Comparing Elastocaloric Cooling and Desiccant Wheel Dehumidifiers for Atmospheric Water Harvesting

Abstract

1. Introduction

1.1. Overview

1.2. Background

1.2.1. Environment

1.2.2. Dehumidifiers

1.2.3. Elastocaloric Cooling

1.2.4. Desiccant Wheels

2. Materials and Methods

2.1. Overview

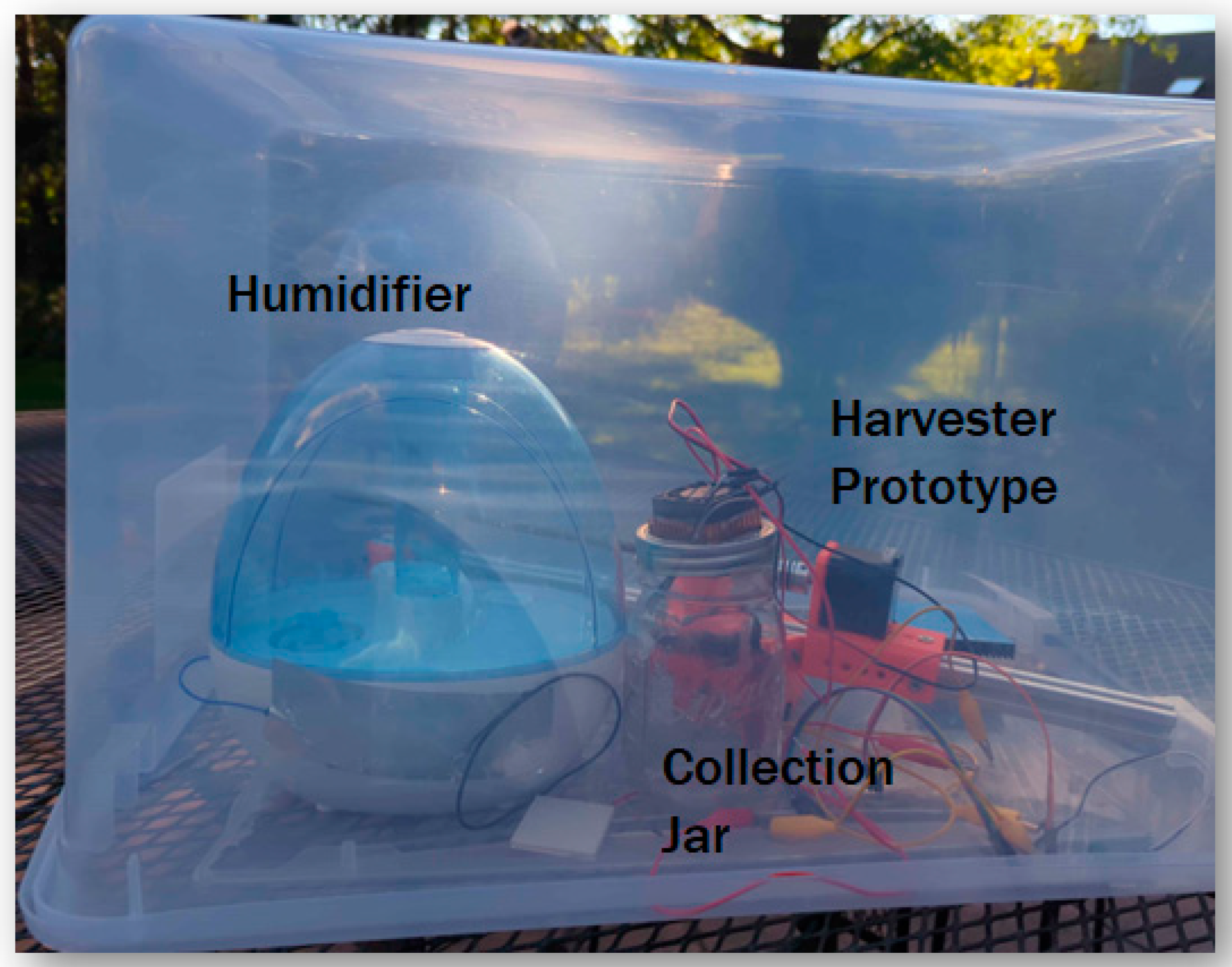

2.2. Experimental Designs

2.3. Experimental Calculations

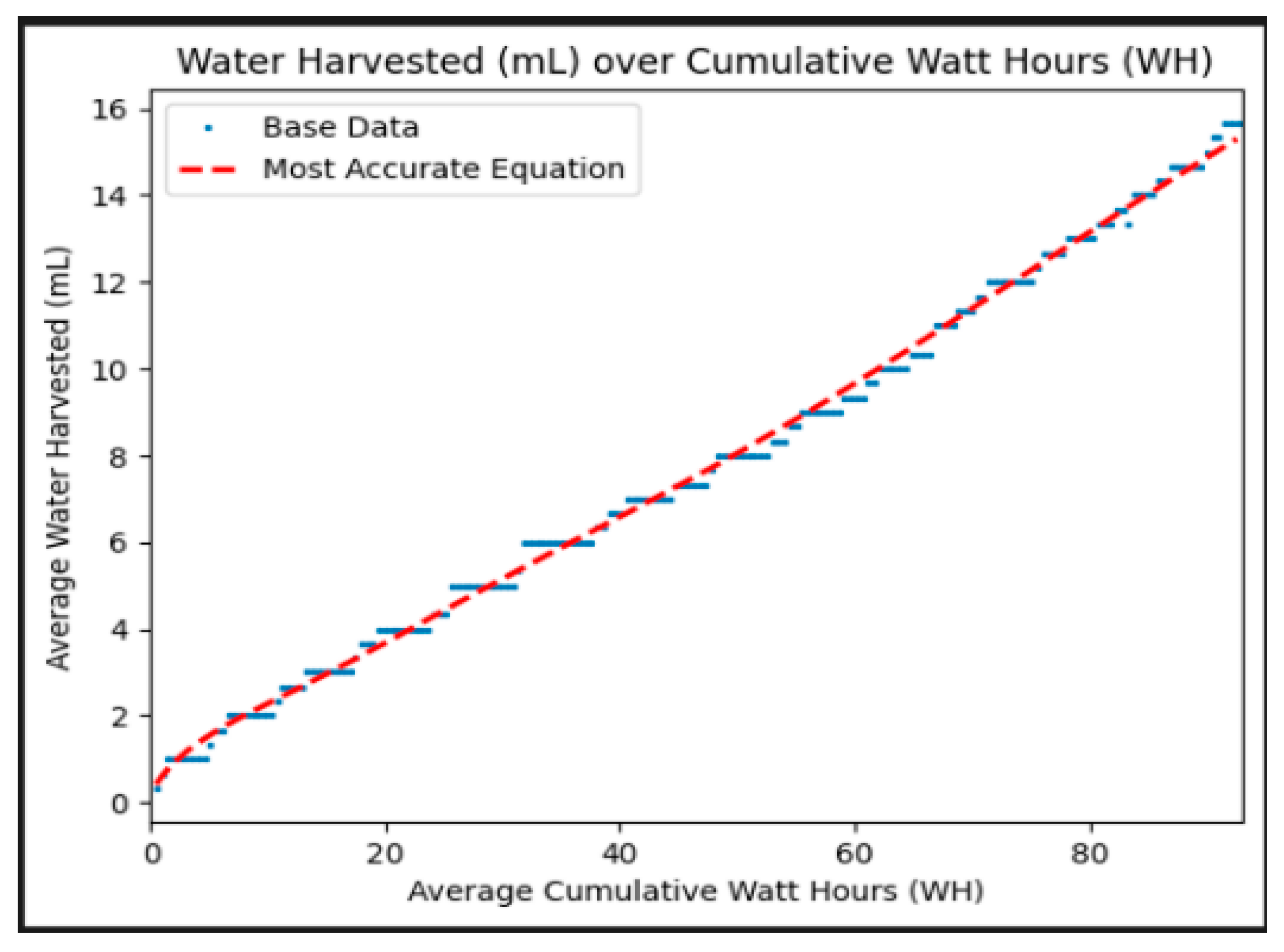

2.4. Model Designs

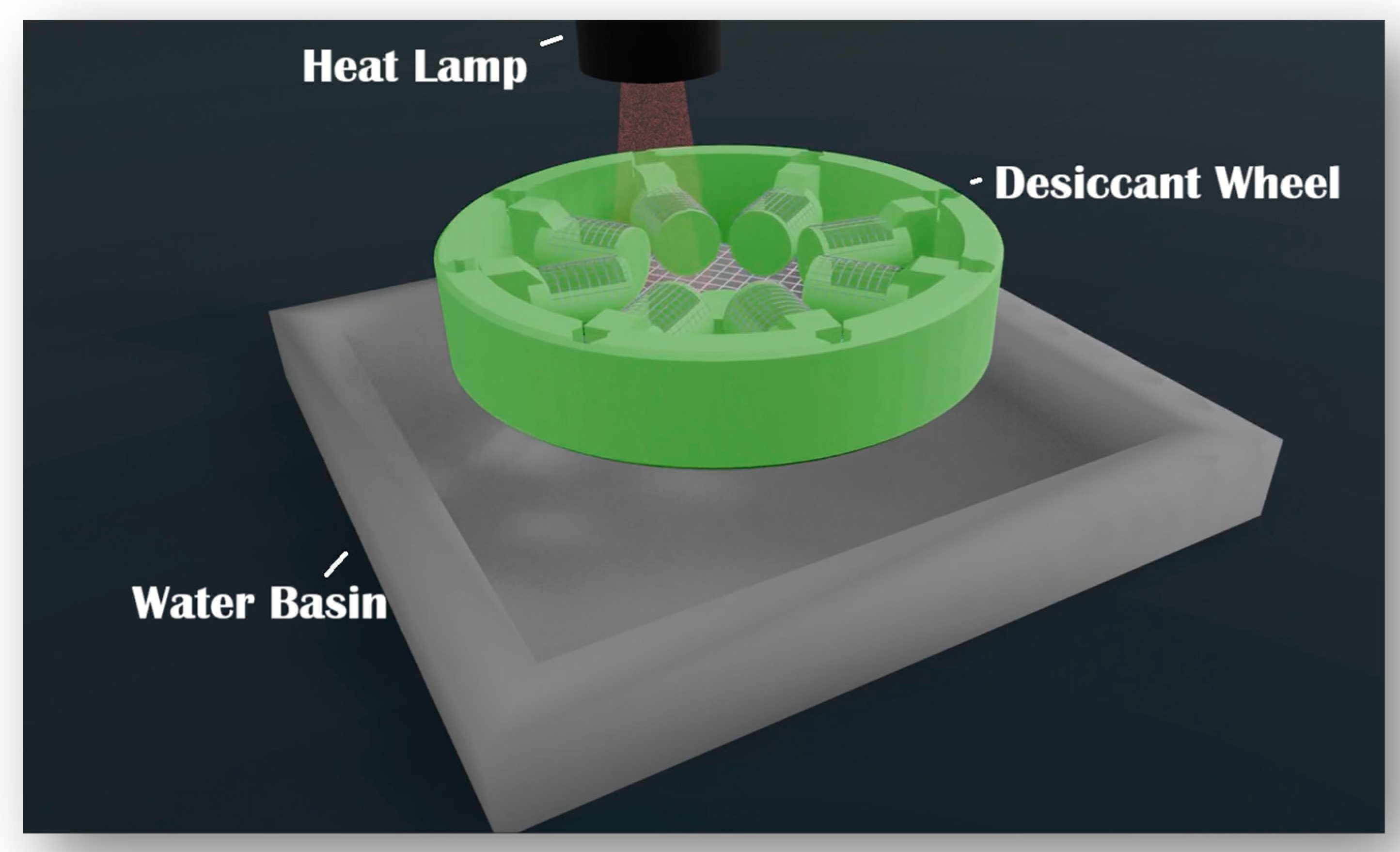

2.4.1. Desiccant Wheel Harvester

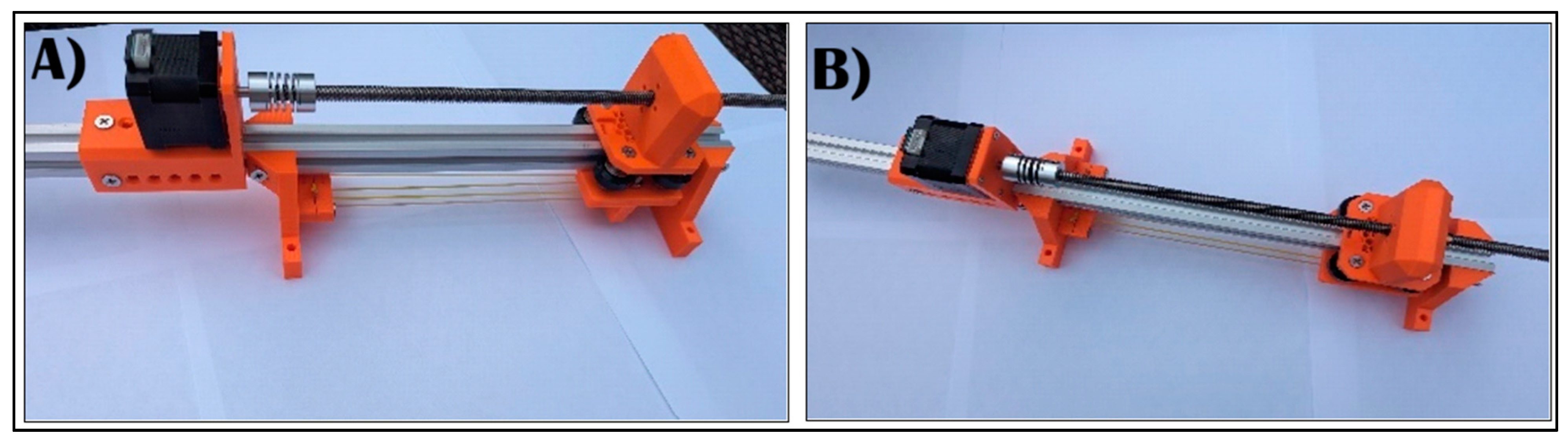

2.4.2. NiTi Harvester

2.5. Testing Methodology

3. Results

3.1. Summary

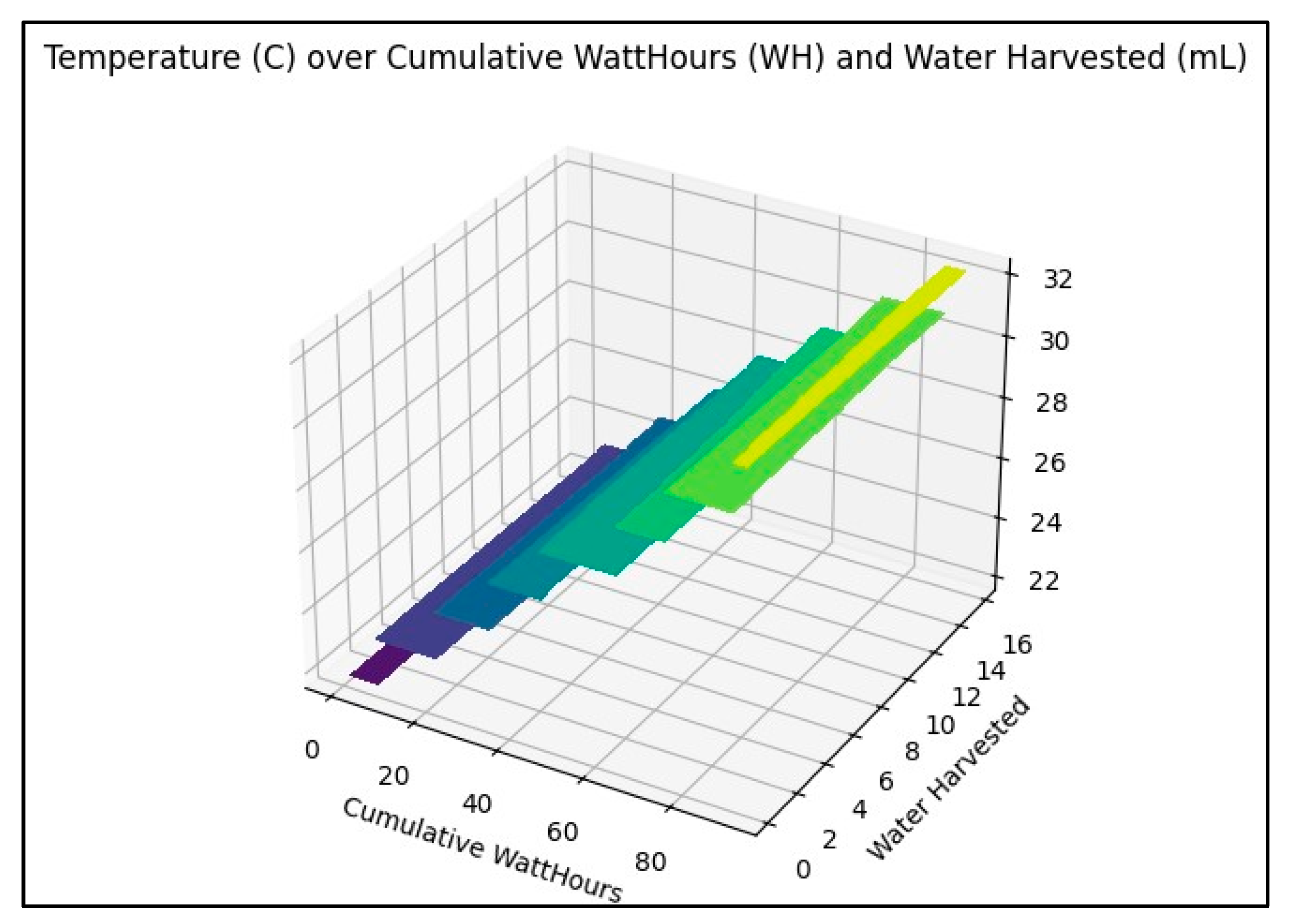

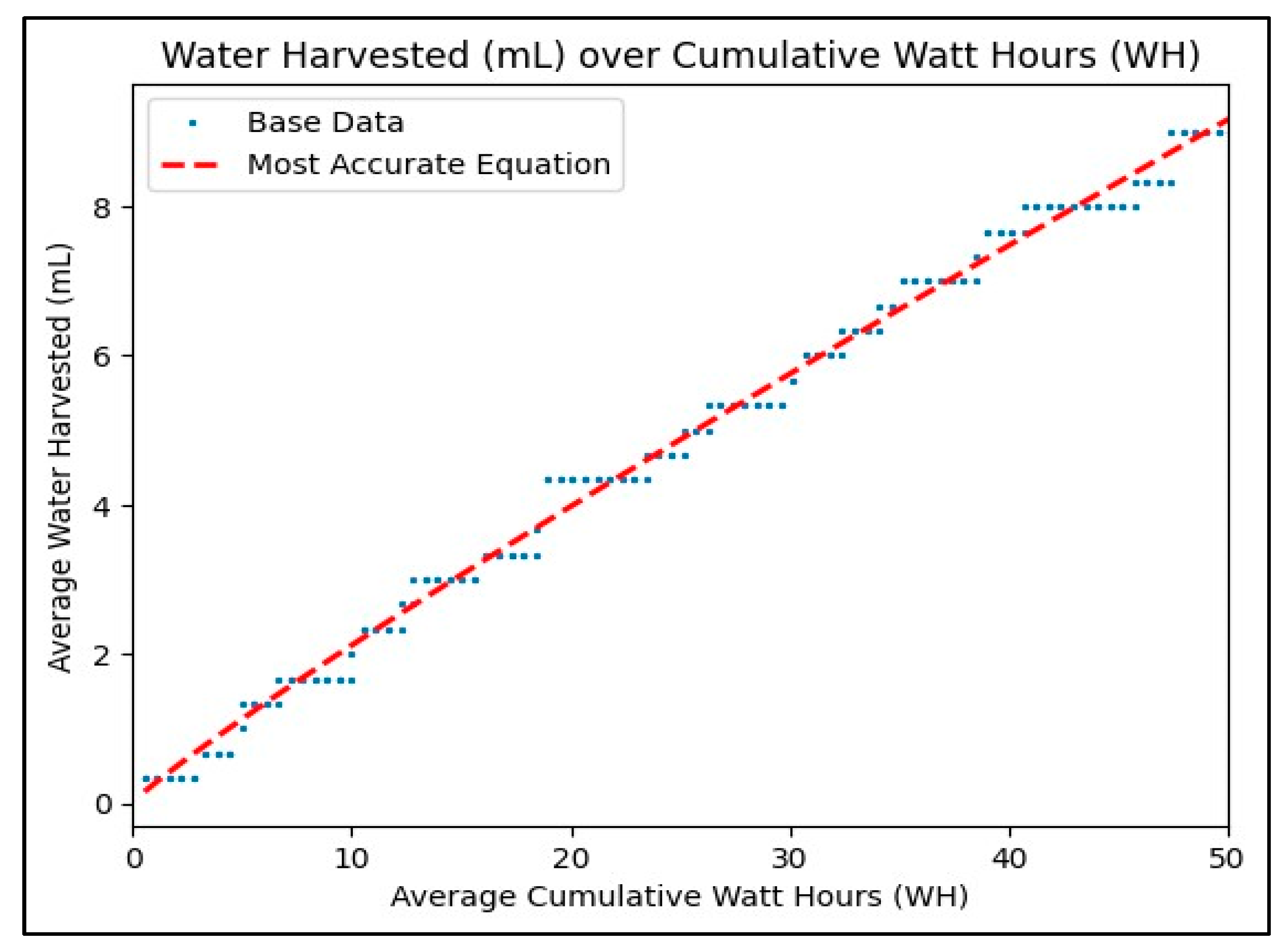

3.2. Desiccant Wheel Design

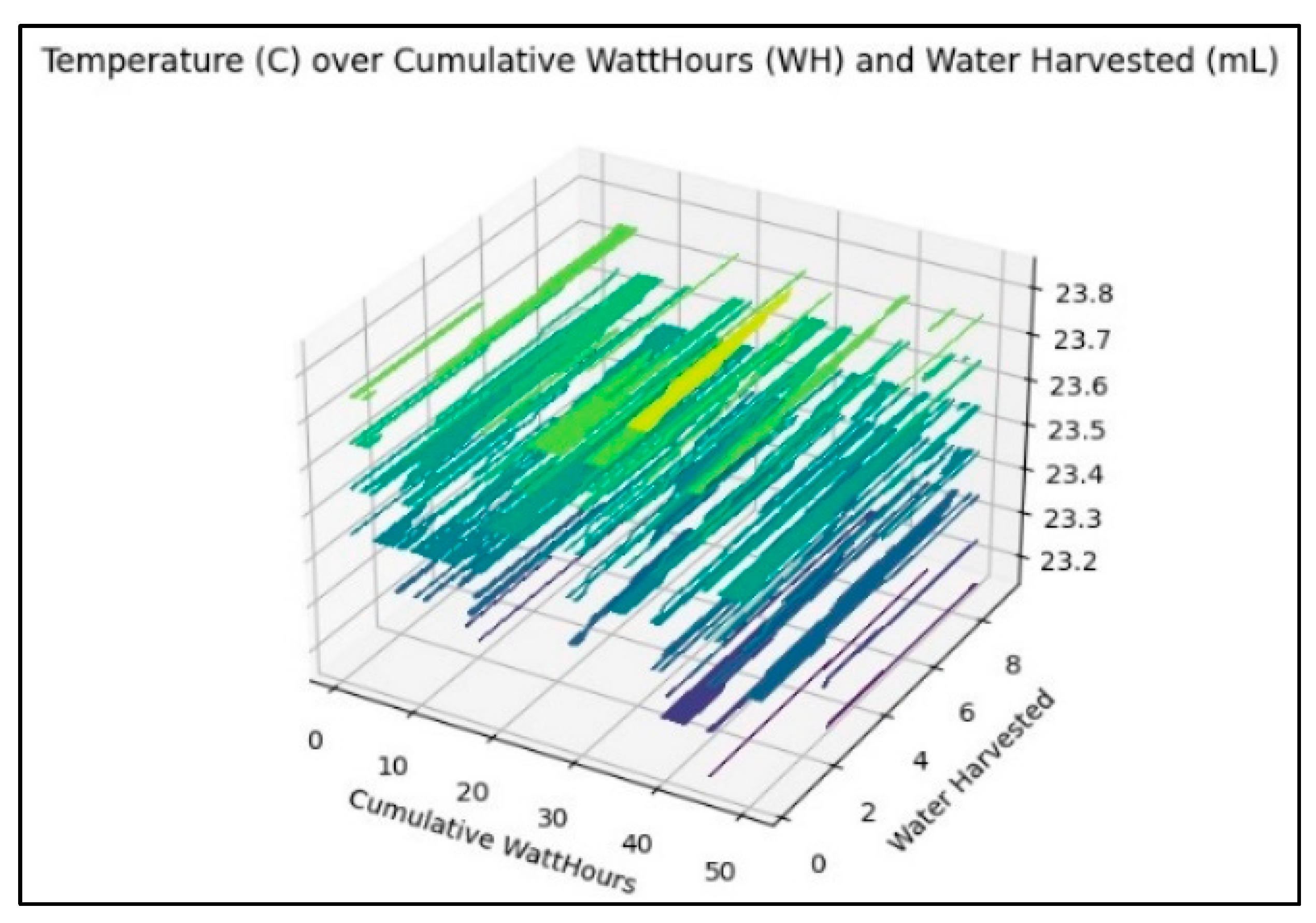

3.3. NiTi Prototype

4. Discussion

4.1. Overview

4.2. Study Limitations

4.3. Future Work

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lopes, R.H.; Silva, C.R.D.V.; Silva, Í.D.S.; Salvador, P.T.C.D.O.; Heller, L.; Uchôa, S.A.D.C. Worldwide surveillance actions and initiatives of drinking water quality: A scoping review. Int. J. Environ. Res. Public Health 2022, 20, 559. [Google Scholar] [CrossRef] [PubMed]

- Ge, F.; Wang, C. Exergy analysis of dehumidification systems: A comparison between the condensing dehumidification and the desiccant wheel dehumidification. Energy Convers. Manag. 2020, 224, 113343. [Google Scholar] [CrossRef]

- Armstrong, L.E.; Johnson, E.C. Water intake, water balance, and the elusive daily water requirement. Nutrients 2018, 10, 1928. [Google Scholar] [CrossRef] [PubMed]

- Braun, H.; von Andrian-Werburg, J.; Malisova, O.; Athanasatou, A.; Kapsokefalou, M.; Ortega, J.; Mora-Rodriguez, R.; Thevis, M. Differing water intake and hydration status in three European countries—A day-to-day analysis. Nutrients 2019, 11, 773. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, Y.; Watanabe, H.; Tanaka, A.; Yasui, M.; Nishihira, J.; Murayama, N. Effect of increased daily water intake and hydration on health in Japanese adults. Nutrients 2020, 12, 1191. [Google Scholar] [CrossRef] [PubMed]

- Raymond, C.; Matthews, T.; Horton, R.M. The emergence of heat and humidity too severe for human tolerance. Sci. Adv. 2020, 6, eaaw1838. [Google Scholar] [CrossRef] [PubMed]

- Slekiene, J.; Mosler, H.J. The link between mental health and safe drinking water behaviors in a vulnerable population in rural Malawi. BMC Psychol. 2019, 7, 44. [Google Scholar] [CrossRef]

- Matthews, T. Humid heat and climate change. Prog. Phys. Geogr. Earth Environ. 2018, 42, 391–405. [Google Scholar] [CrossRef]

- Zhuang, J.; Payyappalli, V.M.; Behrendt, A.; Lukasiewicz, K. Total Cost of Fire in the United States; Fire Protection Research Foundation: Buffalo, NY, USA, 2017. [Google Scholar]

- Liao, Y.; Kousky, C. The fiscal impacts of wildfires on California municipalities. J. Assoc. Environ. Resour. Econ. 2022, 9, 455–493. [Google Scholar] [CrossRef]

- Struzik, E. How Wildfires Are Polluting Rivers and Threatening Water Supplies. YaleEnvironment360. 2 October 2018. Available online: https://e360.yale.edu/features/how-wildfires-are-polluting-rivers-and-threatening-water-supplies (accessed on 18 February 2024).

- Meng, Y.; Dang, Y.; Suib, S.L. Materials and devices for atmospheric water harvesting. Cell Rep. Phys. Sci. 2022, 3, 100976. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, J.; Xia, W.; Mou, X.; Cai, Z. Reusable Hydrophilic–superhydrophobic patterned weft backed woven fabric for high-efficiency water-harvesting application. ACS Sustain. Chem. Eng. 2018, 6, 7216–7220. [Google Scholar] [CrossRef]

- Huang, Z.X.; Liu, X.; Wong, S.C.; Qu, J.P. A single step fabrication of bio-inspired high efficiency and durable water harvester made of polymer membranes. Polymer 2019, 183, 121843. [Google Scholar] [CrossRef]

- Xiang, C.; Yang, X.; Deng, F.; Chen, Z.; Wang, R. Daytime air–water harvesting based on super hygroscopic porous gels with simultaneous adsorption–desorption. Appl. Phys. Rev. 2023, 10, 041413. [Google Scholar] [CrossRef]

- Lu, Z.; Fix, A.J.; Warsinger, D.M.; Braun, J.E.; Ziviani, D. Generalization of second law efficiency for next-generation cooling and dehumidification systems. Energy Convers. Manag. 2024, 300, 117972. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, A.; Choudhary, R. Solar-powered water generation from atmospheric air using desiccant wheel: Theoretical and experimental investigation. Sol. Energy Mater. Sol. Cells 2024, 274, 112969. [Google Scholar] [CrossRef]

- Li, J.; Xing, G.; Qiao, M.; Du, S.; Zhou, T.; Gao, S.; Sun, H.; Jiao, R.; Li, A. Composite porous 3D foam for solar-driven atmospheric water harvesting in low humidity natural environment. Chem. Eng. J. 2024, 490, 151543. [Google Scholar] [CrossRef]

- Shan, H.; Pan, Q.; Xiang, C.; Poredoš, P.; Ma, Q.; Ye, Z.; Hou, G.; Wang, R. High-yield solar-driven atmospheric water harvesting with ultra-high salt content composites encapsulated in porous membrane. Cell Rep. Phys. Sci. 2021, 2, 100664. [Google Scholar] [CrossRef]

- Su, M.; Han, X.; Chong, D.; Wang, J.; Liu, J.; Yan, J. Experimental study on the performance of an improved dehumidification system integrated with precooling and recirculated regenerative rotary desiccant wheel. Appl. Therm. Eng. 2021, 199, 117608. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Zhang, Q.; Ma, F.; Lü, X. Application of deep dehumidification technology in low-humidity industry: A review. Renew. Sustain. Energy Rev. 2024, 193, 114278. [Google Scholar] [CrossRef]

- Cui, J.; Seelecke, S.; Motzki, P.; Sun, Q.; Takeuchi, I. Prototype Progress Report: Elastocaloric Heat Pumps. AM&P Tech. Artic. 2024, 182, 49–52. [Google Scholar]

- Wang, Y.; Liu, Y.; Xu, S.; Zhou, G.; Yu, J.; Qian, S. Towards practical elastocaloric cooling. Commun. Eng. 2023, 2, 79. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Zhu, Z.; Theodorakis, P.E.; Song, J.; Bennacer, R. A lower temperature difference of the elastocaloric effect by natural rubber. Int. J. Refrig. 2023, 155, 163–172. [Google Scholar] [CrossRef]

- Dykstra, D.M.; Lenting, C.; Masurier, A.; Coulais, C. Buckling metamaterials for extreme vibration damping. Adv. Mater. 2023, 35, 2301747. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Bruederlin, F.; Bumke, L.; Ossmer, H.; Quandt, E.; Miyazaki, S.; Kohl, M. SMA Film-Based Elastocaloric Cooling Devices. Shape Mem. Superelasticity 2024, 10, 119–133. [Google Scholar] [CrossRef]

- Cheng, S.; Li, Z.; Lee, W.Z.; Liu, S.; Fu, Y.; Zhao, Y.; Zhang, M. Development of a crankshaft driven single long NiTi tube compressive elastocaloric cooler. Sci. Technol. Built Environ. 2023, 29, 809–822. [Google Scholar] [CrossRef]

- Cui, J.; Wu, Y.; Muehlbauer, J.; Hwang, Y.; Radermacher, R.; Fackler, S.; Wuttig, M.; Takeuchi, I. Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl. Phys. Lett. 2012, 101, 073904. [Google Scholar] [CrossRef]

- Welsch, F.; Kirsch, S.; Louia, F.; Seelecke, S.; Motzki, P. Investigation of the thermal heat exchange between NiTi-wire bundles and airflow for different wire arrangements. In Proceedings of the ASME 2023 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Austin, TX, USA, 11–13 September 2023; Volume 87523, p. V001T04A023. [Google Scholar]

- Cheng, S. Modelling a Single Long NiTi Tube Compressive Elastocaloric Cooler Using Lumped Analysis Method. 31 July 2023. Available online: http://dx.doi.org/10.2139/ssrn.4527433 (accessed on 2 July 2024).

- Liang, D.; Wang, Q.; Chu, K.; Chen, J.; Hua, P.; Ren, F.; Sun, Q. Ultrahigh cycle fatigue of nanocrystalline NiTi tubes for elastocaloric cooling. Appl. Mater. Today 2022, 26, 101377. [Google Scholar] [CrossRef]

- Li, X.; Hua, P.; Sun, Q. Continuous and efficient elastocaloric air cooling by coil-bending. Nat. Commun. 2023, 14, 7982. [Google Scholar] [CrossRef]

- Qian, S.; Catalini, D.; Muehlbauer, J.; Liu, B.; Mevada, H.; Hou, H.; Hwang, Y.; Radermacher, R.; Takeuchi, I. High-performance multimode elastocaloric cooling system. Science 2023, 380, 722–727. [Google Scholar] [CrossRef]

- Cheng, S. Design of a Large-Power Separated Long NiTi Tube Bundle Compressive Elastocaloric Cooler. 31 August 2023. Available online: http://dx.doi.org/10.2139/ssrn.4558662 (accessed on 2 July 2024).

- Xiao, L.; Chi, J.; Luo, K.; Xu, J.; Zhao, D.; Wu, Z.; Luo, E. A highly efficient eco-friendly heat-driven thermoacoustic refrigerator using nitrogen and water. Energy Convers. Manag. 2024, 304, 118251. [Google Scholar] [CrossRef]

- Cirillo, L.; Greco, A.; Masselli, C. The energy performances of an elastocaloric device for air conditioning through numerical investigation. Appl. Therm. Eng. 2024, 236, 121517. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, X.; Guo, Z.; Liu, W. Recent advances in atmosphere water harvesting: Design principle, materials, devices, and applications. Nano Today 2021, 40, 101283. [Google Scholar] [CrossRef]

- Tsujiguchi, T.; Osaka, Y.; Kodama, A. Study on the miniaturization of the desiccant wheel by the optimization of designing/operation concept. J. Chem. Eng. Jpn. 2024, 47, 608–614. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

LaRocco, J.; Tahmina, Q.; Simonis, J.; Vedati, V. Comparing Elastocaloric Cooling and Desiccant Wheel Dehumidifiers for Atmospheric Water Harvesting. Technologies 2024, 12, 178. https://doi.org/10.3390/technologies12100178

LaRocco J, Tahmina Q, Simonis J, Vedati V. Comparing Elastocaloric Cooling and Desiccant Wheel Dehumidifiers for Atmospheric Water Harvesting. Technologies. 2024; 12(10):178. https://doi.org/10.3390/technologies12100178

Chicago/Turabian StyleLaRocco, John, Qudsia Tahmina, John Simonis, and Vidhaath Vedati. 2024. "Comparing Elastocaloric Cooling and Desiccant Wheel Dehumidifiers for Atmospheric Water Harvesting" Technologies 12, no. 10: 178. https://doi.org/10.3390/technologies12100178

APA StyleLaRocco, J., Tahmina, Q., Simonis, J., & Vedati, V. (2024). Comparing Elastocaloric Cooling and Desiccant Wheel Dehumidifiers for Atmospheric Water Harvesting. Technologies, 12(10), 178. https://doi.org/10.3390/technologies12100178