A Sub-1-V Nanopower MOS-Only Voltage Reference

Abstract

1. Introduction

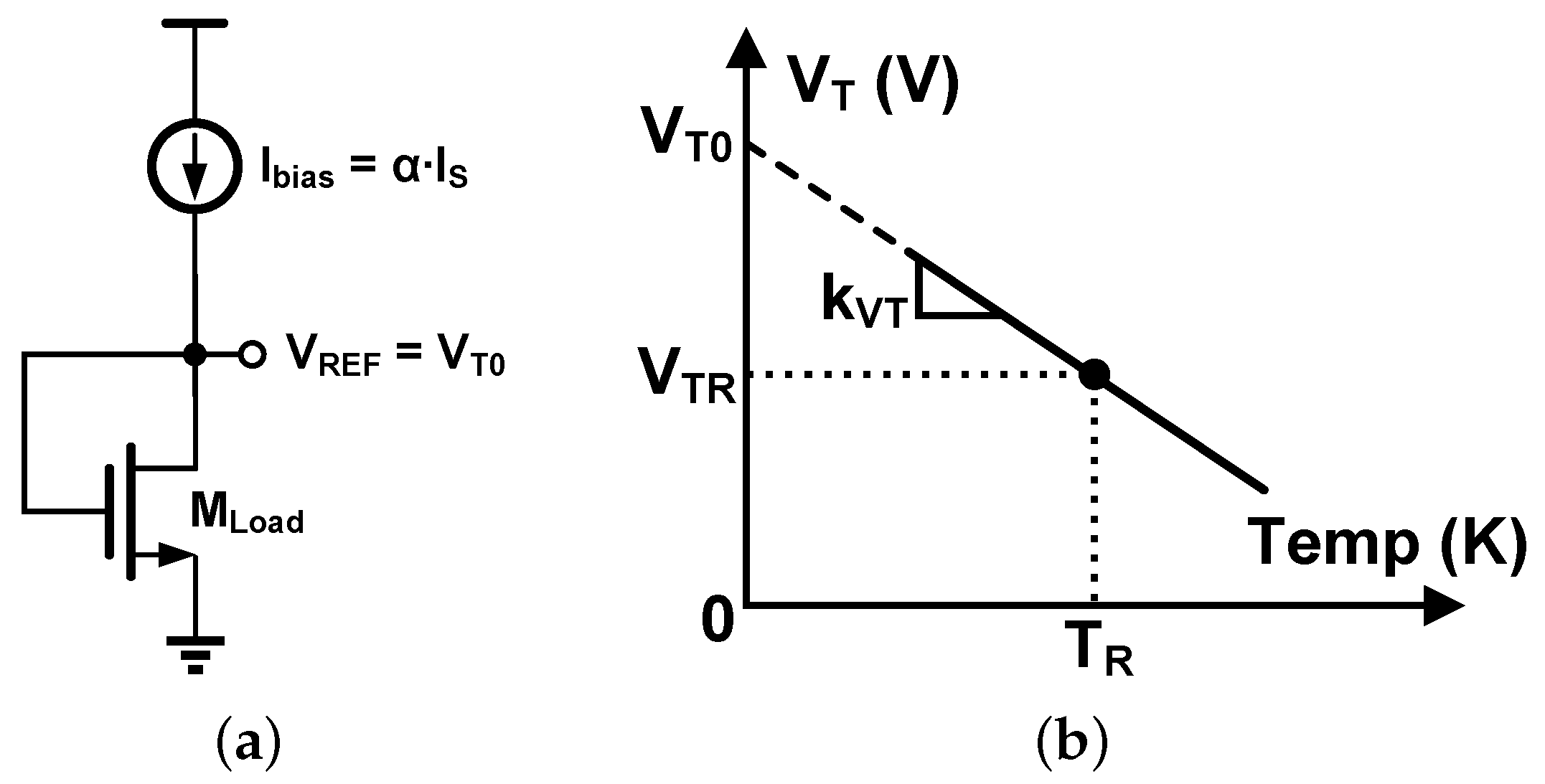

2. Principle of MOS-Only Voltage Reference

2.1. EKV Model

2.2. MOS-Only Voltage Reference Operation Principle

3. Circuit Design

3.1. Proposed Specific Current Source

3.2. Loop Stability

3.3. Output Stage

3.4. Start-Up Circuit

4. Simulation Results

4.1. Temperature Dependence before Trimming

4.2. Temperature Dependence after Trimming

4.3. Frequency Compensation

4.4. Supply Dependence

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Wang, J.; Sun, X.; Cheng, L. A Picowatt CMOS Voltage Reference Operating at 0.5-V Power Supply with Process and Temperature Compensation for Low-Power IoT Systems. IEEE Trans. Circuits Syst. II Express Briefs 2023, 70, 1336–1340. [Google Scholar] [CrossRef]

- Parisi, A.; Finocchiaro, A.; Papotto, G.; Palmisano, G. Nano-Power CMOS Voltage Reference for RF-Powered Systems. IEEE Trans. Circuits Syst. II Express Briefs 2018, 65, 1425–1429. [Google Scholar] [CrossRef]

- Zhu, Z.; Hu, J.; Wang, Y. A 0.45 V, Nano-Watt 0.033% Line Sensitivity MOSFET-Only Sub-Threshold Voltage Reference with No Amplifiers. IEEE Trans. Circuits Syst. I Regul. Pap. 2016, 63, 1370–1380. [Google Scholar] [CrossRef]

- Yan, W.; Li, W.; Liu, R. Nanopower CMOS Sub-Bandgap Reference with 11 ppm/°C Temperature Coefficient. Electron. Lett. 2009, 45, 627. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, X.; Zhang, J.; Zhang, H.; Li, J.; Zhang, R.; Chen, S.; Carusone, A.C. A Nano-Watt MOS-Only Voltage Reference with High-Slope PTAT Voltage Generators. IEEE Trans. Circuits Syst. II Express Briefs 2018, 65, 1–5. [Google Scholar] [CrossRef]

- Kim, M.; Cho, S. A Single BJT Bandgap Reference with Frequency Compensation Exploiting Mirror Pole. IEEE J. Solid-State Circuits 2021, 56, 2902–2912. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhan, C.; Wang, L.; Law, M.K. A −40 °C–125 °C 0.4-µA Low-Noise Bandgap Voltage Reference with 0.8-mA Load Driving Capability Using Shared Feedback Resistors. IEEE Trans. Circuits Syst. II Express Briefs 2022, 69, 4033–4037. [Google Scholar]

- Huang, W.; Liu, L.; Zhu, Z. A Sub-200nW All-in-One Bandgap Voltage and Current Reference without Amplifiers. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 121–125. [Google Scholar] [CrossRef]

- Vita, G.D.; Iannaccone, G. A Sub-1 V, 10 ppm/°C, Nanopower Voltage Reference Generator. In Proceedings of the 2006—32nd European Solid-State Circuits Conference, Montreaux, Switzerland, 19–21 September 2006; pp. 307–310. [Google Scholar]

- Ueno, K.; Hirose, T.; Asai, T.; Amemiya, Y. A 300 nW, 15 ppm/°C, 20 ppm/V CMOS Voltage Reference Circuit Consisting of Subthreshold MOSFETs. IEEE J. Solid-State Circuits 2009, 44, 2047–2054. [Google Scholar] [CrossRef]

- Qiao, H.; Zhan, C.; Chen, Y. A −40 °C to 140 °C Picowatt CMOS Voltage Reference with 0.25-V Power Supply. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 3118–3122. [Google Scholar] [CrossRef]

- Aminzadeh, H. All–MOS Self-Powered Subthreshold Voltage Reference with Enhanced Line Regulation. AEU Int. J. Electron. Commun. 2020, 122, 153245. [Google Scholar] [CrossRef]

- Luong, P.; Christoffersen, C.; Rossi-Aicardi, C.; Dualibe, C. Nanopower, Sub-1 V, CMOS Voltage References with Digitally-Trimmable Temperature Coefficients. IEEE Trans. Circuits Syst. I Regul. Pap. 2017, 64, 787–798. [Google Scholar] [CrossRef]

- De Lima, V.F.; Klimach, H. A 37 nW MOSFET-Only Voltage Reference in 0.13 µm CMOS. In Proceedings of the 2020 33rd Symposium on Integrated Circuits and Systems Design (SBCCI), Campinas, Brazil, 24–28 August 2020; pp. 1–6. [Google Scholar]

- Che, C.; Lei, K.M.; Martins, R.P.; Mak, P.I. A 0.4-V 8400-µm2 Voltage Reference in 65-nm CMOS Exploiting Well-Proximity Effect. IEEE Trans. Circuits Syst. II Express Briefs 2023, 70, 3822–3826. [Google Scholar]

- Parisi, A.; Finocchiaro, A.; Palmisano, G. An accurate 1-V threshold voltage reference for ultra-low power applications. Microelectron. J. 2017, 63, 155–159. [Google Scholar] [CrossRef]

- Fan, H.; Fang, Z.; Li, Y.; Qian, Q.; Kang, X.; Chen, M.; Sun, W. A 3.38-ppm/°C Voltage Reference for Harsh Environment Applications Empowered by the In-Loop Resistance Trimming Technique. IEEE Trans. Circuits Syst. II Express Briefs 2023. early access. [Google Scholar] [CrossRef]

- Navidi, M.M.; Graham, D.W. A Low-Power Voltage Reference Cell with a 1.5 V Output. J. Low Power Electron. Appl. 2018, 8, 19. [Google Scholar] [CrossRef]

- Seok, M.; Kim, G.; Blaauw, D.; Sylvester, D. A Portable 2-Transistor Picowatt Temperature-Compensated Voltage Reference Operating at 0.5 V. IEEE J. Solid-State Circuits 2012, 47, 2534–2545. [Google Scholar] [CrossRef]

- Ji, Y.; Lee, J.; Kim, B.; Park, H.J.; Sim, J.Y. 18.8 A 192pW Hybrid Bandgap-Vth Reference with Process Dependence Compensated by a Dimension-Induced Side-Effect. In Proceedings of the 2019 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 17–21 February 2019; pp. 308–310. [Google Scholar]

- Liu, X.; Liang, S.; Liu, W.; Sun, P. A 2.5 ppm/°C Voltage Reference Combining Traditional BGR and ZTC MOSFET High-Order Curvature Compensation. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 1093–1097. [Google Scholar] [CrossRef]

- Chowdary, G.; Kota, K.; Chatterjee, S. A 1-nW 95-ppm/°C 260-mV Startup-Less Bandgap-Based Voltage Reference. In Proceedings of the 2020 IEEE International Symposium on Circuits and Systems (ISCAS), Seville, Spain, 12–14 October 2020; pp. 1–4. [Google Scholar]

- Enz, C.C.; Krummenacher, F.; Vittoz, E.A. An analytical MOS transistor model valid in all regions of operation and dedicated to low-voltage and low-current applications. Analog Integr. Circuits Signal Process. 1995, 8, 83–114. [Google Scholar] [CrossRef]

- Enz, C.; Chicco, F.; Pezzotta, A. Nanoscale MOSFET Modeling: Part 1: The Simplified EKV Model for the Design of Low-Power Analog Circuits. IEEE Solid-State Circuits Mag. 2017, 9, 26–35. [Google Scholar] [CrossRef]

- Enz, C.; Chicco, F.; Pezzotta, A. Nanoscale MOSFET Modeling: Part 2: Using the Inversion Coefficient as the Primary Design Parameter. IEEE Solid-State Circuits Mag. 2017, 9, 73–81. [Google Scholar] [CrossRef]

- Enz, C.; Chalkiadaki, M.A.; Mangla, A. Low-power analog/RF circuit design based on the inversion coefficient. In Proceedings of the ESSCIRC Conference 2015—41st European Solid-State Circuits Conference (ESSCIRC), Graz, Austria, 14–18 September 2015; IEEE: New York, NY, USA, 2015; pp. 202–208. [Google Scholar]

- Enz, C.; Pezzotta, A. Nanoscale MOSFET modeling for the design of low-power analog and RF circuits. In Proceedings of the 2016 MIXDES—23rd International Conference Mixed Design of Integrated Circuits and Systems, Lodz, Poland, 23–25 June 2016; IEEE: New York, NY, USA, 2016; pp. 21–26. [Google Scholar]

- Jespers, P. The gm/ID Methodology, a Sizing Tool for Low-Voltage Analog CMOS Circuits: The Semi-Empirical and Compact Model Approaches; Springer Science & Business Media: New York, NY, USA, 2009. [Google Scholar]

- Jespers, P.G.A.; Murmann, B. Systematic Design of Analog CMOS Circuits: Using Pre-Computed Lookup Tables; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Filanovsky, I.; Allam, A. Mutual compensation of mobility and threshold voltage temperature effects with applications in CMOS circuits. IEEE Trans. Circuits Syst. I Fundam. Theory Appl. 2001, 48, 876–884. [Google Scholar] [CrossRef]

- Alhasssan, N.; Zhou, Z.; Sánchez Sinencio, E. An All-MOSFET Sub-1-V Voltage Reference with a—51-dB PSR up to 60 MHz. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2017, 25, 919–928. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, J. A 42nA IQ, 1.5–6V VIN, Self-Regulated CMOS Voltage Reference with −93 dB PSR at 10 Hz for Energy Harvesting Systems. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 2357–2361. [Google Scholar] [CrossRef]

| Transistor | Size | Transistor | Size |

|---|---|---|---|

| 0.12/20 (µm/µm) | 4 | ||

| 64 | 5/20 (µm/µm) | ||

| 52 | 2 | ||

| 3 | 2 | ||

| 1 | 5/20 (µm/µm) | ||

| 5/20 (µm/µm) | 3 × 5/20 (µm/µm) | ||

| 104 | (∼) |

| Parameter | This Work | TCASII’23 [1] | TCASII’23 [15] | TCASII’21 [32] | SBCCI’20 [14] | JLPEA’18 [18] |

|---|---|---|---|---|---|---|

| Process (nm) | 55 | 180 | 65 | 180 | 130 | 350 |

| Temp. Range (°C) | −40–120 | −10–100 | −20–80 | −40–85 | −40–125 | −70–85 |

| TC (ppm/°C) | 21.7 | 90 | 79.4 | 60.86 | 28.8 | 42 |

| (mV) | 474.4 | 288 | 107.2 | 985 | 575.2 | 1520 |

| (%) | 5.8 | 0.574 | 2.4 | 2.6 | 4.32 | 2 |

| Supply (V) | 0.8–1.5 | 0.5–2 | 0.4–0.8 | 1.5–6 | 1–1.8 | 1.7–3.3 |

| LS (%/V) | 0.011 | 0.23 | 0.54 | 0.003 | 0.071 | 10 |

| Consumption (nW) | 23.2 | 0.5 | 56.7 | 63 | 36.4 | 1110 |

| PSRR (dB) | −89 (@100 Hz) | −45 (@100 Hz) | −66.5 (@10 Hz) | −93.3 (@10 Hz) | −54.4 (@100 Hz) | −35 (@100 Hz) |

| Area (mm2) | 0.009 | 0.0029 | 0.0084 | 0.015 | 0.0078 | 0.06 |

| Components | 1 Type MOS | 3 Types MOS | MOS + Res | 2 Types MOS | 1 Type MOS | 2 Types MOS + Res |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Lu, Z.; Xu, K.; Dai, H.; Wu, Z.; Yu, X. A Sub-1-V Nanopower MOS-Only Voltage Reference. J. Low Power Electron. Appl. 2024, 14, 13. https://doi.org/10.3390/jlpea14010013

Wang S, Lu Z, Xu K, Dai H, Wu Z, Yu X. A Sub-1-V Nanopower MOS-Only Voltage Reference. Journal of Low Power Electronics and Applications. 2024; 14(1):13. https://doi.org/10.3390/jlpea14010013

Chicago/Turabian StyleWang, Siqi, Zhenghao Lu, Kunpeng Xu, Hongguang Dai, Zhanxia Wu, and Xiaopeng Yu. 2024. "A Sub-1-V Nanopower MOS-Only Voltage Reference" Journal of Low Power Electronics and Applications 14, no. 1: 13. https://doi.org/10.3390/jlpea14010013

APA StyleWang, S., Lu, Z., Xu, K., Dai, H., Wu, Z., & Yu, X. (2024). A Sub-1-V Nanopower MOS-Only Voltage Reference. Journal of Low Power Electronics and Applications, 14(1), 13. https://doi.org/10.3390/jlpea14010013