Abstract

Dust accumulation on photovoltaic (PV) modules is a major factor contributing to reduced power output, lower efficiency, and accelerated material degradation, particularly in arid and industrialized regions. This study presents a comprehensive review and analysis of the influence of dust deposition on PV performance, covering its optical, thermal, and electrical impacts. Findings from global literature indicate that dust-induced efficiency losses typically range from 10% to 70%, depending on particle characteristics, environmental conditions, and surface orientation. Experimental and modeled I–V and P–V characteristics further reveal significant declines in current and power output as soiling levels increase. Through an extensive literature assessment, this paper identifies Machine Learning (ML)-based approaches as emerging and highly effective techniques for dust detection and mitigation. Recent studies demonstrate the integration of image processing, drone-assisted monitoring, and convolutional neural networks (CNNs) to enable automated, real-time soiling assessment. These intelligent methods outperform conventional manual and time-based cleaning strategies in accuracy, scalability, and cost efficiency. By synthesizing current research trends, this review highlights the growing role of ML and data-driven technologies in enhancing PV system reliability, informing predictive maintenance, and supporting sustainable solar energy generation.

Keywords:

dust deposition; solar cell; PV; dust; pollutant; dust effect; efficiency; solar energy; dust size; output power 1. Introduction

Photovoltaic systems, widely adopted as a reliable renewable energy source, are highly susceptible to various environmental factors, including temperature, humidity, wind speed, and particularly dust accumulation, which significantly impacts their performance [1,2,3]. Among these, dust is a prominent factor that substantially reduces panel efficiency and power output as the mass of dust deposition increases [4]. This reduction in efficiency is primarily due to the obstruction of solar irradiance reaching the PV cells, leading to decreased photon absorption and subsequent power generation [5,6]. The extent of this degradation is influenced by several parameters, including the tilt angle of the panels, prevalent climatic conditions, and the specific composition of the dust particles [7]. For instance, particles such as silica, calcite, iron sulfate, sodium, and potassium chlorides frequently found in dust—can dissolve under humid or rainy conditions, creating a tenacious, cement-like film that further adheres dust to the panel surface [8]. This cementation effect significantly complicates removal efforts and exacerbates long-term performance degradation [9]. The accumulation of dust on PV modules can diminish their efficiency by 12% to 20%, with notable reductions in power output observed in various climatic conditions [10]. Specifically, studies have shown that dust deposition can reduce the efficiency of solar cells by approximately 10.49% after 16 weeks, with reported power losses reaching up to 50% when panels remain uncleaned for extended periods [10,11]. This decline is predominantly attributed to the scattering and absorption of incident solar radiation by accumulated dust particles, which reduces the effective solar irradiance reaching the PV cells [12]. At the global scale, Li et al. (2020) [13] integrated long-term satellite observations with photovoltaic performance modeling to quantify the combined effects of atmospheric aerosols and surface soiling on solar power generation. Their study revealed that in heavily polluted and desert regions, PV output can decline by more than 50%, with panel soiling accounting for approximately two-thirds of the total reduction. This research highlights the importance of both air-quality improvement and active cleaning interventions, providing the first global quantification of particulate matter impacts on PV generation. Experimental studies, such as that by Gholami et al. [14], provide critical quantitative insights into the relationship between dust accumulation and PV power loss. Conducting a 70-day outdoor study in Tehran, the authors observed a 21% decline in power output corresponding to a dust surface density of approximately 6 g/m2. Their correlation between dust density and optical transmittance loss remains one of the most cited empirical models, offering valuable guidance for performance prediction and cleaning scheduling.

Beyond dust, a multitude of environmental and climatic elements—such as solar irradiance fluctuations, spectral content variations, and the presence of rain or snow—collectively contribute to the overall performance degradation of PV systems [15]. These environmental factors, encompassing meteorological parameters like humidity and air velocity, interact complexly to influence PV cell efficiency and longevity [16,17]. For example, while shading can significantly reduce power output by up to 92.6%, water droplets may conversely improve power by 5.6% due to cooling effects [18]. However, the presence of contaminants such as solid particles or droplets on PV module surfaces can lead to power losses, decreased system efficiency, and increased operating temperatures, thereby shortening module service life [17]. Furthermore, the combined effects of these factors can lead to substantial performance losses, with some studies indicating reductions of up to 60–70% in extreme cases [19]. Specifically, high humidity often exacerbates the soiling effect by transforming dust into a sticky, difficult-to-remove mud that further compromises PV performance [20,21]. The impact of dust and pollution on solar panel efficiency is further influenced by factors such as solar radiation intensity, ambient temperature, and wind speed [22]. This complex interplay of environmental variables highlights the need for comprehensive modeling approaches that account for synergistic effects on energy yield and module degradation, particularly in diverse climatic zones [21]. Understanding these interactions is crucial for developing accurate predictive models and effective mitigation strategies to maintain optimal performance of solar PV systems globally [7]. Thus, while dust accumulation is a primary concern, the holistic impact of combined environmental stressors necessitates a multi-faceted approach to optimizing PV system design and operation [19,23].

The persistent accumulation of dust on solar PV arrays presents a significant challenge to the widespread adoption and sustained efficiency of solar energy systems [24,25]. This issue not only reduces the energy-harvesting potential of solar power plants but also necessitates increased operational and maintenance costs for cleaning and system upkeep [24]. For instance, uncleaned PV modules can experience up to a 20% reduction in power generation, leading to substantial economic losses over the system’s operational lifetime [26]. Moreover, the financial implications extend beyond lost revenue, as frequent cleaning—particularly in water-scarce regions—introduces additional expenditures and logistical complexities [27]. This problem is particularly acute in arid and semi-arid regions, where high dust concentrations and infrequent precipitation create ideal conditions for rapid dust accretion on PV surfaces [28]. In such environments, power losses due to soiling have been reported to range between 20% and 70% [29]. This substantial degradation underscores the economic infeasibility of PV systems in dust-prone areas without effective mitigation strategies [6]. Consequently, accurately quantifying and predicting the impact of dust accumulation is paramount for optimizing PV system design, deployment, and operational maintenance schedules to ensure long-term economic viability and energy yield [29]. Such predictive models must account for interannual soiling variability, which can increase the spread of P-values by 0–13% in performance forecasting [30]. Therefore, developing robust methodologies for precise soiling loss assessment and forecasting is essential for improving the economic feasibility and reliability of solar power plants, especially in regions highly susceptible to dust deposition [31]. This necessitates the development of sophisticated monitoring techniques and anti-soiling technologies to accurately quantify and mitigate these losses, thereby enhancing the overall performance and reliability of solar PV installations [32]. The issue of soiling, characterized by the deposition of dirt, dust, and other contaminants on PV module surfaces, is recognized as a major impediment to the broader implementation of PV technologies, leading to considerable economic losses [32].

Despite the extensive research on the influence of dust on photovoltaic (PV) systems, several critical knowledge gaps remain. Most previous studies have focused on quantifying power losses caused by dust deposition without adequately addressing the mechanistic relationships between dust type, morphology, environmental dynamics, and their combined optical–thermal effects on PV performance. Moreover, although numerous cleaning and coating techniques have been developed, their scalability, long-term durability, and cost-effectiveness under varying climatic conditions remain insufficiently validated. Another major limitation in the existing literature is the lack of integration between environmental data, predictive analytics, and intelligent maintenance frameworks. Traditional approaches rely heavily on periodic or manual cleaning schedules that fail to account for real-time soiling intensity or regional variability.

To overcome these challenges, this review aims not only to synthesize existing knowledge but also to identify emerging research directions and practical pathways for mitigation. Specifically, the paper highlights the potential of ML and image-based monitoring as novel, data-driven tools for early dust detection, predictive maintenance, and resource-efficient cleaning management. By bridging traditional soiling research with modern computational intelligence, this study seeks to guide the transition from empirical characterization toward smart, adaptive, and sustainable dust mitigation strategies for PV systems.

1.1. Aim and Objectives

The primary aim of this study is to provide a comprehensive assessment of the influence of dust deposition on PV system performance by integrating global research findings to identify key factors affecting energy output, degradation mechanisms, and emerging mitigation strategies. The study further aims to highlight the growing role of data-driven and ML approaches in advancing predictive dust detection and intelligent maintenance for sustainable solar energy generation. To achieve this aim, the study pursues the following specific objectives:

- To review and analyze the physical, optical, and thermal impacts of dust accumulation on PV modules based on recent experimental and modeling studies.

- To compare global findings on dust-induced power losses across different climatic zones, dust compositions, and PV technologies.

- To evaluate current cleaning and mitigation techniques, including hydrophobic coatings, robotic systems, and manual methods, assessing their efficiency, cost, and applicability.

- To identify research trends and bibliometric patterns related to dust effects, maintenance practices, and performance modeling in PV systems.

- To explore the potential of image processing and machine learning techniques as emerging tools for automated dust detection, predictive maintenance, and performance optimization.

- To propose an integrated framework linking environmental, technological, and operational strategies for effective and sustainable dust mitigation in PV systems.

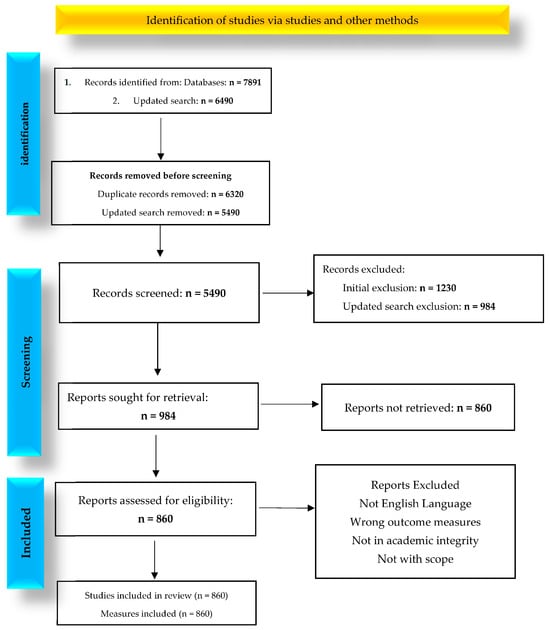

1.2. Metadata Analysis

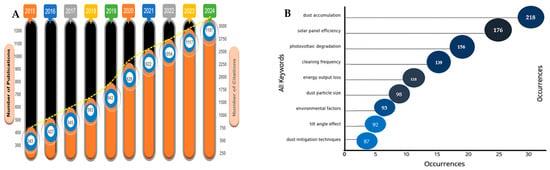

In this review, the literature selection process was carried out systematically using the Scopus database, which provides extensive peer-reviewed coverage of research in photovoltaics, environmental science, and energy systems. The search strategy employed a structured combination of keywords related to dust effects and PV performance—such as dust accumulation, soiling, dust deposition, photovoltaic, solar PV, and cleaning techniques—to ensure comprehensive retrieval of relevant studies. To maintain recency and technological relevance, only articles published between 2015 and 2024 were included. The screening process followed PRISMA-2020 recommendations, and the detailed inclusion and exclusion criteria, along with the full PRISMA flow diagram, are provided in the Appendix A to ensure methodological transparency and reproducibility. As illustrated in Figure 1A, the number of annual publications increased from about 343 in 2015 to nearly 1200 in 2024, with citations rising from less than 450 to over 3250 during the same period. This steady growth highlights the increasing recognition of dust accumulation as a major performance-limiting factor for PV systems, particularly in arid and semi-arid environments. The surge between 2018 and 2021 aligns with intensified field research and the integration of advanced modeling tools for predicting soiling behavior and cleaning optimization. The frequency distribution of keywords generated in R Studio 2025.05.1+513 (Figure 1B) identifies “dust accumulation,” “solar panel efficiency,” and “PV degradation” as the most frequently occurring terms, with respective occurrences of 218, 176, and 156. Additional terms such as “cleaning frequency,” “energy output loss,” and “anti-soiling coatings” indicate a shift from empirical field studies toward proactive, data-driven strategies for soiling mitigation. This trend suggests a growing interest in surface engineering, hydrophobic materials, and predictive maintenance models that incorporate climatic and environmental variables [33,34].

Figure 1.

Metadata Analysis based on Scopus database.

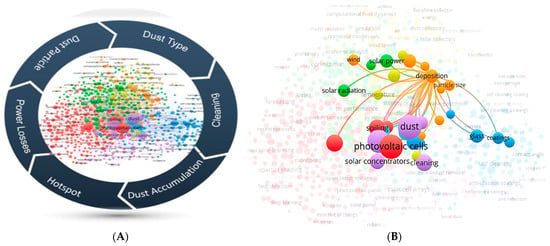

The VOSviewer-based keyword co-occurrence map (version 1.6.20) (Figure 2A) identifies six major research clusters—dust type, dust accumulation, cleaning techniques, hot-spot formation, power losses, and particle characteristics—highlighting the multidisciplinary nature of soiling studies across atmospheric science, materials engineering, and PV performance modeling. The co-word network visualization (Figure 2B) further demonstrates strong conceptual linkages among terms such as soiling, photovoltaic cells, deposition, and solar concentrators, underscoring the convergence of research efforts across domains. The prominent centrality of “dust” indicates its role as the unifying concept connecting optical, environmental, and electrical degradation mechanisms. The clustering patterns also reflect a clear evolution in the field, shifting from descriptive assessments of dust adhesion toward integrated frameworks incorporating machine learning, remote sensing, and multi-scale performance modeling. Overall, the metadata analysis confirms rapid maturation of dust–PV research, accompanied by increasing global collaboration—particularly among institutions in China, India, Saudi Arabia, and the United States. These trends highlight the pressing need for standardized soiling metrics, advanced anti-soiling surface technologies, and cost-effective cleaning strategies to enhance the reliability and bankability of solar energy systems.

Figure 2.

Keyword co-occurrence network of dust–PV studies (A) and dust deposition relation and critical factor (B).

1.3. Research Trend Analysis

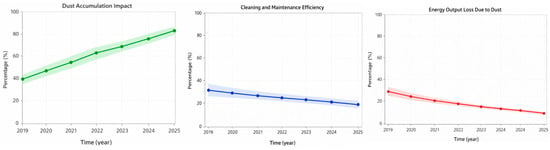

The temporal trend analysis of research themes derived from keyword frequency and abstract text mining (Figure 3) highlights distinct trajectories among the major topics in dust–PV studies between 2019 and 2025. The first trend, labeled “Dust Accumulation Impact,” shows a strong upward pattern, rising from approximately 45% occurrence in 2019 to more than 80% in 2025. This increase reflects a growing global emphasis on understanding the physical and environmental mechanisms that govern particle deposition, adhesion, and optical attenuation on PV surfaces. The trend also indicates a shift toward quantifying the spatiotemporal dynamics of soiling and its dependence on climatic variables such as humidity, wind speed, rainfall frequency, and aerosol composition. The expansion of field-based measurement campaigns and the adoption of machine learning models for soiling prediction have further contributed to this rise.

Figure 3.

Topic Trend Analysis of Dust–PV Research.

In contrast, the topic “Cleaning and Maintenance Efficiency” demonstrates a relatively stable trajectory, fluctuating between 15% and 18% over the same period. This stability suggests that, while cleaning optimization remains an important focus, research has not expanded substantially beyond conventional mechanical and water-based cleaning approaches. Nonetheless, incremental innovations—such as hydrophobic and anti-soiling coatings, electrostatic cleaning systems, and robotic maintenance platforms—continue to sustain interest, particularly for industrial and utility-scale PV deployment. The consistent research volume indicates that this subfield has matured, with current efforts centering on cost reduction and automation rather than fundamental conceptual advances.

Meanwhile, the topic “Energy Output Loss Due to Dust” exhibits a clear decline, decreasing from around 22% in 2019 to below 10% in 2025. This downward trend reflects a broader shift away from general quantification of power loss—formerly the central focus of early studies—toward more specialized investigations into the mechanisms and mitigation of dust-induced degradation. As soiling measurement techniques have become more standardized and field monitoring data more widely available, researchers have increasingly moved beyond empirical yield-loss characterization to concentrate on predictive analytics, techno-economic modeling, and technology-specific sensitivity assessments. Collectively, these thematic evolutions underscore the maturation of dust–PV research: the field has progressed from documenting performance losses to developing proactive, integrated solutions that combine environmental data analytics, material innovation, and system-level optimization.

2. Cause and Effects of Dust Deposited on Solar Cells

The chemical composition, particle size distribution, and morphology of dust significantly influence its adhesion to solar panel surfaces and its optical properties, thereby directly affecting light transmittance and PV performance [35]. For instance, mineral dust—common in arid and semi-arid regions—can cause substantial energy-yield reductions, with reported losses ranging from 1% to more than 50%, depending on exposure duration and dust characteristics [36,37]. Additionally, organic components such as pollen or soot can intensify soiling by increasing adhesion and forming more opaque layers on the module surface [21]. The interplay between these dust properties and environmental factors, such as humidity and wind speed, further complicates the prediction and mitigation of soiling losses, necessitating a detailed understanding of regional dust characteristics [21]. Smaller particles tend to adhere more strongly because of enhanced van der Waals forces, whereas larger, denser particles may settle more quickly but are often more easily removed by wind [21]. Moreover, the spectral properties of dust, such as its absorption and scattering coefficients, are critical in determining the extent of light blockage across the PV spectrum [38]. Understanding these properties is essential for developing effective anti-soiling coatings that can mitigate light-loss mechanisms [23]. Fine dust particles, in particular, are more detrimental due to their strong adhesion and efficient light-blocking behavior [5]. In humid environments, accumulated dust can mix with moisture to form a sludge-like layer, reducing power generation by up to 70% [22]. The specific morphological and elemental composition of dust—such as the aluminosilicates and halite commonly observed during Saharan dust events—further influences its optical and adhesive behavior [21].

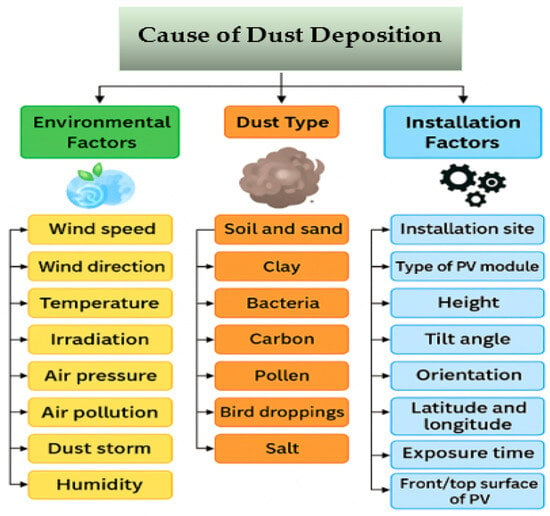

Figure 4 illustrates the major factors influencing dust deposition on PV modules, categorized into three groups: environmental factors, dust characteristics, and installation-related factors. Environmental parameters such as wind speed and direction, temperature, irradiation, air pressure, air pollution, dust storms, and humidity critically determine both the rate and composition of accumulated dust. Wind transports and redistributes particles, while temperature and humidity affect adhesion strength and moisture-driven cementation on PV surfaces. Dust characteristics—including soil and sand particles, clay, bacteria, carbon, pollen, bird droppings, and salt—shape the optical and thermal properties of the deposited layer, influencing transmittance and heat buildup. Installation factors such as module height, tilt angle, orientation, and geographic location (latitude and longitude) determine surface exposure and dust retention potential. Longer exposure durations and suboptimal installation configurations can further accelerate soiling. Overall, this integrated framework highlights that dust deposition is a complex, multifactorial process governed by environmental dynamics, material properties, and system configuration—all of which must be considered for accurate modeling and effective mitigation of PV performance losses [34].

Figure 4.

Causes for dust on PV panels. It is divided into three categories including installation factors, environmental factors as well as dust type.

Dust deposition on PV module surfaces primarily impairs their optical, thermal, and electrical performance through complex, interrelated mechanisms. The accumulation of airborne particles on the glass surface reduces incident solar irradiance due to absorption and scattering, leading to diminished light transmittance and lower photon flux reaching the semiconductor junction. This optical attenuation directly decreases the short-circuit current and overall power conversion efficiency of the solar cells. Furthermore, uneven dust distribution causes localized shading, resulting in non-uniform current generation across the cell surface and accelerating the formation of hotspots—regions of elevated temperature that degrade encapsulant materials and solder joints over time. Thermally, the dust layer also acts as an insulating blanket, impeding convective heat dissipation and raising the operating temperature of the module, which further reduces its open-circuit voltage. The severity of these effects depends on dust characteristics such as particle size, morphology, and chemical composition, as well as environmental conditions including humidity, wind speed, and tilt angle of the PV array. Fine and hygroscopic particles, for example, adhere more strongly to surfaces and can form cemented films under humid conditions that are difficult to remove and cause long-term optical degradation. Consequently, the synergistic effects of optical losses, localized heating, and accelerated material fatigue collectively reduce the reliability, lifespan, and energy yield of PV systems, particularly in arid and industrial environments where soiling rates are highest.

Dust accumulation significantly impacts the transparent cover glass of PV modules by reducing light transmittance and consequently diminishing power output [21]. This reduction is primarily due to the absorption and scattering of solar radiation by the dust layer, which directly impedes photon transmission to the PV cells [17]. The extent of optical degradation is influenced by the dust’s physical properties, including particle size and morphology, with finer particles generally causing greater transmittance reduction due to more efficient light scattering and stronger adhesion [11,21]. The chemical composition of the dust also plays a critical role, as certain inorganic or organic compounds can create more adhesive layers, exacerbating soiling effects and complicating cleaning efforts [39]. Beyond optical degradation, dust accumulation affects the thermal performance of PV panels by elevating operating temperatures, which further reduces conversion efficiency [40]. This temperature rise results from the dust layer acting as an insulating barrier that hinders natural convective cooling of the module surface [39]. Combined optical and thermal effects can cause substantial reductions in power output, with some studies reporting efficiency losses of up to 64%, depending on dust type and concentration [5,39]. These losses are further influenced by environmental factors such as wind speed, humidity, and tilt angle, all of which affect the rate and characteristics of dust accumulation [7]. The impacts are particularly severe in arid and semi-arid regions where dust storms occur frequently, leading to rapid and substantial performance degradation [1,23]. Dust characteristics—including particle size, shape, and elemental composition—are geographically diverse and vary with local environmental conditions such as humidity, wind patterns, and seasonal changes [7,21]. For example, analyses of dust in Évora, southern Portugal, during Saharan dust events revealed agglomerated particles primarily composed of aluminosilicates and halite, along with elements such as aluminum, sulfur, and chlorine [21]. Such variations in dust composition and morphology directly influence the degree of optical attenuation and thermal insulation, resulting in different degradation patterns across various geographical regions and climatic conditions [21]. The combined influence of optical attenuation, thermal insulation, and localized electrical stress not only diminishes instantaneous PV output but also accelerates long-term degradation of solar cell materials and encapsulants. Consequently, accurately assessing energy losses caused by dust accumulation is essential for both performance evaluation and economic analysis of PV systems. Because soiling-induced degradation varies across climatic regions, panel orientations, and exposure durations, a quantitative understanding of these losses provides critical insights for optimizing maintenance schedules and improving predictive modeling accuracy.

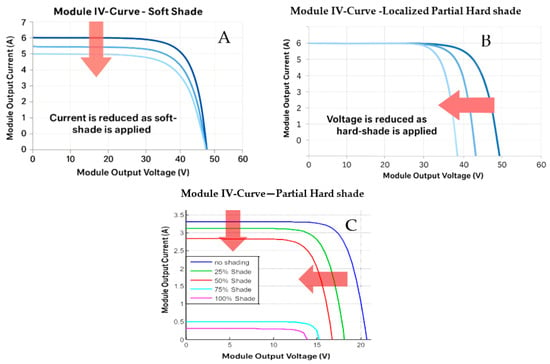

Figure 5 illustrates the I–V characteristics of a PV module under three distinct shading conditions: soft shading (A), localized partial hard shading (B), and partial hard shading (C). Soft shading—such as from clouds, haze, or uniform atmospheric dust—reduces the incident irradiance over the entire module surface, leading to a proportional decrease in output current while the open-circuit voltage remains nearly unchanged. Localized Partial hard shading occurs when a localized section of the module is obstructed by non-uniform contaminants such as bird droppings or accumulated dust patches. In this case, current has less reduction relatively stable at first, but the voltage drops sharply due to the activation of bypass diodes across the shaded cells. Full hard shading, produced by complete obstruction of one or more cells (e.g., by objects or large opaque deposits), results in simultaneous reductions in both current and voltage, creating pronounced distortion in the I–V curve and a significant loss of output power. By comparing these three shading modes, the figure demonstrates how different dust-related shading patterns lead to fundamentally different electrical responses, providing a clearer physical basis for interpreting dust-induced performance losses in PV systems

Figure 5.

Comparison of PV I–V curves under: (A) soft shading, reducing current; (B) localized partial hard shading from localized dust or bird droppings, reducing voltage; and (C) full hard shading, reducing both current and voltage. The figure illustrates how uniform versus non-uniform soiling differently affects module performance [41,42,43].

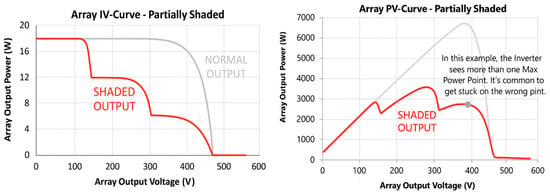

Figure 6 illustrates the influence of partial shading on the current–voltage (I–V) and power–voltage (P–V) characteristics of a PV array. Under uniform irradiance, the array exhibits a single smooth curve with one maximum power point (MPP). However, when partial shading occurs, the shaded modules generate less current, causing multiple step reductions in the I–V curve and the emergence of multiple local maxima in the P–V curve. This phenomenon is due to the activation of bypass diodes that protect shaded cells from reverse biasing but simultaneously segment the array into independent power-generating sections. As shown, the shaded condition results in a significant reduction in both output current and power, with the inverter potentially tracking a local rather than the global MPP—leading to suboptimal energy extraction. Hence, effective MPPT algorithms are essential to distinguish between global and local peaks under such non-uniform conditions [44]. Therefore, the following subsection focuses on the quantification of power loss due to soiling, summarizing measurement techniques, regional variations, and key parameters that influence energy-yield reduction in PV installations [44].

Figure 6.

Effect of Partial Shading on PV Array I–V and P–V Characteristics. Partial shading causes step reductions in the I–V curve and multiple peaks in the P–V curve due to bypass diode activation, resulting in power loss and potential tracking of a local instead of the global maximum power point [45].

Quantification of Power Loss Due to Soiling

The quantification of power loss attributable to soiling on PV modules is critical for accurately assessing system performance and optimizing maintenance schedules. This process often involves direct measurement of power output degradation under controlled and uncontrolled soiling conditions, alongside modeling approaches that predict energy-yield reductions based on dust accumulation rates and optical properties [46]. For instance, studies conducted in arid regions have reported significant power reductions—typically ranging from 15% to 25%—emphasizing the substantial influence of environmental factors such as particle size, wind speed, and panel surface properties [11]. In specific dry climatic regions such as Kuwait, Cyprus, and Egypt, soiling losses can exceed 10%, whereas in other areas, such as Spain, losses between 1% and 7% have been observed [21]. These variations underscore the site-dependent nature of soiling losses, shaped by regional dust characteristics and prevailing meteorological conditions [21,47]. Further research suggests that performance loss rates can reach 60–70% in extreme cases, highlighting the urgent need for effective mitigation strategies to maintain optimal PV system efficiency [47]. Globally, soiling losses are estimated to reduce total energy yield by 4–7%, representing a significant economic burden for PV system owners and operators [21]. Annual losses also vary considerably, with reports of soiling-induced energy reductions exceeding 15% in Egypt and 10% in Saudi Arabia [21].

Dust deposition on the glass surface of PV arrays reduces the transmittance of sunlight to the solar cells, causing a considerable drop in conversion efficiency. Reference [40] presents an experimental investigation of how the tilt angle of PV arrays affects the rate of dust accumulation in a semi-arid environment. Its findings show that airborne pollutants—such as mineral dust and soot—can severely impair solar transmittance through the module surface, leading to reduced irradiance and, consequently, lower power output. The degree of performance reduction depends on factors including particle-size distribution, mineral composition, and ambient environmental conditions [48]. Study [49] also showed that horizontally oriented PV panels accumulate dust more rapidly, resulting in higher performance losses. Natural dust has also been shown to degrade the efficiency of polycrystalline solar cells [50]. Dust deposition can increase module temperature, restrict airflow, and decrease power output, ultimately compromising the overall performance and lifespan of PV systems [51]. Dust concentration and spectral transmittance were also found in [41] to influence the conditioned performance of PV modules.

A recent experimental study in Kuwait highlighted the significant contribution of dust to PV performance losses, emphasizing the role of dust content, wavelength-dependent behavior, and spectral permeability. Environmental conditions—including dust deposition rates and fluctuating weather patterns—can reduce the amount of solar radiation reaching panel surfaces, thereby diminishing efficiency and impacting the economic viability of PV system operators. Study [52] further demonstrated that uneven dust distribution across panel surfaces disrupts thermal balance, causing sharp declines in power output.

The negative impact of accumulated dust and debris on PV performance makes regular inspection, cleaning, and energy-production monitoring essential for maintaining efficiency. Study [53] investigated the effects of soiling on the optical performance and energy yield of CSP and PV arrays in Morocco’s semi-arid climate. By examining a 1 MWe linear Fresnel CSP plant and a 1 MWe PV array, the study found that CSP systems—due to their complex optical pathways—are more susceptible to soiling losses than PV systems. CSP installations exhibited daily average optical losses of 1.21%, whereas PV systems showed losses of 0.24%. Consequently, CSP systems suffer annual energy losses of approximately 17.76%, compared to 1.95% for PV systems, assuming monthly cleaning. Incorporating soiling effects into the LCOE analysis revealed a substantial increase in cost, especially for CSP technologies. The study concluded that cleaning every three weeks provides the optimal trade-off between cleaning expenses and energy gained.

In another study [54] presented a comparative analysis of soiling impacts on PV and CSP arrays. By testing CSP second-surface mirrors and PV glass samples under equivalent surface-dust densities, the study found that CSP systems experience significantly higher optical losses—by a factor of 8 to 14—compared to PV systems. To address this disparity, the authors developed a validated Mie-based model capable of predicting optical soiling losses for both PV and CSP installations, taking into account particle-size distribution, refractive index, and angle of incidence. This model enables the cross-application of soiling data between technologies and improves annual loss estimation, offering valuable insights for optimizing incidence-angle selection in soiling measurements. Study [55] examined the effects of air pollution on two types of 1 kWp PV arrays—tracking flat PV and fixed flat PV. A dataset of 2190 samples, collected every 30 min from June 1 to June 30, 2013 (after cleaning), was analyzed. Environmental parameters such as temperature, irradiation, dust accumulation, power output, pollution index, and energy yield were evaluated. Several regression models were developed to predict PV performance based on these environmental variables. SEM images of both systems were also analyzed. The unique aspect of this work lies in its examination of PV performance under the specific pollution conditions present in Southeast Asia during 2013.

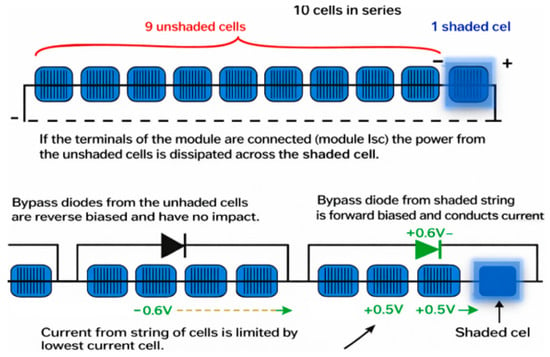

Figure 7 illustrates the behavior of PV cells in a module when partial shading occurs and the protective role of bypass diodes in preventing hotspot formation. In the top diagram, a module consisting of ten series-connected cells includes one shaded cell, which significantly limits the overall current flow through the string. As the shaded cell generates less photocurrent, the unshaded cells continue to produce power, causing a reverse bias across the shaded cell. This reverse bias can lead to localized overheating or “hotspot” effects if left unchecked. The lower diagram shows how bypass diodes, connected in parallel across cell groups, mitigate this issue. When shading occurs, the bypass diode across the affected cell becomes forward-biased (approximately +0.6 V), allowing current to bypass the shaded cell and maintain current flow in the remaining string. Meanwhile, the diodes across the unshaded cells remain reverse-biased, having no influence on current conduction. This mechanism effectively reduces power loss and thermal stress by isolating the shaded section, ensuring that the module operates safely and efficiently even under nonuniform irradiance conditions.

Figure 7.

Current Flow and Bypass Diode Operation in a Partially Shaded PV Module.

Table 1 presents a summary of recent studies investigating the effects of dust deposition on PV performance under various climatic and environmental conditions. The data indicate that dust accumulation can reduce PV efficiency by 10% to over 70%, depending on dust composition, particle size, density, and exposure duration. Regions such as the Middle East, North Africa, and South Asia experience the highest degradation due to frequent dust storms, elevated temperatures, and limited rainfall. In coastal and humid zones, dust mixed with salt and organic matter adheres more strongly, forming hardened layers that are difficult to remove and further reduce transmittance. The findings also reveal that dust particle characteristics significantly influence optical and thermal behavior. Fine particles such as clay and carbon soot cause stronger light absorption and scattering compared to coarse sand. Module type also plays an important role—thin-film modules generally exhibit lower performance losses than crystalline silicon modules due to differences in surface properties and spectral response. Several reviewed studies incorporate predictive models and ML techniques to better estimate soiling impact and cleaning requirements. These methods enable automated detection and classification of dust levels using imaging data, supporting intelligent maintenance scheduling and optimized resource use. Overall, Table 1 highlights that dust-induced degradation is governed by multiple interacting factors—environmental conditions, particle properties, and system configuration. Addressing these influences through improved monitoring, material design, and data-driven diagnostics is essential for enhancing PV system reliability and maintaining consistent power generation.

Table 1.

A quick look at the research work performed on the effect of dust on the efficiency of PV panels in some Asian & African countries.

3. Types of Pollutants and Their Impact on PV

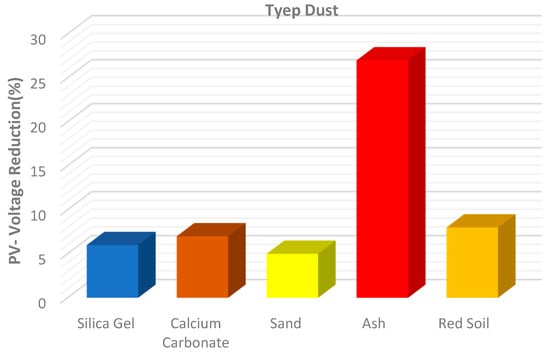

Soiling refers to the deposition and accumulation of aerosol particles and dust on the surface of PV arrays, which can considerably reduce system productivity [86,87]. The characteristics of dust particles—such as phase, type, chemical composition, and physical properties—vary widely depending on environmental conditions, including humidity, wind speed, and air temperature [88]. These factors influence how dust particles disperse, adhere, and accumulate on solar module surfaces. Multiple experimental studies have investigated the influence of mixed air pollutants such as red soil, ash, sand, calcium carbonate, and silica on PV energy output. For example, ref. [89] evaluated the effects of six representative dust pollutants—stone dust, cement dust, sand, coal powder, ash, and laterite—on solar array performance, reaffirming the severe impact of soiling and emphasizing the role of dust characteristics and PV surface materials. A wide range of dust types, including ash, bird droppings, carpet dust, cement, charcoal, clay, coarse sand, stone dust, loam soil, laterite, salt, wood dust, and sandy soil, have been shown to affect solar system efficiency [90]. One often overlooked consequence of atmospheric air pollution is the deterioration of PV performance due to the accumulation of solid particulate matter [62]. Additionally, particulate matter emitted from stone-crushing activities represents another significant environmental factor that reduces PV efficiency [91]. As dust settles on PV modules, the transmittance of solar radiation through the glazing material declines, ultimately lowering the overall efficiency of the system [17]. As dust settles on PV modules, the transmittance of solar radiation through the glazing material declines, ultimately lowering the overall efficiency of the system [64]. As illustrated in [92], common air pollutants—including carbon, calcium carbonate, and soil particles—have been widely reported to influence PV energy output. The composition of deposited dust, often a mixture of multiple pollutants, varies by geographic location. Figure 8 shows that ash deposition on the solar glass surface produces the greatest reduction in voltage compared to other pollutant types, whereas red soil, calcium carbonate, silica, and sand exhibit less severe effects [93].

Figure 8.

Reduction in PV voltage caused by various types of dust [90].

Dust represents the finest and most widely dispersed fraction of atmospheric particulate matter. The effects of various dust types—such as manganese dioxide, calcium oxide, iron oxide, carbon, and natural dust—on PV array surfaces have been reviewed in several studies [94]. Dust accumulation on solar cell surfaces leads to a noticeable decline in their functionality. For instance, one study examining pollution and dust in four inactive regions of Iraq found that environmental dust contained a high proportion of silica, indicating its desert origin and suggesting a significant impact on PV system performance [95]. PV arrays are exposed to outdoor environments where dust deposition is a major contributor to performance degradation. Soiling, defined as the deposition and accumulation of dust and other particulate matter on solar module surfaces, poses a critical challenge in regions with heavy dust loads and low rainfall frequency and intensity [96]. Laboratory studies have investigated the influence of coal dust particles of various sizes and densities on PV module performance, with results evaluated through measurements of output voltage, current, and power [97]. A comprehensive experimental assessment of multiple dust types and their impact on PV performance is presented in [17,64,90,91,92,93,94,95,96,97,98]. Thirteen dust samples—including ash, loam soil, carpet dust, bird droppings, cement, charcoal, coarse sand, laterite, clay, sandy soil, wood dust, stone dust, and salt—were analyzed using a solar simulator, spectrometer, and scanning electron microscopy (SEM) with energy-dispersive X-ray (EDX) analysis to characterize their physical and chemical properties. Digital images of these dust samples are shown in Figure 9.

Figure 9.

Digital images of various dust samples [90]. The dust particles from SEM shows different dust particles which accumulated on the surface of PV module.

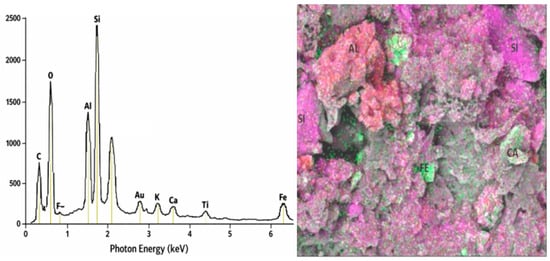

In Oman, PV modules are exposed to a wide range of weather conditions, and dust accumulation presents a significant challenge. Electricity production can be substantially reduced when dust particles—such as ash, limestone, cement, sulfur, sawdust, and brown soil—settle on module surfaces [80]. In Turkey, much higher dust concentrations, mainly originating from marble dust, cement, fly ash, and silica fume, have been shown to cause considerable power losses in PV farms [99]. In study [100] investigated the impact of dust on several solar performance metrics using two fixed flat-plate PV modules: one cleaned regularly and the other left uncleaned to accumulate dust. Dust samples collected from the soiled module were examined using a Hitachi S-4300N SEM (Hitachi, Tokyo, Japan) and EDX analysis to determine particle morphology and elemental composition. The median dust particle diameter ranged from 2 to 8 μm. Microanalysis revealed that the major elements present in the dust included potassium (K peak at 1.800 keV), oxygen (Kα peak at 0.5 keV, ~1600 counts), silicon (Kα peak at 1.8 keV, ~2500 counts), and aluminum (Kα peak at 1.5 keV, ~1300 counts). Trace elements such as calcium, sulfur, and gold were also detected in smaller quantities. The EDX spectrum for these samples is presented in Figure 10.

Figure 10.

SEM result from experimental research. The amount of dust particles &details displayed.

A research investigation on dust materials [83] employed X-ray fluorescence (XRF) analysis to evaluate the elemental composition of dust samples collected from PV panels. The analysis revealed the presence of calcium (9.20%), titanium (0.90%), phosphorus (0.25%), sulfur (0.37%), sodium (1.05%), magnesium (1.70%), potassium (2.75%), aluminum (8.70%), iron (8.50%), and silicon (20.63%), along with the following oxides: SiO2 (36.3%), CaO (8.5%), MgO (2.57%), and Al2O3 (14.9%). Additionally, X-ray diffraction (XRD) analysis conducted by Darwish et al. [101], on dust samples collected in Sharjah, United Arab Emirates, identified various compounds, including NiO (0.09%), SrO (0.13%), Cr2O3 (0.23%), MnO2 (0.20%), SO3 (0.25%), TiO2 (0.50%), K2O (0.87%), MgO (6.30%), Fe2O3 (10.45%), Al2O3 (10.83%), CaO (24.60%), and SiO2 (45.53%). Among these compounds, silicon dioxide was the predominant component, likely due to both natural sources and human activities, as well as the widespread presence of silica-rich materials in the region.

Dust adhesion on PV module surfaces is governed by several physical and chemical mechanisms that depend on particle size, morphology, composition, and environmental conditions. The dominant forces include electrostatic, van der Waals, capillary, and chemical adhesion, each contributing differently to dust accumulation and removal behavior. Electrostatic adhesion occurs when an imbalance of electric charges develops between airborne dust particles and the PV glass surface, generating Coulomb attraction. This mechanism is particularly significant under dry and low-humidity conditions, where fine, non-conductive particles such as silica or clay easily become charged through friction or wind-induced motion. Van der Waals forces, arising from intermolecular attractions, dominate when particles are in close contact with the surface. These forces are short-ranged but can strongly bind fine particles (<10 μm), making them difficult to remove by natural cleaning processes like wind or rainfall. In humid environments, capillary adhesion becomes prominent as water vapor condenses to form liquid bridges between particles and the glass surface, increasing cohesive and adhesive strength. This mechanism explains the formation of “mud-like” films after light rainfall or morning dew. In addition to these physical forces, chemical adhesion occurs when reactive or hygroscopic compounds—such as salts, sulfates, or carbonates—form ionic or covalent bonds with the glass surface. Over time, these reactions can lead to crystallization and cementation of particles, producing a permanent layer that resists conventional cleaning. Overall, physical adhesion mechanisms are typically reversible and can be mitigated through mechanical or hydrodynamic cleaning, whereas chemical adhesion tends to be irreversible and requires specialized coatings, chemical treatments, or mechanical abrasion for effective removal.

Classification and Comparative Impact of Dust and Pollutants on PV Performance

Dust particles that accumulate on PV surfaces can be broadly classified into three major categories based on their origin and composition: natural or mineral dust, organic and biological deposits, and anthropogenic or industrial pollutants. Natural or mineral dust—such as sand, soil, and silicate particles—is the most common type in arid and semi-arid regions. These coarse and opaque particles strongly scatter and absorb solar radiation, resulting in significant decreases in optical transmittance. Their adhesion is primarily governed by van der Waals and gravitational forces, and the associated power loss can reach 30–40% under prolonged exposure without cleaning.

Organic and biological dust, including pollen, bird droppings, and microbial films, typically forms thin but highly adhesive layers. These contaminants alter surface wettability and hydrophobicity, making cleaning more difficult. Although their optical impact is moderate, their chemical activity may lead to permanent surface degradation. Anthropogenic or industrial pollutants—such as soot, carbon black, and metallic oxides from combustion or manufacturing—contain fine, dark particles that strongly absorb light. They adhere through electrostatic and capillary mechanisms, causing rapid efficiency degradation even under light deposition. Such pollutants can also accelerate chemical corrosion and coating wear on glass surfaces.

Overall, the combined optical, chemical, and adhesive behaviors of these pollutant categories determine their cumulative influence on PV performance. Mineral dust mainly reduces short-term transmittance, industrial pollutants contribute to long-term surface degradation, and biological residues influence cleaning frequency and maintenance cycles. Understanding these distinctions is essential for selecting appropriate mitigation technologies, including tailored coatings, automated cleaning systems, and predictive maintenance strategies based on dust type and site-specific conditions.

Table 2 provides a comparative overview of the major categories of dust and pollutants affecting photovoltaic (PV) performance, emphasizing their origin, physical characteristics, adhesion mechanisms, and resulting optical and chemical impacts. The analysis shows that mineral dust, typically dominant in arid and semi-arid climates, causes the most substantial optical attenuation due to its coarse particle size and high opacity, often leading to power losses exceeding 30%. In contrast, anthropogenic pollutants such as soot and metallic oxides—prevalent in industrial and urban regions—exhibit fine particle sizes and strong electrostatic attraction, resulting in faster surface darkening and potential long-term chemical corrosion. Organic and biological contaminants, including pollen and bird droppings, alter surface wettability and can promote microbial growth, increasing maintenance frequency.

Table 2.

Classification and Comparative Impact of Dust and Pollutants on PV Performance.

Marine aerosols and saline dust particularly affect coastal installations through capillary condensation and salt crystallization, which degrade transparency and promote micro-scratching. Agricultural dust represents a mixed composition of mineral and organic particles, with effects that vary depending on season and humidity. Overall, these findings demonstrate that dust-induced degradation mechanisms vary widely across environments, and effective mitigation requires site-specific strategies, including hydrophobic coatings, optimized tilt angles, and adaptive cleaning schedules tailored to local dust composition.

Based on an extensive review of recent literature, Table 3 presents a wide range of dust types and their effects on solar PV performance. It provides a comprehensive overview of how different dust and pollutant categories influence system efficiency across various regions. The table includes information on the cleaning methods used, PV system sizes, specific dust materials encountered, and key findings from numerous studies. It highlights the diversity of soiling challenges—ranging from dirt and fine particulate dust to snow deposits and industrial emissions—and shows how these factors degrade optical transmittance and power output. The table also reflects the performance of different cleaning strategies, such as water-free robotic cleaning, wet robotic cleaning, automated systems, and manual methods, in mitigating soiling-related losses. Additionally, it summarizes the goals of each study, including assessing soiling impacts, optimizing cleaning frequency, designing climate-specific cleaning solutions, and evaluating PV performance under varying environmental influences.

Table 3.

Overview of a large number of pollutants and their impact on PV.

Table 3 thus offers a detailed overview of how diverse dust types and pollutants affect PV systems under different geographical and climatic conditions. It illustrates the relative effectiveness of various cleaning approaches and underscores the need for location-specific soiling management strategies. However, the table does not identify a single universally optimal cleaning method, as the effectiveness of each technique varies according to dust composition, soiling intensity, environmental conditions, and system configuration. To enhance the value of Table 3, several opportunities for further development can be identified: standardizing testing protocols to improve comparability across studies; conducting long-term evaluations to capture seasonal variability and the durability of cleaning approaches; performing cost–benefit analyses of each cleaning method; assessing the environmental impacts of cleaning operations; and integrating advanced monitoring and predictive modeling to optimize cleaning schedules. Expanding the dataset to include more geographical locations, providing more detailed dust characterizations, highlighting emerging cleaning technologies, incorporating economic performance indicators, and including sustainability metrics would further strengthen the table. These improvements would not only enrich Table 3 but also support the development of more effective, sustainable, and economically viable soiling mitigation strategies for the PV industry.

4. Existing Mitigation Strategies and Cleaning Methods

Mitigation strategies for dust accumulation on solar panels are broadly categorized into passive, active, and hybrid approaches, each with varying degrees of effectiveness and practical applicability. Passive methods typically involve surface modifications or coatings designed to reduce dust adhesion or promote self-cleaning, while active methods utilize mechanical or automated cleaning systems, and hybrid approaches combine elements of both. These strategies are essential to combat the performance degradation caused by soiling, which can be particularly severe in arid and semi-arid regions [6,120]. For example, energy production from PV panels in Saudi Arabia decreases by 25% due to dust accumulation, while in the United Arab Emirates and the United States, the decrease is 20% and 15%, respectively [11]. It has been observed that the drop in efficiency due to dust accumulation can reach as high as 33.5% after one month and 65.8% after six months of operation in Saudi Arabia, and can reach 50% in less than three months in Egypt [121]. Similarly, studies in Qatar have shown a 15% decrease in energy yield after just one month, potentially escalating to 68% without rain or cleaning over 234 days [121]. In Palestine, the degradation rate can reach 5% in one week, 7% in Saudi Arabia, and 17.4% in Egypt within one month [24]. This significant depreciation in power output across diverse geographical locations underscores the critical need for advanced and efficient dust mitigation solutions to sustain the economic viability and operational longevity of PV installations [24,122]. Therefore, the selection of an optimal cleaning method requires a comprehensive evaluation of various factors, including capital expenditure, operational and maintenance costs, cleaning efficacy, and environmental considerations such as water and electricity consumption [24]. Given that manual cleaning methods, while effective, can lead to physical damage from cleaning agents and pressure, and consume significant water resources in arid regions, waterless techniques are increasingly being explored as sustainable alternatives [22]. Consequently, research into self-cleaning surfaces and automated robotic systems that minimize or eliminate water usage has gained prominence [22]. A comprehensive review of existing mitigation techniques highlights the necessity of integrating both natural and artificial cleaning methods to effectively manage dust accumulation, considering the specific climatic conditions of a given region [24]. This includes evaluating the efficacy of robotic cleaning systems, which offer precise and systematic dust removal while minimizing human intervention and operational costs in large-scale solar farms [122]. Furthermore, electrostatic cleaning systems have demonstrated promising results, with certain applications achieving up to 90% cleaning efficiency by leveraging coulombic forces to repel dust particles from the panel surface [21]. Moreover, novel coating technologies are being developed to create superhydrophobic or superamphiphobic surfaces, which minimize dust adhesion and facilitate self-cleaning through natural environmental factors like wind or light precipitation. These advanced surface modifications, often incorporating nanomaterials, can significantly reduce the frequency and intensity of active cleaning interventions, thereby lowering operational expenditures and conserving precious resources such as water [123].

The accumulation of dust on PV module surfaces is a major operational challenge that significantly reduces light transmittance, elevates module temperature, and degrades overall system efficiency. To address this issue, a wide range of dust removal techniques has been developed, which can be broadly classified into natural, manual, automated, preventive, and electrostatic cleaning methods. Each category has distinct advantages and limitations depending on climatic conditions, installation scale, resource availability, and economic constraints. A comprehensive understanding of these techniques is essential for selecting an optimal cleaning strategy that balances cleaning efficiency, operational cost, and environmental sustainability.

Natural cleaning represents the simplest and most passive approach, relying primarily on environmental factors such as wind and rainfall to remove dust from PV module surfaces. Wind can effectively dislodge loose and lightweight particles; however, its efficiency is highly dependent on wind velocity, particle adhesion forces, and panel orientation. Light winds may merely redistribute dust rather than remove it, while strong gusts can erode protective coatings or cause micro-scratches on the glass surface. Rainfall, on the other hand, serves as an effective natural washing mechanism that can remove both dry and partially adhered dust particles. The effectiveness of rain cleaning depends on the frequency, duration, and intensity of precipitation, as well as the surface hydrophobicity of the module glass. In humid and high-rainfall regions, natural cleaning can significantly reduce soiling rates, but in arid and semi-arid climates—where precipitation is infrequent—its contribution is negligible. Moreover, light drizzle may increase adhesion by turning dry dust into a sticky mud-like layer, emphasizing that natural cleaning alone cannot be relied upon for consistent performance recovery in dusty environments.

Manual cleaning is the most common and widely practiced method, particularly in small- and medium-scale installations [124]. It involves the physical removal of dust using brushes, sponges, or pressurized water. Brushing techniques are simple and inexpensive, but they pose a risk of surface abrasion, especially when coarse particles such as sand are present. Washing, which typically involves using water or mild detergents, is effective in restoring transmittance but presents sustainability concerns in regions facing water scarcity. Manual washing also requires labor and regular scheduling, contributing to high operational costs for utility-scale solar farms. Furthermore, improper cleaning practices—such as using hard brushes, contaminated water, or cleaning during peak sunlight—can lead to microcracks, delamination, or thermal shock in PV modules. Therefore, while manual cleaning is practical and accessible, its long-term sustainability is limited, and it must be carefully managed to prevent mechanical damage and excessive water consumption.

Automated cleaning techniques have emerged as an advanced alternative, incorporating robotic systems and computer-controlled sprinklers to ensure consistent, water-efficient, and damage-free cleaning [125]. Robotic cleaners, equipped with rotating brushes, microfiber rollers, or air jets, can operate autonomously along the module surface, making them particularly suitable for large-scale solar farms where manual cleaning is impractical. These systems can be powered by small PV panels or battery storage units, minimizing operational energy requirements. Automated water-spraying systems, including computer-controlled sprinklers, allow for precise timing and water distribution, ensuring effective dust removal with minimal resource use. Moreover, these systems can be integrated with monitoring sensors to trigger cleaning cycles based on soiling detection or reduced output performance, enabling predictive maintenance. Although the initial installation cost of automated systems is relatively high, their efficiency, consistency, and ability to operate without human intervention make them increasingly attractive for utility-scale solar applications, especially in desert regions.

Preventive cleaning focuses on minimizing dust adhesion rather than removing accumulated particles. This approach typically involves applying advanced surface coatings—such as hydrophobic, superhydrophobic, or photocatalytic films—that alter the surface energy of PV glass to repel dust and water. Hydrophobic coatings reduce the contact angle between water droplets and the glass surface, enabling rainwater to roll off easily, carrying away dust particles. Photocatalytic coatings, often made of titanium dioxide (TiO2), utilize ultraviolet radiation to decompose organic materials, making it easier for subsequent rainfall or wind to remove residual dust. These coatings offer long-term protection with minimal maintenance; however, their durability, cost, and optical transparency remain critical factors influencing commercial adoption. Regular reapplication may be necessary depending on environmental exposure and coating degradation. Future work must also focus on understanding the physicochemical interactions between dust particles and PV surfaces. Parameters such as particle charge, surface roughness, humidity, and chemical reactivity determine adhesion strength and cleaning difficulty. By quantifying the relative contributions of electrostatic, van der Waals, capillary, and chemical bonding forces, researchers can design materials and coatings tailored to resist specific adhesion types. This mechanistic understanding will guide the development of more effective and environment-specific cleaning technologies.

Electrostatic cleaning, an emerging technology, employs electric fields to repel or remove dust particles without physical contact or water. This method typically integrates transparent electrodes onto the PV surface, which generate oscillating electric fields to dislodge and repel charged dust particles. Electrostatic cleaning offers several advantages, including waterless operation, low maintenance, and suitability for remote or water-deficient areas. Laboratory and field trials have demonstrated cleaning efficiencies of up to 90%, making it a promising technique for large-scale deployment in arid environments. However, challenges such as high initial cost, complex circuitry integration, and reduced effectiveness for non-conductive dust particles must be addressed before widespread commercialization. In summary, the selection of an appropriate dust removal technique depends on a combination of climatic, economic, and technical factors. While natural and manual cleaning remain cost-effective for small systems, automated, preventive, and electrostatic methods represent the future of sustainable and intelligent PV maintenance. Integrating these approaches—through hybrid systems that combine coatings, robotics, and sensor-based monitoring—can significantly enhance PV reliability, reduce maintenance costs, and ensure consistent energy production in dust-prone regions (See Figure 11).

Figure 11.

Solar cleaning model.

The effectiveness of any cleaning method is closely related to the dominant adhesion mechanisms of dust on PV module surfaces. For dust bound primarily by electrostatic or van der Waals forces, simple techniques such as air jets, water rinsing, or electrostatic neutralization can effectively detach particles. However, when capillary adhesion is significant—typically in humid environments or after light rainfall—water alone may not suffice, and mechanical brushing or hydrophobic coatings are required to break liquid bridges between particles and the glass surface. In cases where chemical adhesion dominates, such as with salts or cemented dust layers, chemical cleaning agents or photocatalytic coatings that decompose organic or ionic bonds offer better results. Recent innovations include robotic and electrostatic cleaning systems, which minimize water consumption and human labor while maintaining consistent cleaning quality. The selection of a suitable cleaning strategy thus depends on the environmental conditions, dust composition, and adhesion behavior, underscoring the importance of understanding adhesion mechanisms for optimizing maintenance and enhancing long-term PV.

4.1. Machine Learning in Dust Detection as a Mitigation Technique

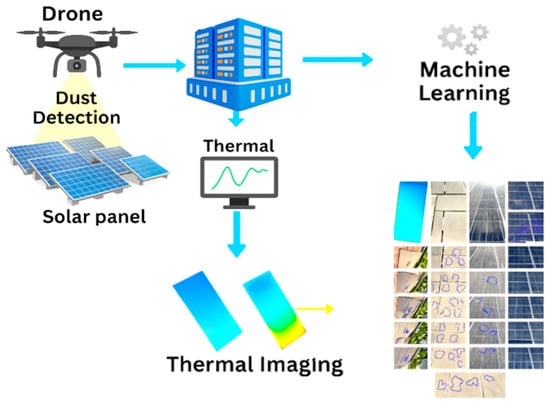

ML, particularly deep learning, has emerged as a promising approach for detecting and mitigating dust accumulation on solar PV modules. Dust deposition on PV panels significantly reduces energy yield, causing power losses of up to 57% depending on dust type, particle size, and environmental conditions. Traditional manual inspection and cleaning methods are labor-intensive and economically inefficient for large solar farms. ML-based systems, on the other hand, offer automated, scalable, and cost-effective solutions for early detection of soiling. Recent research integrates Convolutional Neural Networks (CNNs) for visual analysis of PV modules, enabling automated image-based classification between dusty and clean panels. Pre-trained models such as VGG, ResNet, and DenseNet extract high-level visual features from captured images, which are then processed by classifiers like Support Vector Machines (SVMs) for binary dust detection. In particular, DenseNet169 combined with a linear SVM achieved an 86.79% classification accuracy, making it highly effective for real-time dust monitoring systems. These ML-based systems can be embedded into automated maintenance frameworks, where detected soiling levels trigger timely cleaning operations, thus maintaining panel efficiency and extending module lifespan. Moreover, such systems can leverage surveillance or drone-mounted cameras for continuous observation without disrupting plant operations. The integration of ML in dust detection not only enhances energy generation efficiency but also supports sustainable, low-cost maintenance strategies essential for large-scale solar deployment.

Figure 12 illustrates an integrated framework for automated dust detection and thermal monitoring of solar PV systems using drone-based imaging and machine learning. In this approach, drones equipped with optical and infrared (thermal) cameras capture real-time images of solar panels from above the installation site. The acquired data are transmitted to a centralized data server for preprocessing and analysis. Thermal imaging is employed to identify temperature variations across the PV module surface, which indicate performance degradation due to dust accumulation or partial shading. Concurrently, visual data are used to detect and localize soiling regions using image segmentation algorithms. The processed datasets are then fed into machine learning models, where CNNs and deep transfer learning techniques classify panels based on dust severity and thermal anomalies. This combined thermal–optical approach enhances accuracy in identifying soiling patterns, supports predictive maintenance, and enables efficient operation of large-scale PV plants through intelligent, data-driven monitoring.

Figure 12.

Drone-Assisted Dust Detection and Thermal Imaging Framework for PV Monitoring Using Machine Learning.

Despite these advantages, several important limitations restrict the practical deployment of ML-based soiling prediction systems. ML models require large, high-quality datasets that represent diverse environmental and operational conditions; however, such datasets are often limited, incomplete, or site-specific, leading to poor generalization across regions with different dust characteristics. Implementing ML approaches also increases operational costs due to additional sensors, data acquisition hardware, and computational infrastructure. Furthermore, ML models may become sensitive to noise, susceptible to overfitting, and require continuous retraining as climatic patterns evolve. Therefore, while ML can enhance the understanding of soiling behavior, it should be viewed as a complementary tool rather than a standalone replacement for empirical measurements and field-based diagnostics.

4.2. Standardization and Emerging Dust Mitigation Technologies

A critical research priority is the development of standardized soiling indices and testing protocols that allow reliable comparison of dust effects across different geographic regions and technologies. Currently, inconsistencies in measurement units, sampling frequency, and reporting methods limit the comparability of soiling data. Establishing international standards—similar to IEC or ISO frameworks—would improve the reliability of soiling studies, facilitate benchmarking of cleaning techniques, and support data sharing between research institutions and PV manufacturers. Recent advances demonstrate the potential of hybrid optical–thermal strategies to mitigate soiling and enhance efficiency. For instance, Sheikholeslami and Khalili [126] developed a paraffin-based spectral splitter combined with a ZnO–water nanofluid cooling layer and a self-cleaning SiO2 nanoparticle coating. Their simulations showed that the system improved temperature uniformity by up to 68% and electrical efficiency by nearly 39%, while mitigating the thermal and optical losses caused by dust deposition. This integrative approach illustrates the convergence of spectral management, cooling, and self-cleaning for sustainable PV performance improvement. At the system level, Ghenai et al. [127] conducted a techno-economic assessment of a hybrid PV/fuel cell system in desert environments, emphasizing the influence of temperature and dust accumulation on both energy output and system reliability. Their findings underline that soiling directly affects not only module efficiency but also dispatch strategy, hydrogen production, and levelized cost of energy. Incorporating such effects into system optimization can improve design robustness in arid and dusty climates. The development of biomimetic superhydrophobic coatings has emerged as a promising passive solution for dust mitigation. Latthe et al. [128] fabricated silica nanoparticle-based coatings with water contact angles around 160°, demonstrating strong self-cleaning capability through the lotus effect. Despite excellent repellency, the study also highlighted limitations related to optical transparency and long-term durability, pointing to the need for advanced materials with stable optical and mechanical properties suitable for PV applications.

Several underexplored cleaning and mitigation techniques offer promising opportunities for future PV applications. These include plasma-assisted surface modification, electrostatic repulsion cleaning, self-adaptive photocatalytic coatings, and hybrid robotic–electrostatic systems capable of water-free, autonomous operation. Integrating such techniques with machine learning-based predictive algorithms could enable intelligent, resource-efficient cleaning schedules and enhance system resilience under extreme environmental conditions.

5. Discussion and Future Direction Framework

This section extends beyond bibliometric analysis to outline key scientific and technological directions for future PV research. It emphasizes the need for standardized soiling indices, unified test protocols, and deeper understanding of physical and chemical dust–surface interactions. These aspects are essential for developing next-generation cleaning methods and predictive maintenance systems that can adapt to diverse climatic and operational conditions. Recent developments in dust–PV research demonstrate a clear evolution from descriptive performance loss assessments toward integrated, predictive, and solution-oriented approaches. The growing body of literature reflects a maturing discipline that increasingly combines environmental science, materials innovation, and data-driven maintenance strategies to address the complex interplay between dust deposition, optical attenuation, and system reliability [35]. Bibliometric and metadata analyses confirm that while the early focus was largely on quantifying energy yield losses, contemporary studies emphasize preventive mitigation, predictive modeling, and techno-economic optimization. Moreover, the rise in artificial intelligence, digital twins, and IoT-based monitoring is reshaping the operational paradigm from reactive maintenance to proactive asset management. The following sections synthesize these advancements in two dimensions. presents a detailed Research Trend Analysis (2019–2025) highlighting the thematic shifts and emerging priorities within the field and integrated Framework for Future Improvement, linking environmental, technological, and operational strategies into a unified roadmap for enhancing PV performance and sustainability under dusty conditions.

In addition to these advancements, recent work in simulation-based optimization and cyber-physical risk assessment offers further avenues for strengthening PV system resilience. For example, Kriging-assisted and Latin Hypercube Sampling optimization frameworks have shown strong potential for improving complex control and prediction tasks in energy systems, suggesting their applicability to soiling prediction and adaptive cleaning control strategies [129]. Likewise, studies assessing cyber-attack vulnerabilities in distributed generation networks highlight the growing need to protect data-driven PV monitoring infrastructures as they become more interconnected and IoT-dependent [130]. Integrating such optimization and cybersecurity perspectives into PV soiling research will be essential for developing robust, intelligent, and secure next-generation maintenance frameworks.

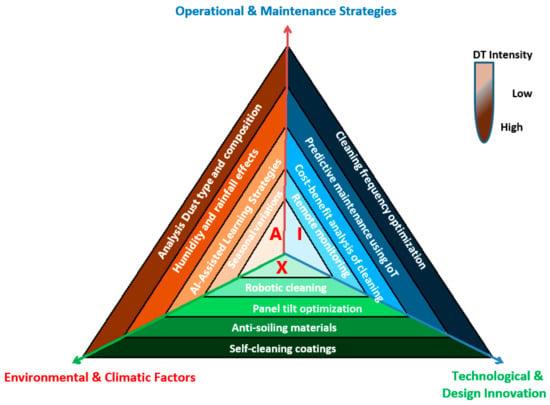

Integrated Framework for Future Improvement

Figure 13 illustrates an integrated triangular framework that links the three core domains influencing dust-induced degradation in PV systems: environmental and climatic factors, technological and design innovation, and operational and maintenance strategies. Each axis represents a critical research and management dimension required to achieve optimal long-term PV performance in dust-prone environments. The environmental and climatic axis (bottom-left) highlights the need to characterize dust type, composition, hygroscopicity, and particle size, as well as to assess humidity, rainfall, and seasonal variations that determine deposition and removal dynamics. Continuous monitoring of these parameters forms the foundation for location-specific mitigation strategies. The technological and design axis (bottom-right) focuses on the development of anti-soiling coatings, self-cleaning surfaces, tilt-angle optimization, and robotic or electrostatic cleaning systems, which together reduce manual maintenance costs and improve transmittance recovery efficiency. Innovation in materials engineering—particularly hydrophobic and photocatalytic coatings—offers the potential to minimize adhesion forces and extend cleaning intervals.

Figure 13.

Framework of Environmental, Technological, and Maintenance Interactions in PV Soiling Research. The color shading illustrates increasing dust-threat intensity and system complexity, reflecting the growing integration of environmental factors, technological solutions, and operational strategies toward optimized photovoltaic performance. Environmental axis (brown): Represents dust properties and climatic variability influencing deposition and removal processes. Technological axis (green): Shows mitigation solutions ranging from passive surface treatments to active cleaning technologies. Operational axis (blue): Illustrates the progression from conventional maintenance to predictive, AI-driven management. A: Adaptive operation integrating environmental data, technology choice, and maintenance planning. I: Intelligent operation enabled by AI, IoT monitoring, and digital-twin-based prediction. X: Baseline operation with limited integration and reactive maintenance.

The third axis, representing operational and maintenance strategies (top), captures the transition from reactive to predictive asset management. This includes the optimization of cleaning frequency, cost–benefit analysis of different maintenance regimes, and the integration of Internet-of-Things (IoT) sensors for remote monitoring and automated decision-making. Artificial-intelligence-assisted learning models and digital-twin simulations are identified as emerging tools for predicting soiling intensity, adapting maintenance schedules dynamically, and minimizing both energy losses and water consumption. The central convergence zone of the triangle (labeled A–I–X) symbolizes the intersection of environmental understanding, technological advancement, and operational intelligence, where integrated decision frameworks can deliver the highest reliability and yield improvement. The gradient bar representing Dust-Threat (DT) Intensity demonstrates how research and mitigation efforts intensify toward the apex as environmental variability and maintenance complexity increase. Overall, advancing standardized protocols, deepening mechanistic understanding, and accelerating the adoption of intelligent, self-cleaning technologies represent the next frontier in dust mitigation research. These directions will guide the evolution of photovoltaic systems toward greater autonomy, efficiency, and sustainability.

6. Conclusions

This study provided a comprehensive synthesis of dust-related research in PV systems by integrating bibliometric mapping, metadata analysis, and in-depth technical evaluation. The results reveal a clear evolution in the field: whereas early studies predominantly quantified energy losses caused by dust accumulation, recent research increasingly emphasizes predictive modeling, preventive mitigation, material innovation, and system-level optimization. This shift reflects a maturing discipline that now considers dust not merely as an operational inconvenience but as a multidimensional challenge that links environmental science, surface chemistry, optical behavior, reliability engineering, and energy economics.