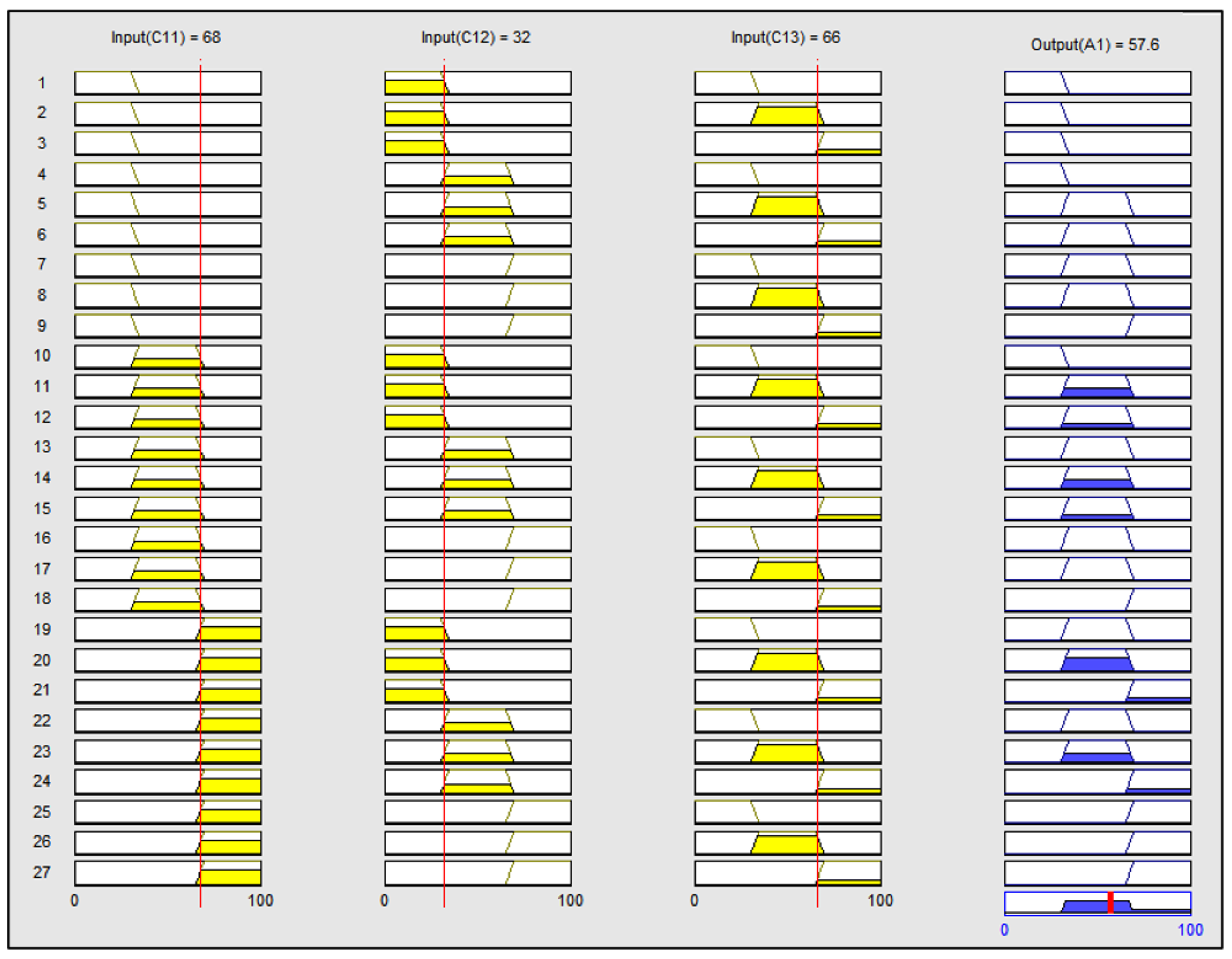

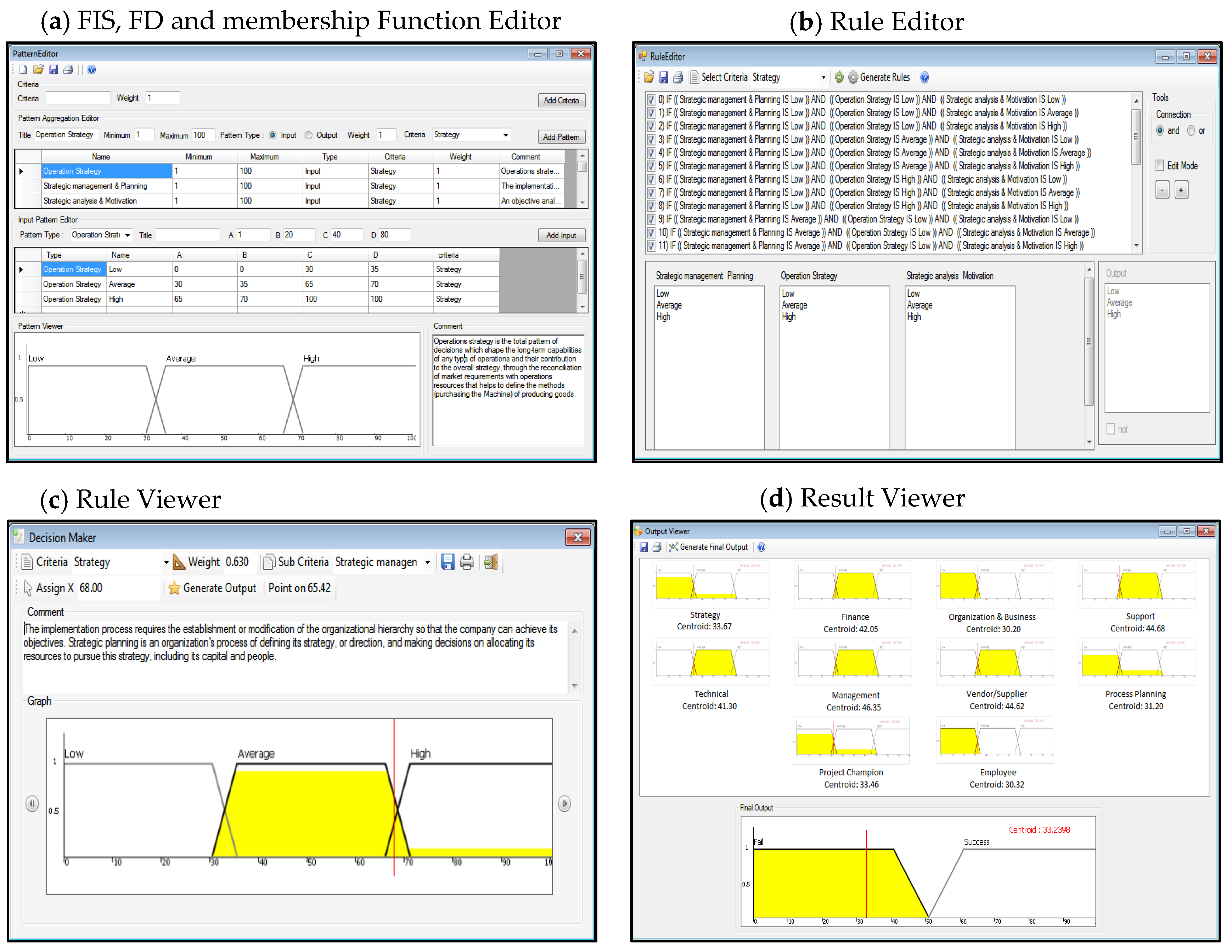

3.3. Description of the Proposed Model

4. Supporting Tool

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Athey, S.; Schmutzler, A. Product and process flexibility in an innovative environment. RAND J. Econ. 1995, 26, 557–574. [Google Scholar] [CrossRef]

- Swink, M.; Nair, A. Capturing the competitive advantages of AMT: Design–manufacturing integration as a complementary asset. J. Oper. Manag. 2007, 25, 736–754. [Google Scholar] [CrossRef]

- Salaheldin, S.I. The impact of organizational characteristics on AMT adoption: A study of Egyptian manufacturers. J. Manuf. Technol. Manag. 2007, 18, 443–460. [Google Scholar] [CrossRef]

- Burcher, P.G.; Lee, G.L. Competitiveness strategies and AMT investment decisions. Integr. Manuf. Syst. 2000, 11, 340–347. [Google Scholar] [CrossRef]

- Waldeck, N.E.; Leffakis, Z.M. HR perceptions and the provision of workforce training in an AMT environment: An empirical study. Omega 2007, 35, 161–172. [Google Scholar] [CrossRef]

- Rong-fu, Z.; Shu-fen, F. Research on Synergy of Advanced Manufacturing Technology and Production Process. In Proceedings of the 2007 International Conference on Management Science and Engineering, Harbin, China, 20–22 August 2007; pp. 873–878. [Google Scholar]

- Sun, H. Current and future patterns of using advanced manufacturing technologies. Technovation 2000, 20, 631–641. [Google Scholar] [CrossRef]

- Spanos, Y.E.; Voudouris, I. Antecedents and trajectories of AMT adoption: The case of Greek manufacturing SMEs. Res. Policy 2009, 38, 144–155. [Google Scholar] [CrossRef]

- Tansel, Y.; Yurdakul, M. Development of a two-stage advanced manufacturing technology option selection model to use in Turkish manufacturing companies. J. Glob. Bus. Adv. 2015, 8, 176–189. [Google Scholar]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Sorooshian, S.; Panigrahi, S. Impacts of the 4th Industrial Revolution on Industries. Walailak J. Sci. Technol. (WJST) 2020, 17, 903–915. [Google Scholar] [CrossRef]

- Lee, W.Y.; Tan, S.T.; Sorooshian, S. Impacts of Industry 4.0 on Malaysian Manufacturing Industries. WSEAS Trans. Bus. Econ. 2019, 16, 355–359. [Google Scholar]

- Leng, J.; Sha, W.; Lin, Z.; Jing, J.; Liu, Q.; Chen, X. Blockchained smart contract pyramid-driven multi-agent autonomous process control for resilient individualised manufacturing towards Industry 5.0. Int. J. Prod. Res. 2022. Available online: https://www.tandfonline.com/doi/citedby/10.1080/00207543.2022.2089929?scroll=top&needAccess=true (accessed on 25 August 2022). [CrossRef]

- Teck, T.S.; Subramaniam, H.; Sorooshian, S. Exploring challenges of the fourth industrial revolution. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 27–30. [Google Scholar] [CrossRef]

- Chen, I.; Small, M. Implementing advanced manufacturing technology: An integrated planning model. Omega 1994, 22, 91–103. [Google Scholar] [CrossRef]

- Yusuff, R.M.; Yee, K.P.; Hashmi, M. A preliminary study on the potential use of the analytical hierarchical process (AHP) to predict advanced manufacturing technology (AMT) implementation. Robot. Comput. Integr. Manuf. 2001, 17, 421–427. [Google Scholar] [CrossRef]

- Burgess, T.F.; Gules, H.K. Buyer–supplier relationships in firms adopting advanced manufacturing technology: An empirical analysis of the implementation of hard and soft technologies. J. Eng. Technol. Manag. 1998, 15, 127–152. [Google Scholar] [CrossRef]

- Sun, H.; Riis, J.O. Organizational, technical, strategic and managerial issues along the implementation process of advanced manufacturing technology—A general framework of implementation guide. Int. J. Hum. Factors Manuf. 1994, 4, 23–36. [Google Scholar] [CrossRef]

- Frohlich, M. How do you successfully adopt an advanced manufacturing technology? Eur. Manag. J. 1998, 16, 151–159. [Google Scholar] [CrossRef]

- Efstathiades, A.; Tassou, S.; Antoniou, A. Strategic planning, transfer and implementation of Advanced Manufacturing Technologies (AMT). Development of an integrated process plan. Technovation 2002, 22, 201–212. [Google Scholar] [CrossRef]

- Iakymenko, N.; Alfnes, E.; Thomassen, M.K. A differentiated approach for justification of advanced manufacturing technologies. Adv. Manuf. 2016, 4, 257–267. [Google Scholar] [CrossRef]

- Kim, J.S.; Chung, G.H. Implementing innovations within organizations: A systematic review and research agenda. Innovation 2017, 19, 372–399. [Google Scholar] [CrossRef]

- Stornelli, A.; Ozcan, S.; Simms, C. Advanced manufacturing technology adoption and innovation: A systematic literature review on barriers, enablers, and innovation types. Res. Policy 2021, 50, 104229. [Google Scholar] [CrossRef]

- Siaminwe, L.; Malama, T.; Chizyuka, C.; Mwenda, H.; Mwanza, M. Strategic Justification of Advanced Manufacturing Technologies Through Manufacturing Technology Research. Int. J. Eng. Res. Technol. 2016, 5, 837–842. [Google Scholar]

- Ribeiro, R.A. Fuzzy multiple attribute decision making: A review and new preference elicitation techniques. Fuzzy Sets Syst. 1996, 78, 155–181. [Google Scholar] [CrossRef]

- Choudhury, A.; Shankar, R.; Tiwari, M. Consensus-based intelligent group decision-making model for the selection of advanced technology. Decis. Support Syst. 2006, 42, 1776–1799. [Google Scholar] [CrossRef]

- Gouvea Da Costa, S.E.; Platts, K.W.; Fleury, A. Strategic selection of advanced manufacturing technologies (AMT), based on the manufacturing vision. Int. J. Comput. Appl. Technol. 2006, 27, 12–23. [Google Scholar] [CrossRef]

- Singh, H.; Khamba, J. An evaluation of AMTs utilisation in Indian industry for enhanced manufacturing performance: Evidence from large-and medium-scale organisations. Int. J. Indian Cult. Bus. Manag. 2009, 2, 585–601. [Google Scholar] [CrossRef]

- Efstathiades, A.; Tassou, S.A.; Oxinos, G.; Antoniou, A. Advanced manufacturing technology transfer and implementation in developing countries: The case of the Cypriot manufacturing industry. Technovation 2000, 20, 93–102. [Google Scholar] [CrossRef]

- Sanchez, A.M. Adopting advanced manufacturing technologies: Experience from Spain. J. Manuf. Syst. 1996, 15, 133–140. [Google Scholar] [CrossRef]

- Singh, H.; Kumar, R. Hybrid methodology for measuring the utilization of advanced manufacturing technologies using AHP and TOPSIS. Benchmarking Int. J. 2013, 20, 169–185. [Google Scholar] [CrossRef]

- Beatty, C.A. Implementing advanced manufacturing technologies: Rules of the road. MIT Sloan Manag. Rev. 1992, 33, 49. [Google Scholar] [CrossRef]

- Tahriri, F.; Dawal, S.Z.M.; Taha, Z. Fuzzy mixed assembly line sequencing and scheduling optimization model using multiobjective dynamic fuzzy GA. Sci. World J. 2014, 2014, 505207. [Google Scholar] [CrossRef]

- Noori, H. Implementing advanced manufacturing technology: The perspective of a newly industrialized country (Malaysia). J. High Technol. Manag. Res. 1997, 8, 1–20. [Google Scholar] [CrossRef]

- Lei, D.; Hitt, M.A.; Goldhar, J.D. Advanced manufacturing technology: Organizational design and strategic flexibility. Organ. Stud. 1996, 17, 501–523. [Google Scholar] [CrossRef]

- Lefebvre, L.A.; Lefebvre, E.; Harvey, J. Intangible assets as determinants of advanced manufacturing technology adoption in SME’s: Toward an evolutionary model. IEEE Trans. Eng. Manag. 1996, 43, 307–322. [Google Scholar] [CrossRef]

- Ramasesh, R.; Jayakumar, M. Economic justification of advanced manufacturing technology. Omega 1993, 21, 289–306. [Google Scholar] [CrossRef]

- Dimnik, T.; Johnston, D. Manufacturing managers and the adoption of advanced manufacturing technology. Omega 1993, 21, 155–162. [Google Scholar] [CrossRef]

- Sohal, A.; Samson, D.; Weill, P. Manufacturing and technology strategy: A survey of planning for AMT. Comput. Integr. Manuf. Syst. 1991, 4, 71–79. [Google Scholar] [CrossRef]

- Dean, J.W., Jr.; Susman, G.I.; Porter, P.S. Technical, economic and political factors in advanced manufacturing technology implementation. J. Eng. Technol. Manag. 1990, 7, 129–144. [Google Scholar] [CrossRef]

- Tyre, M.J.; Hauptman, O. Effectiveness of organizational responses to technological change in the production process. Organ. Sci. 1992, 3, 301–320. [Google Scholar] [CrossRef]

- Zhao, H.; Co, H.C. Adoption and implementation of advanced manufacturing technology in Singapore. Int. J. Prod. Econ. 1997, 48, 7–19. [Google Scholar] [CrossRef]

- Lowe, J.; Sim, A. The diffusion of a manufacturing innovation: The case of JIT and MRPII. Int. J. Technol. Manag. 1993, 8, 244–258. [Google Scholar] [CrossRef]

- Lewis, M.W. Advanced manufacturing technology: A multiparadigm deconstruction and reconstruction of the literature. In Academy of Management Proceedings; Academy of Management: Briarcliff Manor, NY, USA; pp. C1–C9.

- McDermott, C.M.; Stock, G.N. Organizational culture and advanced manufacturing technology implementation. J. Oper. Manag. 1999, 17, 521–533. [Google Scholar] [CrossRef]

- Parthasarthy, R.; Sethi, S.P. The impact of flexible automation on business strategy and organizational structure. Acad. Manag. Rev. 1992, 17, 86–111. [Google Scholar] [CrossRef]

- Zammuto, R.F.; O’Connor, E.J. Gaining advanced manufacturing technologies’ benefits: The roles of organization design and culture. Acad. Manag. Rev. 1992, 17, 701–728. [Google Scholar] [CrossRef]

- Small, M.H.; Yasin, M.M. Developing a framework for the effective planning and implementation of advanced manufacturing technology. Int. J. Oper. Prod. Manag. 1997, 17, 468–489. [Google Scholar] [CrossRef]

- Udo, G.J.; Ehie, I.C. Critical success factors for advanced manufacturing systems. Comput. Ind. Eng. 1996, 31, 91–94. [Google Scholar] [CrossRef]

- Chan, F.; Chan, M.; Lau, H.; Ip, R. Investment appraisal techniques for advanced manufacturing technology (AMT): A literature review. Integr. Manuf. Syst. 2001, 12, 35–47. [Google Scholar] [CrossRef]

- Das, A.; Narasimhan, R. Process-technology fit and its implications for manufacturing performance. J. Oper. Manag. 2001, 19, 521–540. [Google Scholar] [CrossRef]

- Small, M.H. Planning, justifying and installing advanced manufacturing technology: A managerial framework. J. Manuf. Technol. Manag. 2007, 18, 513–537. [Google Scholar] [CrossRef]

- Saberi, S.; Rosnah, M.Y. Advanced Manufacturing Technology Implementation Performance: Towards A Strategic Framework. In Proceedings of the 2011 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 22–24 January 2011. [Google Scholar]

- Alvarado, A. Problems in the implementation process of advanced manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 64, 123–131. [Google Scholar]

- Baldwin, J.; Lin, Z. Impediments to advanced technology adoption for Canadian manufacturers. Res. Policy 2002, 31, 1–18. [Google Scholar] [CrossRef]

- Canada, J.; Sullivan, W. Persistent pitfalls and applicable approaches for justification of advanced manufacturing systems. Eng. Cost Prod. Econ. 1990, 18, 241–253. [Google Scholar] [CrossRef]

- Hynek, J.; Janecek, V. Advanced Manufacturing Technology Projects Justification. In Proceedings of the 2007 IEEE International Conference on Mechatronics, Kumamoto, Japan, 8–10 May 2007; pp. 1–6. [Google Scholar]

- Sukathong, S.; Suksawang, P.; Naenna, T. Analyzing the importance of critical success factors for the adoption of advanced manufacturing technologies. Int. J. Eng. Bus. Manag. 2021, 13, 18479790211055057. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, H.; Chandel, R. Exploring the key success factors of advanced manufacturing technology implementation in Indian manufacturing industry. J. Manuf. Technol. Manag. 2017, 29, 25–40. [Google Scholar] [CrossRef]

- Bhise, D.V.; Sunnapwar, V.K. Developing framework for the implementation of advanced manufacturing technologies in small and medium-sized enterprises. Int. J. Appl. Manag. Technol. 2019, 18, 10. [Google Scholar] [CrossRef]

- Abdel-Kader, M.G.; Dugdale, D. Evaluating investments in advanced manufacturing technology: A fuzzy set theory approach. Br. Account. Rev. 2001, 33, 455–489. [Google Scholar] [CrossRef]

- Monge, C.A.M.; Rao, S.S.; Gonzalez, M.E.; Sohal, A.S. Performance measurement of AMT: A cross-regional study. Benchmarking Int. J. 2006, 13, 135–146. [Google Scholar] [CrossRef]

- Datta, V.; Sambasivarao, K.; Kodali, R.; Deshmukh, S. Multi-attribute decision model using the analytic hierarchy process for the justification of manufacturing systems. Int. J. Prod. Econ. 1992, 28, 227–234. [Google Scholar] [CrossRef]

- Demmel, J.G.; Askin, R.G. A multiple-objective decision model for the evaluation of advanced manufacturing system technologies. J. Manuf. Syst. 1992, 11, 179–194. [Google Scholar] [CrossRef][Green Version]

- Huang, P.Y.; Sakurai, M. Factor automation: The Japanese experience. IEEE Trans. Eng. Manag. 1990, 37, 102–108. [Google Scholar] [CrossRef]

- Sohal, A.S.; Schroder, R.; Uliana, E.O.; Maguire, W. Adoption of AMT by South African manufacturers. Integr. Manuf. Syst. 2001, 12, 15–34. [Google Scholar] [CrossRef]

- Díaz, M.S.; Gil, M.J.Á.; Machuca, J.A.D. Performance measurement systems, competitive priorities, and advanced manufacturing technology: Some evidence from the aeronautical sector. Int. J. Oper. Prod. Manag. 2005, 25, 781–799. [Google Scholar] [CrossRef][Green Version]

- Mital, A.; Pennathur, A. Advanced technologies and humans in manufacturing workplaces: An interdependent relationship. Int. J. Ind. Ergon. 2004, 33, 295–313. [Google Scholar] [CrossRef]

- Saleh, B.; Hacker, M.; Randhawa, S. Factors in capital decisions involving advanced manufacturing technologies. Int. J. Oper. Prod. Manag. 2001, 21, 1265–1288. [Google Scholar] [CrossRef]

- Sohal, A.S.; Burcher, P.G.; Millen, R.; Lee, G. Comparing American and British practices in AMT adoption. Benchmarking Int. J. 1999, 6, 310–324. [Google Scholar] [CrossRef]

- DeRuntz, B.D.; Turner, R.M. Organizational Considerations for Advanced Manufacturing Technology. J. Technol. Stud. 2003, 29, 4–9. [Google Scholar] [CrossRef]

- Mohanty, R. Analysis of justification problems in CIMS review and projection. Prod. Plan. Control. 1993, 4, 260–272. [Google Scholar] [CrossRef]

- Mohanty, R.; Deshmukh, S. Evaluating manufacturing strategy for a learning organization: A case. Int. J. Oper. Prod. Manag. 1999, 19, 308–328. [Google Scholar] [CrossRef]

- Bolden, R.; Waterson, P.; Warr, P.; Clegg, C.; Wall, T. A new taxonomy of modern manufacturing practices. Int. J. Oper. Prod. Manag. 1997, 17, 1112–1130. [Google Scholar] [CrossRef]

- Rosnah, M.; Ahmad, M.M.; Osman, M. Barriers to advanced manufacturing technologies implementation in the small and medium scales industries of a developing country. Int. J. Eng. Technol. 2004, 1, 39–46. [Google Scholar]

- Rao, K.S.; Deshmukh, S. Strategic framework for implementing flexible manufacturing systems in India. Int. J. Oper. Prod. Manag. 1994, 14, 50–63. [Google Scholar]

- Teng, K.L.L.; Seetharaman, A. The selection and management of cost justification techniques among advanced manufacturing technology companies in Malaysia. Int. J. Manag. 2004, 21, 45. [Google Scholar]

- Kotha, S.; Swamidass, P. Strategy, advanced manufacturing technology and performance: Empirical evidence from U.S. manufacturing firms. J. Oper. Manag. 2000, 18, 257–277. [Google Scholar] [CrossRef]

- Low-Lock, K.; Seetharaman, A. Towards a better manufacturing sector: A perspective on the implementation of advanced manufacturing technology in Malaysia. Int. J. Manag. 2003, 20, 234–239. [Google Scholar]

- Shehabuddeen, N.; Probert, D.; Phaal, R. From theory to practice: Challenges in operationalising a technology selection framework. Technovation 2006, 26, 324–335. [Google Scholar] [CrossRef]

- Shepherd, D.; McDemott, C.; Stock, G. Advanced manufacturing technology: Does more radicalness mean more perceived benefits? J. High Technol. Manag. Resour. 2000, 11, 19–33. [Google Scholar] [CrossRef]

- Ordoobadi, S.M. Application of AHP and Taguchi loss functions in evaluation of advanced manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 2593–2605. [Google Scholar] [CrossRef]

- Thomas, A.; Barton, R. Characterizing SME migration towards advanced manufacturing technologies. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 745–756. [Google Scholar] [CrossRef]

- Kwon, C.-W.; Chun, B.G. The effect of strategic technology adoptions by local firms on technology spillover. Econ. Model. 2015, 51, 13–20. [Google Scholar] [CrossRef]

- Schiopu, I. Technology adoption, human capital formation and income differences. J. Macroecon. 2015, 45, 318–335. [Google Scholar] [CrossRef]

- Muita, K.; Westerlund, M.; Rajala, R. The evolution of rapid production: How to adopt novel manufacturing technology. IFAC-Pap. 2015, 48, 32–37. [Google Scholar] [CrossRef]

- Lewis, M.W.; Boyer, K.K. Factors impacting AMT implementation: An integrative and controlled study. J. Eng. Technol. Manag. 2002, 19, 111–130. [Google Scholar] [CrossRef]

- Bhatt, N. Forecasting the Implementation Success of AMT in SMEs using an Integrated AHP-TOPSIS Approach. Glob. J. Enterp. Inf. Syst. 2016, 8, 18–28. [Google Scholar] [CrossRef]

- Singh, R.; Singh, C.D.; Deepak, D. Analyzing performance indicators of advanced manufacturing technology implementation using MCDM. Mater. Today Proc. 2021, 47, 3750–3753. [Google Scholar] [CrossRef]

- Tahriri, F.; Mousavi, M.; Hozhabri Haghighi, S.; Zawiah Md Dawal, S. The application of fuzzy Delphi and fuzzy inference system in supplier ranking and selection. J. Ind. Eng. Int. 2014, 10, 66. [Google Scholar] [CrossRef]

- Ishikawa, A.; Amagasa, M.; Shiga, T.; Tomizawa, G.; Tatsuta, R.; Mieno, H. The max-min Delphi method and fuzzy Delphi method via fuzzy integration. Fuzzy Sets Syst. 1993, 55, 241–253. [Google Scholar] [CrossRef]

- Wang, M.-L.; Lin, Y.-H. To construct a monitoring mechanism of production loss by using Fuzzy Delphi method and fuzzy regression technique–A case study of IC package testing company. Expert Syst. Appl. 2008, 35, 1156–1165. [Google Scholar] [CrossRef]

- Hsu, Y.-L.; Lee, C.-H.; Kreng, V.B. The application of Fuzzy Delphi Method and Fuzzy AHP in lubricant regenerative technology selection. Expert Syst. Appl. 2010, 37, 419–425. [Google Scholar] [CrossRef]

- Ho, Y.-F.; Wang, H.-L. Applying Fuzzy Delphi Method to Select the Variables of a Sustainable Urban System Dynamics Model. In Proceedings of the 26th International Conference of System Dynamics Societ, Athens, Greece, 20–24 July 2008. [Google Scholar]

- Noorderhaven, N. Strategic Decision Making; Duxbury Press: London, England, 1995. [Google Scholar]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning—I. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Kaufman, A.; Gupta, M.M. Introduction to Fuzzy Arithmetic; Van Nostrand Reinhold Company: New York, NY, USA, 1991. [Google Scholar]

| Linguistic Variables | Fuzzy Numbers |

|---|---|

| Very low (or VL) | (0.00, 0.00, 0.30) |

| Low (or L) | (0.00, 0.30, 0.50) |

| Medium (or M) | (0.20, 0.50, 0.80) |

| High (or H) | (0.50, 0.70, 1.00) |

| Very High (or VH) | (0.70, 1.00, 1.00) |

| Input 2 | Input 1 | ||

|---|---|---|---|

| L | A | H | |

| L | L | L | A |

| A | L | A | A |

| H | A | A | H |

| Rule No. | Fuzzy Input Variables | Fuzzy Output Variables | Rule No. | Fuzzy Input Variables | Fuzzy Output Variables | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Output | 1 | 2 | 3 | Output | ||

| 1 | L | L | L | L | 15 | A | A | H | A |

| 2 | L | L | A | L | 16 | A | H | L | A |

| 3 | L | L | H | L | 17 | A | H | A | A |

| 4 | L | A | L | L | 18 | A | H | H | H |

| 5 | L | A | A | A | 19 | H | L | L | A |

| 6 | L | A | H | A | 20 | H | L | A | A |

| 7 | L | H | L | A | 21 | H | L | H | H |

| 8 | L | H | A | A | 22 | H | A | L | A |

| 9 | L | H | H | H | 23 | H | A | A | A |

| 10 | A | L | L | L | 24 | H | A | H | H |

| 11 | A | L | A | A | 25 | H | H | L | H |

| 12 | A | L | H | A | 26 | H | H | A | H |

| 13 | A | A | L | A | 27 | H | H | H | H |

| 14 | A | A | A | A | |||||

| Rule No. | Fuzzy Input Variables | Fuzzy Output Variables | Rule No. | Fuzzy Input Variables | Fuzzy Output Variables | Rule No. | Fuzzy Input Variables | Fuzzy Output Variables | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | ||||||

| 1 | L | L | L | L | L | 28 | A | L | L | L | L | 55 | H | L | L | L | L |

| 2 | L | A | L | L | L | 29 | A | A | L | L | A | 56 | H | A | L | L | A |

| 3 | L | H | L | L | L | 30 | A | H | L | L | A | 57 | H | H | L | L | A |

| 4 | L | L | A | L | L | 31 | A | L | A | L | A | 58 | H | L | A | L | A |

| 5 | L | A | A | L | A | 32 | A | A | A | L | A | 59 | H | A | A | L | A |

| 6 | L | A | H | L | A | 33 | A | A | H | L | A | 60 | H | A | H | L | H |

| 7 | L | H | A | L | A | 34 | A | H | A | L | A | 61 | H | H | A | L | H |

| 8 | L | H | H | L | A | 35 | A | H | H | L | A | 62 | H | H | H | L | H |

| 9 | L | L | A | A | A | 36 | A | L | A | A | A | 63 | H | L | A | A | A |

| 10 | L | L | A | H | A | 37 | A | L | A | H | A | 64 | H | L | A | H | H |

| 11 | L | A | A | A | A | 38 | A | A | A | A | A | 65 | H | A | A | A | A |

| 12 | L | A | H | A | A | 39 | A | A | H | A | A | 66 | H | A | H | A | H |

| 13 | L | A | H | H | A | 40 | A | A | H | H | H | 67 | H | A | H | H | H |

| 14 | L | H | A | A | A | 41 | A | H | A | A | A | 68 | H | H | A | A | H |

| 15 | L | H | H | H | H | 42 | A | H | H | H | H | 69 | H | H | H | H | H |

| 16 | L | H | A | H | A | 43 | A | H | A | H | A | 70 | H | H | A | H | H |

| 17 | L | H | H | A | A | 44 | A | H | H | A | H | 71 | H | H | H | A | H |

| 18 | L | L | H | L | L | 45 | A | L | H | L | A | 72 | H | L | H | L | A |

| 19 | L | L | H | A | A | 46 | A | L | H | A | A | 73 | H | L | H | A | H |

| 20 | L | L | H | H | A | 47 | A | L | H | H | A | 74 | H | L | H | H | H |

| 21 | L | A | A | H | A | 48 | A | A | A | H | A | 75 | H | A | A | H | H |

| 22 | L | L | L | A | L | 49 | A | L | L | A | A | 76 | H | L | L | A | A |

| 23 | L | A | L | A | A | 50 | A | A | L | A | A | 77 | H | A | L | A | A |

| 24 | L | H | L | A | A | 51 | A | H | L | A | A | 78 | H | H | L | A | H |

| 25 | L | L | L | H | L | 52 | A | L | L | H | A | 79 | H | L | L | H | A |

| 26 | L | A | L | H | A | 53 | A | A | L | H | A | 80 | H | A | L | H | H |

| 27 | L | H | L | H | A | 54 | A | H | L | H | H | 81 | H | H | L | H | H |

| No. | Fuzzy Output Variable | Fuzzy Input Variable | |

|---|---|---|---|

| 1 | Strategy (A1) | 1.1 | Operation Strategy (C11) |

| 1.2 | Strategic Management and Planning (C12) | ||

| 1.3 | Strategic Analysis and Motivation (C13) | ||

| 2 | Financial (A2) | 2.1 | Financial Evaluation (C21) |

| 2.2 | Economic Justification (C22) | ||

| 3 | Organization/Business (A3) | 3.1 | Human Resource Management (C31) |

| 3.2 | Organizational Infrastructure and Culture (C32) | ||

| 3.3 | Alignment of AMT with Organization and Business (C33) | ||

| 4 | Support (A4) | 4.1 | Top Management Support (C41) |

| 4.2 | Operating Sponsor (C42) | ||

| 4.3 | Support Systems before Equipment Installation (C43) | ||

| 4.4 | Governance and commitment (C44) | ||

| 5 | Technical (A5) | 5.1 | Think-Tank Linkage (C51) |

| 5.2 | Knowledge and Perfecting Skills (C52) | ||

| 5.3 | Technical Infrastructure and its Influence on Successful Adoption (C53) | ||

| 5.4 | Technology Identification (C54) | ||

| 6 | Management (A6) | 6.1 | Production Management and System (C61) |

| 6.2 | Managers Experimenting with New Technologies (C62) | ||

| 6.3 | Managers’ Personal Beliefs and Understanding of AMT (C63) | ||

| 6.4 | Expectations of AMT (C64) | ||

| 7 | Vendor/Supplier (A7) | 7.1 | Commitment and Relationships with Vendors (C71) |

| 7.2 | Supplier-Related Factors (C72) | ||

| 7.3 | Selection of the Appropriate Technological Supplier(s) (C73) | ||

| 8 | Process/Planning (A8) | 8.1 | Planning Process and Requirements (C81) |

| 8.2 | Product-Process Dependency (C82) | ||

| 9 | Project Champion (A9) | 9.1 | Integration of AMT with Existing Systems (C91) |

| 9.2 | Project Champions and Market Risk (C92) | ||

| 9.3 | Manufacturing Performance (C93) | ||

| 9.4 | Pilot Project (C94) | ||

| 10 | Employee (A10) | 10.1 | Training (C101) |

| 10.2 | Communication and Coordination (C102) | ||

| 10.3 | Lack of Knowledge and Skills (C103) |

| Aspect | D1 | D2 | D3 |

|---|---|---|---|

| A1 | VH | L | H |

| A2 | M | VL | H |

| A3 | VH | M | M |

| A4 | H | VL | L |

| A5 | H | H | VL |

| A6 | M | VH | VL |

| A7 | L | H | M |

| A8 | VL | H | VH |

| A9 | M | M | H |

| A10 | VL | L | VH |

| Aspect | D1 | D2 | D3 | Fuzzy Mean = ∑ D | Value |

|---|---|---|---|---|---|

| A1 | (0.7, 1.0, 1.0) | (0.0, 0.3, 0.5) | (0.5, 0.7, 1.0) | W1 = (0.40, 0.66, 0.83) | 0.630 |

| A2 | (0.2, 0.5, 0.8) | (0.0, 0.0, 0.3) | (0.5, 0.7, 1.0) | W2 = (0.23, 0.40, 0.70) | 0.443 |

| A3 | (0.7, 1.0, 1.0) | (0.2, 0.5, 0.8) | (0.2, 0.5, 0.8) | W3 = (0.36, 0.66, 0.86) | 0.626 |

| A4 | (0.5, 0.7, 1.0) | (0.0, 0.0, 0.3) | (0.0, 0.3, 0.5) | W4 = (0.16, 0.33, 0.60) | 0.363 |

| A5 | (0.5, 0.7, 1.0) | (0.5, 0.7, 1.0) | (0.0, 0.0, 0.3) | W5 = (0.33, 0.46, 0.76) | 0.516 |

| A6 | (0.2, 0.5, 0.8) | (0.7, 1.0, 1.0) | (0.0, 0.0, 0.3) | W6 = (0.30, 0.50, 0.76) | 0.500 |

| A7 | (0.0, 0.3, 0.5) | (0.5, 0.7, 1.0) | (0.2, 0.5, 0.8) | W7 = (0.23, 0.50, 0.76) | 0.496 |

| A8 | (0.0, 0.0, 0.3) | (0.5, 0.7, 1.0) | (0.7, 1.0, 1.0) | W8 = (0.40, 0.56, 0.76) | 0.573 |

| A9 | (0.2, 0.5, 0.8) | (0.2, 0.5, 0.8) | (0.5, 0.7, 1.0) | W9 = (0.30, 0.56, 0.86) | 0.573 |

| A10 | (0.0, 0.0, 0.3) | (0.0, 0.3, 0.5) | (0.7, 1.0, 1.0) | W10 = (0.23, 0.43, 0.60) | 0.420 |

| Rank | Aspect | Value |

|---|---|---|

| 1 | A1 | H(A1) = 0.630 |

| 2 | A3 | H(A3) = 0.626 |

| 3 | A8 | H(A8) = 0.573 |

| 4 | A9 | H(A9) = 0.573 |

| 5 | A5 | H(A5) = 0.516 |

| 6 | A6 | H(A6) = 0.500 |

| 7 | A7 | H(A7) = 0.496 |

| 8 | A2 | H(A2) = 0.443 |

| 9 | A10 | H(A10) = 0.420 |

| 10 | A4 | H(A4) = 0.363 |

| Aspect | Aspect Name | No. of Inputs | Rule Name | No. of Rules | No. of Outputs | Conjunction Operator | Aggregation Operator | Inference Model |

|---|---|---|---|---|---|---|---|---|

| 1 | Strategy | 3 | β | 27 | 1 | Min | Max | Mamdani |

| 2 | Finance | 2 | α | 9 | 1 | Min | Max | Mamdani |

| 3 | Organization/Business | 3 | β | 27 | 1 | Min | Max | Mamdani |

| 4 | Support | 4 | γ | 81 | 1 | Min | Max | Mamdani |

| 5 | Technical | 4 | γ | 81 | 1 | Min | Max | Mamdani |

| 6 | Management | 4 | γ | 81 | 1 | Min | Max | Mamdani |

| 7 | Vendor/Supplier | 3 | β | 27 | 1 | Min | Max | Mamdani |

| 8 | Process/Planning | 2 | α | 9 | 1 | Min | Max | Mamdani |

| 9 | Project Champion | 4 | γ | 81 | 1 | Min | Max | Mamdani |

| 10 | Employee | 3 | β | 27 | 1 | Min | Max | Mamdani |

| Fuzzy Input | Fuzzy Output | Weight of Aspect | Overall Value | |||

|---|---|---|---|---|---|---|

| Name | Value | Name | Value | Name | Value | |

| C11 | 68 | A1 | 57.6 | WA1 | 0.630 | 36.28 |

| C12 | 32 | |||||

| C13 | 66 | |||||

| C21 | 68 | A2 | 69.2 | WA2 | 0.443 | 30.65 |

| C22 | 70 | |||||

| C31 | 82 | A3 | 35 | WA3 | 0.626 | 52.58 |

| C32 | 98 | |||||

| C33 | 12 | |||||

| C41 | 23 | A4 | 65 | WA4 | 0.363 | 18.15 |

| C42 | 36 | |||||

| C43 | 45 | |||||

| C44 | 78 | |||||

| C51 | 45 | A5 | 24 | WA5 | 0.516 | 35.08 |

| C52 | 62 | |||||

| C53 | 67 | |||||

| C54 | 68 | |||||

| C61 | 46 | A6 | 16 | WA6 | 0.500 | 38.15 |

| C62 | 52 | |||||

| C63 | 69 | |||||

| C64 | 78 | |||||

| C71 | 32 | A7 | 79 | WA7 | 0.496 | 28.56 |

| C72 | 66 | |||||

| C73 | 70 | |||||

| C81 | 26 | A8 | 41 | WA8 | 0.573 | 21.43 |

| C82 | 68 | |||||

| C91 | 78 | A9 | 68 | WA9 | 0.573 | 48.13 |

| C92 | 98 | |||||

| C93 | 54 | |||||

| C94 | 49 | |||||

| C101 | 68 | A10 | 93 | WA10 | 0.420 | 21 |

| C102 | 45 | |||||

| C103 | 20 | |||||

| Final Prediction Result of Robot Technology Implementation = 64.21% | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahriri, F.; Mousavi, M.; Galavi, H.; Sorooshian, S. A Decision-Making Model for Predicting Technology Adoption Success. Processes 2022, 10, 2261. https://doi.org/10.3390/pr10112261

Tahriri F, Mousavi M, Galavi H, Sorooshian S. A Decision-Making Model for Predicting Technology Adoption Success. Processes. 2022; 10(11):2261. https://doi.org/10.3390/pr10112261

Chicago/Turabian StyleTahriri, Farzad, Maryam Mousavi, Hadi Galavi, and Shahryar Sorooshian. 2022. "A Decision-Making Model for Predicting Technology Adoption Success" Processes 10, no. 11: 2261. https://doi.org/10.3390/pr10112261

APA StyleTahriri, F., Mousavi, M., Galavi, H., & Sorooshian, S. (2022). A Decision-Making Model for Predicting Technology Adoption Success. Processes, 10(11), 2261. https://doi.org/10.3390/pr10112261