Abstract

The development of technology has influenced agricultural production and the establishment of the Agriculture 4.0 system in practice. This research is focused on the selection of equipment and machinery suppliers for the needs of the MAMEX Company. When selecting suppliers, an approach based on the application of an intuitionistic fuzzy set for decision-making was used. This approach allows the uncertainty present in decision-making to be incorporated, considered, and, hopefully, reduced in order to make a final decision on which of the observed suppliers is the most suitable for this company. Ten criteria were used that enable the application of sustainability in the supply chain. Eight local suppliers of equipment and machinery were observed with these criteria. The results obtained by applying the SWARA (Step-wise Weight Assessment Ratio Analysis) method showed that the most important criterion for selecting suppliers is the reliability and quality of equipment and machinery, while the results of the CORASO (COmpromise Ranking from Alternative Solutions) method showed that the SUP2 supplier is the best choice for establishing partnership relations with the MAMEX company. This supplier should help the MAMEX company improve its business and achieve better results in the market. The contribution of this research is to improve the application of intuitionistic fuzzy sets in decision-making, and to emphasize the importance of equipment and machinery in agricultural production in the Agriculture 4.0 system.

Keywords:

supplier selection; intuitionistic fuzzy set; decision uncertainty; Agriculture 4.0; Bonferroni mean operator MSC:

90B50; 91B06; 94-04

1. Introduction

Agriculture is the oldest production activity and plays a key role in the global economy. Its task is to provide food for the human population, whose number is increasing every day. Therefore, it is necessary to provide additional quantities of food. This can be achieved by increasing the productivity of agricultural production. The use of modern agricultural equipment and machinery helps to achieve this. Equipment and machinery covers a wide range of aspects from sensors, IoT devices, drones, precision-guided machinery, the use of smart irrigation systems and more. The use of this equipment and machinery increases productivity in agricultural production. It is necessary to use appropriate equipment and machinery to improve competitiveness [1], while applying the advantages offered by the Agriculture 4.0 system.

Agriculture 4.0 is the advancement of the agricultural system by applying digital technologies, thus solving the challenges of sustainability, climate change and the growing demand for food. This system enables smarter and more environmentally responsible production [2], which is performed through the optimization of agricultural decisions by applying digital technologies [3]. The Agriculture 4.0 system is based on precision agriculture, where resources are maximized [4], and plays a key role through the process of automation and financial support in agriculture, especially in developing countries [5]. This system uses data obtained through IoT to implement certain measures where weather conditions are predicted, and based on these predictions, certain activities are performed in Agriculture 4.0 [6].

In addition, Agriculture 4.0 combines IoT, AI and robotics to improve productivity and sustainability in agricultural production [7]. This system offers enormous advantages; however, the application of this system is limited in developing countries that are facing a lack of infrastructure and digital skills. The application of digital technologies, especially IoT devices, increases the potential risk of cyber-attacks that can negatively affect the entire system [8]. To monitor all these devices used by the Agriculture 4.0 system, it is necessary to have efficient energy networks that allow the continuous monitoring of all parameters [9], in addition, the application of drones helps to precisely manage resources in this system [10]. In this way, the application of digital technologies transforms traditional methods in agriculture, making agriculture more efficient and sustainable [11].

The Agriculture 4.0 system differs from classical agriculture because in this system, there is a higher digitalization of agricultural production; additionally, the supplier no longer supplies only raw materials and materials but also provides services to make this system function better. The equipment and machinery within this system is more sophisticated and requires greater knowledge in its use compared to classical equipment and machinery. Therefore, the role of the supplier in this system is greater because he no longer sells only equipment and machinery but also services in the form of training and technical support. The farmer switches to this system in order to achieve higher productivity and higher yields and, thus, higher income. The supplier should help him reach these goals, thus emphasizing the importance of the supplier in this system.

In order to achieve this, it is necessary to have a reliable supplier of equipment and machinery that will help reach the set goals [12]. The relationship between the agricultural producer and the supplier is interdependent [13]. In order to improve its business, the supplier must have regular customers, and the agricultural producer must have the right equipment and machinery to improve its business [14]. Therefore, it is very important to establish a proper business relationship between suppliers and customers in order to improve the business of both partners to the general satisfaction of both partners [15].

Suppliers provide access to modern technology [16] that is characteristic of the Agriculture 4.0 system and provide service, training and advice to agricultural producers. In the conditions of globalization and expansion of the world economy, the range of equipment and machinery appearing on the market is enormous. The supplier needs to follow modern trends in agriculture and procure adequate equipment and machinery to help agricultural producers improve production [17]. They consider which equipment and machinery to purchase in order to ensure the quality and reliability of the product for agricultural producers.

The selection of equipment and machinery primarily depends on the supplier from which it is purchased [18]. The selection of a supplier is not a simple decision-making process. The supplier should help in achieving goals. Based on this, it can be said that the selection of a supplier of agricultural equipment and machinery in the Agriculture 4.0 system is complex and multiple factors should be included in order to conduct the supplier evaluation in the right way. The selection of a supplier is a strategic decision that directly affects the long-term efficiency of the business. The wrong choice of supplier entails losses in the business. It is possible to experience downtime due to malfunctions and to reduce productivity and increase the costs of maintaining equipment and machinery.

When choosing a supplier, it is necessary to take into account the volume of production, what the primary production is and what goals are to be achieved [19]. These are just some of the factors that decide which suppliers will be selected. Small local agricultural households need a local supplier who will provide them with quick support and services. On the other hand, large agricultural companies require suppliers who cooperate with international manufacturers of equipment and machinery. Therefore, it is crucial that agricultural producers, regardless of size, have access to quality and reliable equipment and machinery, which implies establishing relationships with trusted suppliers.

In practice, supplier selection is considered a strategic process that requires a systematic approach [20]. In order to select a supplier, it is necessary to consider the characteristics of the supplier using defined criteria [21]. Since there are a large number of criteria, this strategic process is solved by applying multi-criteria decision-making (MCDM) [22]. Using this approach is particularly important when purchasing agricultural equipment and machinery, because it represents an investment that is burdened with a high degree of uncertainty and large financial expenditures. Therefore, it is necessary to create a decision-making model, when selecting a supplier, that is based on the existence of multiple criteria that would enable the right decision to be made.

The criteria that can be included in this decision-making model can be very diverse. When choosing, it is necessary to include various sustainability factors in order to protect the environment and enable future generations to use available resources for agricultural production. Due to the diversity of criteria in this decision-making model, decision-makers (DMs) often experience uncertainty in decision-making, because there is a possibility that some of the suppliers are better than others and that this supplier will not be their choice. This uncertainty is usually accompanied by a lack of all the necessary information that DMs need to have in order to make the right decision.

1.1. Motivation of the Research

In modern market conditions, the choice of suppliers of agricultural equipment and machinery is becoming an important strategic decision that affects the competitiveness, long-term efficiency and productivity of agricultural producers. This is especially important in the Agriculture 4.0 system, where the focus is on modern equipment and machinery that should improve the business of agricultural producers. The changes that have occurred in the market have influenced changes in the choice of suppliers. Nowadays, not only economic aspects are taken into account, but also environmental, technological and social aspects. Therefore, traditional decision-making models are often insufficient for evaluation when these various criteria exist. Additional complexity in this decision-making process is brought about by the fact that DMs often have subjective dilemmas that cause uncertainty and indecision when evaluating criteria and selected suppliers. The application of an intuitionistic fuzzy set (IFS) brings a significant advantage over the classic fuzzy approach. This approach allows the indecision of DMs to be included in the assessment, which is reflected in the form of uncertainty in decision-making. Using this approach, it is possible to encompass complex elements of decision-making and enable a realistic evaluation of suppliers in the Agriculture 4.0 system. The application of IFS allows for better inclusion of the opinions of DMs who often make decisions intuitively, and this decision cannot be subsumed under strictly determined frameworks. Taking into account that the agricultural sector, especially in transition economies, suffers from the lack of systematic methodologies, this research provides an innovative, methodologically robust and practically applicable decision-making model. Based on this, it contributes to the development of the theory of the MCDM system and the practical improvement of the supplier selection process in agriculture, with a focus on sustainability, rationality and reliability. The application of this research develops the theory of decision-making in the real challenges of the agricultural economy in the Agriculture 4.0 system, opening up space for new approaches that better reflect the complexity and uncertainty of the business environment.

1.2. Research Objectives

In order to address the complexity of the decision-making process and the occurrence of uncertainty and insecurity in decision-making, it is necessary to develop a methodological framework that allows for the consideration of subjective DM assessments. Given the need to include sustainable dimensions when selecting suppliers, this paper aims to examine the possibilities of applying IFS in supporting decision-making when selecting suppliers of agricultural equipment and machinery. The research objectives of this study are focused on the development of a model that enables the transparent and flexible evaluation of criteria and suppliers, taking into account the specificities of agricultural production in the Agriculture 4.0 system. Based on this, the following specific objectives of this research are set:

- Identify and evaluate criteria for selecting suppliers of agricultural equipment and machinery, taking into account uncertainty and insecurity.

- Develop and apply a decision-making model based on intuitionistic fuzzy logic that integrates subjective DM assessments.

- Evaluate the results obtained by applying the intuitionistic fuzzy model with different MCDM methods and give recommendations for sustainable supply chains in the Agriculture 4.0 system.

1.3. Research Contribution

The contribution of this research is reflected in the theoretical and practical sense, where the focus is on improving the decision-making process in the selection of suppliers of agricultural equipment and machinery. First, the research contributes to the development of the theoretical framework of MCDM decision-making, where integration with IFS is carried out in the context of supplier selection. In this way, modeling is performed under conditions of uncertainty and insecurity in DM. This approach overcomes the limitations of the classic fuzzy approach. In addition, the literature in the MCDM field in the field of agricultural production and supply chain is enriched. In addition, this paper contributes to the development of group decision-making, where Bonferroni mean operators are used to align DM opinions. Unlike classical means, this operator takes into account the comparison of ratings and their mutual interactions, and with this operator, it is possible to reduce the influence of extreme DM ratings. The values obtained with this operator are, thus, more aligned compared to classical means. Second, the research has a practical contribution, where the model used can serve as a useful DM tool in the Agriculture 4.0 system. This model enables a systematic and sustainable approach to supplier selection. Through defined criteria, economic, technical, environmental and social aspects are included, which allows the decision-making model used to make a more transparent and objective selection of suppliers. This is especially present in developing and transition countries. Third, the research promotes the concept of sustainable supplier selection in the area of procurement in the Agriculture 4.0 system through the inclusion of environmental and social criteria. This contributes to the integration of sustainability among agricultural producers, thereby strengthening awareness of the importance of socially responsible business in rural areas. Fourth, the decision-making model can serve as a basis for future applications where, with certain adjustments, it can be used in other areas of decision-making. This allows for the expansion of the application of IFS wherever there is a certain degree of uncertainty and subjectivity in decision-making.

1.4. Paper Structure

The paper is structured in a logical sequence of selections from introduction to conclusion. The introduction provides the research topic and motivation for the research, as well as the objectives and contributions of this paper. The literature review allows for an understanding of previous research focusing on the application of IFS in supplier selection, and based on this review, the gaps that this paper addresses are defined. The preliminaries selection provides the methodological foundations of IFS as well as the steps of this approach through MCDM methods. This is followed by the case study selection, where a concrete example explains how to select suppliers of equipment and agricultural machinery. The results selection explains how the results were obtained, interprets these results and validates them through other MCDM methods and applies sensitivity analysis. The discussion explains in more detail why these results were obtained and what each supplier must improve in order to improve its position in the ranking and, thus, become more competitive. The practical and theoretical implications of this research are then explained, and limitations and guidelines for future research are provided. Finally, the research is systematized in the conclusion selection.

2. Literature Review

For the purpose of the literature review, a review of studies aimed at selecting suppliers of agricultural equipment and machinery was first presented, followed by a review of studies where IFS was used in supplier selection.

2.1. Selection of Suppliers of Agricultural Equipment and Machinery

Supplier selection is an important element of supply chain management. The complexity of supplier selection is further increasing due to customer and market demands, especially when it comes to the agricultural sector. When selecting suppliers for the purpose of purchasing agricultural equipment and machinery, we find different approaches in practice. Lu et al. [23] emphasized that when selecting agricultural machinery suppliers, there are certain problems in the form of incomplete information for DMs, which is accompanied by subjectivity in decision-making, which affects the final decision. Therefore, these authors used an improved approach to determining weights using the CRITIC (Criteria Importance Through Inter Criteria Correlation)—Entropy method in their approach and used the GRA-TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution) method to determine the ranking of suppliers. This approach showed the highest degree of discrimination, which confirmed the results in this decision-making model. Çalık [24] emphasized that changes in the way of doing business include the application of modern information technology, which has also affected agricultural production. Therefore, he selected a green supplier of agricultural machinery using the Pythagorean fuzzy environment and the methods AHP (analytic hierarchy process) and TOPSIS. Ismail et al. [25] stated that there is great competition between suppliers and those additional efforts are made by suppliers to attract customers. In order to solve this, these authors presented a model based on triangular neutrosophic sets with the methods MEREC (MEthod based on the Removal Effects of Criteria) and MABAC (Multi-Attributive Border Approximation Area Comparison). In practice, other studies on supplier selection in agriculture is also present, but they are not strictly related to the procurement of equipment and machinery in agriculture. Therefore, this specific area of research has not been studied much so far.

2.2. Using Intuitionistic Fuzzy Approaches in Supplier Selection and in Agriculture

The use of IFS in the selection of suppliers has been covered in many studies, so the studies from 2021 will be presented (Table 1).

Table 1.

Using IFS in supplier selection.

Based on this review and other studies not included in this review, it can be concluded that the common application of IFS is used for supplier selection. This principle has been used in various industries but has not been sufficiently used in supplier selection in agriculture. IFS approaches in agriculture have been used for various purposes. Mohanta & Sharanappa, ref. [42] used this approach to determine the efficiency of agricultural production in India based on the application of the intuitionistic fuzzy DEA (data envelopment analysis) model. Kaur et al. [43] used operators to determine the membership function and applied it to various examples in agriculture such as product selection on the farm and production selection on a single farm. Zhou et al. [44] studied the relationship between water, land, energy and CO2 emissions in agriculture under conditions of high uncertainty and resource scarcity and ecological degradation.

Erdoğan [45] used SWARA and MAIRCA (Multi-Attribute Ideal-Real Comparative Analysis) methods on the example of Agriculture 4.0 to examine the perceptions of agricultural producers in this regard. Sarkar et al. [46] used neural networks to predict the yield of pulse production in India. Zhang & Wang [47] used the CRITIC method to assess the quality of services in e-commerce of agricultural products. Zhang et al. [48] applied this approach to agricultural land management in the conservation and sustainable development of forest potential. Xu & Li [49] dealt with the sustainable development of ecological agricultural areas in order to optimize resources. Gurmani et al. [50] dealt with the problem of precision agricultural production and the use of drones in agricultural products, using the TOPSIS method. Kousar et al. [51] worked on planning a sustainable fruit production management system to improve this production. These and similar studies have shown that the application of IFS is wide and that this approach can be used in various practical examples in agriculture. Therefore, this approach can also be used in the selection of suppliers of equipment and machinery in agricultural production.

2.3. Research Gap

During the literature review, certain gaps were identified. These gaps arise from the specificity of this research, which has not been given much attention in practice so far. First, there is a lack of research focusing on the selection of suppliers of agricultural equipment and machinery in the Agriculture 4.0 system. In the seven papers mentioned above, it could be seen that no attention was paid to suppliers within the Agriculture 4.0 system. A similar situation is found in other studies where the focus was on the implementation of this system and not on the importance of suppliers in this system. This research opens up the possibility of developing research directly focused on the selection of suppliers of agricultural equipment and machinery in the Agriculture 4.0 system, which gives a strategic dimension to improving agricultural production. The procurement of equipment and machinery is a long-term investment for agricultural producers, so it is necessary to use a reliable supplier. Second, although the IFS approach is widely used in the agricultural sector, especially in the agricultural supply chain, it is not used enough in practice with a concrete example of supplier selection in this agricultural system. Applying this approach opens up the possibility of including uncertainty and insecurity in the selection of suppliers. Although this has been used in many previous studies, this study will offer a simplification of this approach, which will open up the possibility of improving this decision-making approach. In addition, Bonferroni mean operators are used, which allow for better alignment of DM ratings in supplier selection. Third, previous research has used the selection of sustainable suppliers in agriculture. This research seeks to build on this approach by incorporating sustainability principles into the selection of equipment and machinery suppliers. The specificity of this selection is that suppliers, in addition to supplying equipment and machinery, also offer additional services in terms of training farmers to use new technologies and providing certain support in doing so. Nevertheless, introducing these dimensions into the research model is key to the development of sustainable agricultural production. Sustainability must be present in all processes in the supply chain in order to achieve sustainable agricultural production. Fourth, it is necessary to improve the decision-making system in practice and to incorporate the dimensions of uncertainty and insecurity into the decision-making process. In this way, this process will be improved and contribute to making a more comprehensive decision. Therefore, it is necessary to develop flexible models adapted to the agricultural sector in order to improve decision-making in agriculture. This is especially present in situations where subjective assessments of DMs are present that are subject to influence. Therefore, subjective opinion carries a certain amount of uncertainty, and it is necessary to develop flexible and robust models in agriculture so that the decision is realistic and correct in order to avoid risks in investment decision-making.

3. Preliminary

When applying the classical fuzzy approach, decision-making is based on the use of linguistic terms. In this case, the DM must choose a certain assessment in the form of linguistic terms, which is transformed into the corresponding fuzzy number through the membership function. This approach allows decision-making when the DM does not have complete information. However, this approach does not include uncertainty in decision-making. If the DM does not have complete information, he will be uncertain in his assessments [52]. Uncertainty in decision-making is present because the human factor is included in decision-making, and these decisions are based on the subjectivity of the DM. For this reason, new approaches have been developed that would include uncertainty and insecurity. Thus, Zadeh [53] provided the basics of how to include uncertainty in decision-making. This approach has been elaborated by others and has laid the foundations for the use of Z-numbers in decision-making. On the other hand, to include uncertainty in decision-making, Atanassov [54] developed the IFS. These sets represent an extension of classical fuzzy sets with an additional element that takes into account the uncertainty in decision-making caused by the lack of information available to the DM. In this way, the degree of membership and degree of non-membership to the set A are determined, and based on them, uncertainty is also determined . Determining the degree of non-membership is a specific feature of this approach compared to the classic fuzzy approach.

3.1. Basic Definitions of the Intuitionistic Fuzzy Approach

In order to define the IFS, it is first necessary to define the classical fuzzy set, since IFS is an extension of this classical set. Let X be the basic element of the set A; then, the classical fuzzy set can be defined as

where the membership function of each element determined by the degree of membership in the set .

By extending the classical fuzzy set and introducing the degree of non-membership, an IFS is formed. Let X be the basic element of the set A; then, the IFS can be defined as

where

- is the degree of membership of the element to the set ;

- is the degree of non-membership of the element to the set .

When defining these degrees of membership and non-membership, it is necessary to ensure that their sum does not exceed one (1), and, therefore, for all , the following condition holds:

Based on these relations of the degree of membership and non-membership, the uncertainty is calculated as follows:

This uncertainty value indicates how uncertain it is that an element belongs or does not belong to the set A. Using the IFS allows expressing certainty, uncertainty and undecidability simultaneously [55]. In order to clarify the application of the IFS, the definitions of complement, union and intersection will be given.

The complement of the IFS in the set A is defined as

Atanassov, ref. [44], gave the basics of operations with two sets and :

Alternatively, when calculating distance, you can also use the Euclidean distance, which would be

3.2. Steps of Application of the Intuitionistic Fuzzy Approach

The evaluation of criteria and selected suppliers will be carried out using the same linguistic terms. In order to use these terms in the IFS approach, the degree of membership is first defined followed by the degree of non-membership to the set A. Based on these levels, the degree of uncertainty is determined . This research will use a linguistic term of nine value scales ranging from very very bad to very very good (Table 2). The evaluation by the DM is performed by selecting the appropriate rating according to their opinion for the criteria and then for the suppliers for all the criteria used.

Table 2.

Linguistic terms and degrees of membership and non-membership.

In order to use IFS in this research, it is first necessary to perform certain steps in order to obtain crisp numbers that will be used to determine the importance of criteria in the form of criterion weights and in determining supplier ratings according to the selected criteria. The reason for performing this transformation is that it provides crisp values for both weights and alternative evaluations, so there is no need to modify the method to use IFNs to obtain weights. In this way, this transformation serves as defuzzification when using fuzzy numbers. The transformation procedure is carried out using the following steps.

Step 1. DMs’ criteria and alternatives with linguistic terms (Table 2) are evaluated based on their opinion on how important the criteria are and how much individual suppliers meet these criteria.

Step 2. Linguistic terms are transformed into certain degrees of membership and non-membership, and the degree of uncertainty is calculated on these defined degrees.

Step 3. An aggregate decision matrix for IFN is formed. In this step, two decision matrices are formed for determining the importance of criteria and for evaluating suppliers.

Step 4. The IFN positive ideal solution () and negative ideal solution () are determined. In this step, the best (positive ideal) and worst (negative ideal) solutions are identified based on the aggregate matrix. The ideal value is the value of one (1) for the degree of membership , while the negative ideal solution is actually a value of one (1) for the degree of non-membership .

Step 5. The distance measure where a fuzzy normalized Euclidean equation with three dimensions is used to determine the positive and negative distances is determined.

Step 6. The closeness coefficient (CC) is calculated:

The CC values are then used as crisp numbers and, based on them, the weight of the criteria is determined and the supplier ranking is determined.

4. Case Study

Agricultural production is facing increasing problems in terms of productivity, sustainability and competitiveness. In order to respond to these problems, it is necessary to transform agricultural production through the application of modern technologies that enable more efficient use of resources and better planning of agricultural production. Agriculture 4.0 represents progress in terms of this production through modernization with innovative equipment and machinery that enable more productive and efficient operations where equipment and machinery such as drone sensors, smart irrigation systems and automatic machines guided by GPS systems are used. In order to acquire and apply this technology in practice, it is necessary to have a reliable supplier who will provide quality equipment and machinery as well as service and other things that are needed by agricultural producers.

The company MAMEX d.o.o. from Bijeljina was founded in 2007 and was engaged in the purchase of vegetables from producers in Semberija region of Bosnia and Herzegivina and their export to other countries. In order to increase efficiency and improve competitiveness, in 2010, it invested in greenhouse production, building 30 greenhouses on three hectares of land. Nowadays, MAMEX produces 1800 tons of cucumbers, peppers, lettuce, spinach, beets, garlic and potatoes, and purchases 2800 tons from local producers. About 20% of the products are exported, while the rest are sold through sales channels in Bosnia and Herzegovina.

In order to improve its production and business, the company launched a processing business where they produced food products from vegetables. In order to further improve its business and improve competitiveness, MAMEX decided that it needed to improve its agricultural production by applying elements of the Agriculture 4.0 system. The constant desire to increase efficiency, productivity and product quality has led MAMEX to acquire and maintain modern equipment—from irrigation systems and climate control in greenhouses to packaging and processing equipment as well as the use of automated machinery.

Given the complexity of the company’s business, which is reflected in the purchase of vegetables and the production of food products, it is necessary to have a reliable and flexible supplier of equipment and machinery. The selection of supplier is a strategic decision for MAMEX. Therefore, this company needs a supplier who will be a strategic partner of this company on which it can rely. In order to select this supplier, MAMEX selected five DMs who will evaluate the criteria and the supplier, as follows:

- The first DM manages all strategic segments of the business and makes decisions. He was selected because he has the broadest insight into the company’s work and has many years of experience in cooperation with suppliers.

- The second DM is in charge of monitoring costs. He was selected because his role is directly related to the economic criteria of this study.

- The third DM deals with maintenance and manages equipment and machinery. He was selected because he has the largest number of points of contact when it comes to the procurement of these goods.

- The fourth DM organizes greenhouse production and supervises the equipment used. He was selected because he has knowledge of the work processes in agricultural production.

The fifth DM monitors productivity and trains new workers. He was selected because he can assess how simple the equipment and machinery is and how it contributes to agricultural production.

MAMEX, with the assistance of the selected supplier, will enable the increase in productivity and efficiency of agricultural production and improve the competitiveness of the company through the development of sustainable production. In order to select a supplier, it is first necessary to determine the criteria with which suppliers will be evaluated. In this study, it was decided to use extended criteria for sustainable supplier selection with technical criteria since equipment and machinery are purchased (Table 3). Only on the basis of a detailed analysis of potential suppliers is it possible to make a decision on which supplier will have a long-term impact on the efficiency of this company’s business. These criteria were set up at by considering what MAMEX needed to implement the Agriculture 4.0 system and how to select a supplier for the needs of this system. First, we investigated what each supplier should have, in order to select the best one. However, due to the specificity of this research, it was decided not to go into too much detail, and 10 criteria were selected to evaluate the supplier. Some of these criteria are classic criteria by which suppliers have been evaluated in previous research and some are specific to the Agriculture 4.0 system. After the criteria were selected, an attempt was made to find some of the studies in which they were mentioned and used.

Table 3.

Criteria for selecting suppliers of agricultural equipment and machinery.

With the criteria of innovation, reliability and quality and guarantees, we evaluated whether the selected suppliers have innovative and high-quality equipment that will not break down often and that will meet the set standards of this system. Service support and education and training are focused on the service level that suppliers must provide when selling equipment and machinery for the Agriculture 4.0 system. Suppliers must train company employees so that they can use this equipment and machinery effectively and efficiently. Price and flexibility in payment are related to the financial aspect. Each piece of equipment and machinery must be paid for, so it is very important that the supplier has favorable prices and that it allows payment to be made, for example, in installments or to have agreed credit arrangements as the purchase of this equipment and machinery entails higher financial expenses because it represents an investment. The impact on employment considers the social aspect when selecting suppliers; it is necessary that the implementation of this system contributes to increasing productivity in production, and since MAMAX is partly a processing company, this would further affect the increase in the number of workers and lead to employment. Energy efficiency and sustainability are environmental aspects when selecting suppliers. It is necessary that this equipment and machinery be energy efficient so that there is no increase in costs when using them in practice. In addition, it is necessary to take care of environmental preservation so that future generations can use available resources.

When conducting the research, the specific characteristics the supplier should have were determined. First, it was decided that it would be a local supplier that specializes in new approaches in agriculture and that has many years of experience in the procurement and delivery of equipment and machinery. Then, this supplier must also provide service for this equipment and machinery so that certain malfunctions or regular services can be repaired in a timely manner so that time is not wasted. Finally, this supplier must also provide advisory assistance so that MAMEX can use the purchased equipment and machinery efficiently. Based on these criteria, eight suppliers were selected to be considered. These suppliers are marked with the labels SUP1 to SUP8 in order to protect the identity of these suppliers. This is because if a supplier is not selected for MAMEX, it does not mean that another company will not choose that same supplier as its partner. Each company is specific and has its own needs that a certain supplier can meet. The selected potential suppliers are as follows:

- Supplier 1 (SUP1) sells and services tractors, and offers a wide range of spare parts and attachments

- Supplier 2 (SUP2) specializes in the sale of agricultural machinery, attachments and spare parts, with technical support and consulting to users.

- Supplier 3 (SUP3) offers solutions for soil cultivation, planting, protection and harvesting, including equipment and machinery from renowned manufacturers.

- Supplier 4 (SUP4) sells tractors, attachments, spare parts and lubricants, and provides service and support to farmers.

- Supplier 5 (SUP5) offers professional machinery such as combines tractors and balers, with technical support and user training.

- Supplier 6 (SUP6) offers a wide range of agricultural tools, spare parts and machines, with an emphasis on availability and fast delivery.

- Supplier 7 (SUP7) is focused on the sale of agricultural machinery and spare parts, as well as irrigation and crop protection equipment.

- Supplier 8 (SUP8) offers tractors, implements and other types of agricultural equipment, with additional service and maintenance services.

4.1. Conducting Research

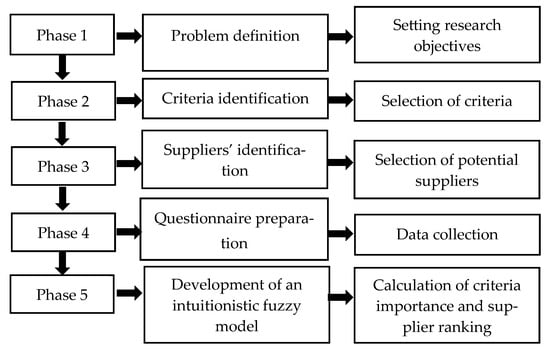

The research was conducted through five mutually complementary phases (Figure 1). This research begins by first defining the problem and research objectives. The problem itself arises from the set research objectives, which is that from all possible suppliers, it is necessary to choose the one that will contribute to the improvement of MAMEX’s business and who will become a business partner that the company can rely on. Choosing the wrong supplier can lead to weaker business results because they cannot contribute to the same extent as another supplier could. Therefore, the next phase of this research is the identification and systematization of criteria. The DM was used in this phase. First, potential criteria that could be used were identified, and from that number of criteria, 15 were selected by elimination, systematization and further analysis and were reduced to 10 criteria that, in the opinion of the DM, were the most important for this selection. Next, the identification of suppliers was carried out with the DM and eight suppliers were selected who met the set conditions. The next phase follows the selection of criteria and potential suppliers, which is the creation of a questionnaire. This questionnaire was then forwarded to the DMs who filled it out and returned it. The data were then collected and prepared for analysis. During phase 5, intuitionistic fuzzy models were formed and prepared for determining the importance of the criteria and for evaluating and ranking suppliers. In this case, the SWARA and CORASO methods will be used.

Figure 1.

Research phases. Source: author composition.

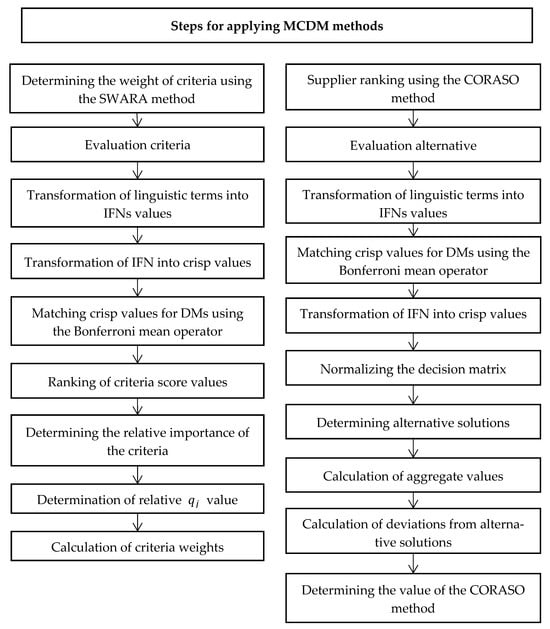

4.2. MCDM Method Steps

The application of MCDM methods was carried out by using the SWARA method to determine the weights of the criteria, while the CORASO method was used to determine the ranking of suppliers. To implement this, DMs must first assess the importance of the criteria and evaluate the alternatives with the selected criteria. The process of applying this research with the selected methods is presented in Figure 2.

Figure 2.

MCDM method steps.

The importance of the criteria was determined using the SWARA method. This method is one of the subjective methods that are subject to subjective assessment by the DM. In addition to these methods, objective methods are also used in practice to determine the importance of criteria. The specificity of these objective methods is that the weight of the criteria is determined in the same way as the alternative ratings. If the ratings of alternatives to a certain criterion vary more in relation to other criteria, its importance will be greater. In objective methods, the weight of the criteria is affected by the rating of the alternative and not the importance of that criterion to the DM. This makes it possible for a criterion that is not important for the decision, according to the DM, to receive the highest importance and one that is significant to have the lowest importance. For this reason, objective methods were not used in this research to determine the importance of criteria, and a subjective method was used instead, namely, the SWARA method. However, it was possible to use a combination of objective and subjective methods to determine the weights, but even then, the objective methods would have a significant influence on the final ranking, so this idea was rejected. This method has been used in practice since 2010 [56], so it has been used in many papers and its validity has been proven in practice.

In order to determine how important individual criteria are for supplier selection, an adapted SWARA method was used. The SWARA method was first used by Keršulienė et al. [56]. This is one of the methods for subjectively determining the weight of criteria [57]. The importance of weights is determined based on DM ratings. The application of this method in this research is performed as follows:

Step 1. Assessment of the importance of criteria by the DM. In this step, DMs provide ratings in the form of linguistic terms (Table 2).

Step 2. Transformation of linguistic terms and application of intuitionistic fuzzy approach definitions to form crisp values.

Step 3. Harmonization of criterion ratings using the Bonferroni mean operator.

Step 4. Ranking the average scores of the criteria.

Step 5. Determining the relative importance of the criteria. The criterion with the highest average score is given a value of one (1). The other criterion values are obtained by subtracting the value of the criterion for which the relative importance of the criterion is calculated from the average value of the better ranked criterion and adding a value of one (1).

Step 6. Determination of relative value. This is performed in such a way that the value one (1) is rewritten for the first ranked criterion, while , the value of the other criteria, is calculated in such a way that, from the value, we can determine the relative importance of that criterion that counts.

Step 7. Calculation of criteria weights. In this step, the individual value is divided by the cumulative value.

After the weights of the criteria were determined, the suppliers were ranked. In this study, the CORASO method was applied. The CORASO method is a new MCDM method that has not been widely used in practice. However, in a study conducted by Puška et al. [58], they showed that this method gives consistent results in contrast to some other much better-known methods. Stević et al. [59] showed that the TOPSIS method does not show consistent ranking when the effects of dynamic decision matrices are calculated. Due to this characteristic and the simplicity of operation, this method was chosen for this study in comparison to some other methods such as VIKOR (Multicriteria Competitive Ranking), MABAC or PROMETHEE (Preference Ranking Organization Method for Enrichment Evaluation).

This method ranks alternatives based on deviations from alternative solutions [58]. Alternative solutions are the highest-value alternatives for individual criteria and the lowest-value alternatives. This method was adapted to this study with the following steps:

Step 1. Supplier evaluation with linguistic terms.

Step 2. Transformation of linguistic terms and application of the definitions of the intuitionistic fuzzy approach. In this step, the formation of the aggregate intuitionistic fuzzy decision matrix is further performed using the Bonferroni mean operator.

Step 3. Establishing the decision matrix. In this step, the sum of intuitionistic fuzzy numbers is transformed into crisp numbers.

Step 4. Normalizing the decision matrix.

Step 5. Determining alternative solutions.

Step 6. Aggregating normalized alternatives.

Step 7. Calculation of aggregate values.

Step 8. Calculation of deviations from alternative solutions.

Step 9. Determining the value of the CORASO method.

The improvement of these methods by applying the Bonferroni mean operator is reflected in the fact that the use of classical analyses for the environments is based on the assumption that all elements are independent. However, decision-making in a company is not a completely independent process because DMs still work together and there is a certain mutual influence. Therefore, it is necessary to include their ratings through interactions when calculating the average rating using the Bonferroni mean operator. In addition, the Bonferroni mean operator is a much more flexible tool for determining the mean value because it supports different forms of aggregating ratings in relation to DM preferences. In addition, it allows for the provision of a balanced aggregation of DM ratings. In this way, the steps of these methods are improved and their use in group decision-making is enabled, taking into account and harmonizing DM ratings.

5. Results

When examining which of the selected suppliers shows the best results, it is first necessary to examine the importance of the selected criteria. The first step of this analysis is the DM’s assessment of the importance of the criteria using linguistic terms (Table 4).

Table 4.

Assessment of the importance of criteria by DMs.

After that, these linguistic terms are transformed into the corresponding intuitionistic numbers according to the defined membership function (Table 2). For example, the value very very good is transformed into an intuitionistic number [0.90, 0.10], the term very good into an intuitionistic number [0.80, 0.10] and the value good into [0.70, 0.20]. Then, the uncertainty value is calculated, which is calculated using Equation (4). For example, for the value very good, the uncertainty value is calculated as follows:

This is calculated for all values and an intuitive decision matrix is formed (Table 5).

Table 5.

Intuitionistic decision matrix.

The next step in calculating the weights using the SWARA method is to transform the intuitive decision matrix into a crisp decision matrix. This is performed by calculating distance measures. In order to calculate these distance measures, positive and negative ideal solutions must be determined. These solutions are determined so that all elements belong to the set and do not belong to the set. In this way, the positive ideal solution is [1, 0], and the negative ideal solution is [0, 1]. Once this is determined, the distance measures are calculated. In the example of criteria C1 and DM1 (E1), this is calculated as follows: (Equations (10)–(12))

Using the same procedure, a crisp decision matrix is formed (Table 6). After that, the average score is calculated using the Bonferroni mean operator. These scores then form the basis for calculating weights using the SWARA method. Using the example of criterion C1, the Bonferroni mean operator is calculated as follows (izraz 13):

Table 6.

Crisp decision matrix and Bonferroni mean operator values.

When calculating the Bonferroni mean operator, first, determine how many DMs there were; in this case, there were five DMs. Then, each DM value is multiplied by the other DM. This is performed in pairs and these values are added. For example, the values of the first DM are multiplied by the values of the other DMs. The value of the first DM is multiplied by the value of the second DM, then, the value of the first DM is multiplied by the value of the third DM, and so on, until the value of the first DM is multiplied by all DM values. This is performed for each DM and the values are added. Then, this is multiplied by the value k(k−1), which is the value 0.05 (1/20). Finally, the root value is calculated and the Bonferroni mean operator values are formed. After that, the Bonferroni mean operator (BMO) values are ranked and the steps of the SWARA method are calculated.

In order to apply the SWARA method, it is necessary to rank the criteria. Thus, the first criterion is ranked C2, followed by criteria C1 and C10 up to criterion C8, which is the lowest ranked criterion. Then, the relative importance values of the criteria are calculated. The value of one (1) is given for the best-ranked criterion, which is criterion C2. Then, this value is calculated for the next criterion, namely, C1, in such a way that the value of the criterion for which the relative importance is calculated is subtracted from the BMO value of the better-ranked criterion, and the value of one (1) is added. In the example of this criterion, the calculation procedure is as follows (Equation (14)):

Respecting this principle, the relative importance of all criteria is calculated. Then, the relative value is calculated. The highest ranked criterion (C2) is overwritten by the value and then, the relative value is calculated, by taking the value of the better-ranked criterion and dividing it by its value. In the example of criterion C1, this calculation is performed as follows (Equation (15)):

In the next step, the values are added for all criteria and the weight of the criteria is calculated. This procedure is performed in such a way that the individual values of the criterion are divided by the total value criterion. The weight calculation procedure for the example of criterion C1 is as follows (Equation (16)):

Determining the weights in this way and using the steps of the SWARA method showed that based on the DM, the most important criterion is C2—Reliability and Quality, followed by C1—Innovation and C10—Sustainability (Table 7). The least important criterion based on these DM ratings is C8—Education and Training. When all the weighted criteria are considered, it can be concluded that there is no significant deviation, so all criteria have significant importance in selecting a supplier.

Table 7.

Calculation of criterion weights using the SWARA method.

After the weights of the criteria have been calculated, the suppliers are ranked. The first step in this process is to evaluate the selected suppliers using the criteria. Each DM provides a score in the form of linguistic terms (Table 8).

Table 8.

Evaluation of suppliers in linguistic terms.

Then, the linguistic terms are converted into intuitionistic values in the same way as for the criteria. Then, a summary intuitionistic decision matrix is formed using BMO. Using this operator, the average intuitionistic value is calculated. Then, the distances from the positive and negative ideal solutions are calculated and the CC value is calculated, which is used as the crisp value for calculating the rank order of the CORASO method (Table 9).

Table 9.

Initial crisp decision matrix.

Due to the specificity of the criteria, and the ratings themselves in the form of linguistic terms, all criteria are in the form of benefit criteria, so normalization is applied for this type of criteria. In this normalization, the values of alternatives to individual criteria are divided by the highest value of the alternative in that criterion (Table 10). In the example of supplier SUP1 and criterion C1, the normalization calculation procedure is performed as follows (Equation (18)):

Table 10.

Normalized decision matrix and alternative solutions.

Then, alternative solutions are determined that represent the highest values of alternatives for individual criteria or the lowest values of alternatives for individual criteria (Table 10).

The next step is to aggregate these normalized values including alternative solutions where individual values are multiplied by the appropriate weights. For example, for supplier SUP1 and criterion C1, this is calculated as follows (Equation (20)):

Then, the values for all suppliers are added up and the deviation from the alternative solutions is calculated (Table 11) and the value of the CORASO method is calculated. In the example of supplier SUP1, this is performed as follows (Equations (22)–(24)):

Table 11.

Calculation of the CORASO method.

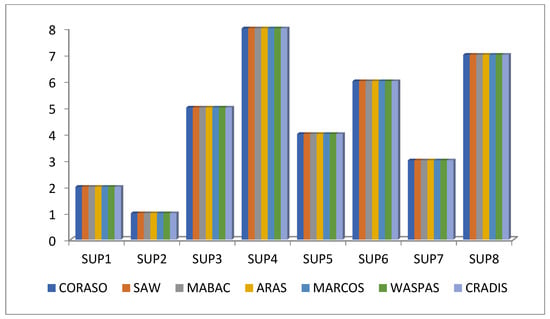

The results of the CORASO method (Table 11) showed that the best-rated supplier was SUP2, followed by SUP1, while the worst-rated supplier was SUP4. Thus, supplier SUP2 represents the best choice for MAMEX according to DM ratings.

5.1. Results Validation

In order to examine the results obtained by the CORASO method, validation of the results using comparative analysis was applied [60,61]. This analysis was performed by using the same initial crisp decision matrix and weights obtained by the SWARA method, but the supplier rankings were performed using the steps of the other methods used. In this study, six MCDM methods were used to determine the ranking. The SAW (simple additive weighting) method is the simplest MCDM method that performs ranking on weighted normalized data. As such, this method is very easy to use and, therefore, it was adopted in this analysis. The MABAC method ranks alternatives based on deviations from the geometric mean [62]. In addition, this method uses more complex normalization, and when weighting normalized data, in addition to multiplication with the weights of the criteria of the normalized data, addition with the weights of the criteria was also performed. The ARAS (additive ratio assessment) method is a simple method that uses a utility function to determine its value. In addition, it uses a percentage normalization where individual alternatives are divided by the sum of all alternative values. Using the MABAC and ARAS methods, the impact of normalization on the ranking of suppliers was examined.

The MARCOS (Measurement of Alternatives and Ranking according to the Compromise Solution) method determines the ranking in relation to ideal and anti-ideal solutions and in relation to the membership function [63]. This method is one of the most widely used newer MCDM methods and is, therefore, included in this analysis. The WASPAS (Weighted Aggregated Sum Product Assessment) method ranks alternatives as a compromise between the two methods WSM (weighted sum model) and WPM (weighted product model). The WAS method is actually a SAW method. The WPM method uses scaling of normalized values with weights. Based on the compromise of these two methods, the ranking was performed. The CRADIS (Compromise Ranking of Alternatives from Distance to Ideal Solution) method uses adapted steps of the TOPSIS, MARCOS and ARAS methods in its steps, but also has steps that are specific only to this method. The SAW, MARCOS, WASPAS and CRADIS methods use the same normalization as the CORASO method, so whether the specific steps of these methods affect the final ranking was examined.

Some of the more well-known methods such as TOPSIS and VIKOR were not used in this analysis because the results of these methods significantly deviate from other methods. Puška et al. [64] showed that using the VIKOR method, obtained rank orders are not related to other methods, and that they deviate greatly from the results of other methods, and 11 different methods were used in the validation assessment. Other studies, such as the study by Stević et al. [59], have shown that the results of the TOPSIS method are unstable and lack consistency. For these reasons, these methods were not used, but rather, the selected methods were used instead.

However, in addition to all this, the results of all these methods show the same ranking as the CORASO method (Figure 3), so the results obtained by applying this method are confirmed, namely, that supplier SUP2 is the best choice for the company MAMEX for purchasing equipment and machinery and establishing partnership relations with this supplier. These relations will assist the company MAMEX in improving its business.

Figure 3.

Results of comparative analysis. Source: author composition.

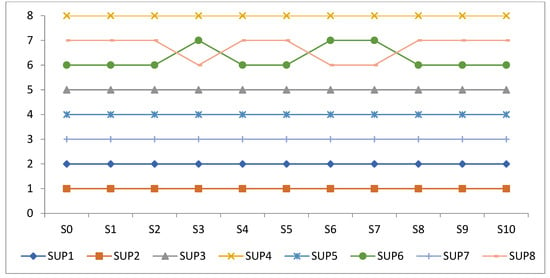

5.2. Sensitivity Analysis

Sensitivity analysis was used to determine the impact of criterion weights on the final ranking of alternatives [65]. These analyses can be performed in different ways [66,67,68,69]. In the performed sensitivity analysis, the weights obtained by the SWARA method were applied. When performing this sensitivity analysis, each individual criterion is reduced by 90%, while the other criteria increase in proportion to that reduction. At the initial weight, the sum of the weight values was equal to one. As the value of one criterion decreases, that sum decreases. For this reason, it is necessary to proportionally increase the weights of the other criteria so that the sum of the weights is equal to one. First, the value of one of the criteria is reduced and then, the values of the other criteria are gradually increased until their sum is approximately equal to one. In the example of scenario S1, the weight value of criterion C1 is reduced from 0.113 to 0.011, while the values of other criteria are increased by 11% in order to compensate for the decrease in the weight value of one criterion. In this way, the sum of the weights is approximately equal to 1, that is, in this way, it is 0.9956, which is almost 1. In other scenarios, the values of other individual criteria decrease, while the values of other criteria that do not decrease increase by 11%. In this way, the impact of that criterion on the ranking of the alternatives was examined, which means that the alternative had better indicators compared to the alternative that is ranked better. The results of this sensitivity analysis show that there is a change in the ranking of suppliers SUP6 and SUP8 (Figure 4). According to three criteria, SUP 6 was ranked worse. In order for the SUP8 supplier to be better than the SUP6 supplier, they need to meet these three criteria.

Figure 4.

Results of sensitivity analysis when reducing the importance of criteria. Source: author composition.

Sensitivity analyses showed that regardless of increasing or decreasing the importance of the criteria, supplier SUP2 is the best in all scenarios and, thus, it is the best choice for MAMEX.

6. Discussion

With changing market conditions, the use of modern equipment and machinery has become necessary in agricultural production. However, with the development of technology, this equipment and machinery has become more sophisticated, and on this basis, the Agriculture 4.0 system has developed. Due to the specificity of this production system, the importance of suppliers is increasing [70]. The supplier is no longer just a supplier of equipment and machinery, but also a partner on whom the company should rely [71], because he needs to provide training on how to use this new equipment and machinery, as well as provide support in the form of repairs and upgrades of this equipment and machinery. As stated in the paper by Erdoğan [45], in order to implement this system, the farmer needs to be trained in the use of digital technologies. In addition to supplying equipment and machinery, the supplier should also organize training for farmers and provide them with support in using these technologies. It is important to choose a supplier who will be a partner to the company and help it achieve its set goals. Modern equipment and machinery used in the Agriculture 4.0 system must enable the agricultural producer to improve their production. It is necessary to procure reliable and efficient equipment and machinery in order to respond to climate change, which negatively affects agricultural production [72]. In addition, it is necessary to choose a supplier that will assist in applying this technology in general due to its specificity. Therefore, as stated in the research by Gurmani et al. [50], it is necessary to obtain this equipment from a reliable supplier. In this research, the selection of equipment and machinery suppliers for the needs of the Agriculture 4.0 system was carried out using the example of the company MAMEX.

Due to the specificity of this procurement, the objectives that the supplier had to meet are specific. These objectives are presented in the criteria with which the suppliers were evaluated. These criteria had to be formed in accordance with the specifics of this system, as shown in the paper by İlbaş et al. [37], who adapted the criteria used to the military industry. Thus, in this study, the criteria were adapted to the selection of suppliers in the Agriculture 4.0 system. The research applied extended sustainable criteria, where the focus was on technical criteria. Equipment and machinery should be reliable, and the supplier should provide all necessary support. These criteria were systematized, and a total of 10 criteria were selected, according to which suppliers were evaluated. The selection of potential suppliers was also specific to this research. The focus of the selection of this supplier was on the possible speed of support and procurement; therefore, local suppliers were used. The point of this is that not only does MAMEX develop, but so does the supplier itself. They would be a partner to this company and meet specific requirements in terms of implementing modern agricultural production. Therefore, the potential supplier had to be ready to improve its business and help MAMEX.

However, the selection of suppliers entails the problem of knowing all suppliers and their business, which requires specific information that is difficult to obtain [73]. For this reason, this decision-making process includes uncertainty in decision-making that is present in DMs, because they do not have all the necessary information. Therefore, they used the IFS that enabled the inclusion of uncertainty in decision-making. This is because the application of a classic fuzzy set allows for the provision of information with incomplete information, but it does not allow for the inclusion of the uncertainty that each DM has when making a decision [74]. IFSs have been used in various studies where it was necessary to choose a supplier; as such, this method of decision-making has been confirmed in practice and, therefore, was taken in this study.

In order to use this approach, it was necessary to adapt the methods to this approach. In this study, the SWARA and CORASO methods were used. In addition to the fact that the methods had to be adapted to this approach, the problem with this decision-making model is that group decision-making was used, so it was necessary to harmonize the DM ratings, because five DMs were used who evaluated the importance of the criteria and suppliers. In order to harmonize these ratings, BMO was further used. The application of this operator further upgraded the approach used in this research.

The results of the application of the SWARA method showed that the most important criteria, according to the DM, are reliability and quality as well as innovation and sustainability. This means that equipment and machinery must first be reliable so that it does not break down and so that it can be used whenever necessary. In addition, it must meet the requirements of MAMEX in terms of quality. The supplier must purchase innovative equipment in order to be able to respond to the increasingly complex requirements that prevail in agriculture. Therefore, it is necessary to implement various measures in a timely manner in order to optimize the conditions for agricultural production. In addition, it is necessary to take into account the sustainability and impact of equipment and machinery on the environment.

The application of the CORASO method has shown that the supplier SUP2 has the best results compared to other suppliers and is the first choice for establishing a partnership. The reason why this supplier was chosen is that it specializes in the sale of agricultural machinery, attachments and spare parts. In addition, it provides technical support and advice to users on which equipment and machinery to purchase in order to have better yields. However, other suppliers should not be underestimated, because this supplier is the best for MAMEX, but another supplier might be better suited for another company. Therefore, the best supplier in one case may not be suitable for all companies in a particular field; rather, it is a specific decision-making process and is specific to each company [75].

6.1. Theoretical and Practical Implications

The implications of this research are multiple. When selecting suppliers of equipment and machinery for the needs of agricultural production in the Agriculture 4.0 system, certain theoretical and practical postulates were set. First, a decision-making model was formed that included criteria that enabled sustainable supplier selection. However, the focus was on technical criteria, because the objects of procurement that need to be purchased from suppliers are technical devices. In this way, when selecting suppliers, the economic, social and environmental dimensions, and not only the technological dimension, were taken into account. The application of this modeling method has established new guidelines for the development of the theory of sustainability, especially when applying the Agriculture 4.0 system. In this way, environmental awareness is strengthened when choosing suppliers, which are key items in the supply chain that are necessary for conducting agricultural production. Applying this approach in practice contributes to the integration of sustainable practices in agricultural production, which affects the awareness of agricultural producers about the importance of sustainability. In addition, it also affects the achievement of socially responsible business, as in the example of the company MAMEX.

The next implications of this research are in the application of the IFS approach, which allows the application of uncertainty in decision-making. Uncertainty is always present when the human factor is involved, and this is the case in most decision-making processes. Therefore, the inclusion of uncertainty in the decision-making process contributes to the theoretical and practical development of this system. New theoretical foundations are being set for the development of new approaches in the application of MCDM methods. These methods must be adapted to this approach, which provides guidelines for how new MCDM methods that appear in practice can be used for the IFS approach. The development of new approaches enriches the decision-making process, especially in agriculture when selecting suppliers of equipment and machinery. This equipment and machinery that is purchased from suppliers is crucial for improving agricultural production and allows greater effects to be achieved with the same resources and fewer resources. Therefore, the implication of this research is emphasizing the importance of equipment and machinery in order to implement the Agriculture 4.0 system.

6.2. Research Limitations

Research limitations are present in every study and, for the most part, usually arise from the research methodology itself [76]. In practice, there are many criteria that could have been used when selecting suppliers of equipment and machinery for the needs of the Agriculture 4.0 system. Other criteria could have been used and, therefore, this choice can be criticized. Further limitations may be related to the suppliers selected in this research. The question can arise about why MAMEX decided to establish a partnership relationship with local suppliers and not go to regional suppliers of equipment and machinery. Regional suppliers can use distribution channels to deliver equipment and machinery to the company very quickly. However, the problem arises when this equipment and machinery breaks down, because then the supplier needs to come to the site of the failure, so it is advantageous to have a local supplier who can quickly provide service services. Limitations can also be considered in regard to the methods used in this research. The SWARA method is one that has been used for many years in decision-making problems. However, like every method, it has certain advantages and disadvantages. Therefore, it is always possible to use other methods, but the application of these other methods entails the problem of other results that could affect the final selection of suppliers. The CORASO method is a newer one that is not used much in practice and that still needs to compete with other methods. It was chosen because the IFS approach has not yet been developed for this method, so it is used as an example to explain how new methods can be developed in the IFS approach. Ultimately, the choice of method is a matter for the researcher and there is always a degree of doubt as to whether the methods used will give good results. Therefore, further analyses are performed that allow these doubts to be removed, namely, comparative analysis and sensitivity analysis. In this study, no more complex methods of comparative analysis were used to validate the research results because all methods used had the same ranking order and there were no deviations. Therefore, it was not necessary to conduct further analyses to examine the results of the CORASO method in relation to other methods. Another limitation of this research could be the use of the IFS approach, because it is more complicated than the classic fuzzy approach. However, with this approach, an attempt was made to include uncertainty in decision-making, which was not possible with the classic approach.

6.3. Directions for Future Research

The limitations of the study should be guidelines for future research in order to remove these limits and, thus, improve future research. This study also aims to improve various areas and, thus, contribute to the development of science. In future research, it is necessary to address only the criteria used for supplier selection. In this way, answers would be obtained to the question of which criterion is more suitable for certain research and which criterion should be used in certain research. Some of the criteria could be observed together and, thus, cover more aspects of supplier selection with fewer criteria. Then, in subsequent research, it is necessary to use other MCDM methods in order to establish which method is more suitable and easier to use, and on the other hand, which methods are safer and more reliable. Therefore, in future research, attention should be paid only to the MCDM method, where its application in various decision-making segments is analyzed. The methodology used, based on the IFS approach, showed good flexibility and reliability in practice, so it should also be used in future research in various areas where there is uncertainty in access.

7. Conclusions

With the development of agricultural production, the importance of agricultural equipment and machinery is increasing. This is especially present in the development of new systems in agriculture such as the Agriculture 4.0 system. In this system, the focus is on automation in agricultural production through the use of more sophisticated equipment and machinery. Therefore, this research was focused on the importance of equipment and machinery in the Agriculture 4.0 system and the supplier of this equipment and machinery. The example of the company MAMEX showed how the IFS approach can be applied when selecting suppliers, including uncertainty and uncertainty in the decision-making process. The specificity of MAMEX is that it is first and foremost an agricultural producer, then a purchaser of agricultural products and, also, a producer of food products. In this way, this company has completed its cycle from the production of agricultural products to the marketing of food products, while also using raw materials from other agricultural producers in the Semberija region of Bosnia and Herzegovina. Based on the impact on the regional development of the Semberija region, the selection of suppliers was based on local suppliers of equipment and machinery in order to further influence the development of this region.

This research is based on the evaluation of selected DMs of the company MAMEX. In order to harmonize the evaluations of these DMs, BMO was applied, which enabled better use of DM ratings when analyzing the results of this research. The results obtained showed that the reliability and quality of this equipment and machinery are the most important criteria and that the SUP2 supplier is the best choice for establishing partnership relations. These relations should help improve the business of the company MAMEX and, on the other hand, improve the business of the SUP2 supplier because they will have a reliable customer who has great potential to further develop their business, which will also affect the development of the SUP2 supplier’s business.

Author Contributions

Conceptualization, A.P. and M.N.; methodology, A.P.; software, A.P.; validation, I.S., B.D. and L.S.; formal analysis, A.P. and M.N.; investigation, S.I.; resources, N.P.; data curation, S.I.; writing—original draft preparation, A.P.; writing—review and editing, I.S.; visualization, A.P.; supervision, L.S.; project administration, B.D.; funding acquisition, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science, Technological Development and Innovation of the Republic of Serbia no. 451-03-136/2025-03/200009 from 4 February 2025.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SWARA | (Step-wise Weight Assessment Ratio Analysis) |

| CORASO | COmpromise Ranking from Alternative SOlutions |

| MCDM | Multi-Criteria Decision-Making |

| DM | Decision-Maker |

| IFS | Intuitionistic Fuzzy Set |

| CRITIC | Criteria Importance Through Inter Criteria Correlation |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| AHP | Analytic Hierarchy Process |

| MEREC | MEthod based on the Removal Effects of Criteria |

| MABAC | Multi-Attributive Border Approximation area Comparison |

| DEA | Data envelopment analysis |

| MAIRCA | Multi-Attribute Ideal-Real Comparative Analysis |

| ARAS | Additive Ratio Assessment |

| MARCOS | Measurement of Alternatives and Ranking according to the Compromise Solution |

| WASPAS | Weighted Aggregated Sum Product Assessment |

| WSM | Weighted Sum Model |

| WPM | Weighted Product Model |

| RAWEC | Ranking of Alternatives with WEights of Criterion |

| SAW | Simple Additive Weighting |

| CRADIS | Compromise Ranking of Alternatives from Distance to Ideal Solution |

References

- Škuflić, L.; Šokčević, S.; Bašić, M. Sustainable Development and Competitiveness: Is There a Need for GCI Reconstruction? Econ. Innov. Econ. Res. J. 2024, 12, 153–173. [Google Scholar] [CrossRef]

- Araújo, S.O.; Peres, R.S.; Barata, J.; Lidon, F.; Ramalho, J.C. Characterising the Agriculture 4.0 Landscape—Emerging Trends, Challenges and Opportunities. Agronomy 2021, 11, 667. [Google Scholar] [CrossRef]

- Zhai, Z.; Martínez, J.F.; Beltran, V.; Martínez, N.L. Decision support systems for agriculture 4.0: Survey and challenges. Comput. Electron. Agric. 2020, 170, 105256. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Enhancing smart farming through the applications of Agriculture 4.0 technologies. Int. J. Intell. Netw. 2022, 3, 150–164. [Google Scholar] [CrossRef]

- Alam, M.F.B.; Tushar, S.R.; Zaman, S.M.; Gonzalez, E.D.R.S.; Bari, A.B.M.M.; Karmaker, C.L. Analysis of the drivers of Agriculture 4.0 implementation in the emerging economies: Implications towards sustainability and food security. Green Technol. Sustain. 2023, 1, 100021. [Google Scholar] [CrossRef]

- Roy, S.K.; De, D. Genetic algorithm based internet of precision agricultural things (IopaT) for agriculture 4.0. Internet Things 2022, 18, 100201. [Google Scholar] [CrossRef]

- Jellason, N.P.; Robinson, E.J.Z.; Ogbaga, C.C. Agriculture 4.0: Is Sub-Saharan Africa Ready? Appl. Sci. 2021, 11, 5750. [Google Scholar] [CrossRef]

- Ferrag, M.A.; Shu, L.; Djallel, H.; Choo, K.-K.R. Deep Learning-Based Intrusion Detection for Distributed Denial of Service Attack in Agriculture 4.0. Electronics 2021, 10, 1257. [Google Scholar] [CrossRef]

- Swain, M.; Zimon, D.; Singh, R.; Hashmi, M.F.; Rashid, M.; Hakak, S. LoRa-LBO: An Experimental Analysis of LoRa Link Budget Optimization in Custom Build IoT Test Bed for Agriculture 4.0. Agronomy 2021, 11, 820. [Google Scholar] [CrossRef]

- Khan, N.; Ray, R.L.; Sargani, G.R.; Ihtisham, M.; Khayyam, M.; Ismail, S. Current Progress and Future Prospects of Agriculture Technology: Gateway to Sustainable Agriculture. Sustainability 2021, 13, 4883. [Google Scholar] [CrossRef]