Development of a Load Monitoring Sensor for the Wire Tightener

Abstract

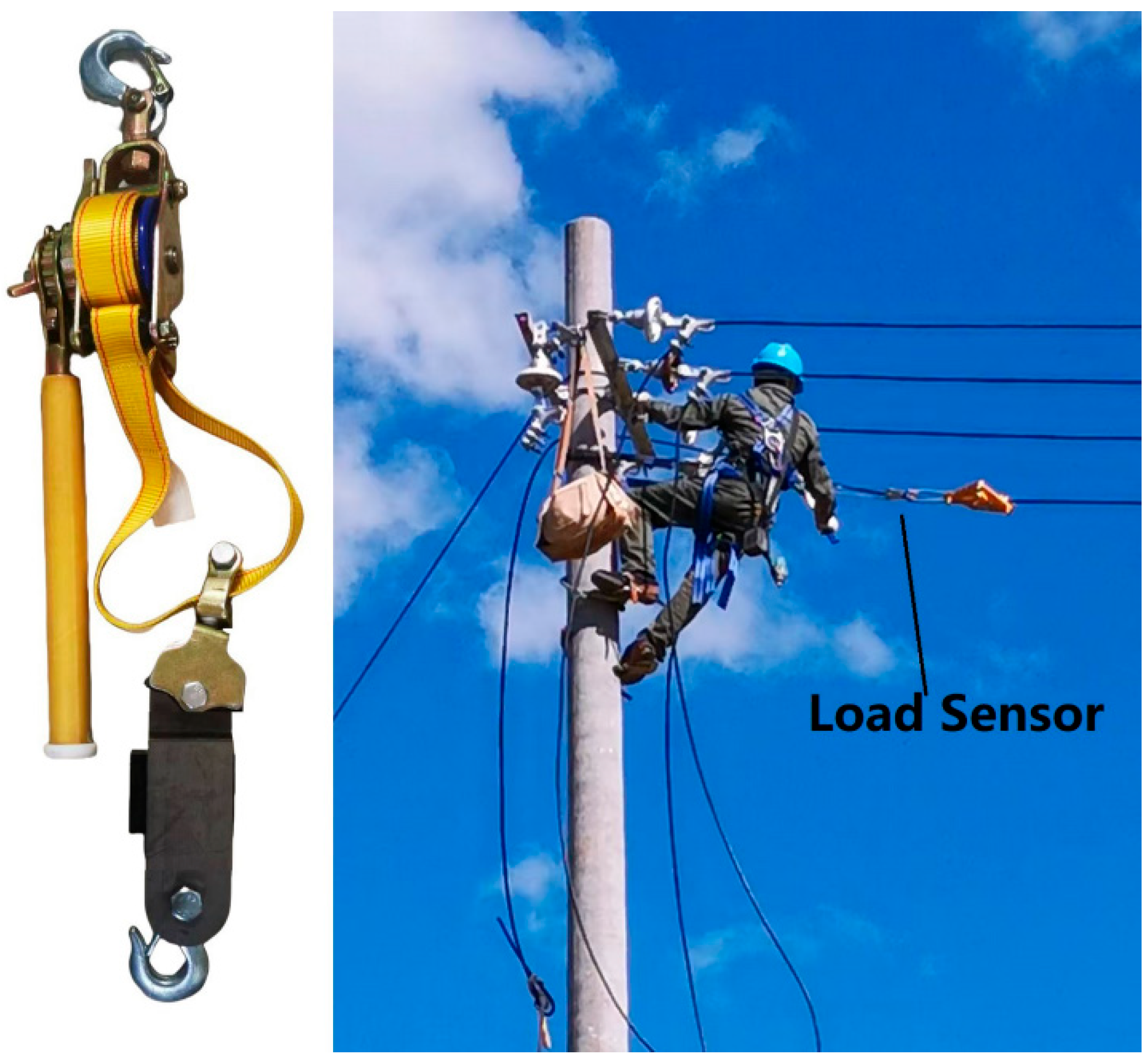

1. Introduction

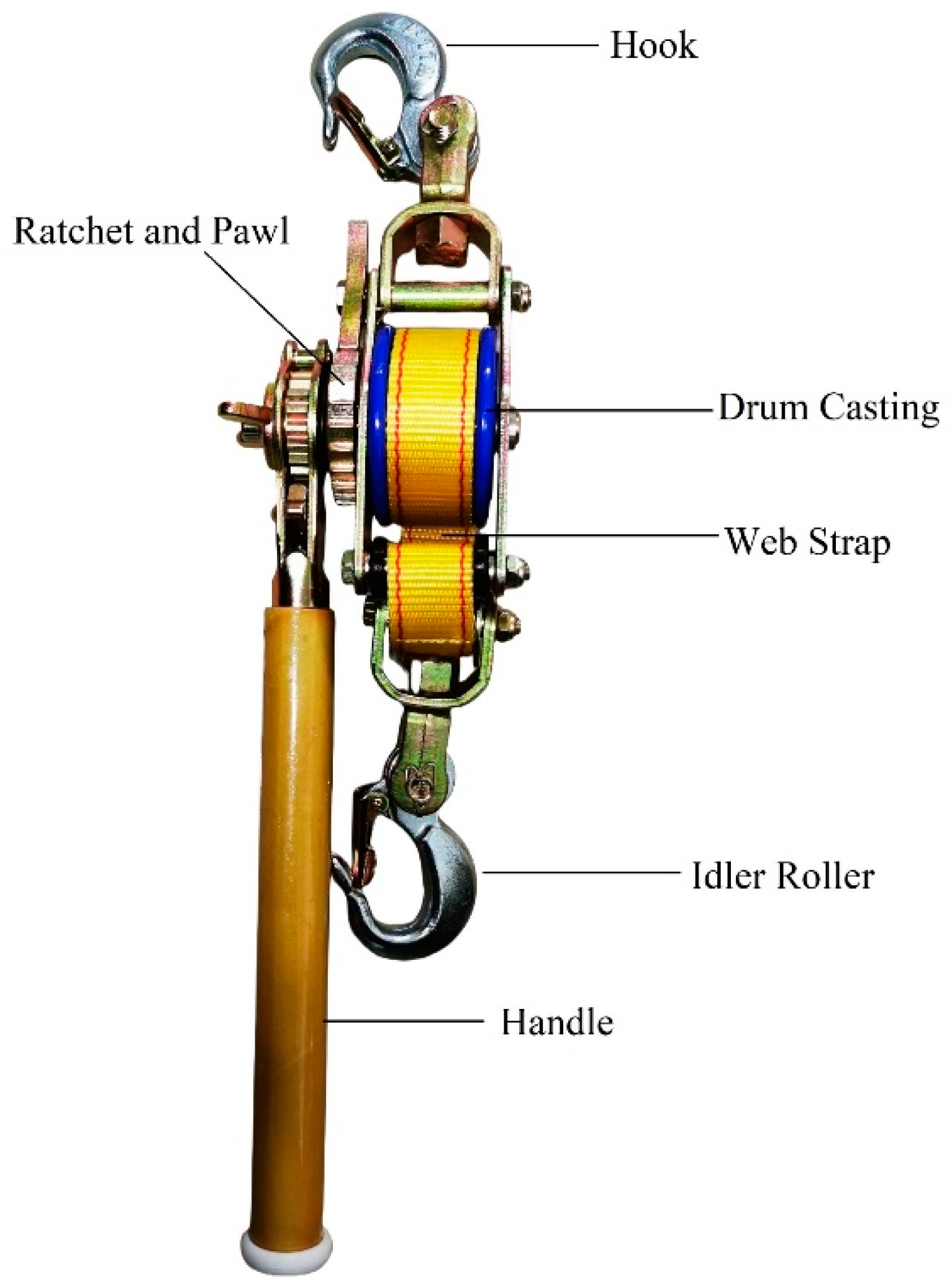

2. Load Monitoring Sensor Functional Analysis

2.1. The Application Scenarios of Tighteners in Power System

2.2. Demand Analysis for Load Monitoring Sensor

2.3. Design Process of Load Monitoring Sensor

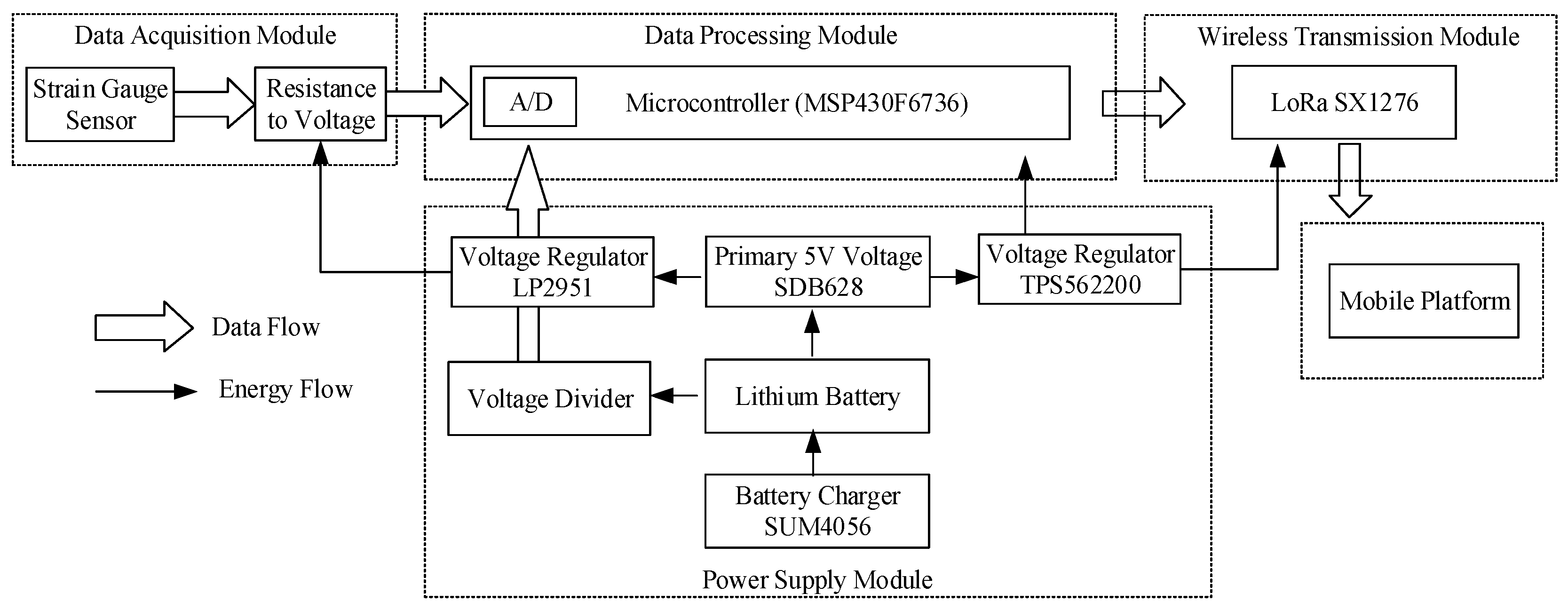

3. Sensor Hardware Design

3.1. Data Acquisition Module

3.2. Data Processing Module

3.3. Wireless Transmission Module

3.4. Power Supply Module

3.5. Hardware Integrated Design

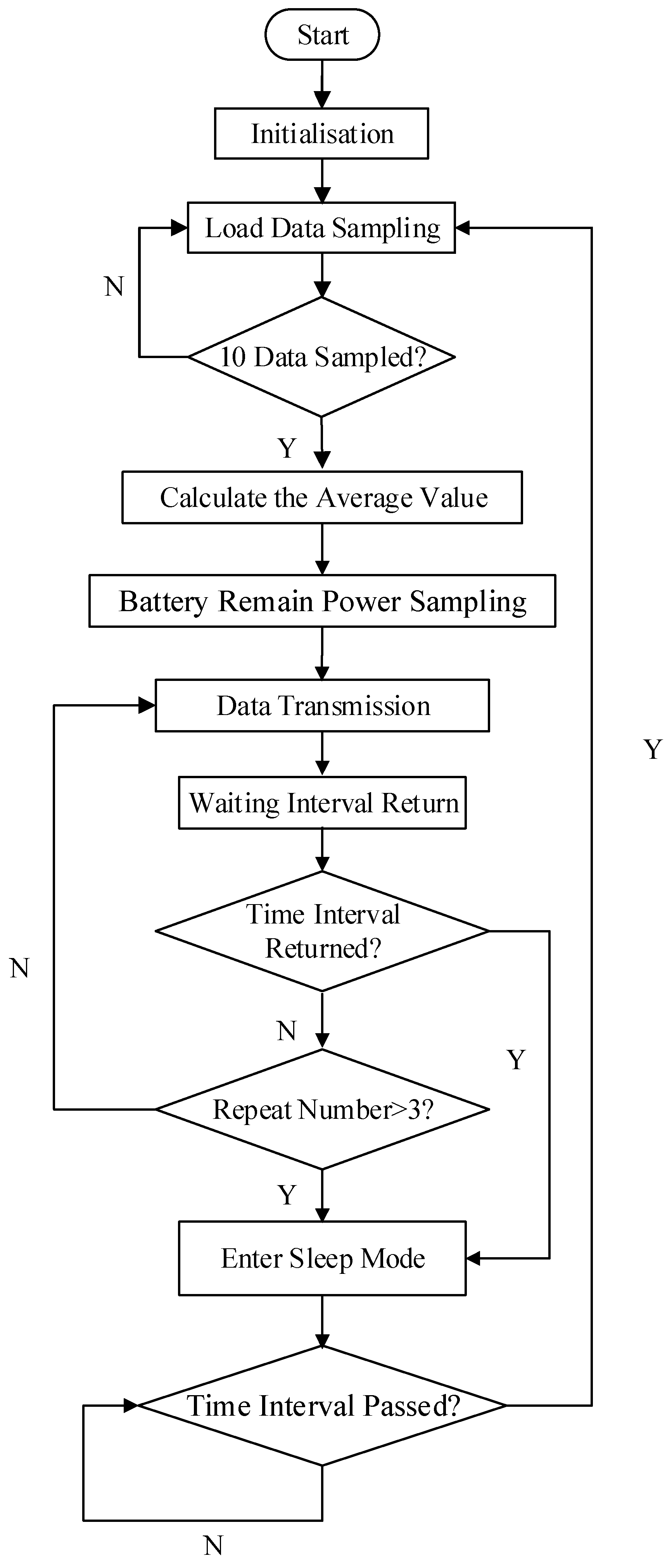

4. Sensor Software Design

4.1. Sensor End Software Design

4.2. Receiver End Software Design

- The acquisition cycle ranges from 1 to 10 min, depending on load variations.

- The cycle shortens as the load increases and lengthens as it decreases. It also shortens when load fluctuations intensify.

- Tt+1 is the next data acquisition interval (in seconds);

- is the average of the latest N samples;

- is the average of the previous N samples;

- The sign function indicates whether the load is increasing or decreasing;

- The weight coefficient α (set to 0.5 in this paper) balances the influence of the load trend and fluctuation intensity;

- represents the normalized standard deviation of recent samples, calculated as

- represents the normalized standard deviation of the first-order differences, calculated as

- quantifies the trend of the load;

- captures the intensity of fluctuations;

- Normalization ensures both metrics lie in the range [0, 1], enabling consistent scaling of the acquisition interval.

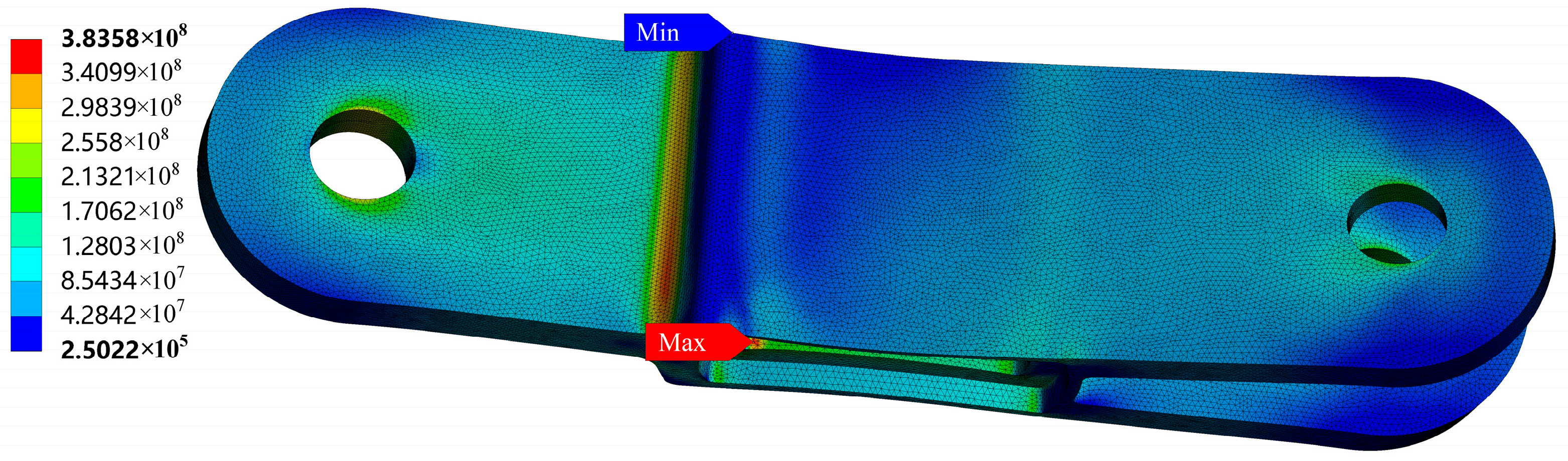

5. Sensor Mechanical Design

6. Results

6.1. The Calibration of Load Sensor

6.2. The Application of Load Sensor

7. Conclusions and Discussion

7.1. Conclusions

- TC4 titanium alloy was used to meet the demands of high load and high safety for its high yield strength (1070 MPa), excellent corrosion resistance, and light weight.

- Low-power LoRa technology was employed for wireless data transmission. By using an ultra-low-power mixed-signal microcontroller and an adaptive sleep–wake strategy, the sensor can operate continuously for 40 h on a 3.7 V, 6000 mAh battery. Future work may include defining data quality metrics—such as whether key information is missed—to optimize the strategy parameters N and α.

- The sensor can be easily bolted between the idler roller and web strap, allowing flexible deployment across various tools and working environments.

- Performance evaluation and calibration showed high linearity (R2 = 0.9999) and low hysteresis loss. The sensor maintains good accuracy across the full load range, with errors within 5% of the full scale.

- The sensor costs approximately USD 100. Although expensive compared to the wire tightener, it is cost-effective compared to potential accident-related damages.

7.2. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SHM | Structural Health Monitoring |

| RSGs | Resistance Strain Gauges |

| OFSs | Optical Fiber Sensors |

| FBG | Fiber Bragg Grating |

| CNTs | Carbon Nanotubes |

| DIC | Digital Image Correlation |

| OLED | Organic Light-Emitting Diode |

| GPS | Global Positioning System |

| GPRS | General Packet Radio Service |

| OPGW | Overhead Ground Wire |

| ADC | Analog-to-Digital Converter |

| CPU | Central Processing Unit |

| IoT | Internet of Things |

| WAN | Wide Area Network |

| MAC | Media Access Control Address |

| UI | User Interface |

References

- Han, J.X. Innovation and Application of Live-Line Working Tools for Distribution Networks. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2020. [Google Scholar]

- DL/T 878-2004; Test Guide of the Insulating Tool for Live Working. China Electricity Council: Beijing, China, 2004.

- Hu, S.H.; Liu, M.X.; Yu, H. Intelligent Monitoring and Alarm Intervention Methods for Hazardous Actions Aimed at the Safety Protection of Live Working Personnel. Digit. Commun. World 2023, 12, 75–77. [Google Scholar]

- Zhao, Y.; Liu, Y.; Li, Y.; Hao, Q. Development and Application of Resistance Strain Force Sensors. Sensors 2020, 20, 5826. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Rab, S.; Pant, B.D.; Maji, S. Design, development and characterization of MEMS silicon diaphragm force sensor. Vacuum 2018, 153, 211–216. [Google Scholar] [CrossRef]

- López-Higuera, J.M. Handbook of Optical Fibre Sensing Technology; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Yassin, M.H.; Farhat, M.H.; Soleimanpour, R.; Michel, N. Fiber Bragg grating (FBG)-based sensors: A review of technology and recent applications in structural health monitoring (SHM) of civil engineering structures. Discov. Civ. Civil. Eng. 2024, 1, 151. [Google Scholar] [CrossRef]

- Mehmood, A.; Mubarak, N.M.; Khalid, M.; Walvekar, R.; Abdullah, E.C.; Siddiqui, M.T.H.; Baloch, H.A.; Nizamuddin, S.; Mazari, S. Graphene based nanomaterials for strain sensor application-a review. J. Environ. Chem. Eng. 2020, 3, 103743. [Google Scholar] [CrossRef]

- Xu, R.; Zheng, X.; Chen, M.; Sun, L.; Chen, J.; Wang, F.; Ma, Y. Enhancing the Linearity and Stability of a Fabric-Based Strain Sensor with Microfolded Graphene Structures. Appl. Sci. 2020, 10, 6230. [Google Scholar] [CrossRef]

- Riyajuddin, S.; Kumar, S.; Gaur, S.P.; Sud, A.; Maruyama, T.; Ali, M.E.; Ghosh, K. Linear piezoresistive strain sensor based on graphene/g-C3N4/PDMS heterostructure. Nanotechnology 2020, 31, 295501. [Google Scholar] [CrossRef] [PubMed]

- Qiu, A.D.; Aakyiir, M.; Wang, R.Y.; Yang, Z.K.; Umer, A.; Lee, I.; Hsu, H.Y.; Ma, J. Stretchable and calibratable graphene sensors for accurate strain measurement. Mater. Adv. 2020, 2, 235–243. [Google Scholar] [CrossRef]

- Peters, W.H.; Ranson, W.F. Digital Imaging Techniques in Experimental Stress Analysis. Opt. Eng. 1982, 21, 427–431. [Google Scholar] [CrossRef]

- Khoo, S.W.; Karuppanan, S.; Tan, C.S. A Review of Surface Deformation and Strain Measurement Using Two-Dimensional Digital Image Correlation. Metrol. Meas. Syst. 2016, 23, 461–480. [Google Scholar] [CrossRef]

- Ge, X.; Cheng, S.; Fu, J.; Zhu, C.G.; Li, S.; Tang, H.; Ma, H.K. Development of intelligent bearing tool for transmission lines. Electr. Eng. 2019, 7, 42–44. [Google Scholar]

- Qin, Z.H.; Tao, J.S.; Chen, T.; Xiong, W.J.; Fang, S.H.; He, M.H. Study on early warning system for tightening conductor of HV transmission line based on stress change rate. Eng. J. Wuhan Univ. 2022, 12, 1285–1292. [Google Scholar]

- Yang, J. Research on Wire Icing Monitoring Based on Tensile Force and Inclination Sensing Using FBG. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2019. [Google Scholar]

- Zhang, L.B.; Tang, B.; Huang, M.X.; Li, F.H.; Liu, G. Development of stress monitoring sensors for internal suspension bracing tower ropes. China Meas. Test 2023, 4, 119–126. [Google Scholar]

- Liu, Z.; Li, Y.; Zhao, L.; Liang, R.; Wang, P. Comparative Evaluation of the Performance of ZigBee and LoRa Wireless Networks in Building Environment. Electronics 2022, 11, 3560. [Google Scholar] [CrossRef]

- GB/T 18857-2019; Technical Guide of Live Working on Distribution Line. China Electricity Council: Beijing, China, 2019.

- Wang, Y.J.; Chi, P.K.; Lin, Y.H.; Lu, T.F.; Sue, C.Y. A six-axis force and torque sensor consisting of compliant mechanisms and full-bridge strain gauges. Measurement 2024, 226, 114151. [Google Scholar] [CrossRef]

- Analog Devices. Driving Strain-Gauge Bridge Sensors with Signal-Conditioning ICs. Available online: https://www.analog.com/en/resources/technical-articles/2022/07/16/08/57/driving-straingauge-bridge-sensors-with-signalconditioning-ics.html (accessed on 20 July 2024).

- Rong, D.; Bofeng, L. Sensor Principle and Engineering Application, 2nd ed.; Electronic Industry Press: Beijing, China, 2021. [Google Scholar]

- Kaner, B.; Asmaz, K. Investigation of using strain gauge in tension, torsion and bending experiments. Sigma J. Eng. Nat. Sci. 2024, 3, 755–766. [Google Scholar] [CrossRef]

- Texas Instruments. MSP430F673x, MSP430F672x Mixed-Signal Microcontrollers. Available online: https://www.ti.com/lit/ds/symlink/msp430f6736.pdf?ts=1758249893391 (accessed on 20 July 2024).

- Texas Instruments. Implementation of a Single-Phase Electronic Watt-Hour Meter Using the MSP430F6736(A). Available online: https://www.ti.com.cn/product/cn/MSP430F6736A (accessed on 20 July 2024).

- Kamal, M.A.; Alam, M.M.; Sajak, A.A.B.; Su’ud, M.M. Requirements, deployments, and challenges of LoRa technology: A survey. Comput. Intell. Neurosci. 2023, 1, 5183062. [Google Scholar] [CrossRef] [PubMed]

- Rahman, H.U.; Ahmad, M.; Ahmad, H.; Habib, M.A. LoRa WAN: State of the Art, Challenges, Protocols and Research Issues. In Proceedings of the 2020 IEEE 23rd International Multitopic Conference (INMIC), Bahawalpur, Pakistan, 5 November 2020. [Google Scholar]

- GB/T 5782-2016; Hexagon Head Bolts. China Machinery Industry Federation: Beijing, China, 2016.

- GB/T 6175-2016; Hexagon Nuts, Style 2. China Machinery Industry Federation: Beijing, China, 2016.

- GB/T 95-2002; Plain Washers-Product Grade C. China Machinery Industry Federation: Beijing, China, 2002.

- GB/T 18037-2008; Technical Requirements and Design Guide for Live Working Tools. China Electricity Council: Beijing, China, 2008.

- Chen, Z.Y.; Huang, H.Z.; Deng, Z.W.; Wu, J. Shrinkage mamba relation network with out-of-distribution data augmentation for rotating machinery fault detection and localization under zero-faulty data. Mech. Syst. Signal Process. 2025, 224, 112145. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Huang, H.Z.; Wu, J.; Wang, Y.H. Zero-faulty sample machinery fault detection via relation network with out-of-distribution data augmentation. Eng. Appl. Artif. Intell. 2025, 141, 109753. [Google Scholar] [CrossRef]

| Type | Wire Strain Gauges | Foil Strain Gauges | Semiconductor Strain Gauges |

|---|---|---|---|

| Sensitive grid thickness | Diameter approx. tens of micro-meters | 0.003–0.01 mm | Depends on the semiconductor structure |

| Performance characteristics | Simple structure and low cost; low sensitivity and poor stability | High precision and good heat hysteresis; large resistance dispersion | High sensitivity; poor stability and obvious nonlinearity |

| Sensitivity factor | Approx. 2 | Approx. 2–5 | Approx. 50–200 |

| Substrate Material | Excitation Voltage | Resistance | Sensitivity | Grid Dimensions |

|---|---|---|---|---|

| steel | 5 V | 350 Ω | 2.0 ± 1% | 4 × 7.5 mm |

| Material | Max Stress (MPa)@ 15 kN | Max Stress (MPa)@ 30 kN | Yield Strength (MPa) |

|---|---|---|---|

| Common Aluminum Alloy | 385 | 764 | 280 |

| 7075 Aluminum Alloy | 383 | 767 | 505 |

| Gray Cast Iron | 383 | 765 | 270 |

| TC4 Titanium Alloy | 383 | 767 | 1070 |

| Given Value (kN) | Test Average Value (kN) | Relative Error (%) |

|---|---|---|

| 5 | 5.02 | 0.40 |

| 10 | 10.05 | 0.50 |

| 15 | 15.07 | 0.47 |

| 20 | 20.08 | 0.40 |

| Average Value of Relative Error | 0.44 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yuan, Q.; Shui, T.; Hu, G.; Chen, X.; Shi, Y. Development of a Load Monitoring Sensor for the Wire Tightener. Electronics 2025, 14, 3716. https://doi.org/10.3390/electronics14183716

Zhang Y, Yuan Q, Shui T, Hu G, Chen X, Shi Y. Development of a Load Monitoring Sensor for the Wire Tightener. Electronics. 2025; 14(18):3716. https://doi.org/10.3390/electronics14183716

Chicago/Turabian StyleZhang, Yuxiong, Qikun Yuan, Tao Shui, Gang Hu, Xuanlin Chen, and Yan Shi. 2025. "Development of a Load Monitoring Sensor for the Wire Tightener" Electronics 14, no. 18: 3716. https://doi.org/10.3390/electronics14183716

APA StyleZhang, Y., Yuan, Q., Shui, T., Hu, G., Chen, X., & Shi, Y. (2025). Development of a Load Monitoring Sensor for the Wire Tightener. Electronics, 14(18), 3716. https://doi.org/10.3390/electronics14183716