Abstract

Manufacturing Resource Planning (MRP) is a widely used approach through manufacturing environments in a variety of sectors. With a tendency to go to specialized, smaller lot sizes in several industries (e.g., the pharmaceutical sector), companies are dealing with capacity bottlenecks if the planning rhythm wheel is not well calibrated or when production lines are not flexible enough in terms of changeover (C/O) and set-up times (S/U) (OEE is too small). A well-established communication system including other enterprise resources or production factors (e.g., Enterprise Resource Planning, ERP) is favorable to any extent. More and more questions arise from stakeholder communities and end-users on whether or not supply chains and manufacturing environments are sustainable and safe. Departments such as Environmental Health, Safety & Sustainability (EHS & S) and Product Stewardship are too often at the “blind” side of the ICT interface. When it comes to product and organizational sustainability, data seems to be lacking in order to conduct sustainability assessments proficiently. Years of intensive research and experience proved that primary data to perform sustainability assessments often are measured through equipment control sensors (e.g., flow rates, temperatures, etc.) and sent to PLCs and many other systems. Nevertheless, these data measurements are in many cases simply not penetrating through the Manufacturing Execution Systems (MES) because these bottom-up engineering data seems to be of little value to planning, procurement, etc. This communication paper deals with how sustainability assessments can be embedded in business operational management systems. After all, who does not want a “live Carbon Footprint” for process improvements and external sustainability reporting instead of a series of expensive resource consuming studies of 4 to 6 months digging into data logs in traditional Life Cycle Assessment (LCA)? This communication paper has taken one step further in coupling business ERP systems with environmental sustainability of products, services and enterprises.

1. Introduction

When Goldratt first introduced his Theory of Constraints (ToC) in The Goal (1984) and The Critical Chain (1997), he did not only refer to manufacturing Value Chains (VCs) sending the boy scouts on the narrow forest trail [1,2]. A metaphoric way of debottlenecking that found its way in various types of management, from office management to business management, from visual management on the floor to the most advanced planning systems. A few decades before, yet another great scientist called Dennis Meadows published his severe concerns on exponential growth due to the industrialism and a limited supply of resources [3]. At first glance, striving towards higher efficiencies and economic growth evermore would be in contrast with Meadows’ Limits to Growth. However, under the Malthusian ceiling, intensification in processing industries is all about doing more with less [4,5,6]. Whether it was Thomas Malthus, Dennis Meadows or Eliyahu Goldratt that pulled the strings, they all shared a complementary vision towards sustainment and sustainability.

Sustainable development in its broadest sense could possibly best be described as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs”, suggested by Brundtland and the World Commission on Environment and Development (WCED) [7]. The aforementioned definition lacks a comprehensive description of “needs”. From an individual or microeconomic perspective, we could reflect the needs of a human being to the Maslov Hierarchy and the utility of that human being given to a certain attribute of a product or service [8]. However, from a societal point of view, sustainability professionals often subdivide between economic prosperity, environmental sustainability and social sustainability (the triple bottom line) [9,10].

Next to sustainability and sustainable development, sustainment is key in quantifying, monitoring and eventually maintaining our efforts towards sustainable development, continuous improvement, Operational Excellence, etc. Measuring performance (prosperity, environmental sustainability and social sustainability) is of utmost importance to evaluate continuous improvement actions or eco-design alternatives in early R&D development stages. A widely used methodology to assess sustainability is Life Cycle Sustainability Assessment (LCSA), reaching out to economic prosperity (Life Cycle Costing, LCC), environmental LCA and social aspects through SLCA. Environmental LCA has extensively been used since the past decade to assess whether or not a (established, enabling or prospective) technology or product is environmentally sustainable, to perform eco-design, for sustainability reporting, to comply with NGO requests, but above all for internal process optimization [11,12,13,14,15,16,17,18]. To this extent it overlaps strongly with the field of Operational Excellence (OE) and the Lean heritage. Until now, the link between ICT tools for Operational Excellence or Business Administration (BA) in general is hardly connected to the data-intensive process modelling software such as ASPEN® or LCA software such as Simapro or OpenLCA.

Several studies, regulations and European Directives have shown the need for a more efficient way to perform LCA through value chains [13,19,20]. As an example, Environmental Product Declarations (EPDs) are becoming mandatory for all building materials within the construction sector [20]. An EPD is a standardized type of report from an LCA. This means that for every building material sold on the market, an LCA has to be conducted, nearly impossible without a certain degree of automation. Together with the European Centre of Innovation and Technology (EIT) and the EIT on Raw Materials, the Digital Agenda (DA) and the Internet of Things (IoT), the European Commission sets objectives for the growth of the European Union (EU) by 2020 [21]. The DA proposes to better exploit the potential of Information and Communication Technologies (ICTs) in order to foster innovation, economic growth and progress. With a strong policy driven focus, the emergence of more efficient LCA methodologies and their use cases are obviously present. Of interest to the reader, other examples are the European Plastics Federation (PlasticsEurope), the Green Procurement Initiative of the United Nations Development Program (UNDP), etc. The next paragraph will elaborate on the possible bottlenecks in integrating such a system as described above, how we can overcome this urge and what are the clear wins towards fully integrating these systems.

2. Potential Bottlenecks in the Integration of Process Modelling and Enterprise Resource Planning (ERP) Systems

2.1. Data Management in Organizations

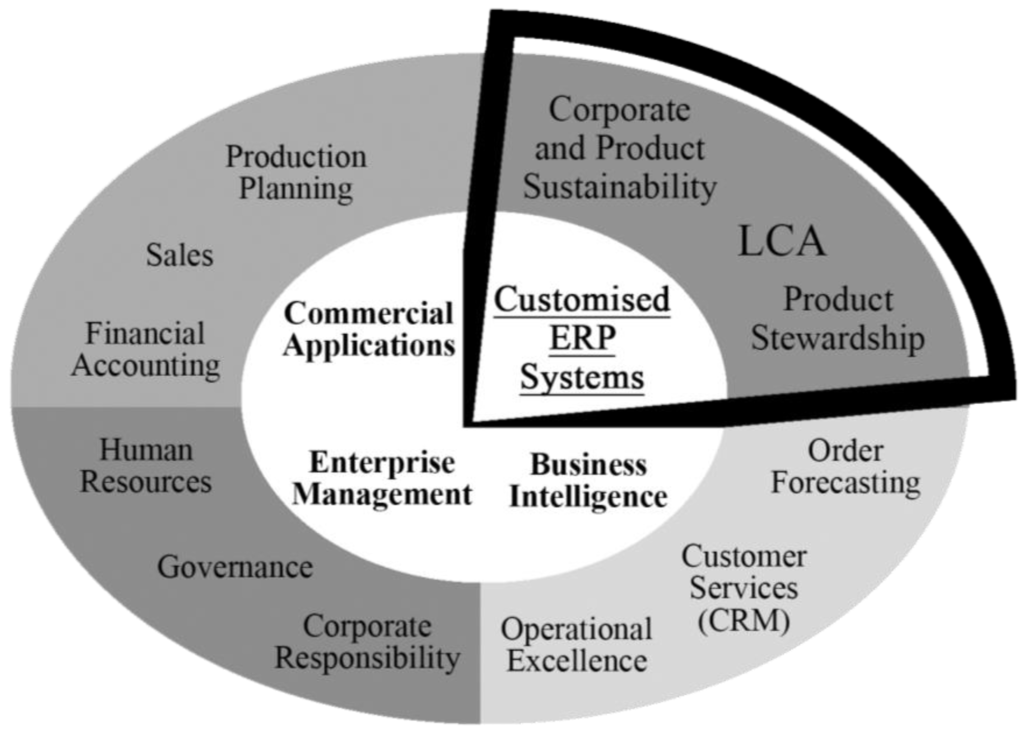

Depending on the type and scale of organization, the sector to which it delivers products and services and its stakeholders, organizational data is structured in business IT and ICT tools and systems. In the processing industry, the horizontal structure of an organization (Production, Planning, Finance, Legal Affairs, Procurement, HR, EHS&S, QA/QC, Engineering, Validation, etc.) stores thousands of terabytes (or pages) creating a data-dependent structure in need of smart and consistent logging systems. Some of them are integrated in so-called Enterprise Resource Planning (ERP) systems, such as SAP and Infor LN. ERP systems are used for a variety of applications as shown in Figure 1, which can potentially be subdivided in four categories: (1) Business Intelligence; (2) Enterprise Management; (3) Commercial Applications and (4) Customized ERP Systems or modules. A widespread example is production planning, which can be based on forecasting, stock levels (push production), a planning rhythm wheel, etc. Whenever the market is saturated or is characterized by a stable demand, push production is often applied. A Manufacturing Resource Planning (MRP) system steers the production based on stock levels and will send orders to suppliers to replenish in-house stock levels.

Figure 1.

Enterprise Resource Planning (ERP) systems are used for a variety of applications, which can potentially be subdivided in four categories: (1) Business Intelligence; (2) Enterprise Management; (3) Commercial Applications and (4) Customized ERP Systems or modules. A widespread example is production planning, which can be based on forecasting, stock levels (push production), a planning rhythm wheel, etc.

An ERP system is generally custom configured for a certain enterprise. The customized applications of resource planning systems are endless [22]. Such customized applications might ease the daily operations of e.g., warehouse management (efficient order pick-up, standardized work, etc.).

The introduction of this paper touched upon the similarity between Lean and sustainable manufacturing, between the visions of Goldratt, Malthus and Meadows. Product and organizational sustainability could be quantified using organizational operational data in a customized ERP module, as has been proposed by De Soete et al. (2014) [14]. The authors provide correlations between the environmental impact of products as response variable and readily available ERP data as candidate predictor variables. Ideally, through machine learning, these correlations can be optimized in a customized module. Further elaboration on the feasibility of new frameworks is given in Section 3: Proposed pathways for integration. The subsections below describe some of the bottlenecks in relying on ERP data and in the integration of tools for corporate and product sustainability assessments. Related to Figure 1 one should take into account these bottlenecks in building customized ERP modules.

2.2. Data Penetration through MES

Production line sensors, logging systems or Supervisory Control And Data Acquisition (SCADA) systems are connected with the ERP systems for the different business departments to work with through the so-called Manufacturing Execution System (MES). The MES could be described as the interface between the plant floor (Gemba) and the ERP system. Possible applications of MES are automated equipment maintenance support and process control [23]. Data from particular sensors (e.g., temperature sensors, level sensors, flow rate sensors, product homogeneity through NIR, etc.) that have no direct use in any ERP module might not penetrate through the MES layer (e.g., for process control). These types of data are essential in sustainability assessments and LCA in general to construct mass and energy balances of the production in scope of the analysis. Without modifications on the data submission path to customized ERP systems, integrating organizational and product sustainability is ERP modules for EHS & S and Product Stewardship is challenging. It will reduce the data quality of the LCA and will require more modelling in the end (e.g., through machine learning) instead of using primary data.

2.3. Consistency in Data Feeding/Logging

Following on De Soete et al. (2014) a feasibility study was performed on using different ERP data in forecasting methods for the environmental sustainability of products, as postulated in the previous subsection. The lack of consistency in data feeding into ERP systems from e.g., operator entries on waste, solvent use, etc., was perceived to be a bottleneck. The use of different units for one and the same physical-chemical variable is another bottleneck to get to work on. A proposed way to deal with these inconsistencies is the proper use of Standard Operating Procedures (SOPs) and sustainment through properly defined Key Performance Indicators (KPIs). These management tools are widely used through organizations to foster consistency and to reduce variability in production environments leading to increased lead times. However, the application of these tools should be more horizontally integrated in order to strive for an effective and efficient usage.

2.4. Supply Chain Transparency

Once a comprehensive data system is sustained in an ERP system, Supply Chain (SC) transparency becomes a key issue to guarantee data quality and visibility into the extended SC. Moreover, it protects any processing company against supply disruptions and unbalanced replenishment. In general, it reduces supply risk effectively. Transparency will become more and more a key issue in global SCs and will further develop as it turns out to be crucial for wider social developments such as globalization, the information age, and the shifting role of states in environmental governance. Transparency in SCs is bound up with positive connotations: the more transparency the better it is for the sustainability of chains and for the empowerment of one’s consumers [24]. Thus also for customized ERP modules, e.g., sustainability assessments, internal SC data management and external SC interfacing, confidentiality issues in data transparency of suppliers, etc., are potential risks or bottlenecks to be monitored and tackled.

2.5. Supply Chain Reliability

Nevertheless, transparency can only be guaranteed if the supply of raw materials through the Supply Chain (SC) is stable and a certain level of business continuity has been reached. The importance of business continuity plans is well recognized by organizations all over the world that are increasingly operating in a global, complex and competitive environment. Their core business and SCs can easily be interrupted by economic, social, political, technical and environment related unforeseen events. Natural disasters, diseases, financial crises, unreliable supply chains leading to disruptions and many more can severely impact growth and performance [25]. The work of Cheung et al. (2014) revealed a paradigm shift in which data generated by manufacturers within the process industries identify failures which they are introducing into the SC [26]. This means that transparency and reliability are strongly related and a consistent use of data is key to enhance performance and avoid disruptions. As a leading example, the pharmaceutical and medical device industries are developing Good Supply Practices (GSPs), next to the Good Manufacturing Practices (GMP) required by the Food and Drug Administration (FDA) and the European Medicine Agency (EMA) in order to foster reliability through the SC [26]. Despite all, supply disruptions are surely enough all too common. To mitigate delivery risk, buyers may either source from multiple suppliers or offer benefits to preferred suppliers to improve SC reliability [27]. These incentives towards suppliers can either be direct (investment subsidy) or indirect (inflated order quantity). Preferably a mixed model of investment subsidy and/or inflated order quantity for the preferred supplier together with multiple supplier sourcing as alternative delivery in case of partial disruption is applied [27].

It is not hard to imagine that if the physical supply of goods or the delivery of services cannot be guaranteed, the penetration of SC data and process data of n-x suppliers to end producers is all but apparent. Even though the supply would theoretically be completely secured, companies might be resistant to data sharing in order to preserve their competitive advantage in the global environment [14]. However, well considered business models can ensure process data sharing with a certain degree of aggregation and black box modelling throughout the SC to enhance the use of primary process data of suppliers for e.g., sustainability assessments through Life Cycle Assessment (LCA). These data sharing models with care for business integrity and confidentiality has the power to lead to shared value through the SC, since LCA can indicate priorities for optimization and resource consumption reduction for all n-x suppliers. If the model fails to deliver reliable data, it might be better to use secondary (averaged) market data as proxy values to reduce data uncertainty of the LCA results. Nonetheless, one should strive for connecting suppliers as much as possible and enhance the use of primary data to create shared value approaches and facilitate assessment of product and corporate sustainability in general.

2.6. Different Languages

Next to data penetration, consistency, transparency and reliability, another bottleneck in this non-exclusive list is related to the programming and interfacing of different data formats to perform sustainability assessments. While correlations models of processing data with environmental data can be made with R, SPSS or any program for statistical analysis, Life Cycle Inventory (LCI) databases are commonly working with extensions such as .xml (extended mark-up language), ecospold (ecoinvent database format), .olca (OpenLCA database format), etc. [14,28]. To convert LCI databases to work with in different software packages, so-called converting tools were developed (e.g., the ones from the European Commission’s Directorate-General Joint Research Centre) [28]. However, engineering modelling software such as ASPEN and LCI data do not speak the same language. Therefore, interfacing different types of data is still to be considered a potential bottleneck in connecting aforementioned modules in MES or ERP systems.

3. Proposed Pathways for Integration

3.1. A Common Framework

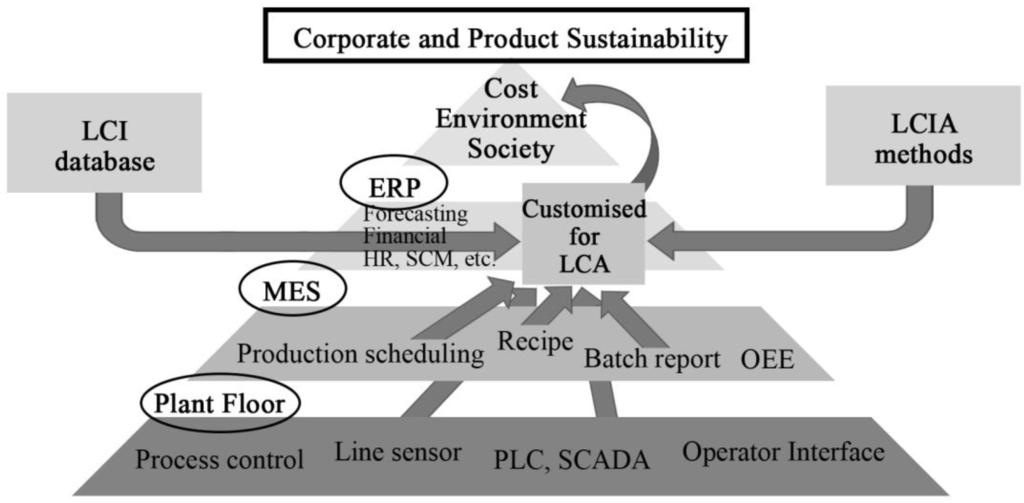

The previous topic highlighted some of the most abundant bottlenecks experienced in implementing sustainability assessments through Life Cycle Assessment (LCA), related to operational management within manufacturing and Supply Chain (SC) environments. Figure 2 illustrates a highly simplified integration of IT/ICT tools in manufacturing environments, where several layers can be distinguished [29,30]. Bearing in mind the tools and principle heritage of Lean Manufacturing and Six Sigma Management, everything starts at the Plant Floor or ”Gemba”, the place where value is essentially created [31,32,33,34]. On the Floor, the bottom up construction of data systems starts with sensors based on all kinds of technologies (volume sensors, mass sensors, structure sensors, temperature sensors, etc.). Most of these sensors send data signals at predefined intervals to logging systems such as Supervisory Control And Data Acquisition (SCADA) systems. Some process variables such as timings are inserted as queries through an Operator Interface (e.g., provided by Siemens) to be used in the construction of Batch Production Reports (BPRs), etc. The measured data is send to the next layer in the programming structure, being the Manufacturing Execution System (MES). In the MES, process data coming from the Floor is being used to create BPRs, calculate performance indicators such as the Overall Equipment Effectiveness (OEE), regulate process control systems and many more. The manufacturing data systems are connected to the corporate enterprise systems. The third layer in the framework is the Enterprise Resource Planning (ERP) system. This third layer allows enterprises to manage their resources from both a top down (production planning) and a bottom up (procurement) approach. From NGOs, policy makers, end-users and the whole stakeholder communities, questions arise on whether or not this supply chain and manufacturing is sustainable and safe. When it comes to product and organizational sustainability for purposes of Product Environmental Footprinting (PEF), Green Procurement and Product Stewardship, data seems to be lacking in order to conduct sustainability assessments proficiently. Years of intensive research by means of backwards stepwise linear regression modelling and experience proved that primary data to perform sustainability assessments often are measured through equipment control sensors (e.g., flow rates, temperatures, concentrations, pressures etc.) and sent to PLCs and many other systems [14]. Nevertheless, these engineering data measurements are in many cases simply not penetrating through the Manufacturing Execution Systems (MES) because they seem to be of little value for existing ERP applications.

Figure 2.

General framework for integrated product and organizational sustainability and data flux from the plant floor, the Manufacturing Execution Systems (MES), ERP systems, Life Cycle Inventory Databases, Impact Assessment Methods and their general translation toward corporate and product sustainability.

An ERP system is generally customized for a certain enterprise. The customized applications of resource planning systems can be adjusted to the needs of an organization. Correlation models between process data (e.g., temperature, mass yield, organic solvent use) and environmental sustainability performance (e.g., cumulative resource consumption, carbon emissions, etc.) that were found by De Soete et al. (2014) and adopted by the Sustainable Development Unit (SDU) of the British National Health Service (NHS) were tested on their feasibility to be integrated in customized ERP applications [14,35]. It was proven that by combining MES data from batch reports (e.g., time duration of a chemical synthesis step), line sensors (e.g., operating temperatures), Bill of Materials (BOM) (e.g., raw material use), indicators for environmental sustainability could be derived (e.g., Cumulative Exergy Extracted from the Natural Environment, CEENE and the Carbon Footprint, CF) [36,37,38,39,40,41,42]. Ideally, these aforementioned correlations, engineering modules, design software such as ASPEN are to be built in in a customized ERP application for LCA (as visualized in Figure 2) in order to couple primary engineering data, Life Cycle Inventory databases (LCI, e.g., ecoinvent) and Life Cycle Impact Assessment Methods (LCIAM, such as CEENE and CF). The role of these different configurations and to what extent they can be automated to generate a ”life footprint” will be elaborated in Section 3.2. With the construction of customized ERP modules for automated sustainability assessments, corporate and product sustainability can be quantified to be used for several applications: Corporate Sustainability Reporting (CSR), continuous improvement actions within the organization, marketing, B2B and B2C communications, etc. Ideally, such a system should be sustained by the top management by means of, e.g., Key Performance Indicators (KPIs).

An exemplary data flux is given below to make the general framework represented in Figure 2 more tangible. As a simplification only the packaging phase of the product life cycle is taken into account. A packaging line in, e.g., the life sciences industries consumes the following resources:

- Material resources: folding box, shipping box, plastics, euro pallet, wrapping foil, etc. These flows are generally available in the Bill of Materials, which can be extracted from procurement ERP applications.

- Energetic resources: power consumption of the packaging line, temperatures of heating air in case of sealing, flow rates of heating air, compressed air consumption, air pressure, HVAC, potentially nitrogen gas flow rates and pressures.These flows are a lot more difficult to find and are scattered in the data management system. For some (e.g., flow rates) one might start from the flow rate sensor to the SCADA system which feeds information into the MES. Generally, one needs to extract these data from different data management systems.

- Auxiliary substances: cleaning media, C/O resources, maintenance resources, etc.

Once all flows with their flow properties (temperature, pressure) are extracted from different systems and sensors, mass and energy balances are generated in the customized LCA modules. These balances of the so-called foreground system need to be mapped with Life Cycle Databases, relating flows entering the site “gate” to the cradle of resource consumption in order to generate a cumulative balance. Last, this so-called Life Cycle Inventory is subject to impact assessment calculations upon integration of Life Cycle Impact Assessment Methods (LCIAM) such as Carbon Footprinting and Resource Footprinting.

What has been elaborated in the previous paragraphs is exactly what is meant with multidisciplinarity. The multidisciplinary approach goes back to the very diverse team of professionals we need to establish sustainability assessment modules for product stewardship, for sustainability reporting and for plant optimization and integration of waste as resources. It is an approach where environmental engineers, business and SAP analysts, ICT experts and operational management professionals have to sit together to obtain the highest shared added value through one’s supply chain and in-house operations. The next section provides a non-exclusive list of types of ERP modules for LCA and Life Cycle Sustainability Assessment (LCSA) in general.

3.2. The Role of Customised ERP Modules for Corporate and Product Sustainability Assessments

As has been elaborated in the previous sections customized ERP modules could offer solutions for automated sustainability assessments in manufacturing or SC environments where primary data tend to be measured but not or only partially penetrating through the MES layer. Depending on the availability, transparency and consistency of measured data (cfr. Section 2) from the production line and SC data of n-x suppliers, the role of the customized ERP module can differ substantially. The three subsections below will highlight the use of regression analysis (touched upon in Section 2 as well), engineering modules and engineering design software such as ASPEN.

3.2.1. Coupling Customized Regression Analysis with ERP Systems for Automated Sustainability Assessments

In environments where data are sufficiently being measured at the production line and process data penetration and transparency through the SC are satisfactory, regression analysis might offer a solution to generate LCA indicators such as CEENE (cumulative resource consumption) or Carbon Footprint directly from readily available data within ERP systems. The customized sustainability assessment module would result in a set of equations to automatically generate an environmental footprint (could be both resource driven and/or emission driven). This option could be classified as the most preferable solution when data measurements are relatively abundant, whether or not penetrating through the MES layer. Ideally through Machine Learning (ML), the module should be able to construct the set of equations and their coefficients (few of them have been proposed by De Soete et al. (2014)) depending on the type of available data in order to reduce the uncertainty on the end result [14,43].

3.2.2. Coupling Engineering Modules with ERP Systems for Automated Sustainability Assessments

In Research and Development (R & D) or other data scarce environments where often prospective or enabling technologies are being tested, technology can be broken down into so-called unit operations (e.g., evaporation, crystallization, absorption, etc.). Engineering models were developed in e.g., the European PROSUITE FP7 Project in order to build mass and energy balances of emerging technologies through a very modular approach based on basic unit operations [44]. These engineering models can be built in in a modular way in ERP systems and linked with the input data of the engineering models. One should bear in mind that uncertainty and variability of the response variable will be characterized with a rather high uncertainty in coupling different unit operations, each of them having a certain degree of uncertainty. However, this pathway might be very promising for the future to anticipate on environmental burdens in an early R&D development stage [17].

3.2.3. Coupling Process Modelling Software with ERP Systems for Automated Sustainability Assessments

A third example in this non-exhaustive list is the coupling of process engineering software such as ASPEN with business ERP systems. In this case, the customized module serves as an interface between the modelling software and ERP and/or other enterprise resource systems. The modelling software is basically feeding into ERP system in terms of integration of systems but maintains its stand-alone character. This can be a preferred option in design stages or if one wants to perform scenario analysis, etc. In terms of integration of process data and SC data it is probably the least preferred solution to foster shared value through the SC actors and automated corporate and product sustainability assessments through LCA and LCSA in general.

4. Conclusions and Outlook

With this paper, the author wanted to take the discussion in introducing environmental sustainability of products, services and enterprises into business Enterprise Resource Planning (ERP) systems one step further. These new ERP applications will foster the sustainability transparency and performance of organizations and their Supply Chains (SCs). Under the condition that appropriate business models protecting competitive advantages are applied, internal optimization (continuous improvement) through the SC actors (n-1, n-2, n-x) can be achieved leading to shared value and Sustainable Supply Chain Management (SSCM), facilitated by e.g., the proposed customized ERP modules. To get to that point, six important potential bottlenecks were highlighted: (1) Data management in organizations; (2) Data penetrations through Manufacturing Execution Systems (MES); (3) Consistency in data logging; (4) SC Transparency; (5) SC Reliability and (6) the language issue. This is a non-exhaustive list of challenges we are facing that should be further explored and investigated. One cannot highlight enough the importance in B2B communications through the SC to make that happen. SCs are complex systems that rarely rely on one sector, thus an inter-sectoral, multidisciplinary approach will be necessary. Not but the least important challenge most probably relies on the fact that building bridges between disciplines, between academics and industry is key in this age of science and information. More specifically, the field of Life Cycle Assessment (LCA) can adopt and apply a substantial amount of tools and lines of thought from operational management such as the Lean heritage and six sigma and vice versa; the Life Cycle Thinking (LCT) approach should be more embedded in continuous improvement actions and operational excellence in order to allocate resources in an efficient and effective way to real bottleneck operations. The next step to take would ideally be to validate this proposed framework by assembling a team with all multidisciplinary aspects and evaluate to what extent and for what uses the different formats of a customized module would serve its needs.

Acknowledgments

The author wants to acknowledge colleagues from the Department of Environmental Chemistry and Technology (Ghent University) and from the European Commission’s Directorate-General Joint Research Centre, Institute of Environmental Sustainability, Unit H.08 Sustainability Assessment for internal proofreading.

Conflicts of Interest

The author clearly declares no conflict of interest in whatsoever.

Abbreviations

| B2B | Business to Business |

| B2C | Business to Customer |

| BOM | Bill of Materials |

| BPR | Batch Production Report |

| CEENE | Cumulative Exergy Extracted from the Natural Environment |

| CF | Carbon Footprint |

| C/O | Changeover |

| CSR | Corporate Sustainability Reporting |

| DA | Digital Agenda |

| EHS&S | Environment, Health, Safety and Sustainability |

| EIT | European Centre for Innovation and Technology |

| EMA | European Medicine Agency |

| EPD | Environmental Product Declaration |

| ERP | Enterprise Resource Planning |

| FDA | Food and Drug Administration |

| GMP | Good Manufacturing Practice |

| GSP | Good Supply Practice |

| HR | Human Resources |

| ICT | Information and Communication Technology |

| IoT | Internet of Things |

| IT | Information Technology |

| KPI | Key Performance Indicator |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LCIAM | Life Cycle Impact Assessment Method |

| LCSA | Life Cycle Sustainability Assessment |

| LCT | Life Cycle Thinking |

| MES | Manufacturing Execution System |

| ML | Machine Learning |

| MRP | Manufacturing Resource Planning |

| NGO | Non-Governmental Organization |

| NHS | National Health Service |

| OEE | Overall Equipment Effectiveness |

| PEF | Product Environmental Footprint |

| PLC | Programmable Logic Controller |

| QA | Quality Assurance |

| QC | Quality Control |

| R&D | Research and Development |

| SC | Supply Chain |

| SCADA | Supervisory Control And Data Acquisition |

| SCM | Supply Chain Management |

| SDU | Sustainable Development Unit |

| SLCA | Social Life Cycle Assessment |

| SOP | Standard Operating Procedure |

| SSCM | Sustainable Supply Chain Management |

| S/U | Set-up |

| ToC | Theory of Constraints |

| UNDP | United Nations Development Program |

| VC | Value Chain |

References

- Goldratt, E.M. Critical Chain; The North River Press Publishing Corporation: Great Barrington, MA, USA, 1997. [Google Scholar]

- Goldratt, E.M.; Cox, J. The Goal: A Process of Ongoing Improvement; The North River Press Publishing Corporation: Great Barrington, MA, USA, 2014. [Google Scholar]

- Meadows, D.H.; Meadows, D. The history and conclusions of The Limits to Growth. Syst. Dyn. Rev. 2007, 23, 191–197. [Google Scholar] [CrossRef]

- Malthus, T.R. An Essay on the Principle of Population. Available online: http://www.esp.org/books/malthus/population/malthus.pdf (accessed on 10 October 2015).

- Dewulf, J.; Van Langenhove, H.; Mulder, J.; van den Berg, M.M.D.; van der Kooi, H.J.; de Swaan Arons, J. Illustrations towards quantifying the sustainability of technology. Green Chem. 2000, 2, 108–114. [Google Scholar] [CrossRef]

- Dewulf, J.; Van Langenhove, H.; Vandamme, E.J. Resource Technology—A challenge for scientists and engineers. J. Chem. Technol. Biotechnol. 2010, 85, 1299–1300. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our common future—Call for action. Environ. Conserv. 1987, 14, 291–294. [Google Scholar] [CrossRef]

- Kainuma, Y.; Tawara, N. A multiple attribute utility theory approach to lean and green supply chain management. Int. J. Prod. Econ. 2006, 101, 99–108. [Google Scholar] [CrossRef]

- Taormina, R.J.; Gao, J.H. Maslow and the motivation hierarchy: measuring satisfaction of the needs. Am. J. Psychol. 2013, 126, 155–177. [Google Scholar] [CrossRef] [PubMed]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Jimenez-Gonzalez, C.; Overcash, M.R. The evolution of life cycle assessment in pharmaceutical and chemical applications—A perspective. Green Chem. 2014, 16, 3392–3400. [Google Scholar] [CrossRef]

- Kralisch, D.; Ott, D.; Gericke, D. Rules and benefits of Life Cycle Assessment in green chemical process and synthesis design: a tutorial review. Green Chem. 2015, 17, 123–145. [Google Scholar] [CrossRef]

- Cespi, D.; Beach, E.S.; Swarr, T.E.; Passarini, F.; Vassura, I.; Dunn, P.J.; Anastas, P.T. Life cycle inventory improvement in the pharmaceutical sector: assessment of the sustainability combining PMI and LCA tools. Green Chem. 2015, 17, 3390–3400. [Google Scholar] [CrossRef]

- De Soete, W.; Debaveye, S.; De Meester, S.; Van der Vorst, G.; Aelterman, W.; Heirman, B.; Cappuyns, P.; Dewulf, J. Environmental Sustainability Assessments of Pharmaceuticals: An Emerging Need for Simplification in Life Cycle Assessments. Environ. Sci. Technol. 2014, 48, 12247–12255. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Gonzalez, C.; Ollech, C.; Pyrz, W.; Hughes, D.; Broxterman, Q.B.; Bhathela, N. Expanding the Boundaries: Developing a Streamlined Tool for Eco-Footprinting of Pharmaceuticals. Org. Process. Res. Dev. 2013, 17, 239–246. [Google Scholar] [CrossRef]

- De Soete, W.; Dewulf, J.; Cappuyns, P.; Van der Vorst, G.; Heirman, B.; Aelterman, W.; Schoeters, K.; Van Langenhove, H. Exergetic Sustainability Assessment of Batch versus Continuous Wet Granulation based Pharmaceutical Tablet Manufacturing: a Cohesive Analysis at Three Different Levels. Green Chem. 2013, 15, 3039–3048. [Google Scholar] [CrossRef]

- De Soete, W.; Boone, L.; Willemse, F.; De Meyer, E.; Heirman, B.; Van Langenhoye, H.; Dewulf, J. Environmental resource footprinting of drug manufacturing: Effects of scale-up and tablet dosage. Resour. Conserv. Recycl. 2014, 91, 82–88. [Google Scholar] [CrossRef]

- Van der Vorst, G.; Van Langenhove, H.; De Paep, F.; Aelterman, W.; Dingenen, J.; Dewulf, J. Exergetic life cycle analysis for the selection of chromatographic separation processes in the pharmaceutical industry: preparative HPLC versus preparative SFC. Green Chem. 2009, 11, 1007–1012. [Google Scholar] [CrossRef]

- European Commission. Directive 2005/32/EC of the European Parliament and of the Council. Available online: http://eur-lex-europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32005L0032&from=EN (accessed on 15 October 2015).

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschoesser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the buliding sector: critical reflections baed on 5 to 10 years experience in different european countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef]

- ISA. eGovernment in the European Union; ISA: Brussels, Belgium, 2015. [Google Scholar]

- Res, M.D.; Bresfelean, V.P.; Ghisoiu, N.; Popa, S.C. Research on the implementation of customized erp solutions for improving business organizaiton. In Proceedings of the 6th International Conference on Business Excellence, Brasov, Romania, 14–15 October 2011; Volume 2, pp. 144–147.

- Li, X.J.; Wang, P.; Huang, X. Mechatronics and Information Technology, Pts 1 and 2; Han, Q., Takahashi, K., Oh, C.H., Luo, Z., Eds.; Trans. Tech. Publications Ltd.: Stafa-Zurich, Switzerland, 2012. [Google Scholar]

- Mol, A.P.J. Transparency and value chain sustainability. J. Clean. Production 2015, 107, 154–161. [Google Scholar] [CrossRef]

- Faertes, D. Reliability of Supply Chains and Business Continuity Management. Proced. Comput. Sci. 2015, 55, 1400–1409. [Google Scholar] [CrossRef]

- Cheung, M.S.; Kashyap, V.; Phillips, M. Increasing supply chain reliability shifting paradigms. Chim. Oggi-Chem. Today 2014, 32, 60–62. [Google Scholar]

- Tang, S.Y.; Gurnani, H.; Gupta, D. Managing Disruptions in Decentralized Supply Chains with Endogenous Supply Process Reliability. Production Oper. Manag. 2014, 23, 1198–1211. [Google Scholar] [CrossRef]

- Andreas, C.; Imo, G.; Srocka, M. The openLCA Format Converter—New Release May 2013; GreenDelta GmbH: Berlin, Germany, 2013. [Google Scholar]

- Hanel, T.; Felden, C. Mechanical, Industrial, and Manufacturing Engineering; Ma, M., Ed.; Information Engineering Research Inst.: Newark, NJ, USA, 2011; pp. 410–413. [Google Scholar]

- Schmidtmann, U.; Kreutz, G.; Barkhoff, M.; Virkus, K.; Stockmann, T.; Jovic, M. Material Flow Optimization Under Aspects of Energy Efficiency. In Proceedings of Iecon: 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Spain, 3–5 November 2009.

- Bicheno, J.; Holweg, M. The Lean Toolbox: The Essential Guide to Lean Transformation, 4th ed.; PICSIE Books: Buckingham, UK, 2009. [Google Scholar]

- Crabtree, R. Driving Operational Excellence: Succesful Lean Six Sigma Secrets to Improve the Bottom Line; MetaOps Publishing, LCC: Livonia, MI, USA, 2010. [Google Scholar]

- Liker, J.K.; Convis, G.L. The Toyota Way to Lean Leadership: Achieving and Sustaining Excellence through Leadership Development; The McGraw-Hill Companies: New York, NY, USA, 2012. [Google Scholar]

- Wilson, L. How To Implement Lean Manufacturing; The McGraw-Hill Companies: New York, NY, USA, 2010. [Google Scholar]

- Penny, T.; Collins, M.; Whiting, A.; Aumônier, S. Care Pathways: Guidance on Appraising Sustainability; Coalition for Sustainable Pharmaceuticals and Medical Devices: London, UK, 2015. [Google Scholar]

- Dewulf, J.; Bosch, M.; E. De Meester, B.; Van der Vorst, G.; Van Langenhove, H.; Hellweg, S.; Huijbregts, M.A.J. Cumulative exergy extraction from the natural environment (CEENE): A comprehensive life cycle impact assessment method for resource accounting. Environ. Sci. Technol. 2007, 41, 8477–8483. [Google Scholar] [CrossRef] [PubMed]

- Taelman, S.E.; De Meester, S.; Schaubroeck, T.; Sakshaug, E.; Alvarenga, R.A.F.; Dewulf, J. Accounting for the occupation of the marine environment as a natural resource in life cycle assessment: An exergy based approach. Resour. Conserv. Recycl. 2014, 91, 1–10. [Google Scholar] [CrossRef]

- Van der Vorst, G.; Dewulf, J.; Aelterman, W.; De Witte, B.; Van Langenhove, H. A Systematic Evaluation of the Resource Consumption of Active Pharmaceutical Ingredient Production at Three Different Levels. Environ. Sci. Technol. 2011, 45, 3040–3046. [Google Scholar] [CrossRef] [PubMed]

- Alvarenga, R.A.F.; Dewulf, J.; Van Langenhove, H.; Huijbregts, M.A.J. Exergy-based accounting for land as a natural resource in life cycle assessment. Int. J. Life Cycle Assess. 2013, 18, 939–947. [Google Scholar] [CrossRef]

- Lenzen, M.; Wood, R.; Wiedmann, T. Uncertainty Analysis for Multi-Region Input-Output Models—A Case Study of the Uk’s Carbon Footprint. Econ. Syst. Res. 2010, 22, 43–63. [Google Scholar] [CrossRef]

- Weidema, B.P.; Thrane, M.; Christensen, P.; Schmidt, J.; Lokke, S. Carbon footprint—A catalyst for life cycle assessment? J. Ind. Ecol. 2008, 12, 3–6. [Google Scholar] [CrossRef]

- Wiedmann, T. Carbon Footprint and Input-Output Analysis—An Introduction. Econ. Syst. Res. 2009, 21, 175–186. [Google Scholar] [CrossRef]

- Liu, Y.B.; Wang, J.M.; Sun, J.G.; ACM. A Machine Learning Approach to Semi-Automating Workflow Staff Assignment; Assoc Computing Machinery: New York, NY, USA, 2007. [Google Scholar]

- De Meester, S.; Dewulf, J.; Roes, L.; Patel, M.K. Prospective Sustainability Assessment of Technologies: Development of Basic Engineering Modules for Prospective Estimations of the Material Flows and Energy Requirements. Available online: http://www.prosuite.org (accessed on 26 November 2015 ).

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).