Abstract

Soft wearable actuators must align with anatomical joints, conform to limb geometry, and operate at low pneumatic pressures. Yet most twisting mechanisms rely on bulky attachment interfaces and relatively high actuation pressures, limiting practicality in assistive applications. This study introduces the first Twisting Soft Sleeve Actuator (TSSA), a self-contained, wearable actuator that produces controlled bidirectional torsion. The design integrates helically folded bellows with internal stabilization layers to suppress radial expansion and enhance torque transmission. The TSSA is fabricated from thermoplastic polyurethane using a Bowden-type fused filament fabrication (FFF) process optimized for airtightness and flexibility. Performance was characterized using a modular test platform that measured angular displacement and output force under positive pressure (up to 75 kPa) and vacuum (down to −85 kPa). A parametric study evaluated the effects of fold width, fold angle, wall thickness, and twist angle. Results demonstrate bidirectional, self-restoring torsion with clockwise rotation of approximately 30 degrees and a peak output force of about 40 N at 75 kPa, while reverse torsional motion occurred under vacuum actuation. The TSSA enables anatomically compatible, low-pressure torsion, supporting scalable, multi-degree-of-freedom sleeve systems for wearable robotics and rehabilitation.

1. Introduction

Soft robotics replaces rigid links and discrete joints with compliant elastomeric bodies that deform continuously under load. This compliance enables safe, low-impedance interaction with the human body, which is essential for wearable biomedical devices that assist, rehabilitate, or augment human movement [1]. Conformability to complex anatomical surfaces and more uniform stress distribution reduce risks common to rigid exoskeletal devices, including pressure injury, joint misalignment, and user discomfort [1]. In addition, lightweight polymer construction and compatibility with monolithic manufacturing methods—such as molding and additive manufacturing—support unobtrusive integration into garments and orthoses, improving usability and cost efficiency [2,3].

Soft actuators convert external stimuli into controlled deformation and are commonly classified by driving mechanism as thermal, electrical, magnetic, or pneumatic. Within thermal systems, shape-memory alloys (SMAs) and twisted–coiled polymers (TCPs) constitute distinct classes with different constraints: SMAs provide very high specific stress and compact form factors, yet their Joule heating and convective cooling cycle limits bandwidth, elevates skin-proximal heat, and accelerates fatigue under rapid cycling [4,5]; TCPs can deliver large strokes with simple fabrication, but their response is strongly temperature dependent, exhibits creep and hysteresis under load, and degrades with repeated thermal cycling unless active thermal management is provided [6]. Electrically driven actuators such as dielectric elastomers and electrohydraulic (HASEL-type) devices achieve large strain and high bandwidth with low moving mass, but they typically require kilovolt-level bias, robust insulation, and careful moisture and contamination control, which imposes nontrivial safety and packaging burdens for body-mounted use [7,8]. Magnetically actuated elastomer composites enable wireless, spatially programmable fields and fast response, yet practically attainable force densities at portable field strengths are modest, and on-body implementations often depend on benchtop coils or moving magnets that add mass, power draw, and workspace constraints [9]. By contrast, pneumatic architectures remain the most mature for wearable and biomedical applications because they combine large, low-impedance deformation with benign failure modes and materials and processes compatible with textiles and additive manufacturing [3,10].

Within pneumatics, fiber-reinforced actuators use helical or braided inextensible filaments to constrain radial expansion and raise blocked force in compact envelopes—attributes valued in orthoses and exosuits—though performance is sensitive to reinforcement angle and placement, manufacturing repeatability can be a bottleneck, and stress concentrations at terminations limit fatigue life [11,12,13]. PneuNet (pneumatic-network) actuators, built from interconnected chambers, offer large bending at modest pressures and are straightforward to mold or print, but they are prone to radial ballooning, pressure-dependent stiffness, and seam fatigue that reduce torque density under load and complicate long-term durability [14,15]. McKibben muscles provide muscle-like power-to-weight and excellent back drivability with well-studied pressure–length behavior, yet their nonlinear, hysteretic response, bulky end fittings, as well as leakage and fatigue at crimps and connectors pose integration and maintenance challenges in compact, multichannel wearable systems [16,17]. Bellows actuators, formed from corrugated chambers, offer significant axial strain, favorable mechanical efficiency, and scalability, and thus remain promising for assistive wearables [18,19,20].

Translating twisting actuation into wearable and biomedical contexts remains especially challenging. Prior work has demonstrated several torsion-capable mechanisms, each with trade-offs that limit practical use. Gorissen et al. achieved torsion by bonding angled balloon arrays back-to-back, but the architecture requires relatively high operating pressures, exhibits limited bandwidth associated with balloon inflation, and is susceptible to delamination at elevated pressures [21]. Jiao et al. used vacuum-induced asymmetric buckling of slanted silicone walls to produce large free twists; however, severe radial ballooning, parasitic bending, loss of rotation under load, and the inherent ceiling of vacuum actuation limit torque density and scalability [22]. Chen et al. introduced a concave silicone bellows constrained by a thin rigid cap to enable bidirectional twist and higher torque; yet the cap reduces compliance, ballooning re-emerges at moderate pressures, and fabrication is nontrivial [23]. Additional approaches underscore further trade-offs: Morin et al. demonstrated geometry-programmed torsion with concentric rings and helically arranged stiff inclusions, but with pronounced ballooning, modest torque, and complex assembly [24]; Gong et al. realized peristaltic rotation using sequentially inflated bladders, at the cost of low torque, multi-valve synchronization, and delamination concerns [25]. Jiang and Zhang integrated a rigid origami frame with a pneumatic muscle to suppress ballooning, sacrificing compliance [26]; and Connolly et al. generated shear-induced twist via helical fiber windings, though repeatability and quantified torque were limited by labor-intensive manufacturing [27].

A critical yet under-addressed challenge across existing actuator technologies is their secure attachment to robotic joints and human anatomy [1,28]. Traditional attachment methods typically involve textile interface layers [29,30], which absorb actuator force due to stretching and degrade structurally over time, compromising actuator efficiency and reliability [31,32]. Moreover, the rotational axis of soft twisting mechanisms does not coincide with the anatomical joint center, complicating alignment and reducing comfort and effectiveness in the wearable system [26]. Soft sleeve actuators (SLAs) mitigate these problems by integrating directly into the limb, improving stability and minimizing transmission losses; however, prior sleeves have primarily delivered linear and bending motions, and a practical twisting sleeve mechanism has not been established [28].

Addressing this critical gap, the current study proposes the Twisting Soft Sleeve Actuator (TSSA), explicitly designed for wearable applications requiring torsional motion. Distinct from traditional solutions reliant on external braces or textile interfaces, the TSSA offers a self-contained wearable platform that ensures stable, comfortable, and efficient attachment directly to the user’s limb. Moreover, the proposed actuator is inherently compatible with existing linear and bending soft sleeve actuators, facilitating complex, multi-degree-of-freedom motions necessary for comprehensive wearable robotic systems (see SI, Section S2). The following sections present the detailed design of the TSSA, its manufacturing methodology, and systematic experimental evaluations. Parametric studies exploring geometric influences on actuator performance further validate the practical efficacy and versatility of the proposed design.

2. Method

2.1. Design of the TSSA

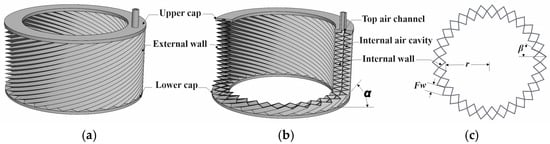

The TSSA was conceived as a bellows sleeve with triangular inner and outer walls interconnected at the apex and base. Baseline geometric and material parameters (Figure 1) are as follows: actuator radius (r) = 30 mm, fold width (FW) = 7 mm, fold angle (β) = 30°, twist angle (α) = 270°, wall thickness (wt) = 0.96 mm, and Shore hardness (sh) = 85. During preliminary pressurization, a reproducible deformation mode was observed in simple bellows sleeves: the inner wall migrated inward while the outer wall ballooned outward, transforming the cross section from circular to elliptical. This cross-sectional drift displaced the effective rotation axis, reduced torsional efficiency by diverting pneumatic work into radial expansion—limitations not explicitly resolved in prior sleeve-type twisting mechanisms.

Figure 1.

Initial model: (a) three-dimensional representation, (b) sectional view, and (c) wall geometry design.

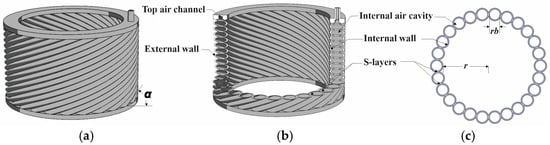

To suppress radial drift, a stabilization layer (S-layer) was introduced to mechanically couple the inner and outer walls and to maintain a nearly uniform annular gap (Figure 2, Figure 3 and Figure 4). The S-layer functions as a distributed shear web, sharing hoop loads and constraining radial motion so that pressure-induced membrane work is directed into the intended torsional degree of freedom. Two simple-bellows variants employing this concept were examined. In the circular-base model (Figure 2), the wall segments at the corrugation base are replaced by circular arcs of radius (rb) = 10 mm to regularize curvature and redistribute bending and membrane stresses, thereby improving tolerance to minor geometric imperfections and delaying local wrinkling. However, the circular arcs increase circumferential (hoop) stiffness relative to V-hinge-like corners; consequently, comparable rotation requires higher actuation pressures—in practice, greater than 200 kPa.

Figure 2.

Circular-base actuator model: (a) three-dimensional representation, (b) sectional view, and (c) wall geometry design.

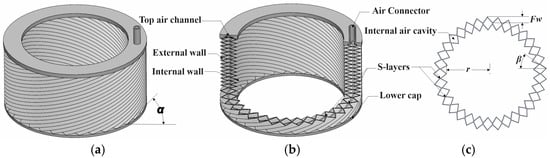

Figure 3.

Simple triangular-base actuator model: (a) three-dimensional representation, (b) sectional view, (c) wall geometry design.

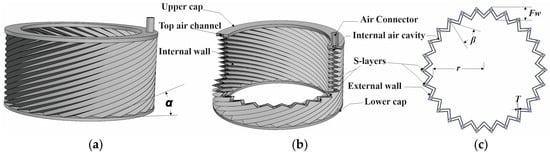

Figure 4.

TSSA: (a) three-dimensional representation, (b) sectional view, and (c) wall geometry design.

In the simple triangular-base sleeve with S-layer (Figure 3), the triangular cross section is retained, and a continuous S-layer of thickness sl = 0.96 mm is added while other parameters match the baseline. This configuration substantially suppresses cross-sectional flattening and stabilizes the rotation axis; in experiments, comparable twist was obtained at approximately 25% lower pressure than the semicircular form. A residual limitation of both simple sleeves is that, being non-folded, they rely on large global membrane stretches; full-stroke twist therefore requires pressures greater than 150 kPa, which is acceptable for benchtop evaluation but burdensome for compact pneumatic sources, and overall flexibility remains limited.

To further address these shortcomings and enhance actuator performance, an advanced bellows architecture termed twisted folded bellows was introduced (Figure 4). In this design, corrugations follow a prescribed helical path, and actuation proceeds by controlled unfolding and rewrapping of many small folded cells rather than by bulk cavity expansion. Under positive pressure, each cell unfolds preferentially along the helix, converting pressure–area work into net unwinding (torsion); under vacuum, the cells rewrap, generating torsion of opposite sign. Each folded segment is sealed and interconnected by slender S-layers, which equalize strain between walls and preserve a near-circular section so that the rotation axis remains well defined throughout the stroke. Top and bottom air manifolds distribute pressure uniformly, promoting synchronous inflation and evacuation and reducing spatial gradients that could otherwise initiate local wrinkling or asymmetric twist. Replacing volumetric expansion with guided fold kinematics thereby improves axis fidelity, enhances repeatability, and lowers the pressure required for practical torsion relative to the simple-bellows sleeves.

The effectiveness of the TSSA depends on several critical geometric parameters (Figure 4). The fold width (FW), defined as the horizontal distance between the peaks and valleys of the bellows corrugations, critically influences the actuator’s achievable twisting angle under positive pressure. Additionally, the helix angle (α) directly correlates with the rotational range, with larger angles facilitating increased twisting motion. The wall thickness (wt) of the bellows is crucial for maintaining airtightness and directly impacts flexibility. The fold angle, defined as the internal angle between two converging inclined sides of each fold, significantly influences structural stability and deformation characteristics. Lastly, the thickness of the S-layer (sl) determines the layer’s rigidity and directly affects the actuator’s overall mechanical behavior. By systematically evaluating and optimizing these parameters, the proposed twisted folded bellows design offers improved rotational performance, enhanced flexibility, and superior suitability for wearable robotic applications.

2.2. Manufacturing of the TSSA

The initial manufacturing attempts for the TSSA employed conventional molding techniques, commonly used for fabricating soft robotic components. Although molding is effective for simple geometries, significant limitations arose when applied to intricate designs such as the TSSA. Major challenges included compromised mechanical integrity, inadequate airtightness, and internal defects—pinholes and interlayer porosity that form leakage paths; entrapped gas voids and bubbles and wall-thickness nonuniformity that concentrate stress; microcracks and interfacial discontinuities from insufficient cure; and, in multi-part builds, weak bond lines prone to delamination. These defects arise chiefly from gas entrapment during casting. In the multi-component assemblies required by the TSSA, weak interfacial joints failed under operating pressures above approximately 150 kPa. Moreover, the molding process frequently produced porous walls with persistent voids that compromised sealing; vacuum degassing and extended cure reduced but did not eliminate these flaws. Increasing wall thickness to at least 5 mm improved airtightness but rendered the sleeves rigid and bulky, diminishing compliance and overall actuation performance.

To address these limitations, additive manufacturing was adopted as a viable alternative. This layer-by-layer process enables fabrication of thin-walled sleeves with enclosed millimeter-scale cavities, helical corrugations, embedded stabilization layers, and integrated air manifolds—features that are difficult to realize with molding without sacrificing airtightness or compliance. In this work, geometrical complexity refers to structures that combine non-demoldable internal passages with thin walls and high-aspect-ratio folds requiring tight control of thickness and curvature, while simultaneously integrating multiple interacting features (helical folds, S-layers, and manifolds) that impose coupled tolerance requirements across the part. The TSSA embodies this complexity through enclosed helical channels on the order of one millimeter, wall thicknesses near one millimeter, compound curvature along the sleeve axis, and co-printed S-layers that must remain registered over internal cavities.

A systematic evaluation considered three families of 3D-printing technologies categorized by feedstock: powder-based, liquid-based, and filament-based. Powder-based methods were initially explored but were found unsuitable for TSSA fabrication. The small internal passages impeded complete powder removal from enclosed cavities, undermining sealing and repeatability. Liquid-based methods, particularly Digital Light Processing (DLP) with flexible resins, overcame powder-removal constraints but introduced new limitations: high resin cost, potential emission of hazardous volatiles requiring specialized ventilation, and limited elongation (typically below 150%), all of which reduce suitability for highly compliant actuators.

Consequently, filament-based printing technologies were identified as promising alternatives due to their capability to utilize highly elastic and cost-effective materials such as Thermoplastic Polyurethane (TPU), which can elongate by more than 600% (see SI, Section S1). However, filament-based printing of flexible materials introduces additional complexities stemming from TPU’s inherent elasticity and flexibility. These properties demand precise control over extrusion parameters, including extrusion temperature, speed, and cooling rates, to ensure dimensional accuracy and structural integrity.

Within filament-based printing systems, two primary extrusion configurations were evaluated: Direct Drive and Bowden extruders (Figure 5). Direct Drive systems, featuring an extruder mounted directly on the print head, initially demonstrated potential due to their compact filament path and consistent extrusion pressure. However, using a Prusa i3 MK3S printer (Prusa Research, Prague, Czech Republic) equipped with a Direct Drive extruder revealed critical limitations. These included significant vibrations causing layer misalignment, poor dimensional accuracy in the x and y axes due to extruder weight, filament entanglement disrupting extended prints, and frequent, difficult-to-clear nozzle clogs. These unresolved challenges rendered the Direct Drive configuration unsuitable for TSSA fabrication.

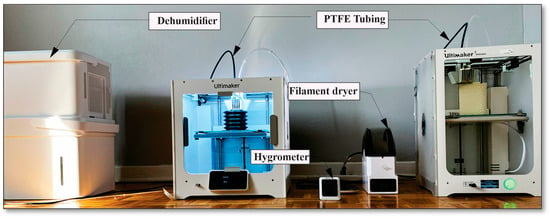

Figure 5.

Controlled-environment additive manufacturing setup for TSSA production.

Alternatively, Bowden extruder systems, characterized by separating the extruder motor from the print head and using a flexible tube to guide the filament, demonstrated enhanced performance. By reducing print head weight, this configuration improved printing precision and speed, although it introduced challenges related to filament buckling, friction within the extended filament path, and delayed extrusion response. These effects were mitigated through targeted process controls: filament tension was tuned to prevent underfeeding and filament deformation; the stock guide was replaced with an ultra-low-friction PTFE tube (Figure 5) to reduce drag and buckling; and retraction was disabled for TPU while extrusion temperature and traverse speed were tuned to minimize pressure transients, oozing, and stringing. Achieving airtight, dimensionally uniform walls in flexible TPU requires tight control of process parameters; therefore, a systematic parameter optimization was undertaken. A structured protocol identified an extrusion temperature of about 235 °C as optimal. Temperatures below about 225 °C caused high melt viscosity, poor interlayer bonding, and micro-void formation, whereas temperatures above about 240 °C led to excessive fluidity, oozing, and delayed solidification. An effective print speed of roughly 15 mm/s balanced dimensional accuracy and interlayer fusion. Slower speeds increased thermal residence and surface defects, whereas faster speeds reduced bonding time, misaligned filament placement, and compromised airtightness. Finally, a flow rate near 110% ensured full bead formation and wall integrity. Lower values induced under-extrusion and porosity, while higher values produced over-extrusion, surface artifacts, and leakage paths. With these settings—together with optimized parameters for layer height, nozzle and bed temperatures, cooling rate, and overall material flow—Bowden-printed sleeves consistently achieved airtightness and pressure resilience, yielding reliable, high-quality TSSA prototypes (see Table 1 for the complete parameter set).

Table 1.

Optimized printing settings.

2.3. Experimental Platform

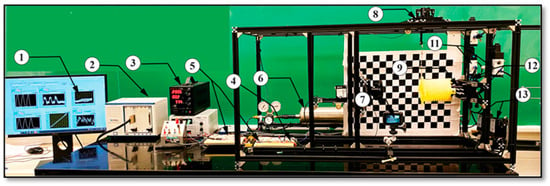

An experimental platform was designed and developed to comprehensively evaluate the performance of the TSSA. This platform, depicted in Figure 6, systematically measures critical performance metrics, including force and twisting angles, ensuring robust analysis across various actuator configurations. Its modular and adaptable design facilitates compatibility with multiple TSSA models, providing precise control over actuator movements and internal pressure conditions, thus ensuring reliable and replicable scientific outcomes.

Figure 6.

Primary components of the experimental platform: (1) graphical user interface, (2) data acquisition system, (3) power supply, (4) vacuum sensor, (5) electric circuit, (6) air buffer tank, (7) 5.3 K camera, (8) force measurement unit, (9) Fixture (11) solenoid valves, (12) pressure transducers, and (13) proportional valve.

The platform’s main structural framework utilizes 2020 V-slot aluminum extrusions combined with aluminum profile corner brackets, three-way corners, and L-shaped connectors to create a stable and adaptable frame. This modular approach allows easy adjustments and modifications, enabling components to be added or repositioned according to specific experimental requirements. Both positive and negative (vacuum) pressure modes are incorporated into the platform. Positive pressure is provided by an air compressor, while negative pressure is generated using two evaluated methods: a vacuum pump and a vacuum ejector. Comparative tests demonstrated that the vacuum ejector outperformed the vacuum pump in flow efficiency, making it the preferred method for experiments requiring rapid and consistent vacuum generation.

Several critical components ensure the precise functionality of the experimental platform. An air buffer tank (Figure 6(6)) stabilizes and maintains consistent air supply pressures to the actuators, essential for reproducible actuator performance. Airflow regulation is achieved using two distinct valve types: solenoid valves and proportional valves. Three electrically operated solenoid valves (Mettleair-4V410, ITI Instrument Tools Industrial Corp., Vaughan, ON, Canada) are employed due to their rapid response times and high-pressure handling capabilities, suitable for rapid pressurization and depressurization scenarios. However, these valves operate only in binary states (fully open or fully closed), limiting their applicability in tasks requiring precise airflow modulation. To address this limitation, proportional valves, specifically the QBX Industrial Electronic Pressure Regulator (Proportion-Air, Inc., McCordsville, IN, USA), are integrated. These valves offer precise airflow control, enabling fine adjustments through electronic signals, with a maximum operating pressure of 1.2 MPa and a flow rate of 1.2 SCFM, ideal for detailed actuator performance studies.

Accurate pressure monitoring is essential for comprehensively assessing actuator performance by correlating force generation and displacement with varying internal pressures. Two types of pressure sensors are utilized. Positive pressure measurements are acquired using 61CP0220100 sensors (Sensata Technologies, Attleboro, MA, USA), covering pressures from 0 to 690 kPa with an accuracy of ±0.75%. These sensors operate within a supply voltage range of 4.5–5.5 VDC, providing reliable and stable data outputs (0.5–4.5 VDC). For vacuum conditions, Panasonic ADP5110 vacuum sensors (Panasonic Industry/Panasonic Corporation, Kadoma, Japan) measure pressures ranging from 0 to −100 kPa with a precision of ±1.25%, ensuring accurate data for vacuum-operated actuator experiments.

Twisting angles generated by the TSSA are precisely measured using a high-resolution camera system. The GoPro Hero11 camera, selected for its ability to capture detailed motion at high resolutions (5.3 K) and high frame rates (240 frames per second), records actuator movements. The captured video data is subsequently analyzed using Kinovea 0.9.5 software, a validated analytical tool widely employed within soft robotics research for accurately measuring angular displacement.

Force measurements are conducted using a custom-designed Force Measurement Unit (FMU), integral to assessing actuator performance across various pressures. The FMU incorporates a precisely aligned force sensor housed within a specialized assembly designed to ensure secure and accurate positioning relative to the actuator. This configuration guarantees accurate force data collection, critical for evaluating actuator capability and stability under different testing conditions.

Finally, sensor-generated signals are captured and processed using a National Instruments Data Acquisition System (NI PXIe-1073) in combination with LabVIEW 18 software. This integrated system converts raw sensor signals into meaningful, real-time visual representations, such as graphs and charts. These visualizations facilitate continuous monitoring of actuator performance, enabling timely and informed adjustments during experimental trials and ensuring high-quality data collection for subsequent analyses.

3. Results

The performance of the TSSA is significantly influenced by key geometric parameters. To evaluate the impact of these parameters on rotational behavior, a comprehensive series of actuator models was designed, manufactured, and rigorously tested using the previously detailed experimental platform. Table 2 summarizes these models and highlights essential geometric parameters, including actuator radius (r), actuator length (l), fold width (Fw), fold angle (β), thickness of stabilization layers (sl), twist angle (α), wall thickness (wt), and Shore hardness (sh). Each parameter, as illustrated in Figure 4, was methodically varied to study its individual and combined effects on the TSSA’s rotational performance. The subsequent sections present detailed analyses of how these parameters affect the actuator’s force output and rotational displacement capabilities.

Table 2.

TSSA models (all dimensions in mm).

3.1. TSSA Force Performance During Rotary Motion

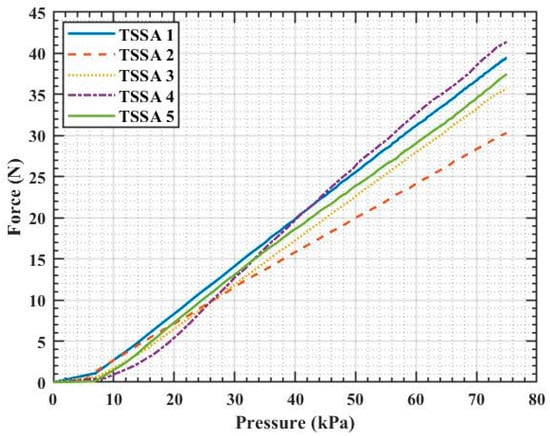

Force performance was assessed using an experimental configuration in which one end of the TSSA was securely anchored, allowing the opposite end to rotate freely. Actuators were incrementally pressurized up to a maximum of 75 kPa, and the resulting forces were measured. The influence of geometric parameters on force generation is depicted in Figure 7.

Figure 7.

Effect of geometric parameters on the generated force of the TSSA.

Fold Width (Fw): Models TSSA5 (14 mm) and TSSA4 (7 mm) were used to investigate the effect of fold width. Increasing the fold width from 7 mm to 14 mm resulted in a reduction in the maximum force output from 41 N to 37.2 N. This decrease can be attributed to the increased surface area of the actuator walls, which dissipates more pneumatic energy through circumferential stretching.

Wall Thickness (wt): The impact of wall thickness was studied by comparing models TSSA1 (0.96 mm) and TSSA2 (1.6 mm). Increasing the wall thickness from 0.96 mm to 1.6 mm significantly reduced the maximum force from 39.4 N to 30.4 N. This reduction is primarily due to increased axial stiffness, which limits the actuator’s deformation, thus requiring higher pressures for equivalent performance and consequently lowering the energy efficiency.

Twist Angle (α): Models TSSA3 (180°) and TSSA1 (270°) were compared to assess the effect of twist angle. Increasing the twist angle from 180° to 270° decreased the maximum force output from 39.4 N to 35.7 N. Higher twist angles impose greater internal structural resistance, thereby negatively affecting force production.

3.2. TSSA Displacement Performance During Rotary Motion

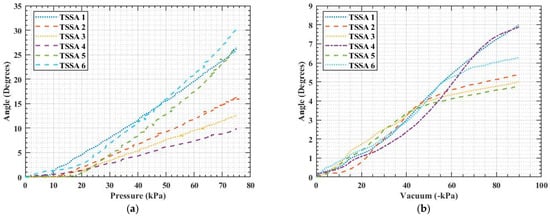

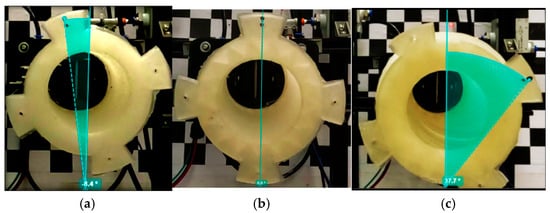

Rotational displacement during twisting was assessed according to established protocols [28,33]. The proximal end of the TSSA was secured, allowing the distal end unrestricted rotational movement. Actuators were tested under positive pressure up to 75 kPa for clockwise motion and under negative pressures down to −85 kPa for counterclockwise motion. Motion capture was conducted using a high-speed 5.3 K camera (GoPro Hero 11), with angular displacements analyzed using Kinovea software. Figure 8 summarizes the key findings.

Figure 8.

Effect of geometric parameters on the generated rotation angle: (a) positive pressure, (b) vacuum.

Fold Angle (β): Models TSSA6 (25°) and TSSA5 (35°) demonstrated the influence of fold angle on rotation. Increasing the fold angle from 25° to 35° reduced clockwise rotation from 30° to 26°, and counterclockwise rotation from 6.2° to 4.5°. These results indicate that higher fold angles restrict the actuator’s flexibility, limiting rotational motion.

Fold Width (Fw): Evaluations comparing models TSSA5 (14 mm) and TSSA4 (7 mm) revealed that a larger fold width significantly decreased rotational angles. Clockwise rotation decreased from 30° to 26°, and counterclockwise rotation decreased from 8° to 5°, indicating that increased fold width reduces rotational capacity due to greater structural stiffness.

Wall Thickness (wt): The effect of wall thickness on rotation was analyzed using models TSSA1 (0.96 mm) and TSSA2 (1.6 mm). Increasing wall thickness resulted in a notable decrease in rotational angles, reducing clockwise rotation from 26° to 19.5° and counterclockwise rotation from 8° to 5.5°. This effect arises from enhanced rigidity and diminished flexibility in thicker-walled actuators.

Twist Angle (α): Comparing TSSA1 (270°) with TSSA3 (180°) indicates that reducing the twist angle impairs rotational capability: clockwise rotation decreases from 26° to 12.5°, and counterclockwise rotation decreases from 8° to 5°. Thus, a smaller twist angle reduces the attainable range of motion.

4. Discussion

This study introduces the first soft sleeve actuation capable of generating controlled rotary motion through the pressurization of a hollow, flexible structure (Figure 9). The key structural innovation enabling this functionality is the integration of a stabilization layer (S-layer) that connects the inner and outer walls of the actuator. This element ensures synchronized motion of both walls under pressurization, thereby suppressing undesired radial deformation and facilitating effective strain transfer into torsional motion. Without this constraint, applied pressure primarily causes bulging or elliptical distortion rather than productive twisting. The inclusion of the S-layer is therefore essential for achieving consistent and controllable rotation in a wearable sleeve format.

Figure 9.

TSSA prototype: (a) counterclockwise motion, (b) resting status, (c) clockwise motion.

A comparison with representative soft twisting actuators (Table 3) clarifies the distinct contribution of the proposed Twisting Soft Sleeve Actuator (TSSA). Because a true sleeve-type torsional mechanism has not been previously reported, the TSSA is benchmarked against conventional soft pneumatic twisting actuators and related torsional modules. Most prior designs are unidirectional, producing rotation in only one sense, which limits usefulness at anatomical joints; by contrast, the TSSA achieves bidirectional twist by combining inflation and vacuum within a single compact structure. Operating pressure further differentiates performance. Several published actuators require 250–310 kPa [34,35] to generate forces in the 2–40 N range, implying bulky compressors and higher energy cost. The TSSA attains approximately 37 N at 75 kPa, yielding a markedly favorable pressure-to-force ratio. This efficiency arises from the folded-bellows architecture with stabilization layers, which channels pressure–area work into controlled, hinge-like unfolding rather than balloon-driven wall stretching. Construction strategy is also consequential: earlier systems often rely on fabric–elastomer laminates or soft–rigid hybrids to suppress ballooning, trading away compliance and complicating on-body integration. The TSSA instead uses a monolithic TPU sleeve (approximately 3.5 mm radial build) with an adjustable internal radius that allows the torsional axis to coincide with the anatomical joint center, thereby eliminating bulky external interfaces, reducing pneumatic dead volume, and improving both energetic and ergonomic efficiency. While these comparisons highlight clear advantages, differences in test fixtures and loading protocols across studies remain a limitation; standardized torque–angle–pressure benchmarks and long-horizon cycling would further substantiate the TSSA’s practical benefits. To examine the role of structural geometry in actuation performance, three S-layer-integrated configurations were investigated: circular bellows, triangular folds, and a folded bellows design. While all configurations generated twisting motion, they differed substantially in terms of required actuation pressure and mechanical flexibility. The circular bellows achieved rotation but required relatively high pressure 160 kPa and exhibited limited compliance. The triangular fold design introduced hinge-like regions, reducing the required actuation pressure to approximately 100 kPa. In contrast, the folded bellows configuration demonstrated the most efficient pressure-to-twist performance, achieving full-range rotation at only 75 kPa. Its geometry concentrated deformation at localized fold roots and minimized dead volume, offering a more practical and efficient actuation mechanism. As a result, the folded bellows design was selected for detailed investigation and characterization.

Table 3.

Comparative summary of soft torsional actuators reported in the literature.

In the next phase, the study addressed the manufacturability of the proposed designs. Conventional molding techniques were inadequate for reproducing the thin walls and complex geometries required for the TSSA. Consequently, additive manufacturing was adopted. Printing with flexible materials introduced several challenges, including filament buckling, inconsistent extrusion, and interlayer bonding issues. These challenges were mitigated through a series of process optimizations. Replacing the Bowden tube with a low-friction PTFE liner significantly reduced feeding resistance and filament instability. Through systematic parameter tuning, a printing temperature of 235 °C was found to provide an optimal balance between flow consistency and interlayer adhesion. The flow rate was increased to 110% to prevent under-extrusion, and the print speed was limited to 15 mm/s to ensure reliable material deposition and dimensional fidelity. These refinements enabled the successful fabrication of fully functional actuators with airtight, flexible walls and consistent performance.

To evaluate the effects of design parameters on sleeve performance, a series of models was fabricated with systematic variation in key geometric features. Increasing the fold width extended the actuator’s range of motion and enhanced the achievable rotational angle. However, its impact on force generation was limited due to increased energy dissipation along the extended fold walls. Similarly, increasing wall thickness negatively affected both the rotational angle and force output. The added stiffness raised the actuation pressure requirement and restricted deformation, revealing a trade-off between structural robustness and responsiveness. Adjusting the fold angle showed that larger angles reduced the overall rotational capability, likely due to greater resistance at the hinge regions. In contrast, increasing the twist angle significantly improved the rotational output without notably decreasing the force, although minor energy losses were observed due to increased internal friction and structural stress.

5. Limitations and Future Work

This study focused on the design, fabrication, and static mechanical evaluation of the first twisting soft sleeve actuator. Several directions should be pursued next. First, numerical modeling is required to predict sleeve behavior under varied loads, boundary conditions, and anatomical contact, and to guide the selection of key geometric and design parameters. Second, closed-loop sensing and control should be enabled by integrating flexible displacement sensors to measure rotation angle in situ—either printed within the sleeve wall or attached as thin laminates—to support accurate estimation and feedback. Third, dynamic performance must be characterized, including step response, bandwidth, efficiency over duty cycles, and controllability during alternating inflation and vacuum actuation. Fourth, portability and energy use should be quantified by measuring air consumption and compatibility with compact pneumatic sources; the small internal gap also suggests potential for passive or portable operation, including harvesting gait energy with passive pneumatic elements to power the sleeve. Finally, scaling and validation should adapt geometry to different anatomical sizes and joint axes, with standardized bench tests followed by longitudinal user trials to evaluate comfort, alignment, and functional benefit in real-world tasks.

6. Conclusions

This study introduces the first twisting soft sleeve mechanism and establishes a coherent framework—from architectural principles to fabrication and quantitative evaluation—for torsional actuation. The TSSA combines a folded-bellows topology with internal stabilization layers that regulate wall kinematics, suppress radial deformation, and channel pressure–area work into controlled, bidirectional rotation. In contrast to prior soft torsional actuators that are typically unidirectional, operate at elevated pressures, or rely on soft–rigid hybrids and textile interfaces, the TSSA delivers clockwise and counterclockwise twist within a compact monolithic TPU sleeve that can be aligned with the anatomical joint center, thereby improving mechanical efficiency and ergonomic compatibility.

A reproducible, airtight manufacturing route was realized using Bowden-type fused-filament printing of thermoplastic polyurethane, with optimized parameters for extrusion temperature, speed, and flow. A modular testbed enabled force and angle characterization under both positive pressure and vacuum, and a systematic parametric study delineated how geometrical parameters shape the torque–angle response at wearable-scale supply pressures. These data yield experimentally grounded design guidelines for tailoring sleeve performance while preserving compliance and comfort.

Taken together, the contributions—novel sleeve-centric geometry, low-pressure bidirectional torsion, and validated manufacturability—establish twisting sleeves as a viable building block for joint-aligned, multi-degree-of-freedom soft robotic systems. The TSSA advances the state of the art by unifying safety, conformity, and efficient pressure utilization in a single, scalable actuator class, thereby providing a rigorous foundation for integration in wearable robotics and related soft-mechatronic platforms.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/electronics14204020/s1, Figure S1. (a) Tensile test experimental setup (b) specimen design. Figure S2. Curve fitting of TPU 85 material using Mooney Rivlin’s 5-parameter mate-rial model. Figure S3. Conceptual integration of TSSA with Bending SLA. Table S1. Hyperelastic models and their corresponding strain energy functions. Table S2. Lists the hyperelastic material constants identified for TPU 85using the Mooney-Rivlin 5-parameter model.

Author Contributions

Conceptualization, M.A. and M.D.; Methodology, M.A. and M.D.; Software, M.A. and M.D.; Validation, M.A. and M.D.; Formal analysis, M.A. and M.D.; Investigation, M.A. and M.D.; Resources, M.A. and M.D.; Data curation, M.A. and M.D.; Writing—original draft, M.A. and M.D.; Writing—review & editing, M.A. and M.D.; Visualization, M.A. and M.D.; Supervision, M.A. and M.D.; Project administration, M.A. and M.D.; Funding acquisition, M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article and Supplementary Materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abboodi, M. Development and Testing of Novel Soft Sleeve Actuators. Ph.D. Dissertation, University of Ottawa, Ottawa, ON, Canada, 2025. [Google Scholar] [CrossRef]

- Xavier, M.S.; Tawk, C.D.; Zolfagharian, A.; Pinskier, J.; Howard, D.; Young, T.; Lai, J.; Harrison, S.M.; Yong, Y.K.; Bodaghi, M.; et al. Soft Pneumatic Actuators: A Review of Design, Fabrication, Modeling, Sensing, Control and Applications. IEEE Access 2022, 10, 59442–59485. [Google Scholar] [CrossRef]

- Thalman, C.; Artemiadis, P. A review of soft wearable robots that provide active assistance: Trends, common actuation methods, fabrication, and applications. Wearable Technol. 2020, 1, e3. [Google Scholar] [CrossRef]

- Kim, M.S.; Heo, J.; Rodrigue, H.; Lee, H.; Pané, S.; Han, M.; Ahn, S. Shape Memory Alloy (SMA) Actuators: The Role of Material, Form, and Scaling Effects. Adv. Mater. 2023, 35, 2208517. [Google Scholar] [CrossRef]

- Srivastava, R.; Alsamhi, S.H.; Murray, N.; Devine, D. Shape Memory Alloy-Based Wearables: A Review, and Conceptual Frameworks on HCI and HRI in Industry 4.0. Sensors 2022, 22, 6802. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Zhang, Z.; Zheng, W. A Twisted and Coiled Polymer Artificial Muscles Driven Soft Crawling Robot Based on Enhanced Antagonistic Configuration. Machines 2022, 10, 142. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Anderson, I.A. Electroactive polymer (EAP) actuators—Background review. Mech. Soft. Mater. 2019, 1, 5. [Google Scholar] [CrossRef]

- Benslimane, M.Y.; Kiil, H.E.; Tryson, M.J. Dielectric electro-active polymer push actuators: Performance and challenges. Polym. Int. 2010, 59, 415–421. [Google Scholar] [CrossRef]

- Peng, C.; Chen, Y.; Yang, B.; Jiang, Z.; Liu, Y.; Liu, Z.; Zhou, L.; Tang, L. Recent Advances of Soft Actuators in Smart Wearable Electronic-Textile. Adv. Mater. 2024, 9, 2400079. [Google Scholar] [CrossRef]

- Tawk, C.; Gao, Y.; Mutlu, R.; Alici, G. Fully 3D Printed Monolithic Soft Gripper with High Conformal Grasping Capability. In Proceedings of the 2019 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Hong Kong, China, 8–12 July 2019; pp. 1139–1144. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Overvelde, J.T.B.; Galloway, K.C.; Wood, R.J.; Bertoldi, K.; Walsh, C.J. Modeling of Soft Fiber-Reinforced Bending Actuators. IEEE Trans. Robot. 2015, 31, 778–789. [Google Scholar] [CrossRef]

- Ma, K.; Jiang, Z.; Gao, S.; Cao, X.; Xu, F. Design and Analysis of Fiber-Reinforced Soft Actuators for Wearable Hand Rehabilitation Device. IEEE Robot. Autom. Lett. 2022, 7, 6115–6122. [Google Scholar] [CrossRef]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, F.; Liu, S.; Tian, Y.; Zhang, D. Modeling and Analysis of Soft Pneumatic Network Bending Actuators. IEEE/ASME Trans. Mechatron. 2021, 26, 2195–2203. [Google Scholar] [CrossRef]

- Manns, M.; Morales, J.; Frohn, P. Additive manufacturing of silicon based PneuNets as soft robotic actuators. Procedia CIRP 2018, 72, 328–333. [Google Scholar] [CrossRef]

- Chou, C.-P.; Hannaford, B. Measurement and modeling of McKibben Pneumatic Artificial Muscles. IEEE Trans. Robot. Autom. 1996, 12, 90–102. [Google Scholar] [CrossRef]

- Davis, S.; Caldwell, D.G. Braid effects on contractile range and friction modeling in pneumatic muscle actuators. Int. J. Robot. Res. 2006, 25, 359–369. [Google Scholar] [CrossRef]

- Seo, S.; Park, W.; Lee, D.; Bae, J. Origami-Structured Actuating Modules for Upper Limb Support. IEEE Robot. Autom. Lett. 2021, 6, 5239–5246. [Google Scholar] [CrossRef]

- Wang, S.; Wu, J.; Yan, P.; Huang, H.; Li, B.; Liu, R. Design of deployable circular structures based on Miura origami pattern. Mech. Mach. Theory 2023, 186, 105350. [Google Scholar] [CrossRef]

- Yap, H.K.; Lim, J.H.; Nasrallah, F.; Low, F.Z.; Goh, J.C.H.; Yeow, R.C.H. MRC-glove: A fMRI compatible soft robotic glove for hand rehabilitation application. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Singapore, 11–14 August 2015; pp. 735–740. [Google Scholar] [CrossRef]

- Gorissen, B.; Chishiro, T.; Shimomura, S.; Reynaerts, D.; De Volder, M.; Konishi, S. Flexible pneumatic twisting actuators and their application to tilting micromirrors. Sens. Actuators A Phys. 2014, 216, 426–431. [Google Scholar] [CrossRef]

- Jiao, Z.; Ji, C.; Zou, J.; Yang, H.; Pan, M. Vacuum-Powered Soft Pneumatic Twisting Actuators to Empower New Capabilities for Soft Robots. Adv. Mater. Technol. 2019, 4, 1800429. [Google Scholar] [CrossRef]

- Chen, F.; Miao, Y.; Gu, G.; Zhu, X. Soft Twisting Pneumatic Actuators Enabled by Freeform Surface Design. IEEE Robot. Autom. Lett. 2021, 6, 5253–5260. [Google Scholar] [CrossRef]

- Morin, S.A.; Shevchenko, Y.; Lessing, J.; Kwok, S.W.; Shepherd, R.F.; Stokes, A.A.; Whitesides, G.M. Using ‘click-e-Bricks’ to Make 3D Elastomeric Structures. Adv. Mater. 2014, 26, 5991–5999. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Yang, K.; Xie, J.; Wang, Y.; Kulkarni, P.; Hobbs, A.S.; Mazzeo, A.D. Rotary Actuators Based on Pneumatically Driven Elastomeric Structures. Adv. Mater. 2016, 28, 7533–7538. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, K. A Novel Torsional Actuator Augmenting Twisting Skeleton and Artificial Muscle for Robots in Extreme Environments. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 9318–9324. [Google Scholar] [CrossRef]

- Connolly, F.; Polygerinos, P.; Walsh, C.J.; Bertoldi, K. Mechanical Programming of Soft Actuators by Varying Fiber Angle. Soft. Robot. 2015, 2, 26–32. [Google Scholar] [CrossRef]

- Abboodi, M.; Doumit, M. Development and Testing of Novel Soft Sleeve Actuators. IEEE Access 2024, 12, 39995–40010. [Google Scholar] [CrossRef]

- Asbeck, A.T.; Schmidt, K.; Walsh, C.J. Soft exosuit for hip assistance. Robot. Auton. Syst. 2015, 73, 102–110. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Asbeck, A.T.; De Rossi, S.M.M.; Holt, K.G.; Walsh, C.J. A biologically inspired soft exosuit for walking assistance. Int. J. Rob. Res. 2015, 34, 744–762. [Google Scholar] [CrossRef]

- Wehner, M.; Quinlivan, B.; Aubin, P.M.; Martinez-Villalpando, E.; Baumann, M.; Stirling, L.; Holt, K.; Wood, R.; Walsh, C. A lightweight soft exosuit for gait assistance. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3362–3369. [Google Scholar] [CrossRef]

- Polygerinos, P.; Lyne, S.; Wang, Z.; Nicolini, L.F.; Mosadegh, B.; Whitesides, G.M.; Walsh, C.J. Towards a soft pneumatic glove for hand rehabilitation. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 1512–1517. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, K. Modeling, optimization, and control of a variable stiffness pneumatic rotary joint with soft-rigid hybrid twisting modules. Mech. Mach. Theory 2025, 205, 105899. [Google Scholar] [CrossRef]

- Paternò, L.; Tortora, G.; Menciassi, A. Hybrid Soft–Rigid Actuators for Minimally Invasive Surgery. Soft. Robot. 2018, 5, 783–799. [Google Scholar] [CrossRef]

- Ye, X.; Zhu, S.; Qian, X.; Zhang, M.; Wang, X. V-Shape Pneumatic Torsional Actuator: A Building Block for Soft Grasper and Manipulator. Soft. Robot. 2022, 9, 562–576. [Google Scholar] [CrossRef] [PubMed]

- Bhat, A.; Jaipurkar, S.S.; Low, L.T.; Yeow, R.C.-H. Reconfigurable Soft Pneumatic Actuators Using Extensible Fabric-Based Skins. Soft. Robot. 2023, 10, 923–936. [Google Scholar] [CrossRef] [PubMed]

- Jin, T.; Li, L.; Wang, T.; Wang, G.; Cai, J.; Tian, Y.; Zhang, Q. Origami-Inspired Soft Actuators for Stimulus Perception and Crawling Robot Applications. IEEE Trans. Robot. 2022, 38, 748–764. [Google Scholar] [CrossRef]

- Li, D.; Fan, D.; Zhu, R.; Lei, Q.; Liao, Y.; Yang, X.; Pan, Y.; Wang, Z.; Wu, Y.; Liu, S.; et al. Origami-Inspired Soft Twisting Actuator. Soft. Robot. 2023, 10, 395–409. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).