Abstract

The efficiency of emergency response operations is critically dependent on the strategic storage and allocation of emergency supplies. Proper management of these resources reduces economic impacts and ensures prompt availability in crises. This study addresses the challenges and existing practices in emergency reserve warehousing, with a specific focus on a Fangshan District case study. It introduces optimized storage strategies and principles for storage location assignment, taking into account both planar and three-dimensional storage configurations. The study employs two pallet types to establish basic assumptions and formulates two models: one for standard pallets in three-dimensional storage and another for special pallets in planar storage, including scenarios for their combined usage. Utilizing an advanced non-dominated genetic algorithm (NSGA-II) with an elite strategy, the study conducts simulations and analyses of these models under various scenarios. The findings indicate that the application of the second scenario significantly improves storage location optimization in emergency reserve warehouses.

Keywords:

emergency supply reserve; storage location optimization; NSGA-II; planar and three-dimensional storage integration MSC:

90-08

1. Introduction

Recently, the world has witnessed an increase in emergency events, presenting significant challenges to emergency management systems globally [1]. The efficient management of emergency relief materials is a cornerstone in addressing these challenges. These materials are crucial in emergency rescue and disaster response, as they minimize economic losses and ensure rapid response during crises. The strategic stockpiling and quick deployment of these supplies are, therefore, paramount, highlighting the importance of effective emergency supply reserve management within the broader emergency response framework.

Effective management of emergency supplies is a matter of efficient logistics and a crucial element in national security and disaster response preparedness [2]. A well-organized reserve of emergency materials can significantly impact the outcome of disaster management efforts. In this context, the storage and allocation of emergency supplies in warehouses becomes a critical area of focus. The ability to quickly access and distribute these supplies in times of need is a key factor in the effective management of emergencies.

Contemporary research in this field, as delineated by authors like [3,4], primarily focuses on the dispatch of emergency supplies and the strategic location of emergency reserve warehouses. However, there is a noticeable gap in research addressing the complexities and specific requirements of mixed-type warehouses, where automated three-dimensional and planar storage spaces coexist. While the trend towards automated storage solutions is on the rise, many emergency warehouses, constrained by the unique characteristics of emergency materials and cost considerations, have yet to fully adopt these systems.

To bridge these gaps, our study introduces tailored storage strategies and principles specifically designed for emergency reserve warehouses. We propose an innovative mathematical planning model, drawing inspiration from the works of [5,6], to optimize storage location assignments in mixed-type warehouses. This model marks a significant advancement in the field, accommodating the unique characteristics of emergency materials while addressing operational challenges specific to mixed-type warehouses. By employing a non-dominated genetic algorithm, similar to approaches used by [7,8], our model is applied to a case study of a warehouse in Fangshan District. This application demonstrates its practicality and effectiveness in enhancing the efficiency of emergency material reserves, contributing to the broader discourse on emergency supply management and optimization.

The structure of the remainder of this paper is as follows: Section 2 presents a thorough literature review, exploring the current state of research in this area. Section 3 details the methodology and the specific approaches employed in our study. Section 4 discusses the application of the model to the Fangshan District warehouse and presents the simulation results. Finally, Section 5 draws conclusions.

2. Literature Review

The effective management of emergency supplies, particularly in the context of strategic storage and rapid deployment, has garnered significant attention in recent times. This literature review delves into three critical aspects of emergency supply chain management: emergency stockpiles, storage location assignment in warehouses, and multi-objective optimization in storage location assignment. Each of these aspects plays a vital role in enhancing the responsiveness and efficiency of emergency management systems globally.

2.1. Emergency Stockpiles

The literature on emergency stockpiles has historically focused on various aspects, from strategic site selection to risk management and operational efficiency in emergency logistics.

Campbell and Jones (2011) explored models for the optimal sizing and siting of emergency stockpiles, integrating disaster risk assessments with cost modelling [9]. This approach highlighted the crucial balance between logistical practicality and cost-effectiveness [10]. In a similar vein, Ma et al. (2019) proposed a hierarchical supplemental location-allocation model for Disaster Supply Warehouses (DSWs), emphasizing resource consolidation [4]. Both studies underscore the importance of strategic planning in the spatial arrangement of emergency supplies. Lodree and Taskin (2008) introduced an insurance policy framework to assist decision-makers in balancing risks and benefits associated with stocking decisions [11]. This study laid the groundwork for understanding the risk management aspect of emergency stockpiling. Liu et al. (2018) further contributed to this area by developing a cooperative contingency inventory model and proposing game theory-based coordination mechanisms to facilitate supply chain cooperation [12]. Roni et al. (2015) investigated a hybrid inventory management strategy that catered to both regular and emergency demands [13]. Their approach of employing interpolation and mixed integer programming for rapid response optimization offered insights into efficient space management in emergency logistics situations. Complementing this, Geng et al. (2021) incorporated human factors, like victim pain perception costs, into their model, emphasizing the need for human-centric approaches in emergency supply logistics [14]. Uncertainties and dynamic inventory replenishment and carryover are considered [15]. Iqbal et al. (2018) recommended statistical models for assessing the location and distribution of relief supplies in natural disaster management [16]. Their method of using the PRISM model checker for real-life scenario analysis provided a valuable tool for optimizing storage space allocation decisions. This perspective was aligned with Shehadeh and Tucker (2022) focus on prepositioning inventory and determining warehouse locations for disaster seasons, emphasizing the need for strategic preparation and planning [17]. Wang and Zhu (2022) addressed specific challenges such as cross-border infectious diseases, material stockpile imbalances, and regional supply differences by applying an improved adaptive genetic algorithm [18]. Their approach was instrumental in optimizing storage locations in response to varying emergency scenarios.

Collectively, these studies contributed diverse perspectives on strategic storage location assignment in emergency reserve warehouses. They provided a foundation for the development of comprehensive models that integrate logistical efficiency, strategic planning, risk management, and human-centric considerations for effective emergency stockpile management.

2.2. Storage Location Assignment Problem in Warehouses

The storage location assignment problem in warehouses is a complex task involving the strategic placement of diverse goods across various shelf positions to minimize inventory costs, maximize operational efficiency, and optimize space utilization [19,20]. This process integrates various elements such as equipment, tools, workers, shelf types, goods characteristics, and spatial planning.

Several studies have made significant contributions to this field. Yan et al. (2018) focused on storage optimization and assignment for electronic products in three-dimensional warehouses, employing dynamic strategies and developing a multi-objective model tailored for such environments [3]. Their approach highlighted the need for adaptable and versatile storage solutions in modern warehouses. Bassey and Zelibe (2022) proposed a novel two-level storage location-inventory system constrained by response times, integrating lateral transhipment and implementing an (S-1, S) inventory control strategy [21]. This study reflects the evolving complexity of warehouse management, emphasizing the integration of inventory systems with spatial organization. A novel four-quadrant judgment framework is established to optimize storage location allocation by analyzing the correlation and turnover frequency of items [22]. Lei et al. (2019) developed an integrated optimization model for mixed cargo crating and storage location assignment, focusing on reducing the operational time of stacker cranes [23]. Park et al. (2006) and Zhang et al. (2020) investigated partitioned storage operations and e-commerce warehouse models, respectively, each contributing unique perspectives on storage efficiency and classification [24,25]. These studies highlight the need for customized approaches in different warehouse settings. Guerriero et al. (2013) addressed product distribution in multi-story warehouses, aiming to minimize lead times, inventory, and logistics costs while maintaining high service levels [26]. This approach is crucial in high-density storage environments. Muppani and Adil (2008) utilized a Simulated Annealing Algorithm for class formation and storage location assignment, considering product combinations and associated costs [27], while Jiao et al. (2018) built a multi-objective model emphasizing automated warehouse operation times and product stacking strategies [28]. Heragu et al. (2005) and Chan and Chan (2011) added dimensions of collaborative scheduling and real-case simulation studies, respectively, to the discourse on warehouse storage assignment, highlighting the importance of practical, real-world applications and the need to match storage systems with customer order types [29,30].

Collectively, these studies illuminate the diverse factors influencing storage location assignments, such as frequency of access, shelf stability, and cargo relevance. However, research specifically addressing storage location assignments in emergency reserve warehouses remains limited. This gap calls for more targeted research that adapts these broader insights to the unique demands of emergency material reserves. By integrating existing knowledge with specific analyses of emergency warehouses, as in the case of the Fangshan District emergency material reserve warehouse, we can develop optimized storage location assignment models that cater to both planar and three-dimensional storage needs in emergency scenarios.

2.3. Multi-Objective Optimization in Storage Location Assignment

Multi-objective optimization (MOO) plays a crucial role in addressing complex problems that require simultaneous optimization of multiple objectives, particularly in the intricate domain of storage location assignment in emergency reserve warehouses [31,32]. The interrelated nature of objective functions in this field demands an approach that can effectively balance and optimize diverse goals.

Ma et al. (2023) laid the groundwork by introducing MOO and NSGA-II foundations, reviewing enhancements to NSGA-II, and exploring its engineering applications, which opened new directions for MOO in NSGA-II [33]. Complementing this, Nastasi et al. (2018) and Peng et al. (2021) evaluated popular MOO algorithms in automated warehouses, including NSGA-II and the Strength Pareto Genetic Algorithm 2 [5,6]. They highlighted the utility of these algorithms in handling complex warehouse optimization problems, including storage location assignment and crane scheduling in the iron and steelmaking industries. Yan et al. (2018) and Lee et al. (2020) focused on specific aspects of storage optimization [3,7]. Yan et al. (2018) developed a multi-objective model for storage location assignment of electronic products in three-dimensional warehouses using a dynamic strategy [3], while Lee et al. (2020) presented an integrated approach employing MOEAs to improve the efficiency of warehouse order-picking operations [7]. Dkhil et al. (2018) and Zhang et al. (2023) explored novel applications of MOO in maritime container terminals and non-traditional layout warehouses, respectively [8,34]. Dkhil et al. (2018) proposed a multi-objective Tabu Search algorithm to solve the integrated problem of location assignment and Straddle carrier Scheduling [34], while Zhang et al. (2023) devised an optimization algorithm for storage location assignments in non-traditional layouts, focusing on order-picking efficiency and shelf stability [8]. Wang et al. (2019) and Roshan et al. (2019) further expanded the scope of MOO [35,36]. Wang et al. (2019) established a model for flood control material storage location allocation, emphasizing retrieval efficiency and shelf stability, and transformed a multi-objective problem into a single-objective one using a weighting method [35]. Roshan et al. (2019) developed a product layout model in a class-based storage system, considering energy consumption optimization and sustainability [36].

These studies demonstrate the effectiveness of heuristic algorithms, particularly NSGA-II and its variants, in solving multi-objective optimization problems in warehouse storage location assignments. Their enhanced global search capabilities and convergence make them suitable for addressing the unique challenges and objectives in emergency reserve warehouses. By leveraging these advanced algorithms, it is possible to achieve a more optimized solution for the storage location assignment problem, ensuring efficient and effective management of emergency reserves.

3. Data and Methods

In this section, the methodology and data employed in the study are presented, with a focus on emergency reserve warehouses. The approach includes a detailed problem description and model formulation, followed by an extensive process of model building. This encompasses the establishment of key assumptions and variable settings. Subsequently, the study delves into specialized modelling techniques for different types of pallets and storage scenarios. This multifaceted approach is designed to address the complexities of storage location assignment in emergency reserve warehouses, taking into account various scenarios and pallet types.

3.1. Problem Description and Model Formulation

Compared with the general warehouse, the emergency supplies have a large reserve, relatively few types of characteristics, and at the same time will be periodically replaced according to the specific circumstances, so the emergency supplies reserve studied in this paper should be used in the randomized classification storage strategy.

The focus of this study is emergency reserve warehouses, which primarily store emergency supplies for regional needs. These warehouses typically house supplies for disaster relief, such as tents, clothing, and equipment, but rarely include items requiring refrigeration or special storage conditions. Due to the diverse nature and size of stored materials, these warehouses are usually equipped with both three-dimensional and planar storage areas. Standard pallet-sized materials are confined to the three-dimensional area, while oversized items like tents, unsuitable for standard pallets (special pallets), are stored in the planar area.

3.1.1. Storage Area Configuration

The warehouse uses 1000 × 1200 specifications of the standard pallet; tents and other materials over the pallet specifications are stored only in the planar storage areas. In order to improve operational efficiency, the warehouse customized 1000 × 2200 specifications of the special pallet used to be more than the pallet specifications of the materials. We ensured that all materials could be palletized for storage.

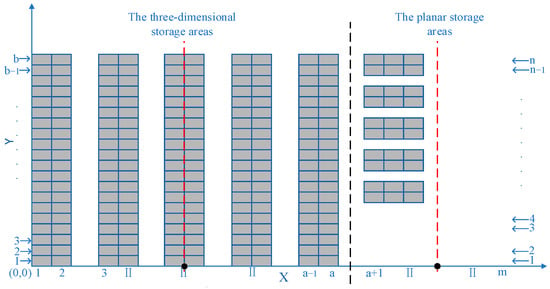

- The emergency reserve warehouses are divided into three-dimensional and planar areas, as shown in Figure 1.

Figure 1. Emergency reserve warehouse storage area.

Figure 1. Emergency reserve warehouse storage area. - Each area has an entrance and exit linked to a common temporary storage zone.

- The three-dimensional area consists of a rows, with each row having b columns and c layers.

- Coordinates are set with the southwest corner as the origin; the closest shelves to the origin are labelled as the first row and column, and the bottom layer as the first layer.

- Planar storage is divided into e sections, each containing q×w cargo spaces, totaling e×q rows and e×w columns.

- Coordinates in the planar area start from (a+1,1,1), with the xth row and yth column marked as (x, y, 1).

3.1.2. Pallet Specifications

- The special pallet occupies two standard cargo spaces, with coordinates taken from the standard space closest to the origin.

- Both normal and standard pallets have the same dimensions in the warehouse, with specialist elongated pallets being approximately twice as long and designed for materials exceeding standard pallet dimensions.

3.1.3. Storage Scenarios

- Scenario 1: Standard pallet materials are stored exclusively in the three-dimensional area, while specialist pallet materials are confined to the planar area.

- Scenario 2: Removes area restrictions, allowing both standard and specialist pallets to be stored in either the three-dimensional or planar storage areas. This scenario considers reducing annual palletizing costs and other expenses, taking into account the height and weight of materials to avoid unstable stacking.

3.1.4. Objective

The study aims to optimize cargo space utilization in the emergency reserve warehouses, using standard pallets as the smallest storage unit and accommodating the different pallet specifications. The model will explore both storage scenarios, assessing their effectiveness in terms of cost reduction and efficient space utilization.

3.2. Model Building

3.2.1. Assumptions

To simplify the model and align it with the practical context of emergency reserve warehouses, the following assumptions are made for the optimization model of storage location assignment:

Single material per pallet: Each pallet in the warehouse stores only one type of emergency material. The quantity of material on each pallet is determined by the material’s weight and package size, arranged by professionals. The same quantity and stacking mode apply whether materials are stored in the three-dimensional or planar storage areas.

Known rate and mass: The common rate and mass of each pallet of material in the warehouse are constants. Pallet locations within the warehouse are represented using coordinates (, , ).

Uniform mass distribution: The mass of material on each pallet is uniformly distributed, and the stored material does not extend beyond the pallet.

Storage space specifications: Each storage space in the three-dimensional storage area is uniform in size. In the planar storage area, each section can be divided into q × w cargo spaces, each capable of storing a standard pallet or two connected cargo spaces for a special pallet.

Storage within bay limits: All palletized materials must be stored within the designated bay, not exceeding the bay height in the three-dimensional storage area.

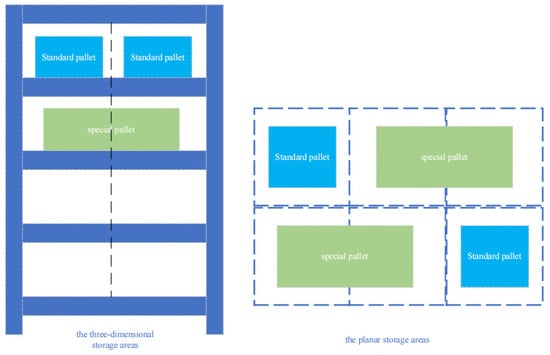

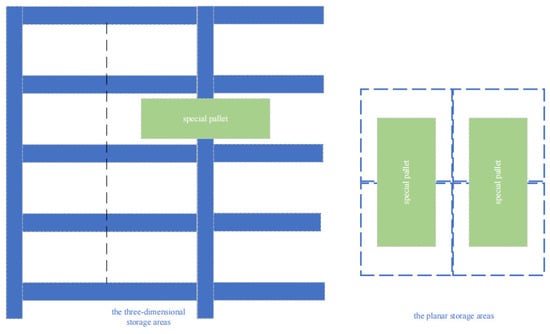

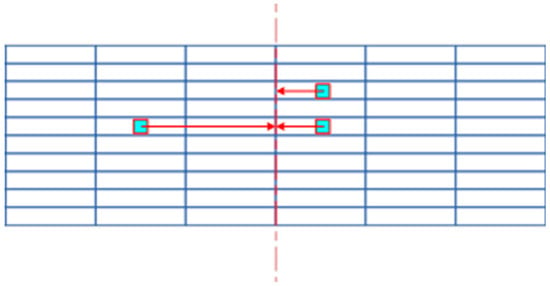

Specific pallet storage: The storage of standard and special pallets follows a specified pattern (Figure 2), ensuring all pallets are stored within delineated bays and avoiding unallowable storage situations (Figure 3).

Figure 2.

Allowable occurrences of pallet storage.

Figure 3.

Unallowable pallet storage situations.

Exclusion of certain factors: The model does not account for the mass and thickness of racks and pallets, distances between racks, aisles in the warehouse, or stacking in planar storage areas.

Forklift usage: Only forklift trucks are considered for warehouse operations.

Forklift operation time: The average time for forklifts to reach a storage area and adjust to pick up a standard pallet is , for a special pallet is , and the average manual handling time after reaching the storage area is .

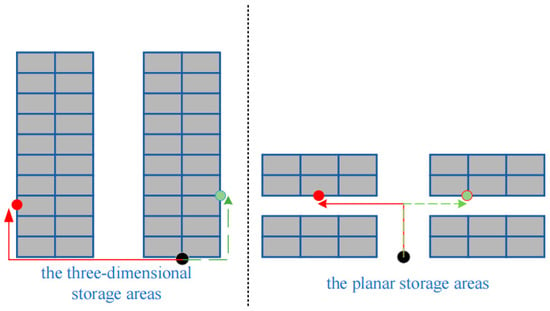

Constant forklift speed: Forklift speeds in the warehouse are considered as a fixed average, disregarding acceleration, deceleration, cornering, or power constraints.

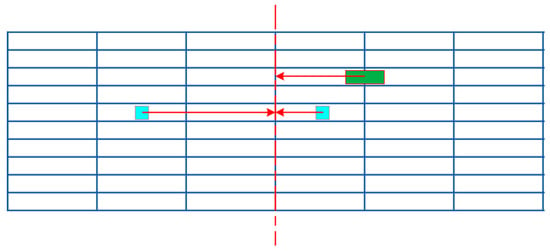

Forklift operational constraints: In each operation, the forklift can only transport one standard pallet or one special pallet from either the three-dimensional storage area or the planar storage area. The designated routes for the forklift to access these pallets are illustrated in Figure 4. The routes are marked with red dots and lines for the standard pallets and green dots and lines for the special pallets. No other scenarios or variations in the forklift’s route or capacity are considered in this model. This assumption ensures a consistent and streamlined approach to evaluating and optimizing the forklift’s operational efficiency within the warehouse.

Figure 4.

Example of a forklift’s route of travel to access a pallet.

Forklift capacity: Forklifts can handle one standard or one special pallet at a time in either the three-dimensional or planar storage area. Forklift routes for accessing pallets are predefined.

Material quality and efficiency: The quality of the material does not impact the efficiency of forklift operations, and splitting operations in the storage area is not considered.

Handling of excess material: Surplus material from inbound and outbound operations that do not meet the standard or special pallet quantities is not returned to storage but placed in the bulk storage area.

Storage area access: Each storage area has a centrally located entrance and exit on the south side, with operations accessing only their respective areas, disregarding the distance between the entrance and exit.

Exclusion of other operations: The effects of other operations within the warehouse are not considered in this model.

These assumptions are designed to streamline the model, focusing on the key aspects of cargo space assignment while omitting less impactful or overly complex factors. They provide a structured framework for analyzing and optimizing storage strategies in emergency reserve warehouses.

3.2.2. Variable Settings

: the average speed of the forklift moving in the x-direction;

: the average speed of the forklift moving in the y-direction;

: the average speed of a forklift moving in the z-direction;

: the number of the row, where pallet i is stored. If pallet i is a special pallet, that is stored in the planar area, then is the left row that is occupied by the special pallet, i.e., the special pallet uses the rows and ;

: the number of the column, where pallet i is stored. If pallet i is a special pallet, that is stored in the three-dimensional area, then is the first column that is occupied by the special pallet, i.e., the special pallet uses the columns and ;

: the number of the lever, where pallet i is stored. If pallet i is stored in the planar area it holds ;

the number of levels of pallet i storage bays;

: the length and width of individual bays in a three-dimensional storage area;

h: height of a single bay in a three-dimensional storage area;

: length and width of individual bays in planar storage areas;

: average time spent by forklifts adjusting their operations while handling standard pallets in a three-dimensional storage area;

: average time spent by forklifts in a three-dimensional storage area to adjust their operations when handling special pallets;

: average time of manual handling operations for pallet i in planar storage areas;

: Test the parity of the value of the coordinates xi of tray i in the three-dimensional storage area, if , then , if , then ;

: Test the parity of the value of the coordinates of tray i in planar storage areas, if , then , if , then ;

: The generic value of the reserve corresponding to pallet i;

: Determine if tray i belongs to special pallet, if so , if not then ;

: Determine the attribution of goods i, , when , the goods are , when , the value of ;

: Whether pallet i is stored in the th bay of the x row of shelving in the three-dimensional storage area;

: Whether pallet j is stored in the th bay of the x row of shelving in the three-dimensional storage area;

: Whether pallet j is stored in the th bay of the y column of bays in planar storage areas;

: Determine whether the materials stored on pallet i and pallet j are the same material, if they are the same material then , if not then ;

I: Use of standard pallets, ;

S: Use of special pallets, ;

R: Simultaneous use of standard and specialist pallets, , ,;

: The number of standardized bays that can be divided in each small area within a flat storage area is the number , q denotes the number of rows, and w denotes the number of columns.

3.3. Modeling of Space Assignment for Standard Pallets

The model emphasizes the importance of ‘high generality’ materials—those commonly needed across various types of disasters. The higher the number of applicable disasters, the higher the versatility of the emergency supply reserve, and the more they should be stored closer to the exit of the warehouse, and the opposite is true for the materials with lower versatility. Unlike standard warehousing operations that assess goods based on turnover, emergency supply dispatches, marked by their unpredictability, require a broader assessment of material utility. This is quantified by evaluating the frequency of each type of reserve material across a spectrum of disaster scenarios. Therefore, the model aims to strategically position materials with higher generality closer to the entrance and exit of the warehouse. This strategic placement is designed to minimize the travel distance for forklifts and other equipment, thus, reducing the time required for loading and unloading operations in emergency situations.

Based on the foundational assumptions, the model assigns storage coordinates (xi, yi, zi) to the ith standard pallet in a three-dimensional storage area. Equation (1) for calculating the access time incorporates the impact of the pallet’s shelf position on handling operations within this area:

The first part of Equation (1) indicates the moving time that the forklift needs in the three-dimensional storage area in the horizontal direction of the handling operation. Txi is the parity test coefficient of the value of xi. When the value of xi is odd, the value is 0, and vice versa. When the value of xi is an even number of shelves, take the value of 1. The second part of the forklift is in the vertical direction of the handling operation of the moving time. The last part of the equation is the average handling time of the forklift to adjust a standard pallet. The sum of these three components gives the total time taken for handling operations of a standard pallet in the three-dimensional storage area. This comprehensive calculation considers the specific positional factors within the warehouse, ensuring a more accurate and efficient approach to handling and storage operations.

In the context of a planar storage area, the access time calculation for a standard pallet differs from that in a three-dimensional storage area, primarily due to the absence of vertical displacement for the forklift. However, the handling time generally increases in planar areas. The equation to calculate the access time in a planar storage area is as follows:

The first part of Equation (2) indicates that the forklift in the planar storage area is in the horizontal direction of the handling operation moving time. Tyi is the parity test coefficient of the value of yi. When the value of yi is odd, take the value of 1, and vice versa. When the value of yi is even, take the value of 0. The second part of the forklift in the planar storage area handles the standard pallet of the average time spent on manual work. The sum of these two components gives the total handling operation time for a standard pallet in the planar storage area. This formula reflects the unique operational dynamics of planar storage, considering the reduced complexity of movements but increased manual handling compared to three-dimensional storage.

Incorporating the high generality material priority target into the model, the handling time of each pallet is adjusted by multiplying it with its corresponding generality coefficient. This approach is based on the principle that materials with higher generality (i.e., those more commonly used in various emergency scenarios) should incur less handling time in the warehouse. The rationale is to expedite the handling process in emergencies, ensuring quick and efficient access to essential supplies. The optimization model for cargo space assignment in both the three-dimensional and planar storage areas can be expressed by the following formula, where pi represents the generality coefficient of the materials stored on the pallet, and α and β are coefficients determining the storage area in which the pallet is located.

Shelf stability objective: this study focuses on optimizing cargo space assignment in an emergency warehouse, with pallets as the primary unit. Due to significant variations in the weight of goods on each pallet, the study proposes a simplified method to ensure shelf stability by calculating the center of gravity. To facilitate this calculation, the weight of the material assigned to each standard pallet i is multiplied by the height of its assigned cargo space. In this model, the height of the cargo spaces in the planar storage area and the first layer of the three-dimensional storage area is set to zero. This approach is used to compute the overall center of gravity of the shelves, ensuring stability in the warehouse layout. The equation for this calculation can be expressed as follows:

In a three-dimensional storage area, the concentration of heavy pallets on one side of a shelf row can lead to instability. To ensure that reserve materials are evenly distributed, thereby preventing shelf instability caused by uneven load-bearing on either side, consider the scenario depicted in Figure 5. The blue point illustrates the position of a standard pallet. The aim is to minimize the disparity in the weight of reserve materials on each side of the shelf and their distance from the shelf’s central axis. This concept leads to Equation (5), where assesses whether pallets are on the same carrier.

Figure 5.

Schematic diagram of standard pallet storage in single-row racking.

Consequently, we derive the formula for standard pallet stabilization in relation to the shelf’s overall center of gravity, as represented in Equation (6). This formula is pivotal in maintaining shelf balance, crucial for safe and efficient warehouse operations, especially in an emergency context where quick and stable access to supplies is essential.

In the context of emergency reserves, materials prepared for disaster response are often procured in bulk by the government. Moreover, when a disaster occurs, these materials typically require large-scale transportation. To facilitate this, it’s crucial to arrange similar emergency reserve materials in close proximity within the warehouse. This proximity simplifies large-scale retrieval and storage operations.

To quantify this arrangement, we consider the standard pallet i with storage coordinates (xi, yi, zi), and a similar reserve material pallet j with coordinates (xj, yj, zj). From this, Equation (7) is derived, where Oij is an indicator function determining if pallets i and j contain the same type of material. Oij assumes a value of 1 when both pallets belong to the same category of reserve materials and 0 otherwise:

The objective is to minimize the positional differences between all standard pallets containing the same type of reserve materials. A lower value in this calculation is preferable, as it indicates closer proximity of similar materials, facilitating more efficient storage and retrieval processes. This concept is encapsulated in Equation (8):

3.4. Modeling Cargo Assignment for Special Pallets

Special pallets, due to their larger size, occupy two adjacent cargo spaces. As outlined in the previous section’s basic assumptions, they require specific placement within the warehouse. For programming purposes, the identification coordinates of special pallets are designated similarly to standard pallets. Additionally, the adjacent cargo space is reserved exclusively for special pallet use and cannot accommodate other pallets.

When prioritizing special pallets with high generality, the model first considers their placement in the three-dimensional storage area, which is in line with the high generality priority principle. The impact of the special pallets on handling operations, given their occupation of two adjacent standard cargo spaces, is quantified in Equation (9), which calculates the handling time for special pallets in the three-dimensional storage areas.

The first component of Equation (9) represents the forklift’s horizontal movement time during handling operations in the three-dimensional storage area. Here, Txi, the parity test coefficient for xi, is assigned a value of 0 when xi is odd, indicating an odd-numbered shelf row. Conversely, for even-numbered shelves, Txi is set to 1. The second part of the equation calculates the forklift’s vertical movement time in the handling operation. The final segment quantifies the average time the forklift spends adjusting while managing the special pallet. This adjustment time is crucial for ensuring safe and efficient pallet handling. The sum of these three components—horizontal movement, vertical movement, and adjustment time—constitutes the total operation time required for handling special pallets within the three-dimensional storage area. This comprehensive measure is integral to optimizing warehouse operations, particularly in managing diverse pallet types under varying storage conditions.

When in a planar storage area, the handling time for special pallets is:

In Equation (10), the initial segment calculates the horizontal movement time of the forklift during handling operations within the planar storage area. The parity test coefficient, Tyi, corresponds to the value of yi. It assumes a value of 1 when yi is odd, reflecting an odd-positioned storage space, and conversely, it is set to 0 for even-valued yi, indicating an even-positioned space. The second portion of the formula accounts for the average time the forklift spends on manual operations specific to handling special pallets in the planar storage area. The aggregate of these two components yields the total operation time for managing special pallets in the planar storage environment. This calculation is essential in optimizing the handling efficiency of special pallets, a critical aspect in streamlining operations within the spatially diverse environment of planar storage areas.

Incorporating a versatility factor into the management of emergency stockpiles stored on special pallets leads to the development of a high-priority formula for these pallets, denoted as Equation (11). This formula is essential for prioritizing highly versatile materials in emergency situations:

Furthermore, the stability goal for the overall center of gravity of shelves storing special pallets is critical. The calculation methodology for special pallets aligns with that for standard pallets in terms of assessing their impact on vertical shelf stability. However, in a three-dimensional storage area, the center of gravity for special and standard pallets on the shelf varies, as illustrated in Figure 6. Here, the green point represents the position of special pallets, while the blue point indicates standard pallets. Assuming a uniform distribution of material mass in each cargo space, we can derive a shelf-level stabilization formula for special pallets:

Figure 6.

Schematic of standard and special pallet storage in single-row racking.

Consequently, we obtain Equation (12) for standard pallet stabilization concerning the shelf’s overall center of gravity:

Additionally, to calculate the proximity of special pallets storing the same type of goods, similar to the approach for standard pallets, we use their identifying coordinates. This approach results in Equation (13), which is instrumental in ensuring that similar goods are stored adjacently for optimized retrieval and storage efficiency:

These equations collectively enhance the operational efficiency of emergency stockpile warehouses, ensuring stability and accessibility of vital emergency supplies.

3.5. Modeling Planar and Three-Dimensional Storage Integration in Different Contexts

This study addressed the cargo space assignment optimization problem by examining two distinct scenarios:

Scenario 1: This scenario restricts special pallets to the planar storage area and standard pallets to the three-dimensional storage area, reflecting the warehouse’s current storage methodology.

Scenario 2: Both special and standard pallets are permitted to be stored in either the three-dimensional or planar storage areas, offering a more flexible storage approach.

For Scenario 1, the expression for calculating the overall inbound and outbound travel time for cargo space assignment is detailed in Equation (14). Conversely, Scenario 2 introduces a high versatility priority target for pallets, represented in Equation (15). These equations are pivotal in evaluating the efficiency of each scenario, aiding in determining the most effective cargo space assignment strategy for emergency warehouses.

In optimizing the overall shelf stability objective, this study distinguishes between two distinct scenarios: Scenario 1, which exclusively addresses the access of standard pallet reserve materials, with the formula for calculating overall shelf stability in this context delineated in Equation (16); and Scenario 2, which broadens the scope to encompass both standard and special pallet reserve materials within the three-dimensional storage area, with the corresponding shelf stability calculation articulated in Equation (17). These scenarios facilitate a nuanced analysis of shelf stability, tailored to the specific storage configurations and pallet types within an emergency warehouse setting.

Regarding the proximity targets for the same type of stockpile, the calculation remains consistent across both scenarios. The formula for determining the adjacency of similar stockpiles in both Scenario 1 and Scenario 2 is expressed in Equation (18).

Upon a comprehensive analysis of the preceding research, this study addresses the integrated space assignment optimization problem for a Fangshan District emergency reserve warehouse, encompassing both planar and three-dimensional storage areas. This optimization challenge is defined by two interrelated and mutually constraining objective functions. To address this complexity, the study consolidates these functions into a singular multi-objective decision optimization problem, as demonstrated below:

The optimization model is subject to several key constraints:

Equation (19) represents the multi-objective optimization function for Scenario 1. Equation (20) corresponds to the multi-objective optimization function for Scenario 2. Equation (21) ensures the correct placement of special pallets in the three-dimensional storage area. Equation (22) mandates that the two cargo spaces occupied by special pallets in this area are adjacent and not encroached upon by other pallets. Equation (23) governs the proper positioning of special pallets in the planar storage area. Equation (24) specifies that two adjacent cargo spaces in the planar area are to be occupied by special pallets. Equation (25) states that each cargo space in the warehouse is to be used only once. Equation (26) dictates the standard pallet storage locations under Scenario 1. Equation (27) determines the storage locations for special pallets under Scenario 1. Equation (28) defines the maximum range of values for pallet locations under Scenario 2. These formulas and constraints collectively form a robust framework for the multi-objective optimization of cargo space assignment in an emergency reserve warehouse, ensuring efficient and effective use of storage space in both planar and three-dimensional areas.

The constructed objective functions in this paper exhibit mutual constraints. Objective function one aims to position high generality goods as close to the exit as possible, while objective function two focuses on placing goods on the shelf as close to the ground as possible, aiming to reduce shelf moment difference. This necessitates concentrating goods of the same kind on both sides of the shelf center or dispersing them symmetrically on the left and right sides of the shelf. However, optimizing either objective function may worsen the other. When operating time is reduced, and similar goods are stored close to each other, it concentrates them near the exit, deteriorating shelf stability. Conversely, improving shelf stability by clustering similar goods near each other also concentrates them at the center of the shelves, increasing warehouse operating time. Thus, optimizing one or both objective functions may negatively impact other function values.

4. Model Solving and Simulation Analysis

This section details the procedures and outcomes of solving the model and conducting simulation analyses for optimizing storage location assignments in emergency reserve warehouses. The approach integrates innovative algorithm designs, rapid non-dominated sorting methods, and comprehensive data analysis to address the complexities of cargo space allocation. The following subsections outline the specific methodologies and findings.

4.1. Design of Solution Algorithms

4.1.1. Algorithm Coding Design

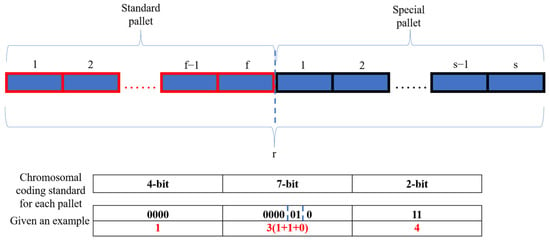

The initial step in our algorithm design involves chromosome coding, which is essential for binary division into two sub-string sequences of chromosomes. As depicted in Figure 7, the first f chromosome segments represent the standard pallet of materials, while the subsequent s segments are allocated for the special pallets, such as tents and materials exceeding standard pallet dimensions. The length of each code segment is tailored to the specific requirements of the emergency stockpile warehouse.

Figure 7.

Chromosome coding schematic.

In the warehouse’s three-dimensional storage area, there are five groups of through racks arranged back-to-back, with each row convertible into a designated number of standard cargo spaces. The planar storage area consists of 14 smaller sections, each comprising a specific number of standard cargo spaces. The coordinates of each pallet in the warehouse are represented by a 13-bit binary sequence, correlating to the xi, yi, and zi coordinates.

In the warehouse, the maximum range of xi is 1~16, the maximum range of yi is 1~20, and the maximum range of zi is 1~4, xi, the coordinates of the 4-bit binary encoding, can be expressed as a decimal number of 0~15, which is then incremented by 1 to convert to a decimal code, resulting in a range from 1 to 16; yi is represented by a 7-bit binary encoding expression, divided into 4 + 2 + 1 of the three segments of binary coding. The first 4-bit code also represents values from 1 to 16, while the last two segments are converted to corresponding decimals, representing values from 0 to 3 and 0 to 1, respectively. The conversion of the three sections of the code can be expressed after the addition of 1~20 decimal numbers. Similarly, zi is encoded with a 2-bit binary code, representing decimal numbers from 0 to 3, which are then incremented by 1 to express values from 1 to 4. After conversion, the three sections of the code can express decimal numbers ranging from 1 to 20.

This coding effectively represents the pallet’s precise location within the warehouse. For instance, as shown in Figure 7, the example pallet located at (1, 3, 4) corresponds to row 1, column 3, and level 4 in the warehouse.

This chromosome coding approach is instrumental in enabling an accurate and efficient algorithm for solving the model, particularly in the complex environment of emergency stockpile warehouses with diverse storage requirements.

4.1.2. Rapid Non-Dominated Sorting

In addressing the cargo space allocation problem presented in this study, we implement a rapid non-dominated sorting method. Let us assume our population size is P. This represents the number of individuals dominating P, and np is the set comprising other individuals that are dominated by individual P. Each individual in this context corresponds to a distinct cargo space allocation solution. If we compare any two individuals, say i and j, and find that all function values of individual i are less than those corresponding to individual j, it implies that the individual i’s solution is superior to that of individual j. The process unfolds as follows:

Step 1: Calculate np and bp for each individual in the population;

Step 2: Identify individuals with bp = 0 and place them into set F1. This set, F1, represents the foremost tier of non-dominated solution sets.

Step 3: For all individuals i in F1, find their corresponding set Si. Iterate through all individuals q within Si, decrementing np by 1 for each. If np drops to 0, add individual q to the subsequent set F2.

Step 4: Employing F1 as the initial non-dominated tier, apply the procedure from Step 3 to the individuals in F2. Continue this pattern until all tiers within the population are classified.

This method is crucial for efficiently sorting and prioritizing cargo space allocation solutions, ensuring the most effective strategies are identified for implementation in the emergency warehouse context. It enables a systematic and hierarchical evaluation of potential solutions based on their dominance, streamlining the decision-making process in complex operational environments.

4.1.3. Crowding Comparison Calculator

This subsection focuses on the concept of crowding in the context of our solution algorithm. Crowding refers to the differentiation of an individual solution i within the population, particularly in relation to its neighboring solutions (i − 1 and i + 1). When individuals i − 1 and i + 1 are more widely spaced, it indicates a greater crowding for individual i. This spatial distinction is crucial as it enhances population diversity by promoting more unique solutions.

Crowding is calculated by the equation:

where id denotes the crowding at point i, denotes the jth objective function value for i + 1 individuals, and denotes the jth objective function value for i − 1 individuals.

After the previous two steps, each individual i in the population is assigned a non-dominated sequence, determined by the non-dominated ordering imark (level) and a crowding degree id. Subsequently, a crowding comparison operator is established, grounded on both the non-dominated sequence and the crowding degree.

This approach is integral to the optimization process, as it allows for a refined selection of solutions based on not just their non-dominance but also on the diversity they bring to the solution pool, thereby enhancing the overall effectiveness of the algorithm in the operations research domain.

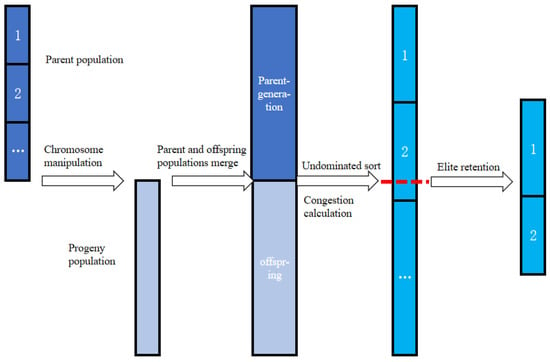

4.1.4. Elite Retention Strategies for Merging Parent and Child Populations

The elite retention strategy is a pivotal approach in evolutionary algorithms, particularly when merging parent and offspring populations. It involves combining these populations and subjecting them to the same competitive mechanism to ensure the preservation of the most superior individuals. This approach significantly mitigates the loss of previously discovered optimal solutions. The elite retention strategy map, as illustrated in Figure 8, outlines the operational steps as follows:

Figure 8.

Elite retention strategy map.

Step 1: The initial population undergoes genetic operations and is then merged with its offspring, forming an augmented population double its original size (2N).

Step 2: This expanded population of 2N undergoes rapid non-dominated sorting. From this process, the top N individuals with the lowest ordinal values are selected. In cases where only a subset of individuals with a specific ordinal value qualify for the top N, crowding degree is employed as a deciding factor. Individuals with higher crowding values are chosen to advance into the subsequent population.

4.1.5. Chromosome Manipulation

The chromosome manipulation process is a critical component of our optimization model, particularly for cargo space allocation. It involves several key operations:

Selection operation: First, fast non-dominated sorting and congestion distance calculations are applied to all individuals in the population. This process evaluates the relative superiority and inferiority of each individual, enabling the selection of the best performers through an elite strategy, thereby forming a new, optimized population.

Crossover operation: In the context of this paper, each chromosome represents a unique cargo space allocation solution. The crossover operation involves creating a new cargo space allocation solution by interchanging the cargo space numbers at specific positions. We employ partial matching crossover for this purpose. During each iteration, the first two chromosomes, chosen based on the elite retention strategy, serve as the parent individuals for crossover. A random crossover point is generated, and the partial gene segments post this point are exchanged, resulting in a novel individual.

Mutation operation: Mutation is instrumental in enhancing the population’s diversity and preventing premature convergence. For the cargo space assignment problem addressed in this paper, we draw inspiration from similar optimization problems to define a reasonable mutation probability. This approach involves mutating the previously established binary chromosome codes, ensuring a broad exploration of potential solutions and maintaining genetic variety within the population.

4.2. Simulation of Cargo Space Assignment Optimization for Emergency Reserve Warehouses

4.2.1. Data Collection and Parameterization

This subsection focuses on the optimization model for cargo space assignment in integrated planar and three-dimensional storage areas of emergency reserve warehouses under various scenarios. We adopt a non-dominated genetic algorithm with an elite retention strategy to solve the model. This approach is applied to an empirical analysis of an emergency reserve warehouse in Fangshan District, aiming to validate the proposed cargo space assignment optimization model and assess the impact of different scenarios on warehouse space allocation.

The warehouse, covering approximately 900 square meters, is equipped with both three-dimensional and planar storage areas. It utilizes standard pallets for most goods, while materials exceeding pallet specifications are stored exclusively in the planar area. To enhance operational efficiency, special pallets are custom-designed for future use with oversized materials.

The emergency reserve warehouse currently houses 13 types of goods distributed across 422 pallets. The basic data for these items are outlined in Table 1.

Table 1.

Basic data on emergency reserves in warehouses.

The three-dimensional storage area comprises five groups of back-to-back through racks, with each row accommodating a certain number of standard cargo spaces. The planar storage area is divided into 14 sections, each partitioned into additional standard cargo spaces. The detailed specifications and other related parameters are presented in Table 2.

Table 2.

Relevant parameter data.

4.2.2. Model Solving and Results Analysis

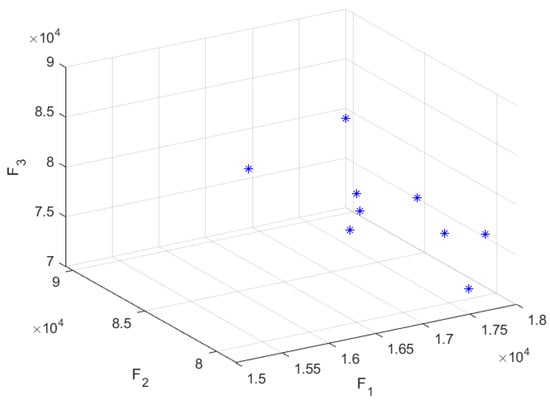

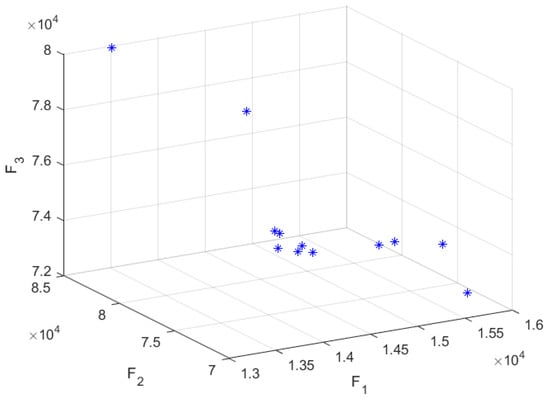

In this subsection, we input the current cargo space distribution data into the developed cargo space allocation model and calculate the initial values of the three objective functions. To solve the model under both scenarios, we employ the enhanced NSGA-II algorithm with an elite retention strategy, as previously discussed. The algorithm’s parameters are set with a maximum iteration limit of 500 generations, a population size of 100, a crossover probability of 0.8, and a mutation probability of 0.1. MATLAB 2024a is utilized to execute the model, with the results illustrated in Figure 9 for Scenario 1 and Figure 10 for Scenario 2.

Figure 9.

Scenario 1 model solution maps.

Figure 10.

Scenario 2 model solution maps.

In Scenario 1, nine feasible solution sets are identified, while Scenario 2 yields twelve sets, as detailed in Table 3. These solutions showcase the objective function values (rounded to two decimal places), highlighting the interdependencies among the three objectives. These results demonstrate the intricate balance and mutual constraints between the prioritization of high-frequency shipments, shelf stability, and the adjacency of similar goods in the warehouse. The analysis provides vital insights into the effectiveness of the proposed models in optimizing cargo space allocation, thereby enhancing operational efficiency in emergency reserve warehouses.

Table 3.

Objective function value.

In evaluating the optimization efficiency of our model for cargo space allocation under different scenarios, we compared the average improvements in three objective functions with the initial state. The results, as shown in Table 4, illustrate significant enhancements in all objectives.

Table 4.

Optimizing efficiency in different scenarios.

In our analysis of Scenario 1 for cargo space assignment optimization, the efficiency in optimizing high versatility material prioritization is notable at 28.48%. The overall stability of the shelf shows an even more significant improvement, with an optimization efficiency of 37.78%. Additionally, the efficiency in optimizing the adjacency of similar materials is 28.21%. These figures underscore a marked enhancement in the overall cargo space optimization process, with all three objectives demonstrating substantial improvements.

Comparatively, in Scenario 2, the optimization efficiency for prioritizing high versatility materials escalates to 38.46%, surpassing Scenario 1 by 9.98%. The shelf stability objective shows an efficiency improvement of 41.48%, a 3.7% increase from Scenario 1. The efficiency in optimizing the adjacency of similar materials reaches 31.46%, improving by 3.25% over Scenario 1. This highlights that Scenario 2 significantly reduces operation time for high-versatility materials, with more modest yet notable enhancements in shelf stability and the proximity of similar reserve materials.

Table 5 showcases the dynamic shifts in cargo space allocation between standard and special pallets across the two scenarios. In Scenario 2, relocating all special pallets into the three-dimensional storage area markedly reduces the overall operation time and intensity for warehouse access.

Table 5.

Pallet coordinates in different scenarios.

Based on these findings, this study recommends a storage model where both standard and special pallets can be accommodated in both the three-dimensional and planar storage areas. This approach not only ensures the overall stability of the shelves and proximity of similar reserve materials but also significantly reduces the intensity of warehousing operations, ultimately saving time in material handling within the warehouse.

5. Conclusions

In the face of escalating natural and man-made disasters worldwide, the effective management of emergency reserve warehouses has become a critical aspect of disaster response and preparedness. This paper delves into the complex dynamics of emergency reserve materials, noted for their extensive storage capacities, prolonged storage periods, and infrequent transportation requirements. The presence of both standard and special pallets, as well as the utilization of planar and three-dimensional storage areas, forms the basis of an in-depth investigation into optimizing cargo space assignments under various scenarios. The application of a non-dominated genetic algorithm, enhanced with an elite strategy, has revealed that a new scenario—enabling the storage of both standard and special pallets in either planar or three-dimensional storage areas—significantly optimizes warehouse handling operations. Finally, this study constructs and empirically analyzes models specifically designed for an emergency material reserve warehouse in the Fangshan District, thereby demonstrating the practical application and efficiency of these models. This finding is crucial for advancing the strategic management of emergency reserves and enhancing readiness and response capabilities in critical situations.

Despite the fact that this research has made some progress compared to previous studies, there are still a number of unexplored aspects. First, cargo space assignment will be different for the types of emergency supplies, which is the future research of cargo space optimization of the emergency reserve warehouse. Second, future research should integrate additional factors, such as procurement batches and the number of operating equipment in the warehouse. This integration would make the model more representative of actual operational environments. Third, future research might consider the integration of IoT for dynamic tracking of inventory levels, stochastic demand, AI algorithms for predictive analysis of supply needs during emergencies. The multi-objective optimization algorithm, such as MOEA/D, SPEA2 and the improved Pareto evolution algorithm, are added to further explore the multi-objective optimization problem in the field of emergency logistics.

Author Contributions

Conceptualization, C.L., T.C. and Y.W.; methodology, K.Z. and T.C.; software, C.L. and T.C.; validation, T.C. and Y.W.; formal analysis, C.L., T.C. and Y.W.; investigation, C.L., T.C. and Y.W.; resources, T.C., Y.W. and K.Z.; data curation, X.Y. and C.W.; writing—original draft preparation, C.L., T.C. and Y.W.; writing—review and editing, X.Y. and C.W.; visualization, X.Y. and C.W.; supervision, C.L.; project administration, C.L.; funding acquisition, C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Beijing Municipal Social Science Foundation “Research on the Dynamic Synergistic Path of Beijing-Tianjin-Hebei Logistics System under Industry Transfer” (17GLB020).

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

No potential conflict of interest was reported by the authors.

References

- Huang, D.; Wang, S.; Liu, Z. A systematic review of prediction methods for emergency management. Int. J. Disaster Risk Reduct. 2021, 62, 102412. [Google Scholar] [CrossRef]

- Ballestín, F.; Pérez, Á.; Quintanilla, S. A multistage heuristic for storage and retrieval problems in a warehouse with random storage. Int. Trans. Oper. Res. 2020, 27, 1699–1728. [Google Scholar] [CrossRef]

- Yan, B.; Yan, C.; Long, F.; Tan, X.C. Multi-objective optimization of electronic product goods location assignment in stereoscopic warehouse based on adaptive genetic algorithm. J. Intell. Manuf. 2018, 29, 1273–1285. [Google Scholar] [CrossRef]

- Ma, Y.J.; Xu, W.; Qin, L.J.; Zhao, X.J.; Du, J. Hierarchical supplement location-allocation optimization for disaster supply warehouses in the Beijing-Tianjin-Hebei region of China. Geomat. Nat. Hazards Risk 2019, 10, 102–117. [Google Scholar] [CrossRef]

- Nastasi, G.; Colla, V.; Cateni, S.; Campigli, S. Implementation and comparison of algorithms for multi-objective optimization based on genetic algorithms applied to the management of an automated warehouse. J. Intell. Manuf. 2018, 29, 1545–1557. [Google Scholar] [CrossRef]

- Peng, G.Z.; Wu, Y.Q.; Zhang, C.J.; Shen, W.M. Integrated optimization of storage location assignment and crane scheduling in an unmanned slab yard. Comput. Ind. Eng. 2021, 161, 107623. [Google Scholar] [CrossRef]

- Lee, I.G.; Chung, S.H.; Yoon, S.W. Two-stage storage assignment to minimize travel time and congestion for warehouse order picking operations. Comput. Ind. Eng. 2020, 139, 106129. [Google Scholar] [CrossRef]

- Zhang, X.; Mo, T.T.; Zhang, Y.G. Optimization of Storage Location Assignment for Non-Traditional Layout Warehouses Based on the Firework Algorithm. Sustainability 2023, 15, 10242. [Google Scholar] [CrossRef]

- Campbell, A.M.; Jones, P.C. Prepositioning supplies in preparation for disasters. Eur. J. Oper. Res. 2011, 209, 156–165. [Google Scholar] [CrossRef]

- Turkeš, R.; Sörensen, K.; Cuervo, D.P. Design of experiments in humanitarian logistics: Facility decision making in disaster preparedness. Int. Trans. Oper. Res. 2023, 30, 4078–4106. [Google Scholar] [CrossRef]

- Lodree, E.J.; Taskin, S. An insurance risk management framework for disaster relief and supply chain disruption inventory planning. J. Oper. Res. Soc. 2008, 59, 674–684. [Google Scholar] [CrossRef]

- Liu, J.G.; Zhou, H.; Wang, J.J. The coordination mechanisms of emergency inventory model under supply disruptions. Soft Comput. 2018, 22, 5479–5489. [Google Scholar] [CrossRef]

- Roni, M.S.; Jin, M.Z.; Eksioglu, S.D. A hybrid inventory management system responding to regular demand and surge demand. Omega-Int. J. Manag. Sci. 2015, 52, 190–200. [Google Scholar] [CrossRef]

- Geng, J.X.; Hou, H.P.; Geng, S.Q. Optimization of Warehouse Location and Supplies Allocation for Emergency Rescue under Joint Government-Enterprise Cooperation Considering Disaster Victims’ Distress Perception. Sustainability 2021, 13, 10560. [Google Scholar] [CrossRef]

- Hu, Q.; Hu, Y.; Li, X. Multi-period emergency facility location-routing problems under uncertainty and risk aversion. Socio-Econ. Plan. Sci. 2024, 96, 102093. [Google Scholar] [CrossRef]

- Iqbal, S.; Sardar, M.U.; Lodhi, F.K.; Hasan, O. Statistical model checking of relief supply location and distribution in natural disaster management. Int. J. Disaster Risk Reduct. 2018, 31, 1043–1053. [Google Scholar] [CrossRef]

- Shehadeh, K.S.; Tucker, E.L. Stochastic optimization models for location and inventory prepositioning of disaster relief supplies. Transp. Res. Part C-Emerg. Technol. 2022, 144, 103871. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Zhu, X.X. A Multi-Regional Collaborative Optimization Model of Emergency Medical Materials for Responding to COVID-19. Processes 2022, 10, 1488. [Google Scholar] [CrossRef]

- Yin, L.; Zhong, R.R.; Wang, J. Ontology based package design in fresh E-Commerce logistics. Expert Syst. Appl. 2023, 212, 118783. [Google Scholar] [CrossRef]

- Boysen, N.; de Koster, R. 50 years of warehousing research—An operations research perspective. Eur. J. Oper. Res. 2024, 320, 449–464. [Google Scholar] [CrossRef]

- Bassey, U.N.; Zelibe, S.C. Two-echelon inventory location model with response time requirement and lateral transshipment. Heliyon 2022, 8, e10353. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Zhao, M.; Li, H. Data-driven simulation methodology for exploring optimal storage location assignment scheme in warehouses. Comput. Ind. Eng. 2024, 198, 110627. [Google Scholar] [CrossRef]

- Lei, B.; Jiang, Z.Y.; Mu, H.B. Integrated Optimization of Mixed Cargo Packing and Cargo Location Assignment in Automated Storage and Retrieval Systems. Discret. Dyn. Nat. Soc. 2019, 2019, 9072847. [Google Scholar] [CrossRef]

- Park, B.C.; Foley, R.D.; Frazelle, E.H. Performance of miniload systems with two-class storage. Eur. J. Oper. Res. 2006, 170, 144–155. [Google Scholar] [CrossRef]

- Zhang, S.W.; Fu, L.P.; Chen, R.; Mei, Y. Optimizing the Cargo Location Assignment of Retail E-Commerce Based on an Artificial Fish Swarm Algorithm. Math. Probl. Eng. 2020, 2020, 5609873. [Google Scholar] [CrossRef]

- Guerriero, F.; Musmanno, R.; Pisacane, O.; Rende, F. A mathematical model for the Multi-Levels Product Allocation Problem in a warehouse with compatibility constraints. Appl. Math. Model. 2013, 37, 4385–4398. [Google Scholar] [CrossRef]

- Muppani, V.R.; Adil, G.K. Efficient formation of storage classes for warehouse storage location assignment: A simulated annealing approach. Omega-Int. J. Manag. Sci. 2008, 36, 609–618. [Google Scholar] [CrossRef]

- Jiao, Y.L.; Xing, X.C.; Zhang, P.; Xu, L.C.; Liu, X.R. Multi-objective storage location allocation optimization and simulation analysis of automated warehouse based on multi-population genetic algorithm. Concurr. Eng.-Res. Appl. 2018, 26, 367–377. [Google Scholar] [CrossRef]

- Heragu, S.S.; Du, L.; Mantel, R.J.; Schuur, P.C. Mathematical model for warehouse design and product allocation. Int. J. Prod. Res. 2005, 43, 327–338. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Chan, H.K. Improving the productivity of order picking of a manual-pick and multi-level rack distribution warehouse through the implementation of class-based storage. Expert Syst. Appl. 2011, 38, 2686–2700. [Google Scholar] [CrossRef]

- Zhu, L.; Zhou, Y.; Jiang, R.; Su, Q. Surgical cases assignment problem using a multi-objective squirrel search algorithm. Expert Syst. Appl. 2024, 235, 121217. [Google Scholar] [CrossRef]

- Zhao, Q.; Zuo, Y.; Ai, L.; Liu, H. Integrated location and inventory planning in service parts logistics with last-mile delivery outsourcing. Comput. Ind. Eng. 2024, 189, 109998. [Google Scholar] [CrossRef]

- Ma, H.P.; Zhang, Y.J.; Sun, S.Y.; Liu, T.; Shan, Y. A comprehensive survey on NSGA-II for multi-objective optimization and applications. Artif. Intell. Rev. 2023, 56, 15217–15270. [Google Scholar] [CrossRef]

- Dkhil, H.; Yassine, A.; Chabchoub, H. Multi-objective optimization of the integrated problem of location assignment and straddle carrier scheduling in maritime container terminal at import. J. Oper. Res. Soc. 2018, 69, 247–269. [Google Scholar] [CrossRef]

- Wang, W.; Yang, J.; Huang, L.; Proverbs, D.; Wei, J.B. Intelligent Storage Location Allocation with Multiple Objectives for Flood Control Materials. Water 2019, 11, 1537. [Google Scholar] [CrossRef]

- Roshan, K.; Shojaie, A.; Javadi, M. Advanced allocation policy in class-based storage to improve AS/RS efficiency toward green manufacturing. Int. J. Environ. Sci. Technol. 2019, 16, 5695–5706. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).