Abstract

In nuclear experimental, training and teaching laboratories such as a subcritical reactor facility, huge measures of external radiation doses could be caused by neutron and gamma radiation. It becomes imperative to place the health and safety of staff and students in the reactor facility under proper scrutiny. The protection of these individuals against ionization radiation is facilitated by expected dose mapping and shielding calculations. A three-dimensional (3D) Monte Carlo model was developed to calculate the dose rate from neutrons and gamma, using the ANSI/ANS-6.1.1 and the ICRP-74 flux-to-dose conversion factors. Estimation for the dose was conducted across 39 areas located throughout the reactor hall of the facility and its training platform. It was found that the range of the dose rate magnitude is between 7.50 E−01 μSv/h and 1.96 E−04 μSv/h in normal operation mode. During reactor start-up/shut-down mode, it was observed that a large area of the facility can experience exposure to a significant radiation field. This field ranges from 2.99 E+03 μSv/h to 3.12 E+01 μSv/h. There exists no noticeable disparity between results using the ICRP-74 or ANSI/ANS-6.1.1 flux-to-dose rate conversion factors. It was found that the dose rate due to gamma rays is higher than that of neutrons.

1. Introduction

One of the most relevant safety aspects of reactor operation and design is adequate shielding against radiation during steady-state operation and start-up/shut-down modes. Over the years, universities around the world have introduced subcritical reactors as a capable teaching instrument for nuclear engineering [1,2,3,4,5,6,7]. Recently, the Jordan University of Science and Technology (JUST) introduced a subcritical reactor that is fueled with low-enriched uranium (LEU) oxide [4]. Several studies have been conducted in nuclear facilities at universities where researchers and students are present and maybe exposed to high dose levels [8,9]. Determining these levels throughout the reactor hall from both neutrons and gamma rays is paramount for the safety and staff in the vicinity of the operation.

In our current study, the MCNP5 (Monte Carlo N-particle) code [10] is used to conduct studies on neutron and photon flux mapping around the reactor. Also, calculations were made pertaining to their contributions to the dose rate along the axial and radial directions.

Under the requirements stipulated by the 2007 publication of 10 CFR 835 (Occupational Radiation Protection), it was inferred that an updated set of weighting factors based on ICRP-60 [11] recommendations should be used. In its study for a better implementation of neutron dosimetry, Sandia National Laboratories recommended that the ICRP-74 flux-to-dose equivalent rate conversion factors are appropriate for neutron exposure determination [9].

In our current study, the conversion of neutron and gamma fluxes to dose rates using ANSI/ANS-6.11 [12] and ICRP-74 [13] flux to human biological dose rate conversion factors as well as their inter-comparison has been performed. Investigations on neutron and gamma contributions to overall total dose have also been performed. Obtained results will be used in shielding design optimization. Comparisons were also made between calculated doses and common occupational hazards. These comparisons included common safety standards recommended by local and international radiation protection organizations including the National Council on Radiation Protection and Measurements (NCRP), the International Commission on Radiological Protection (ICRP) and the International Atomic Energy Agency (IAEA) [14], in order to avoid the harmful radiation effects.

The Subcritical Reactor

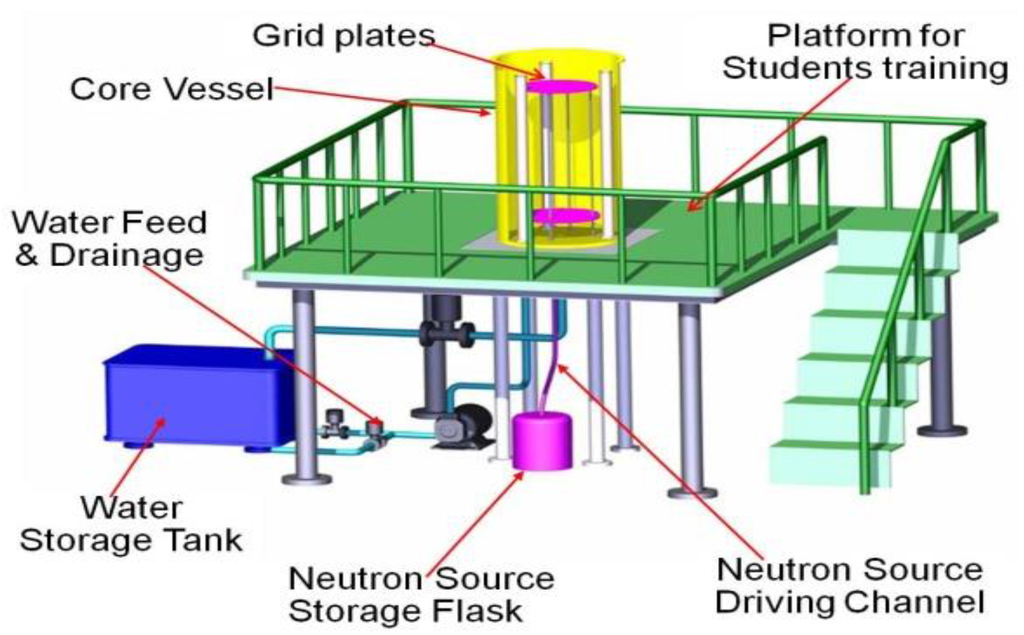

The subcritical facility is an open-tank, uranium-fueled light water reactor, utilized for the experimentation and education of students. In terms of operation, the reactor utilizes a plutonium beryllium (Pu-Be) neutron source to sustain a chain reaction [4].

The reactor core is loaded with 313 fuel rods in a 19.1-mm-pitch square lattice that expands to a 20 cm radius and a height of 55 cm. The PWR fuel structural pattern provides the framework for the uranium oxide (UO2) fuel rods, with an enrichment level of 3.4 wt. % 235U, and zirconium alloy (Zr-4) cladding.

The reactor vessel is 120 cm in diameter and 132 cm in height. The vessel envelops the nuclear core with a water layer measuring 40 cm on the sides and 38.5 cm on the top and bottom. The thick layer of water located around the core serves both as a neutron reflector, and as neutron shielding, preventing neutrons from leaking around the reactor area. This ensures the reduction of radiation around the reactor area [4].

In its operational state, the neutron source is positioned under the core at the centerline below the lower grid plate. The plutonium beryllium (Pu-Be) neutron source has an activity of 2.96 E+10 Bq (0.8 Ci) with a neutron emission of 1.19 E+6 n/s. The source moves from its underground storage flask into the reactor by a pneumatic system, through a plastic hose.

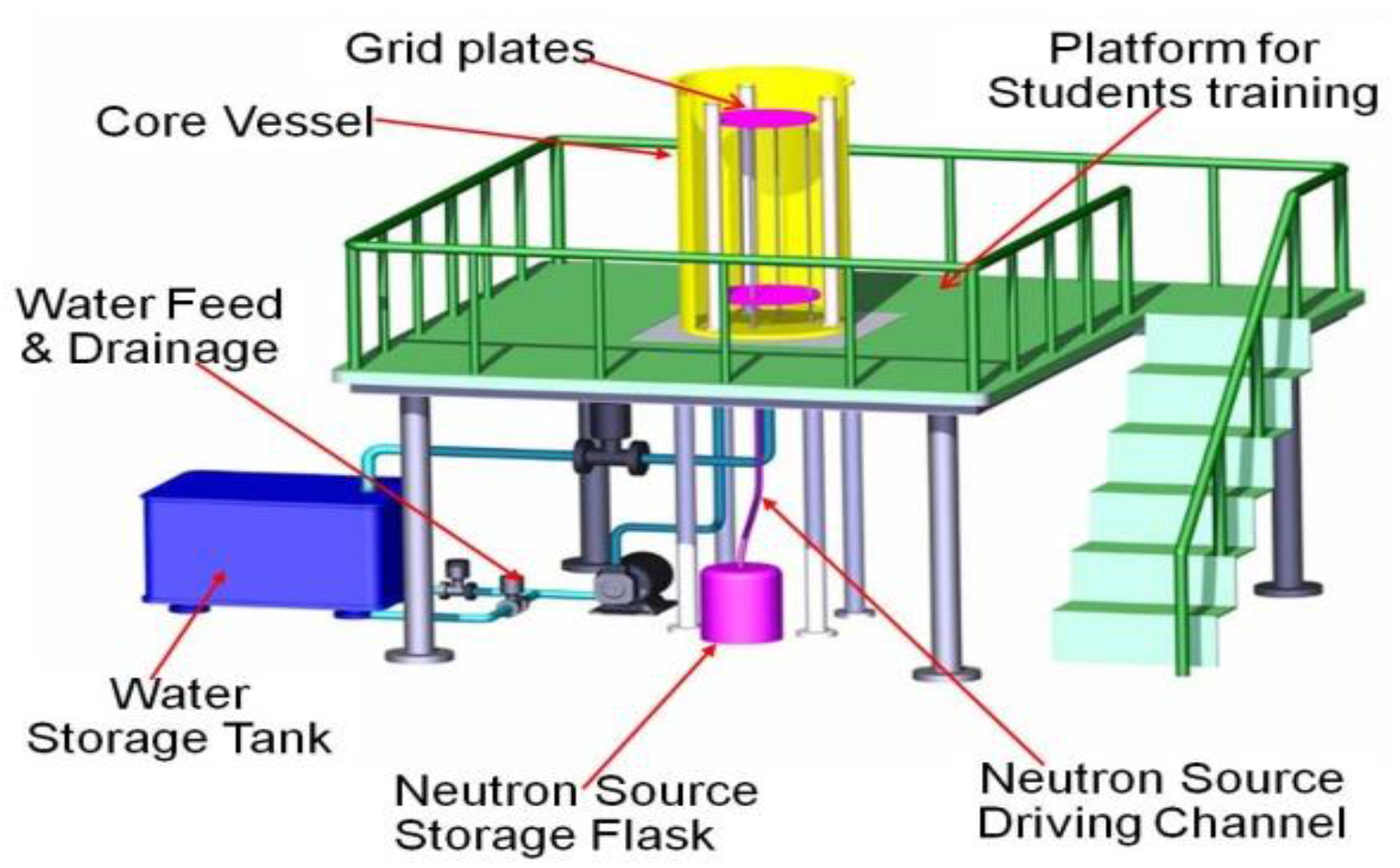

The training platform is positioned around the reactor core, which enables clear observations of various features of the reactor. The reactor platform is positioned 1.8 m from the ground, and the whole experimental system situated inside a reactor hall, measuring 6.8 × 10.5 m. Figure 1 shows the layout design of the subcritical facility.

Figure 1.

Schematic design of the subcritical reactor systems and platform [4].

2. Methodology

The calculation of dose rates using the fixed source (nps) simulation is performed utilizing the MCNP-5 Monte Carlo code [10]. Neutron and gamma doses are tallied by volume-average flux tallies (F4), and modified to dose by means of flux-to-dose conversion factors (DE and DF card). These cards are efficient in conversions from calculated particle flux to human biological dose which serves as a replica for dose conversion. It is imperative to infer that in our calculations, two separate sources of radiation will contribute to exposure. These sources include the subcritical core and the Pu-Be source. The subcritical core is where fission-released neutrons and gammas are tallied. Secondly, the Pu-Be, situated under the core, releases neutrons and gammas from its Alpha-Be reaction.

Fixed source calculations were performed using a detailed three-dimensional (3D) model of the subcritical assembly. Two sets of conversion factors were used in calculating the dose rate which was denominated in Rem/hr. These flux-to-dose conversion factor sets include the ANSI/ANS-6.1.1 and the ICRP-74. ANSI/ANS-6.1.1 is an acronym that stands for American National Standards Institute and America Nuclear Society while ICRP-74, on the other hand, stands for the International Commission on Radiological Protection.

The ICRP-74 provides an extensive and authoritative set of data linking the operational quantities defined by the ICRU with the dosimetric and protection quantities defined by the ICRP. The operational quantities provide a satisfactory basis for most of the measurements for radiation protection against external radiations [13]. Energy fitting parameters are provided by the ANSI/ANS-6.1.1 (1977) to ensure the maximum and optimal dose equivalent located in slab phantoms and utilized for effective dose replications [12].

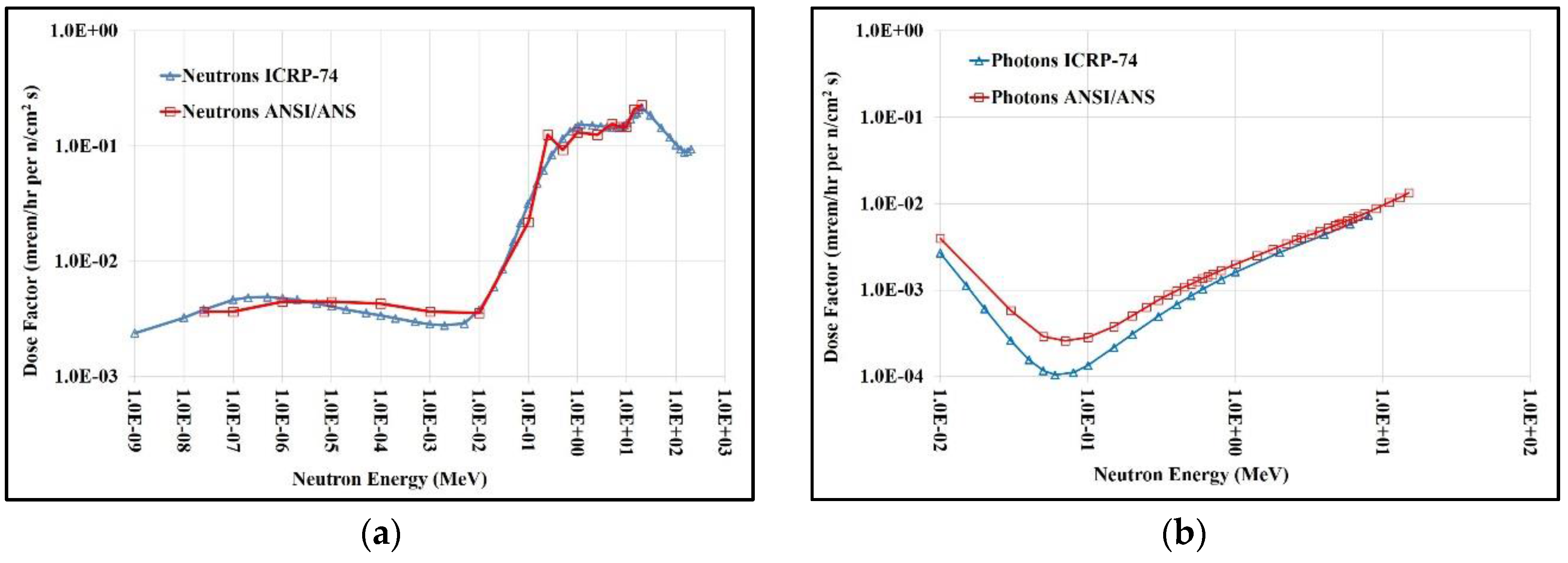

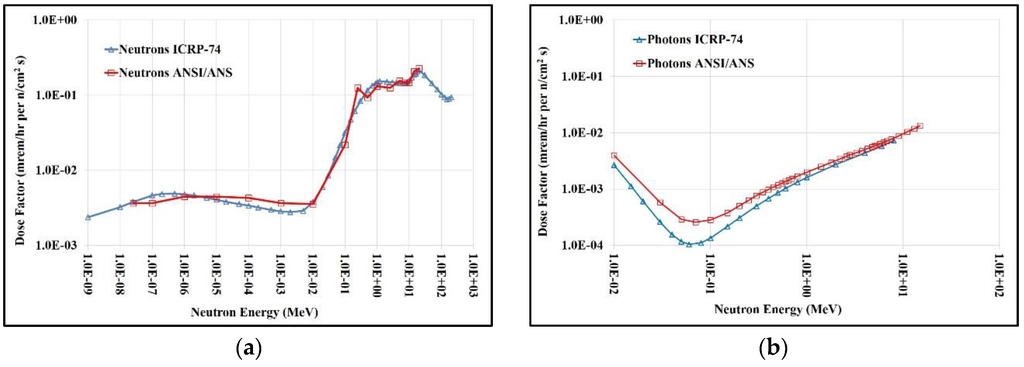

Despite the small amount of irregularities in conversion factors between the two sets, it appears that the health physics community affirms that there are no significant differences between both sets, where it is believed that accepted levels of accuracy lie around 20%. Figure 2 shows the flux-to-dose rate conversion factors for photons and neutrons from ICRP-74 and ANSI/ANS. The conversion factors are plotted on a log-log scale as recommended by the ICRP and ANSI, creating a straight line between any two points, for the proper interpolation between points.

Figure 2.

The flux-to-dose equivalent rate conversion factors on a log-log scale, as recommended by the ICRP and ANSI: (a) Neutrons (b) Photons.

In this paper, results obtained by Monte Carlo MCNP calculations for two distinct modes of operation are presented. The first mode is when the neutron source is positioned inside the reactor during normal operation, and the second mode (reactor shut-down and start-up) is when the neutron source is moved from its storage flask to the reactor, and put back. Two distinct calculations were conducted for each mode. The first calculation involves the tallying of neutrons and gamma obtained from the (n, γ) reaction. On the other hand, the second calculation involves the tallying of emitted photons directly from the source and other radioactive materials located in the core.

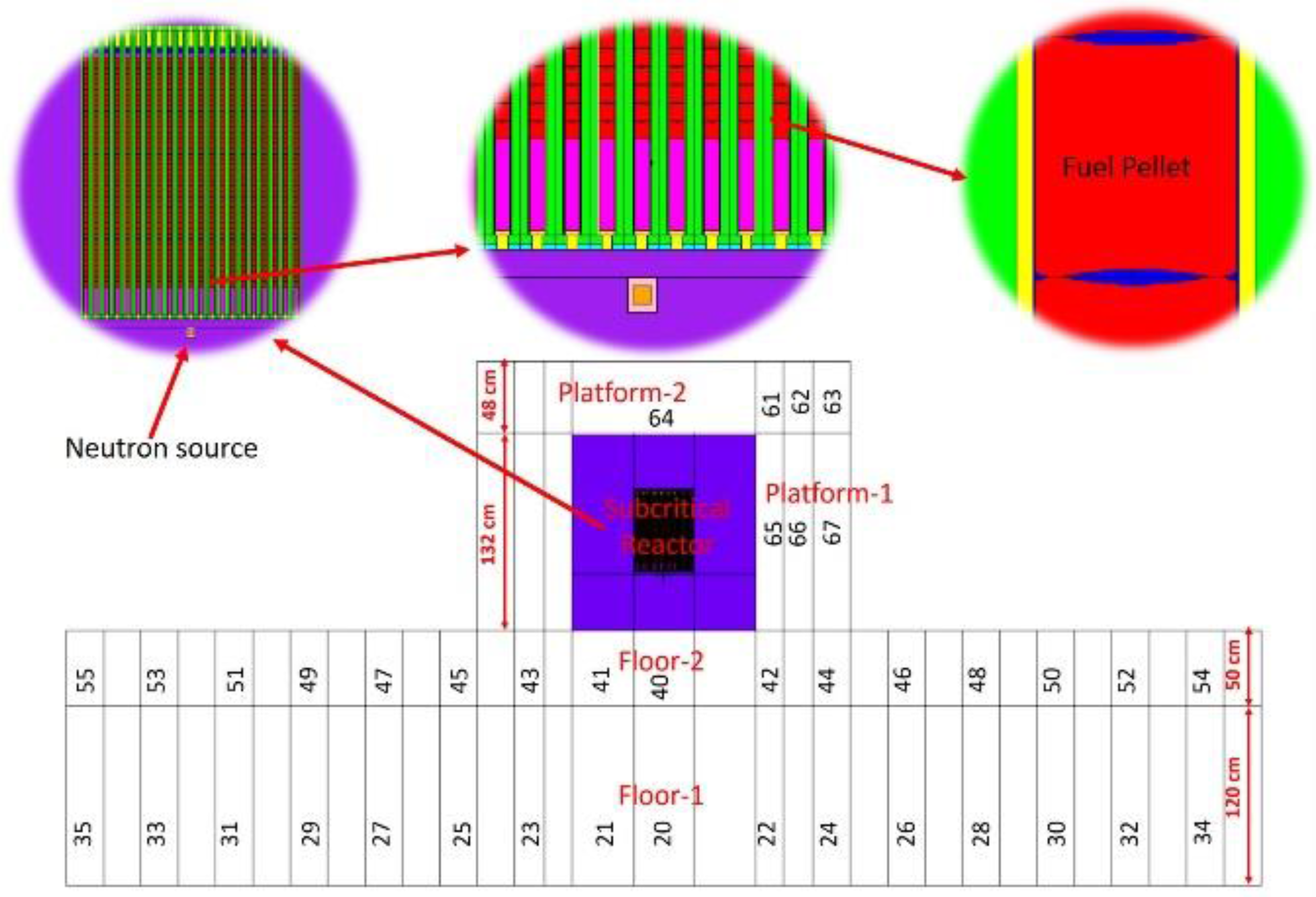

2.1. Reactor Modeling

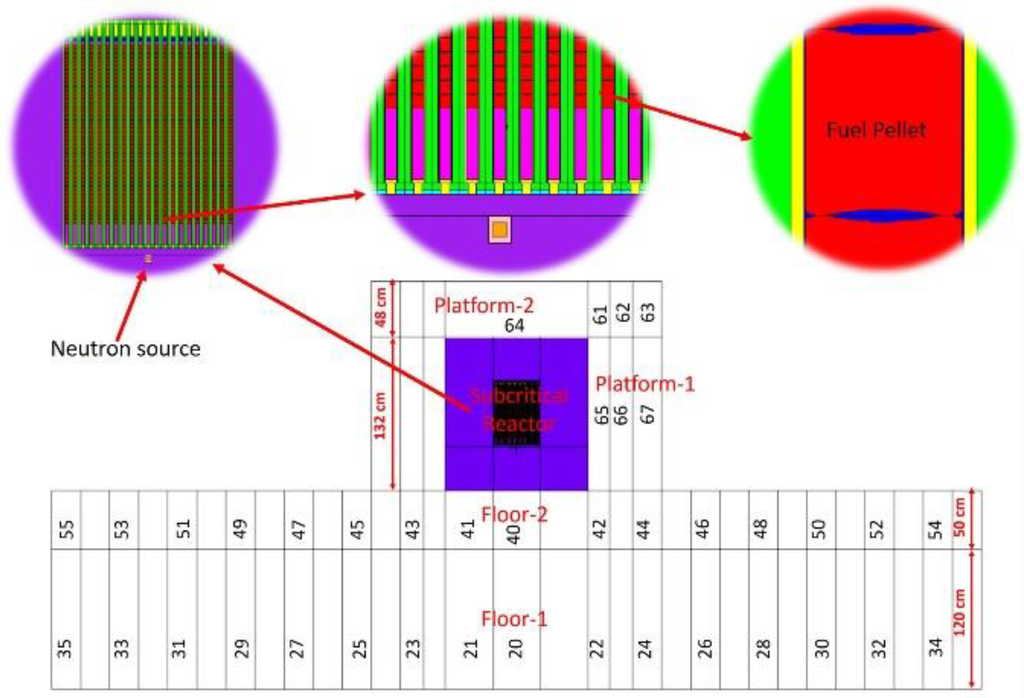

A detailed 3D MCNP model was developed based on reactor design parameters, which were also used for modeling the reflector, source, support structure, moderator and fuel as depicted in Figure 4. Version 1.51 of the Monte Carlo code MCNP5 was used to perform the calculations, using the continuous energy neutron ENDF/B-VII.0 cross-section data libraries [10]. Before the computations were performed, the code was installed and tested by running the radiation shielding validation suite containing benchmarks of international experiments and conducting a results comparison thereafter [10].

2.2. Source Modeling

The Pu-Be neutron source was modeled using exact three-dimensional geometrical dimensions based on exact design parameters, and actual technical specifications were used in modeling the material compositions (atom densities).

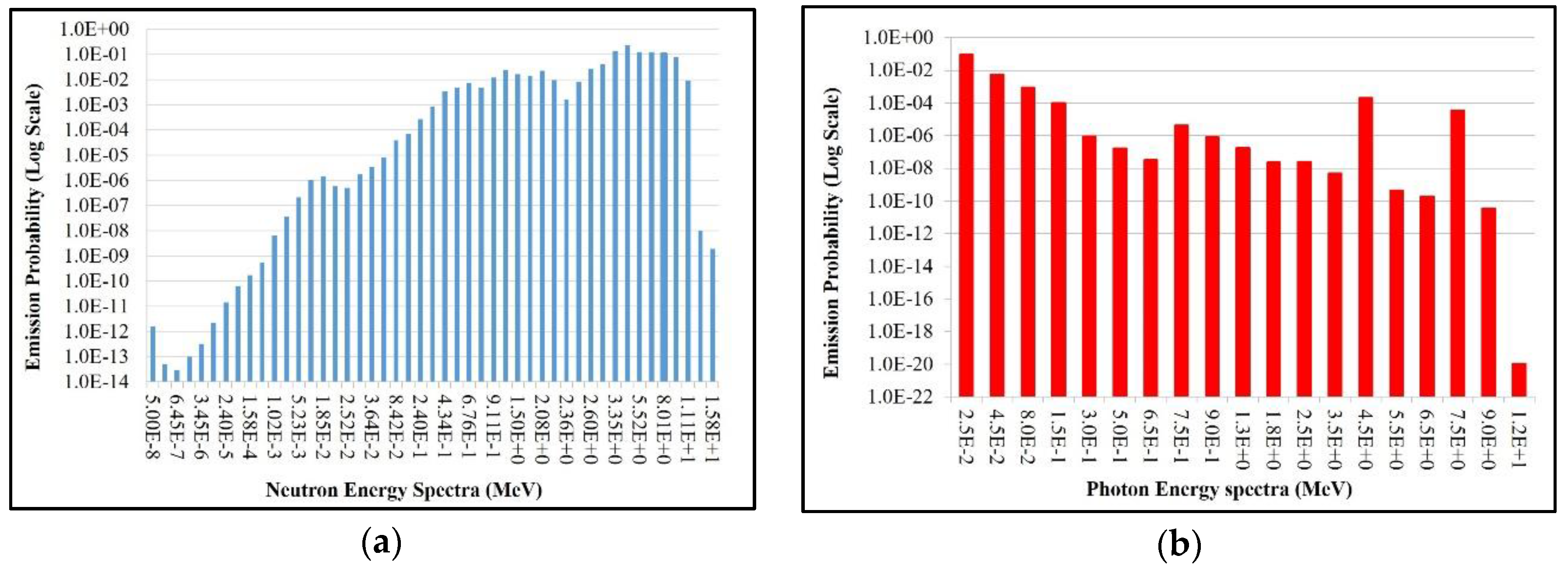

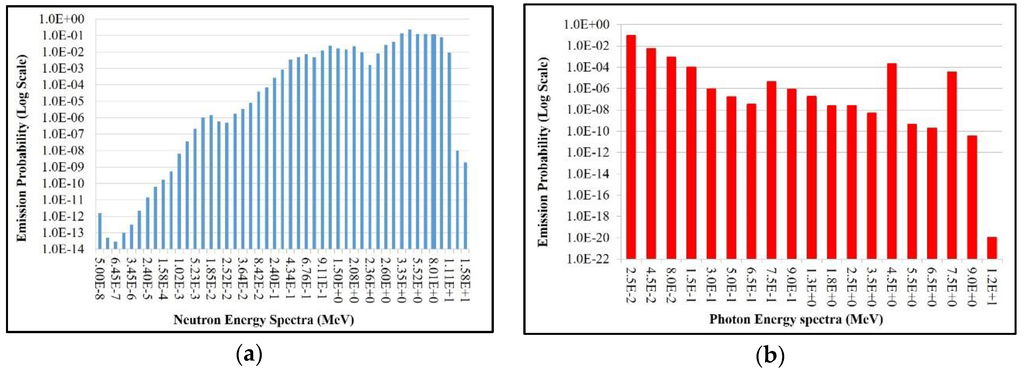

The energy spectra of the neutron/photon source energies (MeV) and the probability whereby neutrons/photons are emitted at that particular level of energy [15,16] were modeled. Source neutron and photon intensities (1.91 E+6 neutrons/s and 3.455 E+9 photons/s) and spectra were modeled in MCNP using the source specification card (sdef) with 47 energy bins for neutrons and 19 energy bins for photons. Figure 3 depicts the MCNP modeling of the source emission of neutrons and photons, including its probability distribution.

Figure 3.

MCNP modeling of the probability distribution of the source neutrons and photons emissions: (a) Using 47 energy bins for neutrons; (b) Using 19 energy bins for photons.

2.3. Dose Regions

In view of the fact that students and trainees are most likely to be present in the reactor hall and on the training platform, these two areas are of most importance in mapping the dose rate in the subcritical facility.

The division of the reactor hall into 32 zones, extending in a 400 cm radius from the centerline of the reactor, is depicted in Figure 4. Axially the figure also contains two layers from the floor. Floor 1 is the first layer and it has a height extending to 120 cm from the ground level. Floor 2 is the second layer and it measures 50 cm in height, and it is situated at the top of the first floor. Division into two distinct height levels (0–120 cm and 120–170 cm) was performed to evaluate exposure to lower and upper body parts separately.

Figure 4.

MCNP cross-sectional view (x-z) of dose mapping zones in the subcritical reactor hall, showing the height of floor 1, floor 2, platform 1, platform 2 (in red), and the cell numbers (in black). Magnified view of the core with the neutron source, fuel rods, and fuel pelt are shown on top.

The training platform is segmented into seven distinct regions with extensions reaching 180 cm from the floor of the platform. Platform 1 is the first layer of the platform, measuring 132 cm in height around the reactor vessel. This serves as the allocation for students to stand and conduct series of experiments. On the other hand, platform 2 is the second layer, measuring 48 cm in height and placed on the first layer, and extending above the reactor vessel.

3. Results and Discussion

Table 1 contains results obtained using the ICRP-74 flux-to-dose equivalent conversion factors [13] under the reactor’s normal operation and the start-up/shut-down procedures. The results are for the total dose rates due to neutrons, gamma rays from the neutron gamma reaction (n, γ) and gammas produced from fission and the Pu-Be source. The results are for all of the cells in each zone (see Figure 4) covering all areas located within the reactor facility. These dose rates together with their corresponding relative computation errors were added to obtain the total dose rate at 99.7% calculation confidence.

Table 1.

The dose rates due to neutrons (n, γ) and photons during normal reactor operation, using the ICRP-74 flux-to-dose equivalent rate conversion factors for all of the areas in the reactor hall.

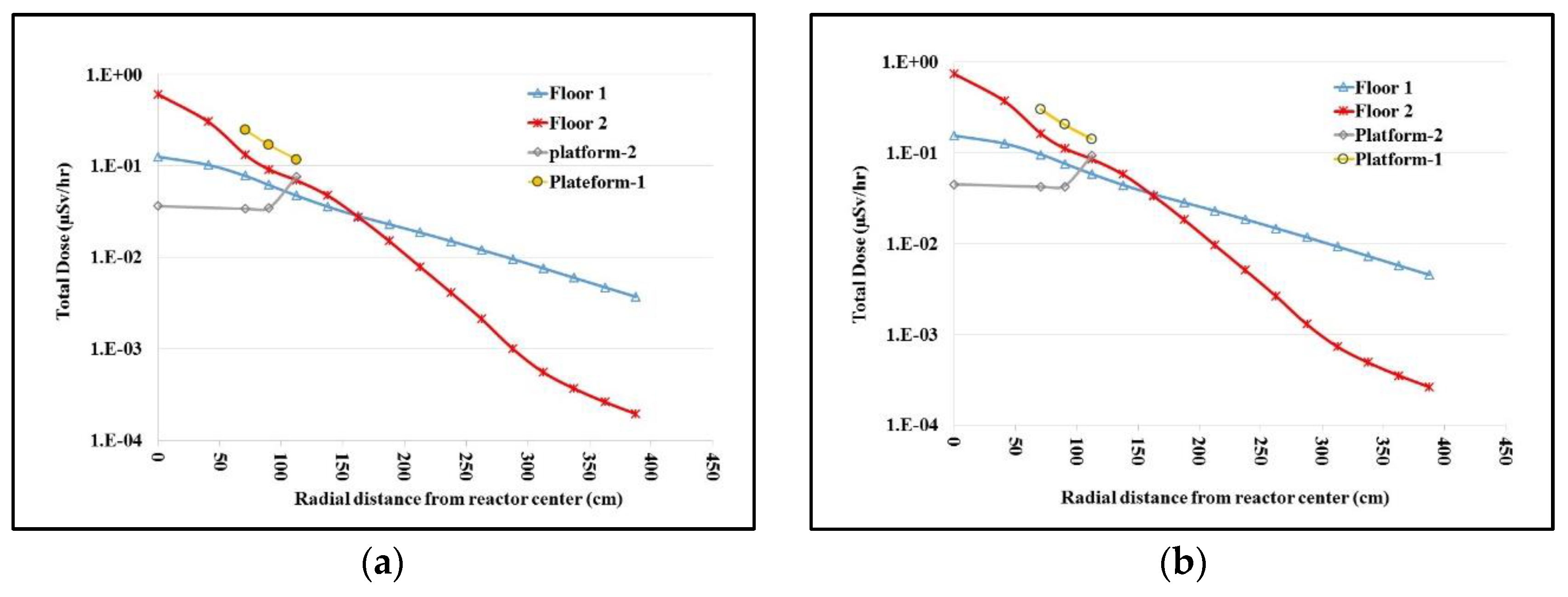

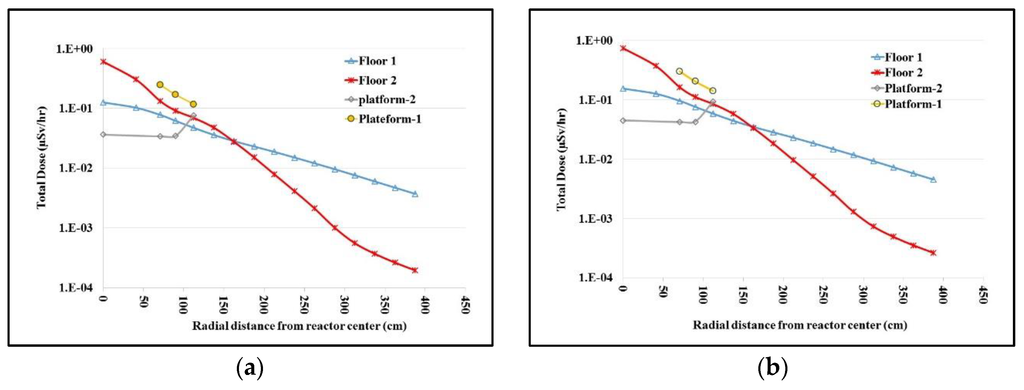

Figure 5a shows the calculated total dose rate obtained during normal operation versus the radial distance from the center of the reactor. These results are obtained using the ICRP-74 flux-to-dose equivalent rate conversion factors. From the figure, it can be inferred that the maximum total dose rate is 6.09 E−01 µSv/hr in areas that are situated on floor 2, below the reactor. This is followed by the area close to the vessel on the training platform (platform-1), where the calculated dose rate is 2.48 E−01 µSv/hr. In absolute terms, the figure depicts that aside from the area located below the reactor core, the second highest dose during operation was calculated on the training platform.

Figure 5.

The total dose rate in the reactor hall vs. the radial distance from the reactor center during normal operation: (a) Using ICRP-74 flux-to-dose conversion factors; (b) Using ANSI/ANS flux-to-dose conversion factors.

The total dose rate obtained using the ANSI/ANS-6.1.1 flux-to-dose equivalent rate conversion factors [12] during normal operation ranges from 2.65 E−04 µSv/hr to 7.50 E−01 µSv/hr as depicted in Figure 5b. It can be inferred that there is a good agreement between the maximum total dose rate of 7.50 E−01 µSv/hr and the dose obtained using the ICRP-74 factors, which are situated within the same area located directly beneath the reactor.

This trend is followed by an area located adjacent to the vessel on the training platform where the dose rate is estimated to be 3.04 E−01 µSv/hr. In fact, Figure 5 depicts that aside from the area located beneath the reactor core, the second highest dose rate during normal operation is on the platform. The figures show a decrease of the dose rate on top of the reactor (platform 2) compared to that of the dose rate under the reactor (floor 2). This asymmetry is due to the impact of the Pu-Be source located below the core rather than in the axial center of the core during reactor operation.

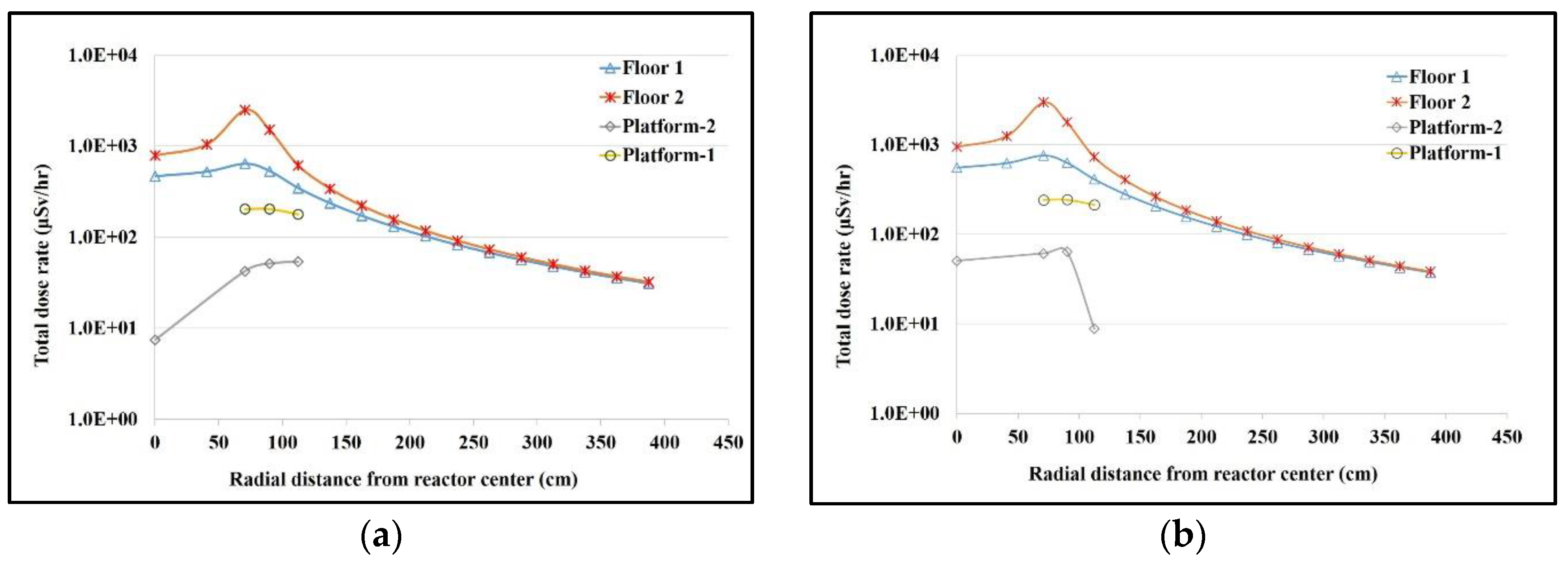

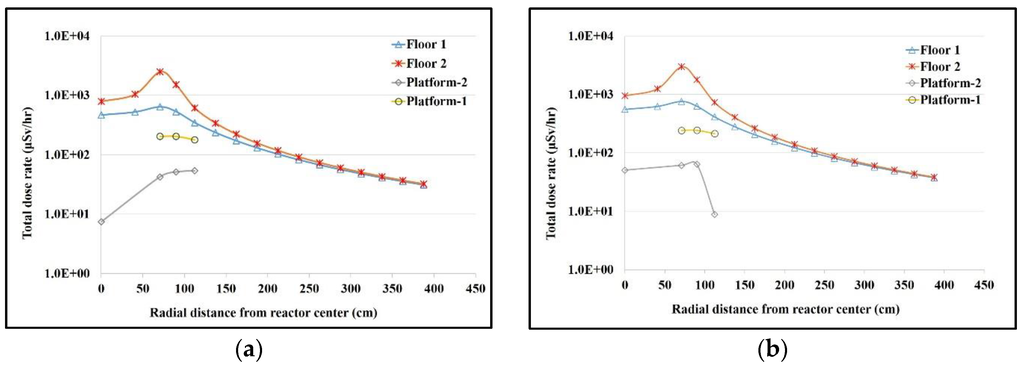

Figure 6a shows the calculated total dose rate during the start-up and shutdown modes versus the radial distance from the reactor center. These calculations were performed using the ICRP-74 factors. Results show that the maximum dose rate of 2.51 E+03 µSv/hr is at floor 2, situated 50 cm below the reactor, as shown in Figure 5a. At this point, the source moves to enter the reactor for start-up, or to leave the reactor to its storage flask for shut-down. In this scenario the dose rate is calculate with the Pu-Be source located 44 cm below the reactor and a 77.8 cm radius away from the reactor center, in cell number 42, as illustrated in Figure 4.

Figure 6.

The total dose rate in the reactor hall during start-up and shut-down operations: (a) Using ICRP-74 flux-to-dose conversion factors; (b) Using ANSI/ANS flux-to-dose conversion factors.

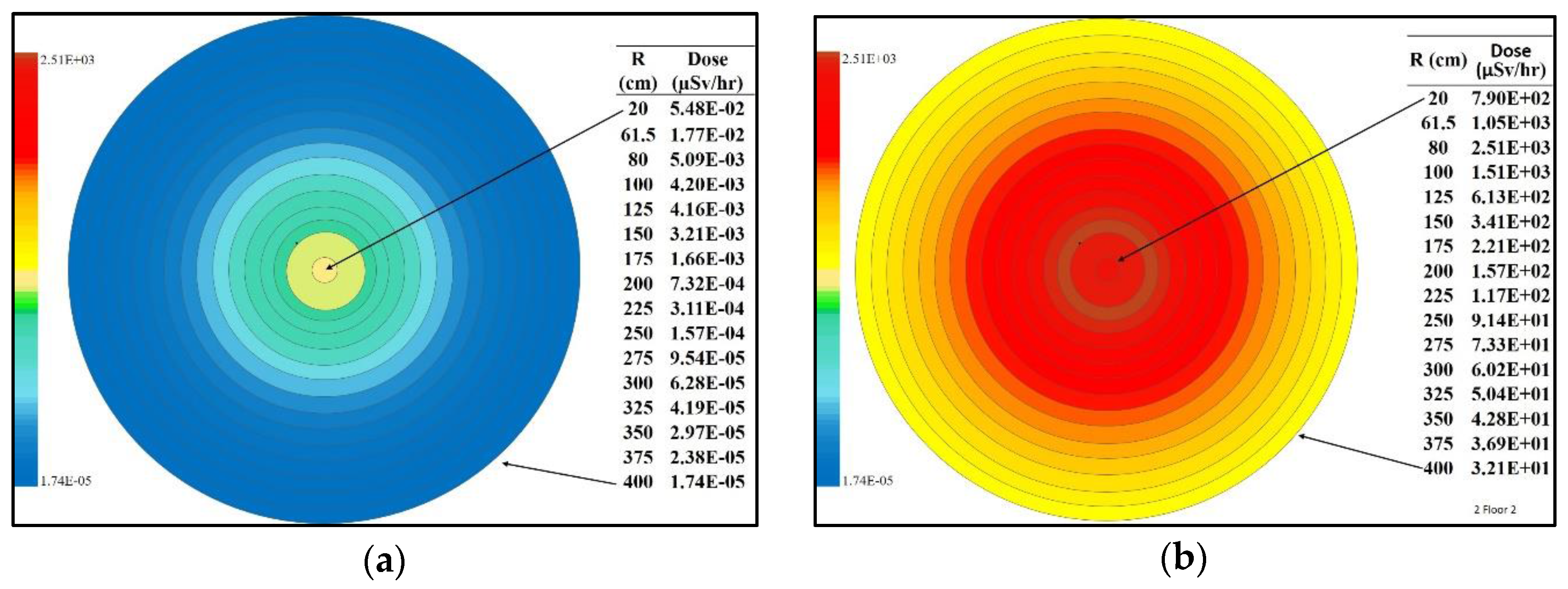

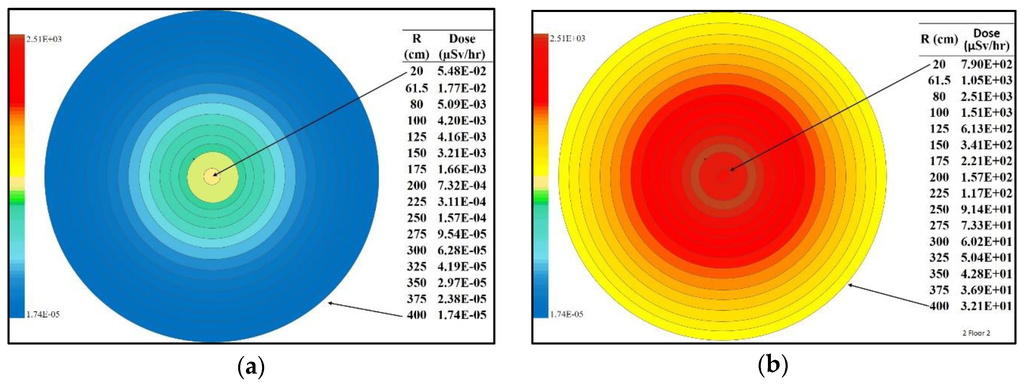

In this scenario, the total dose is higher than the normal operation mode by three orders of magnitude. This is due to the fact that the Pu-Be source moves in an unshielded tube which exposes the reactor hall to direct radiation. This is illustrated in Figure 7 where the dose rate in floor 2 is shown vs. the radial distance from the reactor centerline in both scenarios, the normal operation and start-up/shut-down mode. Although this process occurs within a short period, it could present a safety hazard (i.e., if the source would get stuck in the tube, damage to the tube, etc.). Especially since this is the dose rate that will be received by the upper body, as it extends from 120 cm to 170 cm from the floor level, such exposure poses the highest risk to the human body.

Figure 7.

Spectrum of the dose rate (µSv/hr) vs. the radial distance from the reactor centerline, for cells number 40 through 55 at the floor 2 level (120–170 cm in height) using ICRP-74 factors: (a) During normal operation mode; (b) During start-up/shut-down operation mode.

Figure 6b depicts the total dose rate during the start-up and shut-down operation procedure, using the ANSI/ANS-6.1.1 flux-to-dose equivalent rate conversion factors. Results show that the maximum total dose of 2.99 E+3 µSv/hr is found at 70 cm radially from the reactor center, as shown in Figure 6a. This value is again in agreement with that obtained using ICRP-74 factors.

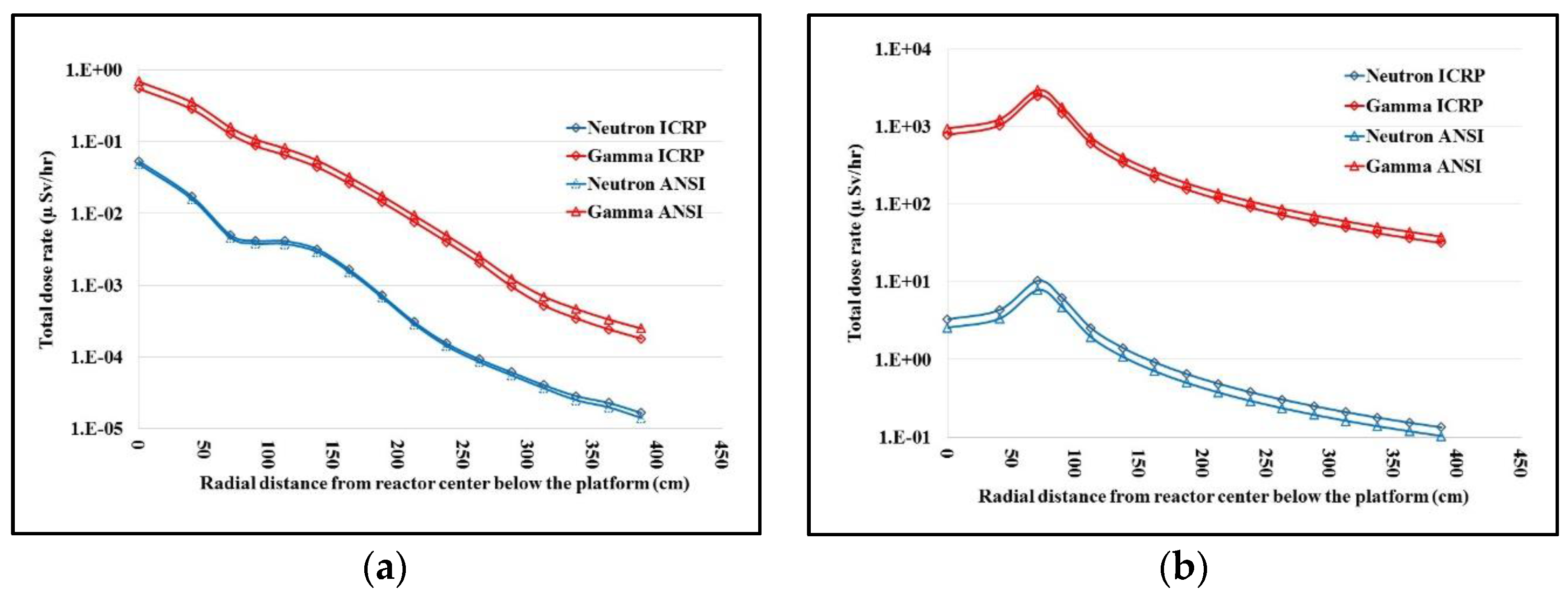

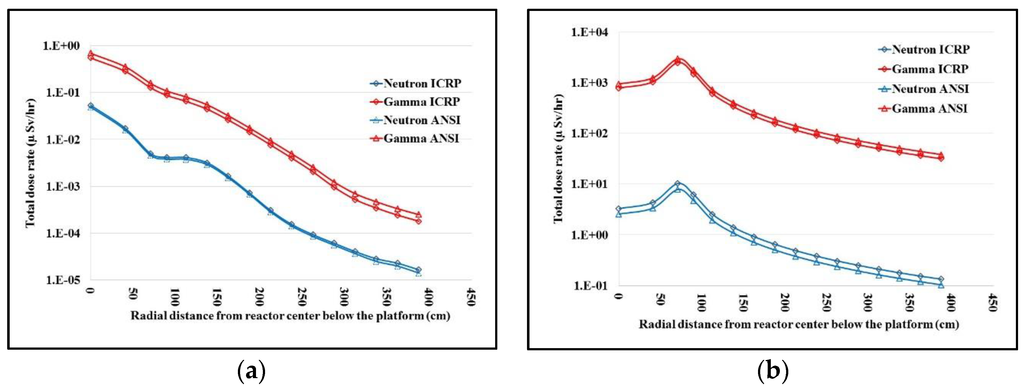

It is also imperative to conduct critical investigations to ascertain the source of the dose, and to compare the dose rates due to gamma rays with those obtained due to neutrons, in the two distinct modes of operation. It is equally imperative to state that the gamma dose rate is higher than that of the neutrons whether the reactor is in operation or in start-up/shut-down mode, across all of the 39 regions located within the reactor hall. In Figure 8a,b, the neutron and gamma dose rates in floor 2 of the reactor hall under the platform are depicted in two diverse modes of operation, using ANSI/ANS and ICRP factors.

Figure 8.

The total dose rate (µSv/hr) from neutrons and gammas, in the reactor hall below the platform level (floor 2), using ICRP-74 and ANSI/ANS factors: (a) During normal operation mode; (b) During start-up/shut-down operation mode.

4. Conclusions

This work represents our efforts to simulate and estimate the dose rate in an enriched uranium-fueled subcritical assembly facility using MCNP5. In the model used, the magnitude of the dose rate in the reactor hall during normal operation ranged between 7.50 E−01 μSv/h and 1.96 E−04 μSv/h. Such dose rates are regarded as low in conformity with environmental and occupational hazards, including safety standards that have been propounded by the international and national radiation organizations (IAEA) in an effort to help curb and limit the effects posed by harmful radiation.

The start-up/shut-down mode presents a more challenging scenario because values ranging from 2.99 E+03 μSv/h to 7.45 μSv/h were obtained as the magnitude of the dose rate in the reactor hall. Floor 2, which is situated below the reactor platform, houses the dose whose maximum value is 2990 μSv/h. It is at this point that the neutron source driving channel is situated. The minimum dose of 7.45 μSv/h is in the zone right above the reactor core (platform 2).

A more challenging scenario is presented by the second case, especially in the event of the neutron source getting stuck during the start-up/shut-down operation. The maximum dose rate in this case of 2990 μSv/h can result in a significant external radiation dose. Such a dose rate far exceeds the international standards of radiation protection organizations (IAEA), who all set the annual limits to 1000 μSv for the general public. Although the probability of such an accident is low, protective measures should be taken into consideration to prevent any unnecessary exposure. Recommendations made include the consideration of this scenario as an integral component of reactor safety analysis study.

Throughout the subcritical reactor facility and in both modes of operation, the dose rate due to gamma rays is found to be greater than that due to neutrons. Results showed no degree of significant disparities whether one chooses to utilize the ICRP-74 or the ANSI/ANS-6.1.1flux-to-dose equivalent rate conversion factors. It is worthwhile to state that these results are in conformity with good agreements.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Szieberth, M.; Klujber, G.; Kloosterman, J.L.; de Haas, D. Measurement of multiple α-modes at the Delphi subcritical assembly by neutron noise techniques. Ann. Nucl. Energy 2015, 75, 146–157. [Google Scholar] [CrossRef]

- Maldonado, G.I.; Xoubi, N.; Zhao, Z. Enhancement of a subcritical experimental facility via MCNP simulations. Ann. Nucl. Energy 2008, 35, 263–268. [Google Scholar] [CrossRef]

- Vega-Carrillo, H.R.; Esparza-Garcia, I.R.; Sanchez, A. Features of a subcritical nuclear reactor. Ann. Nucl. Energy 2015, 75, 101–106. [Google Scholar] [CrossRef]

- Xoubi, N. Design, development and installation of Jordan subcritical assembly. Sci. Technol. Nucl. Install. 2013, 2013. [Google Scholar] [CrossRef]

- O´Kelly, D.S.; Braisted, J.D.; Hurst, B.J.; Krause, M.G.; Welch, L.S. University of Texas accelerator driven subcritical experiments. In Proceedings of the 8th International Topical Meeting on Nuclear Applications and Utilization of Accelerators (ACCAPP’07), Pocatello, ID, USA, 29 July–2 August 2007; pp. 843–847.

- Pyeon, C.H.; Hirano, Y.; Misawa, T.; Unesaki, H.; Ichihara, C.; Iwasaki, T.; Shiroya, S. Preliminary experiments on accelerator-driven subcritical reactor with pulsed neutron generator in Kyoto University Critical Assembly. J. Nucl. Sci. Technol. 2007, 44, 1368–1378. [Google Scholar] [CrossRef]

- Burholt, G.; MacMahon, T. The university of London reactor centre, Ascot, England. J. Radioanal. Nucl. Chem. 1979, 53, 365–372. [Google Scholar] [CrossRef]

- Remetti, R.; Andreoli, G.; Keshishian, S. Monte carlo calculation of the neutron effective dose rate at the outer surface of the biological shield of HTR-10 reactor. Nucl. Eng. Des. 2012, 243, 148–152. [Google Scholar] [CrossRef]

- Ward, D.C. Impact of Switching to the ICRP-74 Neutron Flux-to-Dose Equivalent Rate Conversion Factors at the Sandia National Laboratory Building 818 Neutron Source Range, 2009. Available online: http://prod.sandia.gov/techlib/access-control.cgi/2009/091144.pdf (accessed on 28 June 2016).

- Forrest, B.; Kiedrowski, B.; Bull, J. MCNP5-1.60 Release Notes; LA-UR-I0-06235; Los Alamos National Laboratory: Los Alamos, NM, USA, 2010. [Google Scholar]

- ICRP. 1990 Recommendations of the International Commission on Radiation Protection; Pergamon Press Ltd.: Oxford, UK, 1990; Volume 21. [Google Scholar]

- American Nuclear Society. ANSI/ANS-6.1.1-1977, Neutron and Gamma-Ray Flux-Rate Factors; American Nuclear Society: La Grange Park, IL, USA, 1977. [Google Scholar]

- International Committee on Radiological Protection (ICRP). 1997 Conversion Coefficients for use in Radiological Protection against External Radiation; Elsevier: Amsterdam, The Netherlands, 1996; Volume 26, No. 3/4. [Google Scholar]

- IAEA. International Basic Safety Standards for Protecting against Ionizing Radiation and for the Safety of Radiation Sources; Safety Series No. 115; IAEA: Vienna, Austria, 1996. [Google Scholar]

- Anderson, M.E.; Bond, W.H. Neutron spectrum of a plutonium-beryllium source. Nucl. Phys. 1963, 43, 330–338. [Google Scholar] [CrossRef]

- Barros, S.; Gallego, E.; Lorente, A.; Goncalves, I.; Vaz, P.; Vega-Carrillo, H.R.; Zankl, M. Neutron spectra and dosimetric assessment around a neutron Howitzer container. Prog. Nucl. Sci. Technol. 2014, 4, 757–761. [Google Scholar] [CrossRef]

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).