Determining the Optimal Inventory and Number of Shipments for a Two-Resource Supply Chain with Correlated Demands and Remanufacturing Products Allowing Backorder

Abstract

1. Introduction

2. System Conditions and Symbols

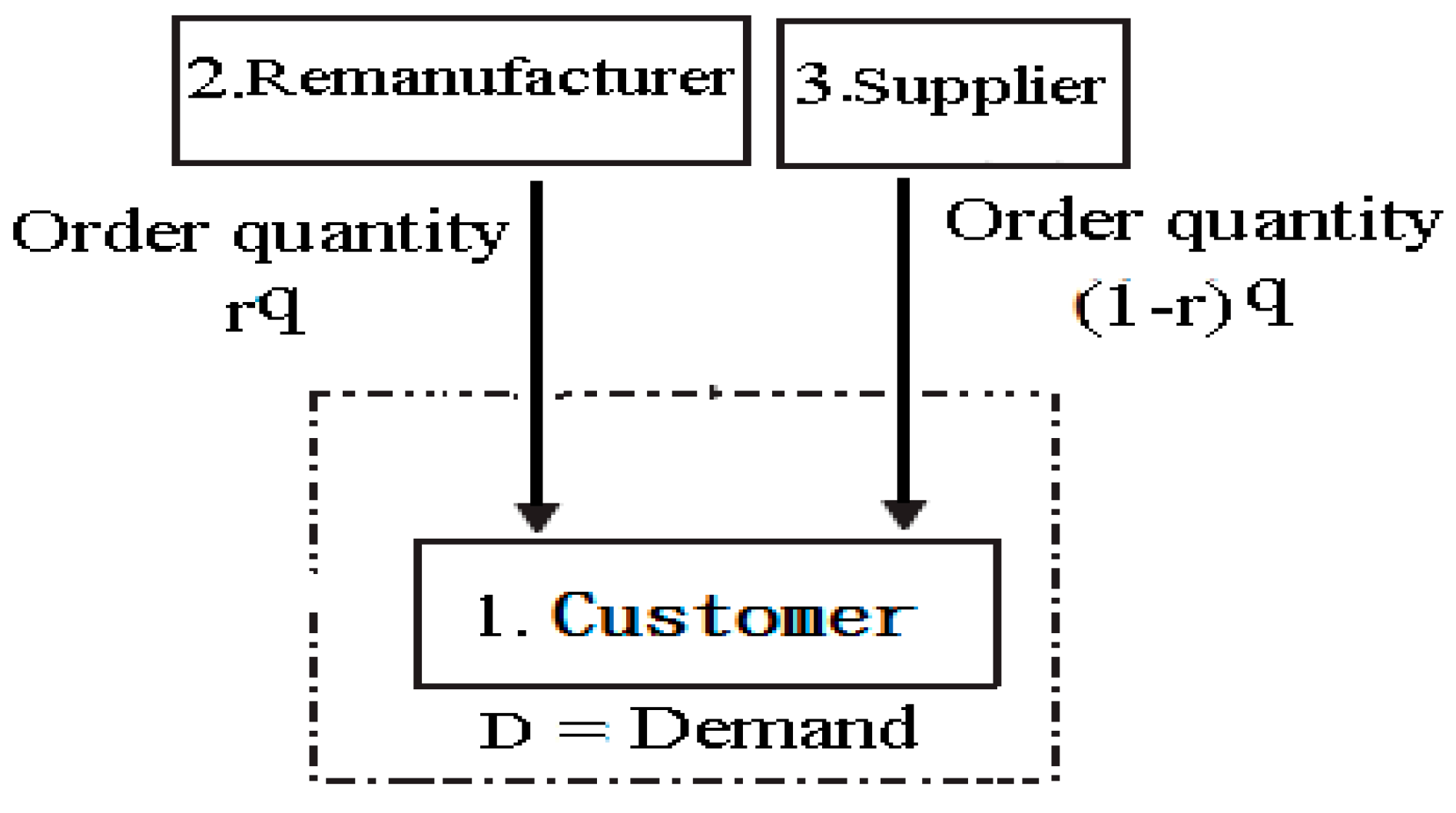

- The three-echelon inventory system consists of a single supplier, a single remanufacturer and a single customer (downstream manufacturer).

- A single product is considered.

- The remanufacturing rate and demand rate are known.

- The screening rate is higher than the remanufacturing rate and demand rate.

- The lead-time and defect rate are fixed.

- There is an unlimited planning period.

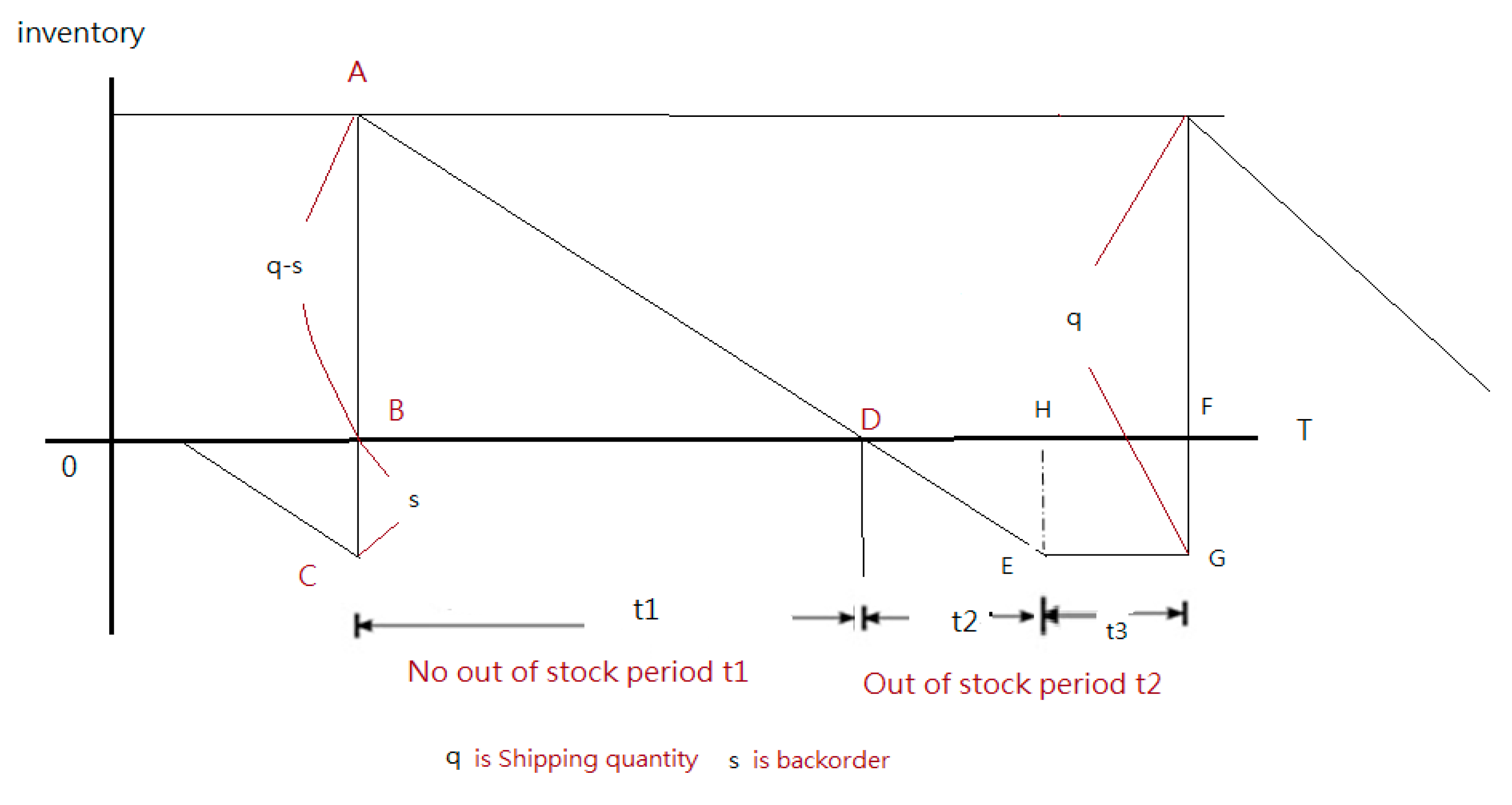

- Allow supply backorder and out-of-stock inventory.

- Not consider quantity discounts.

- Not consider inventory space constraints.

3. Model Formulation

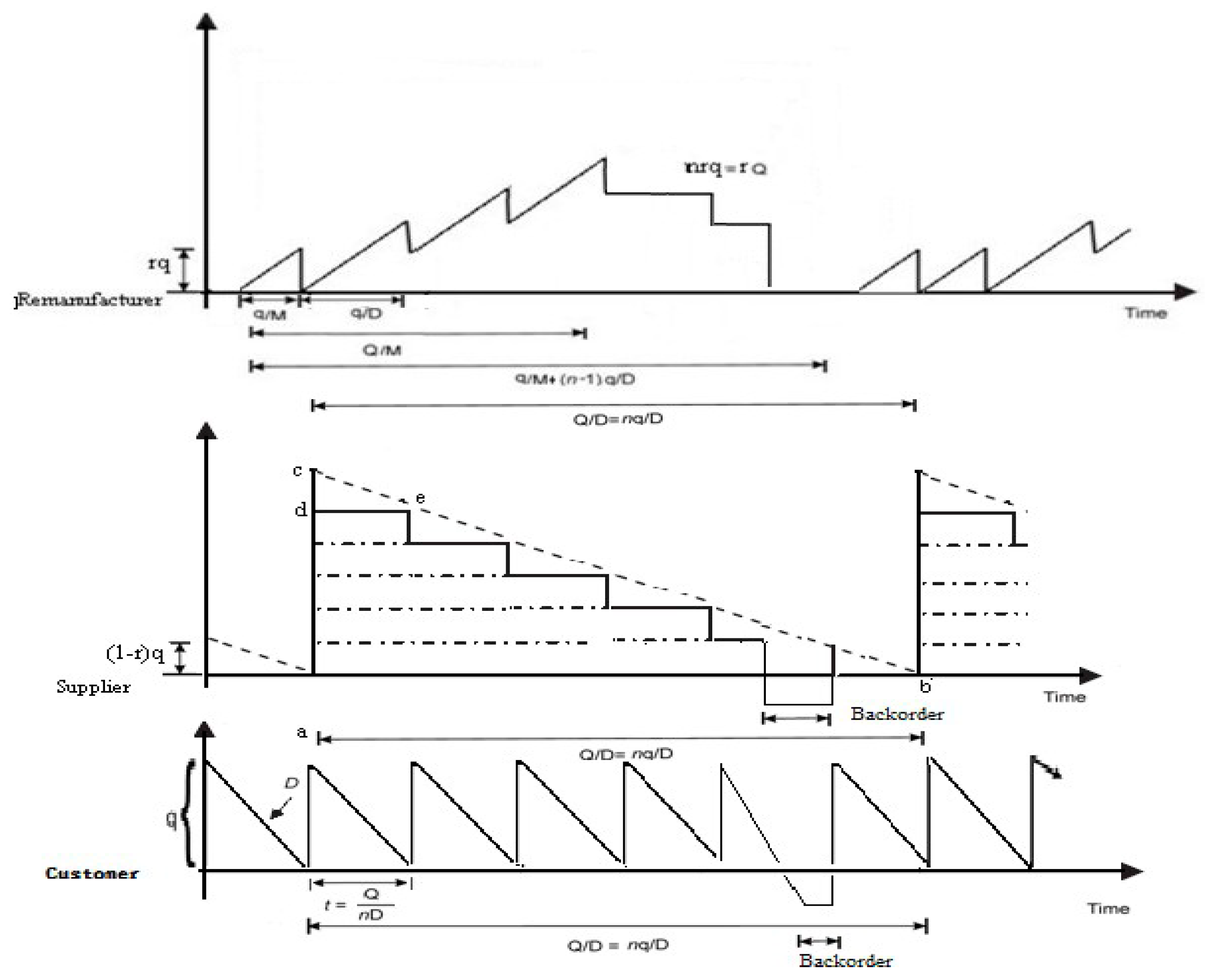

3.1. Establishing Model 1: The Supplier and Remanufacturer Splits a Shipment into Several Small Lot Sizes for Customer (Downstream Manufacturer) without Dective Items for a Backorder Model

| = + + [] | the formula means TC(M) |

| + + + | the formula means TC(S) |

| + + | the formula means TC(B) |

| + | the formula means TC(Cs) |

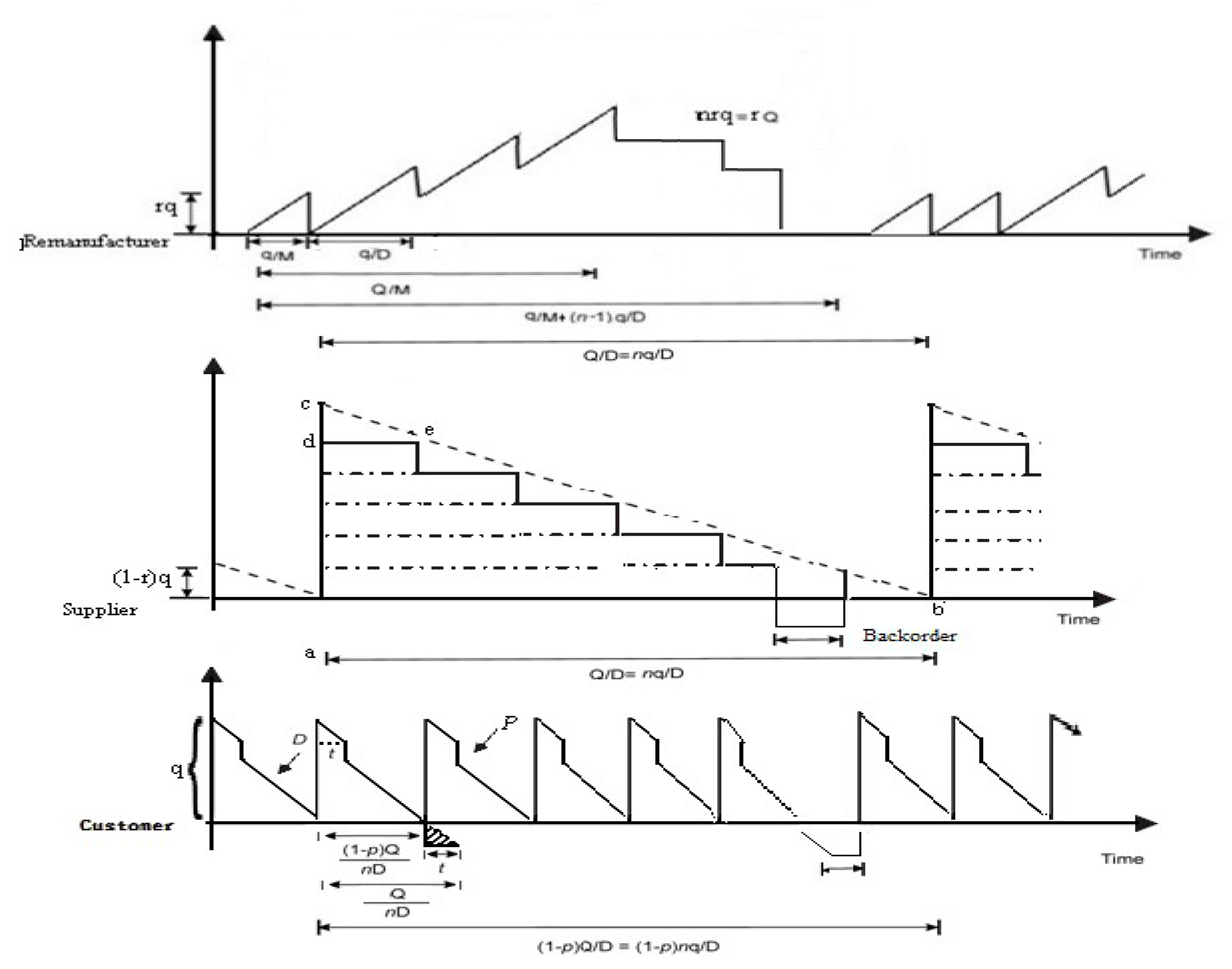

3.2. Model 2: The Supplier and Remanufacturer Splits a Shipment into Several Small Lot Sizes for Demand (Downstream Manufacturer) with Defective Items

4. Numerical Analysis

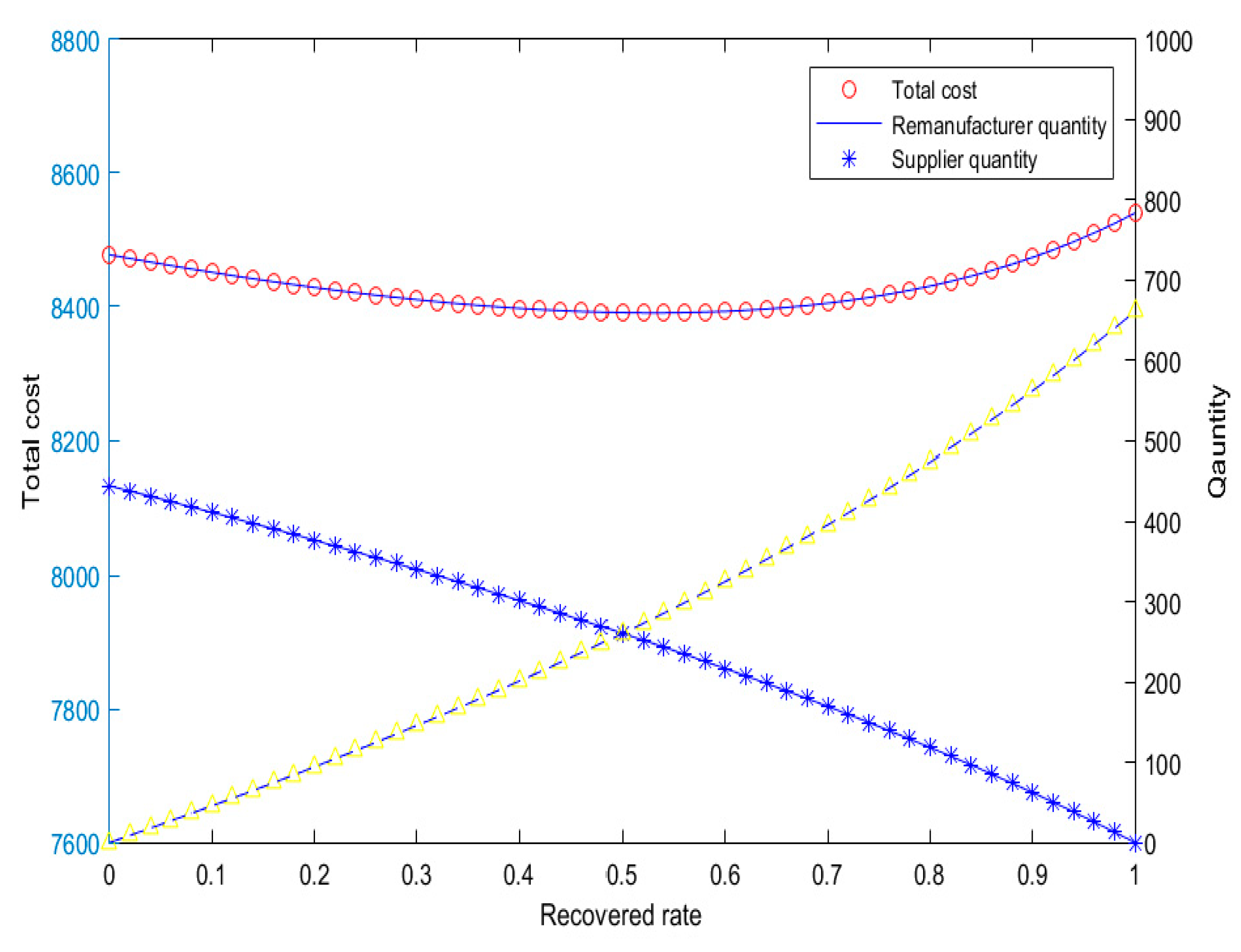

- Under the condition of a shipment split into several small lot sizes, it shows that when Fm is constant, r (rq is order remanufacturing quantity of upstream level), n** and Q** increases, ETC** decreases then increase at reversal point. Regardless of whether there is a defective item, in the case of multiple shipments, under the same backorder ratio (β) and number of shipments(n**), different recovery rates(r) have different cost-saving rates (CS). The higher the recovery rate (r), the higher the cost-saving rate (CS). Since the replacement cost of the recovered product is lower, so that it can be provided to the customer at a cheaper price, the customer’s acquisition cost is lower, which represents a higher cost savings. Thus, managers should pay attention to the economic value of transportation and recycling strategies to increase the company’s overall operating profit.

- In contrast, in the single-shipment (n = 1) transportation supply chain, when r increases, Q ** decreases, ETC ** increases, and CS increases. The total cost is higher than the multi-batch method. Therefore, the best strategy is to integrate upstream and downstream supply chain, in order to reduce the overall cost compared to stand-alone strategies

- When r is constant, Fm and Q** increase, β and n** decreases (because n** = [n*] is an integer and leads to some Q** increases). ETC** and ETC** n=1 increase, but CS decreases. The results same as the traditional EOQ model and the transportation model.

- In Table 3, if the shortage is not allowed, the total expected cost is obtained by shipping 6 times with n** = 6, r = 0.6. The ETC = 5754 is the lowest. If the shortage is considered, ß = 0.05, n** = 6, r = 0.7, the cost is 6270 as the lowest, so in this article, the replacement rate r and the shortage rate ß will affect the total expected cost. In the follow-up research, we can discuss the interference between the two variable recovery rate (r) and backorder rate (β).

- When the screening rate (x), demand rate (D) and defect rate (p) increase, then Q ** and ETC ** also increase. The screening rate (x) increases, that is, the more defective products are selected, the more customers will increase the number of orders and reduce the cost of holding, thus Q ** and ETC ** increase. This result corresponds to the works of Maddah and Jaber (2008)[33], Maddah et al. (2010) [34] and Lin, T-Y. (2013) [15].

- As Demand rate (D) increases, Q ** and ETC ** increase. Because customers will generate a large number of orders in order to meet the demand. When the defect rate(p) increases, Q ** and ETC ** increases. Since the higher the defect rate, the higher the number of orders and the higher the number of deliveries, the total annual cost will increase as well.

- When backorder rate (β) is higher, Q ** and ETC ** increase. Because the higher the out-of-stock rate and the higher the number of deliveries, the total cost will increase

5. Summary and Conclusions

- In the two-stage remanufacturer and supplier supportable stocks, it shows the best ordering recovered rate r* (r* q) for the customer. Therefore, the small batch delivery method can save costs more than a single shipment, so it is better to adopt the upstream and downstream integration strategy of the supply chain than the single strategy.

- The replacement rate and the backorder rate will increase expected total cost. After considering the backorder rate, under a specific number of shipments, replacement rate, and screening rate, the expected total cost will increase as the backorder rate increases. In the sensitivity analysis, it is also found that the increase of the screening rate, demand rate, defect rate and backorder rate will increase the total cost. Therefore, the ordering strategy adopted by the management personnel needs to decentralize the source of supply. Procurement should avoid concentrating on a few resettlement or supplier sources to ensure the company’s best inventory policy.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chan, H.K.; Yin, S.; Chan, F.T.S. Implementing just-in-time philosophy to reverse logistics systems: A review. Int. J. Prod. Res. 2010, 48, 6293–6313. [Google Scholar] [CrossRef]

- Alamri, A.A. Theory and methodology on the global optimal solution to a general reverse logistics inventory model for deteriorating items and time-varying rates. Comput. Ind. Eng. 2011, 60, 236–247. [Google Scholar] [CrossRef]

- Ahmadi Rad, M.; Tarokh, M.; Khoshalhan, F. Single-Setup-Multiple-Deliveries for a Single Supplier-Single Buyer with Single Product and Backorder. J. Ind. Eng. Prod. Res. 2011, 22, 1–10. [Google Scholar]

- Lin, C.-C.; Su, C.-T. Inventory model for the batch processing of defective products in manufacturing and remanufacturing. Adv. Mater. Res. 2013, 756–759, 4604–4611. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z. Optimal integrated production inventory system for imperfect quality items considering unequal shipment policy. Int. J. Ind. Syst. Eng. 2015, 19, 206–238. [Google Scholar] [CrossRef]

- Wakhid, A.J.; Rahmad, S.; Pringggo, W.L. Coordinating a two-level supply chain with defective items, inspection errors and price-sensitive demand. Songklanakarin J. Sci. Technol. 2018, 40, 135–145. [Google Scholar]

- Chiu, Y.S.P. Combining a cost-benefit algorithm for ECTEP into the product structure diagram. Int. J. Mater. Prod. Technol. 2005, 22, 339–350. [Google Scholar] [CrossRef]

- El Saadany, A.M.A.; Jaber, M.Y. A production/remanufacturing inventory model with price and quality dependant return rate. Comput. Ind. Eng. 2010, 58, 352–362. [Google Scholar] [CrossRef]

- El Saadany, A.M.A.; Jaber, M.Y. A production/remanufacture model with returns subassemblies managed differently. Int. J. Prod. Econ. 2011, 133, 119–126. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Issues in environmentally conscious manufacturing and product recovery: A survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Jaber, M.Y.; El Saadany, A.M.A. The production, remanufacture and waste disposal model with lost sales. Int. J. Prod. Econ. 2009, 120, 115–124. [Google Scholar] [CrossRef]

- Jaber, M.Y.; El Saadany, A.M.A. An economic and production remanufacturing model with learning effects. Int. J. Prod. Econ. 2011, 131, 115–127. [Google Scholar] [CrossRef]

- Hodgson, J.P.E.; Warburton, R.D.H. Inventory resonances in multi-echelon supply chains. Int. J. Logist. Res. Appl. Lead. J. Supply Chain Manag. 2009, 12, 299–311. [Google Scholar] [CrossRef]

- Akcali, E.; Cetinkaya, S. Quantitative models for inventory and production planning in closed-loop supply chains. Int. J. Prod. Res. 2011, 49, 2373–2407. [Google Scholar] [CrossRef]

- Lin, T.-Y. Coordination policy for a two-stage supply chain considering quantity discounts and overlapped delivery with imperfect quality. Comput. Ind. Eng. 2013, 66, 53–62. [Google Scholar] [CrossRef]

- Dyckhoff, H.; Lackes, R.; Reese, H. (Eds.) Supply Chain Management and Reverse Logistics; Springer: New York, NY, USA, 2003. [Google Scholar]

- Flapper, S.D.P.; Van Nunen, J.; Van Wassenhove, L.N. (Eds.) Managing Closed-Loop Supply Chains; Springer: Berlin, Germany, 2005. [Google Scholar]

- Xiao, Z.; Tian, Y.; Yuan, Z. The Impacts of Regulations and Financial Development on the Operations of Supply Chains with Greenhouse Gas Emissions. Int. J. Environ. Res. Public Health 2018, 15, 378. [Google Scholar] [CrossRef] [PubMed]

- Verhoeven, P.; Sinn, F.; Herden, T.T. Examples from Blockchain Implementations in Logistics and Supply Chain Management: Exploring the Mindful Use of a New Technology. Logistics 2018, 2, 20. [Google Scholar] [CrossRef]

- Yi, Y.; Li, J. Cost-sharing contracts for energy saving and emissions reduction of a supply chain under the conditions of government subsidies and a carbon tax. Sustainability 2018, 10, 895. [Google Scholar]

- Tanaka, R.; Ishigaki, A.; Suzuki, T.; Hamada, M.; Kawai, W. Data analysis of shipment for textiles and apparel from logistics warehouse to store considering disposal risk. Sustainability 2019, 11, 259. [Google Scholar] [CrossRef]

- Guide, V.D.R., Jr.; Van Wassenhove, L.N. The reverse supply chain. Harv. Bus. Rev. 2002, 80, 25–26. [Google Scholar]

- Thierry, M.; Salomon, M.; Van Nunen, J.; Van Wassenhove, L.N. Strategic issues in product recovery management. Calif. Manag. Rev. 1995, 37, 114–128. [Google Scholar] [CrossRef]

- Lin, C.-C.; Lin, C.-W. Defective item inventory model with remanufacturing or replenishing in an integrated supply chain. Int. J. Integr. Supply Manag. 2011, 6, 254–269. [Google Scholar] [CrossRef]

- Yuan, K.F.; Gao, Y. Inventory decision-making models for a closed-loop supply chain system. Int. J. Prod. Res. 2010, 48, 6155–6187. [Google Scholar] [CrossRef]

- Mitra, S. Analysis of a two-echelon inventory system with returns. Omega 2009, 37, 106–115. [Google Scholar] [CrossRef]

- Mitra, S. Inventory management in a two-echelon closed-loop supply chain with correlated demands and returns. Comput. Ind. Eng. 2012, 62, 870–879. [Google Scholar] [CrossRef]

- Lin, C.-C. The effect of defective Items on inventory model of supply chain and reverse logistics. Ph.D. Thesis, Department of Industrial Engineering and Management, National Yunlin University of Science and Technology, Yunlin city, Taiwan, 2014; pp. 25–40. [Google Scholar]

- Kim, S.L.; Ha, D. A JIT lot-splitting model for supply chain management: Enhancing buyer–supplier linkage. Int. J. Prod. Econ. 2003, 86, 1–10. [Google Scholar] [CrossRef]

- Ouyang, L.Y.; Yeh, N.C.; Wu, K.S. Mixture inventory models with backorders and lost sales for variable lead time. J. Oper. Res. Soc. 1996, 47, 829–832. [Google Scholar] [CrossRef]

- Ouyang, L.Y.; Wu, K.S. Mixture inventory model involving variable lead time with service level constraint. Comput. Oper. Res. 1997, 24, 875–882. [Google Scholar] [CrossRef]

- Salameh, M.K.; Jaber, M.Y. Economic production quantity model for items with imperfect quality. Int. J. Prod. Econ. 2000, 64, 59–64. [Google Scholar] [CrossRef]

- Maddah, B.; Jaber, M.Y. Economic order quantity for items with imperfect quality: Revisited. Int. J. Prod. Econ. 2008, 112, 808–815. [Google Scholar] [CrossRef]

- Maddah, B.; Salameh, M.K.; Karame, C.H. Lot sizing with random yield and different qualities. Appl. Math. Model. 2010, 33, 1997–2009. [Google Scholar] [CrossRef]

| For the Remanufacturer | For the Supplier | For the Customer | |||

|---|---|---|---|---|---|

| Set-up cost for remanufacturer | Set-up cost for supplier | Ordering cost for customer | |||

| Inventory holding cost per unit per period for remanufacturer | Inventory holding cost per unit per period for supplier | Inventory holding cost per unit per period for customer | |||

| Remanufacturing rate | Demand rate | Batch size/order quantity | |||

| Recovery rate (0 < r < 1) | Integer multiple | p | Defect rate | ||

| Cycle time length | Screening rate | Unit screening cost | |||

| Transportation cost for remanufacturer | Transportation cost for supplier | Shortage cost | |||

| t1 | No out-of-stock period | t2 | Out-of-stock period | s | Backorder quantity |

| L | Lead time for replenishment | π0 | Profit margin per unit of goods | πx | Backorder discount per unit for goods |

| β | Backorder ratio | Rq | Stock quantity in reorder of point (ROP) | Q | Total quantity (Q = n*q) |

| For the Remanufacturer | For the Supplier | For the Customer | |||

|---|---|---|---|---|---|

| Setup cost for remanufacturer | = $300/cycle | Setup cost for Supplier | = $600/cycle, | Ordering cost for buyer | = $25/cycle |

| Remanufacturer’s inventory holding cost | = $3/per unit/per year | Supplier’s inventory holding cost | = $3/per unit/per year | Customer’s inventory holding cost | = $5/per unit/per year |

| Remanufacturing rate | = 19,200 units/year, | Demand rate | = 4800 units/year, | Screening rate | = 152,000 units/year |

| Transportation cost for remanufacturer | = $25/delivery, | Transportation cost for supplier | = $25/delivery, | Except defect rate | = 0.02. |

| Profit margin per unit | π0 = 5% | Backorder discount | πx = 5% | Backorder ratio | β = 0.05 |

| With a Shipment Split into Several Small Lot Sizes(nq = Q) | With a Single Shipment (n = 1) | Model 1 | Model 2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 1 | Model 2 | ||||||||||

| CS | CS | ||||||||||||

| = 10 | 0.1 | 4 | 1933 | 6368* (5841 + 527) | 4 | 1960 | 8869 (8270 + 599) | 1375 | 7113 (6830 + 283) | 1388 | 9567 (9103 + 464) | 16.46% | 12.11% |

| β=0.05 | 0.2 | 5 | 2067 | 6334 (5810 + 524) | 5 | 2097 | 8841 (8265 + 579) | 1365 | 7165 (6883 + 282) | 1377 | 9620 (9130 + 490) | 18.06% | 13.17% |

| 0.3 | 5 | 2142 | 6302 (5780 + 522) | 5 | 2174 | 8817 (8234 + 583) | 1355 | 7217 (6894 + 323) | 1368 | 9672 (9320 + 352) | 19.64% | 14.18% | |

| 0.4 | 5 | 2225 | 6278 (5759 + 519) | 5 | 2261 | 8800 (8210 + 590) | 1345 | 7269 (6919 + 350) | 1358 | 9725 (9423 + 302) | 21.09% | 15.11% | |

| 0.5 | 5 | 2421 | 6279 (5758 + 521) | 5 | 2358 | 8792 (8215 + 577) | 1335 | 7320 (6934 + 386) | 1347 | 9776 (9502 + 274) | 21.99% | 15.88% | |

| 0.6 | 6 | 2547 | 6274 (5754 + 520) | 6 | 2593 | 8818 (8321 + 497) | 1326 | 7370 (6993 + 377) | 1338 | 9828 (9632 + 196) | 23.01% | 16.18% | |

| 0.7 | 6 | 2551 | 6270 (5760 + 510) | 6 | 2597 | 8825 (8341 + 484) | 1327 | 7372 (7003 + 369) | 1336 | 9856 (9679 + 177) | 23.03% | 16.22% | |

| = 25 | 0.1 | 4 | 1987 | 6545 (6010 + 535) | 4 | 2014 | 9043 (8437 + 606) | 1385 | 7168 (6880 + 288) | 1398 | 9622 (9242 + 380) | 13.98% | 10.46% |

| β = 0.05 | 0.2 | 4 | 2045 | 6514 (5906 + 608) | 4 | 2075 | 9019 (8419 + 600) | 1375 | 7221 (6889 + 332) | 1388 | 9675 (9272 + 403) | 15.49% | 11.44% |

| 0.3 | 4 | 2109 | 6488 (5868 + 620) | 4 | 2142 | 8999 (8405 + 594) | 1365 | 7273 (6895 + 378) | 1378 | 9728 (9302 + 426) | 16.90% | 12.38% | |

| 0.4 | 4 | 2180 | 6467 (5826 + 639) | 4 | 2215 | 8985 (8397 + 6368) | 1356 | 7325 (6932 + 393) | 1368 | 9780 (9340 + 440) | 18.23% | 13.22% | |

| 0.5 | 4 | 2258 | 6453 (5864 + 589) | 4 | 2297 | 8978 (8412 + 566) | 1346 | 7377 (6950 + 427) | 1359 | 9833 (9410 + 423) | 19.42% | 13.99% | |

| 0.6 | 5 | 2508 | 6465 (5873 + 592) | 5 | 2388 | 8981 (8459 + 522) | 1337 | 7428 (6973 + 455) | 1348 | 9884 (9519 + 365) | 20.09% | 14.60% | |

| = 100 | 0.1 | 2 | 1871 | 7188 (6632 + 556) | 2 | 1902 | 9674 (9049 + 625) | 1437 | 7438 (7104 + 334) | 1451 | 9890 (9488 + 402) | 7.13% | 5.72% |

| β = 0.05 | 0.2 | 2 | 1895 | 7189 (6596 + 593) | 2 | 1927 | 9680 (9036 + 644) | 1427 | 7493 (7132 + 361) | 1440 | 9946 (9520 + 426) | 7.97% | 6.29% |

| 0.3 | 3 | 2175 | 7176 (6570 + 606) | 3 | 2210 | 9674 (9028 + 646) | 1417 | 7547 (7286 + 261) | 1430 | 10,001 (9584 + 417) | 9.04% | 7.02% | |

| 0.4 | 3 | 2231 | 7163 (6536 + 627) | 3 | 2268 | 9666 (8995 + 6368) | 1407 | 7601 (7365 + 236) | 1420 | 10,055 (9610 + 445) | 10.14% | 7.74% | |

| 0.5 | 3 | 2291 | 7152 (6522 + 630) | 3 | 2332 | 9664 (9012 + 652) | 1396 | 7655 (7487 + 171) | 1410 | 10,109 (9639 + 470) | 11.17% | 8.40% | |

| 0.6 | 3 | 2357 | 7148 (6556 + 592) | 3 | 2400 | 9667 (9032 + 635) | 1387 | 7708 (7584 + 124) | 1399 | 10,163 (9689 + 474) | 12.09% | 9.00% | |

| β | |||||||

|---|---|---|---|---|---|---|---|

| 152,000 | 4800 | 0.02 | 0.01 | 3 | 4.0 | 1960 | 8952 |

| 4.5 | 4.0 | 2056 | 9221 | ||||

| 0.05 | 3 | 3.0 | 2265 | 10,192 | |||

| 4.5 | 4.0 | 2190 | 9645 | ||||

| 0.03 | 0.01 | 3 | 4.0 | 2065 | 9094 | ||

| 4.5 | 4.0 | 2072 | 9188 | ||||

| 0.05 | 3 | 4.0 | 2199 | 9508 | |||

| 4.5 | 4.0 | 2205 | 9608 | ||||

| 7200 | 0.02 | 0.01 | 3 | 4.0 | 2519 | 11,885 | |

| 4.5 | 4.0 | 2530 | 11,989 | ||||

| 0.05 | 3 | 4.0 | 2681 | 12,396 | |||

| 4.5 | 4.0 | 2694 | 12,506 | ||||

| 0.03 | 0.01 | 3 | 4.0 | 2537 | 11,952 | ||

| 4.5 | 4.0 | 2548 | 11,956 | ||||

| 0.05 | 3 | 4.0 | 2700 | 12,357 | |||

| 4.5 | 4.0 | 2713 | 12,469 | ||||

| 228,000 | 4800 | 0.02 | 0.01 | 3 | 4.0 | 2051 | 9127 |

| 4.5 | 4.0 | 2057 | 9220 | ||||

| 0.05 | 3 | 4.0 | 2184 | 9545 | |||

| 4.5 | 4.0 | 2190 | 9644 | ||||

| 0.03 | 0.01 | 3 | 4.0 | 2065 | 9293 | ||

| 4.5 | 4.0 | 2072 | 9186 | ||||

| 0.05 | 3 | 4.0 | 2199 | 9507 | |||

| 4.5 | 4.0 | 2205 | 9607 | ||||

| 7200 | 0.02 | 0.01 | 3 | 4.0 | 2519 | 11,884 | |

| 4.5 | 4.0 | 2530 | 11,988 | ||||

| 0.05 | 3 | 4.0 | 2681 | 12,395 | |||

| 4.5 | 4.0 | 2694 | 12,505 | ||||

| 0.03 | 0.01 | 3 | 4.0 | 2537 | 11,850 | ||

| 4.5 | 4.0 | 2548 | 11,955 | ||||

| 0.05 | 3 | 4.0 | 2701 | 12,356 | |||

| 4.5 | 4.0 | 2713 | 12,468 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, T.-F.; Lin, C.-C.; Lin, C.-L. Determining the Optimal Inventory and Number of Shipments for a Two-Resource Supply Chain with Correlated Demands and Remanufacturing Products Allowing Backorder. Mathematics 2020, 8, 548. https://doi.org/10.3390/math8040548

Ho T-F, Lin C-C, Lin C-L. Determining the Optimal Inventory and Number of Shipments for a Two-Resource Supply Chain with Correlated Demands and Remanufacturing Products Allowing Backorder. Mathematics. 2020; 8(4):548. https://doi.org/10.3390/math8040548

Chicago/Turabian StyleHo, Tseng-Fung, Chi-Chung Lin, and Chih-Ling Lin. 2020. "Determining the Optimal Inventory and Number of Shipments for a Two-Resource Supply Chain with Correlated Demands and Remanufacturing Products Allowing Backorder" Mathematics 8, no. 4: 548. https://doi.org/10.3390/math8040548

APA StyleHo, T.-F., Lin, C.-C., & Lin, C.-L. (2020). Determining the Optimal Inventory and Number of Shipments for a Two-Resource Supply Chain with Correlated Demands and Remanufacturing Products Allowing Backorder. Mathematics, 8(4), 548. https://doi.org/10.3390/math8040548