Effects of Varying the Fin Width, Fin Height, Gate Dielectric Material, and Gate Length on the DC and RF Performance of a 14-nm SOI FinFET Structure

Abstract

1. Introduction

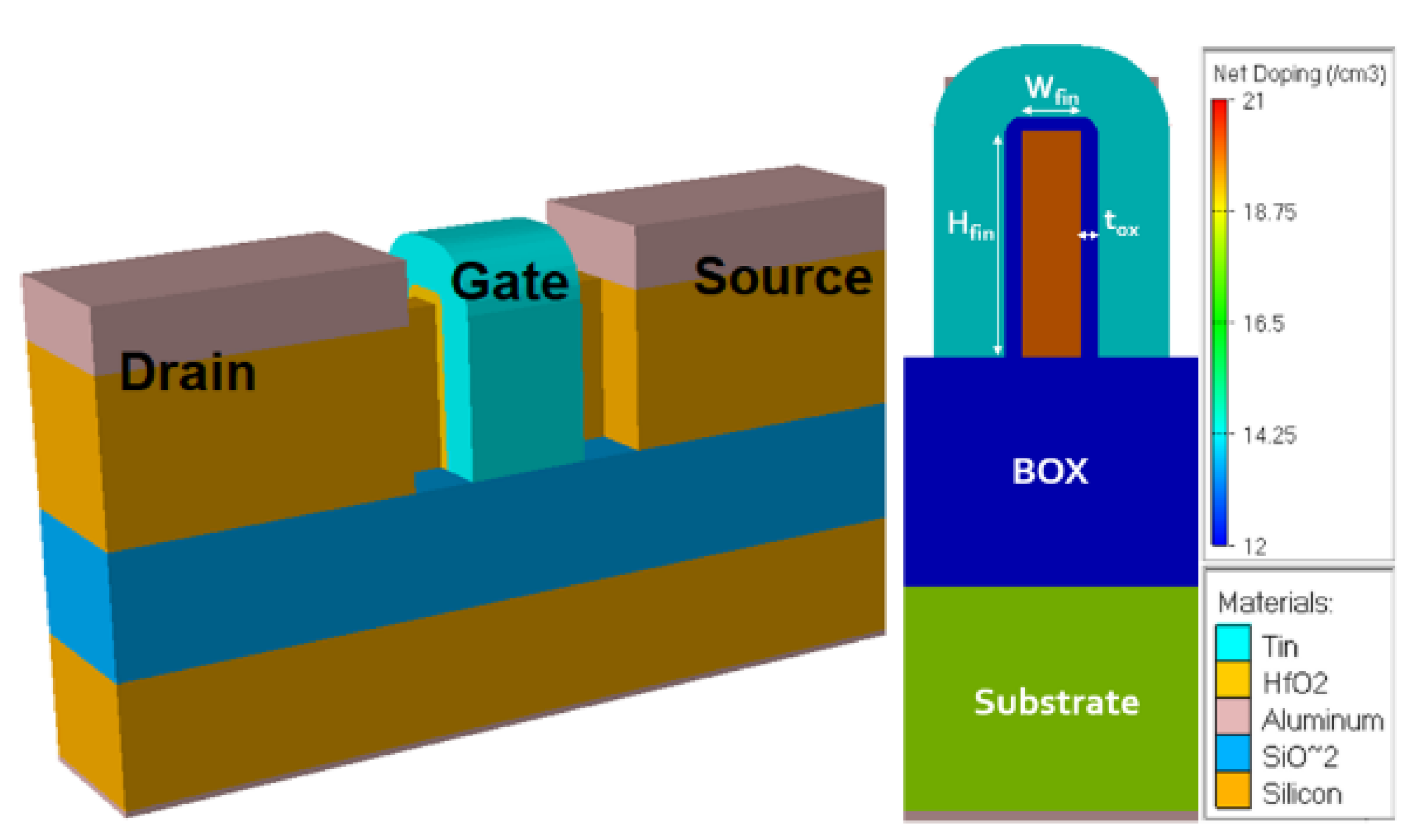

2. Device Structure

3. Simulation Model

Device Validation

4. Results and Discussion

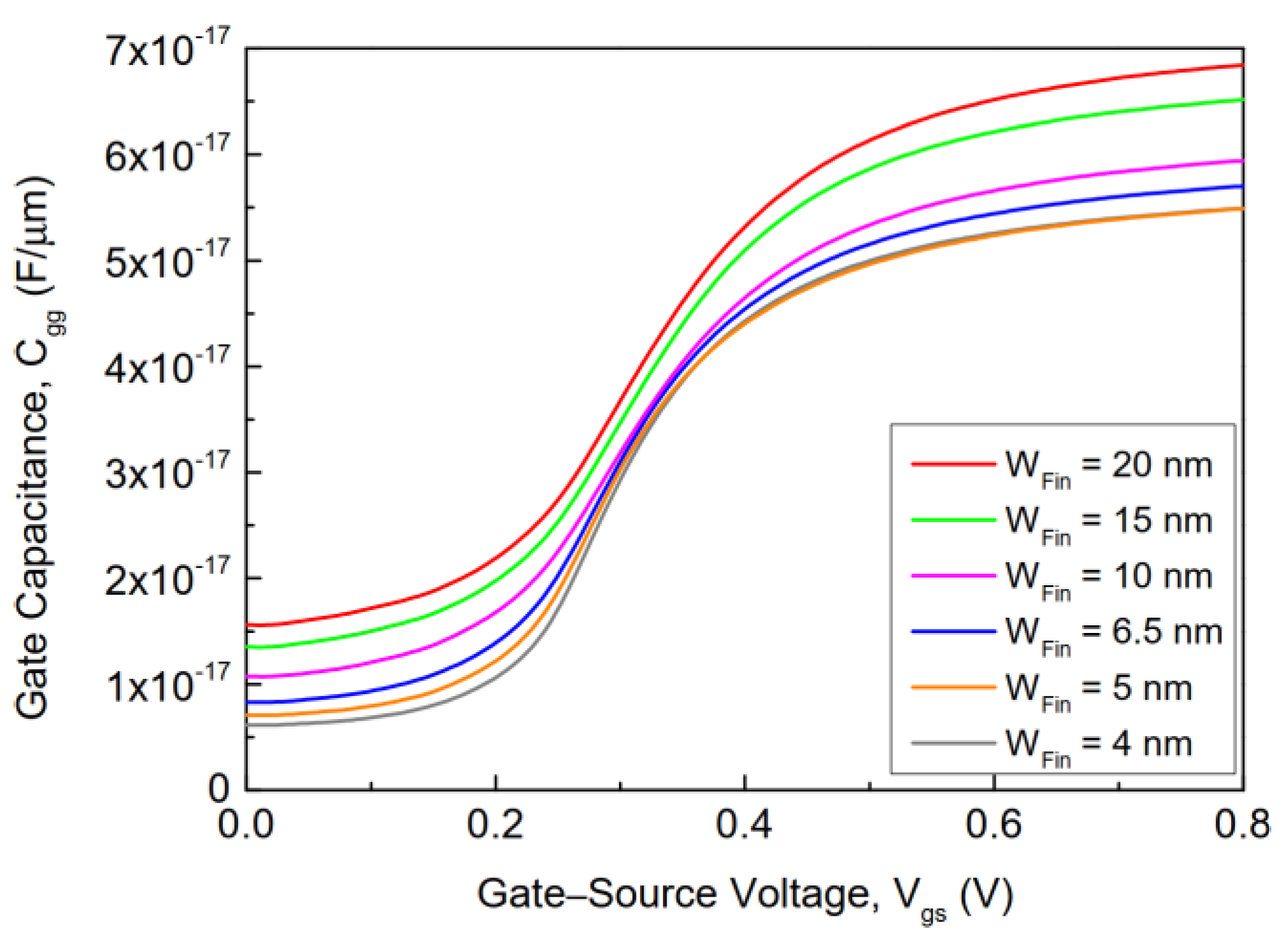

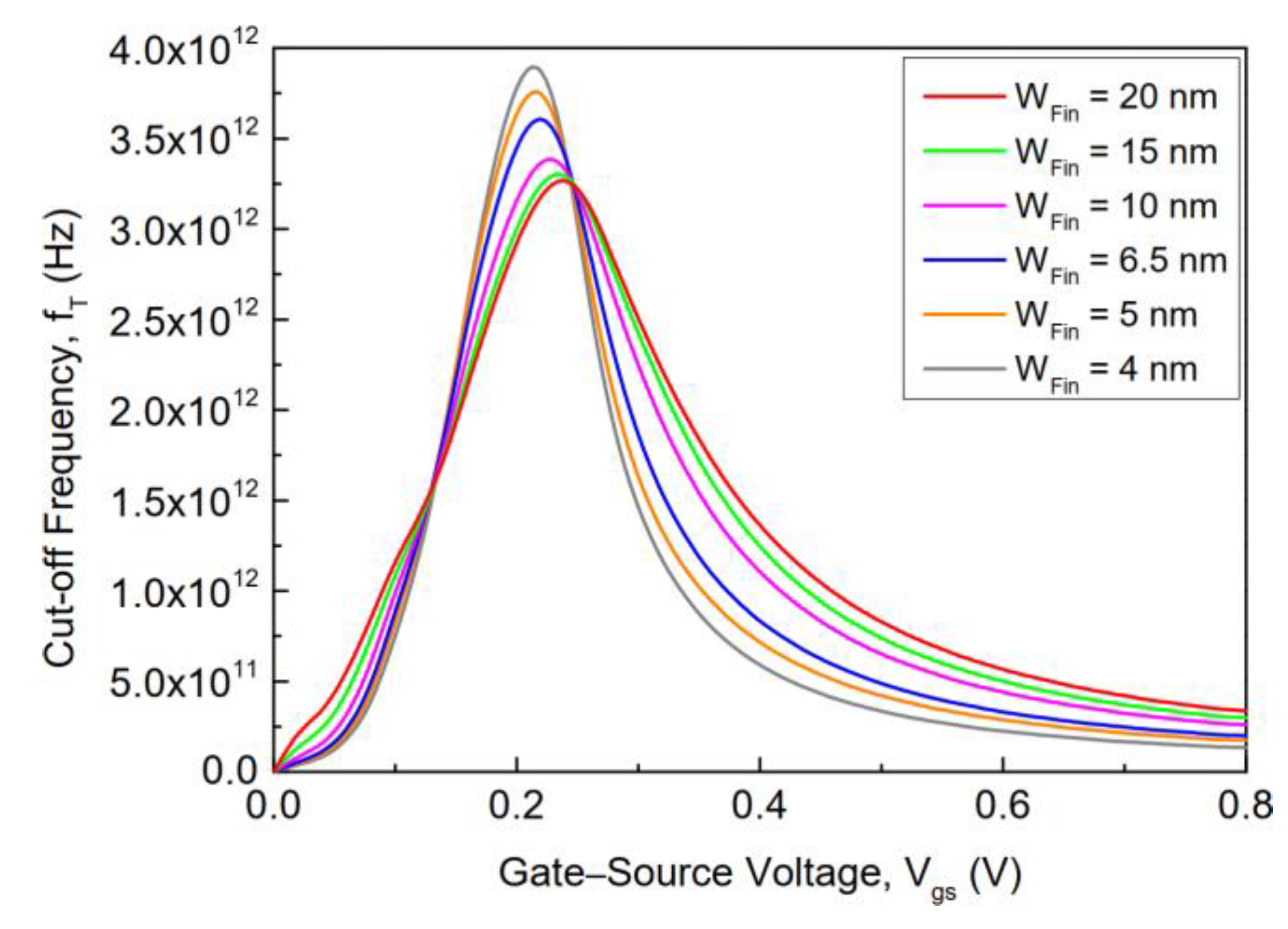

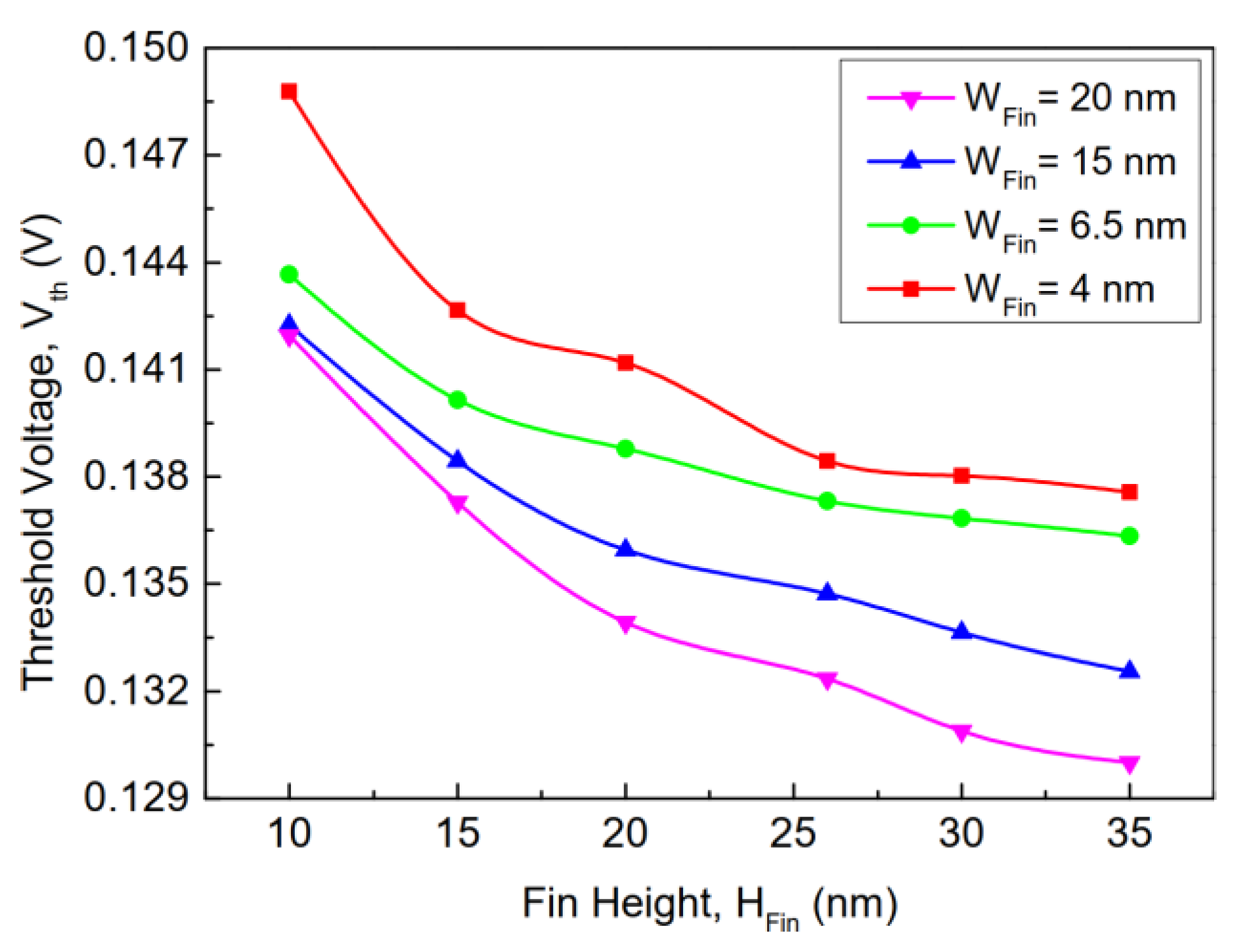

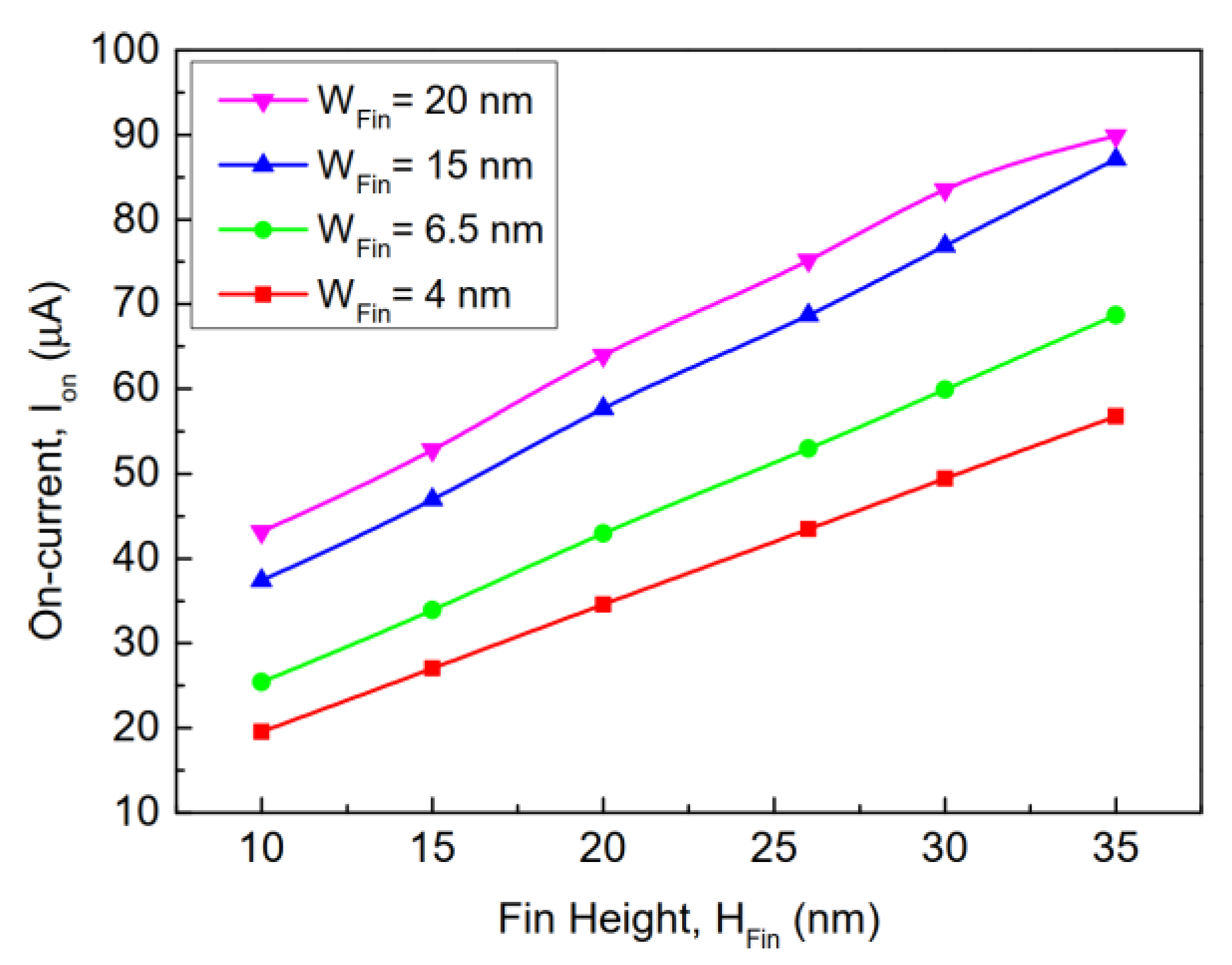

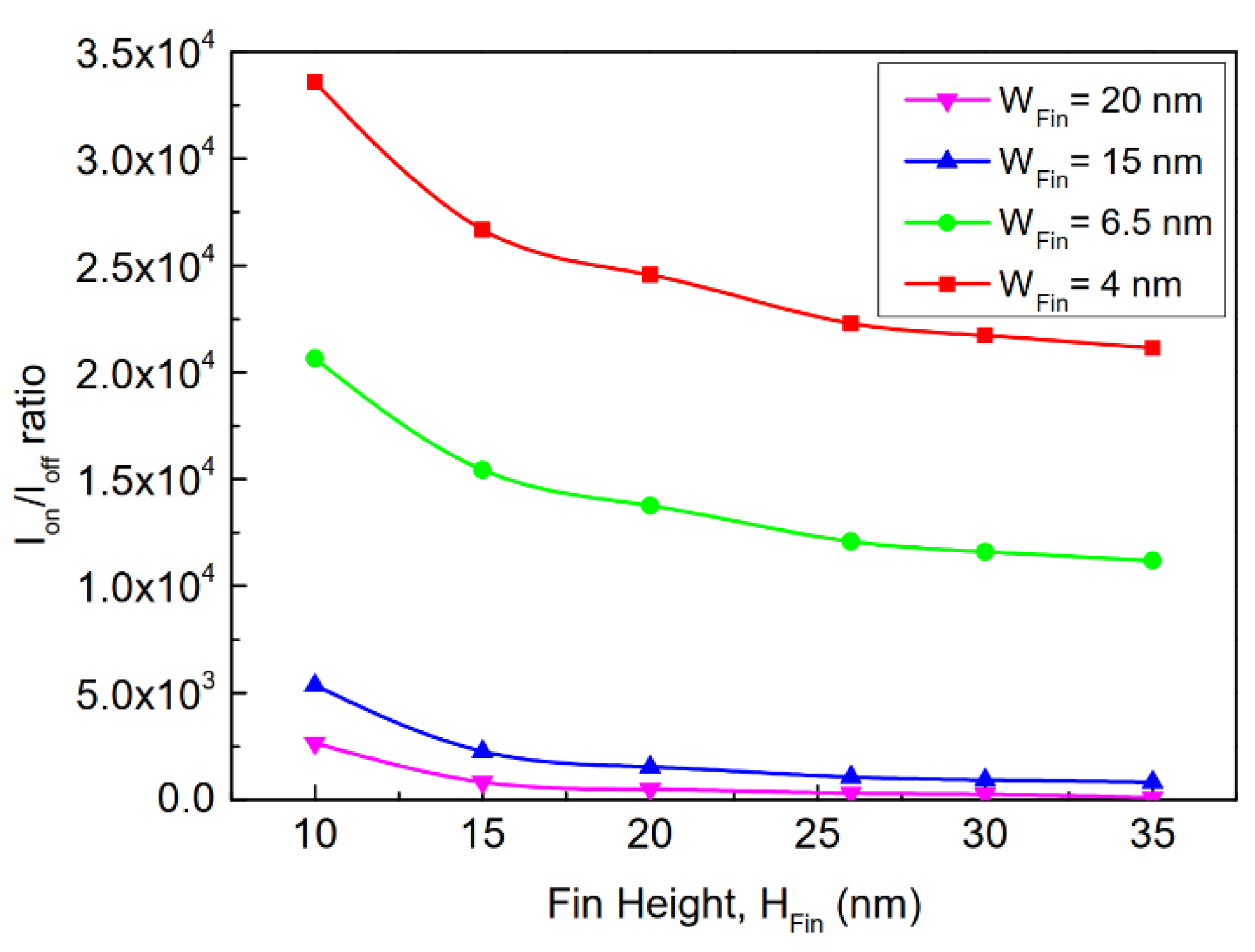

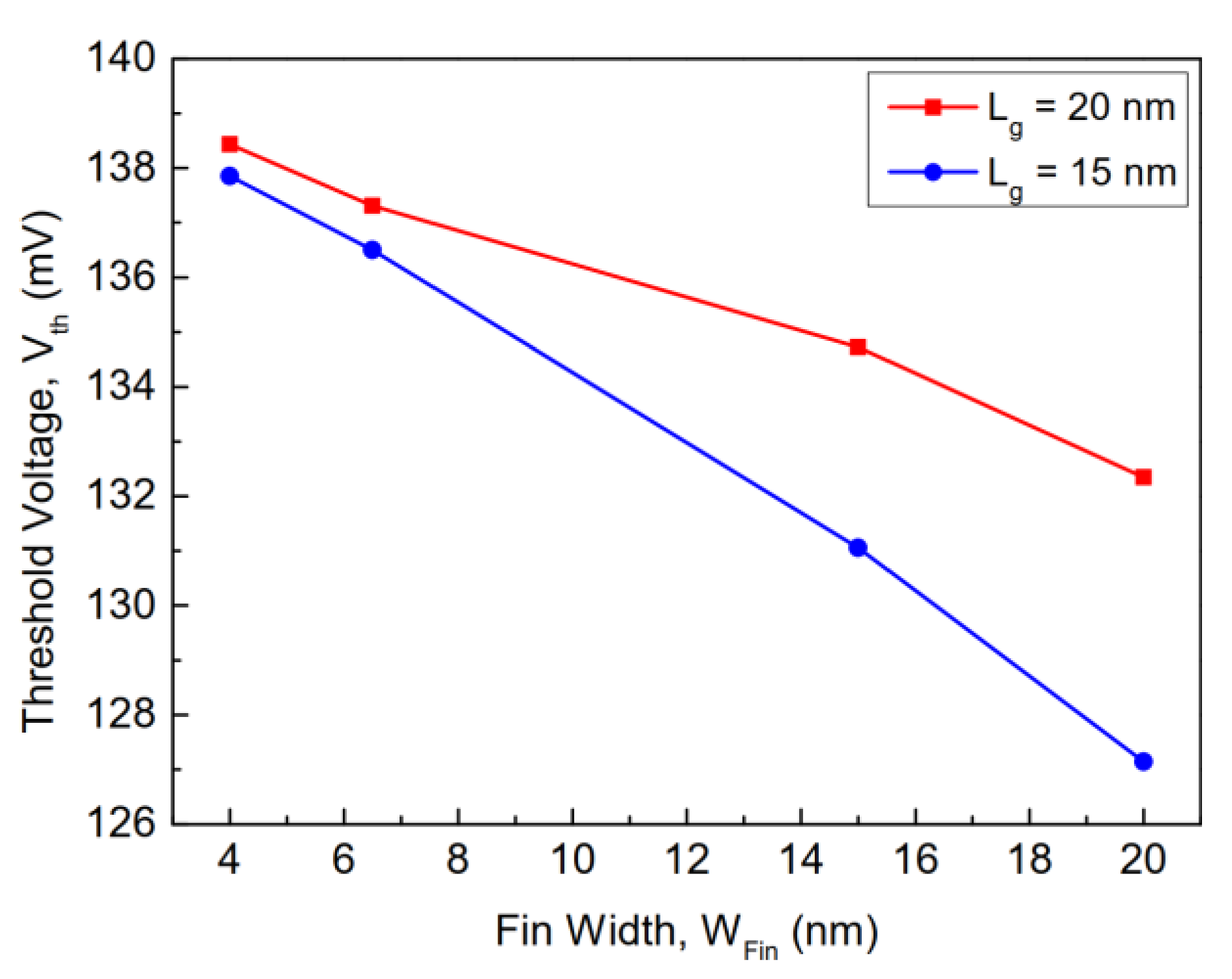

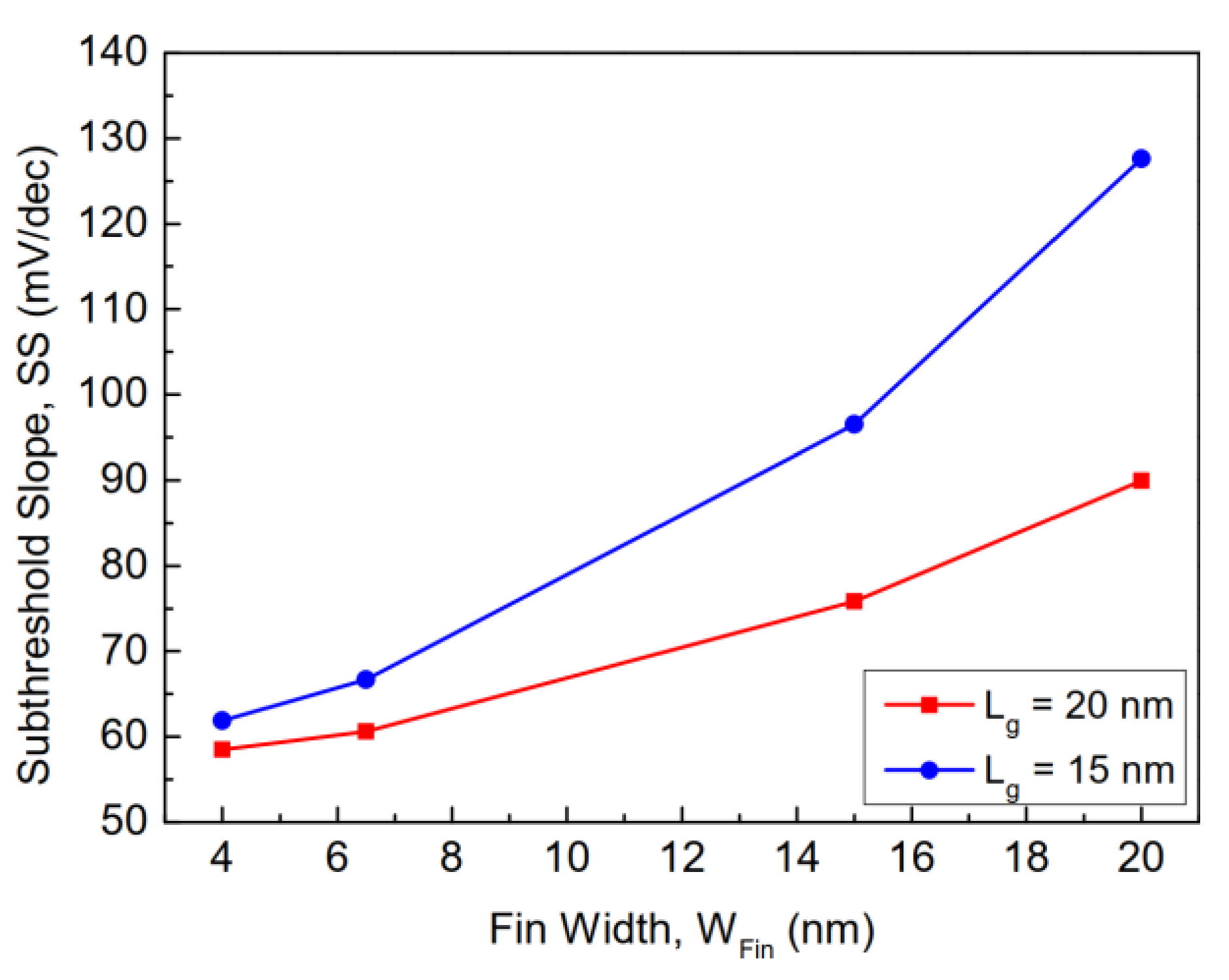

4.1. Effects of the Fin Width/Height on Device Performance

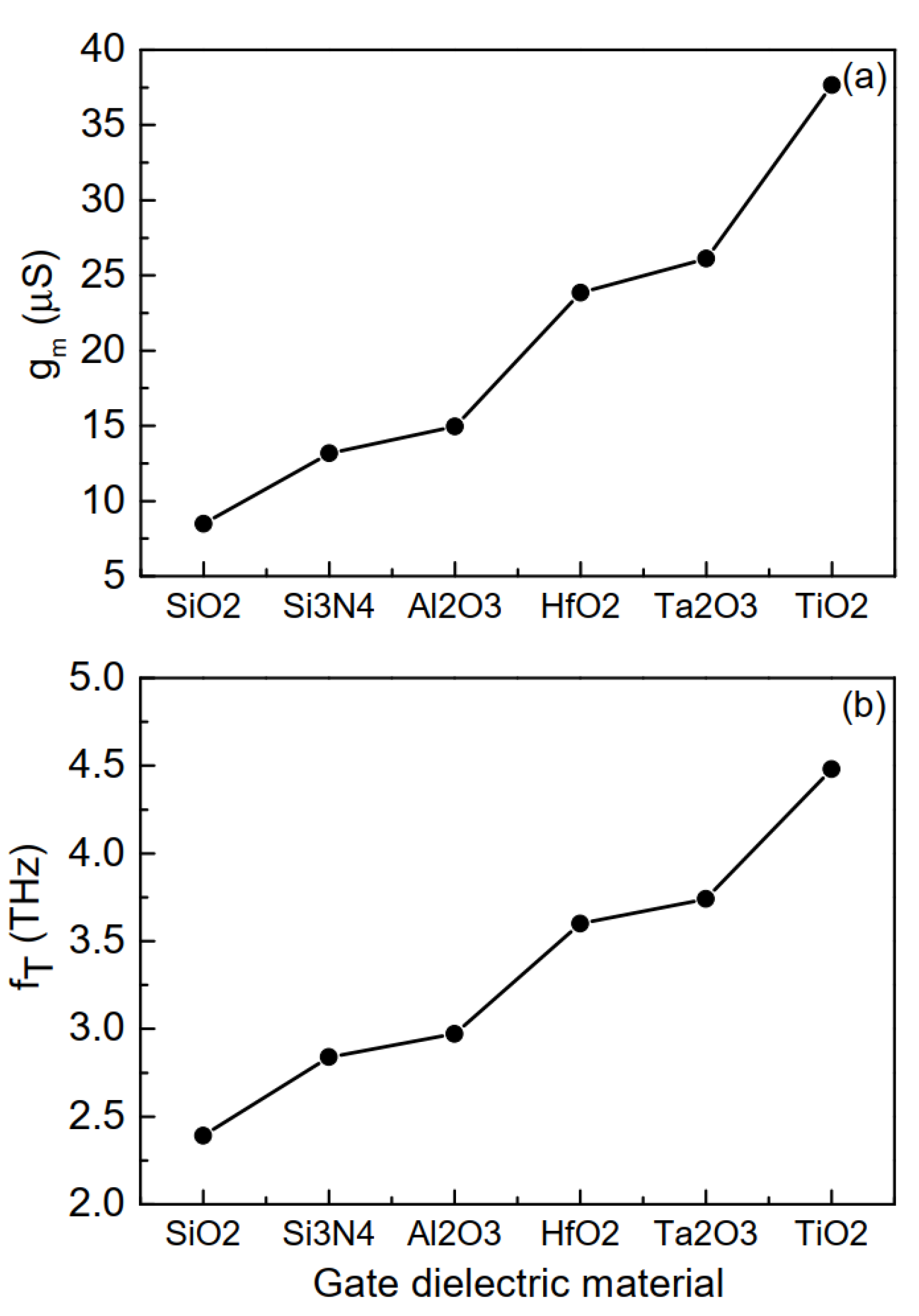

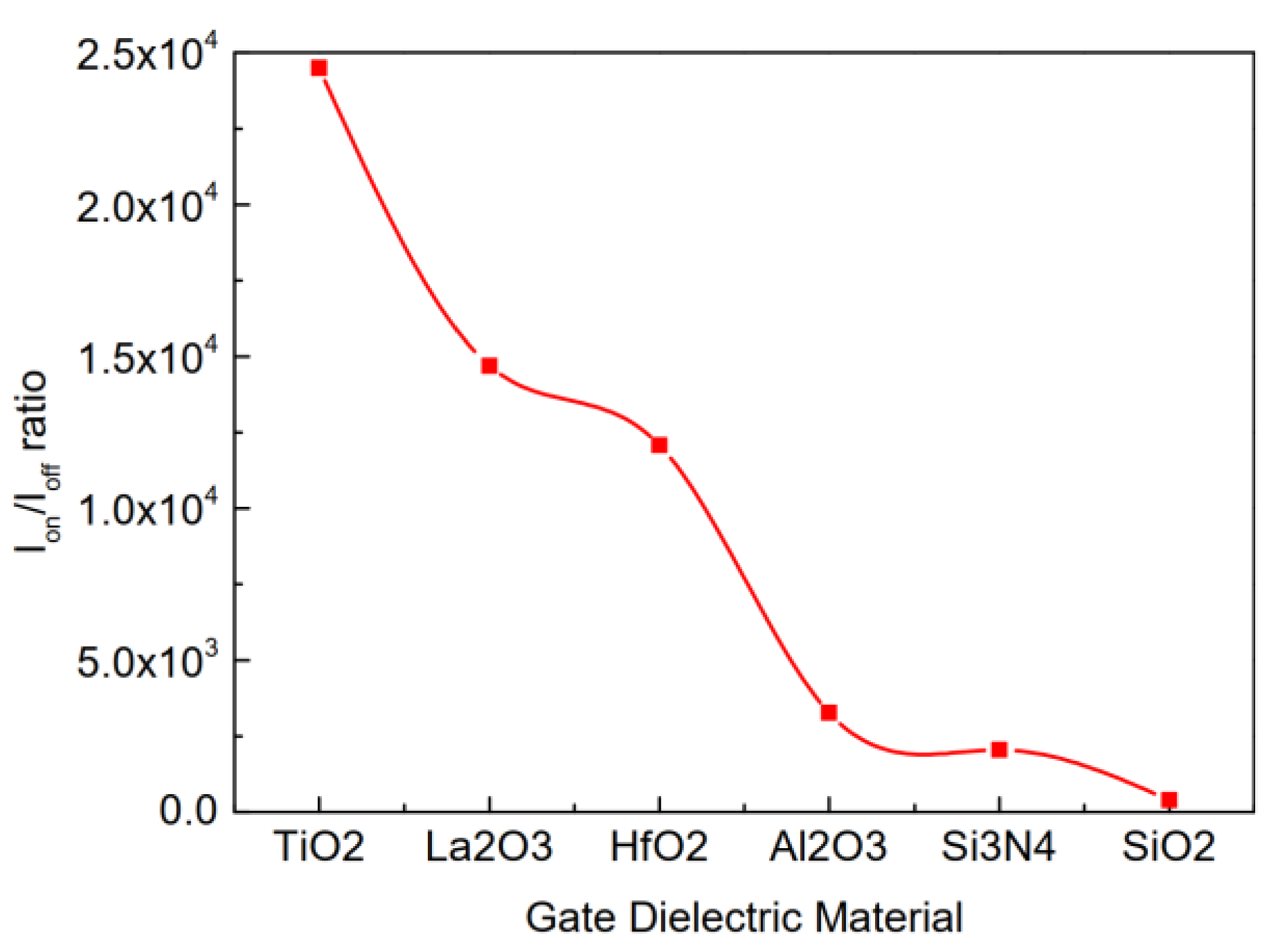

4.2. Impact of High-k Dielectric Materials on Device Performance

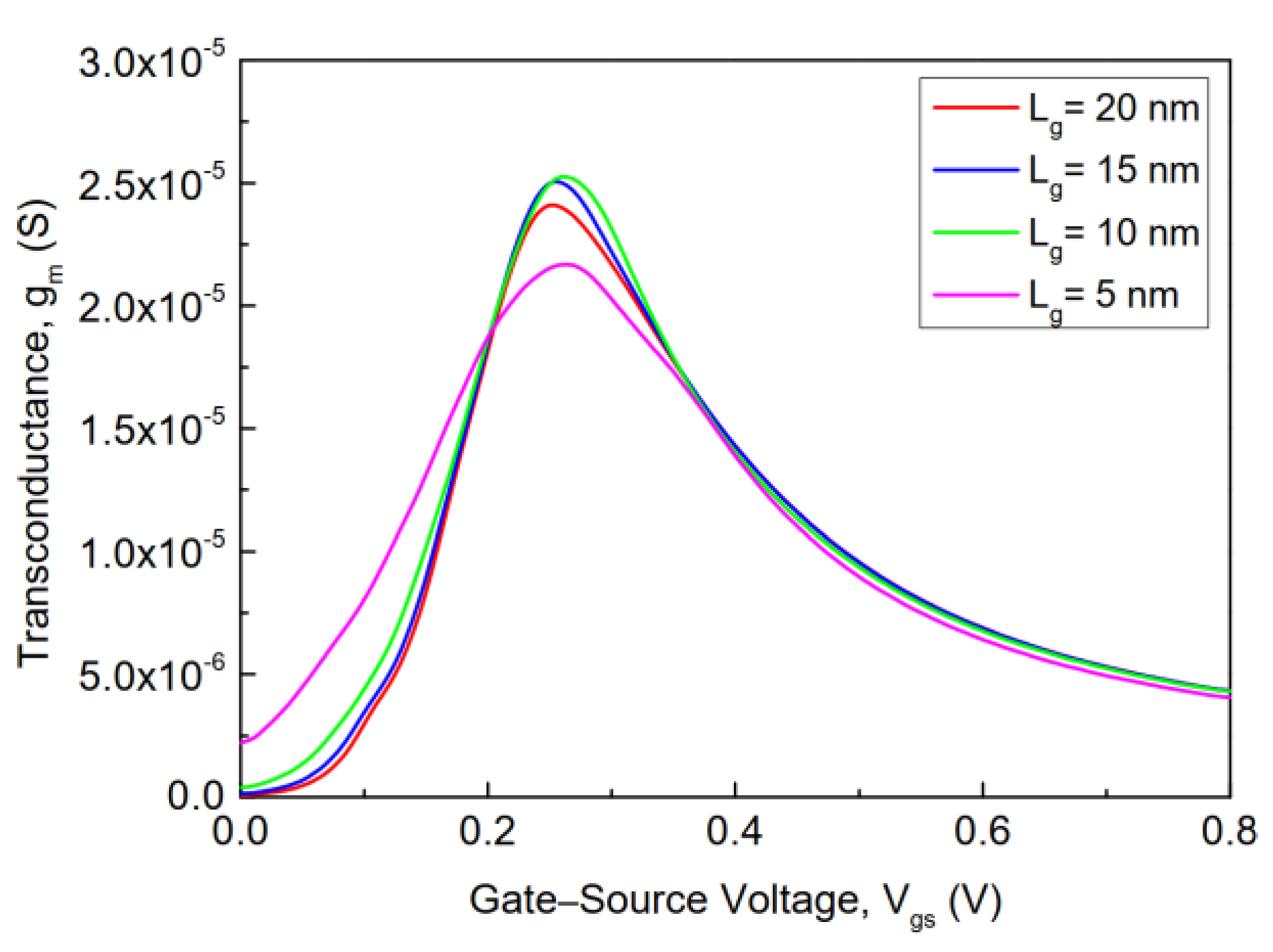

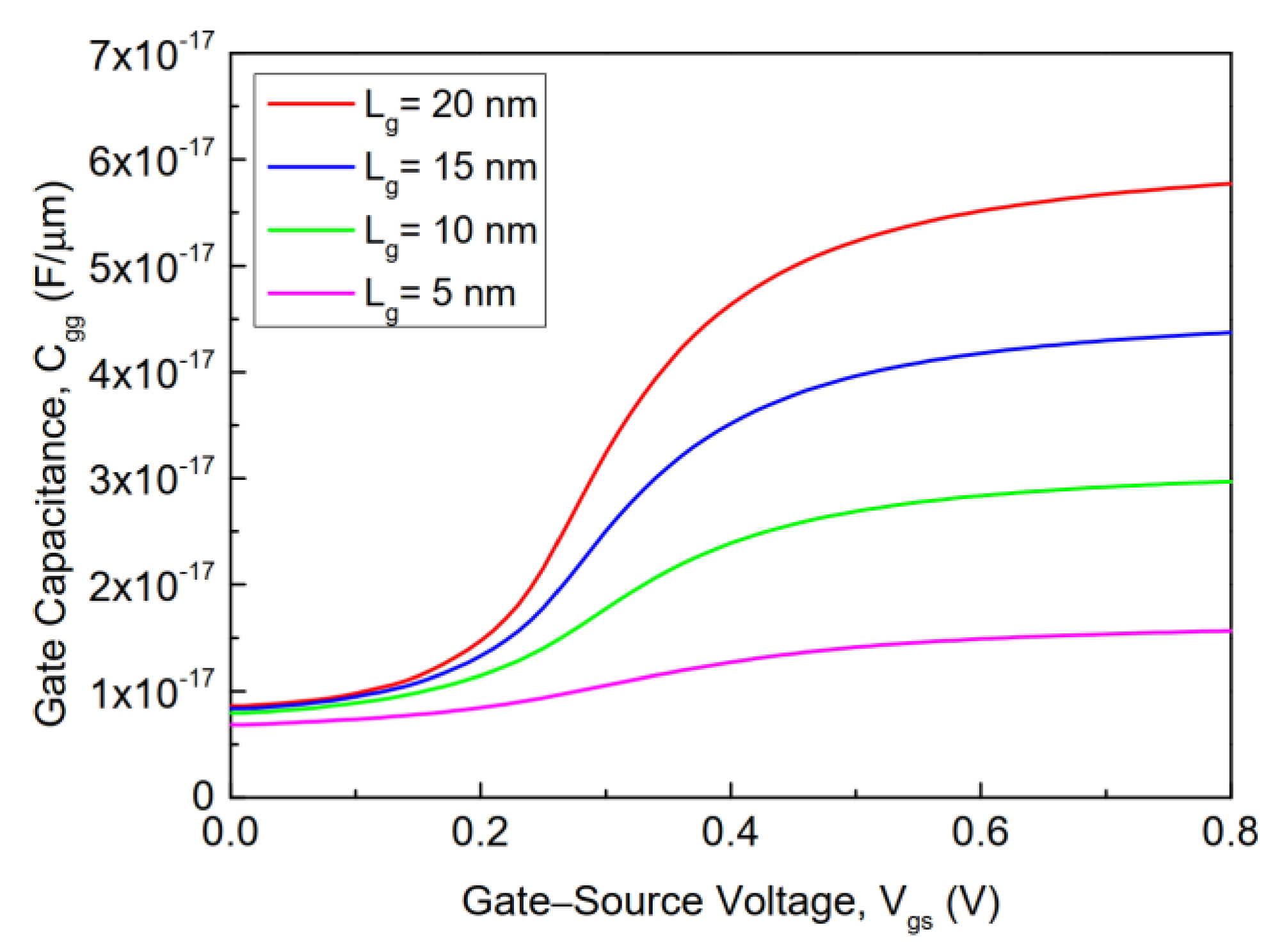

4.3. Impact of the Gate Length on Device Performance

4.4. Device Optimization

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, C.H.; Greene, B.; Narasimha, S.; Cai, J.; Bryant, A.; Radens, C.; Narayanan, V.; Linder, B.; Ho, H.; Aiyar, A.; et al. High performance 14nm SOI FinFET CMOS technology with 0.0174 µm 2 embedded DRAM and 15 levels of Cu metallization. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 3–8. [Google Scholar]

- Sun, J.; Li, X.; Sun, Y.; Shi, Y. Impact of geometry, doping, temperature, and boundary conductivity on thermal characteristics of 14-nm bulk and SOI FinFETs. IEEE Trans. Device Mater. Reliab. 2020, 20, 119–127. [Google Scholar] [CrossRef]

- Kumar, U.S.; Rao, V.R. A thermal-aware device design considerations for nanoscale SOI and bulk FinFETs. IEEE Trans. Electron Devices 2015, 63, 280–287. [Google Scholar] [CrossRef]

- Jena, K.; Swain, R.; Lenka, T.R. Effect of thin gate dielectrics on DC, radio frequency and linearity characteristics of lattice-matched AlInN/AlN/GaN metal–oxide–semiconductor high electron mobility transistor. IET Circuits Devices Syst. 2016, 10, 423–432. [Google Scholar] [CrossRef]

- Mishra, S.; Parihar, N.; Anandkrishnan, R.; Dabhi, C.K.; Chauhan, Y.S.; Mahapatra, S. NBTI-related variability impact on 14-nm node FinFET SRAM performance and static power: Correlation to time zero fluctuations. IEEE Trans. Electron Devices 2018, 65, 4846–4853. [Google Scholar] [CrossRef]

- Boukortt, N.; Patanè, S.; Crupi, G. 3D investigation of 8-nm tapered n-FinFET model. Silicon 2020, 12, 1585–1591. [Google Scholar] [CrossRef]

- Boukortt, N.; Hadri, B.; Patanè, S.; Caddemi, A.; Crupi, G. Investigation on TG n-FinFET parameters by varying channel doping concentration and gate length. Silicon 2017, 9, 885–893. [Google Scholar] [CrossRef]

- Yoon, J.-S.; Baek, R.-H. Device Design Guideline of 5-nm-Node FinFETs and Nanosheet FETs for Analog/RF Applications. IEEE Access. 2020, 8, 189395–189403. [Google Scholar] [CrossRef]

- Boukortt, N.; Hadri, B.; Patanè, S.; Caddemi, A.; Crupi, G. Electrical Characteristics of 8-nm SOI n-FinFETs. Silicon 2016, 8, 497–503. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; Hadri, B.; Caddemi, A.; Crupi, G.; Patane, S. 3-D Simulation of Nanoscale SOI n-FinFET at a Gate Length of 8 nm Using ATLAS SILVACO. Trans. Electr. Electron. Mater. 2015, 16, 156–161. [Google Scholar] [CrossRef][Green Version]

- Boukortt, N.E.I.; Hadri, B.; Caddemi, A.; Crupi, G.; Patane, S. Temperature Dependence of Electrical Parameters of Silicon-on-Insulator Triple Gate n-Channel Fin Field Effect Transistor. Trans. Electr. Electron. Mater. 2016, 17, 329–334. [Google Scholar] [CrossRef]

- Natarajan, S.; Agostinelli, M.; Akbar, S.; Bost, M.; Bowonder, A.; Chikarmane, V.; Chouksey, S.; Dasgupta, A.; Fischer, K.; Fu, Q.; et al. A 14 nm logic technology featuring 2 nd-generation finfet, air-gapped interconnects, self-aligned double patterning and a 0.0588 µm 2 sram cell size. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 3–7. [Google Scholar]

- User Guide Manual, ATLAS, Version 5.28.1.R USA; Silvaco Inc.: San Francisco, CA, USA, 2019.

- Subramanian, V.; Parvais, B.; Borremans, J.; Mercha, A.; Linten, D.; Wambacq, P.; Loo, J.; Dehan, M.; Gustin, C.; Collaert, N.; et al. Planar Bulk MOSFETs Versus FinFETs: An Analog/RF Perspective. IEEE Trans. Electron. Devices 2006, 53, 3071–3079. [Google Scholar] [CrossRef]

- Martinez-Lopez, A.G.; Cerdeira, A.; Tinoco, J.C.; Alvarado, J.; Padron, W.Y.; Mendoza, C.; Raskin, J.-P. RF modeling of 40-nm SOI triple-gate FinFET. Int. J. Numer. Model. 2015, 28, 465–478. [Google Scholar] [CrossRef]

- Crupi, G.; Schreurs, D.M.P.; Caddemi, A. Effects of gate-length scaling on microwave MOSFET performance. Electronics 2017, 6, 62. [Google Scholar] [CrossRef]

- Sreenivasulu, V.B.; Narendar, V. A comprehensive analysis of junctionless tri-gate (TG) FinFET towards low-power and high-frequency applications at 5-nm gate length. Silicon 2021, 1–13. [Google Scholar] [CrossRef]

- Huang, S.E.; Yu, C.L.; Su, P. Investigation of fin-width sensitivity of threshold voltage for InGaAs and Si negative-capacitance FinFETs considering quantum-confinement effect. IEEE Trans. Electron Devices 2019, 66, 2538–2543. [Google Scholar] [CrossRef]

- Colinge, J.P. Multiple-gate soi mosfets. Solid-State Electron. 2004, 48, 897–905. [Google Scholar] [CrossRef]

- Kurniawan, E.D.; Yang, H.; Lin, C.C.; Wu, Y.C. Effect of fin shape of tapered FinFETs on the device performance in 5-nm node CMOS technology. Microelectron. Reliab. 2018, 83, 254–259. [Google Scholar] [CrossRef]

- Thorp, J.S.; Evans, D.; Al-Naief, M.; Akhtaruzzaman, M. The dielectric properties of aluminium nitride substrates for microelectronics packaging. J. Mater. Sci. 1990, 25, 4965–4971. [Google Scholar] [CrossRef]

- Gorchichko, M.; Cao, Y.; Zhang, E.X.; Yan, D.; Gong, H.; Zhao, S.E.; Wang, P.; Jiang, R.; Liang, C.; Fleetwood, D.M.; et al. Total-ionizing-dose effects and low-frequency noise in 30-nm gate-length bulk and SOI FinFETs with SiO2/HfO2 gate dielectrics. IEEE Trans. Nucl. Sci. 2019, 67, 245–252. [Google Scholar] [CrossRef]

- Crupi, G.; Caddemi, A.; Schreurs, D.M.M.-P.; Wiatr, W.; Mercha, A. Microwave noise modeling of FinFETs. Solid-State Electron. 2011, 56, 18–22. [Google Scholar] [CrossRef]

- Crupi, G.; Schreurs, D.M.M.-P.; Caddemi, A.; Angelov, I.; Homayouni, M.; Raffo, A.; Vannini, G.; Parvais, B. Purely analytical extraction of an improved nonlinear FinFET model including non-quasi-static effects. Microelectron. Eng. 2009, 86, 2283–2289. [Google Scholar] [CrossRef]

- Jin, X.; Ou, J.J.; Chen, C.H.; Liu, W.; Deen, M.J.; Gray, P.R.; Hu, C. An effective gate resistance model for CMOS RF and noise modeling. In Proceedings of the International Electron Devices Meeting 1998. Technical Digest (Cat. No.98CH36217), San Francisco, CA, USA, 6–9 December 1998; pp. 961–964. [Google Scholar]

- Park, J.; Kim, J.; Showdhury, S.; Shin, C.; Rhee, H.; Yeo, M.S.; Cho, E.C.; Yi, J. Electrical Characteristics of Bulk FinFET According to Spacer Length. Electronics 2020, 9, 1283. [Google Scholar] [CrossRef]

- Lee, K.L.; He, R.Y.; Huang, H.W.; Yeh, C.C.; Li, I.H.; Cheng, O. A study of fin width effect on the performance of FinFET. In Proceedings of the 2015 IEEE 22nd International Symposium on the Physical and Failure Analysis of Integrated Circuits, Hsinchu, Taiwan, 29 June–2 July 2015; pp. 503–504. [Google Scholar]

- Zhang, J.; Niu, G.; Cai, W.; Imura, K. Comparison of PMOS and NMOS in a 14-nm RF FinFET technology: RF Characteristics and Compact Modeling. In Proceedings of the 2020 IEEE 20th Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems (SiRF), San Antonio, TX, USA, 26–29 January 2020; pp. 47–49. [Google Scholar]

- Wang, G.; Qin, C.; Yin, H.; Luo, J.; Duan, N.; Yang, P.; Gao, X.; Yang, T.; Li, J.; Yan, J.; et al. Study of SiGe selective epitaxial process integration with high-k and metal gate for 16/14nm nodes FinFET technology. Microelectron. Eng. 2016, 163, 49–54. [Google Scholar] [CrossRef]

- Mah, S.K.; Ker, P.J.; Ahmad, I.; Zainul Abidin, N.F.; Ali Gamel, M.M. A Feasible Alternative to FDSOI and FinFET: Optimization of W/La2O3/Si Planar PMOS with 14 nm Gate-Length. Materials 2021, 14, 5721. [Google Scholar] [CrossRef]

- Santermans, S.; Barge, D.; Hellings, G.; Mori, C.B.; Migacz, K.J.; Rip, J.; Spampinato, V.; Vos, R.; Du Bois, B.; Chaudhuri, A.R.; et al. 50 nm Gate Length FinFET Biosensor & the Outlook for Single-Molecule Detection. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEEE-IEDM), San Francisco, CA, USA, 12–18 December 2020; pp. 35.4.1–35.4.4. [Google Scholar]

- Rani, D.; Rollo, S.; Olthuis, W.; Krishnamoorthy, S.; Pascual García, C. Combining Chemical Functionalization and FinFET Geometry for Field Effect Sensors as Accessible Technology to Optimize pH Sensing. Chemosensors 2021, 9, 20. [Google Scholar] [CrossRef]

- Medina-Bailon, C.; Kumar, N.; Dhar, R.P.S.; Todorova, I.; Lenoble, D.; Georgiev, V.P.; García, C.P. Comprehensive Analytical Modelling of an Absolute pH Sensor. Sensors 2021, 21, 5190. [Google Scholar] [CrossRef]

- Coluccio, M.L.; Pullano, S.A.; Vismara, M.F.M.; Coppedè, N.; Perozziello, G.; Candeloro, P.; Gentile, F.; Malara, N. Emerging Designs of Electronic Devices in Biomedicine. Micromachines 2020, 11, 123. [Google Scholar] [CrossRef] [PubMed]

- Dixit, A.; Samajdar, D.P.; Chauhan, V. Sensitivity Analysis of a Novel Negative Capacitance FinFET for Label-Free Biosensing. IEEE Trans. Electron Devices 2021, 68, 5204–5210. [Google Scholar] [CrossRef]

- Daneshgar, S.; Dasgupta, K.; Thakkar, C.; Chakrabarti, A.; Levy, C.S.; Jaussi, J.E.; Casper, B. High-Power Generation for mm-Wave 5G Power Amplifiers in Deep Submicrometer Planar and FinFET Bulk CMOS. IEEE Trans. Microw. Theory Tech. 2020, 68, 2041–2056. [Google Scholar] [CrossRef]

- Whittaker, K.; Rizkalla, M.; Ytterdal, T. A Low Power FinFET Charge Pump for Energy Harvesting Applications. In Proceedings of the 2020 IEEE 63rd International Midwest Symposium on Circuits and Systems (MWSCAS), Springfield, MA, USA, 9–12 August 2020; pp. 1048–1051. [Google Scholar] [CrossRef]

- Cai, C.; Gao, S.; Zhao, P.; Yu, J.; Zhao, K.; Xu, L.; Li, D.; He, Z.; Yang, G.; Liu, T.; et al. SEE Sensitivity Evaluation for Commercial 16 nm SRAM-FPGA. Electronics 2019, 8, 1531. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Channel length, Lg | 20 nm |

| Fin height, Hfin | 26 nm |

| Fin width, Wfin | 6.5 nm |

| S/D length, LS/D | 50 nm |

| S/D extension length, LS/D | 7 nm |

| Buried oxide (SiO2) thickness, tBOX | 50 nm |

| Gate dielectric (HfO2) thickness, tox | 4 nm |

| Channel doping (boron, p-type), Nch | 1016 cm−3 |

| S/D doping (arsenic, n-type), NS/D | 1021 cm−3 |

| S/D extension doping (arsenic, n-type) | 1019 cm−3 |

| Si substrate doping (boron, p-type) | 1016 cm−3 |

| Gate work function (TiN (Sn), Φm) | 4.32 eV |

| Device Characteristics | This Work | Ref. [1] | Ref. [2] |

|---|---|---|---|

| Vdd (mV) | 800 | 800 | 800 |

| Vth, lin (mV) | 137 | - | 162 |

| Vth, sat (mV) | 120 | - | 147 |

| Ion, lin (µA) | 8.11 | 7.06 | 7.64 |

| Ion, sat (µA) | 53.6 | - | 58.15 |

| Ioff, lin (nA) | 1.89 | 2.51 | 1.43 |

| Ioff, sat (nA) | 4.22 | - | 2.51 |

| Ion, lin/Ioff, lin | 4.29 × 103 | - | 5.32 × 103 |

| Ion, sat/Ioff, sat | 1.27 × 104 | - | 2.32 × 104 |

| SSlin (mV/dec) | 61 | 67 | 62.83 |

| SSsat (mV/dec) | 64.91 | - | 63.45 |

| DIBL (mV/V) | 43.32 | 55 | 20.5 |

| Device Characteristics | Calibrated Device | Optimized Device | FinFET [28] | FinFET (IRDS 2020) [29] | FinFET [30] |

|---|---|---|---|---|---|

| Vdd (mV) | 800 | 800 | - | - | - |

| Vth, lin (mV) | 137.31 | 143.6 | - | - | - |

| Vth, sat (mV) | 120 | 110.5 | - | 240 | 233.55 |

| Ion, lin (µA) | 8.11 | 17.49 | - | - | - |

| Ion, sat (µA) | 53.6 | 148.93 | - | 68.62 | 10.9 (/µA) |

| Ioff, lin (nA) | 1.89 | 1.89 | - | - | - |

| Ioff, sat (nA) | 4.22 | 5.35 | - | 1.76 | 80.6 (/µA) |

| Ion, lin/Ioff, lin | 4.29 × 103 | 9.24 × 103 | - | - | - |

| Ion, sat/Ioff, sat | 1.27 × 104 | 2.77 × 104 | - | 38.933 | 135.236 |

| SSlin (mV/dec) | 60.60 | 58.80 | 80 | - | - |

| SSsat (mV/dec) | 64.91 | 58.22 | - | 72 | 76.98 |

| DIBL (mV/V) | 43.32 | 22.65 | 75 | 50 | 68.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boukortt, N.E.I.; Lenka, T.R.; Patanè, S.; Crupi, G. Effects of Varying the Fin Width, Fin Height, Gate Dielectric Material, and Gate Length on the DC and RF Performance of a 14-nm SOI FinFET Structure. Electronics 2022, 11, 91. https://doi.org/10.3390/electronics11010091

Boukortt NEI, Lenka TR, Patanè S, Crupi G. Effects of Varying the Fin Width, Fin Height, Gate Dielectric Material, and Gate Length on the DC and RF Performance of a 14-nm SOI FinFET Structure. Electronics. 2022; 11(1):91. https://doi.org/10.3390/electronics11010091

Chicago/Turabian StyleBoukortt, Nour El I., Trupti Ranjan Lenka, Salvatore Patanè, and Giovanni Crupi. 2022. "Effects of Varying the Fin Width, Fin Height, Gate Dielectric Material, and Gate Length on the DC and RF Performance of a 14-nm SOI FinFET Structure" Electronics 11, no. 1: 91. https://doi.org/10.3390/electronics11010091

APA StyleBoukortt, N. E. I., Lenka, T. R., Patanè, S., & Crupi, G. (2022). Effects of Varying the Fin Width, Fin Height, Gate Dielectric Material, and Gate Length on the DC and RF Performance of a 14-nm SOI FinFET Structure. Electronics, 11(1), 91. https://doi.org/10.3390/electronics11010091