1. Introduction

Bicycle industry is one of Taiwan’s most internationally competitive industries. In 1986, with an unprecedented record of exporting more than 10 million units, Taiwan has become a “bike kingdom”. In the 2000s, in order to get rid of the competition, the leading producer GIANTA began to promote A-Team and further industrial integration to strengthen competitiveness. A-Team is a dual-core inter-organizational learning alliance headed by GIANT and MERIDA. A-Team introduces TPS, integrates the industrial supply system of upstream and downstream suppliers, conducts collaborative management, collaborative R&D, and collaborative marketing. Through inter-organizational learning and co-creation, they have effectively improved production lead time, inventory, productivity, and quality, and enhanced overall competitiveness and opened up the gap in capabilities with emerging countries such as China. Thereafter, based on TPS, with the development of industry 4.0, GIANT began to work on the application of industry 4.0 related technologies in order to further enhance customer value.

This paper aims to apply the new architecture “Lean Smart Manufacturing: a conceptual framework and solution-based co-creative platform” proposed by the authors, which combines Lean Production and Industry 4.0, to conduct an empirical study focusing on A-Team which constructed in Taiwan’s bicycle industry and GIANT, to see how GIANT implement the “Lean Smart Manufacturing” and construct the co-creative platform, and balance differentiation and open innovation. Not only the implementation of “Lean Smart Manufacturing”, but also to further explore the implementation of the two solutions proposed in the new architecture, especially “strategic solution based co-creative platform”, to examine the mechanism that the bicycle enterprises and industry enhance their competitiveness.

The research method is as follows. In order to do more in-depth qualitative research, this study adopts the methodology of case study. In addition to the company’s HP, company annual reports, public papers, mainly through factory visits and interviews were analyzed to obtain information and data. From August 2018 to March 2019, the author interviewed the world leading company, GIANT, A-Team’s promoter, and its major suppliers (see the Interview Data). Based on the information and data obtained from the factory observations and interviews, the “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform” framework will be used for analysis, and the integration of Lean Production and Industry 4.0 by GIANT will be also confirmed, so as to clarify the purpose of this study.

This paper is organized in the following order. First, in the context of the rise of Industry 4.0 and smart manufacturing, the research trends and connotations of Industry 4.0 are reviewed, and the latest theories and related theories about Lean Production System and Industry 4.0 are explored. Second, with the support of relevant theories, the “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform” is further explained. Next, the mechanism and connotation of A-Team constructed in Taiwan’s famous bicycle industry cluster are explained. Finally, in the post-A-Team era, the practices of the “Lean Smart Manufacturing” architecture and the “strategic solution based co-creative platform” for the GIANT enterprise group (G-Team) and its major suppliers are examined, and the implications are further explored.

2. Literature Reviews

Industry 4.0 delivers faster, more flexible, and more efficient processes by aggregating data generated from machines and analyzing it, enabling them to achieve effective and optimized decisions, and produce higher quality products at lower cost. In turn, it will enhance the competitiveness of manufacturing industry, promote industrial growth, and change the type of labor through human-machine collaboration [

1,

2,

3,

4,

5].

Rüßmann et al. [

2] pointed out that Industry 4.0 would affect producers’ entire value chain, from design to after-sales service. For example: (1) Insular manufacturing cells will be replaced by fully automated, integrated production lines; (2) products, production processes will be designed and commissioned virtually in one integrated process and through the collaboration of producers and suppliers; (3) manufacturing processes will increase in flexibility and allow for the economic production of small lot sizes; (4) manufacturing processes will be enhanced through learning and self-optimizing pieces of equipment; (5) automated logistics, using autonomous vehicles and robots, will adjust automatically to production needs. In this way, in the production process, the production cycle and delivery time can be shortened, and the production efficiency can be improved, and the large-scale customized small lot production can be realized, and the production quality can be improved through deep learning.

Porter and Heppelmann [

6] believe that through the interconnection of IoT smart products, data has changed the value chain of enterprises and created new values. On the one hand, companies have also faced new strategic judgments, which in turn affects their value activity. Industry 4.0 forces the manufacturing industry to think about the business strategy and business model of the enterprise. The smart network system shifts the focus of the supply from the product to the service, which means “servitization” and customization, and to change from “production” to “production + service” or service-oriented.

Buer et al. [

7] advocates combining Industry 4.0 with Lean Production, with its decentralized control, can balance productivity, and flexibility. Industry 4.0 and Lean Production can add value to customers together [

8]. Lean Production System might be an enabler toward a successful and sustainable implementation of Industry 4.0 in the production environment [

9]. Although Lean Production is an effective way to increase productivity while reducing costs, it still has its limitations, especially in the production environments characterized by demand volatility, high product mix, and reduced lot sizes, smart manufacturing of Industry 4.0 will be the solution to this limitation [

10]. The Lean Production System will not fade because of Industry 4.0. On the contrary, the principles of Lean Production are even more important under the blessing of the new technologies. The fourth industrial revolution will enable enterprises to implement real Lean Production System [

11].

Storbacka [

12] has developed a solution business model framework. The framework consists of a solution process with four phases (develop solutions, create demand, sell solutions, and deliver solutions) and three groups of cross-functionality issues (commercialization, industrialization, and solution platform). The research points to the importance of cross-functional alignment within firms, and an effective solution business model requires the intricate coordination of resources and business processes across all functions. Storbacka and Pennanen [

13] believe that the development of a solution business must start with four dimensions: (1) customer embeddedness, (2) offering integratedness, (3) operational adaptiveness, and (4) organizational networkness. Nobeoka [

14] pointed out that there are changes of customer value into tacit nature in the past few years. because of the tacit of customer value, the value sought by customers is difficult to express, and it is necessary to create value with customers.

Regarding open innovation, professor Chesbrough [

15] of Berkeley University proposed “Open Innovation is a paradigm that assumes that firms can and should use external ideas as well as internal ideas and internal and external paths to market, as the firms look to advance their technology”.

Companies working on an open strategy must combine their knowledge and ideas acquired from outside the company with their own knowledge to create their own value and earn their value as revenue [

15,

16]. And in order to utilize open innovation and lead to success, ingenuity and effort are needed to construct a “value creation and acquisition mechanism (Business Model)” [

16,

17].

When referring to inter-organizational learning and innovation, having an organizational ability to advance inter-organizational learning using inter-enterprise networks leads to a competitive advantage. Typically, Toyota establishes a cooperative relationship with suppliers in R&D and shares development of next-generation products. In other words, it is the point that companies build inter-organizational networks that are effective in promoting inter-organizational learning and innovation [

18].

3. Analysis Framework

For smart manufacturing, the company must develop five core competencies: comprehensive resource management, smart production, digital decision-making, smart supply chain, and smart factory [

19], but its fundamental goal is to create customer value.

The Lean Production from the Toyota Production System advocates “pull manufacturing” and “leveled production”, which essentially has features, such as customer value, streamlined processes, stable and predictable output. These features are the goals pursued by Industry 4.0. Toyota insists on: (1) computerization of the process, (2) brainstorming and “improvement”, and (3) learning together with suppliers. And these three major insistences are also the soft power that governs the success of smart manufacturing.

Relatively speaking, sticking to the realism of Lean Production, it is possible to ignore the new smart ability of ICT technology. In other words, ICT technology affects the rapid development of manufacturing, the cheapness and popularity of sensors, and enables the IoT to provide scientifically based excellent issues and problem-solving ability. Let Lean Production further emphasize the combination of customer value and value creation from data acquisition and analysis from sensors, to form the Lean Smart Manufacturing, which completely eliminates waste and has individual customization, may be the most important contribution of Industry 4.0.

There are three challenges to practicing smart manufacturing. First, sticking to downstream process is the customer, paying attention to the contribution to the final customer. From the observation of the actual process of downstream process or the contribution to the final customer, propose solutions and pursue a win-win situation. Including material management, component processing, machine assembly, product shipment, and customer service, only when fully implemented can the smart manufacturing effect be achieved.

Second, adhering to service-oriented logic. Customer value is not in product performance, but from the customer’s experience value or perception process. The service-oriented logic that values customer value is the main indicator of the solution business from selling products to providing solutions.

Third, to create an open co-creative platform and trust mechanism. In the era of the IoT, information is far-reaching, and openness can further create value. Trust can move from information sharing to value sharing and prevent information outflows.

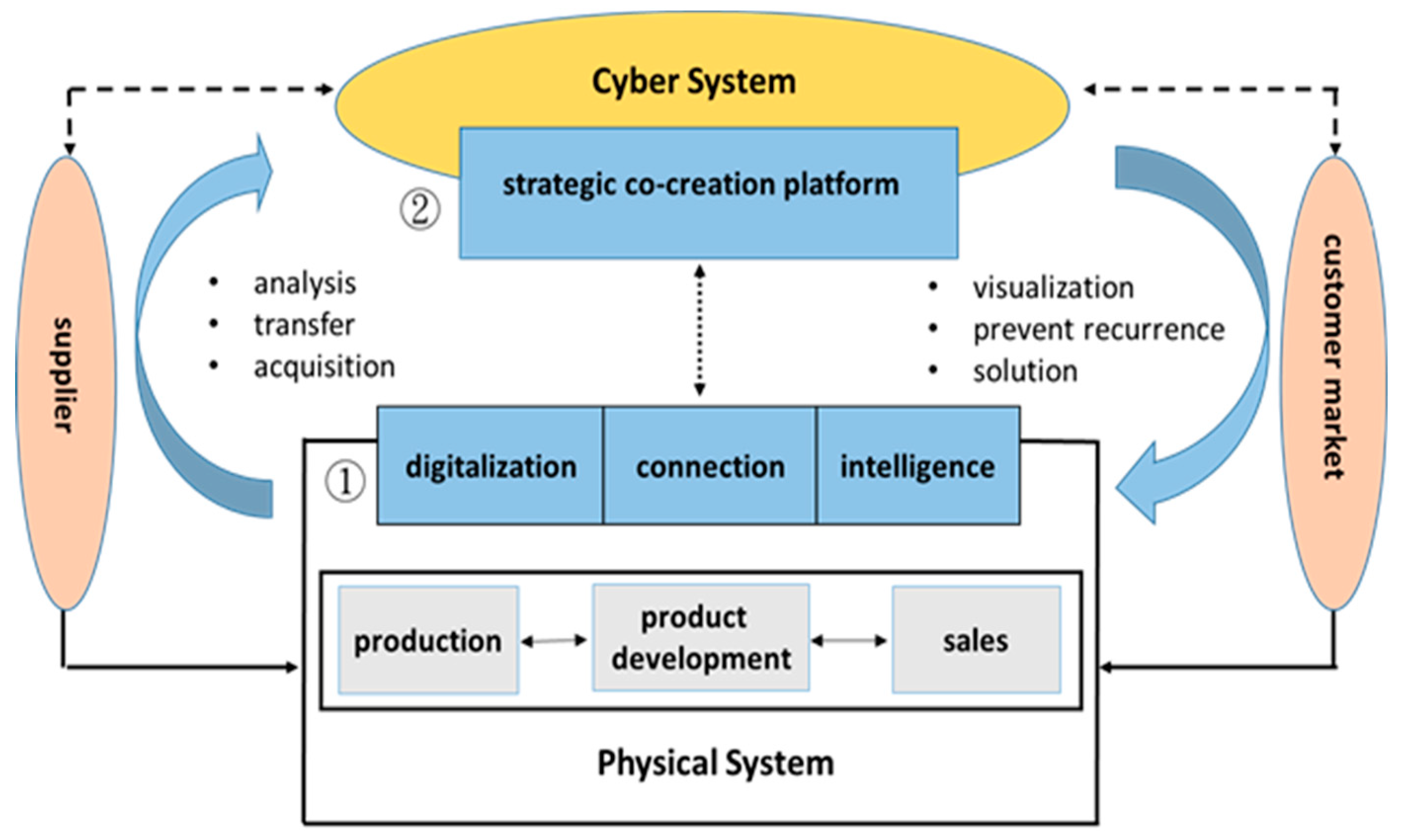

Li et al. [

20] proposed the framework of “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform”, pointing out that smart manufacturing that drives manufacturing innovation is a self-disciplined factory which responds to individual customer needs through the interaction of the physical system of the factory and the cyber system. It consists of three fields (

Figure 1). The first is the field of physical systems, and the second is the field of cyber systems. The third is the solution platform, which was established to make the overall system operate effectively. The first-stage solution platform of Lean Smart Manufacturing is placed in the physical system, which consists of three elements: digitization, connection, and intelligence, while the second-stage solution platform focuses on strategic co-creation.

The solution platform of the first stage is placed in the physical system. By digitization, connection, and intelligence, the knowledge of experience from equipment, personnel and customers are effectively linked into organizational capabilities, to solve various problems at the manufacturing site autonomously and flexibly.

The second-stage solution platform focuses on strategic co-creation and is a problem-solving mechanism formed by combining suppliers and customers. It is not only a pull system that can integrate R&D and manufacturing capabilities inside and outside the company and flexibly respond to individual customer needs, it is also a source of differentiation for companies.

First of all, the first phase of Lean Smart Manufacturing begins with the linkage of the various departments of the physical system, with the continuous improvement of each department and the digitalization of information as the main axis, that is, digitalization and connection under the Lean, to achieve smart aims. For manufacturing companies, the continuous improvement and organizational capabilities of physical systems are an important basis for supporting CPS to create value.

Second, the second stage is to collect the digital information obtained by the physical system into the cyber system, and construct a problem-solving mechanism that can analyze and utilize the information, especially in combination with suppliers, customers, and even other complementary enterprises, to create a strategic co-creative platform. This network platform enables the Lean and smart systems to effectively connect with external organizations, creating a problem-solving mechanism that continuously creates customer value through differentiation.

Finally, through the interaction of these two stages, it will play an overall problem-solving mechanism such as CPS visualization, prevention of recurrence, and co-creation, effectively responding to customer needs and creating customer value. Integrating the above two stages of the solution platform forms a strategic solution based co-creative platform.

Then, after explaining the mechanism and connotation of A-Team constructed in Taiwan’s famous bicycle industry cluster, the paper will examine the practices of the “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform” for the GIANT and its major suppliers (G-Team) in the post-A-Team era, and further explore the implication.

4. A-Team

4.1. A-Team’s Background and Purpose

The background of A-Team’s establishment stems from the following three factors: a strong sense of crisis, an anxiety of industry hollowing, recognition of TPS and cooperation with Japanese companies. Because of the narrow domestic market in Taiwan, early bicycle producers were OEM-produced and adopted an export-oriented development. In 1980, Taiwan exported more than 3 million units, surpassing Japan. In 1986, it exported more than 10 million units and became the world’s largest exporter. However, in 2000, China’s bicycle export volume and export amount exceeded Taiwan’s, so Taiwan’s “bicycle kingdom” title was replaced by China [

21]. Since the beginning of 1990, GIANT and MERIDA have expanded their production investment in China, but Chinese bicycle producers have started price competition. Because of price competition, their performance was sluggish, and the future was full a sense of crisis. Focusing on Taiwan’s good technology and related talents, in order to activate the bicycle industry and not allowed to fall into the industry hollowing, therefore, under the promotion of GIANT, A-Team was established with its competitor MERIDA and 11 suppliers [

22,

23].

Another background to the establishment of A-Team was that GIANT introduced TPS in 2000. In the 1980s, GIANT paid attention to TPS and learned by itself, but the results were not good. Since 2000, GIANT has participated in the government’s plan to improve its industrial competitiveness, and with the assistance of Taiwan Toyota, it has begun to promote TPS within GIANT. At this time, GIANT’s top management recognized the power of TPS and believed that it should improve the ability of the supply system to help improve competitiveness of the industry. In order to defend the Taiwan bicycle industry, and based on the “Power of Partnership” and “Future of Cycling” concept, combined with MERIDA and 11 suppliers to form A-Team, promote collaborative improvement, collaborative R&D, collaborative marketing, and strive to enhance industrial competitiveness and marketing in Taiwan [

23].

4.2. A-Team’s Effectiveness

A-Team is a dual-core inter-organizational learning alliance headed by GIANT and MERIDA. A-Team introduces TPS, integrates the industrial supply system of upstream and downstream manufacturers, conducts collaborative management, collaborative R&D, and collaborative marketing, effectively improving lead time, inventory, productivity, and quality. Through inter-organizational learning and co-creation, it has enhanced competitiveness of the entire industry and opened up the gap between emerging countries such as China.

Yung [

24] believes that, first of all, the bicycle is a typical product of “modular architecture”. Under the development of “commoditization”, GIANT has promoted through A-Team’s mechanism of inter-organizational learning and communication. Knowledge sharing and integration and technology development have enabled innovation and high value-added product development. Second, A-Team realizes the sharing of intangible resources and tangible resources through “co-opetition” rather than the competition between the general companies, thus achieving the ability to change from cost advantage to differentiated advantage. He called on the Taiwan bicycle industry to develop high value-added products of the “integral architecture”.

The Taiwan bicycle Industry alliance A-Team was established at the end of 2002, and was made public domestically and abroad during the International Bike Exhibition in the spring of 2003. At the end of 2016 it was publicly announced that: A-Team has reached the goal of upgrading the bicycle industry and will be transferred to the Taiwan Bicycle Association (TBA) as a platform for knowledge sharing and learning in the industry. Liu et al. [

11] believes that A-Team has established the following three paradigms:

(1) Effectively driving the upgrade of the bicycle industry. The strong sense of crisis and the vision of industrial development of industry leaders have effectively promoted the overall upgrade of the main assembly makers and parts makers.

(2) Having a continuous value creation model, from the integration of upstream and downstream suppliers to implement Lean Production, extended to the introduction of quality management systems such as TQM and TPM. They strengthened the infrastructure of joint R&D and jointly developed the market, from coexistence to co-creation.

(3) Combining Lean and customer value creation to enhance added value of products. In the past 14 years, the export volume has continued to rise, and the average unit price has increased from $124 in 2002 to $502 in 2016.

When A-Team presented some problems after reaching the overall goal, the most obvious one was the relative benefit. In other words, the bicycle industry as a whole has improved its competitive advantage through differentiation when compared to other countries, however, in the 10 years of A-Team development, although the products are segmented, the production strength of MERIDA has approached GIANT. In fact, the theory of industrial management also points out that “isomorphism” will hinder the idea of individual differentiation. From this perspective, after A-Team’s success to effectively create a gap with the capabilities of emerging countries, it is of great significance to pursue individual differentiation again.

5. Case Study: GIANT (G-Team)

5.1. About GIANT

GIANT (Giant Manufacturing Co. Ltd.), established in 1972, is currently the world’s largest bicycle manufacturer, and was originally an OEM manufacturer when it was founded, but as a Taiwanese company, to build its own brand (GIANT) as early as 1981. Efforts have made a significant contribution to establishing Taiwan as a “bike kingdom”. Meanwhile, GIANT has formed an A-Team and has pulled A-Team with MERIDA until the 2016 dissolution. The current GIANT group has 9 production bases, 14 overseas sales subsidiaries, and approximately 11,125 exclusive stores (GIANT’s HP).

GIANT’s Taiwan headquarter plant does not have the same production capacity as the China plant, but is in charge of developing and manufacturing carbon and aluminum alloy frames with world-class technology, and as a production plant for high-end products in small lot, multi-variety production, emphasis on quality and design over mass production. With a focus on technological innovation, GIANT has become the world’s first manufacturer to successfully mass produce high-end aluminum frame bikes. It is also a pioneer in lowering the carbon frame to a price that can be reached by general riders.

Even after A-Team’s dissolution, GIANT is promoting G-Team with its own suppliers in a loose manner, promoting TPS and Industry 4.0.

5.2. Introduction of Industry 4.0 and Business Transformation

In recent years, GIANT has actively strengthened its digital capabilities, developed customized big data analytics, and smart manufacturing decision-making systems, and gradually adopted cross-enterprise virtual vertical integration of upstream and downstream in the supply chain. In turn, the data and information collected from the entire value chain of design, development, production, and service are shared and communicated through the “open innovation platform” to instantly grasp and analyze the needs of end users, in order to optimize the resource management and application, and improve the agility of the supply chain to drive innovation in production and service technology, even business model innovation. Introduction of Industry 4.0 and business transformation of GIANT as below:

(1) Importing Industry 4.0 and using data power—through the cloud computing platform, QR Code, Bluetooth, and other technologies, the first-hand user data is obtained in large quantities and accurately, and it is transformed into a part of product design. In 2018, new ERP had been introduced to integrate production and sales information in various markets around the world. GIANT uses Industry 4.0 as a strategy for production innovation and promotes the integration of Lean Production with Industry 4.0.

(2) Re-positioning the market role and re-shaping the value of the product—transforming the function of the bicycle from the past mobility to fitness, LOHAS, and fashion, and adjusting the design through market repositioning to make products produce different values.

(3) People-oriented to grasp the core value of products—hold the most important “user experience” of bicycles, and spread the digital transformation from products to services and marketing to achieve the vision of integration of people, vehicles, and stores.

The introduction of technology from Industry 4.0 such as IoT and big data has further implemented the concept of servitization and customization, and repositioned products and valued the solution value of “user experience”.

GIANT accurately captures the opinions and messages of consumers through the concept of IoT. The practice of the IoT concept of GIANT is originally used for traceability of production and sales. Through QR Code, products can be mastered from parts management, body production, shipping, inventory, and other information. Since 2014, GIANT has also extended its functions to the customer service system. When customers purchase bicycles at the store, they can register the vehicle number in the store through the QR Code to enable the head office to immediately capture the user information and master user information and conduct sales management.

With the full replacement of ERP (enterprise resource planning), GIANT uses SAP (SAP Taiwan) to integrate production and sales information from all markets in the world to a single digital platform. It is expected that through the timely interconnection of information, properly managed manufacturing and inventory to quickly assist in corporate decision-making, as well as expand potential market opportunities to realize the vision of the group’s transition to Industry 4.0. With the continuous expansion of the global operation scale, the management system originally used by GIANT is no longer sufficient. It is expected to break the past information island problem and strengthen the interconnection and cooperation between factories through a single systemized platform. On the one hand, facing the Industry 4.0 era, GIANT signed the SAP S/4HANA Cloud in February 2018, hoping to integrate the production and operation information of multinational bases and conduct big data analysis and forecast feedback through a single digital platform, to manage inventory in real time, improve production efficiency, gain immediate business insight, make more effective decisions, establish brand differentiation advantages, and enhance global competitiveness.

5.3. Collaboration and Integration with the Suppliers

GIANT uses the technology of Industry 4.0 to gradually build Lean Smart Manufacturing. Especially in the connection between development and business, to build a co-creative platform for interaction with customers, and in terms of suppliers, they are slowly interconnected through IoT and digitalization, as a result GIANT will effectively build a sustained mechanism to strengthen competitiveness. In the future, GIANT will be able to effectively integrate customers, R&D resources, and suppliers by jointly establishing a strategic solution based co-creative platform, and let smart factories with differentiated advantages use smart logistics to deliver to customers, to put into practice a co-creative win-win scenario.

In the A-Team era, under the promotion of collaborative improvement, collaborative R&D, and collaborative marketing, GIANT and its suppliers have achieved results in the introduction of TPS, and the collaboration and integration with suppliers have established a good foundation. How to use the technology of Industry 4.0 and further construct the “open innovation platform” will be the focus of the GIANT group. The following is a brief description of the collaboration, TPS, and IoT introduction of the main suppliers.

5.3.1. Collaboration with the Suppliers

Here, let us take SR SUNTOUR as an example for describing the case of collaborative development in A-Team. The front fork is one of the important parts for bicycles, the major parts manufacturer, Japanese firm SR SUNTOUR, was established in 1987 in Taiwan. It produces aluminum/carbon components for bicycles, is now an industry leader in the manufacturing and development of front forks, especially suspension forks.

In recent years, their structures and functions have become more complicated year after year. Therefore, at the time of developing each frame, GIANT, who is the largest customer of SR SUNTOUR, will first discuss with SR SUNTOUR on the issues of materials, functions, weight related to the front fork, taking into consideration the performance of the entire bicycle. That is, through the mechanism of collaborative improvement and the collaborative R&D of A-Team, to cooperate in the development and production of diversified products. As a result of establishing a close cooperative relationship through A-Team, this kind of cooperative development has become possible.

In the A-Team era, collaboration with the suppliers have a good foundation, and G-team will continue this foundation in the future.

5.3.2. Application of TPS and IoT

First, we mention the introduction of TPS. TEKTRO’s main products are bicycle brake systems and related accessories, as well as forging of magnesium and aluminum alloys. It has the world-renowned private brand “TEKTRO”. TEKTRO can be regarded as one of the most thorough manufacturers to promote TPS, even the GIANT founder Liu appreciates the effectiveness of its implementation. In order to cooperate with A-Team’s production transformation and physical strengthening, TEKTRO set up a TPS reading club to allow cadres to communicate and discuss continuously, and stress that everything should be “inspired by necessity” and DIY many tailor-made appliances to reduce unnecessary waste.

FORMULA is one of the most representative companies in Taiwan that manufactures wheel sets with the XERO brand and high design ability. Through the TPS Promotion Center, they enjoy great results. The process is reduced, the amount of storage is reduced, and the efficiency is improved.

Cheng Shin Rubber is the largest tire company in Taiwan. In 2018, the company ranked ninth in the world, mainly by selling its products under the “Cheng Shin” and “MAXXIS” brands. Cheng Shin Rubber & SR SUNTOUR emphasizes “visual management” such as visualization of management status, visualization of production lines, and work visualization. In addition to quality, special emphasis on TPM, they are dedicated to the maintenance of production equipment, to achieve TPS, TPM, TQM trinity.

Next, we describe IoT application and strengthening of the link of SCM. Several of the suppliers interviewed claimed that Lean Production combined with Industry 4.0 to achieve certain performance. Based on TPS, Industry 4.0 helps to avoid waste, reduce defects, standardization, then bring rationalization and efficiency of production processes, and strengthen inventory management and overall management efficiency. So far, suppliers have mainly applied digitalization and linked through IoT. TEKTRO and Cheng Shin Rubber have been able to achieve M2M, while SR SUNTOUR comprehensively uses QR Code to integrate information and links. Each supplier uses sensor to generate data for visual management, and managers can check it at any time through an office computer screen or mobile phone.

Currently, the procurement/supply of suppliers and GIANT is linked through the “EC Procurement Platform”. GIANT has open access and uses the “EC Procurement platform” to help the suppliers know when to ship and know its quantity. This platform provides download specifications and quantity related information, but it must be transferred to the system of suppliers such as SR SUNTOUR and TEKTRO. The QR Code is used for the components, and after it is delivered to the GIANT, the QR Code is linked to its production system.

TEKTRO, Cheng Shin Rubber, FORMULA, KMC, and SRAM have built SAP’s ERP system. After the new ERP was implemented in May 2019, GIANT started to link with individual suppliers. It is expected that by the end of 2019, the SAP system between GIANT and the main suppliers will be interoperable, and the construction of “open innovation platform” to share information with the supply chain will be achieved. For suppliers, the new ERP will make delivery information clearer, plan changes easier to match, and reduce inventory.

5.4. Verification of the Practical Structure of “Lean Smart Manufacturing”

The author [

20] proposed a practical structure of “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform”, and advocated “Lean, then Smart”. Continuous improvement and process rationalization of the physical system can enhance the ability of the cyber system to solve problems and optimize decision-making and increase its value. In addition, they pointed out that the problem-solving strategic co-creative platform can realize the unique competitiveness and differentiation (differentiation and open innovation are achieved at the same time) of the enterprise and improve the creativity of customer value by co-creation through network connection.

The first is the physical system realm. As early as the A-Team era, GIANT has achieved a high level of TPS. On the one hand, the integration of upstream and downstream suppliers to implement Lean Production, extended to the introduction of quality management systems such as TQM and TPM. In the cyber system realm, the big data analysis is actively introduced, and the management executives also recognize that big data can be a big benefit for GIANT. Although the application of CPS at the factory site is still preliminary, the cloud analysis of marketing and customer service has a high level.

Then there is a two-stage solution platform. In the first-stage solution platform of the physical system, digitalization and connection on the basis of Lean has gradually reached the goal of intelligence. GIANT pursues labor saving, unmanned, and improves efficiency, reduces defective products, and continuous improvement. It is dedicated to the digitalization of expertise, and also introduced digital quality system EQS, digitalization has produced great benefits. Self-developing software, constructing machine networking, including domestic and foreign equipment, communication protocols are already available for networking. In the near future, GIANT will combine the machinery manufacturers to develop a set of M2M automation equipment.

The second-stage solution platform integrates the digital information obtained by the physical system into the cyber system, and constructs a problem-solving mechanism that can analyze and utilize the information, especially to work together with suppliers, customers, and even other complementary companies to form a strategic co-creative platform. This network platform enables the Lean Smart System to effectively connect external organizations and form a problem-solving mechanism that can continuously create customer value through differentiation, which will greatly enhance the customization capabilities of GIANT.

GIANT uses the technology of Industry 4.0 to gradually build Lean Smart Manufacturing. Especially in the connection between development and business, to build a co-creation platform for interaction with customers (customization and servitization can be implemented), and in terms of suppliers, they are slowly connecting with IoT and digitalization, and further leverage the SAP system to build an “open innovation platform” with suppliers to continuously enhance both differentiation and competitiveness.

Through the cloud computing platform, QR Code, Bluetooth, and other technologies, the first-hand user data is obtained in large quantities and accurately, and turned into a part of product design. In April 2018, the introduction of a new ERP was launched (starting operation in May 2019) to integrate production and sales information in various markets around the world.

With regard to cloud computing = service cloud, various data will be collected at the production site and collected into the server to form big data, then the computing software will be used to retrieve the data and convert the data into useful information for decision-making and execution. It will also track and predict the health of your equipment through SCADA, providing early inspection and repair, reducing failures and downtime, and reducing losses. GIANT uses big data analytics to develop tools such as predictive maintenance and yield improvement to achieve the basic goal of smart production.

In terms of the construction of the manufacturing platform with suppliers, GIANT will integrate SCM with suppliers through the new ERP. At present, it has established an “EC Procurement Platform” with each supplier, mainly using QR Code. After the completion of the new ERP in May 2019, GIANT is starting to integrate with TEKTRO, Cheng Shin Rubber, FORMULA, KMC, and SRAM etc., and begin to use SAP to construct a new “communication protocol” and conversion platform for system information sharing with the suppliers, to achieve the construction of the “open innovation platform”. In this way, GIANT can know the production status of the suppliers, when it is completed, and even enter the inventory system of the suppliers to withdraw the parts. Strengthening the link of SCM will enable flexible changes (plan changes, etc.,) to promote the characteristics of GIANT’s customized production that pursues customer value.

5.5. Integration of Industry 4.0 and Lean Production

The following is a verification of GIANT’s strategy of producing innovation with Industry 4.0 and promoting the integration of Lean Production and Industry 4.0. In this case, four aspects of the combination of Industry 4.0 with Lean Production proposed by IFS (Innovative Factory Systems) of German DFKI (German Research Center for Artificial Intelligence) are used to analyze and confirm the integration of the two (

Table 1).

Regarding the Smart Machine, M2M (machine to machine) has been implemented, such as the automatic robot arm of the welding project, and some components have started to implement automatic handling. GIANT developed its own software to construct the machine network, including domestic and foreign equipment, and the “communication protocol” is available. With the QR Codes or RFID built by CPS, in addition to the Kanban function, the Poka-yoke function is more precise. For Smart Operator, devices such as augmented and virtual reality have not been imported. Smart product, such as bicycle pedals, can collect pressure data and improve (Kaizen) products. With regard to the Smart Planner, the Kanban function has become more flexible, and the production is basically moving toward a one-piece flow production, which can take advantage of its bicycle customization. Furthermore, GIANT attaches great importance to visual management. In addition to the on-site real time visualization of production status, the management can grasp the situation and adjust it at any time through a smart phone. Through the blessing of Industry 4.0, Lean Production is more sophisticated and intelligent. The cloud computing achieves the principle of no waste, the principle of zero defects is achieved by big data, the standardization principle is achieved by digitalization, and the overall goal of improving efficiency, reducing defects and continuous improvement is achieved.

6. Findings and Discussion

A-Team was formally established on 1 January 2003 by GIANT and MERIDA and 11 suppliers (22 suppliers in 2005), forming a learning alliance to create value together. It introduces TPS, integrates upstream and downstream suppliers for collaborative management and collaborative R&D, and collaborative marketing. A-Team has established three paradigms: (1) Effectively driving the upgrading of the bicycle industry, (2) moving from coexistence to co-creation, with a continuous value creation model, and (3) combining Lean and customer value creation to enhance added value of products.

After the dissolution of A-Team in 2016, GIANT introduced Lean Smart Manufacturing to its group, and actively constructed a digital strategic co-creative platform. GIANT combines Lean Production and Industry 4.0 to achieve synergy and efficiency. The technology of Industry 4.0 is used to further construct the open co-creative platform of the enterprise group, and to create customer value by combining suppliers and customers.

After effectively creating a gap in capabilities with emerging countries such as China, when A-Team made its departure, the members once again pursued the differentiation of individual companies. GIANT uses the technology of Industry 4.0 to gradually build Lean Smart Manufacturing. Especially in the connection between development and business, to build a co-creative platform for interaction with customers. And in terms of suppliers, they are slowly interconnected through IoT and digital. Further, the SAP system is combined with suppliers to construct an “open innovation platform” to continuously enhance differentiation and enhance competitiveness.

On the other hand, from the verification of the integration of Lean Production and Industry 4.0, it shows that through the blessing of Industry 4.0, Lean Production is more sophisticated and intelligent, the overall goal of improving efficiency, reducing defects, and continuous improvement is achieved.

In the inspection of the practical structure of “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform”, first, this case is in line with the implementation of the “Lean, then Smart” advocated by the authors. Second, through the “co-creation” of the strategic solution based co-creative platform, the company has gradually realized the unique competitiveness and differentiation, as well as improving the creativity of customer value, especially the ability to greatly enhance the customization of GIANT, and thereby increase its added value.

7. Conclusion and Implication

Fujimoto [

25] has divided the relationship between Industry 4.0 and digitalization into three layers: High Sky (ICT System = Weightless World), Low Sky (FA-ICT Interface = Middle Range), and Ground (FA System, Manufacturing Site = Weighty World). He pointed out that the main battlefield for manufacturing is the huge Low Sky, and also recommended to establish a “communication protocol” across enterprises (especially within enterprise groups) to build a network platform.

Through the “co-creation” of the strategic solution based co-creative platform, the GIANT has gradually realized the unique competitiveness and differentiation. Although this case is still in the development stage, it has the basic form of “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform”. The empirical research can prove the importance of combining Industry 4.0 with Lean Production and the importance of creating an open innovation platform under the trend of a large number of customization and manufacturing services; to jointly establish a strategic solution-based co-creative platform, effectively integrate customers, R&D resources and suppliers, and let smart factories with differentiated advantages use smart logistics to deliver to customers, to put into a practice co-creative win-win scenario. The results of this case, as we advocate the use of differentiated advantages of “Lean Smart Manufacturing”, pragmatically from the establishment of the smart factory platform on the physical system, gradually extended to the strategic co-creative platform of the cyber system.

This study reconfirmed the benefits of combining Lean production and smart manufacturing through literature review and empirical evidence. Especially, in the application of “Lean Smart Manufacturing: a conceptual framework and solution based co-creative platform” architecture, there are still few cases of enterprise practice, so this study has considerable meaning as a preliminary exploration and verification. In the future, other Taiwanese cross-enterprise groups or Japanese corporate groups will be studied and examined, through further research to achieve generalization of results.