A Higher-Order Theory for Nonlinear Dynamic of an FG Porous Piezoelectric Microtube Exposed to a Periodic Load

Abstract

1. Introduction

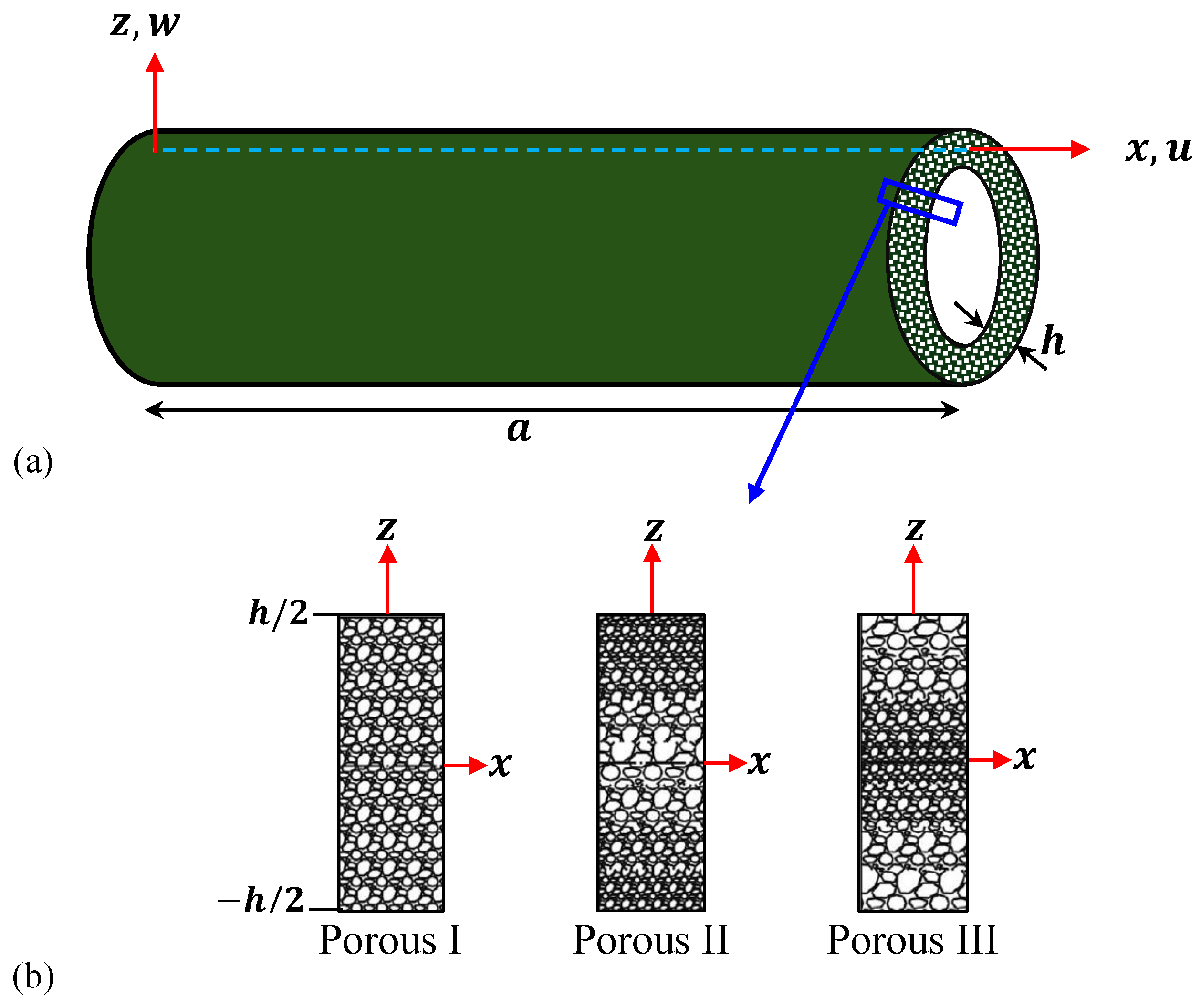

2. Problem Formulation

2.1. Electric Field

2.2. Hygrothermal Field

2.3. Porosity Distribution Types

2.3.1. Porous I

2.3.2. Porous II

2.3.3. Porous III

2.4. Equations of Motion

3. Solution Procedure

3.1. Nonlinear Dynamic Solution

3.2. Linear Dynamic Solution

3.2.1. Frequency Solution

3.2.2. Wave Propagation Solution

4. Numerical Results and Discussion

4.1. Verification

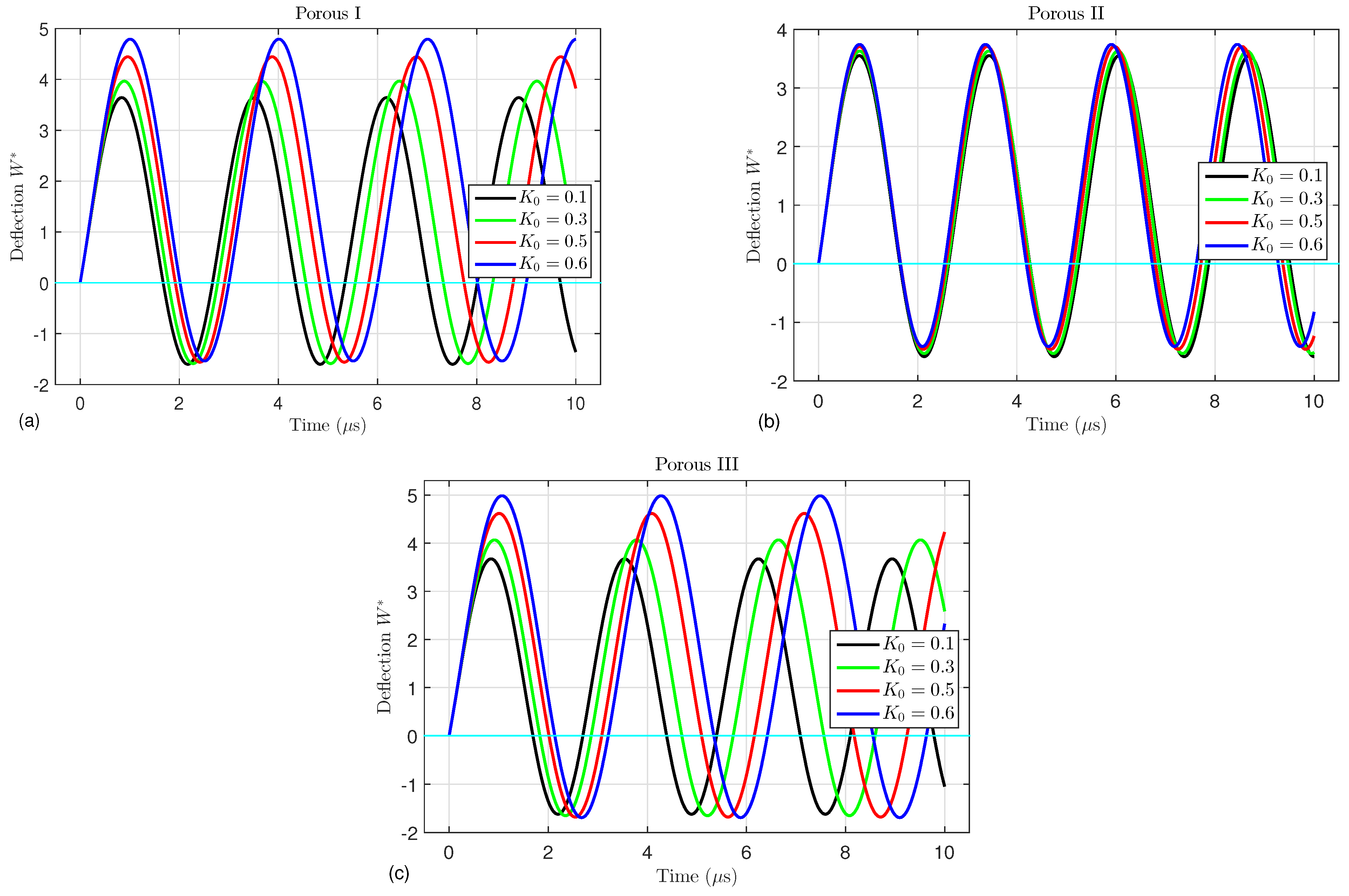

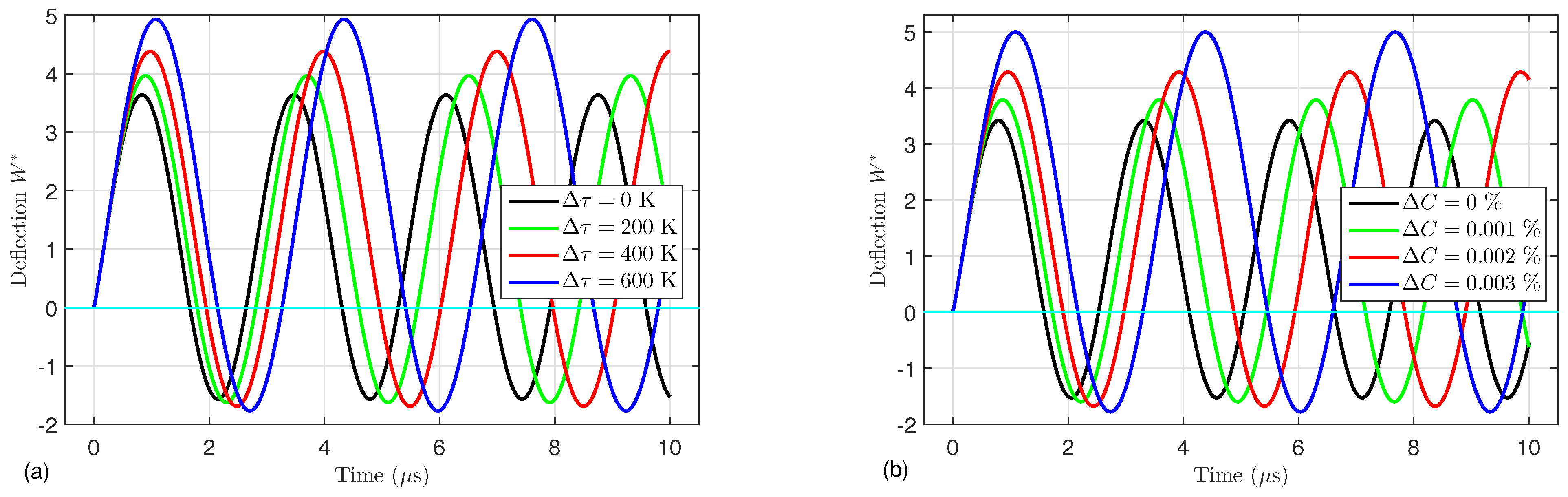

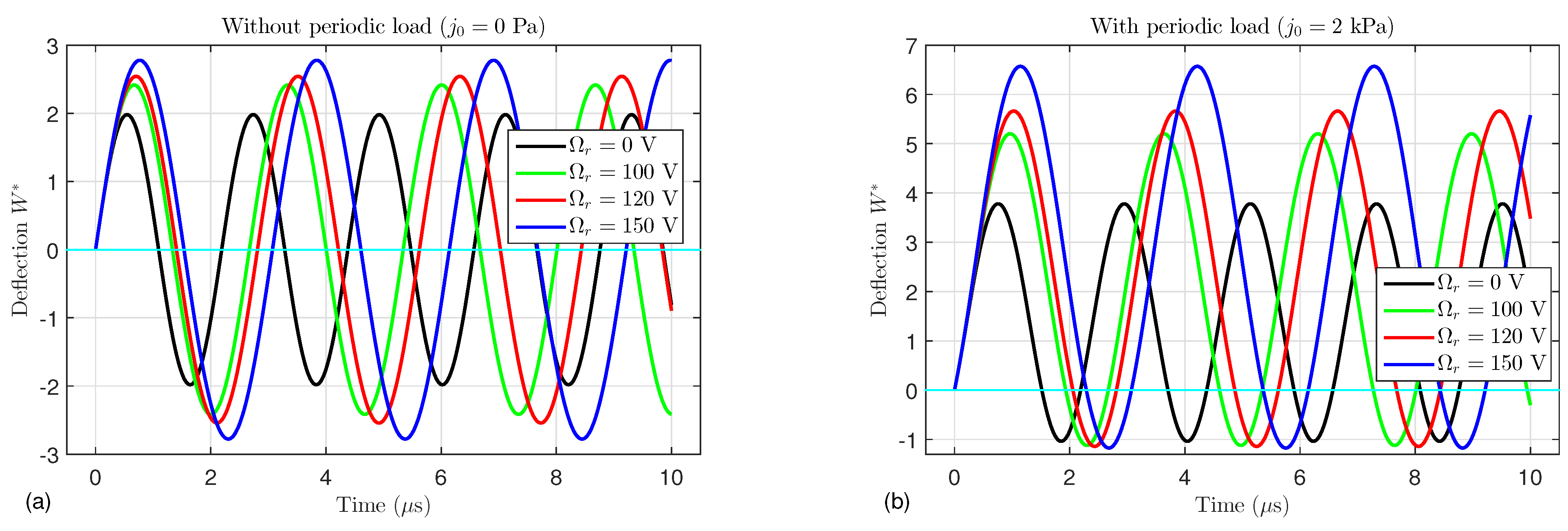

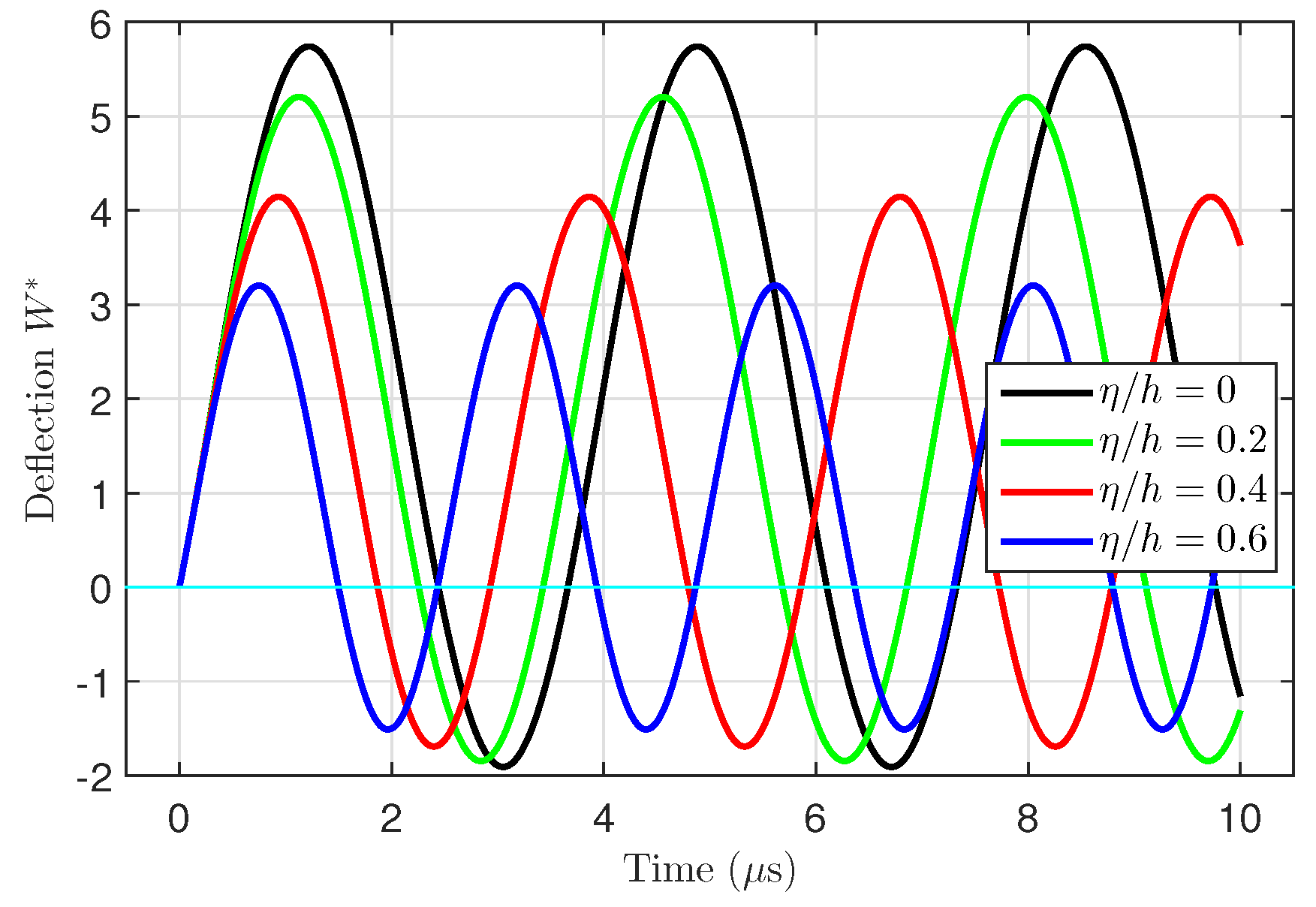

4.2. Nonlinear Dynamic Results

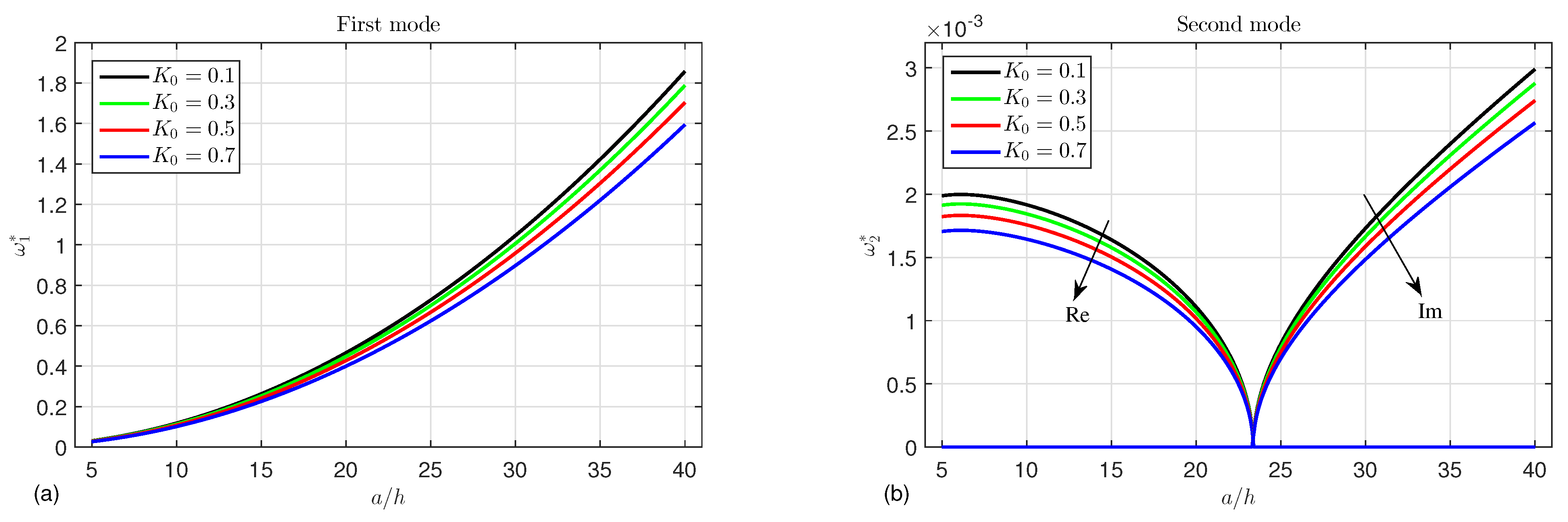

4.3. Frequency Results

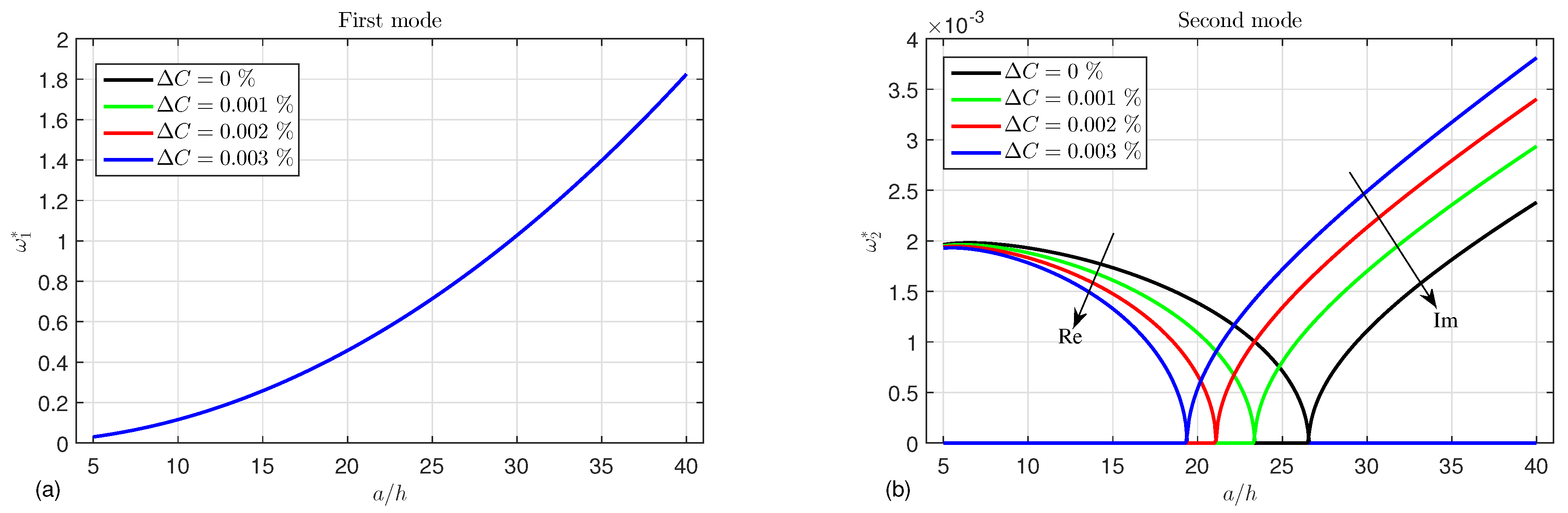

4.4. Wave Propagation Results

5. Conclusions

- The nonlinear dynamic deflection increases as the porosity coefficient, temperature, moisture, periodic load, and length-to-thickness ratio increase because the microtubes become weaker.

- The material length scale parameter has a stiffening effect on the microtube, so the deflection decreases as the material parameter increases.

- Since the presence of the porosities, temperature, moisture, and electric voltage leads to a decrement in the tube stiffness, the eigenfrequency decreases.

- The wave frequency and phase velocity decrease with increasing porosity factor, indicating its dampening effect.

- The present model can be used to transport petroleum or any other fluid in very hot environments because the presence of pores in the pipe wall reduces the effect of temperature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rezaiee-Pajand, M.; Hozhabrossadati, S.M. Analytical and numerical method for free vibration of double-axially functionally graded beams. Compos. Struct. 2016, 152, 488–498. [Google Scholar] [CrossRef]

- Sofiyev, A. On the solution of dynamic stability problem of functionally graded viscoelastic plates with different initial conditions in viscoelastic media. Mathematics 2023, 11, 823. [Google Scholar] [CrossRef]

- Yang, S.; Sun, X.; Cai, Z. Isogeometric analysis for free vibration of functionally graded plates using a new quasi-3D spectral displacement formulation. Mathematics 2023, 11, 2660. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, S.h.; Han, W. The static shape control for intelligent structures. Finite Elem. Anal. Des. 1997, 26, 303–314. [Google Scholar] [CrossRef]

- He, X.; Ng, T.; Sivashanker, S.; Liew, K. Active control of FGM plates with integrated piezoelectric sensors and actuators. Int. J. Solids Struct. 2001, 38, 1641–1655. [Google Scholar] [CrossRef]

- Fakhari, V.; Ohadi, A.; Yousefian, P. Nonlinear free and forced vibration behavior of functionally graded plate with piezoelectric layers in thermal environment. Compos. Struct. 2011, 93, 2310–2321. [Google Scholar] [CrossRef]

- Kulikov, G.; Plotnikova, S. A new approach to three-dimensional exact solutions for functionally graded piezoelectric laminated plates. Compos. Struct. 2013, 106, 33–46. [Google Scholar] [CrossRef]

- Kulikov, G.M.; Plotnikova, S. Three-dimensional exact analysis of piezoelectric laminated plates via a sampling surfaces method. Int. J. Solids Struct. 2013, 50, 1916–1929. [Google Scholar] [CrossRef]

- Mirzavand, B.; Eslami, M.; Reddy, J. Dynamic thermal postbuckling analysis of shear deformable piezoelectric-FGM cylindrical shells. J. Therm. Stress. 2013, 36, 189–206. [Google Scholar] [CrossRef]

- Moradi-Dastjerdi, R.; Behdinan, K. Free vibration response of smart sandwich plates with porous CNT-reinforced and piezoelectric layers. Appl. Math. Model. 2021, 96, 66–79. [Google Scholar] [CrossRef]

- Abazid, M.A.; Sobhy, M. Thermo-electro-mechanical bending of FG piezoelectric microplates on Pasternak foundation based on a four-variable plate model and the modified couple stress theory. Microsyst. Technol. 2018, 24, 1227–1245. [Google Scholar] [CrossRef]

- Al Mukahal, F.H.; Abazid, M.A.; Sobhy, M. Investigating Electromechanical Buckling Response of FG-GPL-Reinforced Piezoelectric Doubly Curved Shallow Shells Embedded in an Elastic Substrate. Materials 2023, 16, 2975. [Google Scholar] [CrossRef] [PubMed]

- Sobhy, M.; Radwan, A.F. Porosity and size effects on electro-hygrothermal bending of FG sandwich piezoelectric cylindrical shells with porous core via a four-variable shell theory. Case Stud. Therm. Eng. 2023, 45, 102934. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, W. Nonlinear Oscillations of a Composite Stepped Piezoelectric Cantilever Plate with Aerodynamic Force and External Excitation. Mathematics 2023, 11, 3034. [Google Scholar] [CrossRef]

- Alsebai, F.; Al Mukahal, F.H.; Sobhy, M. Semi-analytical solution for thermo-piezoelectric bending of FG porous plates reinforced with graphene platelets. Mathematics 2022, 10, 4104. [Google Scholar] [CrossRef]

- Zeeshan; Ahammad, N.A.; Shah, N.A.; Chung, J.D.; Khan, M.S. Computational and stability analysis of MHD time-dependent thermal reaction flow impinging on a vertical porous plate enclosing magnetic Prandtl number and thermal radiation effect. Mathematics 2023, 11, 1376. [Google Scholar] [CrossRef]

- Talebitooti, R.; Zarastvand, M. The effect of nature of porous material on diffuse field acoustic transmission of the sandwich aerospace composite doubly curved shell. Aerosp. Sci. Technol. 2018, 78, 157–170. [Google Scholar] [CrossRef]

- Melaibari, A.; Mohamed, S.A.; Assie, A.E.; Shanab, R.A.; Eltaher, M.A. Static response of 2D FG porous plates resting on elastic foundation using midplane and neutral surfaces with movable constraints. Mathematics 2022, 10, 4784. [Google Scholar] [CrossRef]

- Melaibari, A.; Mohamed, S.A.; Assie, A.E.; Shanab, R.A.; Eltaher, M.A. Free vibration characteristics of bidirectional graded porous plates with elastic foundations using 2D-DQM. Mathematics 2022, 11, 46. [Google Scholar] [CrossRef]

- Qin, Q.; Zheng, X.; Zhang, J.; Yuan, C.; Wang, T. Dynamic response of square sandwich plates with a metal foam core subjected to low-velocity impact. Int. J. Impact Eng. 2018, 111, 222–235. [Google Scholar] [CrossRef]

- Cong, P.H.; Chien, T.M.; Khoa, N.D.; Duc, N.D. Nonlinear thermomechanical buckling and post-buckling response of porous FGM plates using Reddy’s HSDT. Aerosp. Sci. Technol. 2018, 77, 419–428. [Google Scholar] [CrossRef]

- Sobhy, M. Size-dependent hygro-thermal buckling of porous FGM sandwich microplates and microbeams using a novel four-variable shear deformation theory. Int. J. Appl. Mech. 2020, 12, 2050017. [Google Scholar] [CrossRef]

- Amir, S.; Arshid, E.; Arani, M.R.G. Size-dependent magneto-electro-elastic vibration analysis of FG saturated porous annular/circular micro sandwich plates embedded with nano-composite face sheets subjected to multi-physical pre loads. Smart Struct. Syst. Int. J. 2019, 23, 429–447. [Google Scholar]

- Safaei, B.; Onyibo, E.C.; Hurdoganoglu, D. Thermal buckling and bending analyses of carbon foam beams sandwiched by composite faces under axial compression. Facta Univ. Ser. Mech. Eng. 2022, 20, 589–615. [Google Scholar] [CrossRef]

- Yang, F.; Chong, A.; Lam, D.C.C.; Tong, P. Couple stress based strain gradient theory for elasticity. Int. J. Solids Struct. 2002, 39, 2731–2743. [Google Scholar] [CrossRef]

- Ke, L.L.; Liu, C.; Wang, Y.S. Free vibration of nonlocal piezoelectric nanoplates under various boundary conditions. Phys. E Low-Dimens. Syst. Nanostruct. 2015, 66, 93–106. [Google Scholar] [CrossRef]

- Zhang, B.; He, Y.; Liu, D.; Gan, Z.; Shen, L. A non-classical Mindlin plate finite element based on a modified couple stress theory. Eur. J. Mech.-A/Solids 2013, 42, 63–80. [Google Scholar] [CrossRef]

- Bodaghi, M.; Shakeri, M. An analytical approach for free vibration and transient response of functionally graded piezoelectric cylindrical panels subjected to impulsive loads. Compos. Struct. 2012, 94, 1721–1735. [Google Scholar] [CrossRef]

- Sobhy, M.; Alsaleh, F. Nonlinear bending of FG metal/graphene sandwich microplates with metal foam core resting on nonlinear elastic foundations via a new plate theory. Mech. Based Des. Struct. Mach. 2024, 52, 3842–3869. [Google Scholar] [CrossRef]

- Chen, W.; Li, L.; Xu, M. A modified couple stress model for bending analysis of composite laminated beams with first order shear deformation. Compos. Struct. 2011, 93, 2723–2732. [Google Scholar] [CrossRef]

- Jung, W.Y.; Han, S.C.; Park, W.T. A modified couple stress theory for buckling analysis of S-FGM nanoplates embedded in Pasternak elastic medium. Compos. Part B Eng. 2014, 60, 746–756. [Google Scholar] [CrossRef]

- Reddy, J.; Pang, S. Nonlocal continuum theories of beams for the analysis of carbon nanotubes. J. Appl. Phys. 2008, 103, 023511. [Google Scholar] [CrossRef]

- Tang, Y.; Xu, J.; Yang, T. Natural dynamic characteristics of a circular cylindrical Timoshenko tube made of three-directional functionally graded material. Appl. Math. Mech. 2022, 43, 479–496. [Google Scholar] [CrossRef]

- Murmu, T.; Pradhan, S. Thermo-mechanical vibration of a single-walled carbon nanotube embedded in an elastic medium based on nonlocal elasticity theory. Comput. Mater. Sci. 2009, 46, 854–859. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Salari, E. Thermo-mechanical vibration analysis of a single-walled carbon nanotube embedded in an elastic medium based on higher-order shear deformation beam theory. J. Mech. Sci. Technol. 2015, 29, 3797–3803. [Google Scholar] [CrossRef]

- Ansari, R.; Sahmani, S. Small scale effect on vibrational response of single-walled carbon nanotubes with different boundary conditions based on nonlocal beam models. Commun. Nonlinear Sci. Numer. Simul. 2012, 17, 1965–1979. [Google Scholar] [CrossRef]

- Ke, L.L.; Wang, Y.S.; Yang, J.; Kitipornchai, S. Free vibration of size-dependent magneto-electro-elastic nanoplates based on the nonlocal theory. Acta Mech. Sin. 2014, 30, 516–525. [Google Scholar] [CrossRef]

- Ke, L.L.; Wang, Y.S.; Wang, Z.D. Nonlinear vibration of the piezoelectric nanobeams based on the nonlocal theory. Compos. Struct. 2012, 94, 2038–2047. [Google Scholar] [CrossRef]

- Zenkour, A.; Sobhy, M. Thermal buckling of various types of FGM sandwich plates. Compos. Struct. 2010, 93, 93–102. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, B.; Wang, K. Nonlinear vibration of piezoelectric sandwich nanoplates with functionally graded porous core with consideration of flexoelectric effect. Compos. Struct. 2019, 207, 340–351. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Taheri, F. Analytical solution and statistical analysis of buckling capacity of sandwich plates with uniform and non-uniform porous core reinforced with graphene nanoplatelets. Compos. Struct. 2020, 252, 112700. [Google Scholar] [CrossRef]

- Bamdad, M.; Mohammadimehr, M.; Alambeigi, K. Analysis of sandwich Timoshenko porous beam with temperature-dependent material properties: Magneto-electro-elastic vibration and buckling solution. J. Vib. Control 2019, 25, 2875–2893. [Google Scholar] [CrossRef]

- Brush, D.O.; Almroth, B.O.; Hutchinson, J. Buckling of bars, plates, and shells. J. Appl. Mech. 1975, 42, 911. [Google Scholar] [CrossRef]

- Shariat, B.S.; Eslami, M. Buckling of thick functionally graded plates under mechanical and thermal loads. Compos. Struct. 2007, 78, 433–439. [Google Scholar] [CrossRef]

- Li, L.; Hu, Y.; Ling, L. Wave propagation in viscoelastic single-walled carbon nanotubes with surface effect under magnetic field based on nonlocal strain gradient theory. Phys. E Low-Dimens. Syst. Nanostruct. 2016, 75, 118–124. [Google Scholar] [CrossRef]

- Ilyashenko, A.V.; Kuznetsov, S.V. Pochhammer–Chree waves: Polarization of the axially symmetric modes. Arch. Appl. Mech. 2018, 88, 1385–1394. [Google Scholar] [CrossRef]

- Reddy, J. Microstructure-dependent couple stress theories of functionally graded beams. J. Mech. Phys. Solids 2011, 59, 2382–2399. [Google Scholar] [CrossRef]

| Reddy [47] | Present | Reddy [47] | Present | Reddy [47] | Present | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CBT | FBT | CBT | FBT | CBT | FBT | |||||||

| 0.0 | 9.86 | 9.83 | 9.82 | 39.32 | 38.82 | 38.80 | 88.02 | 85.63 | 85.52 | |||

| 0.2 | 10.68 | 10.65 | 10.65 | 42.60 | 42.06 | 42.10 | 95.36 | 92.78 | 92.96 | |||

| 0.4 | 12.84 | 12.80 | 12.80 | 51.20 | 50.52 | 50.72 | 114.61 | 111.34 | 112.34 | |||

| 0.6 | 15.79 | 15.73 | 15.76 | 62.97 | 62.01 | 62.50 | 140.97 | 136.39 | 138.75 | |||

| 0.8 | 19.18 | 19.08 | 19.14 | 76.47 | 75.05 | 75.99 | 171.18 | 164.51 | 168.91 | |||

| 1.0 | 22.80 | 22.66 | 22.76 | 90.92 | 88.84 | 90.42 | 203.54 | 193.82 | 201.142 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Muhammadi, M.F.S.; Al Mukahal, F.H.H.; Sobhy, M. A Higher-Order Theory for Nonlinear Dynamic of an FG Porous Piezoelectric Microtube Exposed to a Periodic Load. Mathematics 2024, 12, 3422. https://doi.org/10.3390/math12213422

Al Muhammadi MFS, Al Mukahal FHH, Sobhy M. A Higher-Order Theory for Nonlinear Dynamic of an FG Porous Piezoelectric Microtube Exposed to a Periodic Load. Mathematics. 2024; 12(21):3422. https://doi.org/10.3390/math12213422

Chicago/Turabian StyleAl Muhammadi, Marwa F. S., Fatemah H. H. Al Mukahal, and Mohammed Sobhy. 2024. "A Higher-Order Theory for Nonlinear Dynamic of an FG Porous Piezoelectric Microtube Exposed to a Periodic Load" Mathematics 12, no. 21: 3422. https://doi.org/10.3390/math12213422

APA StyleAl Muhammadi, M. F. S., Al Mukahal, F. H. H., & Sobhy, M. (2024). A Higher-Order Theory for Nonlinear Dynamic of an FG Porous Piezoelectric Microtube Exposed to a Periodic Load. Mathematics, 12(21), 3422. https://doi.org/10.3390/math12213422