Abstract

Due to rapid population growth and industrialization, the demand for electrical energy and its consumption has reached a critical point where it is no longer sustainable or stable. Therefore, it is imperative to explore new and reliable energy generation alternatives considering technical and economic perspectives, regardless of whether the community is isolated or urbanized. The research introduces a mixed-integer non-linear programming model of an energy supply chain that combines the roles of a manufacturer and retailer within a dynamic solar energy framework. The study highlights the manufacturer’s significant efforts to sustain itself in a competitive market and emphasizes the importance of government subsidies to support this approach. To meet the demands of a dynamic environment, a non-continuous demand function is utilized to generate and transmit energy at a highly sustainable level, promoting ecological balance. The model’s validity is confirmed through experimental evaluation using two case studies. Furthermore, by increasing the demand by 50%, this study demonstrates the potential for economic growth, resulting in a 20% profit for the manufacturer in the retail sector. This research ensures improved energy efficiency and greener consumption practices and addresses the optimal distribution of renewable energy to minimize imbalances. Finally, it reveals a pathway to sustainable development that promotes technological advancements while minimizing costs, offering a cost-effective scenario for the foreseeable future.

Keywords:

energy supply chain; dynamic environment; greener consumption; renewable energy; sustainable development MSC:

90B05; 90B06

1. Introduction

Meteorological change is the greatest sustainable challenge due to the increased use of electrical energy systems. In addition, energy consumption has huge potential for the rapid growth of industrialization and urbanization procedures. Accordingly, with the rigid and continuous growth of energy consumption, the contradiction between energy distribution and demand will worsen, and the rising energy price will be the largest threat to global security. Most survivors are located in rural regions with minimum income where the access to wiring standards is quite high concerning the expenditure of electric maintenance. The different demographic and societal characteristic addresses the need to meet the energy demand under several regional and non-regional solutions. However, the government keeps price-regulated renewable energy to minimize the cost of electricity generation in the competitive market. The inefficient subsidy methodology has resulted in faulty energy (ENG) use and excessive consumption. Numerous analysts of the ENG industry have long believed that energy efficiency (ENEFF) offers an enormous opportunity through ENG preservation strategies to save and minimize negative expenses associated with ENG utilization. Government intervention encourages ENEFF to enhance the consumption of renewable energy (RE). Additionally, imperfect information provokes consumers and enterprises not to undertake privately profitable investments in ENEFF, which implies investment inefficiency. It deploys the cost-minimization magnitude of ENEFF and actual realization intensity that causes the impression on research questions on production and consumption in ENG. Thus, this study investigates the reasons behind the ENEFF gap and emphasizes utility consistency. It promotes how ENEFF financing interrelates behavioral economics with applicative regions. On the other hand, the lowest price of methodological innovation and development of RE assists from rich to poor due to poor targeting of econometric evaluation, which implies solar energy (SENG) is a poverty mitigation program that aims to append solar capacity in terms of benefit to millions of national or international citizens. It supports solar installation in high-poverty rural villages that may earn an additional income for each household each year. Indeed, its implication based on the sunbeam condition is a primary determinant, whereas the local financial circumstances will be the secondary consideration for the poverty alleviation strategy. In these circumstances, the novel econometric model assesses the effect of green financing, RE, industrial upgradation, and economic development in the research. The minimal investment assists in achieving sustainable development. Thus, the practical application strengthens its intended research objective to minimize rural poverty. However, there is a lack of systematic evaluation in earlier scientific econometric studies. In eliminating the research gap, the scientific mechanism explores the effect of RE installation on poverty alleviation areas, which is the fundamental contribution of this study. Therefore, implementing the non-linear optimization strategy is to gradually be accomplished over time in highly substandard regions to generate sustainable financing.

In recent decades, the random disposal of waste products has affected the surrounding environment directly or indirectly. Keeping the environmental effects, the manufacturer produces green, sustainable products using renewable resources (RRs). The market expectation and customer satisfaction can be met when the operating cost is reduced for better industrialization, resulting in higher demand for RRs than non-renewable resources (NRRs). Appropriate utilization of raw materials and their abundant availability generates ENG. The energy planners can upgrade their procurement planning over the real-time system to sustain the competitive market and utilize renewable energy in a long-term perspective concerning the factors in the logistics environment. Furthermore, the enhancement of ENEFF meets the operational challenges by improving the skill development of laborers under a dynamic energy supply chain (ENSC) environment. As a result, the manufacturer expects to attract more customers according to the higher level of ENEFF under the benefit of the cost-learning effect. A sustainable green ENSC model was designed under social and economic sustainability in Nayak et al. [1]. The model was specially developed for Vietnam’s fashion and retail organizations by keeping environmental awareness, including the force of labor and sustainable materials, and RRs in the future. A sustainable supply chain was developed in Yadav et al. [2] to minimize the waste in the entire chain. That research considered demand as the cross-price elasticity to make the model profitable. They proved that the preservation technology dramatically impacts the environment and economic issues in the entire system. The recurrent gated unit-based methodology was compared with all other forecasting methods in Yang et al. [3] to evaluate the experimental evaluation at the highest accuracy level to formulate energy regulations and design an alternative ENG program. The technology was used to improve prediction accuracy to provide the superiority of conventional prediction trend models. A fuzzy goal programming approach was applied by Kokkinos and Karayannis [4] to evaluate alternative energy forms under tangible and intangible criteria. It estimated multidisciplinary knowledge in a hierarchical analytic manner. The research implemented low-carbon ENG mechanisms to support policy-making procedures and optimized the pair-wise interrelations under predetermined criteria.

Sustainability ensures the fulfillment of the basic requirements for the ENEFF with minimal effect on the environment. It has been observed that some harmful wastes generated during SENG generation affect the ecosystem directly. Greening of ENSC management was developed in Sharma et al. [5], where they focused on the significant impact of the environment. The model introduced several sources of ENG and related challenges. Their model was designed as an alternative source of persistent sustainability in India. Several disruptions were discussed by Emenike and Falcone [6], focusing on a positive impact on ENSC management. It highlighted losses and shortages during shutdowns. The model emphasized the derivation of a resilient ENSC system through optimization techniques. An artificial neural network with fuzzy wavelets was applied to estimate the ENG demand in Iran, which is discussed in Ahmadi et al. [7]. It predicted ENG consumption at a lower level of complexity. The genetic algorithm approach used the consumer planning mechanism to estimate the cost-minimization problem in Ionescu et al. [8]. The total cost of ENG from RRs was affected because ENG production has become more reasonable than other traditional resources. However, focusing on renewable energy (RE) for environmental benefit, every commercial organization is always willing to explore its competitive strategy in developing an integrated ENSC model for environmental awareness. In this context, an effective and successful environment-friendly ENSC management is needed in a particular situation on the RRs along with sustainability in the future. On investigation, SENG can potentially be a suitable ENG solution for future rural areas. It replaces all conventional ENGs and differentiates from the traditional ENG without neglecting the impacts on the life cycle. Due to the fastest expansion of SENG, the number of wastes can be managed and disposed of by effectively keeping the greening level in the environment.

Thus, the scope of this study covers the worldwide development of RE with the challenging form of tough global competition for non-accepting government subsidies. It takes an in-depth look to produce alternative ENG by ignoring the negative impact on the environment. The objective is to determine the performance of using SENG under the economic barriers required to overcome the worldwide RE sector. The research covers producing RE to meet international criteria that analyze the past, current, and future trends by implementing a better, even more beneficial methodology in the world renewable industry.

1.1. Research Gaps

Scientific research enhances the social and environmental concerns to make a long-run constructive energy supply chain. In this regard, the following gaps in research are searched and summarized below:

- A new alternative ENG generation is sought due to the growing electricity demand with limited capital investment. This study proposes to represent an environmental and economic aspect highlighting the importance of the necessity of the ENG crisis. It helps to reduce the high-cost ENG generation.

- Sustainability ensures the needs of ENG, and it is highly concerned about the environment. It substitutes an alternative technology in place of conventional ENG. It also bridges the gap between employment and the economy.

- A huge economic investment is integrated to establish a strong value chain. This study establishes a profitable ENG system to generate abundant RE by reducing the initial economic investment and promises to enhance ENG efficiency globally.

1.2. Contributions

Based on the discussions of perspective, the proposed work considers the following major contributions, which are listed below:

- RE resources allow unlimited exploration, which does not reduce their availability as long as they are utilized. This research initiates a reliable, low-maintenance operating cost where its effects are safe and non-polluted for overall development. SENG becomes a vital alternative that is economically and environmentally well accepted for isolated areas with a high cost of conventional energy. Sustainability is a novel solution to measure performance through energy generation and consumption.

- Utilizing a dynamic system is the learning tool for sustainable ENG strategies and environmental awareness. It makes the interaction between socio-environment and economy-oriented ENSC. This study proposes an ENSC in a dynamic environment.

- SENG plays a substantial role in achieving sustainable development for ENG solutions. Its application always satisfies daily needs and meets the employment market to achieve its growth sufficiently. This research proposes sustainable development by providing ENG needs, employment opportunities, and enhancing environmental protection to draw a vision of future applications by modeling under a green ENSC framework.

- ENEFF brings an enormous opportunity to enhance the efficiency in every economic sector for SENG generation.

1.3. Orientation of the Research

The next part of this research paper is divided into the following sections. A representation of the literature review of relevant documents is detailed in Section 2. Section 3 defines problem formulation with the solution methodology of the proposed problem. The experimental investigation with its solutions analysis is provided in Section 4. The managerial implication is presented in Section 5. Conclusions and scope for future research based on the proposed study are presented in Section 6.

2. Related Literature

Related works are illustrated in the following subsections to expand the knowledge.

2.1. ENSC with Sustainability

An application of RE under new innovative ideas was initiated in Singh et al. [9] to discuss the trend of the recent methodology of RE. The research analyzed the profitability of the system associated with cost-related formulas. A biomass ENSC operation management model was developed by Mafakheri and Nasiri [10] to utilize RRs for ENG production. There, ENSC played a role in biomass production efficiently. A two-stage ENSC model for food waste products was developed in Sarkar et al. [11]. In the first stage, a linear model was designed with the production, utilization, and discard of products, where food waste was collected from the first stage and recycled into food products. The second stage utilized recycled products with the nullification of waste. Deteriorated products were only utilized in the first stage. The circular economy concept was introduced in that model. Cost minimization was performed to demonstrate the model, and an algebraic procedure was applied to obtain the optimal solution globally. A tax-regulated sustainable ENSC management model was developed by Mishra et al. [12] with a restriction of carbon emissions. Here, linear and non-linear price-dependent demand were considered to develop the model. First, they designed a sustainable inventory management model under manageable carbon emissions. Two strategies were introduced to optimize the model’s prolonged sustainability. A real-life experiment was illustrated to verify the model. A complex multiple-stage green ENSC management with a highly perishable blood product was developed in Tayyab et al. [13]. This model aimed to reduce the duplication of blood facilities by developing a green network for blood platelet distribution and collection. The model helped to reduce green ENSC costs dynamically. An environment-sustainable supply chain model was developed in Hasan [14] to perform operational activities and make the relationships between environmental policies and operational performance. But, they did not consider any energy factors in the study.

A novel and efficient meta-heuristic technique was applied in Moayedi andMosavi [15] to optimize using a neural network for an effective RE to harvest sustainable ENG. An AHP-based multiple criteria sustainable ENSC management model was developed by Mastrocinque et al. [16] in the RRs sector. The model incorporated logical and quantitative information. Photovoltaic ENG was compared with European countries. The model provided a powerful tool to sustain investment decisions in the photovoltaic ENG sector. An energy accounting analysis managed and applied at the ENSC level was discussed in Tian and Sarkis [17]. Supplier selection was performed by using this model for actual energy measures. The model included environmental and business resource externalities for evaluation. A system dynamics approach in renewable ENSC was designed by Saavedra et al. [18]. It was classified into three groups of analysis. Finally, the simulation approach was applied to develop the model in RE systems. A hyper-connected logistic solution was made in Banyai [19] to decrease the consumption of ENG globally. Products were delivered to different locations by that model. A model over fast scheduling was optimized to enhance the efficiency in ENG using some operations. An optimization was performed on black holes using a heuristic approach to validate with several functions. Reflection in cement and concrete transactions by carbon dioxide (CO) emissions was a critical issue to market failure and was discussed in Filippo et al. [20]. The model evaluated carbon emissions costs effectively through carbon pricing policies under revenue generation.

According to the supply chain network, there are internal and external relationships between interdependent enterprises and business units to maximize profit and ENEFF through the performance of consumer satisfaction. This type of relationship is identified in an analytic dimension to conduct the structured review and sharpen the consequent research gaps, highlighting the operational point of view.

2.2. Sustainable RE

An interactive multi-criteria decision analysis instrument was analyzed by Ransikarbum et al. [21] under sustainability paradigms. Potential sources’ decisions were evaluated for the different criteria. Diverse renewable energies were reviewed in Osman et al. [22] with environmental and economic aspects in several countries. An establishment of zero-carbon emissions of decarbonization promised to limit global temperature rise. A renewable power generation sector was developed by Jelti et al. [23], where the performance was measured qualitatively by illustrating several barriers in ENSC management. The indicators that were related to the performance are identified through this model. ENG derived from RRs and NRRs made a positive impact on the environment. Expansion and effective utilization in energy analysis were made using donor-side evaluation in Alkhuzaim et al. [24]. An energy-based performance was evaluated on environment-sustainable ENSC management effectively. Energy analysis was applied for supplier selection, material sourcing, and the circular financial flow of the design. A thermodynamics analysis was done on the liquefied natural gas chain in Bouabidi et al. [25]. Several optimization techniques, integration, and multiple-scale opportunities were represented in the model. The goal of the model was to reduce utility generation by minimizing fuel utilization. SENG and fuel cells were potentially suitable for that model to enhance the chain for ENG delivery. Clear photovoltaic and photo-electro-chemical cells were used to generate electric power and ENG storage of hydrogen fuel in closed-loop ENSC management in Patel et al. [26]. A direct application of electrical potentiality was designed for manufacturing hydrogen to resolve the hydrogen delivery burden and generate continuous production of green ENG.

Sampaio and Gonzalez [27] discussed a non-probabilistic evaluative approach for a sample. They were raising awareness regarding its benefits and maximizing the application of new methodology-generated photovoltaic ENG in the RE market. The model created the need for future research in ENSC coordination economically and influenced the position of such technologies in the market. Pan et al. [28] discussed integrated regulations and techniques established in WTE ENSC. Several types of ENSC were illustrated using portfolio regulations to achieve a circular economy system. A total of eight critical factors were introduced to execute the strategies effectively. Three major technical challenge areas were addressed by Garcia and You [29] to design an ENSC. The challenges helped to model the problem, and algorithms and computation helped to take a challenge in future research opportunities. A policy was initiated by government, industry, and non-government organizations to reduce the overall environmental impact and construct a sustainable future. A hybrid life cycle assessment technique was used to apply in Dadhich et al. [30] in the plasterboard ENSC for the UK construction industry to identify and analyze the product using several intervention options. A distributed photovoltaic system created spillovers to reduce complementary costs in Matsuo [31]. Here, utility-scale deployment helped to build local photovoltaic competencies to facilitate value-needed chains. Application of spillovers enabled wide adoption of distributed photovoltaic in emerging and developing countries with an appropriate strategy. Integrating green ENSC through environmental procurement, production, design and information system, logistics, and distribution was developed by [32] with reverse logistics results in an innovative sustainable generation. The model reduced and eliminated solid waste and carbon emissions to maximize customer satisfaction. It played a vital role in implementing recycling, reduction, and reuse through the expanded use of eco-friendly products. It constructed several effective pathways to perform a sustainable ENSC. A collaborative orientation in ENSC was conducted in Mridha et al. [33] to affect ENSC’s environmental and social sustainability. Performance was measured in Zhang et al. [34] for manufacturer–retailer green ENSC, where the manufacturer set the level of ENEFF and wholesale price, and the retailer set the product’s selling cost. Manufacturers and retailers achieved more profits under some restrictions. The model explored an energetic environment to measure the ENSC performance by a comparative scenario.

The investigation concluded that the energy potential is significant in the studied region. However, further analysis needs to be conducted regarding its availability to assess the techno-economic feasibility of utilizing alternative ENG resources. However, renewable methodologies and their development are still undergoing research from modern commercial perspectives. Additionally, an evaluation is performed to determine the initial feasibility of significant sustainable production for successful RE.

2.3. Sustainable ENEFF

ENEFF is a vital issue to measure the products’ overall environmental performance, specifically household appliances.

An implementation of environmental projects with long-term financial commitment was discussed by Li and Umair [35]. Several robustness investigations supported sustainable development and demonstrated local and global growth. Government intervention enhanced the green growth in western and central regions of EU countries, which was explained by Razzaq et al. [36]. The study indicated that the marginal contribution of the digital green economy towards green growth was more responsive to ensure regional green development. An efficient biomass ENSC network was designed by [37] to improve bio-energy production economically. A coordinated game-theoretic approach was formulated with suppliers, hubs, and convertors of ENG in this model to examine the interaction between the members of ENSC. Green alternatives replaced NRRs for the gasification process, and the study was designed by [38]. It was developed specifically to evaluate the techno-economic feasibility of the biomass process of gasification. A photovoltaic SENG chain was developed in Almarshoud and Adam [39] in Saudi Arabia for the target of the year 2030 to increase the demand for ENG. Different situations with different activities related to this model were examined and analyzed. The model studied the value chain of photovoltaic SENG on socio-economic development in Saudi Arabia. A waste-to-ENSC model was developed in [40] by reducing environmental impurity and generating ENG from bio-waste. The model aimed to maximize the production time and inducement cost. It was suitable for domestic and commercial biogas production ENSC. A cost-efficient biomass ENSC network was designed by Aranguren et al. [41] to compete with NRR. A hub-and-spoke model with a stochastic scenario was developed for optimal production to minimize the costs concerning, minimizing the computational burden. Case studies were used to verify the model using real data. Batteries that lost their working power were reused and distributed ENG systems by offering resource-circular solutions in [42]. The model maximized the entire chain profit between three interactive sectors. It highlighted the implication of lost batteries by designing a new policy-effective model. High production of RE was discussed in Habib et al. [43], where raw materials are from waste animal fat. The model reduced the total cost of the ENSC through a possibilistic approach. The model validated sustainability within an ENSC using a waste reduction concept. Hybrid modeling was derived from Colombian ENG supply and demand perspectives by system dynamics hypothesis in Morcillo et al. [44]. It emphasized that a greater share of permanent capacity was guaranteed for the short-term scenario. Still, the variable dimension became vulnerable due to its increment in long-term prices. An additional capacity had overcome such critical situations by installing conventional and non-conventional resources.

A systematic approach to encourage sustainable investment and economic support co-operates and contributes to ENG reduction. SENG was recognized as an RR, the alternative to all conventional ENG resources, and minimized the carbon emissions in India, as discussed in Kar et al. [45]. The solar industry regulated the policy and utilized the capacity and investment of capital to aware the customer. Risks and uncertainties in Japan and the entire world were discussed in Kiriyama and Kajikawa [46]. An ENG system was required to secure resilience for humans. Here, the problem was modeled with ENG security from four perspectives. Control power and demand generation using certain supply restrictions and shortages were discussed by Dawn et al. [47]. They expanded ENG reliability to increase power generation by keeping environmental, social, and economic benefits from a country’s perspective. The model analyzed the current scenarios, availability, and policies for SENG in India. A two-echelon cooperative and non-cooperative ENSC model was developed in Yenipazarli [48] to invest in an eco-efficient innovation by improving environmental performance and increasing the product’s value. In the non-cooperative scenario, the retailer imposed an eco-efficient effort invested by the supplier. In a cooperative scenario, collaboration was made between two parties concerning a scrutinized contract assignment. A novel trading platform based on smart peer-to-peer incentives was developed in Neagu et al. [49] for prosumer ENG trading in a microgrid model. Various trading scenarios were implemented in an anonymous blockchain contract ledger. The scheme was examined on a low-voltage microgrid model to investigate its feasibility concerning a real-time network. An analysis was performed by [50] on the heterogeneous effects of several environmental policies. The tripartite evolutionary model was constructed to examine the effect of environmental regulations on the profitability of the government.

Sustainability in the supply chain supports the ENEFF and the effort of the environment [51]. Nowadays, environmental issues are increasing due to the consumption of fossil fuels in an increasing way. An ENSC model was designed with a clean ENG by [52] to regulate policies for photovoltaic ENG. There, a carbon emission photovoltaic model was designed. The results showed that product development and waste recycling efficiency are highly improved by reducing carbon emissions from photovoltaic ENSC. An energy principle was introduced by [53] in an ENSC system to reach an ENEFF resource to user demands. Multiple objectives with mixed-integer programming problems were designed for that model to balance financial and utilizable goals. The computed result showed the minimization of energy losses to make a sustainable ENSC system. A contract on the blockchain system was represented in [54] with two case studies. The system implemented the contract through the contract transactions smartly. An application for innovative ENEFF in ENSC management was discussed by [55]. It provided the awareness for sustainable use of several ENEFF types to indicate the important key factors for the barriers of social aspects. The obtained result showed effective cost savings and innovative ENSC operations. A general mixed-integer linear programming model was developed in [56]. Using two case studies, it demonstrated the construction of carbon capture methods in fossil power industries. An interdependent relationship between water and ENG was made in Fan et al. [57] to identify the key direct and indirect ENG consumption factors. The model provided a better opportunity for savings in ENG and water conservation. The result showed that water consumption and utilization were better suited for indirect ENG. A robust hybrid scenario-based solar photovoltaic ENSC model was designed by [58] to design a resilient photovoltaic ENSC under hazardous uncertainty. The model incorporated proactive and reactive resilience methodologies using a real-life experiment to investigate the capabilities concerning the uncertain correlated parameters.

The review highlights a growing research trend that remains to be covered to serve the diverse needs of ENG sectors. The gaps concern the parameters of ENEFF and environmental sustainability initiatives. It offers the opportunity to identify the areas of investigation to design research dimensions and propose recommendations in ENSC. Thus, sustainability becomes a vital issue concerning the environmental and social aspects. However, Table 1 describes a comparative study of the proposed research with the existing literature. It is based on sustainability in the supply chain environment. The focal point of the study is to enhance sustainability and ENEFF under certain restrictions. Table 1 shows that the proposed model is designed under the ENSC environment towards sustainability by keeping the environmental awareness and economic growth in the existing literature.

Table 1.

Contribution of the proposed study to the literature.

There are numerous issues of RE development, but implementable and reliable RE solutions towards sustainable development were created to establish the renewable industry with minimal cost investment. To ensure the sustainability of ENSC with subsequent economic evolution, the government has to intensify the further implementation of RE and ENEFF programs in long-term commitment. The proactive approach introduces the RE regulations to generate a conducive regulatory framework that would allow more participation from government and non-government enterprises, even from societal perspectives. Thus, the research enriches an environmental awareness towards sustainable development and encourages generating RE for the extensive global facet. However, an ENSC model is designed in the proposed research to generate green SENG by keeping sustainability in the dynamic environment.

3. Problem Formulation with Solution Methodology

The proposed problem and the corresponding solution methodology are discussed in this section. Notations and assumptions are given in this section.

3.1. Notation, Assumptions, and Problem Statement

The following notations and assumptions are considered, and the problem statement is defined briefly in this section.

3.1.1. Notation

The following notation has been considered to propose the problem under the ENSC environment, represented by Table 2.

Table 2.

Input parameters and decision variables with their descriptions.

3.1.2. Assumptions

The following assumptions are considered in designing the proposed model:

- The model is developed only for RE resources, which increases environmental awareness by reducing the utilization of NRR.

- The ENEFF of the product is inspected using a differential function. There are multiple benefits of ENEFF, including impact on climate change, improved health, indoor conditions, security of ENG, and reduction of the price risk for ENG consumers.

- In this study, non-realistic SENG is not allowed. It provides suitable energy for our houses and environment significantly.

- Shortages are not allowed as energy is supplied whenever the demand appears.

3.1.3. Problem Statement

Nowadays, the ENG demand keeps increasing because of the upgradation of technologies and the consumption of electrical ENG. Despite these, the carbon footprint concerns the resident who uses the resources. This is why the reduction of this issue is needed to have a healthy environment. RE is a kind of ENG that can gain from natural resources and keep renewing within the lifespan of humans. Furthermore, it provides the benchmark to establish more renewable industries around the globe to minimize the utilization of non-renewable energy resources. In this context, a mixed-integer non-linear programming-based manufacturer–retailer ENSC model is designed to generate sustainable solar energy. This research aims to maximize profit concerning the environmental and economic aspects. It aims to increase household benefits by using green technology in the long run. In a realistic scenario, a residential electricity crisis cannot reach the competitiveness of the ENG market. In these circumstances, an alternative ENG provides a better facility to resolve the ongoing ENG crisis by enhancing its efficiency through minimal expenditure.

In the proposed research, the ENEFF of the product is formulated as a differential function in which is considered an ENEFF improvement variable whose values vary over time. It is more important that when there is no improvement in the efficiency of ENG, at that time, the shortages will begin [2,59]. The depreciation of the product starts during the shortage period. The interrelated machinery equipment automatically falls in the period of shortages. Therefore, the ENEFF improvement expression is written in the following manner,

The associative cost of ENEFF improvement is formulated by C and is considered a quadratic function that increases over time [33]. The ENEFF improvement cost over time, which is influenced by the manufacturer, is expressed as

3.2. Model Formulation

The following considerations are assumed to develop the proposed model.

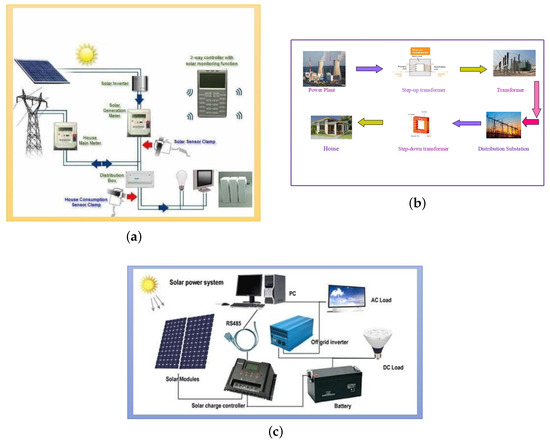

Electricity generation and distribution from the power plant to the house is represented in Figure 1 using a solar control system. Figure 1a describes the control system of SENG. Then, SENG is generated from the power plant and distributed to houses, designed by the diagram Figure 1b. The household appliances become active using SENG (Figure 1c). In the proposed research, the customer’s demand function is considered non-continuous. The production is influenced by the improvements of ENEFF, and simultaneously, the customers focus on the environmental awareness of the produced products. If the product’s ENEFF exceeds the standard grade , it is officially accepted as the higher ENEFF product in the demand market. Otherwise, it is accepted as the under ENEFF product in the demand market [59]. Nowadays, customers increase their attention to the environmental impact of the product. The demand function of highly ENEFF products is expressed in the following manner.

Figure 1.

Operating principle of solar energy system and its domiciliary applications: (a) Working principle of solar power system; (b) Generation of energy from power plant to house; (c) Application of solar energy for household needs.

and are positive constants representing probable and sensitive market demand with price, respectively. represents the piece-wise function of the level of ENEFF improvement of . Therefore, it is formulated as

In this case, always , i.e., if the ENEFF of a product reaches the level of the standard grade, then the demand for this particular product will increase significantly. Therefore, objective functions are formulated concerning the manufacturer and the retailer as

Therefore, the proposed optimization problem can be written as

and

subject to the constraint

Therefore, the proposed maximization problem of the manufacturer and the retailer can be restated as

subject to the constraint

3.3. Solution Methodology

The computer application reduces computational time and is more progressive with precise, reliable solutions. It replaces human mental activities in real-time computational stages and becomes an alternative approach to a conventional methodology. The study demonstrates the usefulness of modeling, optimizing, and controlling the system complexity in a wide range of applications of SENG. However, Equation (5) is a profit maximization problem for both the manufacturer and retailer in the ENSC environment. It is optimized with the decision variables concerning specific constraints. It is a non-linear programming model. LINGO optimization package 18 is applied as a solution of the non-linear optimization technique to obtain the optimal solutions of the proposed model. Thus, the following two consequent subsections are considered to elaborate the methodology.

3.3.1. Solution Flowchart

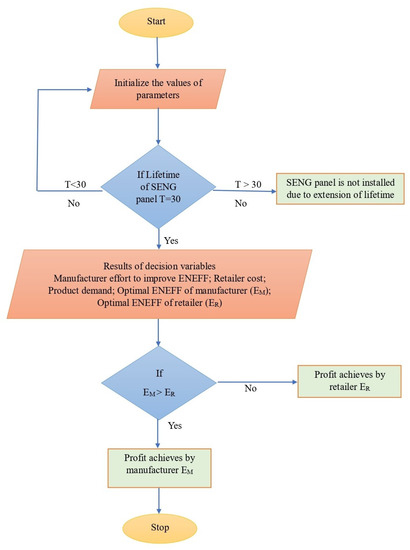

A flowchart is a graphical representation of the process following a sequential order. It describes several steps, like the production process and service process. In this section, the sequential steps of the methodology are discussed. The input parameters are initialized according to the proposed problem in the first step. Next, a decision on the lifetime of the SENG panel has been made. If the SENG panel lifetime exceeds the maximum time, then the installation of the SENG panels is not completed. Otherwise, the optimal solutions are obtained. The necessary materials for the SENG installation cannot be collected for the extreme time limit. The ENEFF of the SENG panel is completely lost after a specific time. Therefore, changing the panel after a particular time improves efficiency. The procedure continues until and unless the SENG panel lifetime is equivalent to a certain time. Another decision is held on comparing the obtaining product ENEFF of the manufacturer and the retailer. However, the proposed model’s solution methodology flowchart is represented by Figure 2.

Figure 2.

Diagrammatic representation of the proposed ENSC model.

3.3.2. Solution Algorithm

Algorithm 1 is a representation of well-defined instructions. It is used to solve a specific problem or to perform a specific calculation. This subsection defines the sequential steps for solving the proposed problem sequentially by performing the following operations with a certain computation.

| Algorithm 1 A representation of well-defined instructions. |

| Step 1. Input all initial values of parameters in the ENSC environment under the initial time. |

| Step 2. Equation (4) is utilized to obtain the optimal solution of the manufacturer (EM) and retailer (ER) for ENEFF in the ENSC environment. |

| Step 3. Solution of the decision variables is obtained by applying the value of EM and ER. |

| Step 4. An analytic computation is performed using the input variables to obtain the values of the decision variables. |

4. Experimental Investigation with Its Solutions Analysis

Discussions about numerical experiments, case studies, and sensitivity analysis are given in this section.

4.1. Numerical Experiment

The proposed research is a profit maximization problem with two objective functions, where the objective functions of the manufacturer and retailer are optimized under a certain constraint of ENEFF expression. LINGO optimization package 18 has been applied as a solution method to obtain the results. The computational time is 0.33 s. The computer has the following specifications: 8 GB RAM, Intel(R) Core(TM)i5, CPU 2.80 GHz, 64-bit, and Windows 11 Home. In the research, the numerical experiment is represented along with two case studies. A sensitivity analysis is performed in this section to understand the proposed problem better.

4.1.1. Experiment on Proposed ENSC Model

The first representation of the proposed problem is to calculate the total market capacity demand on the SENG panel, which is Q = 8000 MW. Here, the lifetime of the SENG panel ; co-efficient of ENEFF for product improvement ; rate of decaying of the ENEFF of the product . Therefore, implies that the amount of ENEFF improvement at time t is 1782 MW, and implies that the effort of a manufacturer for improving ENEFF at time t is 450 MW. The associated cost with ENEFF for the product improvement concerning t by the manufacturer USD 5. The cost of ENEFF for the product improvement at time t, i.e., USD 50,625. = co-efficient of retailer cost is 45 and = co-efficient of ENEFF for product improvement is . Therefore, the demand at the time t is 6337 MW. The retailer’s cost of the product USD 2186. The optimal ENEFF of the manufacturer and retailer is USD 33,948 and USD 29,728, respectively, which implies that the manufacturer gains approximately more profit than a retailer concerning the ENEFF of the product.

4.1.2. Case Study 1

The problem in designing renewable SENG prevents ENG insecurity [60].

The total market demand capacity on the SENG panel is . Here, the lifetime of the SENG panel , the co-efficient of ENEFF for product improvement , and the rate of decaying of the ENEFF of the product . Therefore, implies that the amount of ENEFF improvement at time t is 1559 MW, and implies that the effort of a manufacturer for improving ENEFF at time t is 312 MW. The associated cost with ENEFF for the product improvement concerning t by the manufacturer USD 6. The cost of ENEFF for the product improvement at time t, i.e., USD 30,750. = co-efficient of the retailer’s cost is 40, and = co-efficient of ENEFF for product improvement is . Therefore, the demand at the time t is 5939 MW. The retailer’s product cost USD 2000. The optimal ENEFF of the manufacturer and retailer is USD 29,621 and USD 26,781, respectively, which implies that the manufacturer gains approximately more profit than the retailer concerning the ENEFF of the product.

4.1.3. Case Study 2

The problem in designing for the production of green ENSC is examined using SENG [61].

The total market demand capacity on the SENG panel is MW. Here, the lifetime of the SENG panel ; co-efficient of ENEFF for product improvement ; rate of decaying of the ENEFF of the product . Therefore, implies that the amount of ENEFF improvement at time t is 1376 MW, and implies that the effort of a manufacturer for improving ENEFF at time t is 312 MW. The associated cost with ENEFF for the product improvement concerning t by the manufacturer USD 4. The cost of ENEFF for the product improvement at time t, i.e., USD 19,469. = co-efficient of the retailer’s cost is 50, and = co-efficient of ENEFF for product improvement is . Therefore, the demand at the time t is 4430 MW. The retailer’s product cost USD 1900. The optimal ENEFF of the manufacturer and retailer is USD 25,702 and USD 24,050, respectively, which implies that the manufacturer gains approximately more profit than a retailer concerning the ENEFF of the product.

4.1.4. Sensitivity Analysis

In the proposed research, a sensitivity analysis is made on the parameter variations and the reflection on decision variables, which is summarized in the following manner in Table 3.

Table 3.

Sensitivity analysis for efficiency of SENG.

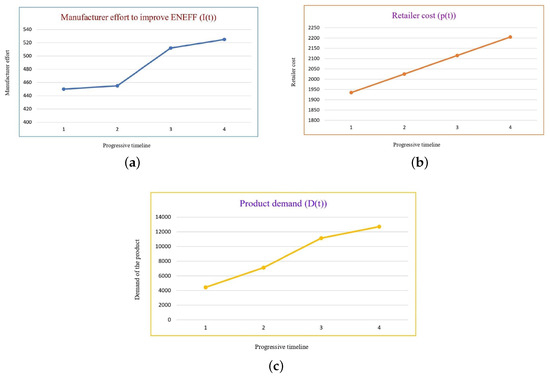

- The effort of a manufacturer to improve ENEFF increases with the changes in initial parameters. It is observed that nearly 14% of the effort gradually increased.

- The demand for the product gradually increased with the improvement of ENEFF in the ENSC model. The market demand is increased by more than 50%.

- The retailer’s cost increases with the slight parameter changes in the ENSC model.

- The value of ENEFF of the manufacturer and retailer increases or decreases are fully dependent on the effort of a manufacturer to improve ENEFF and the product’s market demand. It increases by about 16% to 25%.

In this context, Figure 3a–c represent the sensitivity analysis on the changes of input parameters of the ENSC model. Graphs represent the manufacturer’s effort to improve the ENEFF, retailer cost, market demand of the product, ENEFF of the manufacturer, and ENEFF of the retailer, respectively. However, Figure 3 investigates that the value of decision variables increases with the input parameters’ increasing value. Similarly, it is observed that the value of decision variables is decreased concerning the decreasing rate of input parameters. Therefore, graphs indicate that the decision variables’ value is highly proportionate with the input parameters of the ENSC model.

Figure 3.

Various approaches of sensitivity investigation under ENSC environment: (a) Sensitivity of manufacturer effort; (b) Sensitivity of retailing product cost; (c) Sensitivity analysis of product demand.

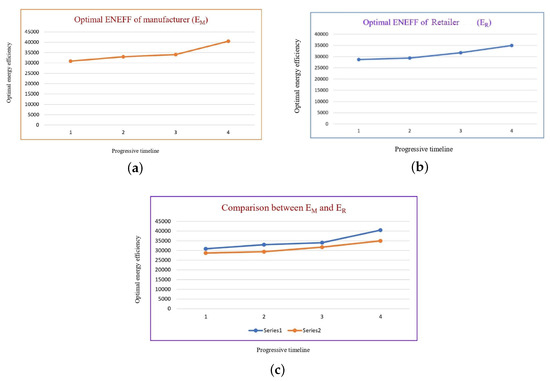

Accordingly, Figure 4a,b represent optimal solutions of ENEFF of the manufacturer and retailer under the ENSC environment, whereas Figure 4c represents the graph by comparing the ENEFF of the manufacturer and the ENEFF of the retailer. Therefore, Figure 4 estimates that the manufacturer achieves more profit than the retailer on the SENG panel installation for the proposed problem. Thus, a sensitivity analysis is performed on energy effort versus energy efficiency, represented by Figure 3 and Figure 4.

Figure 4.

Sensitivity investigation on economic benefit of overall energy system: (a) Sensitivity of manufacturer optimal energy efficiency; (b) Sensitivity of retailer optimal energy efficiency; (c) Sensitivity comparison between manufacturer and retailer under optimism.

4.2. Results and Discussions

This section analyzes results obtained from numerical experiments. According to the experimental solution, the parameter lies between 0.35 and 0.45, and and lie between 40 to 49 and 0.20 to 0.35, respectively. The value lies between 0.01 to 0.02 and 4.8 to 5.5 for the parameter and , respectively. In the proposed research, all solutions are obtained using the optimization technique, and finally, a comparative study is made, which is discussed in the following manner:

- The value of decision variables of the manufacturer’s effort to improve ENEFF (), retailer product cost (), product demand over time (), optimal ENEFF of the manufacturer (), and optimal ENEFF of the retailer () vary concerning the variations of input parameters accordingly. It is observed that the values of the decision variables have increased by increasing the value of the parameters. The optimal profit of the manufacturer is obtained by about 25% to 35% than the retailer due to the SENG installation. Therefore, the analysis ensures that the ENEFF is more profitable for the SENG panel installation.

- In the experimental analysis, it is observed that the product demand is strongly dependent on the total market capacity. The product demand () obtained from the proposed problem is 6337 MW concerning the total market capacity of 8000 MW and 5939 MW, and 4430 MW from two case studies concerning the total market capacity 6000 MW and 5000 MW, respectively. There are nearly 9% and 29% more demand for the product from the proposed problem than the case studies. Thus, the product demand increases or decreases concerning the total market capacity of the product. Hence, the demand is highly proportionate to the total market capacity of the product.

- The manufacturer’s effort () is increased by about 30% due to the enhancement of ENEFF compared to the two case studies.

- The retailer’s product cost () is obtained from the proposed problem as USD 2186 and USD 2000, and USD 1900 from two case studies, respectively, which is by about 9% and 13% reduced than the proposed research, comparatively.

- Optimal ENEFF for the manufacturer () are USD 33,948, USD 29,621, and USD 25,702 are obtained from the proposed problem and two case studies, respectively, which analyze the research study. It is by about 13% and 24% higher than the two cases comparatively. Similarly, the optimal ENEFF for the retailer () is USD 29,728, USD 26,781, and USD 24,050 obtained from the proposed problem and two case studies, respectively which analyze nearly 10% and 19% higher than the two cases comparatively. Therefore, the analysis confirms that ENEFF for the manufacturer can produce more profit-oriented and customer-acceptable products by keeping environmental awareness than the retailer.

- In the sensitivity analysis, it is observed that the profit of the manufacturer and retailer gradually increased concerning the increment of input parameters, and its effect is shown in some other parameters in optimal cases. The generation of RE provides nearly 40% more benefit than the generation of non-renewable energy. Hence, the manufacturer achieves nearly 35% more benefit than the retailer to generate SENG comparatively.

Therefore, after the numerical analysis and comparative study, it is summarized that the proposed problem is more beneficial than the two case studies during increasing product demand. The total market capacity is always greater than the total demand for the product. Otherwise, it falls on the shortage scenarios. But, the research is not concerned about the shortages. However, it emphasizes an SENG framework that maintains sustainability and environmental awareness. The study reveals that without government intervention, SENG generation can achieve a satisfactory level by ignoring all negative issues. The experimental evaluation ensures by about 5% to 15% profit can be obtained from the manufacturer compared to the retailer. Thus, it is concluded that the manufacturer problem is more suitable and profitable for the SENG panel installation.

5. Managerial Implications

Green ENG has become a new commercial potential. Our empirical findings establish a standardized business essential SENG model for both on-grid and off-grid scenarios, which benefits every country. All the restrictions should be removed for producing sustainable SENG to develop solar resources economically. However, photovoltaic manufacturing produces less toxic and hazardous products that never affect the environment. Therefore, SENG is less affected by pollutants than other ENG resources. However, it highly depends on expertise and improved technology. In this proposed research, a profitable SENG is utilized in cities and urban areas irrespective of the characteristics of buildings geometrically. However, the model has the following managerial impacts.

- Impact 1. Beneficial needs of SENG provide a supportive policy to enhance the ENG. It maximizes the co-benefits resulting from supporting ENG access. A well-developed system fulfills the basic and important opportunities in a crisis.

- Impact 2. Developing a solar power setup is an excellent solar electrification project in the national and international regions. The solar photovoltaic electrification system has emerged in these areas nowadays. The evolution of infrastructure for solar power systems is the better methodological option for solving the power crisis. SENG provides customer comfort to some extent and contributes to the economy. Thinking and planning regarding the SENG system to determine a positive outcome for self-employment and increasing the workforce is essential to sustain financial benefits. A job opportunity is created where solar technicians provide post-sales service to the consumer and educate them on operating and maintaining the solar equipment. Thus, employment opportunities can increase for family earnings. The government provides training programs for technical skills to expand its services in urban areas.

- Impact 3. ENG consumption provides an alternative economical solution for ENG providers. SENG is the constant generation of ENG in a real consumption situation, enabling change in the management transition decision.

- Impact 4. High manufacturing cost affects the price of SENG cells. If the assistance charge increases, then a minimum number of installations occurs; if it decreases, a powerhouse is installed for efficiency purposes. In this regard, there is a chance to improve the efficiency of the ENSC model.

- Impact 5. A profit-oriented SENG photovoltaic system with innovative constructions and improved methodologies provides environmental awareness in the system. Minimization of waste and recycling are the most favorable solutions to recommend the impacts on environmental resources technologically.

6. Conclusions and Future Trends

This research constructed three major beneficiary arguments for generating clean ENG: enhanced ENG security, environmental preservation and benefits, and potential increment in economic growth. Indeed, the adequate implication on employment opportunities of RE provided strong export markets through the development of enormous centralized ENG resources. The essential requirement of the emerging green economy was a long-term policy that should be consistent. The innovative information could be practical for policymakers to design long-range ENG programs for stimulating financial aspects. On the other hand, investment in ENEFF offered a high payoff and was often an implementable approach. Thus, this study investigated additional government support for aggressive ENEFF regulations by diminishing market barriers, enhancing communistic awareness, and facilitating financing expenditure. Thus, a sustainable RE was produced by keeping environmental awareness. It interacted with socio-environment and economy-oriented ENSC in a dynamic environment. It investigated how monetary expenditures affect RE for the generation of ENG. The approach enhanced sustainability to protect the environment by improving the ENEFF. It increased the 14% effort of ENEFF by meeting 50% of SENG market demand. Even the manufacturer obtained 12% profit by generating SENG than the retailer. Therefore, the research contributed to sustainable SENG production and consumption at the high greening level. Even though it ensured a cost-effective operational framework with reliable technological evolution under the ENSC environment for a large-scale perspective, it enhanced the retailing strategy of RE and sustained in the competitive market by neglecting all risk parameters. The experimental solution suggested that the RE provides an opportunity to achieve sustainable goals and encourages the global ENG transformation and methodological competition by developing a new ENG industry. It stimulated economic growth and alleviated ENG deficiency by increasing ENG supply to the regional and isolated regions. It optimized the consumption of ENG and assisted in improving the efficiency of an ENG system by reducing the dependency on conventional ENG. With the increasing depletion of non-renewable ENG, the reasonable prices of ENG and atmospheric change would become more beneficial to achieve societal goals and positively impact the macro-economic sector by enhancing the overall efficiency of the ENG structure.

Based on considerations, this theoretical and practical study was essential due to the severe conflict between ENG demand and ecological issues. The application of the dynamic growth trend of RE was discussed by developing a mathematical model in [62]. The research implemented sustainable development strategies by developing and utilizing the RE to solve variable practical problems. It analyzed the equilibrium point of the model and evaluated the power values of SENG to identify the exact problem and bring economic and social outcomes to the community. The theoretical, technical, and practical developments were investigated by [63]. The comparative analysis was performed in the southeastern region to assess the potential resources dynamically. A comprehensive experimental framework was investigated by [64] to encourage the customer to adopt the RE. The study estimated the causal impact of the electricity utilities and an ENG market price for communal ENG transactions. It stimulated the ENG consumption and storage to embrace RE preservation concerning socio-economic interaction. To summarize, the keys to promoting the RE with cost-effective pricing were establishing stable and long-term aspects to expand the RE supply. It ensured the fundamental rights of financially backward residents to access the modernized ENG under a reasonable and effective mechanism.

In addition, the solar industry establishment is more technologically invested than other power industries, which unpredictably affects systems’ consistency and efficiency over their lifetime. It is necessary to monitor the solar power industry during the operations phase. The analysis of these results provides the economic, social, and environmental benefits. The proposed research is designed for a hybrid energy system that reduces the intermittent issue of renewable energy generation units. The performance may be observed under the combined effect of operational competition and market competition concerning the ENSC environment in the future. Further, it may be extended by an additional maintenance operation at the production house. However, the proposed ENSC model can be extended with some following corresponding suggestions:

- The government intervention may strive to remove the gap between demand and supply.

- Energy storage should be a priority during the unavailability of solar energy, even if it can diminish the power crisis.

- The industry should monitor and provide training facilities on solar systems to maintain service quality.

- Generation of SENG is still an essential measure by reducing the cooling and heating ENG consumption.

- Minimizing the ENG consumption by maximizing the solar ENEFF in the early remote area should be the focus of future research. It may be a problem of multiple objectives.

- Extension of the proposed research is not only considering the consumption of ENG but also needing to be conscious of human support.

- Subsidies may be included in future research to minimize the initial investment.

- Proper analysis provides the right direction to establish a reliable solar power industry in remote areas in the future.

- Simulation is an appropriate way to study the results for a specific problem on a city scale [65]. The software demonstrates the mutual reflection between establishing and calculating the ENG consumption.

- The proposed research may extend to a different form of clean and perpetual ENG dynamically.

The perception of the non-renewable resources migration to RRs could contribute to the economy subject to the sales and services for the consumer to access and afford the system. Based on these discussions, initially, it consisted of their construction and production, whereas the utility-scale system was included in the termination stage. However, it investigated the following exciting findings to promote the research:

- Firstly, the consumption of SENG facilitated the reduction of carbon content ENGs. Our finding implied that human-generated and climatic interests were reduced by decreasing carbon-dependent ENGs. The impact on the consumption of SENG indicated to achieve an approach level of RE.

- Secondly, it confirmed that the consumption of SENG and the environmental impression made a bi-directional relationship in almost all countries.

- The initial expenditure was one of the extensive disadvantages of installing a solar energy system.

- The cost of renewable energy was high compared to non-renewable utility-supplied electricity. Solar energy was becoming more price-sensitive to energy shortages.

- The energy efficiency of solar systems could overcome problems during their installation.

Generating electricity through solar framework has become a silent revolution for sustainable sources of ENG. There was a massive possibility to strengthen the SENG business under government intervention by motivating the merchandising magnet and the consumers. Therefore, a uni-directional relationship was followed for both the SENG and ecological impressions. Some well-established systems, along with environmental awareness, could not be excluded. Therefore, some more associated environmental impacts may be included in future research to be considered an extension of the model.

Author Contributions

Conceptualization, B.S.; Methodology, S.B.; Formal analysis, M.S.; Investigation, M.S.; Resources, L.T.; Writing—original draft, S.B.; Visualization, L.T.; Supervision, B.S.; Funding acquisition, B.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this research.

Abbreviations

| ENG | Energy |

| ENSC | Energy Supply Chain |

| ENEFF | Energy Efficiency |

| SENG | Solar Energy |

| RR | Renewable Resources |

| NRR | Non-Renewable Resources |

| RE | Renewable Energy |

References

- Nayak, R.; Akbari, M.; Far, S.M. Recent sustainable trends in Vietnam’s fashion supply chain. J. Clean. Prod. 2019, 225, 291–303. [Google Scholar] [CrossRef]

- Yadav, D.; Kumari, R.; Kumar, N.; Sarkar, B. Reduction of waste and carbon emission through the selection of items with cross-price elasticity of demand to form a sustainable supply chain with preservation technology. J. Clean. Prod. 2021, 297, 126298. [Google Scholar] [CrossRef]

- Yang, C.H.; Chen, B.H.; Wu, C.H.; Chen, K.C.; Chuang, L.Y. Deep Learning for Forecasting Electricity Demand in Taiwan. Mathematics 2022, 10, 2547. [Google Scholar] [CrossRef]

- Kokkinos, K.; Karayannis, V. Supportiveness of low-carbon energy technology policy using fuzzy multicriteria decision-making methodologies. Mathematics 2020, 8, 1178. [Google Scholar] [CrossRef]

- Sharma, D.; Sharma, J.K.; Srivastava, B.K.; Sinha, S. Usage of solar over nuclear as an alternate energy source in support of green & sustainable supply chain practices in India. Turkish J. Comput. Math. Edu. 2021, 2, 4572–4581. [Google Scholar]

- Emenike, S.N.; Falcone, G. A review on energy supply chain resilience through optimization. Renew. Sustain. Energy Rev. 2020, 134, 110088. [Google Scholar] [CrossRef]

- Ahmadi, M.; Soofiabadi, M.; Nikpour, M.; Naderi, H.; Abdullah, L.; Arandian, B. Developing a deep neural network with fuzzy wavelets and integrating an inline PSO to predict energy consumption patterns in urban buildings. Mathematics 2022, 10, 1270. [Google Scholar] [CrossRef]

- Ionescu, L.-M.; Bizon, N.; Mazare, A.-G.; Belu, N. Reducing the cost of electricity by optimizing real-time consumer planning using a new genetic algorithm-based strategy. Mathematics 2020, 8, 1144. [Google Scholar] [CrossRef]

- Singh, S.K.; Chauhan, A.; Sarkar, B. Sustainable biodiesel supply chain model based on waste animal fat with subsidy and advertisement. J. Clean. Prod. 2023, 382, 134806. [Google Scholar] [CrossRef]

- Mafakheri, F.; Nasiri, F. Modeling of biomass-to-energy supply chain operations: Applications, challenges and research directions. Energy Polic. 2014, 67, 116–126. [Google Scholar] [CrossRef]

- Sarkar, B.; Debnath, A.; Chiu, A.S.F.; Ahmed, W. Circular economy-driven two-stage supply chain management for nullifying waste. J. Clean. Prod. 2022, 339, 130513. [Google Scholar] [CrossRef]

- Mishra, U.; Wu, J.Z.; Sarkar, B. Optimum sustainable inventory management with backorder and deterioration under controllable carbon emissions. J. Clean. Prod. 2021, 279, 123699. [Google Scholar] [CrossRef]

- Tayyab, M.; Jemai, J.; Lim, H.; Sarkar, B. A sustainable development framework for a cleaner multi-item multi-stage textile production system with a process improvement initiative. J. Clean. Prod. 2020, 246, 119055. [Google Scholar] [CrossRef]

- Hasan, M. Sustainable supply chain management practices and operational performance. Am. J. Ind. Bus. Manag. 2013, 3, 26787. [Google Scholar] [CrossRef]

- Moayedi, H.; Mosavi, A. An innovative metaheuristic strategy for solar energy management through a neural networks framework. Energies 2021, 14, 1196. [Google Scholar] [CrossRef]

- Mastrocinque, E.; Ramirez, F.J.; Honrubia-Escribano, A.; Pham, D.T. An AHP-based multi-criteria model for sustainable supply chain development in the renewable energy sector. Expert Syst. Appl. 2020, 150, 113321. [Google Scholar] [CrossRef]

- Tian, X.; Sarkis, J. Expanding green supply chain performance measurement through emergy accounting and analysis. Int. J. Prod. Econ. 2020, 25, 107576. [Google Scholar] [CrossRef]

- Saavedra, M.M.R.; Fontes, D.H.O.; Freires, F.G.M. Sustainable and renewable energy supply chain: A system dynamics overview. Renew. Sustain. Energy Rev. 2018, 82, 247–259. [Google Scholar] [CrossRef]

- Banyai, T. Real-time decision making in first mile and last mile logistics: How smart scheduling affects energy efficiency of hyperconnected supply chain solutions. Energies 2018, 11, 1833. [Google Scholar] [CrossRef]

- Filippo, J.D.; Karpman, J.; DeShazo, J.R. The impacts of policies to reduce CO2 emissions within the concrete supply chain. Cem. Concr. Compos. 2019, 101, 67–82. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Chanthakhot, W.; Glimm, T.; Janmontree, J. Evaluation of sourcing decision for hydrogen supply chain using an integrated multi-criteria decision analysis (MCDA) tool. Resources 2023, 12, 48. [Google Scholar] [CrossRef]

- Osman, A.I.; Chen, L.; Yang, M.; Msigwa, G.; Farghali, M.; Fawzy, S.; Rooney, D.W.; Yap, P.S. Cost, environmental impact, and resilience of renewable energy under a changing climate: A review. Environ. Chem. Lett. 2023, 21, 741–764. [Google Scholar] [CrossRef]

- Jelti, F.; Allouhi, A.; Buker, M.S.; Saadani, R.; Jamil, A. Renewable power generation: A supply chain perspective. Sustainability 2021, 13, 1271. [Google Scholar] [CrossRef]

- Alkhuzaim, L.; Zhu, Q.; Sarkis, J. Evaluating emergy analysis at the Nexus of circular economy and sustainable supply chain management. Sustain. Prod. Consump. 2021, 25, 413–424. [Google Scholar] [CrossRef]

- Bouabidi, Z.; Katebah, M.A.; Hussein, M.M.; Shazed, A.R.; Al-Musleh, E.I. Towards improved and multi-scale liquefied natural gas supply chains: Thermodynamic analysis. Comput. Chem. Eng. 2021, 151, 107359. [Google Scholar] [CrossRef]

- Patel, M.; Kim, S.; Nguyen, T.T.; Kim, J.; Wong, C.P. Transparent sustainable energy platform: Closed-loop energy chain of solar-electric-hydrogen by transparent photovoltaics, photo-electro-chemical cells and fuel system. Nano Energy 2021, 90, 106496. [Google Scholar] [CrossRef]

- Sampaio, P.G.V.; Gonzalez, M.O.A. Photovoltaic solar energy: Conceptual framework. Renew. Sustain. Energy Rev. 2017, 74, 590–601. [Google Scholar] [CrossRef]

- Pan, S.Y.; Du, M.A.; Huang, I.T.; Liu, I.H.; Chang, E.E.; Chiang, P.C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Garcia, D.J.; You, F. Supply chain design and optimization: Challenges and opportunities. Comput. Chem. Eng. 2015, 81, 153–170. [Google Scholar] [CrossRef]

- Dadhich, P.; Genovese, A.; Kumar, N.; Acquaye, A. Developing sustainable supply chains in the UK construction industry: A case study. Int. J. Prod. Econ. 2015, 164, 271–284. [Google Scholar] [CrossRef]

- Matsuo, T. Fostering grid-connected solar energy in emerging markets: The role of learning spillovers. Energy Res. Soc. Sci. 2019, 57, 101227. [Google Scholar] [CrossRef]

- Verma, D.; Dixit, R.V.; Singh, K. Green supply chain management: A necessity for sustainable development. IUP J. Supply Chain Manag. 2018, 15, 40–58. [Google Scholar]

- Mridha, B.; Pareek, S.; Goswami, A.; Sarkar, B. Joint effects of production quality improvement of biofuel and carbon emissions towards a smart sustainable supply chain management. J. Clean. Prod. 2023, 386, 135629. [Google Scholar] [CrossRef]

- Zhang, Q.; Tang, W.; Zhang, J. Green supply chain performance with cost learning and operational inefficiency effects. J. Clean. Prod. 2015, 112, 3267–3284. [Google Scholar] [CrossRef]

- Li, C.Z.; Umair, M. Cost, Does green finance development goals affects renewable energy in China. Renew. Energy. 2023, 203, 898–905. [Google Scholar] [CrossRef]

- Razzaq, A.; Sharif, A.; Ozturk, I.; Skare, M. Asymmetric influence of digital finance, and renewable energy technology innovation on green growth in China. Renew. Energy 2023, 202, 310–319. [Google Scholar] [CrossRef]

- Vazifeh, Z.; Mafakheri, F.; An, C. Biomass supply chain coordination for remote communities: A game-theoretic modeling and analysis approach. Sustain. Cities Soc. 2021, 69, 102819. [Google Scholar] [CrossRef]

- Lo, S.L.Y.; How, B.S.; Teng, S.Y.; Lam, H.L.; Lim, C.H.; Rhamdhani, A.M.; Sunarso, J. Stochastic techno-economic evaluation model for biomass supply chain: A biomass gasification case study with supply chain uncertainties. Renew. Sustain. Energy Rev. 2021, 151, 111644. [Google Scholar] [CrossRef]

- Almarshoud, A.F.; Adam, E. A transition toward localizing the value chain of photovoltaic energy in Saudi Arabia. Clean Tech. Environ. Policy 2021, 23, 2049–2059. [Google Scholar] [CrossRef]

- Iqbal, M.W.; Kang, Y. Waste-to-energy supply chain management with energy feasibility condition. J. Clean. Prod. 2021, 291, 125231. [Google Scholar] [CrossRef]

- Aranguren, M.; Castillo-Villar, K.K.; Aboytes-Ojeda, M. A two-stage stochastic model for co-firing biomass supply chain networks. J. Clean. Prod. 2021, 319, 128582. [Google Scholar] [CrossRef]

- Jing, R.; Wang, J.; Shah, N.; Guo, M. Emerging supply chain of utilising electrical vehicle retired batteries in distributed energy systems. Adv. Appl. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- Habib, M.S.; Asghar, O.; Hussain, A.; Imran, M.; Mughal, M.P.; Sarkar, B. A robust possibilistic programming approach toward animal fat-based biodiesel supply chain network design under uncertain environment. J. Clean. Prod. 2021, 278, 122403. [Google Scholar] [CrossRef]

- Morcillo, J.D.; Angulo, F.; Franco, C.J. Simulation and analysis of renewable and nonrenewable capacity scenarios under hybrid modeling: A case study. Mathematics 2021, 9, 1560. [Google Scholar] [CrossRef]

- Kar, S.K.; Sharma, A.; Roy, B. Solar energy market developments in India. Renew. Sustain. Energy Rev. 2016, 62, 121–133. [Google Scholar] [CrossRef]

- Kiriyama, E.; Kajikawa, Y. A multilayered analysis of energy security research and the energy supply process. Appl. Energy 2014, 123, 415–423. [Google Scholar] [CrossRef]

- Dawn, S.; Tiwari, P.K.; Goswami, A.K.; Mishra, M.K. Recent developments of solar energy in India: Perspectives, strategies and future goals. Renew. Sustain. Energy Rev. 2016, 62, 215–235. [Google Scholar] [CrossRef]

- Yenipazarli, A. To collaborate or not to collaborate: Prompting upstream eco-efficient innovation in a supply chain. Eur. J. Oper. Res. 2017, 260, 571–587. [Google Scholar] [CrossRef]

- Neagu, B.-C.; Ivanov, O.; Grigoras, G.; Gavrilas, M. A new vision on the prosumers energy surplus trading considering smart peer-to-peer contracts. Mathematics 2019, 8, 235. [Google Scholar] [CrossRef]

- Wang, M.; Lian, S.; Yin, S.; Dong, H. A three-player game model for promoting the diffusion of green technology in manufacturing enterprises from the perspective of supply and demand. Mathematics 2020, 8, 1585. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability and energy-efficient supply chain management: A review of research trends and proposed guidelines. Energies 2018, 11, 275. [Google Scholar] [CrossRef]

- Saxena, N.; Sarkar, B.; Wee, H.M.; Reong, S.; Singh, S.R.; Hsiao, Y.L. A reverse logistics model with eco-design under the Stackelberg-Nash equilibrium and centralized framework. J. Clean. Prod. 2023, 387, 135789. [Google Scholar] [CrossRef]

- Yan, B.; Somma, M.D.; Bianco, N.; Luh, P.B.; Graditi, G.; Mongibello, L.; Nasco, V. Exergy-based operation optimization of a distributed energy system through the energy-supply chain. Appl. Therm. Eng. 2016, 101, 741–751. [Google Scholar] [CrossRef]

- Khatoon, A.; Verma, P.; Southernhood, J.; Massey, B.; Corcoran, P. Blockchain in energy efficiency: Potential applications and benefits. Energies 2019, 12, 3317. [Google Scholar] [CrossRef]

- Jraisat, L.; Hattar, C. The awareness of renewable energy efficiency for supply chain management. Organ. Stud. Innov. Rev. 2017, 3, 1–5. [Google Scholar]

- Saif, Y.; Almansoori, A. A capacity expansion planning model for integrated water desalination and power supply chain problem. Energy Convers. Manag. 2016, 122, 462–476. [Google Scholar] [CrossRef]

- Fan, J.L.; Kong, L.S.; Zhang, X.; Wang, J.D. Energy-water Nexus embodied in the supply chain of China: Direct and indirect perspectives. Energy Convers. Manag. 2019, 183, 126–136. [Google Scholar] [CrossRef]

- Dehghani, E.; Jabalameli, M.S.; Jabbarzadeh, A.; Pishvaee, M.S. Resilient solar photovoltaic supply chain network design under business-as-usual and hazard uncertainties. Comput. Chem. Eng. 2018, 111, 288–310. [Google Scholar] [CrossRef]

- Saha, S.; Chatterjee, D.; Sarkar, B. The ramification of dynamic investment on the promotion and preservation technology for inventory management through a modified flower pollination algorithm. J. Retail. Consum. Serv. 2021, 58, 102326. [Google Scholar] [CrossRef]

- Iram, R.; Anser, M.K.; Awan, R.U.; Ali, A.; Abbas, Q.; Chaudhry, I.S. Prioritization of renewable solar energy to prevent energy insecurity: An integrated role. Singap. Econ. Rev. 2021, 66, 391–412. [Google Scholar] [CrossRef]

- Khan, M.A.; Shankiti, A.; Ziani, A.; Idriss, H. Demonstration of green hydrogen production using solar energy at 28% efficiency and evaluation of its economic viability. Sustain. Energy Fuels 2021, 5, 1085–1095. [Google Scholar] [CrossRef]

- Li, J. Evaluation of dynamic growth trend of renewable energy based on mathematical model. Energy Rep. 2023, 9, 48–56. [Google Scholar] [CrossRef]

- Sala, D.; Bashynska, I.; Pavlova, O.; Pavlov, K.; Chorna, N.; Chornyi, R. Investment and innovation activity of renewable energy sources in the electric power industry in the south-eastern region of Ukraine. Energies 2023, 16, 2363. [Google Scholar] [CrossRef]

- Mochi, P.; Pandya, K.; Soares, J.; Vale, Z. Optimizing power exchange cost considering behavioral intervention in local energy community. Mathematics 2023, 11, 2367. [Google Scholar] [CrossRef]

- Riaz, M.; Farid, H.M.A.; Jana, C.; Pal, M.; Sarkar, B. Efficient city supply chain management through spherical fuzzy dynamic multistage decision analysis. Eng. App. Artif. Intell. 2023, 126, 106712. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).