Abstract

Adsorbents are used to remove impurities such as carbon monoxide, carbon dioxide, methane, and hydrogen sulfide in the pressure swing adsorption process of biohydrogen production. These impurities are present in the produced gas along with hydrogen and often cause voltage reduction in fuel cells and shorten the lifespan of catalysts. Zeolite A is a typical adsorbent, and more recently, hydroxyl aluminum silicate clay (Has-Clay) and Kanuma clay have been suggested as alternatives. We conducted a life-cycle assessment (LCA) of zeolite A, Has-Clay, and Kanuma clay, and evaluated their environmental impact based on the ReCiPe midpoint method. Kanuma clay had the least impact in all of the environmental categories. The largest contributions for zeolite A and Has-Clay were in the categories of climate change and fossil depletion. In the climate change category, production of 1 kg of Has-Clay and zeolite A was estimated to emit 17.142 kg CO2 eq and 2.352 kg CO2 eq, respectively. In the fossil depletion category, the values were estimated to be 3.999 kg oil eq and 1.039 kg oil eq, respectively. These LCA results will be useful in designing and using adsorbents in pressure swing adsorption processes to meet environmental challenges associated with sustainable biohydrogen production.

1. Introduction

Biohydrogen produced from biomass is receiving increasing attention because of its energy-saving, environmentally friendly, and carbon-neutral properties as compared with many conventional hydrogen-producing processes (e.g., water electrolysis and reformation of hydrocarbon fuels) [1,2,3,4]. Current biomass technologies include thermochemical (pyrolysis, gasification) and biological (biophotolysis, biological water gas shift reaction and fermentation) approaches [1]. Biological processes are mostly operated at ambient temperatures and pressures, so they are less energy intensive and more environmentally attractive than thermochemical processes. In terms of energy and exergy efficiency, gasification offers more potential advantages over most currently used technologies [5,6,7]. With gasification, high hydrogen yields have been achieved by reforming dried biomass with superheated steam, but a significant amount of impurities are also present in the product gas [2]. These impurities mix with hydrochloric acid (HCl), carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), hydrogen sulfide (H2S), and other compounds and hamper the production of biohydrogen, and the performance of further applications, such as fuel cells. During exposure to 5, 10, 20 and 50 ppm H2S/H2, it took 7.2, 2.9, 2.0 and 1.5 h for cell voltage to fall to 0.3 Volts [8]. Similarly, there is damage due to the influence of HCl contamination. A chloride ion concentration as low as 10 ppm could induce platinum dissolution as chloride complexes, which affects performance [9].

A promising method to remove impurities is pressure swing adsorption (PSA), which performs well from an economic perspective [8,9,10,11,12]. PSA for H2 purification usually uses multiple beds, and the adsorption and desorption operations are carried out simultaneously. Each bed has a series of layers of different adsorbents. Prior to designing a PSA process, the preferred adsorbent must be chosen. Typical adsorbent is zeolite A, which has often been used to absorb CO and/or CO2 [10,13,14,15]; it is a synthetic zeolite developed as a detergent builder [16,17]. Zeolite A also has shown higher adsorption capacities for H2S [18]. To extend the adsorption range in a lower pressure range, hydroxyl aluminum silicate clay (Has-Clay) has been introduced to the PSA process and showed high selectivity for CO2 and H2S in 0.1–0.6 MPaG [19]. Has-Clay is a complex of hydroxyl aluminum silicate and low crystalline clay developed as an adsorbent for desiccant air-conditioning systems [20]. Another candidate, Kanuma clay has also been applied to successfully remove HCl in the PSA process [21] (Table 1). It is named after the Kanuma mining region of Tochigi Prefecture, Japan. It is a pumice formed from weathered volcanic ash and is usually used in Bonsai, cosmetics, and water purification systems due to its high moisture content [22]. It has also been applied in the chemical industry sector to remove phosphorus from aqueous solutions [23].

Table 1.

Inventory of zeolite A (1000 kg) [14].

A few reports have addressed the environmental burden of biohydrogen production associated with the PSA process [24,25]. However, they focused on the performance of adsorbents and system optimization of the PSA process, and did not include a life-cycle assessment (LCA) of the production of adsorbents. For a comprehensive discussion of the environmental impact of biohydrogen production in the PSA process, it is necessary to extend the system boundary to include the production of adsorbents [26].

In this report, we aimed to generate a life-cycle inventory (LCI) for the production of Has-Clay and Kanuma clay, and compare the environmental impact of those to zeolite A by using LCA, which were chosen to consider the application of biohydrogen to fuel cells. We also conducted a sensitivity analysis on Has-Clay, by evaluating three different production volumes under laboratory conditions requiring different amounts of energy.

2. Methods

2.1. Goal and System Definition

The goal of this LCA was to estimate the environmental impacts of the material acquisition and manufacture of three adsorbents (zeolite A, Has-Clay, and Kanuma clay) in the PSA process of biohydrogen production and to identify the processes associated with these adsorbents that have the largest negative impacts. The systems were limited in the material acquisition and manufacture of three adsorbents. The LCA was performed according to ISO 14040 standards [27].

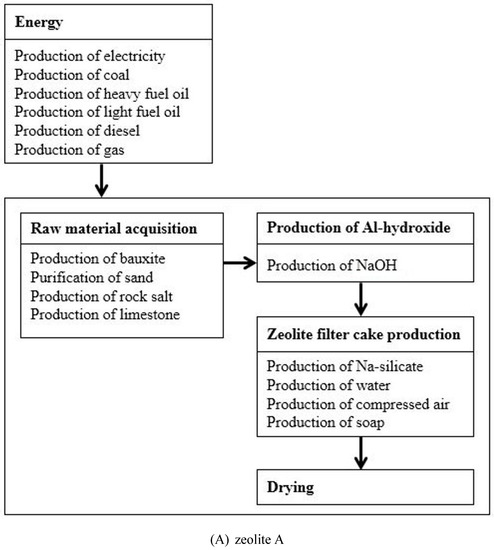

We established the system boundaries and inventories of Has-Clay and Kanuma through interviews and a literature review (Figure 1). Those of zeolite A were obtained from [16]. The functional unit for the comparison among the three adsorbents was defined as 1 kg.

Figure 1.

System boundaries of the process studied in this work: (A) Zeolite A, modified from [14], (B) Has-Clay, and (C) Kanuma clay.

2.2. Life-Cycle Inventory

An LCI of inputs of materials during the material acquisition and the manufacture of the adsorbents was obtained using the Ecoinvent v.3 databases [28], a literature review [16,20], and interviews of relevant personnel at the Kanuma mine, Gunma Prefecture, Japan (Table 1, Table 2 and Table 3). SimaPro v.8.3.0.0 was used to build the life-cycle models. We assumed that infrastructure, such as production facilities that are used repeatedly, were common to all processes and thus did not include them in the assessment.

Table 2.

Inventory of Has-Clay, normalized to three production volumes, 1.1 kg, 5.5 kg, and 11 kg.

Table 3.

Inventory of Kanuma clay, normalized to 1 kg.

2.2.1. Zeolite A

The inventory of zeolite A was obtained from [14], which described the commercial production process of 1000 kg anhydrous zeolite A powder (Table 2). Briefly, the raw materials used to produce this amount of zeolite A are bauxite (762 kg), sand (467 kg), rock salt (222 kg), and limestone (40 kg). Sodium chloride is electrolyzed to produce caustic soda (NaOH), which is used to convert bauxite to sodium aluminate and sand to water glass (sodium silicate). The sodium silicate and sodium aluminate solutions are mixed together, resulting in the formation of amorphous sodium aluminosilicate, which is then hydrothermally crystallized and filtered to yield zeolite A filter cake that is further processed to a powder.

2.2.2. HAS-Clay

The following steps are assumed for the process of producing 1.1 kg of Has-Clay: 0.9 kg of water glass is diluted in 4.5 kg of water to make 0.40 mol/L silica (Si) solution, and 1.7 kg of aluminum sulfate is diluted in 4.0 kg of water to make 0.45 mol/L aluminum (Al) solution (the Si/Al mol ratio is set at 0.89). The Si/Al solutions are mixed and adjusted to pH 7.0 by adding sodium hydroxide. After 1 h of mixing, the solution is heated for 18 h at 98 °C, desalted using 120 kg of water, and dried for 1 h at 250 °C [18] to produce the Has-Clay. As shown in Table 3, we estimated the input amounts for three production volumes (1.1, 5.5, and 11 kg).

2.2.3. Kanuma Clay

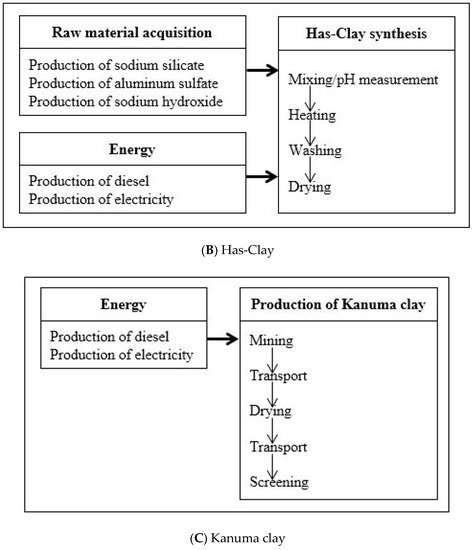

Inventory data were collected from a clay-mining company, Obari Co., Ltd., in Tochigi Prefecture, Japan. The mining area is about 7000 m2 and is located in an open field in Kanuma city. A 1.5 m thick layer of Kanuma pumice is below about 50 cm of surface soil and 2 m of Kanto loam (Figure 2A). The pumice is dug up and transported via 10-ton truck to a drying field. The field has 15 plastic greenhouses about 5 m in width and 50 m in length (Figure 2B). The pumice is naturally dried for about a week in the greenhouses, where a loader spreads and mixes the pumice before it is crushed by a crusher. The dried pumice is then transferred to a screening facility where it is sorted by grain size (Figure 2C). The amounts normalized to 1 kg of clay are presented in Table 4.

Figure 2.

(A) Kanuma clay layer (lower reddish layer) at the Kanuma mine, (B) a drying facility, and (C) a screening facility.

Table 4.

The life cycle impact assessment from raw material acquisition and production processes for 1 kg of zeolite A, Has-Clay, and Kanuma clay.

2.3. Impact Assessment Methods and Impact Categories

We estimated impacts on climate change using SimaPro v.8.3.0.0, where background data were acquired from the Ecoinvent 3.0 database [28]. To calculate the impact of the LCI, the ReCiPe midpoint (H) method was used to cover a wide range impact categories, 18 in this case. ReCiPe is a relatively new method developed based on CML 2001 and Ecoindicator 99. The advantage of ReCiPe relative to other methods is it has the broadest set of midpoint impact categories [29].

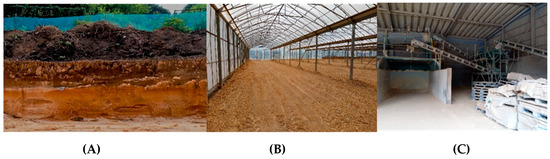

3. Process Contribution

We evaluated the environmental impacts obtained at the midpoint categories of the ReCiPe method (Table 4). For Has-Clay, the inventory process for producing 5.5 kg was adopted because it was the most efficient. Overall, Kanuma clay had the lowest values in all 18 environmental categories, indicating that it would be the most environmentally friendly adsorbent among the three candidates. The two most notable differences between zeolite A and Has-Clay were in the categories of climate change and fossil depletion, and zeolite A was lower in each case.

The relative contributions of the specific inputs to the specific impact categories were assessed for each adsorbent. The input contributions describe in detail which processes contribute to each environmental impact. The greatest adverse impacts were in the climate change and fossil depletion categories for each adsorbent (Figure 3).

Figure 3.

Environmental impacts of zeolite A, Has-Clay, and Kanuma clay (per 1 kg).

The life-cycle stage that had the greatest contribution (67% to climate change and 40% to fossil depletion) to adverse impacts for Has-Clay was electricity, which was used in the heating, mixing, and drying stages. In particular, heating the Si/Al solution at 98 °C for 18 h used the most electricity, consuming 23.4 kWh, 46.8 kWh, and 70.2 kWh at the production scales of 1.1 kg, 5.5 kg, and 11 kg, respectively.

The greatest impact from zeolite A was also from electricity (42%) at the adsorbent manufacturing stage for climate change (Table 4, Figure 3). The production of natural gas caused an adverse impact in the fossil depletion category (37%). Of the raw materials acquired, sodium silicate had the greatest contribution to adverse impacts for climate change and fossil depletion.

Kanuma clay had the least impact in the impact categories. The inputs consisted only of light fuel oil and electricity. Light fuel oil was consumed during mining, transportation, and drying and contributed 65% to climate change and 96% to fossil depletion. Transportation accounted for the greatest consumption of light fuel oil, 6.5 L (Table 4). These impacts could be reduced by placing processing facilities closer to the mining operation.

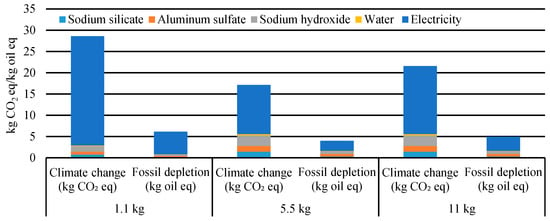

4. Sensitivity Analysis

A sensitivity analysis was conducted on the production volume of Has-Clay to evaluate any potential for environmental improvements. Has-Clay was virtually synthesized in three production volumes, 1.1 kg, 5.5 kg, and 11 kg. Figure 4 compares the climate change and fossil depletion for the three scales. Of the three, the 5.5 kg scale showed the least impacts, with values of 17.14 kg CO2 eq and 4.00 kg oil eq for climate change and fossil depletion, respectively, about one-half of the values for the 1.1 kg production scale.

Figure 4.

Sensitivity analysis of Has-Clay production scale; 1.1 kg, 5.5 kg, and 11 kg.

Even when the production scale was increased, the greatest contribution was still from electricity used, especially in heating. The heating and drying equipment were used more efficiently at the larger production scales, and the relative amount of electricity consumed was reduced, contributing to an overall decreased environmental impact. To further reduce the impacts, an alternative production process involving a more energy-efficient heating process or facility would be necessary.

5. Selection of Adsorbents for Environmentally Friendly Biohydrogen Production

The environmental burden of biohydrogen production is highly impacted by the adsorbents, which affect the operating pressure and temperature related to the energy consumption. That is, it is necessary to consider both the adsorption capacity and the environmental burden of adsorbents for the environmentally friendly biohydrogen production system. In this study, we generated LCI of possible candidates; zeolite A, Has-Clay, and Kanuma clay, under consideration for the application of biohydrogen to fuel cells, and compared environmental impacts of those. Results showed that Kanuma clay would be the most environmentally friendly, followed by zeolite A and Has-Clay. However, Kanuma clay are limited to HCl adsorption at present [21]. Hence, Has-Clay could work at low-pressure operation and be expected to be less of an environmental burden, however it expressed lower H2S adsorption capacity than zeolite A (zeolite 5A) at certain conditions (Table 5). Therefore, for further study, the optimization of the PSA process, including the use of multi-bed PSA with less of an environmental burden and high adsorption capacity, is necessary.

Table 5.

Adsorption capacity for hydrogen sulfide and hydrochloric acid, and the environmental impact of zeolite A, Has-Clay, and Kanuma clay.

6. Conclusions

The LCA results indicate that Kanuma clay is the most environmentally friendly alternative in all of the environmental impact categories, followed by zeolite A and Has-Clay, respectively. The differences among these adsorbents were expressed in the categories of climate change and fossil depletion. The highest impacts were estimated for electricity use in the production processes of zeolite A and Has-Clay and in the production of raw materials such as sodium silicate and sodium hydroxide. For the Has-Clay, optimization of the production volume was required to reduce the environmental impact by optimizing the use of electricity used in heating and drying. To minimize the environmental impacts to a greater extent, it would be necessary to design a production process that uses energy more efficiently.

Additional study is suggested to extend the system to include the transportation of adsorbents to the biohydrogen plant and the production of biohydrogen, where the adsorption capacity of each adsorbent is accounted for to assess environmental impacts throughout the system. A more complete analysis would enable researchers to optimize the adsorbent content to meet a suitable adsorption capacity and various environmental challenges. Regeneration and reuse of adsorbents is a promising strategy to minimize environmental impacts associated with their production and transportation. It would also reduce the impact of the disposal of the adsorbents. The types of LCI data illustrated in this research are imperative to promote more sustainable biohydrogen production.

Author Contributions

Y.S. and K.D. conceived the study. Y.S. designed the research and performed the assessments. M.S. and T.T. supported data collection and supervised the analysis. All authors discussed the results and contributed to the final manuscript.

Funding

This research received no external funding.

Acknowledgments

This research received no external funding. We thank Takahiro Ugajin from Obari Co., Ltd. for allowing us to conduct field work at the mining sites, which greatly assisted in data collection.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ni, M.; Leung, D.Y.C.; Leung, M.K.H.; Sumathy, K. An overview of hydrogen production from biomass. Fuel Process Technol. 2006, 87, 461–472. [Google Scholar] [CrossRef]

- Holladay, J.D.; Hu, J.; King, D.L.; Wang, Y. An overview of hydrogen production technologies. Catal. Today 2009, 139, 244–260. [Google Scholar] [CrossRef]

- Argun, H.; Kargi, F. Bio-hydrogen production by different operational modes of dark and photo-fermentation: An overview. Int. J. Hydrog. Energy 2011, 36, 7443–7459. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U., Jr.; Steele, P.H. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Das, D.; Veziroglu, T.N. Hydrogen production by biological processes: A survey of literature. Int. J. Hydrog. Energy 2001, 26, 13–28. [Google Scholar] [CrossRef]

- Kothari, R.; Buddhi, D.; Sarhney, R.L. Sources and technology for hydrogen production: A review. Int. J. Glob. Energy Issues 2004, 21, 154–178. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrog. Energy 2015, 40, 11094–11111. [Google Scholar] [CrossRef]

- Shi, W.; Yi, B.; Hou, M.; Jing, F.; Yu, H.; Ming, P. The influence of hydrogen sulfide on proton exchange membrane fuel cell anodes. J. Power Sources 2007, 164, 272–277. [Google Scholar] [CrossRef]

- Yadav, A.P.; Nishikata, A.; Tsuru, T. Effect of halogen ions on platinum dissolution under potential cycling in 0.5 M H2SO4 solution. Electrochim. Acta 2007, 52, 7444–7452. [Google Scholar] [CrossRef]

- Sircar, S.; Golden, T.C. Purification of hydrogen by pressure swing adsorption. Sep. Sci. Technol. 2000, 35, 667–687. [Google Scholar] [CrossRef]

- Serbezov, A.; Sotirchos, S.V. Semianalytical solution for multicomponent PSA: Application to PSA process design. Sep. Purif. Technol. 2003, 31, 203–223. [Google Scholar] [CrossRef]

- Ribeiro, A.M.; Grande, C.A.; Lopes, F.V.; Loureiro, J.M.; Rodrigues, A.E. A parametric study of layered bed PSA for hydrogen purification. Chem. Eng. Sci. 2008, 63, 5258–5273. [Google Scholar] [CrossRef]

- Lopes, F.V.; Grande, C.A.; Ribeiro, A.M.; Loureiro, J.M.; Evaggelos, O.; Nikolakis, V.; Rodrigues, A.E. Adsorption of H2, CO2, CH4, CO, N2 and H2O in activated carbon and zeolite for hydrogen production. Sep. Sci. Technol. 2009, 44, 1045–1073. [Google Scholar] [CrossRef]

- Yang, J.; Han, S.; Cho, C.; Lee, C.H.; Lee, H. Bulk separation of hydrogen mixtures by a one-column PSA process. Sep. Technol. 1995, 5, 239–249. [Google Scholar] [CrossRef]

- Baksh, M.S.A.; Ackley, M.W. Pressure Swing Adsorption Process for the Production of Hydrogen. U.S. Patent No. 6,340,382, 22 January 2002. [Google Scholar]

- Fawer, M.; Postlethwaite, D.; Klüppel, H.J. Life Cycle Inventory for the Production of Zeolite A for Detergents. Int. J. Life Cycle Assess. 1998, 3, 71–74. [Google Scholar] [CrossRef]

- Michalev, T.; Petrov, I. The Removal of Heavy Metal Ions by Synthetic Zeolites: A Review; University of Ruse: Ruse, Bulgaria, 2012; Volume 51, pp. 79–84. [Google Scholar]

- Alonso-Vicario, A.; Ochoa-Gómez, J.R.; Gil-Río, S.; Gómez-Jiménez-Aberasturi, O.; Ramírez-López, C.A.; Torrecilla-Soria, J.; Domínguez, A. Purification and upgrading of biogas by pressure swing adsorption on synthetic and natural zeolites. Microporous Mesoporous Mater. 2010, 134, 100–107. [Google Scholar] [CrossRef]

- Kuroda, S.; Nagaishi, T.; Kameyama, M.; Koido, K.; Seo, Y.; Dowaki, K. Hydroxyl aluminium silicate clay for biohydrogen purification by pressure swing adsorption: Physical properties, adsorption isotherm, multicomponent breakthrough curve modelling, and cycle simulation. Int. J. Hydrog. Energy 2018, 43, 16573–16588. [Google Scholar] [CrossRef]

- Suzuki, M.; Maeda, M. Development of the adsorbent for desiccant air-conditioning system by the inorganic porous material of clay family. Trans. JSRAE 2012, 29, 89–96. [Google Scholar]

- Saruya, H.; Seo, Y.; Kameyama, M.; Suzuki, M.; Dowaki, K. Performance tests of HCl removal at low temperature in use of mixed adsorbents. In Proceedings of the 7th Joint Conference on Renewable Energy and Nanotechnology, Ube, Japan, 1–3 December 2018. [Google Scholar]

- Kanazawa, J. Relationship between the soil sorption constants for pesticides and their physicochemical properties. Environ. Chem. 1998, 8, 477–484. [Google Scholar] [CrossRef]

- Yang, S. Development of Adsorbents for Phosphate Removal from Aqueous Solution. Ph.D. Thesis, University of Tsukuba, Tsukuba, Japan, 2013. [Google Scholar]

- Kondo, S.; Nagaishi, T.; Dowaki, K. Analyses of exergy and environmental impact on bio-H2 production system. J. Jpn. Inst. Energy 2018, 97, 77–87. [Google Scholar] [CrossRef]

- Dowaki, K.; Kuroda, S.; Saruya, H.; Katayama, N.; Seo, Y.; Ishiyama, T.; Sato, K.; Kameyama, M. A LCA on the H2S and HCI removal procedures using tin Has-Clay. J. Jpn. Inst. Energy 2018, 97, 160–170. [Google Scholar] [CrossRef]

- Zoller, U. (Ed.) Handbook of Detergents, Part B: Environmental Impact; CRC Press: Boca Raton, FL, USA, 2004; Volume 121. [Google Scholar]

- Guinée, J.B. Handbook on life cycle assessment operational guide to the ISO standards. Int. J. Life Cycle Assess. 2002, 7, 311. [Google Scholar] [CrossRef]

- Frischknecht, R.; Rebitzer, G. The ecoinvent database system: A comprehensive web-based LCA database. J. Clean. Prod. 2005, 13, 1337–1343. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008: A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level, 1st ed.; Ministry of Housing, Spatial Planning and Environment (VROM): Bilthoven, The Netherlands, 2009.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).