Abstract

In recent times, circulating fluidized beds have become increasingly important in various industries, such as in the metallurgy, pharmaceuticals, and food-processing industries, due to their excellent fuel adaptability and environmental friendliness. Therefore, how to diagnose fluidized bed flow faults more efficiently and handle them earlier are important issues that cannot be ignored. This article starts with an introduction to fluidized beds and their common fault phenomena, and then integrates the research of scholars on fluidized bed characteristic-monitoring methods and fault diagnosis methods in recent years and summarizes the shortcomings of each method. Subsequently, a summary and induction of data-driven fault diagnosis methods for circulating fluidized beds are conducted, and the applicability, advantages, and disadvantages of each method are pointed out. Finally, this article presents some of the main challenges currently faced and suggests several possible future development directions.

1. Introduction

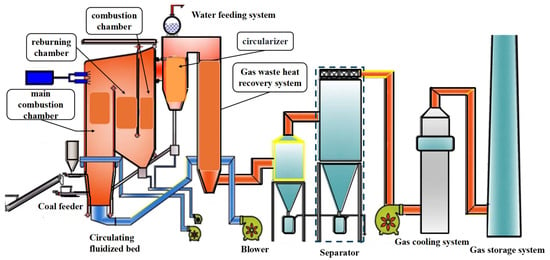

As the core technology of coal utilization technology, the circulating fluidized bed (CFB) enables the efficient and clean utilization of coal. In this process, solid coal is converted into combustible gas. The CFB is a fluidized bed in which gas and solid particles are separated, and the solid particles are recirculated within the system. The unique features of the CFB, including its fuel adaptability, high efficiency, and low environmental impact, have led to its extensive use in a variety of sectors such as chemical engineering, metallurgy, energy, and environmental protection []. Figure 1 shows the principle of the CFB.

Figure 1.

The principle of the CFB.

One of the key characteristics of the CFB is the movement of many solid coal particles along a designated circulation loop. However, the inherent complexity and unstable environment of CFB systems pose significant challenges in maintaining stable particle circulation, which is crucial for system performance. Flow regime failures in particle circulation can occur easily, leading to catastrophic consequences such as system breakdowns, economic losses, or even safety risks []. Therefore, monitoring the CFB particle circulation process and diagnosing early-stage failures are crucial for ensuring long-term stable operation and improving production efficiency []. To guarantee the stable operation of the CFB particle circulation process, the first step is to deeply understand and analyze the potential types of faults and their flow mechanisms during CFB operation. The main contributions of this paper regarding the failure mechanisms and fault diagnosis methods of CFB are as follows:

(1) A comprehensive summary of CFB failure types, including an overview of CFB operating principles and an analysis of various failure causes and their impacts.

(2) A detailed review of statistic-based fault diagnosis methods, evaluating the advantages and limitations of different approaches employed in CFB systems.

(3) A discussion of the latest developments in data-driven fault diagnosis techniques, including a systematic examination of the methods, their strengths, and their limitations.

(4) An exploration of the methods for collecting CFB-related datasets, which are critical for developing and refining accurate fault prediction models.

(5) An analysis of the key challenges in diagnosing CFB flow faults, such as the acquisition of high-quality data and the interpretability of fault detection models, along with potential future research directions.

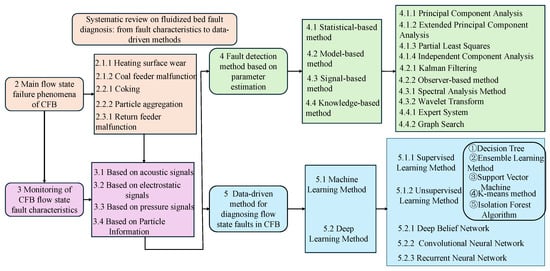

The research structure of this paper on circulating fluidized beds is illustrated in Figure 2.

Figure 2.

The research structure of this paper on CFB.

2. Main Flow State Failure Phenomena of CFB

CFB systems are widely used in the energy, chemical, and other fields due to their advantages of efficient combustion, low pollution emissions, and wide fuel adaptability. However, due to the strong nonlinearity and multi-scale coupling characteristics of its internal gas–solid two-phase flow, as well as the operating environment of high temperature, high pressure, and high wear, CFB is prone to various failures during long-term operation, seriously affecting the stability, safety, and economy of the system. These faults include both deterministic faults with clear physical characteristics (such as heating surface wear, mechanical structure damage), as well as stochastic faults that require statistical analysis of process parameters (such as particle agglomeration, progressive coking), and even composite faults involving a mixture of the two (such as blockage of the return feeder). The characteristic differences between faults are shown in the following Table 1.

Table 1.

Comparison table of types and diagnostic methods of fluidized bed faults.

There are significant differences in the occurrence mechanism, evolution law, and detection methods of different types of faults. Therefore, it is crucial to have a deep understanding of the characteristics of typical CFB faults and select appropriate diagnostic strategies accordingly to achieve early warning and optimize operation and maintenance.

2.1. Deterministic Faults

Deterministic faults usually have clear and observable physical characteristics or mechanical damage, and their occurrence is often directly related to material wear, structural failure, or operating parameter exceeding limits. For example, wear on the heating surface and mechanical failures in the coal feeding system are typical deterministic faults, and their development process usually follows deterministic laws.

2.1.1. Heating Surface Wear

In the CFB, the movement and collision of fuel particles and their friction with the heating surface can cause varying degrees of wear on the heating surface. Wear of the heating surface includes the wear of the convective heating surface, the wear of the return device, the wear of the water-cooled wall tubes and the wear of the separator-heating surface, whereby the wear of the water-cooled wall tubes occurs most frequently. Due to the combustion process in the CFB, the gas and solid particles in the central area rise with the airflow and gradually accumulate on the wall after being subjected to the high-speed fluidization wind in the central region. The solid particles in the surrounding four wall areas flow in the opposite direction along the inner wall of the furnace, forming a core flow model, which leads to wall wear []. If the water-cooled wall tube is worn, this leads to a certain temperature loss in this area and impairs the combustion efficiency of the material. Severe wear may even cause blockage of the CFB or other fluidization faults, resulting in CFB shutdown []. Zhao et al. [] pointed out that the wear of the water-cooled wall tubes can affect the particle concentration, flow velocity, and fuel gas composition in the bed. This, in turn, affects the flow condition of the CFB. In addition, the wear of the heating surface reduces its surface area, which reduces the thermal conductivity and heat output. This affects the thermal energy utilization of the entire system.

2.1.2. Coal Feeder Malfunction

The coal feeder is a vital equipment in CFB boilers. It can transport coal materials evenly and continuously into the furnace, ensure a stable fuel supply and support the combustion process of the fluidized bed. Failures in coal feeding include coal blockage, coal transportation, air and powder leakage, etc. [].

(1) Coal blockage faults: The moisture content of coal is an essential factor affecting coal blockage faults. If the moisture content of the coal entering the furnace is too high, the viscosity of the coal will increase, making the coal material easier to clump and block in the coal bin. In addition, during the operation of CFB boilers, due to design, operation, or environmental factors, coal blockage can easily occur in the coal feeding system, which not only affects the regular operation of the boiler, but may also pose a threat to safety and stability [].

(2) Transportation faults: The main reason for the transportation failure of the coal feeder is the poor transportation of coal materials. If the moisture content of coal is too high, or the particle size is too large, it will cause blockage of the conveying pipeline due to increased transportation difficulty. In addition, abnormal equipment operation, such as screw or belt wear, drive system failure, and uneven coal dropping from the coal bin can also affect the stability of the conveying process, leading to transportation failures.

(3) Air and powder leakage faults: The main reason for air and powder leakage in coal feeders is poor sealing performance. If the sealing device ages or is improperly installed, it can cause airflow leakage, which will carry coal powder out of the equipment. In addition, long-term operation of equipment operation leading to wear and tear of pipelines or shells, as well as factors such as excessive system operating pressure, can also exacerbate air and powder leakage problems.

In addition to coking faults, heating surface wear, particle agglomeration faults, coal feeding system faults, and feeder blockage faults, CFB also includes several other types of faults. Some of these faults include fan faults, furnace explosions, boiler water supply machines, steam and water pipeline damage, a sudden reduction in electrical load, high or low bed temperature, high or low bed pressure, cooler faults, and secondary combustion in the tail flue.

2.2. Statistical Faults

Statistical faults typically arise from complex interactions among multiple variables, demonstrating significant uncertainty in both occurrence and progression that cannot be reliably predicted using deterministic models alone. For instance, the development of faults like catalyst deactivation or bed material segregation depends on stochastic variations in operational parameters and particle properties, manifesting inherent probabilistic characteristics.

2.2.1. Coking

Coking usually forms in localized areas within the bed, which leads to poor local fluidization or unstable flow conditions. Coking in CFB boilers is mainly divided into three types: low-temperature coking, high-temperature coking, and progressive coking [].

Low-temperature coking: The coking phenomenon caused by local overheating when the temperature during CFB operation is lower than the deformation temperature of the ash is called low-temperature coking. It often occurs during equipment startup and ignition.

High-temperature coking refers to the phenomenon of coking caused by a significant increase in bed temperature during the operation of a fluidized bed, due to factors such as high carbon content and delayed heat dissipation. This phenomenon occurs when the bed temperature exceeds the melting point of the ash residue.

Progressive coking: Progressive coking is more difficult to detect compared to the first two types, but it is more common. It is usually caused by the addition of too-large coal particles or poor quality of the air distribution system during CFB operation.

Generally, the normal fluidization process of the CFB is disturbed by coking, resulting in a local temperature rise and uncontrolled bed temperature. This further exacerbates equipment wear and damage to the heating surface. For enterprises, coking problems increase operating and maintenance costs and may cause downtime, affect production continuity and economic benefits, and even lead to safety hazards [].

2.2.2. Particle Aggregation

Particle agglomeration refers to the phenomenon of particles agglomerating into larger particle clusters during CFB operation due to the interaction between the particles. This phenomenon can lead to blockage of the local CFB, thereby affecting the overall stability of the CFB. Qi et al. [] pointed out that viscous forces can cause the particles to agglomerate more easily during fluidization, thereby affecting normal fluidization. Zhou et al. [] investigated the forms of agglomerates in the CFB and found that macroscopic agglomerates are deposited at the bottom of the bed, while small agglomerates and free particles are evenly distributed in the CFB. These studies suggest that particle clusters can alter the distribution and flow characteristics of particles in the bed, which affects the overall performance of the CFB. In addition, the size and distribution of bubbles can also affect the formation and stability of particle aggregation. For example, larger bubbles can carry more particles, enhance the contact and aggregation between particles, and thus accelerate the generation of aggregates. Some studies have indicated that particle agglomeration can cause changes in the fluid dynamics characteristics inside the CFB, such as changes in bed expansion ratio and axial velocity distribution. These changes may intensify the frequency of collision between particles and thus promote the formation of larger particle aggregates []. As the agglomeration phenomenon becomes increasingly strong, the size of the agglomerates in the CFB will also gradually increase. At this point, they not only affect the efficiency of particle movement in the CFB, but also cause flow faults such as channeling, collapse, and blockage in the CFB, ultimately leading to the shutdown of the CFB.

2.3. Composite Faults

Composite faults have both deterministic and stochastic characteristics, and their diagnosis requires a combination of physical mechanism analysis and data statistical methods. This type of malfunction includes both observable physical anomalies (such as pressure drop caused by blockage of the return feeder) and random factors that are difficult to directly quantify (such as uneven material flow).

Return Feeder Malfunction

The return feed plays a crucial role in CFB boilers. It can transport the high-temperature materials separated by the separator back into the furnace and thus maintain a stable bed temperature and a fluidized state of the materials. By adjusting the return feeder, the circulation of materials can be controlled, which changes the concentration distribution of materials in the furnace, significantly affecting the combustion rate, heat transfer efficiency and desulfurization performance. The faults of the return feeder mainly include overheating of the combustion chamber [], system air leakage [], blockage of the air cap [], and detachment of the casting material [].

(1) Overheating of the combustion chamber: The overheating of the combustion chamber is mainly caused by insufficient material circulation in the return feeder, low return gas velocity, or uneven fuel distribution, which may cause high-temperature materials to fail to return to the furnace in time for cooling or excessive concentration of local combustion. In addition, excessive ash discharge can reduce the bed material, lower the heat capacity, and make it difficult to absorb the heat generated by combustion. Abnormal cooling systems can also exacerbate poor heat dissipation and lead to overheating problems.

(2) System air leakage: The air leakage in the return feeder system is mainly caused by poor sealing performance, loose connections, or pipeline wear. Air leakage can disrupt the pressure balance within the return feeder, resulting in poor material return or reduced return volume. At the same time, the introduced cold air can lower the furnace temperature, which affects combustion efficiency and system stability. If the air leakage is serious, it may also exacerbate material wear and system heat loss.

(3) Blockage of the air cap: The accumulation of granular materials, ash or impurities usually causes the blockage of the return feeder air cap. This leads to an uneven distribution of the airflow, a decrease in the velocity of the return gas, and an obstruction of material reflux, which impairs the material circulation and the fluidization effect in the furnace. In severe cases, it may also cause material return interruption or localized overheating problems, which will affect the combustion and heat transfer efficiency of the boiler.

(4) Detachment of the casting material: If a CFB boiler is improperly controlled or the system is operated for long time, the casting material at the inlet of the cyclone separator and return feeder may fall off and deposit at the bottom of the return feeder. This can cover the air cap and further affect the material fluidization process. A small number of small particles falling off has a minor impact, but a large amount of falling cast material can cause poor fluidization, disturb the balance of return materials, trigger intermittent return materials, affect the stable operation of the boiler, and even cause blockage and coking of the return material feeder in severe cases [].

Various faults in CFB can disrupt particle flow patterns, reduce heat and mass transfer efficiency and energy utilization, accelerate wear and coking, shorten equipment lifespan, and increase operating costs. Early detection of fault can help to ensure that the faults are rectified earlier. This is significant to maintain the efficiency of CFB, save energy, reduce consumption and improve enterprise profitability. However, due to the diverse faults and complex internal environment of CFB, early features are often hidden and difficult to detect. Thus, fault detection of CFB still imposes significant challenges.

3. Monitoring of CFB Flow State Fault Characteristics

The classification system of fluidized bed fault diagnosis methods proposed in this article is based on the core principles and implementation paths of the methods, systematically dividing existing methods into two fundamental paradigms: parameter-estimation-based methods that rely on physical/statistical models and expert knowledge, and data-driven methods that utilize algorithms to learn patterns from operational data. This dichotomy reflects their distinct knowledge foundations—while parameter estimation methods (further subdivided into statistic-based, model-based, signal-based, and knowledge-based approaches) derive diagnostic logic from first principles and domain expertise, data-driven methods (encompassing both traditional machine learning and deep learning) extract diagnostic rules directly from system behavior data. The classification standard deliberately spans three orthogonal dimensions: (1) dependence on prior knowledge (from complete physical model reliance to purely data-driven), (2) temporal characteristics of detectable faults (from slow-evolving to transient), and (3) implementation complexity (from laboratory-grade to field-deployable). This multidimensional framework not only preserves the methodological distinctions emphasized in the existing literature, but also provides operators with clear guidance for selecting approaches matching their specific fault detection latency requirements and available infrastructure.

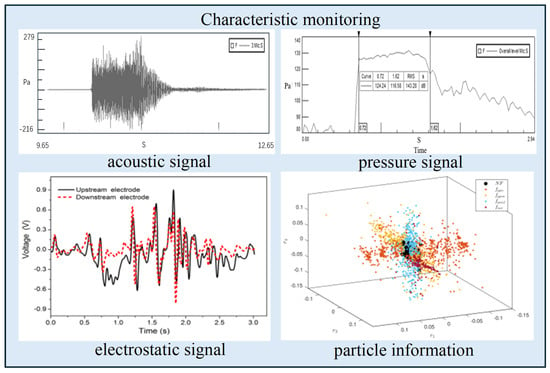

CFB is a typical gas–solid reaction system, in which the fluidized state of the particles in the bed exhibits multi-scale inter-phase coupling such as microscale, mesoscale, and macroscale, as well as physical nonlinear coupling. Due to the superposition of time and space, as well as the complex interrelationships between the signals representing a mixed state, it is difficult to accurately characterize the fault information, which affects the accuracy and efficiency of fault diagnosis. The macroscopic fault characteristics are mainly manifested as macroscopic particle flow anomalies caused by many particle pulsations. The main characteristic of mesoscale faults is that due to the interactions and high-speed impacts between particles and the wall, particles reunite and cause local particle flow anomalies. The main characteristic of microscale faults is the high-speed collision between many particles dispersed in the bed, which results in abnormal flow of single particles caused by high-temperature friction. As established in Section 2, different fault types exhibit distinct characteristics. This necessitates targeted monitoring techniques, which we systematically categorize based on their sensing modalities: acoustic, electrostatic, pressure, and particle-level measurements. The summary diagram of CFN fault characteristic monitoring is shown in Figure 3. The resulting multi-source signals serve as the primary input for both the parameter estimation (Section 4) and data-driven (Section 5) fault diagnosis frameworks discussed later.

Figure 3.

Summary diagram of CFB fault characteristic monitoring.

3.1. Fault Monitoring Based on Acoustic Signals

Regarding acoustic signals, faults are mainly monitored by measuring the acoustic signals of the inner and outer walls of CFB. The principle is to measure the acoustic wave signal based on acoustic emission measurement technology, analyze the acoustic wave signal using a fast Fourier transform, and then establish a measurement model for the main frequency of the acoustic wave. This can then be used to establish a quantitative relationship between the main frequency of the acoustic wave and the particle size. Several studies [,] have achieved monitoring of coking faults in CFB layers through the use of acoustic measurement technology. It was found that the main frequency of the acoustic signal decreases when polymer particles agglomerate in the CFB. From this, it can be determined whether particle agglomeration has occurred in the CFB. However, the experiment also showed that the method for monitoring defects in CFB with acoustic signals has poor directionality and a large divergence angle. Due to the tendency of acoustic wave signals to diverge, energy dissipation is severe, which makes it challenging to detect the signal and leads to low resolution and easy misjudgment of faults.

3.2. Fault Monitoring Based on Electrostatic Signal

Regarding electrostatic signals, faults are mainly monitored by installing metal probes in the CFB to measure the electrostatic current inside the CFB. Qi et al. [] used electrostatic measurements to characterize particle motion in CFB fluidization and investigated the size, shape, rising velocity, and generation frequency of bubbles in a two-dimensional CFB by imaging using a two-dimensional electrostatic sensor array to monitor changes in gas–solid fluidization in the CFB. Yan et al. [] used electrostatic measurements to monitor the agglomeration phenomenon in the CFB and compared the electrostatic currents of the CFB under normal operating conditions and the CFB under fault conditions. From the study, it was found that the electrostatic currents would change significantly when the CFB malfunctioned. However, the CFB fault-monitoring method by electrostatic measurement requires the insertion of a metal probe into the reactor, which can easily lead to disturbance of the internal flow state in practical industrial devices. It is also difficult in many existing industrial devices because of holes to be drilled in the wall.

3.3. Fault Monitoring Based on Pressure Signals

The pressure signal is mainly monitored for faults by measuring the fluctuation signal of the pressure inside the CFB. Pressure signals can be calculated by conventional instruments, which are easy to operate and can dynamically reflect the fluidization state inside the entire bed, making them widely used. Zhang et al. [] used pressure fluctuations to characterize coking faults inside CFB and analyzed the signals using statistical averaging, standard deviation, wavelet analysis, and homogeneity index methods. It was detected that blockage of the return channel would cause frequent pressure fluctuations. Gao et al. [] owed significant fluctuations in the pressure signal inside the bed by changing the different inlet angles of CFB. Jiang et al. [] used a data-driven model to monitor the production efficiency and expected efficiency of the CFB and believed that changes in the structure of CFB equipment alter the flow and internal pressure signals of the main particles in the bed. Meanwhile, Widuch et al. [] diagnosed faults such as internal coking in the CFB due to frequent fluctuations in the internal pressure difference. Internal coking in the CFB resulted in particle accumulation, slowed flow rate, and intermittent particle return.

The pressure signal can provide comprehensive feedback on the characteristics of the gas flow state changes in the bed, such as the geometric structure of the bed and control parameters. Compared with other methods, it has obvious advantages and is widely used. However, if the pressure signal has abnormalities, the fault has often already occurred and is not suitable for early fault diagnosis.

3.4. Fault Monitoring Based on Particle Information

The direct characterization of particle size in CFB is highly sensitive to the occurrence of early failures in time or space. Research has shown that particle information in CFB beds is a good “early warning indicator” of changes in the gas–solid flow state of the CFB [].

Ma et al. [] established a microscale particle model based on the Reynolds number of particles and the concentrations of dense and dilute phases. The new model effectively captures the changes in particle concentration at different sphere diameters and is an essential basis for characterization of fault characteristics. Kong et al. [] analyzed the fault signals inside the CFB riser and pointed out that the dynamic behavior of particle agglomeration generates pressure fluctuations, which are early signs of failure. Xia et al. [] pointed out that particle agglomeration affects the overall distribution and motion state of particles in the bed, which, in turn, affects the fluidization state and internal pressure fluctuations of particles. Large agglomerates are easily formed near the edge of the wall, and the local particle positions are apparent. Lu et al. [] analyzed the gas–solid two-phase particle flow in CFB based on actual fault types and concluded that the dynamic behavior of gas–solid multi-scale structures is closely related to early faults.

However, there are currently few applications of particle information in monitoring the characteristics of CFB flow faults. On the one hand, the measurement methods are limited; and on the other hand, there is a lack of a theoretical system. It is a challenge to make reasonable predictions for various problems encountered in applications that rely primarily on the accumulation of past experience and have a certain degree of blindness.

It should be noted that Section 3 focuses on the physical perception and primary feature extraction of multi-source signals (sound waves, static electricity, pressure, etc.), providing input data foundation for subsequent diagnostic methods; Section 4 (Parameter Estimation Methods) and Section 5 (Data-Driven Methods), respectively, conduct high-order analysis and decision-making on the features extracted in Section 3 from the perspectives of mechanism modeling and statistical learning.

4. Fault Detection Method Based on Parameter Estimation

Building upon the fault signatures identified through monitoring techniques (Section 3), traditional diagnostic approaches can be classified into four paradigms—statistic-based, model-based, signal-based, and knowledge-based. Each paradigm interprets the multi-source measurements (acoustic, electrostatic, pressure and particle-level signals) at a different level of abstraction: statistical methods extract correlation structures, model-based methods compare against first-principal predictions, signal-based methods leverage time–frequency features, and knowledge-based methods encode expert rules. This taxonomy not only aligns with the sensing modalities of Section 3 but also sets the stage for the data-driven methodologies discussed in Section 5.

4.1. Statistic-Based Method

Statistical methods usually require a large amount of historical data to calculate statistical indicators, then characterize data features through unsupervised multivariate statistical analysis, and finally compare with thresholds to analyze and diagnose results []. The specific process of using statistical methods for fault diagnosis is shown in Figure 4.

Figure 4.

Flowchart of CFB fault diagnosis method based on parameter estimation.

Common statistical methods for fault diagnosis include principal component analysis (PCA), augmented principal component analysis, partial least squares (PLS), independent component analysis (ICA), etc.

4.1.1. Principal Component Analysis

The principle of principal component analysis (PCA) is to project high-dimensional data onto a low-dimensional space and use the cumulative contribution rate to determine the number of orthogonal bases selected. While preserving the main part of the data as much as possible, the original data is projected onto orthogonal bases to obtain new features of the data []. The core calculation formula can be expressed as follows:

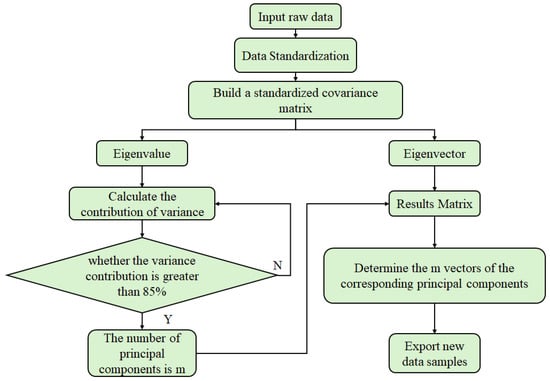

Among them, is the original data matrix, is the eigenvector matrix, and is the principal component score matrix []. The principle is shown in Figure 5.

Figure 5.

The principle of PCA.

PCA, as one of the main statistical methods, is widely used in the field of fault diagnosis. In the field of fluidized bed fault diagnosis, PCA can extract key features of multi-sensor data in fluidized beds through dimensionality reduction and combine statistical measures to achieve fault diagnosis and localization. Zhang et al. [] used the PCA method to process data and determine key input variables for modeling. The comparison showed that the accuracy of fault diagnosis was improved in the model with PCA participation, which can reflect the actual operation of nonlinear systems. Fan [] further strengthened the data-processing capability of PCA by improving mutual information and combining with principal component analysis, and proposed a new feature extraction method, MIPCA.

PCA has significant implications for linear and steady-state systems, especially under the statistical assumption that variables are independent and normally distributed with no autocorrelation in time. However, in actual dynamic systems, steady-state shifts are often caused by disturbances and the monitoring data may not meet these statistical requirements, such as autocorrelation or no normal distribution. These biases weaken the performance of traditional static PCA algorithms [].

4.1.2. Extended Principal Component Analysis

The extended PCA method has become an effective solution for improving adaptability and stability of results. The extended PCA method is a general term for advanced methods proposed by studies based on PCA, such as Kernel Principal Component Analysis (KPCA), Dynamic Principal Component Analysis (DPCA), etc. Such methods can adapt to the nonlinear characteristics or dynamic changes in complex systems and improve the ability to detect and diagnose faults. These methods address the limitations of traditional PCA in processing high-dimensional, nonlinear, and time-varying data and meet a broader range of practical needs through various improvements.

(1) KPCA:

KPCA introduces kernel functions based on PCA to reduce the dimensionality of the input data and improve its ability to handle nonlinear data. Experiments have shown that compared to PCA, KPCA is better at removing noise from the raw data and significantly reducing computational complexity for fault detection in chemical processes []. Simmini et al. [] also pointed out that the Gaussian kernel used in KPCA ensures good accuracy attributes while maintaining sufficient generalization properties through a self-adjusting process, making KPCA more effective at dealing with nonlinear phenomena than PCA.

(2) DPCA:

Based on PCA, DPCA also considers the influence of variables on the time series, making DPCA more sensitive to data correlation and more suitable for detecting faults with sequence correlation []. Guerfel et al. [] used an innovative DPCA method to detect and identify specific faults during system operation. This method can generate a concise set of detection indicators that are specifically respond to faults in certain sequences and are insensitive to faults in other types of sequences. The experimental results show that the improved DPCA method is much more efficient at detecting faults in specific sequence than the PCA method.

Through application to practical cases, the improved DPCA and KPCA methods are much more efficient at identifying specific faults than the PCA method.

In the future, the development of PCA in fluidized bed fault diagnosis may focus on nonlinear extension (such as the combination of kernel KPCA and deep autoencoder), dynamic adaptive modeling (such as sliding window PCA and online learning fusion), and multimodal data fusion (such as combining heterogeneous signals such as sound waves and pressure) while enhancing interpretability (such as contribution graph optimization) to meet the real-time requirements of industrial scenarios.

4.1.3. Partial Least Squares

Partial least squares (PLS) is a linear statistical method that combines principal component analysis, correlation analysis, and multiple linear regression functions []. The core is to establish a correlation model between the independent variable X and the dependent variable Y through latent variables:

where is the predictor variable matrix; is the response variable matrix (dependent variable); is the score matrix of (latent variable); is the score matrix (latent variable) of ; is the load matrix of ; Q is the load matrix of ; is the residual matrix of ; and is the residual matrix of [].

The PLS algorithm establishes a relationship model between the independent and dependent variables and then determines whether a fault has occurred based on the difference between the predicted and actual values of the model. Therefore, PLS mainly achieves early diagnosis of faults and analysis of key variable contributions by establishing latent variable relationship models between fluidized bed process variables and fault indicators.

The limitations of partial least squares regression include the following: the principal components of the model lack clear physical meaning and are difficult to interpret; these are sensitive to noise and outliers, which can affect prediction accuracy; and the selection of the number of latent variables is complex and can easily lead to overfitting or underfitting. In addition, PLS is based on linear assumptions and is difficult to handle in nonlinear problems, resulting in low computational efficiency when analyzing large-scale data analysis. Therefore, studies are committed to coupling PLS with other methods to avoid the limitations of PLS.

(1) MI-PLS:

Aljunaid et al. [] proposed a method called MI-PLS. This method is based on PLS and decomposes selected parts into quality-related and unrelated components by utilizing mutual information, which is then used to construct quality-related monitoring statistics. In practical application, the proposed MI-PLS method has proven to have a lower computational load compared to PLS and significantly improves diagnostic performance.

(2) IPLS:

Li [] proposed an Interval Partial Least Squares (IPLS) method based on the coupling of contribution graphs and partial least squares to diagnose faults related to variables, and its effectiveness has been verified by experiments. Experiments have shown that the IPLS-based contribution graph method has better fault detection and diagnosis capabilities compared to PLS due to the ability of IPLS to discriminate quality-related variables.

(3) IEPLS:

Kong [] proposed an improved quality-related fault diagnosis method based on Efficient Partial Least Squares (EPLS) to enhance its application effectiveness in quality-related fault detection. After verification, IEPLS significantly improved both the detection and false alarm rates, thereby greatly enhancing fault diagnosis accuracy.

However, in PLS-based methods, many impurities remain in the main part when the variables are decomposed. These impurities can interfere with the acquisition of other fault information and affect the safety of the system process. However, the removal of these impurities decreases the detection rate of quality-independent faults, which also limits the adaptability of this method in practical applications. The effective removal of noise while retaining key features that are sensitive to faults has become an important research direction based on PLS methods.

Due to the strong nonlinearity and time-varying nature of multiphase flow in fluidized beds, PLS methods will focus on developing dynamic weighted noise reduction technology in the future. By introducing a flow characteristic adaptive adjustment mechanism, intelligent noise filtering will be achieved while retaining key fault information. Meanwhile, the hybrid modeling method combined with deep learning will enhance the parsing ability of PLS for complex fluidized features.

4.1.4. Independent Component Analysis

The principle of Independent Component Analysis (ICA) is to assume that the captured data during operation is a mixture of multiple independent source signals and then to find an unmixing matrix by calculation. The mixed data is then decomposed to obtain a feature set with independent features. The basic principal formula is as follows:

where is the observed mixed signal (such as sensor data), with a dimension of ; is the unknown independent source signal (such as fault characteristics or potential factors); and is a mixing matrix that describes how signals are linearly mixed [].

Based on these independent features, different potential factors or fault modes can be diagnosed []. This analysis method, which assumes the independence of the signal source, gives ICA significant advantages in dealing with non-Gaussian and multi-source interference problems in complex processes. In the process of fluidized bed fault diagnosis, ICA can effectively identify and locate fault features by separating independent source components from the signals of multiple sensors in the fluidized bed. However, traditional ICA methods exhibit certain limitations in presence of noise interference, dynamic processes, and nonlinear mixed signals, such as high sensitivity to noise and difficulties in handling temporal correlations or nonlinear features. To further improve the adaptability and robustness of ICA, several studies have proposed a series of extension methods based on traditional ICA. These extensions have been enhanced for specific problems, such as introducing kernel functions, dynamic characteristics, adaptability, sparsity or nonlinear modeling techniques into ICA, thereby expanding its application scope and significantly improving diagnostic performance.

(1) KICA:

Kernel Independent Component Analysis (KICA) is a coupled method that introduces kernel functions based on ICA. Chao et al. [] used the KICA method in their research on fault detection and applied it to capture nonlinear structures in data. The data show that the Kernel Independent Component Analysis (KICA) method can detect slow faults faster than the Independent Component Analysis method, and that the KICA method can significantly improve detection performance on other faults and statistics.

(2) DICA:

Due to the dynamic and nonlinear nature of the observed statistical values in most industrial processes. Guo et al. [] proposed a method for fault detection and diagnosis based on dynamic independent component analysis (DICA). In this method, an augmented matrix with time-delay variables is constructed to apply independent component analysis to extract statistically independent, non-Gaussian signal sources from the processed data and finally calculate statistics to monitor the sample condition. The simulation results show that DICA can effectively detect faults in multivariate dynamic processes.

(3) AICA:

Lu et al. [] proposed an adaptive independent component analysis (AICA) method to solve the problem of selecting independent components when using ICA for process detection. This method first uses a separation matrix to establish an association matrix that represents the similarity of the independent components. At the same time, the independent component with the lowest probability density is selected as a particularly independent component (PIC) by kernel density estimation. Then, several ordinary independent components (CICs) with similar mutation characteristics to PIC are selected through the association matrix. Finally, PIC and CICs are used to construct monitoring statistics for process detection. The simulation test results show that the proposed method can better adapt to changing environments than ICA.

In the early days, ICA was widely applied and expanded due to its powerful signal separation ability and wide range of applications. However, with the rapid growth of data scale and the increasing complexity of analysis requirements, the applicability and accuracy of ICA are significantly limited, and therefore the applicable scenarios are also restricted. Zhang et al. [] pointed out that ICA relies on assumptions such as statistical independence, non-Gaussian distribution, and linear mixing, which are difficult to fully satisfy in practical applications. It is also sensitive to noise and has permutation and scaling ambiguity in solutions, leading to a decrease in performance in high-dimensional data or complex scenes. It is necessary to combine other technologies such as deep learning or physical models to improve robustness.

Due to the strong nonlinearity and time-varying nature of multiphase flow in fluidized beds, the future development of ICA methods will focus on the following directions: the dynamic adaptive ICA algorithm, which solves the problem of arrangement ambiguity by introducing flow characteristic feedback mechanism, and simultaneously physically constraining the ICA model and combining it with the gas–solid two-phase flow dynamics equation to enhance the physical interpretability of feature separation. These improvements will significantly enhance the fault feature extraction capability of ICA under complex fluidized conditions.

4.2. Model-Based Method

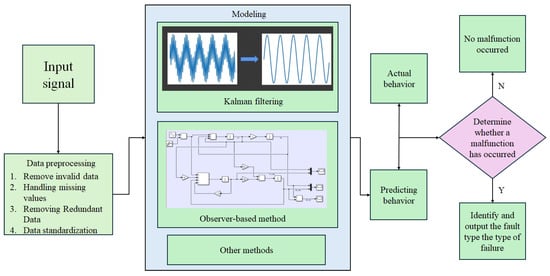

Model-based fault diagnosis methods rely on modeling mathematical models of system behavior. By collecting real-time correlation information between devices in regular operation and abnormal states, analyzing and comparing the differences between the predicted behavior of the model and the actual performance of the device, these can determine whether the device has malfunctioned and locate the type of the fault [], as shown in Figure 6. These methods rely heavily on mathematical or physical modeling to detect faults by identifying deviations between the actual operating state and the expected state of the model. Model-based methods primarily include Kalman filtering and observer-based methods.

Figure 6.

Schematic diagram of model-based fault diagnosis method.

4.2.1. Kalman Filtering

The primary function of the Kalman filtering is to decompose the prediction error to obtain an approximation function when both the initial state vector and the interference term follow a normal distribution, and then use this function to estimate all unknown parameters in the model. The state vector is corrected after obtaining new observed data []. The principal formula is as follows:

where is the Kalman gain and is the observation matrix [].

In complex dynamic systems, Zhou et al. [] achieved dynamic optimization of task scheduling using a deep reinforcement learning framework. Similarly, Kalman filtering can process system noise and detect faults based on the difference between state prediction and actual measurement. Therefore, it is widely used in state estimation and fault diagnosis, especially for systems with high process noise and dynamic characteristics. In fluidized bed fault diagnosis, Kalman filtering can effectively detect typical faults such as gas–solid flow anomalies and temperature/pressure fluctuations through real-time state estimation and residual analysis. Cho [] used a Kalman filter to estimate the state variables of the system to detect faults by comparing the residuals between measured and estimated values in the absence of system faults. In addition, once a fault is detected, the Kalman filter can be combined with artificial neural networks for further fault-type diagnosis, to identify specific fault patterns. After actual testing, the proposed method has been shown to be effective and provide good results. Han et al. [] proposed a method for fault detection based on model-based quadratic Kalman filtering. The model linearizes and discretizes the Kalman filter. Secondly, the first Kalman filter is used for denoising, and the second Kalman filter is used for trend removal and residual calculation for detection. The simulation and experimental results show that the proposed method can accurately detect sudden and initial faults and has advantages such as noise reduction, adaptability, avoidance of divergence, and a high detection rate.

There are currently several extensions of Kalman filtering, including the Extended Kalman Filter (EKF) [], Unscented Kalman Filter (UKF) [], and Particle Filter (PF) []. Kalman filtering has become the primary technical method for processing state estimation of nonlinear systems due to its excellent ability to handle nonlinear systems. However, the Kalman filter method requires strong linear assumptions for the system and has difficulty in handling complex nonlinear systems.

Therefore, the future development of Kalman filtering will focus on three directions: First, a deep Kalman hybrid architecture is developed to compensate for nonlinear errors through neural networks. Secondly, an adaptive noise covariance mechanism is constructed to track real-time changes in the flow regime. Finally, a multi-scale estimation framework is established to handle the movement of bubbles/particles at different scales in a layered manner. These improvements will significantly enhance its applicability in complex fluidized bed conditions.

4.2.2. Observer-Based Method

The principle of observer-based methods is to construct a state observer, estimate the state variables of the system, and compare them with the actual measurements to detect faults in the system. It is applicable to the process in which the system state can be accurately estimated by some form of observer or estimator. In fluidized bed fault diagnosis, the observer-based method can effectively identify typical faults such as abnormal bubbles and particle agglomeration by constructing a gas–solid flow state observer. Jeong et al. [] proposed a fault detection method based on observer residuals for diagnosing whether a machine is in normal working condition. This method mainly identifies faults by extracting fault signal information based on the theory of observer-based methods and the defined relationship between fault signals. After simulation, it has been shown that the observer-based method can effectively improve the ability of the method to diagnose faults. Vijay et al. [] proposed a nonlinear observer-based method for fault diagnosis. This method designs two nonlinear adaptive observers based on input to state stability in cascaded systems, each sensitive to the factors that cause system failures. Experiments have shown that the simultaneous use of two observers can significantly improve fault resolution and has a wide range of application. Bernardi [] proposed a fault diagnosis scheme based on two types of observers. This scheme consists of two types of observers, both of which are used for fault detection, isolation, and evaluation, where the objects are actuators and sensors. The simulation results have confirmed the performance and effectiveness of the proposed scheme in nonlinear systems with external disturbances. Although observer-based methods can estimate complex system states, it may be difficult to accurately estimate system states in nonlinear or high-noise environments, leading to a decrease in the accuracy of the method.

Therefore, in the future, observer-based methods will focus on developing deep-learning-enhanced nonlinear observers and adaptive multimodal observers to improve their state estimation accuracy and fault diagnosis robustness under strong nonlinear and high-noise conditions in fluidized beds.

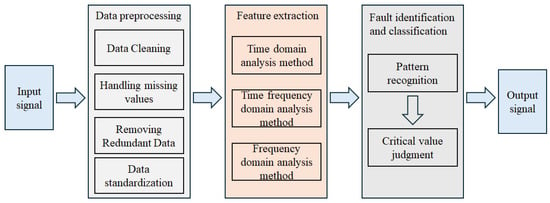

4.3. Signal-Based Method

The signal-based method relies mainly on the signal data collected during the acquisition process and does not require the establishment of complex mathematical models for the system. The detection of faults is carried out by analyzing the frequency and time domain characteristics of signals. The basic principle is shown in Figure 7.

Figure 7.

Schematic diagram of signal-based fault diagnosis method.

4.3.1. Spectral Analysis Method

The method of spectral analysis method can be traced back to the early 19th century, when the French mathematician Fourier proposed the Fourier series while investigating heat conduction problems and later proposed the Fourier transform, thus laying the theoretical foundation for spectral analysis. With the development of computer technology, the fast Fourier transform (FFT) algorithm was developed in the 1960s, which significantly improved the computing power of spectral analysis and promoted its widespread application in signal processing, communication, acoustics, and many other areas. The principle of spectrum analysis is to convert time-domain signals into frequency-domain signals composed of various frequency signals and their strengths and weaknesses through the Fourier transform, to show the energy distribution of signals at different frequencies. The principal formula is as follows:

where represents the time-domain signal; represents the frequency-domain representation of signal , used to describe the energy distribution of the signal at different frequencies f; and is a complex exponential basis function used to project time-domain signals into the frequency domain [].

In fluidized bed fault diagnosis, spectral analysis can effectively identify key fault signals such as abnormal bubble frequency and particle collision characteristics. By using techniques such as bandpass filters, signal components within the target frequency range can be further extracted, thereby achieving accurate analysis and processing of the signal []. This method is therefore more suitable for vibration monitoring and fault detection in rotating machinery. Zhang [] proposed a fault diagnosis method based on spectral analysis for spiral drum coal washing machines in coal mines to accurately identify faults in these machines. This method analyzes the frequency spectrum of vibration signals to determine their fluctuation in the time domain. This enables more intuitive observation of the frequency spectrum characteristics of vibration signals and accurate diagnosis of faults and vibrations in coal mine spiral drum coal washing machines. The experimental results show that this method has a strong capability of spectral analysis of abnormal vibration signals and can accurately identify fault types. Zou et al. [] designed a multifunctional signal spectrum analyzer and constructed signal generators and spectrum analysis modules on two PCs connected via Ethernet using the LabVIEW platform. The system can generate waveform signals with noise and analyze the amplitude spectrum and phase spectrum of the signal through low-pass filtering, windowing and smoothing. Ultimately, the spectrum analyzer demonstrated exemplary performance and stability in test operation, proving its suitability for practical use the fault diagnosis and monitoring of chemical plants. These studies provide essential references for the further application of virtual instrument technology in industrial monitoring. Overall, spectrum analysis can effectively identify periodic faults and mechanical vibration faults, but it is less sensitive to nonperiodic faults and is severely affected by noise. Therefore, when diagnosing flow faults in fluidized beds, it is usually necessary to combine other analysis methods to improve diagnostic accuracy.

Therefore, in the future, spectrum analysis methods will focus on developing adaptive noise suppression techniques and time–frequency joint analysis methods to enhance their ability to detect nonperiodic flow faults in fluidized beds.

4.3.2. Wavelet Transform

The wavelet transform (WT) is a multi-resolution analysis method that can simultaneously capture the time and frequency domain information of signals and detect faults by analyzing the characteristic changes in signals at different scales. In fluidized bed fault diagnosis, the wavelet transform can effectively capture transient characteristics such as bubble rupture and particle agglomeration, achieving early warning of faults. It is more suitable for processing non-stationary signals, such as instantaneous faults and sudden abnormal situations in chemical processes. Yu et al. [] proposed a fault diagnosis system based on the wavelet transform. The principle is to decompose the fault data of equipment using the multidimensional wavelet decomposition method, combined with integrated information processing and hardware integration design, to achieve the development and design of a collaborative remote diagnosis system for equipment faults. The experimental results show that the designed fault diagnosis system based on the wavelet transform has good adaptability and a strong ability of fault reliability detection. In order to improve the expression effect of vibration signal characteristics of traditional one-dimensional bearings, Zhao et al. [] applied the wavelet transform to the fault diagnosis of bearings. This method converts the one-dimensional vibration time series signal of rolling bearings into a two-dimensional time–frequency map using wavelet transform, allowing for more efficient extraction of fault features in the subsequent steps. The experimental results show that the proposed method can accurately identify different types and severities of faults and extract feature information with high discrimination, excellent generalization ability, and strong robustness. Malla et al. [] used a discrete wavelet transform (DWT) method based on the wavelet transform for fault detection, classification, and localization. According to the simulation results, this method can effectively handle non-stationary and irregular transient signals, and its fault detection capability is also excellent.

In general, the wavelet transform can analyze non-stationary signals and is more suitable for detecting sudden faults and instantaneous anomalies, but it requires the selection of appropriate wavelet basis functions, and the analysis process is complex. In the future, wavelet transform will focus on developing adaptive wavelet basis selection algorithms and intelligent parameter optimization techniques to simplify its application process in fluidized bed transient fault diagnosis and improve detection accuracy.

4.4. Knowledge-Based Method

Knowledge-based fault diagnosis methods typically use manual experience, expert systems, or integrated knowledge databases in combination with historical data and expert experience to diagnose faults. This type of method is suitable for complex process systems without precise models.

4.4.1. Expert System

The expert system (ES) relies primarily on experts in specific fields to establish a knowledge base for dealing with specific problems based on their long-term accumulated experience and practical knowledge. In fluidized bed fault diagnosis, expert systems can integrate operational experience and process knowledge to achieve intelligent diagnosis of typical faults such as gas–solid flow anomalies and heat transfer deterioration. Rule analysis and reasoning are used to fault diagnosis is carried out, and solutions are found []. This method is more suitable for complex and challenging model chemical processes. Expert systems are mainly divided into three types: rule-based expert systems, case-based expert systems, and neural-network-based expert systems []. The principle of rule-based expert systems is that the expert system encodes the knowledge and experience of the experts into a set of IF-THEN rules. The system outputs the fault type if the process data conforms to specific rules []. In this method, the rules represent the reasoning process of experts; so, the rule-based expert systems will have better interpretability when solving problems. The principle of case-based expert systems is to use historical cases to solve current issues []. When a problem arises, the system searches for similar cases in the case library established by the system and applies similar solutions to solve the problem. Therefore, this method relies heavily on the quality and comprehensiveness of the system case library. If the case library is not sufficiently complete, the quality of the solutions offered by the system is usually not high. Due to the rapid development of computer technology, more complex training processes have gradually become feasible. As a result, expert systems based on neural systems are gradually being widely applied. Neural-network-based expert systems typically require a large amount of data for training. Therefore, neural-network-based expert systems have better adaptability and generalization ability [], and but the decision-making process of neural-network-based expert systems is often more difficult to understand []. In the future, expert systems will develop towards the direction of “interpretable deep learning” by integrating symbolic reasoning and neural networks, enhancing decision transparency while maintaining the adaptability of fluidized bed fault diagnosis, and developing a lightweight training framework based on physical constraints to reduce data requirements.

4.4.2. Graph Search

Graph search is a method used for finding paths or nodes in graphically structured data. In fluidized bed fault diagnosis, the graph search method can effectively identify flow anomalies and fault propagation paths by constructing gas–solid flow state transition diagrams. Graph search has a variety of applications in computer science, artificial intelligence, network analysis, and other fields. It is particularly suitable for analyzing social networks, path planning, data structures, and natural language processing. Kranakis et al. [] explores the application of graph algorithms in distributed systems and evaluates the impact of knowledge graphs on the competitive ratio. In this study, the proposed search algorithm covers distributed computing topics such as stability and security. Zaitsev and Kruchkov [], in their study, combined the graph search method with the machine learning method for system state monitoring. The principle is to use graph neural networks for predictive diagnosis of inertial navigation systems and classify and diagnose system states through machine learning methods.

In summary, the graph search method is an intuitive, flexible, and suitable algorithm for multi-objective optimization. However, its computational complexity is high, and its efficiency in handling large-scale complex systems is limited. In fluidized bed systems, the graph search method can optimize the particle motion path and gas–solid distribution in fluidized beds, improving accuracy of process control and operational efficiency. However, the complex dynamic characteristics of fluidized beds may lead to slower convergence speed of the algorithm, requiring coupling with other algorithms to improve applicability. In the future, graph search algorithms will focus on developing adaptive path optimization strategies based on reinforcement learning. By combining the multiphase flow dynamics of fluidized beds, heuristic rules will be constructed to reduce computational complexity while improving search efficiency for large-scale complex systems.

To better compare the characteristics of different parameter estimation-based, the advantages and disadvantages of these methods are summarized in Table 2. Table 2 lists the applicable scenarios, advantages, and limitations of each technique, in order to visually understand the performance and applicability of different techniques in practical applications.

Table 2.

Comparison table of various methods based on parameter estimation.

From the perspective of accuracy and recall data, traditional parameter estimation methods such as PCA (accuracy 85–92%, recall 78–85%) and PLS (accuracy 80–87%, recall 75–83%) have shown stable performance in some deterministic fault diagnosis, but their overall performance has obvious bottlenecks. This limitation is mainly reflected in three aspects: Firstly, traditional methods have strong assumptions about data distribution (such as PCA requiring Gaussian distribution and linear relationship), and when faced with common non-Gaussian noise and nonlinear features in fluidized bed systems, their accuracy will significantly decrease. Secondly, the recall rates of these methods are generally below 90%, indicating their insufficient ability to detect early weak faults and composite faults- Furthermore, the performance of parameter estimation methods is highly dependent on expert experience (such as PCA principal component selection and PLS latent variable determination), making it difficult to achieve adaptive optimization in practical industrial scenarios.

Overall, statistical methods are heavily influenced by data and have limited ability to process dynamic changes; signal-based methods are only good in their applicable directions and have low universality; model-based methods and knowledge-based methods are difficult to apply to dynamically changing and complex chemical processes due to the challenges of modeling and knowledge accumulation []. In the complex, highly nonlinear, and numerous coupled systems of fluidized bed flow, these fault diagnosis methods are challenging to effectively meet their requirements. Therefore, finding a practical and feasible diagnostic method to solve the problem of fluidized bed flow state faults remains an important issue that needs to be addressed urgently.

5. Data-Driven Method for Diagnosing Flow State Faults in CFB

In today’s era of rapid technological development, the reliability and security of complex systems are crucial for enterprises and even countries. Therefore, with the continuous advancement of sensor technology and the significant improvement in data storage capabilities, data-driven fault diagnosis methods have emerged, opening up new ways to ensure the stable operation of various systems, including fluidized bed system. In fault diagnosis, early fluidized bed fault diagnosis methods were often limited by model accuracy and complexity. However, with their unique advantages, data-driven fault diagnosis methods provide a more flexible, efficient, and widely applicable solution. They do not rely on precise physical models, but instead mine the inherent features of data from a large amount of measured data and utilize advanced data analysis techniques and algorithms to achieve accurate detection, localization, and diagnosis of system faults []. To date, data-driven fault diagnosis methods have achieved significant results in the field of intelligent industrial manufacturing, and with the continuous development of modern industrial technology, data-driven fault diagnosis technology will also be further improved and its application scenarios will become increasingly widespread.

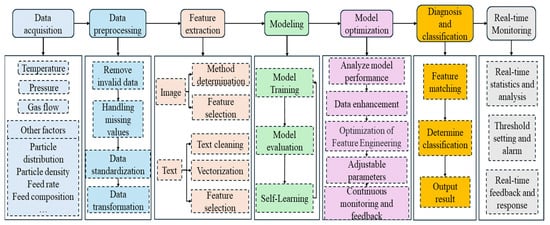

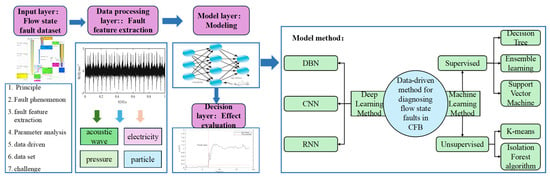

The data-driven fault diagnosis methods are mainly divided into two categories: machine learning methods and deep learning methods. The approximate diagnosis process and method classification diagram of the data-driven fluidized bed flow state fault diagnosis method are shown in Figure 8.

Figure 8.

Process and classification diagram of data-driven fault diagnosis method.

5.1. Machine Learning Method

The machine learning method aims to utilize artificial intelligence technology to enable computer systems to automatically learn patterns from acquired data and diagnose faults. In practical diagnosis, machine-learning-based fault diagnosis methods mainly include steps such as data collection, manual feature extraction, and fault diagnosis []. Among them, accurately extracting fault features is related to the accuracy and efficiency of fault recognition. Therefore, training the model to extract fault features more efficiently has always been the top priority of machine learning methods.

Depending on availability of labeled training data, machine learning methods are divided into two types: supervised and unsupervised.

5.1.1. Supervised Learning Method

Supervised learning refers to the method of continuous training with data to minimize the error in the system output. It is mainly used for classification (e.g., to determine the classification of an item) and prediction (e.g., to predict a particular data item for the next year based on previous years’ data). Decision trees, support vector machines, and neural networks are among the supervised learning methods.

(1) Decision Tree:

Decision tree (DT) is a powerful data mining tool that efficiently captures hidden rules in historical fault data through learning []. In fluidized bed fault diagnosis, decision trees can quickly classify and locate faults such as abnormal bubbles and particle agglomeration by analyzing multidimensional parameters such as temperature and pressure. The decision tree model consists of nodes and edges, with nodes representing an object and branches representing selection. Its distinctive feature is that it splits to the next branch based on the selected features, and it usually plays a role in fault detection for judgment. Due to its intuitive and easy-to-understand process of fault diagnosis, it greatly improves the accuracy and efficiency of fault diagnosis and has, therefore, received widespread attention and research in the field of fault diagnosis []. Also, the fault diagnosis of fluidized bed flow usually involves complex fault types and multivariate features. Decision trees can classify different types of faults layer by layer and quickly localize problems through hierarchical state evaluations (such as temperature, pressure, gas flow rate, etc.). This structured classification method is suitable for fault diagnosis and analysis of complex fluidized bed processes.

Avelin et al. [] proposed a decision support method based on dynamic data correction and Bayesian networks for CFB boiler fault diagnosis, which is closely related to decision trees in concept and application. The author established a dynamic correlation between sensor data and system process variables by establishing a physical simulation model and developing a causal relationship diagram for early fault diagnosis and decision support in fluidized bed systems. Li et al. [] proposed an analysis method that combines decision tree classification models and fully connected neural networks, significantly improving the accuracy of fault-type detection and achieving quantitative and qualitative analysis of fault-type features. In this framework, the decision tree model performs preliminary fault screening through classification features in this framework, providing reliable input data for subsequent neural network analysis. The experimental results show that the method performs well in both the training and validation stages, demonstrating good generalization ability and validating the important role of decision trees in feature selection and classification tasks. Mauricio et al. [] used a specific combination of two decision trees to detect fault and classify monitoring variables. The first decision tree was used to determine whether the system had experienced a fault, while the second decision tree identified the type of fault. This method significantly improves fault diagnosis performance while having excellent comprehensibility. Kherif et al. [] proposed a diagnosis technique that combines the KNN algorithm and the decision tree principle. This method uses decision trees to optimize the number of neighbors and distance types in the KNN algorithm. This improves the accuracy of the classifier and highlights the important contribution of decision trees in optimizing parameter selection and improving diagnostic accuracy. In the future, decision trees will focus on developing adaptive deep decision forests based on the multiphase flow characteristics of fluidized beds. By integrating physical constraints and dynamic pruning techniques, they will enhance diagnostic robustness for complex operating conditions while maintaining parameter optimization advantages.

(2) Ensemble Learning Method:

The principle of the ensemble learning method is to integrate multiple learners in order to compensate for the shortcomings of a single learner. In fluidized bed fault diagnosis, ensemble learning can significantly improve the diagnostic accuracy of complex faults such as gas–solid flow anomalies and heat transfer deterioration by integrating the advantages of multiple models. Through this integration, an ensemble model can be formed that is more comprehensive and accurate than any single individual learner []. In addition, the integrated learning method can reduce the misjudgment rate of a single model by integrating multiple learners and can be applied to processes with high data dimensions, complex structures, and fuzzy features []. Various complex variables and nonlinear relationships are usually involved in the fault diagnosis of fluidized bed, and a single model can be challenging to accurately capture all characteristics. However, integrated learning can significantly improve the accuracy and robustness of diagnosis by combining several basic models (such as decision tree, random forest, support vector machine, etc.). The weighted average of various models can reduce the bias of and variance in a single model, allowing for a better fit to the characteristics of diversity of fluidized bed faults.

Ye et al. [] constructed two integrated models, LeNetU AdaBoost and LeNetU Bagging, to address various fault encountered in offshore wind turbines operations. After a comparative analysis, the diagnostic performance of this research method was found to be superior to any single fault diagnosis model for small fault dataset. Wen et al. [] combined ensemble learning techniques with optimized base learners using operational data to predict NOx emissions under different conditions in coal-fired boilers. The model achieves high prediction accuracy and generalization performance by integrating feature optimization and advanced learning algorithms. Eskandari et al. [] developed a probabilistic ensemble learning model that combines multiple algorithms for fault diagnosis. The experimental results have shown that the proposed method has higher diagnosis accuracy even at low mismatch values and high fault impedances. Moreover, the comparative results show that the proposed method outperforms individual machine learning algorithms.

Considering the advantages of ensemble learning in fluidized bed fault diagnosis, future research can further explore the following directions: by introducing a dynamic weight adjustment mechanism and combining it with the multiphase flow characteristics of fluidized beds, an adaptive ensemble learning framework can be developed to achieve more stable and accurate fault diagnosis in complex working conditions.

(3) Support Vector Machine:

The support vector machine (SVM) was first proposed by VAPINK et al. [] and is a learning strategy based on statistical learning from past statistical data. In fluidized bed fault diagnosis, the support vector machine can effectively identify typical fault modes such as abnormal gas–solid flow state and uneven temperature distribution by constructing the optimal classification hyperplane. Its essence is to discover patterns and learn by examining data. The principal formula of the SVM is as follows:

The function of the first formula is to minimize the objective function, while the second formula is a constraint condition used to ensure that the vast majority of samples are correctly classified and located outside the boundary. These two formulas together form the core mathematical framework of the SVM, which uses convex optimization to find the optimal decision boundary that can maximize the classification interval and tolerate noise.

Support vector machines can effectively solve problems such as overfitting and local minima and have advantages that other machine learning methods cannot match: their computational complexity depends mainly on the number of support vectors rather than the dimensionality of the sample space, avoiding the “curse of dimensionality” problem to a certain extent. Therefore, the SVM has made significant progress in many fields, such as facial recognition, nonlinear function estimation, bioinformatics, handwritten digit recognition, and time series prediction [].

Guan [] used support vector machines to model fluidized bed systems, improving the prediction accuracy and generalization ability of the model. The research has shown that the nonlinear modeling ability and strong prediction performance of support vector machines provide new ideas for the optimization design and control strategies of fluidized beds and are effective tools for solving modeling and control problems in fluidized bed systems. Niu et al. [] have also proposed that support vector machines in fluidized bed systems can predict key factors such as material distribution, airflow patterns, and temperature changes more accurately compared to other methods. Therefore, support vector machines can more sensitively identify and capture the fault characteristics during the operation of fluidized beds. Venkata et al. [] discussed in detail the advantages of SVM in processing unbalanced datasets, such as improving classification accuracy by the SVM-forest algorithm, and demonstrated its practical application in detecting fluidized bed fault. Zhang [] analyzed the problem of small sample machine learning in fault diagnosis of mechanical equipment and concluded that traditional methods often have difficulty maintaining high accuracy in the case of insufficient samples, while SVM can better cope with this problem. To this end, he improved the binary tree structure used by SVM in multi-class classification tasks and optimized it by carefully selecting the kernel function and its parameters. The application of the improved algorithm in fault diagnosis experiments shows that the accuracy of fault diagnosis has been significantly improved. In the future, support vector machines may focus on developing adaptive kernel function optimization methods based on the multiphase flow characteristics of fluidized beds, enhancing small sample learning capabilities through the integration of transfer learning frameworks, and improving diagnostic robustness for complex operating conditions while maintaining the advantage of minimizing structural risks.

It is worth mentioning that a key challenge in applying supervised learning to fluidized bed fault diagnosis is the inherent class imbalance, where normal operating data often far exceeds fault samples. But, currently, there are several effective strategies to solve this problem:

(1) Synthetic Minority Oversampling Technique (SMOTE): This algorithm generates synthetic samples for minority classes by interpolating between existing instances in feature space. Unlike simple oversampling, SMOTE creates meaningful new data points along the line segments connecting k-nearest neighbors of minority class samples, effectively expanding the decision regions for rare fault types while avoiding overfitting [].

(2) Cost-sensitive learning: This approach assigns higher misclassification penalties to minority classes during model training. For support vector machines, this translates to asymmetric penalty parameters C+ and C− for positive and negative classes, respectively, forcing the decision boundary to shift toward the majority class [].

(3) Focal loss: Originally developed for object detection, focal loss modifies the standard cross-entropy loss by down-weighting well-classified examples and focusing on hard misclassified samples. This is particularly effective for deep learning models handling severe class imbalance as it automatically adjusts the learning focus during training without requiring sample rebalancing [].

Recent studies have demonstrated the effectiveness of these methods in similar industrial applications. For instance, Zhou et al. [] achieved a 28% improvement in rare fault detection accuracy by combining SMOTE with ensemble boosting in chemical process monitoring, while Zhang et al. [] reported focal loss reducing false negatives by 41% in rotating machinery fault diagnosis compared to traditional sampling methods.

5.1.2. Unsupervised Learning Method

In unsupervised learning, machines can autonomously use different measurement methods to classify highly similar data into the same category and explore the structure and patterns of the data. Since the data used for model training is not labeled with pre-defined labels, unsupervised learning methods are gaining popularity in anomaly data recognition [].

Unsupervised learning methods are mainly used for tasks such as clustering (e.g., clustering different behaviors of people towards something), dimensionality reduction (e.g., principal component analysis to reduce high dimensional data to low dimensions), etc. The k-means method and the Isolation Forest algorithm are typical unsupervised learning methods.

(1) K-means Method:

The K-means clustering algorithm is a clustering analysis method that solves problems through an iterative process. In fluidized bed fault diagnosis, the K-means algorithm can effectively identify abnormal operating conditions and fault modes by clustering analysis of multidimensional operating parameters such as temperature and pressure. It can partition datasets without prior knowledge [] and is often used in data mining and machine learning. The core idea of this algorithm is to divide data into different clusters based on their similarity. It first assigns the data points to the nearest cluster center and then updates the cluster centers to minimize the sum of distances between data points within each cluster and their centers. Through this process, the algorithm can classify and cluster the data [].