Abstract

Supply Chain (SC) Optimization is a key activity in today’s industry with the goal of increasing operational efficiency, reducing costs, and improving customer satisfaction. Traditional optimization methods often struggle to effectively use resources while handling complex and dynamic Supply chain networks. This paper introduces a novel biomimetic metaheuristic algorithm called the Wombat Optimization Algorithm (WOA) for supply chain optimization. This algorithm replicates the natural behaviors observed in wombats living in the wild, particularly focusing on their foraging tactics and evasive maneuvers towards predators. The theory of WOA is described and then mathematically modeled in two phases: (i) exploration based on the simulation of wombat movements during foraging and trying to find food and (ii) exploitation based on simulating wombat movements when diving towards nearby tunnels to defend against its predators. The effectiveness of WOA in addressing optimization challenges is assessed by handling the CEC 2017 test suite across various problem dimensions, including 10, 30, 50, and 100. The findings of the optimization indicate that WOA demonstrates a strong ability to effectively manage exploration and exploitation, and maintains a balance between them throughout the search phase to deliver optimal solutions for optimization problems. A total of twelve well-known metaheuristic algorithms are called upon to test their performance against WOA in the optimization process. The outcomes of the simulations reveal that WOA outperforms the other algorithms, achieving superior results across most benchmark functions and securing the top ranking as the most efficient optimizer. Using a Wilcoxon rank sum test statistical analysis, it has been proven that WOA outperforms other algorithms significantly. WOA is put to the test with twenty-two constrained optimization problems from the CEC 2011 test suite and four engineering design problems to showcase its ability to solve real-world optimization problems. The results of the simulations demonstrate that WOA excels in real-world applications by delivering superior solutions and outperforming its competitors.

MSC:

90C59

1. Introduction

Supply Chain Management (SCM) plays a vital role in the success and competitiveness of modern businesses by ensuring the seamless flow of goods and services from suppliers to the final customer [1]. The complexity of supply chain networks, with multiple overlapping firms, dynamic demand patterns, and resource constraints, poses significant challenges for optimal performance [2]. Supply chain quality is essential for businesses to increase efficiency, reduce costs, and adapt to market demand that changes at every moment [3,4].

Various studies have been presented in the literature in the field of SCM. A novus multi-objective three-stage supply chain network is proposed, which aims to optimize sustainability, resiliency and responsive measures, simultaneously [5]. To uncover optimal strategic and planning choices, a multi-objective mixed integer programming framework is proposed to analyze Supply Chains from environmental, economic, and technological standpoints, while handling multiple periods, products, supply zones, and various feedstocks [6]. A behavioral three-way decision making model with a Fermatean fuzzy Mahalanobis distance is proposed to deal with SCM problems [7]. For supply chain management in hesitant situations, a new model based on an interval type-2 Pythagorean fuzzy set is proposed [8]. A multi-objective, multi-product, and multi-period two-stage sustainable opened- and closed-loop supply chain plan is proposed to maintain the supply among production centers and various hospitals during the COVID-19 pandemic situation [9].

One of the fundamental aspects of SCM is the integration of key processes and functions within and across organizations. Effective SCM requires collaboration not only among different departments within a company but also with external partners such as suppliers, manufacturers, distributors, and retailers. This collaborative approach enables organizations to streamline operations, reduce costs, improve quality, and respond quickly to changing market demands [10]. Furthermore, advancements in technology have revolutionized SCM practices, enabling a real-time visibility and control over supply chain activities. For instance, the use of data analytics, Artificial Intelligence, and the Internet of Things (IoT) has enabled companies to gather and analyze vast amounts of data, leading to better forecasting accuracy, inventory optimization, and decision-making. These technological innovations have transformed SCM into the “Triple-A Supply Chain”—agile, adaptable, and aligned with the overarching business strategy [11]. SCM plays a pivotal role in driving operational efficiency, enhancing customer satisfaction, and creating a competitive advantage. By embracing collaboration, leveraging technology, and addressing emerging challenges, organizations can build resilient, sustainable, and agile supply chains that are well-positioned to thrive in an increasingly complex and interconnected world.

Traditional optimization techniques such as linear programming and mathematical modeling have been widely used for supply chain optimization [12]. However, these methods often struggle to cope with the inherent complexity and uncertainty of real-world supply chains. Consequently, there is an increased interest in developing metaheuristic algorithms that take inspiration from nature to efficiently solve Supply Chain Optimization problems [13]. Among these bio-inspired optimization methods, swarm intelligence-based algorithms have shown promise due to their ability to mimic collective biological systems. One such algorithm inspired by the feeding behavior of the honeybee swarm is Bee Swarm Optimization (BSO). BSO mimics the spatially embedded cooperation and decision-making processes found in honey bee colonies, making it ideally suited for optimization projects characterized by large solution areas and dynamic environments [14].

Optimization problems involve multiple possible solutions, with the goal of finding the most optimal solution from all the options available [15]. These problems are typically represented mathematically through decision variables, constraints, and an objective function. The primary objective in optimization is to assign values to the decision variables in a way that maximizes or minimizes the objective function while satisfying the problem’s constraints [16]. Problem-solving methods for optimizing solutions can fall into deterministic and stochastic categories [17].

Although deterministic approaches excel in solving convex, differentiable, continuous, linear, and low-dimensional optimization problems, they struggle when faced with complex optimization problems, particularly in high dimensions where they may become trapped at local optima [18]. In real-world applications within mathematics, engineering, and other fields, many optimization problems are complex, non-convex, non-derivative, discontinuous, nonlinear, and high-dimensional. The limitations and challenges of deterministic approaches in handling such optimization problems have prompted researchers to develop stochastic approaches [19].

Metaheuristic algorithms are recognized as efficient stochastic methods capable of generating optimal solutions for optimization problems through random search within the problem-solving space. Employing random operators and trial-and-error processes, these algorithms initially create a set of candidate solutions as the algorithm population. Through iteration and algorithm update steps, the positions of population members are altered to enhance these candidates, ultimately leading to the identification of the most optimal solution encountered throughout the algorithm’s execution [20]. The randomness involved in the process of metaheuristic algorithms implies that reaching the global optimum is not guaranteed. However, the results achieved through these algorithms are deemed acceptable as they are situated near the global optimum. Hence, these outcomes are referred to as quasi-optimal solutions. Enhancing these quasi-optimal solutions to be closer to the global optimum stands as a significant goal in the realm of metaheuristic algorithms and optimization. Consequently, this pursuit serves as the primary driving force for researchers in their quest to create numerous innovative metaheuristic algorithms [21].

Effectively managing a random search at both global and local levels is essential for the success of metaheuristic algorithms in optimization processes. Global search involves a deep exploration of the problem-solving space to avoid being trapped in local optima and in order to pinpoint the main optima region. On the other hand, a local search focuses on exploitating the near solutions and potential areas within the problem-solving space to achieve improved outcomes closer to the global optimum. To handle the stochastic search effectively, a metaheuristic algorithm must strike a balance between exploration and exploitation throughout the problem-solving process [22].

The main research question is whether new metaheuristic algorithms are still necessary despite the variety that already exists. The No Free Lunch (NFL) theorem [23] addresses this concern by stating that there is no one universal metaheuristic algorithm that can outperform all others for every optimization problem. This means that the effectiveness of a metaheuristic algorithm for one set of optimization challenges does not guarantee a similar success for a different set. Therefore, the outcome of implementing a metaheuristic algorithm in an optimization scenario cannot be predicted as a definite success or failure. As per the NFL theorem, it is possible for an algorithm to achieve the best solution when dealing with one optimization problem, but it may get trapped in a local optimum when faced with another problem. The NFL theorem promotes ongoing research in metaheuristic algorithms, pushing researchers to develop innovative approaches to solving optimization problems effectively. This theorem has inspired the authors of this paper to introduce a novel metaheuristic algorithm for addressing optimization challenges.

Motivated by the NFL theorem, the aspects of innovation, novelty, and originality of this paper are in introducing a new metaheuristic algorithm called Wombat Optimization Algorithm (WOA) that imitates the behavior of wombats in their habitat.

What is evident from the best knowledge obtained from the literature review, so far, is that no metaheuristic algorithm has been designed based on the simulation of wombats’ natural behaviors. Meanwhile, the activity of foraging and the escaping strategy from predators are intelligent processes among wombats that have a special potential in the design of a new optimizer. In order to address this research gap in the studies of metaheuristic algorithms, in this paper, a new biomimetics metaheuristic algorithm is designed based on the mathematical modeling of wombats’ natural behaviors in the wild.

The key contributions of this paper are as listed:

- WOA is designed based on simulating wombat’s natural behaviors in the wild.

- The basic inspiration of WOA is taken from the foraging of the wombat and the strategy of this animal when escaping from its predators.

- The theory of WOA is expressed and mathematically modeled in two phases: (i) the exploration based on the simulation of wombat movements during foraging and (ii) the exploitation based on simulating wombat movements when it dives towards nearby tunnels to defend against its predators.

- The capability of WOA in optimization applications has been evaluated in the CEC 2017 test suite for problem dimensions equal to 10, 30, 50, and 100.

- WOA’s ability to tackle optimization tasks in real-world applications has been evaluated on twenty-two constrained optimization problems from the CEC 2011 test suite and four engineering design problems.

- Two well-known metaheuristic algorithms are employed to compare with the performance of WOA.

This paper is organized in the following manner: firstly, a literature review is outlined in Section 2. Next, the proposed Wombat Optimization Algorithm (WOA) is introduced and outlined in Section 3. Section 4 covers simulation studies and their results. The efficacy of WOA in addressing real-world applications is explored in Section 5. Lastly, conclusions and recommendations for future research are detailed in Section 6.

2. Literature Review

Metaheuristic algorithms have drawn on influences from various natural sources, including swarm behavior in the animal kingdom, principles of biology and genetics, concepts from the field of physics, studies of human behavior, and evolutionary occurrences. These algorithms can be categorized into five distinct groups based on the design inspiration they exhibit: swarm-based, evolutionary-based, physics-based, human-based, and game-based approaches.

Swarm-based metaheuristic algorithms are inspired by the natural swarming behaviors of various animals in their design, including insects, birds, aquatic creatures, reptiles, and other wildlife species. Among the most famous swarm-based metaheuristic algorithms are: Ant Colony Optimization (ACO) [24], Particle Swarm Optimization (PSO) [25], Firefly Algorithm (FA) [14,26], and Artificial Bee Colony (ABC) [27]. ACO used in its design the skill of ants in finding the optimal communication path between the colony and the food source. PSO is inspired in its design by the search process in the movement of fish and birds with the aim of finding food sources. FA is developed inspired by the optical communication and information exchange between fireflies. The butterfly optimization algorithm (BA) is an advanced metaheuristic for optimization created by Arora that draws inspiration from biology, which is centered on the behavior of butterflies when they are seeking food [28]. ABC is designed based on modeling the hierarchical cooperation and activities of colony bees to obtain food resources. Mantis Search Algorithm (MSA) is developed based on modeling the sexual cannibalism and hunting behavior of praying mantises [29]. Genghis Khan Shark Optimizer (GKSO) is inspired, in its design, by the Genghis Khan shark’s hunting and self-defense strategy in the wild [30]. Gazelle Optimization Algorithm (GOA) uses, in its design, gazelles’ survival ability in their predator-dominated environment [31]. Among natural behaviors in wildlife, foraging, hunting strategy, survival efforts, chasing processes, digging, and migration are very significant; they are employed as sources of inspiration in the design of algorithms such as: Whale Algorithm (WA) [32], Reptile Search Algorithm (RSA) [33], Orca Predation Algorithm (OPA) [34], Grey Wolf Optimizer (GWO) [35], Tunicate Swarm Algorithm (TSA) [36], African Vultures Optimization Algorithm (AVOA) [37], Marine Predator Algorithm (MPA) [38], and White Shark Optimizer (WSO) [39].

Evolutionary metaheuristic algorithms draw upon principles from biology and genetics, incorporating ideas such as natural selection, survival of the fittest, Darwin’s theory of evolution, and other related evolutionary principles in their design. Among the most popular evolutionary-based metaheuristic algorithms are Genetic Algorithm (GA) [40] and Differential Evolution (DE) [41]. GA and DE use, in their design, a simulation of the reproduction process, and apply genetic and biological concepts such as mutation, selection, and crossover. The basic inspiration in the design of Artificial Immune System (AIS) comes from the mechanism of the human body’s defense system against microbes and diseases [42]. Some other evolutionary-based metaheuristic algorithms are: Cultural Algorithm (CA) [43], Genetic programming (GP) [44], and Evolution Strategy (ES) [45].

Physics-based metaheuristic algorithms are use their design of phenomena, transformations, processes, forces, laws, and other concepts of physics. Simulated Annealing (SA) is one of the most widely used physics-based metaheuristic algorithms. The main idea in the design of SA comes from the physical transformations in the metal annealing process, where with the aim of achieving the ideal crystal, the metals are first melted under heat, then slowly cooled and frozen [46]. Gravitational Search Algorithm (GSA) [47] is inspired by modeling the gravitational attraction between objects at different distances. Fick’s Law Optimization (FLA) is designed based on the modeling of Fick’s first law of diffusion, which according to this law, molecules tend to diffuse from higher to lower concentration areas [48]. Rime (RIME) algorithm is designed with inspiration from the physical phenomenon of rime-ice [49]. Some other physics-based metaheuristic algorithms are: Thermal Exchange Optimization (TEO) [50], Water Cycle Algorithm (WCA) [51], Nuclear Reaction Optimization (NRO) [52], Henry Gas Optimization (HGO) [53], Lichtenberg Algorithm (LA) [54], Multi-Verse Optimizer (MVO) [55], Electro-Magnetism Optimization (EMO) [56], Black Hole Algorithm (BHA) [57], and Archimedes Optimization Algorithm (AOA) [58].

Human-based metaheuristic algorithms use, in their design, behaviors, choices, thoughts, decisions, teaching and learning processes, and other human activities in individual and social life. Teaching-Learning Based Optimization (TLBO) [59] can be mentioned among the most widely used human-based metaheuristic algorithms. TLBO uses the modeling of educational communication and knowledge exchange in the classroom environment between the teacher and students and students with each other. Mother Optimization Algorithm (MOA) is proposed with inspiration from Eshrat’s care of her children [60]. Mountaineering Team-Based Optimization (MTBO) is developed with the inspiration of social behavior and human cooperation needed to reach a mountaintop [61]. Deep Sleep Optimizer (DSO) is developed inspired by the sleeping patterns of humans and is based on modeling the fall and rise of homeostatic pressure during the human sleep process [62]. Some other human-based metaheuristic algorithms are: Gaining Sharing Knowledge based Algorithm (GSK) [63], Fireworks Algorithm (FA) [64], War Strategy Optimization (WSO) [65], Coronavirus Herd Immunity Optimizer (CHIO) [66], and Ali Baba and the Forty Thieves (AFT) [67].

Game-based metaheuristic algorithms use, in their design, the rules of individual and team games as well as the behavior of players, coaches, runners, and other influential people in these games. Volleyball Premier League (VPL) [68] and Running City Game Optimizer (RCGO) [69] are examples of game-based metaheuristic algorithms.

Supply chain management (SCM) has evolved from a simple logistical process to a critical strategic tool for businesses worldwide. It involves the coordination of various activities, including procurement, production, inventory management, and distribution, to ensure the smooth flow of goods and services from suppliers to end customers. This holistic approach to managing the flow of materials, information, and finances across the entire supply chain has become indispensable in today’s competitive business environment [70]. With the increasing complexity and dynamic nature of modern supply chains, traditional optimization techniques often fall short in providing optimal solutions within reasonable time frames. This has led to the emergence of metaheuristic algorithms as powerful optimization tools capable of addressing the challenges posed by real-world SCM problems [71]. Unlike traditional optimization methods, which may get stuck in local optima, metaheuristics offer robust and flexible approaches for finding high-quality solutions in a reasonable amount of time [72]. The application of metaheuristic algorithms in SCM is vast and encompasses various areas such as inventory management, facility location, vehicle routing, production scheduling, and supply chain network design. For example, metaheuristic algorithms can be used to optimize inventory replenishment policies, minimize transportation costs, balance production capacities, and design resilient supply chain networks [73].

An overview of the applications of metaheuristic algorithms in dealing with SCM is presented in Table 1.

Table 1.

Applications of metaheuristic algorithms on SCM problem.

3. Wombat Optimization Algorithm

In this section, first, the basic inspiration employed in designing the proposed Wombat Optimization Algorithm (WOA) approach is described, then its implementation steps are mathematically modeled.

3.1. Inspiration of WOA

A wombat is a short-legged, muscular quadrupedal marsupials of the family Vombatidae, which is native to Australia [98]. This animal is adaptable and habitat tolerant, and lives in heathland, mountainous, and forested areas of eastern and southern Australia, as well as in an isolated patch in Epping Forest National Park in central Queensland [99]. The appearance characteristics of wombats are as follows: their fur color can vary from gray to black or from a sandy color to brown. Wombats are about 1 m long and weigh between 17 and 39 kg [99,100]. An image of the wombat is shown in Figure 1.

Figure 1.

Wombat taken from: free media Wikimedia Commons.

The wombat is an herbivore animal whose main diet is grass and also feeds on roots, bark, herbs, and sedges. Wombats have adapted to survive in habitats with limited nutrition and low food availability. Using the burrows permits wombats to maximize their foraging range and creates a thermally stable environment that helps in the maintenance of a low metabolic rate. Their energy-efficient foraging strategies and low metabolic rates lead to very low energy requirements, allowing them to survive on low-quality food and inhabit areas of scarce food availability. Although wombats can subsist on low-quality diets, their survival still relies on the availability of a habitat that provides adequate nutrition, as nutritional stress increases the risk of illness and death for animals [101].

Wombats have great skill and ability in digging. They dig extensive burrow systems with their powerful claws and rodent-like front teeth. The backward-facing pouch is a special distinctive adaptation in wombats. This pouch has the advantage of the wombat not collecting soil on its young in the pouch while digging. In addition to the effect of an increased foraging range, these excavated tunnels are a suitable defensive position for wombats when they are attacked by their predators. Wombats are slow animals and move slowly; however, when attacked and threatened, they run away at a speed of 40 km/h. Tasmanian and Dingos are the main predators of wombats. When a wombat is attacked by a predator, it dives into one of the nearby tunnels and uses its rump to stop the pursuing predator. The main defense of wombats is their toughened rear hide, with most of the posterior made of cartilage. This feature, as well as not having a substantial tail, makes the stalking predator who enters the tunnel unable to bite the wombat and hunt it [99].

Among the wombat’s natural behaviors and lifestyles in the wild, two stand out the most: (i) their extensive foraging activity in the wild and (ii) their escape strategy from predators by diving into nearby tunnels. The mathematical modeling of these intelligent processes in the wombat lifestyle was employed in order to design a new metaheuristic algorithm called Wombat Optimization Algorithm (WOA), which is presented below.

3.2. Algorithm Initialization

The proposed WOA approach is a population-based metaheuristic algorithm, where wombats form the population members of the algorithm. In order to visualize and create a mentality, the habitat of wombats in the wild corresponds to the problem-solving space, and the position of each wombat in this habitat corresponds to the position of a candidate solution in the problem-solving space. Each wombat determines values for decision variables based on its position in the problem-solving space. Therefore, each wombat as a WOA member corresponds to a candidate solution to the problem that can be mathematically modeled using a vector. The community of wombats in the form of these vectors together makes the WOA population, which can be mathematically modeled using a matrix according to Equation (1). At the beginning of the implementation of the algorithm, the position of each wombat in the problem-solving space is randomly initialized using Equation (2).

Here, is the WOA population matrix, is the th wombat (i.e., candidate solution), is its th dimension in the search space (i.e., decision variable), is the number of wombat population, is the number of decision variables, is a random number in interval , and and are the lower bound and upper bound of the th decision variable, respectively.

As stated, the position of each wombat represents a candidate solution to the problem. Therefore, the objective function of the problem corresponding to each wombat can be evaluated. The set of evaluated values for the objective function of the problem can be represented using a vector using Equation (3).

Here, is the vector of the evaluated objective function and is the evaluated objective function based on the th wombat.

The evaluated values for the objective function are considered as a suitable criterion for measuring the quality of candidate solutions and population members. Thus, the best evaluated value for the objective function corresponds to the best WOA member, and the worst value obtained for the objective function corresponds to the worst WOA member. Since the position of the wombats in the problem-solving space is updated in each iteration, the best member of the population must also be updated in each iteration.

3.3. Mathematical Modelling of WOA

The proposed approach of WOA is able to provide suitable solutions for optimization problems in an iteration-based process based on the searching power of its members in the problem-solving space. The design of WOA was inspired by the natural behavior of wombats in nature. In the WOA design, the position of the wombats in the problem-solving space is updated in each iteration in two phases: (i) an exploration based on the simulation of the foraging process of the wombats and (ii) an exploitation based on the simulation of the strategy of the wombats escaping from their predators towards the tunnels. The full description and mathematical model of each of these phases of updating the position of wombats in the problem-solving space is presented below.

3.3.1. Phase 1: Foraging Process (Exploration Phase)

In the first phase of WOA, the position of wombats in the problem-solving space is updated based on the simulation of this animal’s foraging strategy. The wombat is a herbivorous animal that has a high searching power for finding forage in a wide range of its habitat. Modeling the position change of the wombat while moving towards forage leads to the creation of extensive changes in the position of WOA members in the problem-solving space and, as a result, increasing the exploration power of the algorithm in order to manage the global search. In the WOA design, for each wombat, the position of other population members that have a better value for the objective function is considered as the forage position. The set of forage positions for each wombat is identified using Equation (4).

Here, is the set of candidate forage positions for the th wombat, is the population member with a better objective function value than the th wombat, and is its objective function value.

In the design of WOA, it is assumed that the wombat chooses one of these fodder positions completely randomly and moves towards it. Based on the modeling of the wombat’s movement towards the selected forage in this foraging process, a new position for each WOA member is calculated using Equation (5). This new position, if it leads to the improvement of the objective function value, replaces the previous position of the corresponding member using Equation (6).

Here, is the selected forage position for the th wombat, is its th dimension, is the new position calculated for the th wombat based on the foraging phase of the proposed WOA, is its th dimension, is its objective function value, are random numbers from the interval , and are numbers which are randomly selected as 1 or 2.

3.3.2. Phase 2: Escape Strategy (Exploitation Phase)

In the second phase of WOA, the position of wombats in the problem-solving space is updated based on the simulation of the escape strategy of this animal against the attacks of its predators. The wombat, with its high digging ability, makes many tunnels in its habitat. When the wombat is in danger and attacked by a predator, it escapes by diving towards one of the tunnels located near it and tries to save itself. Modeling the wombat’s position change while escaping from the predator towards the tunnel leads to small changes in the position of the WOA members in the problem-solving space, and, as a result, increases the exploitation power of the algorithm in order to manage the local search.

In the WOA design based on the modeling of the wombat’s position change and dive towards the nearby tunnel, a new position for each member of the WOA is calculated using Equation (7). This new position, if it leads to the improvement of the value of the objective function, replaces the previous position of the corresponding member using Equation (8).

Here, is the new position calculated for the th wombat based on the escape phase of the proposed WOA, is its th dimension, is its objective function value, are random numbers from the interval , and is the iteration counter.

3.4. Repetition Process, Pseudocode, and Flowchart of WOA

The first iteration of WOA is completed after updating the position of all wombats in the problem-solving space based on foraging and escape phases. After that, with the updated values, the algorithm enters the next iteration; the process of updating the position of wombats in the problem-solving space continues until the last iteration of the algorithm based on Equations (4)–(8). In each iteration, the position of the best wombat is identified and stored as the best candidate solution. After the full implementation of the algorithm, the best candidate solution obtained during the iterations of the algorithm is presented as the WOA solution for the given problem.

Different criteria can be considered as the stopping condition of the algorithm. Among these criteria, we can mention: (i) the maximum number of algorithm iterations—in this case, the algorithm stops after passing the specified number of iterations; (ii) the maximum number of objective function evaluations (FEs)—in this case, after the number of evaluations of the objective function reaches the maximum number of FEs (MFEs), which is specified at the beginning of the implementation, the algorithm stops; (iii) the error determined between the successive solutions obtained—in this case, when the difference between the solutions obtained during several iterations of the algorithm is very small, based on the comparison of this difference with a “specified value”, the algorithm stops.

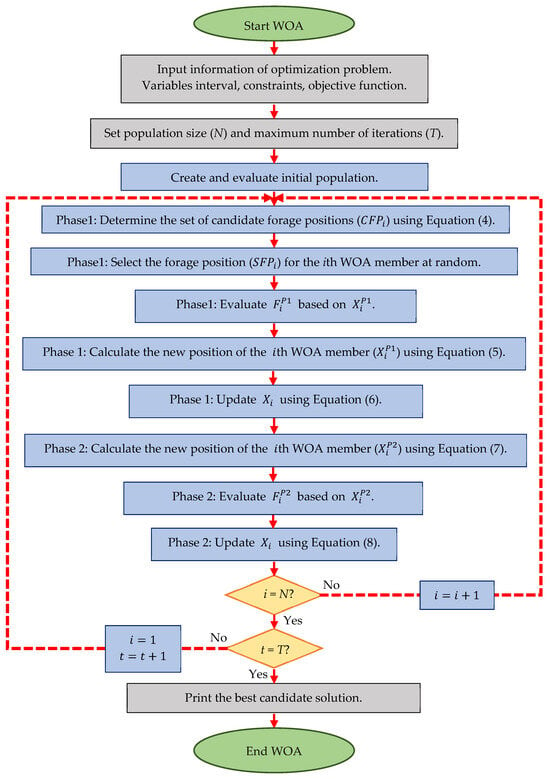

The implementation steps of WOA are shown as a flowchart in Figure 2, and the WOA pseudocode is presented in Algorithm 1.

Figure 2.

Flowchart of WOA.

| Algorithm 1. Pseudocode of WOA | ||||

| Start WOA. | ||||

| 1. | Input problem information: variables, objective function, and constraints. | |||

| 2. | Set WOA population size (N) and iterations (T). | |||

| 3. | Generate the initial population matrix at random using Equation (2). | |||

| 4. | Evaluate the objective function. | |||

| 5. | For to T | |||

| 6. | For to | |||

| 7. | Phase 1: foraging process (exploration phase) | |||

| 8. | Determine the candidate foraging positions set for the ith wombat using Equation (4). | |||

| 9. | Select the target foraging position for the ith wombat at random. | |||

| 10. | Calculate new position of ith wombat using Equation (5). | |||

| 11. | Update ith wombat using Equation (6). | |||

| 12. | Phase 2: escape strategy (exploitation phase) | |||

| 13. | Calculate new position of ith wombat using Equation (7). | |||

| 14. | Update ith wombat using Equation (8). | |||

| 15. | end | |||

| 16. | Save the best candidate solution so far. | |||

| 17. | end | |||

| 18. | Output the best quasi-optimal solution obtained with the WOA. | |||

| End WOA. | ||||

3.5. Computational Complexity of WOA

In this subsection, the computational complexity of the proposed WOA approach is evaluated. The preparation and initialization steps of WOA have a computational complexity equal to O(Nm), where N is the number of wombats and m is the number of decision variables of the problem. In each iteration, the position of the wombats in the problem-solving space is updated in two phases: foraging and escape. Therefore, the process of updating the position of wombats has a computational complexity equal to O(2NmT), where T is the maximum number of iterations of the algorithm. According to this, the total computational complexity of the proposed WOA approach is equal to O(Nm(1 + 2T)).

4. Simulation Studies and Results

In this section, the ability of WOA to tackle optimization problems is evaluated on the CEC 2017 test suite.

4.1. Performance Comparison

Twelve well-known metaheuristic algorithms consisting of GA [40], PSO [25], GSA [47], TLBO [59], MVO [55], GWO [35], WA [32], MPA [38], TSA [36], RSA [33], AVOA [37], and WSO [39] are employed to compete with the performance of WOA. The simulation results are presented using six statistical indicators: mean, best, worst, standard deviation (std), median, and rank.

Considering that in order to optimize each of the benchmark functions, metaheuristic algorithms are used in several independent implementations, the statistical indicators are described as follows:

- Mean: represents the average values obtained for the objective function from independent executions.

- Best: indicates the best value obtained for the objective function among the values obtained from independent executions.

- Worst: represents the worst value obtained for the objective function among the values obtained from independent executions.

- std: represents the standard deviation between the values obtained for the objective function from independent runs.

- Median: represents the median index between the values obtained for the objective function from independent executions.

- Rank: indicates the rank of each metaheuristic algorithm in competition with other metaheuristic algorithms in dealing with the corresponding benchmark function. The evaluated values for the mean index have been applied as a ranking criterion for metaheuristic algorithms in handling each of the benchmark functions.

It should be mentioned that in order to provide a fair comparison, in the simulation studies, the original versions of competing algorithms published by their main researchers have been used. Also, regarding GA and PSO, the standard versions published by Professor Seyed Ali Mirjalili have been used. Also, the complete information and details about the experimental test suites and their optimal values are available in their respective references introduced in each subsection.

4.2. Evaluation CEC 2017 Test Suite

In this subsection, the ability of WOA and competitor algorithms to tackle the CEC 2017 test suite is challenged. The CEC 2017 test suite consists of thirty benchmark functions, as follows: (i) three unimodal functions of C17-F1 to C17-F3, (ii) seven multimodal functions of C17-F4 to C17-F10, (iii) ten hybrid functions of C17-F11 to C17-F20, and (iv) ten composition functions of C17-F21 to C17-F30. Among the functions of this test suite, C17-F2 is not considered in simulation studies due to its unstable behavior (as with all similar papers). Complete information, details, and descriptions of the CEC 2017 test suite are available at [102]. Based on the mentioned reference, the CEC 2017 test suite is designed to evaluate the performance of metaheuristic algorithms in handling optimization problems. Also, in order to provide a scalability analysis, it is recommended that this evaluation be conducted for the problem size equal to 10, 30, 50, and 100. The WOA approach along with competitor algorithms are employed in handling the CEC 2017 test suite in fifty-one independent runs, where each run consists of 10,000 m function evaluations (FEs), where m is the number of problem dimensions.

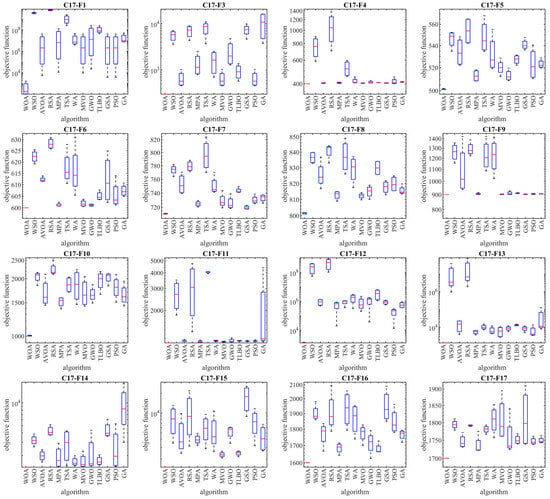

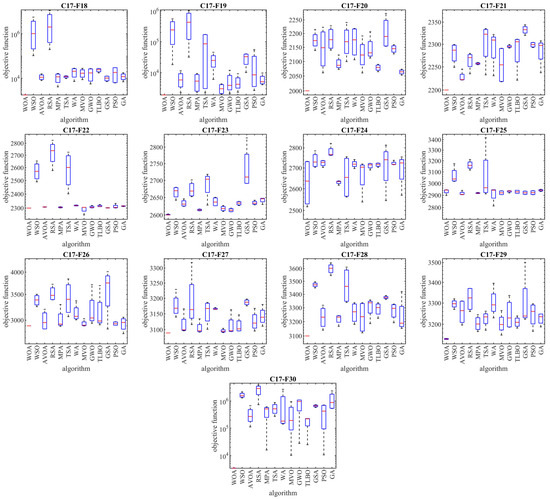

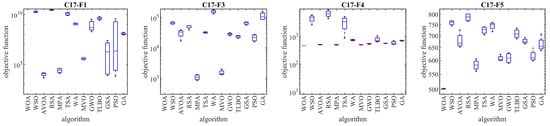

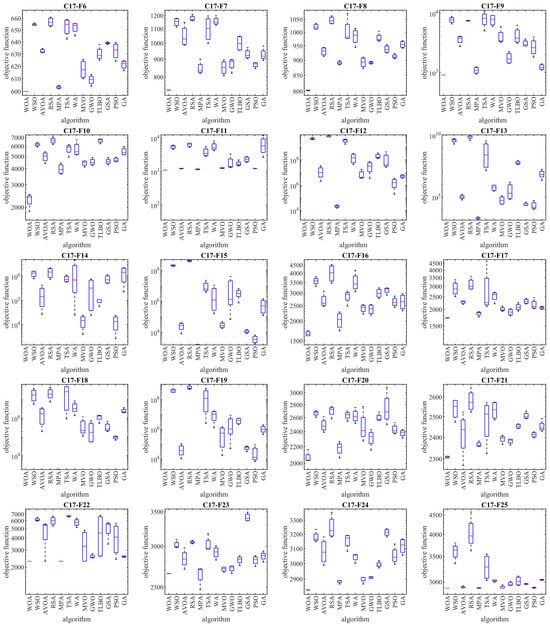

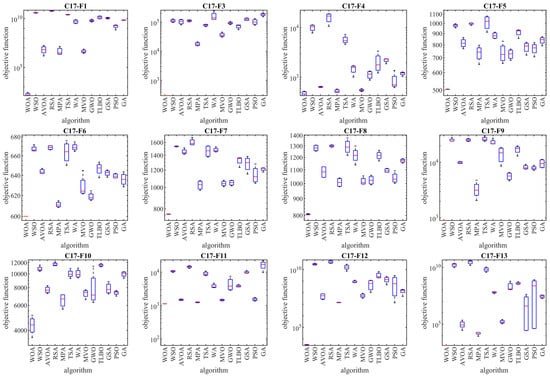

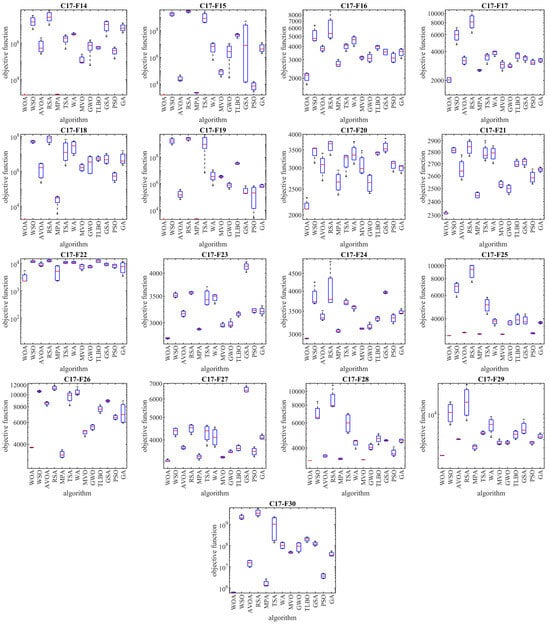

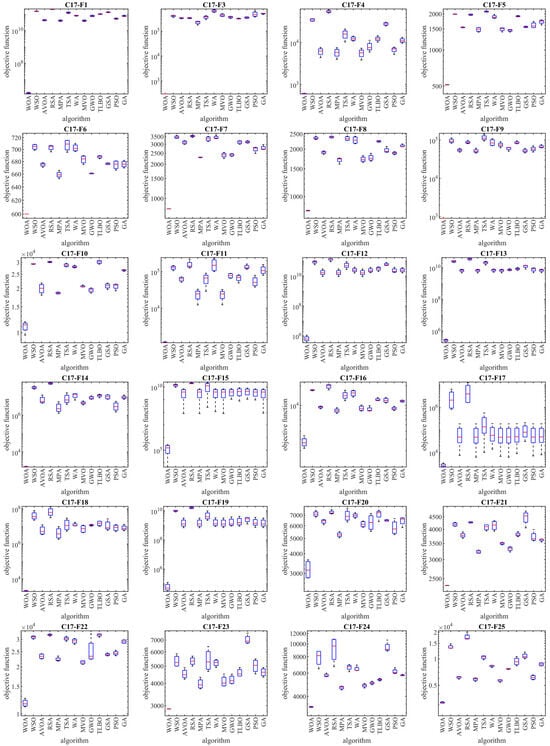

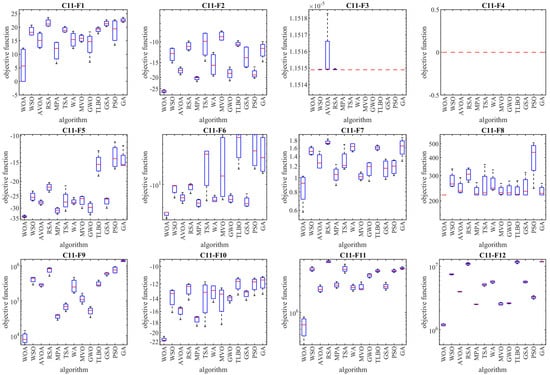

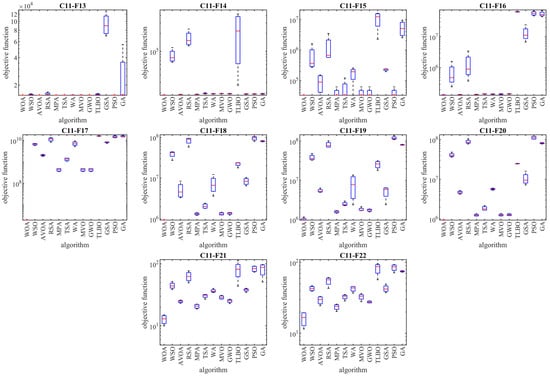

The implementation results of the WOA and competitor algorithms, in order to tackle the CEC 2017 test suite, are reported in Table 2, Table 3, Table 4 and Table 5. The boxplot diagrams obtained from the implementation of metaheuristic algorithms in the CEC 2017 test suite are plotted in Figure 3, Figure 4, Figure 5 and Figure 6. What is evident based on the analysis of simulation results and the performance of metaheuristic algorithms, in handling the CEC 2017 test suite for the problem dimension equal to 10 (m = 10), is that WOA has been the first best optimizer for the functions C17-F1, C17-F3 to C17-F21, C17-F23, C17-F24, and C17-F26 to C17-F30. For the problem dimension equal to 30 (m = 30), the proposed WOA approach is the first best optimizer for functions C17-F1, C17-F3 to C17-F22, C17-F24, C17-F25, and C17-F27 to C17-F30. For the problem dimension equal to 50 (m = 50), the proposed WOA approach is the first best optimizer for functions C17-F1, C17-F3 to C17-F25, and C17-F27 to C17-F30. For the problem dimension equal to 100 (m = 100), the proposed WOA approach is the first best optimizer for functions C17-F1 and C17-F3 to C17-F30.

Table 2.

Optimization results of CEC 2017 test suite (dimension = 10).

Table 3.

Optimization results of CEC 2017 test suite (dimension = 30).

Table 4.

Optimization results of CEC 2017 test suite (dimension = 50).

Table 5.

Optimization results of CEC 2017 test suite (dimension = 100).

Figure 3.

Boxplot diagrams of WOA and competitor algorithms’ performances on CEC 2017 test suite (dimension = 10).

Figure 4.

Boxplot diagrams of WOA and competitor algorithms’ performances on CEC 2017 test suite (dimension = 30).

Figure 5.

Boxplot diagrams of WOA and competitor algorithms’ performances on CEC 2017 test suite (dimension = 50).

Figure 6.

Boxplot diagrams of WOA and competitor algorithms performances on CEC 2017 test suite (dimension = 100).

As mentioned, the CEC 2017 test suite has functions of unimodal, multimodal, hybrid, and composition types. Each of these types of functions have been chosen with a special motivation to measure the quality of metaheuristic algorithms.

Unimodal functions C17-F1 and C17-F3 are types of functions that do not have local optima and only have one main optimal solution. These types of functions are suitable in order to evaluate the exploitation ability of metaheuristic algorithms in local search management with the aim of achieving solutions closer to the global optimum. The findings obtained from the optimization results of unimodal functions show that WOA has a high ability in the exploitation and local search by providing better results for these functions and obtaining the rank of the first best optimization.

Multimodal functions C17-F4 to C17-F10 are types of functions that have several local optimal solutions in addition to the main optimum. These types of functions challenge the exploration ability of metaheuristic algorithms in providing a global search and escaping from local optima. The findings obtained from the optimization of multimodal functions show that WOA, by achieving better results in most of the multimodal benchmark functions C17-F4 to C17-F10 and obtaining the rank of the first best optimizer, has a successful performance in its exploration to manage the global search in the problem-solving space.

Hybrid functions C17-F11 to C17-F20 and composition functions C17-F21 to C17-F30 are complex optimization problems for which it is very challenging to find a suitable solution. These types of optimization problems are very suitable for evaluating the ability of metaheuristic algorithms in balancing the exploration and exploitation during the search process. The analysis of the simulation results shows that WOA achieved better results in most of the benchmark functions C17-F11 to C17-F30 compared to the competing algorithms and was identified as the first best optimizer for these functions. The findings obtained from the optimization results of hybrid and composition functions show that WOA has a high ability to balance the exploration and exploitation during the search process in the problem-solving space in order to identify the main optimal area, escape from local optima, and converge towards the global optima.

The optimization findings are that WOA has achieved suitable solutions for the CEC 2017 test suite with its high capability in managing exploration and exploitation, and balancing them during the search process. The simulation findings are that WOA provided a superior performance by providing better results for most of the benchmark functions and obtained the rank of the first best optimizer in order to tackle the CEC 2017 test suite for problem dimensions equal to 10, 30, 50, and 100.

4.3. Statistical Analysis

Comparing the performance of metaheuristic algorithms using statistical indicators showed that WOA provided a superior performance against competitor algorithms in handling the CEC 2017 test suite. In this subsection, using statistical analysis, it has been checked whether this superiority of WOA is statistically significant or not. For this purpose, the Wilcoxon rank sum test [103] is employed, which is a non-parametric test effective in determining the significant difference between the means of two data samples. In this test, the presence or absence of a significant difference between the performance of two metaheuristic algorithms is determined using a criterion called the p-value.

The results of implementing the Wilcoxon rank sum test on the performance of WOA against the performance of each of the competitor algorithms are reported in Table 6. Based on the obtained results, in cases where the p-value is less than 0.05, WOA has a statistically significant superiority in its competition with the corresponding algorithm. The findings obtained from the statistical analysis are that WOA has a significant statistical superiority over all twelve competitor algorithms in order to tackle the CEC 2017 test suite for all four problem dimensions equal to 10, 30, 50, and 100.

Table 6.

Wilcoxon rank sum test results.

5. WOA for Real-World Applications

One of the most special applications of metaheuristic algorithms is their efficiency in handling real world applications. In this section, the ability of WOA to tackle optimization tasks in real world applications is evaluated. With this aim, twenty-two constrained optimization problems from the CEC 2011 test suite and four engineering design problems have been selected.

5.1. Evaluation of CEC 2011 Test Suite

In this subsection, the capability of WOA and competitor algorithms to tackle the CEC 2011 test suite is challenged. The CEC 2011 test suite consists of twenty-two constrained optimization problems from real-world applications. The complete information, details, and description of the CEC 2011 test suite are available at [104]. The proposed WOA approach and each of the competitor algorithms are implemented in the CEC-2011 functions in twenty-five independent implementations, where each implementation contains 150,000 FEs.

The optimization results of the CEC 2011 test suite using WOA and competitor algorithms are reported in Table 7. The boxplot diagrams obtained from the implementation of metaheuristic algorithms on this test suite are plotted in Figure 7. The optimization results confirm that WOA has a high ability to manage exploration and exploitation, and establishing a balance between them has achieved suitable solutions for CEC 2011 test suite optimization problems. Simulation results show that WOA has provided a superior performance compared to competitor algorithms in order to tackle the CEC 2011 test suite, by achieving better results for all twenty-two optimization problems, from C11-F1 to C11-F22. In addition, the results obtained from the statistical analysis (reported in the last row of Table 7) confirm that WOA has a significant statistical superiority against all twelve competitor algorithms. The simulation findings are that WOA has an effective and promising performance for solving optimization tasks in real-world applications.

Table 7.

Optimization results of CEC 2011 test suite.

Figure 7.

Boxplot diagrams of WOA and competitor algorithms’ performances on CEC 2011 test suite.

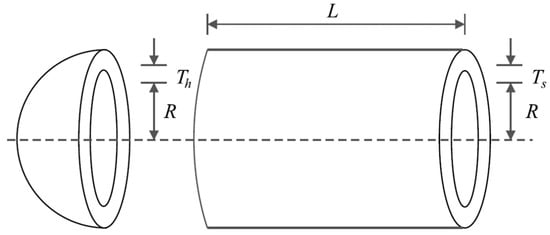

5.2. Pressure Vessel Design Problem

Pressure vessel design is a design challenge in engineering according to the schematic shown in Figure 8, whose main goal is to minimize the construction cost. The mathematical model of this design is as follows [105]:

Figure 8.

Schematic of pressure vessel design.

Subject to:

With

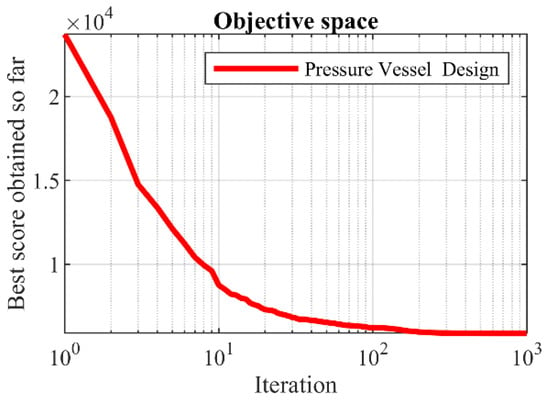

The results of tackling the pressure vessel design by employing WOA and competitor algorithms are presented in Table 8 and Table 9. The convergence curve of WOA, which shows the process of achieving a suitable solution for the pressure vessel design, is drawn in Figure 9. Based on the optimization results, WOA has provided the optimal design with the value of the objective function equal to (5882.8955) and the values of the design variables equal to (0.7780271, 0.3845792, and 40.312284, 200). From the simulation results, WOA has a superior performance compared to competitor algorithms for solving the pressure vessel design; this is because it provides better results for statistical indicators and design variables.

Table 8.

Performance of optimization algorithms on pressure vessel design problem.

Table 9.

Statistical results of optimization algorithms on pressure vessel design problem.

Figure 9.

WOA’s performance convergence curve on pressure vessel design.

5.3. Speed Reducer Design Problem

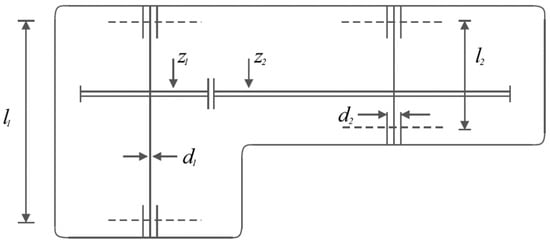

The speed reducer design is a design challenge in engineering according to the schematic shown in Figure 10, whose main goal is to minimize the weight of the speed reducer. The mathematical model of this design is as follows [106,107]:

Figure 10.

Schematic of speed reducer design.

Subject to:

With

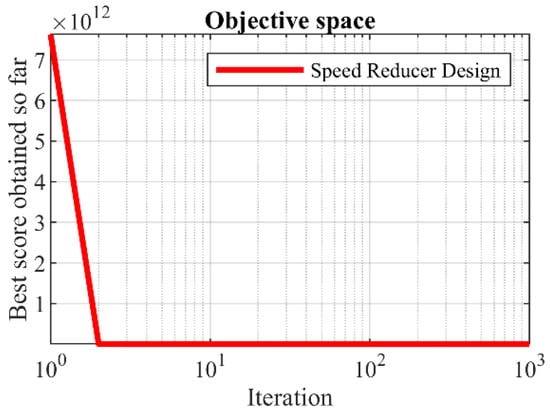

The results of employing WOA and competitor algorithms to tackle the speed reducer design are published in Table 10 and Table 11. The convergence curve of WOA while achieving the optimal solution for the speed reducer design is plotted in Figure 11. Based on the optimization results, WOA has provided the optimal design with the value of the objective function equal to (2996.3482) and the values of the design variables equal to (3.5, 0.7, 17, 7.3, 7.8, 3.3502147, and 5.2866832). From the analysis of simulation results, it can be concluded that WOA has provided a superior performance compared to competitor algorithms in order to tackle the speed reducer design.

Table 10.

Performance of optimization algorithms on speed reducer design problem.

Table 11.

Statistical results of optimization algorithms on speed reducer design problem.

Figure 11.

WOA’s performance convergence curve on speed reducer design.

5.4. Welded Beam Design

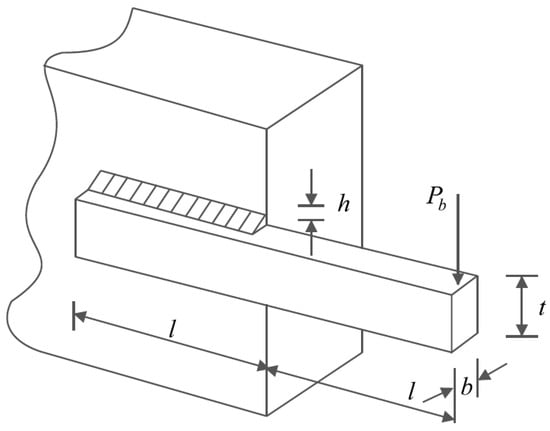

Welded beam design is a design challenge in engineering according to the schematic shown in Figure 12, whose main goal is to minimize the fabrication cost. The mathematical model of this design is as follows [32]:

Figure 12.

Schematic of welded beam design.

Subject to:

where

With

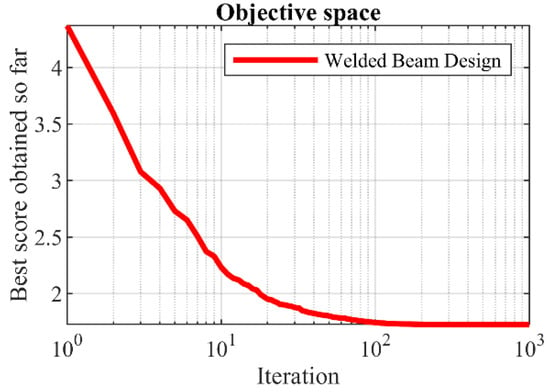

The implementation results of the WOA and competitor algorithms to tackle a welded beam design are reported in Table 12 and Table 13. The convergence curve of WOA, which shows the process of achieving the solution for a welded beam design, is drawn in Figure 13. Based on the optimization results, WOA has provided the optimal design with the value of the objective function equal to (1.7246798) and the values of the design variables equal to (0.2057296, 3.4704887, 9.0366239, and 0.2057296). Comparing the performance of metaheuristic algorithms shows that WOA has provided a superior performance by achieving better results for statistical indicators and design variables in competition with competitor algorithms in order to tackle the welded beam design.

Table 12.

Performance of optimization algorithms on welded beam design problem.

Table 13.

Statistical results of optimization algorithms on welded beam design problem.

Figure 13.

WOA’s performance convergence curve on welded beam design.

5.5. Tension/Compression Spring Design

Tension/compression spring design is a design challenge in engineering according to the schematic shown in Figure 14, whose main goal is to minimize the construction cost. The mathematical model of this design is as follows [32]:

Figure 14.

Schematic of tension/compression spring design.

Subject to:

With

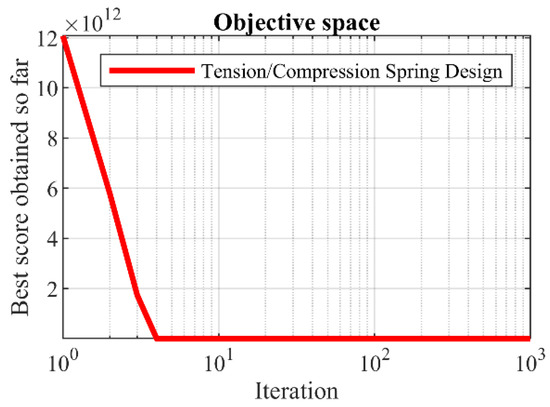

The results of dealing with a tension/compression spring design by employing WOA and competitor algorithms are published in Table 14 and Table 15. The convergence curve of WOA during reaching the appropriate solution for the tension/compression spring design is drawn in Figure 15. Based on the optimization results, WOA provided the optimal design with the value of the objective function equal to (0.0126019) and the values of the design variables equal to (0.0516891, 0.3567177, and 11.288966). The analysis of simulation results and the performance of metaheuristic algorithms shows that WOA provided a superior performance compared to competitor algorithms in order to tackle the tension/compression spring design, by achieving better results for statistical indicators and design variables. The WOA convergence curve shown in Figure 15 shows the process of achieving the optimal solution for the tension/compression spring objective function during successive iterations of the algorithm. As it turns out, WOA identified the region containing the original optimum in the initial iterations with high power in global search and exploration. Then WOA, relying on its high ability in local search and exploitation, tries, until the last iterations of the algorithm, to obtain better values for the objective function and converge to the global optimum. The convergence curve shows that WOA has a high power in exploring, exploiting, and balancing them during algorithm iterations.

Table 14.

Performance of optimization algorithms on tension/compression spring design problem.

Table 15.

Statistical results of optimization algorithms on tension/compression spring design problem.

Figure 15.

WOA’s performance convergence curve on tension/compression spring.

5.6. Application and Advantages of WOA for Supply Chain Management

While introducing the applications of the Wombat Optimization Algorithm (WOA) in supply chain management (SCM), its unique capabilities are distinguished by its optimal risk management, multi-objective information, agile operations, decisions to be collaborative, and sustainable development efforts, and offer advantages over traditional quality systems.

- Risk management and resilience: WOA can help improve the supply chain resilience by identifying and mitigating potential risks such as supply chain disruptions, natural disasters, and demand fluctuations on the snow. By incorporating risks into the optimization process, WOA helps companies create robust supply chain models that can better adapt to unexpected disruptions compared to traditional models.

- Multi-Objective Optimization: WOA can handle multi-objective optimization problems, where conflicting objectives such as cost minimization, lead time minimization, and service level maximization need to be balanced by the exploration–exploitation equilibrium of WOA on its Pareto front in contrast to the feasible search for trade-offs, giving decision makers the best solutions to choose from; traditional systems may struggle to meet many objective optimization problems and manage them effectively, as they often require complex changes or goal accumulations.

- Dynamic and real-time optimization: WOA can be optimized in dynamic and real-time optimization scenarios where supply chain conditions change over time, such as demand fluctuations, disruptions, or capacity constraints. By constantly updating solutions based on the latest information, WOA enables companies to make the right decisions in a timely manner to optimize supply chains. Traditional systems may require a periodic reassessment or manual intervention to accommodate dynamic situations, resulting in suboptimal solutions or increased response times.

- Collaboration and coordination optimization: WOA can optimize collaborative and coordinated decision-making among multiple entities within the supply chain, such as suppliers, manufacturers, distributors, and retailers. By optimizing decisions across the entire supply chain network, WOA helps companies achieve synergies and efficiencies that may not be achievable through localized optimizations. Traditional schemes often focus on optimizing individual components of the supply chain in isolation, leading to a suboptimal overall performance due to the lack of coordination and collaboration.

- Sustainability and green logistics: WOA can incorporate sustainability criteria such as carbon emissions, energy consumption, and the environmental impact into the optimization process, enabling companies to design more sustainable and environmentally friendly supply chain strategies. By optimizing supply chain operations with sustainability objectives in mind, WOA helps companies reduce their ecological footprint and achieve corporate social responsibility goals. Traditional schemes may overlook sustainability considerations or treat them as constraints rather than optimization objectives, resulting in less environmentally sustainable supply chain designs.

In summary, the Wombat Optimization Algorithm offers several advantages over traditional optimization schemes in various areas of supply chain management, including risk management, multi-objective optimization, dynamic optimization, collaboration optimization, and sustainability. Its nature-inspired approach and flexibility make it well-suited for addressing the complex and dynamic challenges faced by modern supply chains.

6. Conclusions and Future Works

In this paper, a new biomimetics metaheuristic algorithm named Wombat Optimization Algorithm (WOA) is used for supply chain optimization, and imitates wombat behaviors in nature. WOA’s basic inspiration was taken from the wombat’s foraging process and the animal’s escape strategy when faced with its predators. The theory of WOA was expressed and then mathematically modeled in two phases: (i) exploration based on the simulation of wombat movement during foraging and trying to find food and (ii) exploitation based on simulating wombat movements when diving towards nearby tunnels to defend against its predators. WOA’s ability to solve optimization problems was tested in the CEC 2017 test suite for problem dimensions equal to 10, 30, 50, and 100. The optimization results showed that WOA achieves suitable solutions for optimization problems with its high capability for managing exploration and exploitation, and balancing them during the search process. The quality of the results obtained from WOA was compared with the performance of twelve well-known metaheuristic algorithms. The simulation results showed that WOA has provided a superior performance in competition with the compared algorithms, by providing better results in most of the benchmark functions and achieving the rank of the first best optimizer. WOA’s ability to tackle optimization tasks in real-world applications was challenged in twenty-two constrained optimization problems from the CEC 2011 test suite and four engineering design problems. The results of this implementation showed that WOA, while providing better results compared to competitor algorithms, has an effective performance when addressing optimization issues in real world applications.

The introduction of WOA presents several research proposals for further work. The development of binary and multi-objective versions of WOA is one of the most special research potentials of this study for future works. Another research potential of WOA is its application to deal with supply chain applications. Employing WOA to tackle optimization problems in various sciences and optimization tasks in real-world applications is another suggestion of this paper for further work in the future.

Author Contributions

Conceptualization, Z.B. and K.K.; Methodology, Z.B., M.D. and Y.G.; Software, M.D. and Y.G.; Validation, K.K.; Investigation, K.K.; Writing—original draft, K.K. and M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Benmamoun, Z.; Hachimi, H.; Amine, A. Inventory management optimization using lean six-sigma Case of Spare parts Moroccan company. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Rabat, Morocco, 11–13 April 2017; pp. 1722–1730. [Google Scholar]

- Khlie, K.; Abdullah, A. Redesigning the hospital supply chain for enhanced performance using a lean methodology. Int. J. Ind. Eng 2013, 12, 917–927. [Google Scholar] [CrossRef]

- Jebbor, I.; Benmamoun, Z.; Hachimi, H. Optimizing Manufacturing Cycles to Improve Production: Application in the Traditional Shipyard Industry. Processes 2023, 11, 3136. [Google Scholar] [CrossRef]

- Khlie, K.; Abouabdellah, A. Identification of the patient requirements using lean six sigma and data mining. Int. J. Eng. 2017, 30, 691–699. [Google Scholar]

- Mondal, A.; Giri, B.K.; Roy, S.K.; Deveci, M.; Pamucar, D. Sustainable-resilient-responsive supply chain with demand prediction: An interval type-2 robust programming approach. Eng. Appl. Artif. Intell. 2024, 133, 108133. [Google Scholar] [CrossRef]

- Mondal, A.; Giri, B.K.; Roy, S.K. An integrated sustainable bio-fuel and bio-energy supply chain: A novel approach based on DEMATEL and fuzzy-random robust flexible programming with Me measure. Appl. Energy 2023, 343, 121225. [Google Scholar] [CrossRef]

- Mondal, A.; Roy, S.K. Behavioural three-way decision making with Fermatean fuzzy Mahalanobis distance: Application to the supply chain management problems. Appl. Soft Comput. 2024, 151, 111182. [Google Scholar] [CrossRef]

- Mondal, A.; Roy, S.K. Application of Choquet integral in interval type-2 Pythagorean fuzzy sustainable supply chain management under risk. Int. J. Intell. Syst. 2022, 37, 217–263. [Google Scholar] [CrossRef]

- Mondal, A.; Roy, S.K. Multi-objective sustainable opened- and closed-loop supply chain under mixed uncertainty during COVID-19 pandemic situation. Comput. Ind. Eng. 2021, 159, 107453. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning, and Operation, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Lee, H.L. The triple-A supply chain. Harv. Bus. Rev. 2004, 82, 102–113. [Google Scholar]

- Raouf, Y.; Benmamoun, Z.; Hachimi, H.; Jebbor, I.; Haqqi, M.; Akikiz, M. Towards a Smart and Sustainable Industry: Cycle Time optimization. In Proceedings of the 2023 3rd International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Mohammedia, Morocco, 18–19 May 2023; pp. 1–7. [Google Scholar]

- BOUAZZA, S.; Benmamoun, Z.; Hachimi, H. Optimization of logistics to support the African’s development. In Proceedings of the 2019 5th International Conference on Optimization and Applications (ICOA), Kenitra, Morocco, 25–26 April 2019; pp. 1–5. [Google Scholar]

- Elkhechafi, M.; Benmamoun, Z.; Hachimi, H.; Amine, A.; Elkettani, Y. Firefly Algorithm for Supply Chain Optimization. Lobachevskii J. Math. 2018, 39, 355–367. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, T.; Ma, S.; Chen, M. Dandelion Optimizer: A nature-inspired metaheuristic algorithm for engineering applications. Eng. Appl. Artif. Intell. 2022, 114, 105075. [Google Scholar] [CrossRef]

- Sergeyev, Y.D.; Kvasov, D.; Mukhametzhanov, M. On the efficiency of nature-inspired metaheuristics in expensive global optimization with limited budget. Sci. Rep. 2018, 8, 453. [Google Scholar] [CrossRef] [PubMed]

- Liberti, L.; Kucherenko, S. Comparison of deterministic and stochastic approaches to global optimization. Int. Trans. Oper. Res. 2005, 12, 263–285. [Google Scholar] [CrossRef]

- Koc, I.; Atay, Y.; Babaoglu, I. Discrete tree seed algorithm for urban land readjustment. Eng. Appl. Artif. Intell. 2022, 112, 104783. [Google Scholar] [CrossRef]

- Liñán, D.A.; Contreras-Zarazúa, G.; Sánchez-Ramírez, E.; Segovia-Hernández, J.G.; Ricardez-Sandoval, L.A. A hybrid deterministic-stochastic algorithm for the optimal design of process flowsheets with ordered discrete decisions. Comput. Chem. Eng. 2024, 180, 108501. [Google Scholar] [CrossRef]

- de Armas, J.; Lalla-Ruiz, E.; Tilahun, S.L.; Voß, S. Similarity in metaheuristics: A gentle step towards a comparison methodology. Nat. Comput. 2022, 21, 265–287. [Google Scholar] [CrossRef]

- Kumar, G.; Saha, R.; Conti, M.; Devgun, T.; Thomas, R. GREPHRO: Nature-inspired optimization duo for Internet-of-Things. Internet Things 2024, 25, 101067. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Zhang, Z.; Fan, H.; Zhang, J.; Mirjalili, S.; Khodadadi, N.; Cao, Q. Electric eel foraging optimization: A new bio-inspired optimizer for engineering applications. Expert Syst. Appl. 2024, 238, 122200. [Google Scholar] [CrossRef]

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef]

- Dorigo, M.; Maniezzo, V.; Colorni, A. Ant system: Optimization by a colony of cooperating agents. IEEE Trans. Syst. Man Cybern. Part B Cybern. 1996, 26, 29–41. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Yang, X.-S. Firefly algorithm, stochastic test functions and design optimisation. Int. J. Bio-Inspired Comput. 2010, 2, 78–84. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. Artificial bee colony (ABC) optimization algorithm for solving constrained optimization problems. In Proceedings of the International Fuzzy Systems Association World Congress, Cancun, Mexico, 18–21 June 2007; pp. 789–798. [Google Scholar]

- Benmamoun, Z.; Fethallah, W.; Ahlaqqach, M.; Jebbor, I.; Benmamoun, M.; Elkhechafi, M. Butterfly Algorithm for Sustainable Lot Size Optimization. Sustainability 2023, 15, 11761. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R.; Zidan, M.; Jameel, M.; Abouhawwash, M. Mantis Search Algorithm: A novel bio-inspired algorithm for global optimization and engineering design problems. Comput. Methods Appl. Mech. Eng. 2023, 415, 116200. [Google Scholar] [CrossRef]

- Hu, G.; Guo, Y.; Wei, G.; Abualigah, L. Genghis Khan shark optimizer: A novel nature-inspired algorithm for engineering optimization. Adv. Eng. Inform. 2023, 58, 102210. [Google Scholar] [CrossRef]

- Agushaka, J.O.; Ezugwu, A.E.; Abualigah, L. Gazelle optimization algorithm: A novel nature-inspired metaheuristic optimizer. Neural Comput. Appl. 2023, 35, 4099–4131. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The whale optimization algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Abualigah, L.; Abd Elaziz, M.; Sumari, P.; Geem, Z.W.; Gandomi, A.H. Reptile Search Algorithm (RSA): A nature-inspired meta-heuristic optimizer. Expert Syst. Appl. 2022, 191, 116158. [Google Scholar] [CrossRef]

- Jiang, Y.; Wu, Q.; Zhu, S.; Zhang, L. Orca predation algorithm: A novel bio-inspired algorithm for global optimization problems. Expert Syst. Appl. 2022, 188, 116026. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Kaur, S.; Awasthi, L.K.; Sangal, A.L.; Dhiman, G. Tunicate Swarm Algorithm: A new bio-inspired based metaheuristic paradigm for global optimization. Eng. Appl. Artif. Intell. 2020, 90, 103541. [Google Scholar] [CrossRef]

- Abdollahzadeh, B.; Gharehchopogh, F.S.; Mirjalili, S. African vultures optimization algorithm: A new nature-inspired metaheuristic algorithm for global optimization problems. Comput. Ind. Eng. 2021, 158, 107408. [Google Scholar] [CrossRef]

- Faramarzi, A.; Heidarinejad, M.; Mirjalili, S.; Gandomi, A.H. Marine Predators Algorithm: A nature-inspired metaheuristic. Expert Syst. Appl. 2020, 152, 113377. [Google Scholar] [CrossRef]

- Braik, M.; Hammouri, A.; Atwan, J.; Al-Betar, M.A.; Awadallah, M.A. White Shark Optimizer: A novel bio-inspired meta-heuristic algorithm for global optimization problems. Knowl.-Based Syst. 2022, 243, 108457. [Google Scholar] [CrossRef]

- Goldberg, D.E.; Holland, J.H. Genetic Algorithms and Machine Learning. Mach. Learn. 1988, 3, 95–99. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution–A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- De Castro, L.N.; Timmis, J.I. Artificial immune systems as a novel soft computing paradigm. Soft Comput. 2003, 7, 526–544. [Google Scholar] [CrossRef]

- Reynolds, R.G. An introduction to cultural algorithms. In Proceedings of the Third Annual Conference on Evolutionary Programming, San Diego, CA, USA, 24–26 February 1994; pp. 131–139. [Google Scholar]

- Koza, J.R.; Koza, J.R. Genetic Programming: On the Programming of Computers by Means of Natural Selection; MIT Press: Cambridge, MA, USA, 1992; Volume 1. [Google Scholar]

- Beyer, H.-G.; Schwefel, H.-P. Evolution strategies–a comprehensive introduction. Nat. Comput. 2002, 1, 3–52. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Rashedi, E.; Nezamabadi-Pour, H.; Saryazdi, S. GSA: A gravitational search algorithm. Inf. Sci. 2009, 179, 2232–2248. [Google Scholar] [CrossRef]

- Hashim, F.A.; Mostafa, R.R.; Hussien, A.G.; Mirjalili, S.; Sallam, K.M. Fick’s Law Algorithm: A physical law-based algorithm for numerical optimization. Knowl.-Based Syst. 2023, 260, 110146. [Google Scholar] [CrossRef]

- Su, H.; Zhao, D.; Heidari, A.A.; Liu, L.; Zhang, X.; Mafarja, M.; Chen, H. RIME: A physics-based optimization. Neurocomputing 2023, 532, 183–214. [Google Scholar] [CrossRef]

- Kaveh, A.; Dadras, A. A novel meta-heuristic optimization algorithm: Thermal exchange optimization. Adv. Eng. Softw. 2017, 110, 69–84. [Google Scholar] [CrossRef]

- Eskandar, H.; Sadollah, A.; Bahreininejad, A.; Hamdi, M. Water cycle algorithm–A novel metaheuristic optimization method for solving constrained engineering optimization problems. Comput. Struct. 2012, 110, 151–166. [Google Scholar] [CrossRef]

- Wei, Z.; Huang, C.; Wang, X.; Han, T.; Li, Y. Nuclear reaction optimization: A novel and powerful physics-based algorithm for global optimization. IEEE Access 2019, 7, 66084–66109. [Google Scholar] [CrossRef]

- Hashim, F.A.; Houssein, E.H.; Mabrouk, M.S.; Al-Atabany, W.; Mirjalili, S. Henry gas solubility optimization: A novel physics-based algorithm. Future Gener. Comput. Syst. 2019, 101, 646–667. [Google Scholar] [CrossRef]

- Pereira, J.L.J.; Francisco, M.B.; Diniz, C.A.; Oliver, G.A.; Cunha, S.S., Jr.; Gomes, G.F. Lichtenberg algorithm: A novel hybrid physics-based meta-heuristic for global optimization. Expert Syst. Appl. 2021, 170, 114522. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Hatamlou, A. Multi-verse optimizer: A nature-inspired algorithm for global optimization. Neural Comput. Appl. 2016, 27, 495–513. [Google Scholar] [CrossRef]

- Cuevas, E.; Oliva, D.; Zaldivar, D.; Pérez-Cisneros, M.; Sossa, H. Circle detection using electro-magnetism optimization. Inf. Sci. 2012, 182, 40–55. [Google Scholar] [CrossRef]

- Hatamlou, A. Black hole: A new heuristic optimization approach for data clustering. Inf. Sci. 2013, 222, 175–184. [Google Scholar] [CrossRef]

- Hashim, F.A.; Hussain, K.; Houssein, E.H.; Mabrouk, M.S.; Al-Atabany, W. Archimedes optimization algorithm: A new metaheuristic algorithm for solving optimization problems. Appl. Intell. 2021, 51, 1531–1551. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D. Teaching–learning-based optimization: A novel method for constrained mechanical design optimization problems. Comput.-Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Matoušová, I.; Trojovský, P.; Dehghani, M.; Trojovská, E.; Kostra, J. Mother optimization algorithm: A new human-based metaheuristic approach for solving engineering optimization. Sci. Rep. 2023, 13, 10312. [Google Scholar] [CrossRef] [PubMed]

- Faridmehr, I.; Nehdi, M.L.; Davoudkhani, I.F.; Poolad, A. Mountaineering Team-Based Optimization: A Novel Human-Based Metaheuristic Algorithm. Mathematics 2023, 11, 1273. [Google Scholar] [CrossRef]

- Oladejo, S.O.; Ekwe, S.O.; Akinyemi, L.A.; Mirjalili, S.A. The Deep Sleep Optimiser: A Human-Based Metaheuristic Approach. IEEE Access 2023, 11, 83639–83665. [Google Scholar] [CrossRef]

- Mohamed, A.W.; Hadi, A.A.; Mohamed, A.K. Gaining-sharing knowledge based algorithm for solving optimization problems: A novel nature-inspired algorithm. Int. J. Mach. Learn. Cybern. 2020, 11, 1501–1529. [Google Scholar] [CrossRef]

- Tan, Y.; Zhu, Y. Fireworks algorithm for optimization. In Proceedings of the Advances in Swarm Intelligence: First International Conference, ICSI 2010, Proceedings, Part I 1, Beijing, China, 12–15 June 2010; pp. 355–364. [Google Scholar]

- Ayyarao, T.L.; RamaKrishna, N.; Elavarasam, R.M.; Polumahanthi, N.; Rambabu, M.; Saini, G.; Khan, B.; Alatas, B. War Strategy Optimization Algorithm: A New Effective Metaheuristic Algorithm for Global Optimization. IEEE Access 2022, 10, 25073–25105. [Google Scholar] [CrossRef]

- Al-Betar, M.A.; Alyasseri, Z.A.A.; Awadallah, M.A.; Abu Doush, I. Coronavirus herd immunity optimizer (CHIO). Neural Comput. Appl. 2021, 33, 5011–5042. [Google Scholar] [CrossRef] [PubMed]

- Braik, M.; Ryalat, M.H.; Al-Zoubi, H. A novel meta-heuristic algorithm for solving numerical optimization problems: Ali Baba and the forty thieves. Neural Comput. Appl. 2022, 34, 409–455. [Google Scholar] [CrossRef]

- Moghdani, R.; Salimifard, K. Volleyball premier league algorithm. Appl. Soft Comput. 2018, 64, 161–185. [Google Scholar] [CrossRef]

- Ma, B.; Hu, Y.; Lu, P.; Liu, Y. Running city game optimizer: A game-based metaheuristic optimization algorithm for global optimization. J. Comput. Des. Eng. 2023, 10, 65–107. [Google Scholar] [CrossRef]

- Kosasih, E.E.; Papadakis, E.; Baryannis, G.; Brintrup, A. A review of explainable artificial intelligence in supply chain management using neurosymbolic approaches. Int. J. Prod. Res. 2024, 62, 1510–1540. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Machado, R.L. Application of optimization methods in the closed-loop supply chain: A literature review. J. Comb. Optim. 2021, 41, 357–400. [Google Scholar] [CrossRef]

- Toaza, B.; Esztergár-Kiss, D. A review of metaheuristic algorithms for solving TSP-based scheduling optimization problems. Appl. Soft Comput. 2023, 148, 110908. [Google Scholar] [CrossRef]

- Abualigah, L.; Hanandeh, E.S.; Zitar, R.A.; Thanh, C.-L.; Khatir, S.; Gandomi, A.H. Revolutionizing sustainable supply chain management: A review of metaheuristics. Eng. Appl. Artif. Intell. 2023, 126, 106839. [Google Scholar] [CrossRef]

- Patne, K.; Shukla, N.; Kiridena, S.; Tiwari, M.K. Solving closed-loop supply chain problems using game theoretic particle swarm optimisation. Int. J. Prod. Res. 2018, 56, 5836–5853. [Google Scholar] [CrossRef]

- Hong, J.; Diabat, A.; Panicker, V.V.; Rajagopalan, S. A two-stage supply chain problem with fixed costs: An ant colony optimization approach. Int. J. Prod. Econ. 2018, 204, 214–226. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, D.; Chen, Y.; Yu, D.; Wang, L.; Li, K. Fast artificial bee colony algorithm with complex network and naive bayes classifier for supply chain network management. Soft Comput. 2019, 23, 13321–13337. [Google Scholar] [CrossRef]

- Cheraghalipour, A.; Paydar, M.M.; Hajiaghaei-Keshteli, M. Designing and solving a bi-level model for rice supply chain using the evolutionary algorithms. Comput. Electron. Agric. 2019, 162, 651–668. [Google Scholar] [CrossRef]

- Yu, W.; Hou, G.; Li, J. Supply chain joint inventory management and cost optimization based on ant colony algorithm and fuzzy model. Teh. Vjesn. 2019, 26, 1729–1737. [Google Scholar]

- Xiong, F.; Gong, P.; Jin, P.; Fan, J. Supply chain scheduling optimization based on genetic particle swarm optimization algorithm. Clust. Comput. 2019, 22 (Suppl. 6), 14767–14775. [Google Scholar] [CrossRef]

- Igiri, C.P.; Singh, Y.; Bhargava, D.; Shikaa, S. Improved African buffalo optimisation algorithm for petroleum product supply chain management. Int. J. Grid Util. Comput. 2020, 11, 769–779. [Google Scholar] [CrossRef]

- Sinha, A.K.; Anand, A. Optimizing supply chain network for perishable products using improved bacteria foraging algorithm. Appl. Soft Comput. 2020, 86, 105921. [Google Scholar] [CrossRef]

- Nezamoddini, N.; Gholami, A.; Aqlan, F. A risk-based optimization framework for integrated supply chains using genetic algorithm and artificial neural networks. Int. J. Prod. Econ. 2020, 225, 107569. [Google Scholar] [CrossRef]

- Keshavarz-Ghorbani, F.; Pasandideh, S.H.R. Optimizing a two-level closed-loop supply chain under the vendor managed inventory contract and learning: Fibonacci, GA, IWO, MFO algorithms. Neural Comput. Appl. 2021, 33, 9425–9450. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Dulebenets, M.A.; Hajiaghaei–Keshteli, M.; Tavakkoli-Moghaddam, R.; Safaeian, M.; Mirzahosseinian, H. Two hybrid meta-heuristic algorithms for a dual-channel closed-loop supply chain network design problem in the tire industry under uncertainty. Adv. Eng. Inform. 2021, 50, 101418. [Google Scholar] [CrossRef]

- Fathi, M.; Khakifirooz, M.; Diabat, A.; Chen, H. An integrated queuing-stochastic optimization hybrid Genetic Algorithm for a location-inventory supply chain network. Int. J. Prod. Econ. 2021, 237, 108139. [Google Scholar] [CrossRef]

- Ehtesham Rasi, R.; Sohanian, M. A multi-objective optimization model for sustainable supply chain network with using genetic algorithm. J. Model. Manag. 2021, 16, 714–727. [Google Scholar] [CrossRef]

- Seydanlou, P.; Jolai, F.; Tavakkoli-Moghaddam, R.; Fathollahi-Fard, A.M. A multi-objective optimization framework for a sustainable closed-loop supply chain network in the olive industry: Hybrid meta-heuristic algorithms. Expert Syst. Appl. 2022, 203, 117566. [Google Scholar] [CrossRef]

- Karami, D. Supply Chain Network Design Using Particle Swarm Optimization (PSO) Algorithm. Int. J. Ind. Eng. Oper. Res. 2022, 4, 1–8. [Google Scholar]

- Chaharmahali, G.; Ghandalipour, D.; Jasemi, M.; Molla-Alizadeh-Zavardehi, S. Modified metaheuristic algorithms to design a closed-loop supply chain network considering quantity discount and fixed-charge transportation. Expert Syst. Appl. 2022, 202, 117364. [Google Scholar] [CrossRef]

- Chouhan, V.K.; Goodarzian, F.; Esfandiari, M.; Abraham, A. Designing a New Supply Chain Network Considering Transportation Delays Using Meta-heuristics. In Intelligent and Fuzzy Techniques for Emerging Conditions and Digital Transformation, Proceedings of the INFUS 2021 Conference, Istanbul, Turkey, 24–26 August 2021; Kahraman, C., Cebi, S., Cevik Onar, S., Oztaysi, B., Tolga, A.C., Sari, I.U., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 570–579. [Google Scholar]

- Mohammed, A.; Al-shaibani, M.S.; Duffuaa, S.O. A meta-heuristic-based algorithm for designing multi-objective multi-echelon supply chain network. Appl. Soft Comput. 2023, 147, 110774. [Google Scholar] [CrossRef]

- Pérez, C.; Climent, L.; Nicoló, G.; Arbelaez, A.; Salido, M.A. A hybrid metaheuristic with learning for a real supply chain scheduling problem. Eng. Appl. Artif. Intell. 2023, 126, 107188. [Google Scholar] [CrossRef]

- Kuo, R.; Luthfiansyah, M.F.; Masruroh, N.A.; Zulvia, F.E. Application of improved multi-objective particle swarm optimization algorithm to solve disruption for the two-stage vehicle routing problem with time windows. Expert Syst. Appl. 2023, 225, 120009. [Google Scholar] [CrossRef]

- Sadeghi, A.H.; Bani, E.A.; Fallahi, A.; Handfield, R. Grey wolf optimizer and whale optimization algorithm for stochastic inventory management of reusable products in a two-level supply chain. IEEE Access 2023, 11, 40278–40297. [Google Scholar] [CrossRef]

- Golmohammadi, A.-M.; Abedsoltan, H.; Goli, A.; Ali, I. Multi-objective dragonfly algorithm for optimizing a sustainable supply chain under resource sharing conditions. Comput. Ind. Eng. 2024, 187, 109837. [Google Scholar] [CrossRef]

- Hamidian, N.; Paydar, M.M.; Hajiaghaei-Keshteli, M. A hybrid meta-heuristic approach to design a Bi-objective cosmetic tourism supply chain: A case study. Eng. Appl. Artif. Intell. 2024, 127, 107331. [Google Scholar] [CrossRef]

- Pham, V.H.S.; Nguyen, V.N.; Nguyen Dang, N.T. Hybrid whale optimization algorithm for enhanced routing of limited capacity vehicles in supply chain management. Sci. Rep. 2024, 14, 793. [Google Scholar] [CrossRef] [PubMed]