Identification of Innovative Opportunities Based on Product Scenario Evolution

Abstract

:1. Introduction

2. Related Research

2.1. Research and Methods of Opportunity Identification

2.2. Application of Scenario

3. Concept of Product Scenario

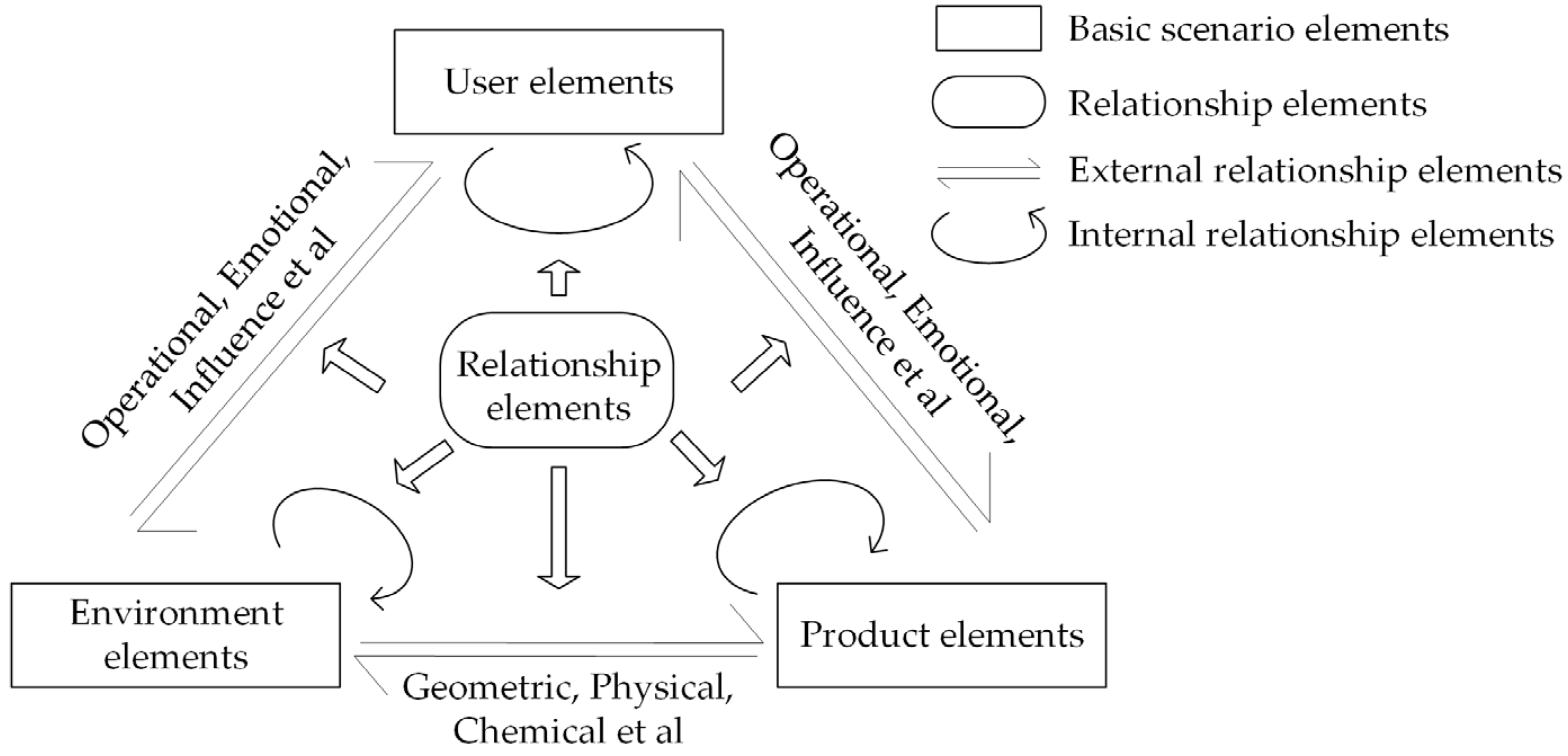

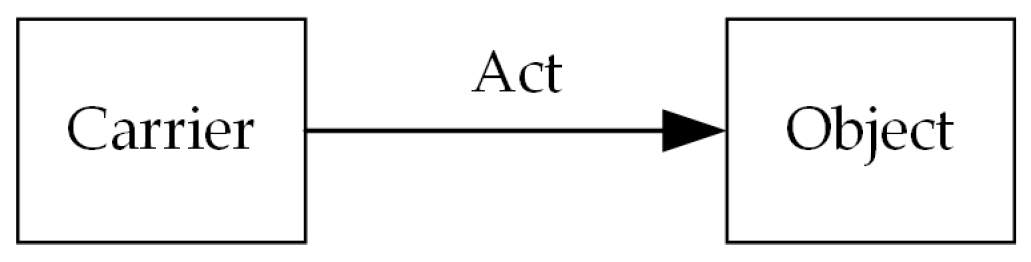

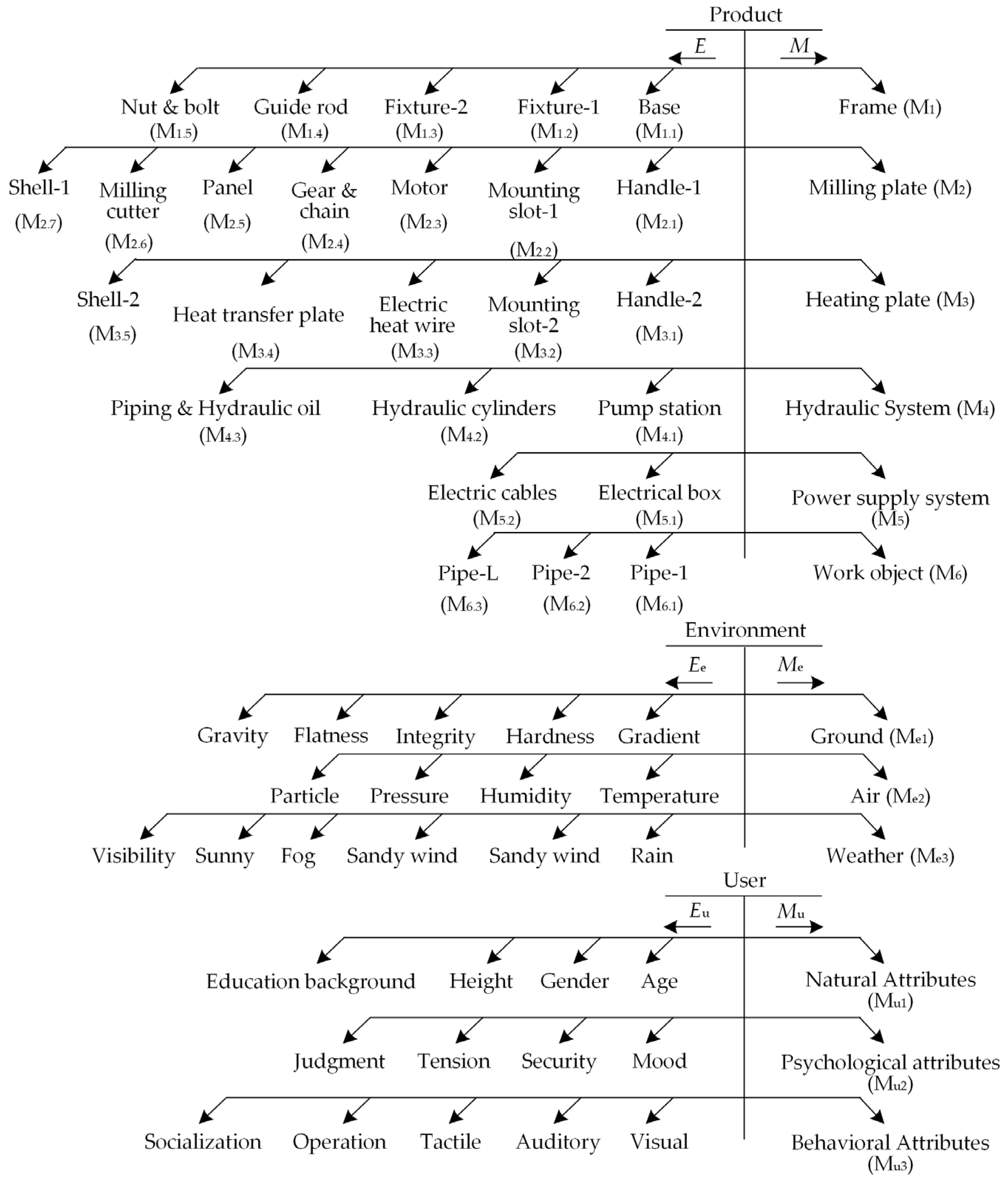

3.1. Scenario Elements of Product Scenario

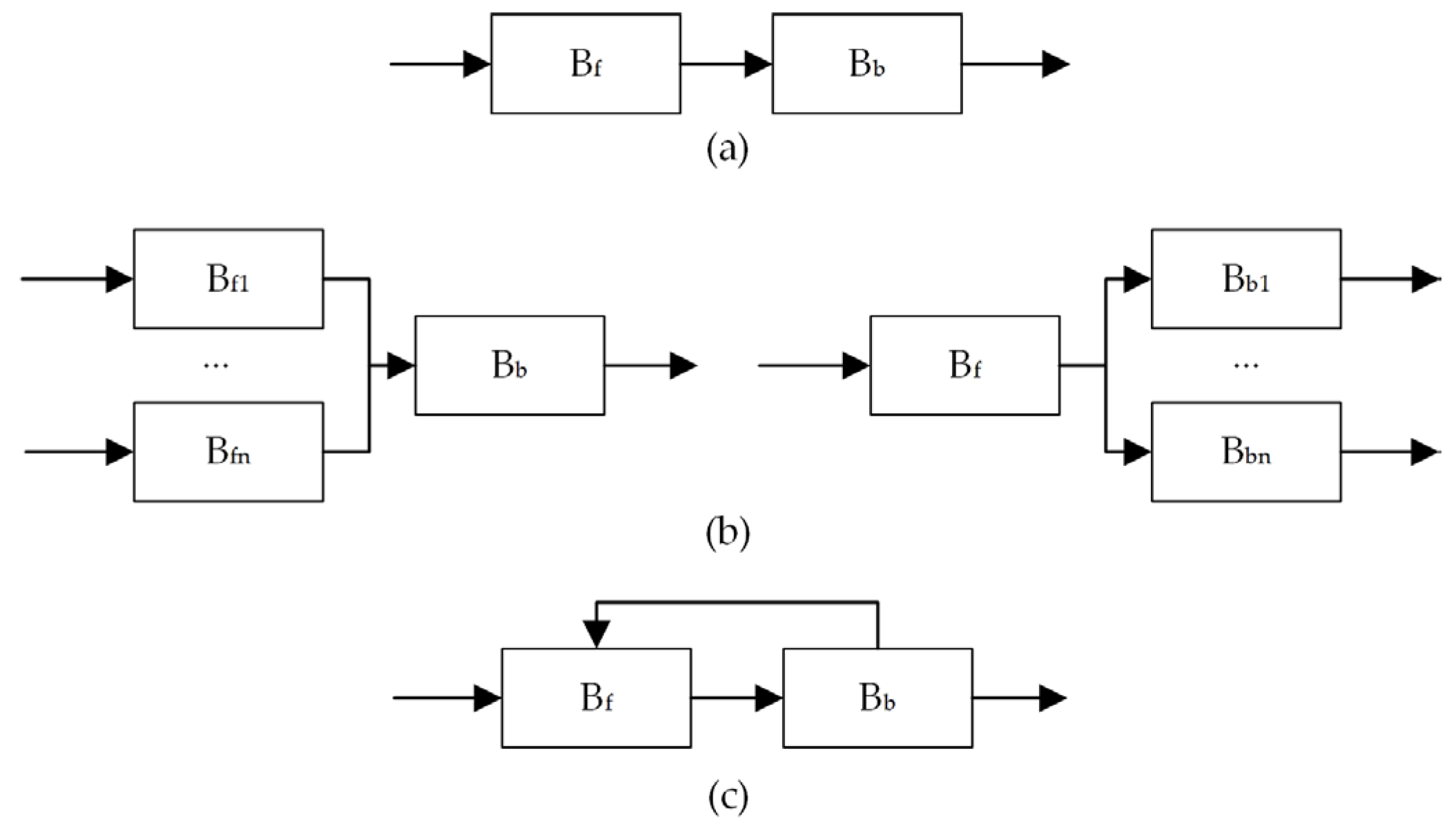

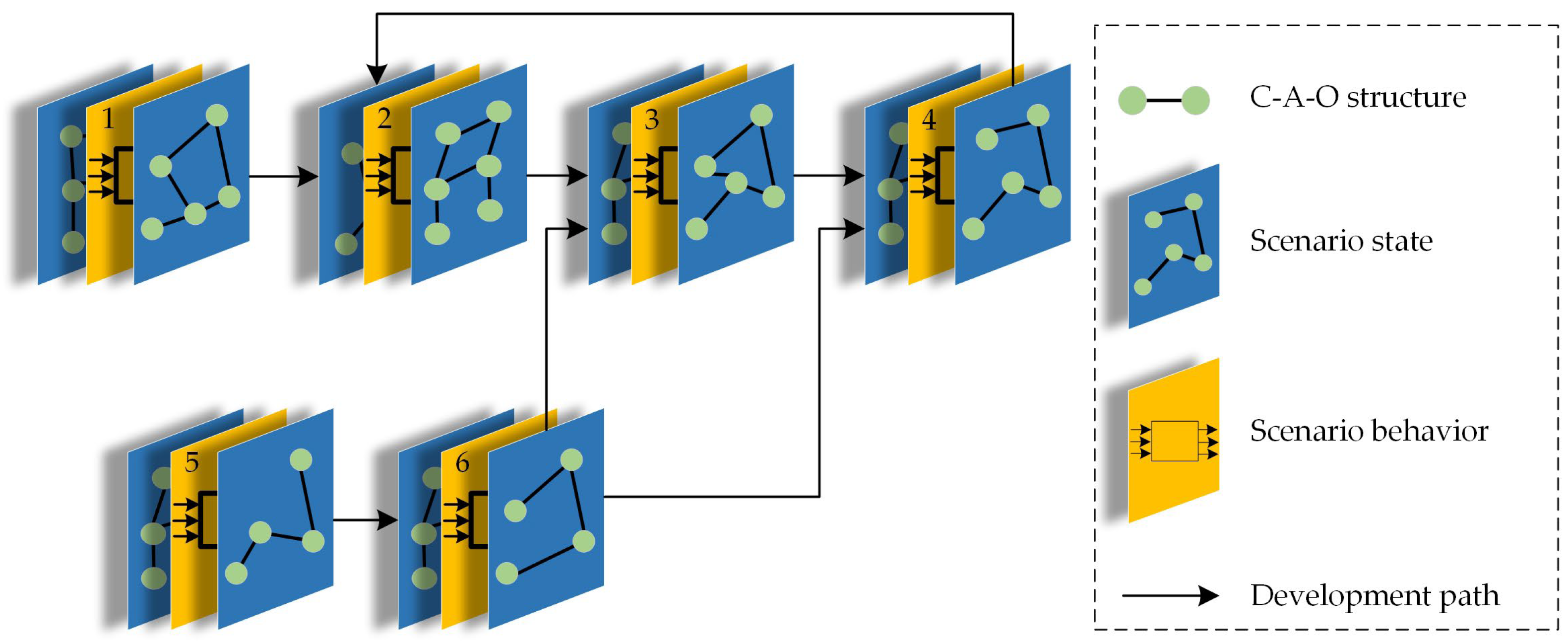

3.2. Development of Product Scenario

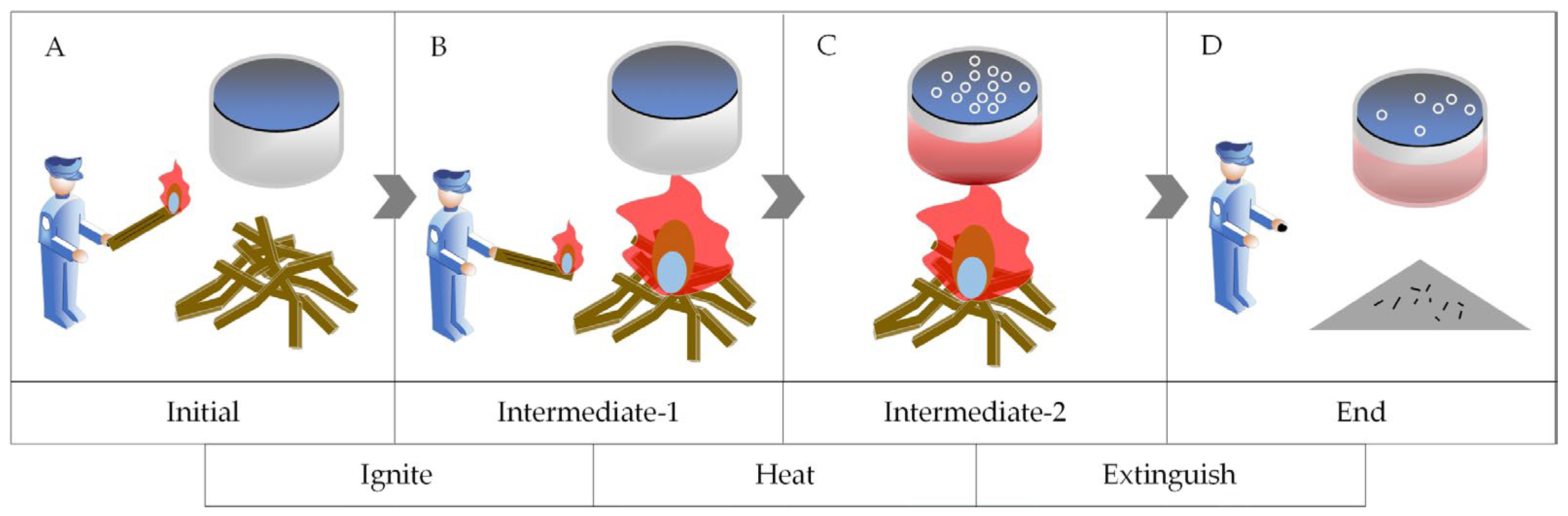

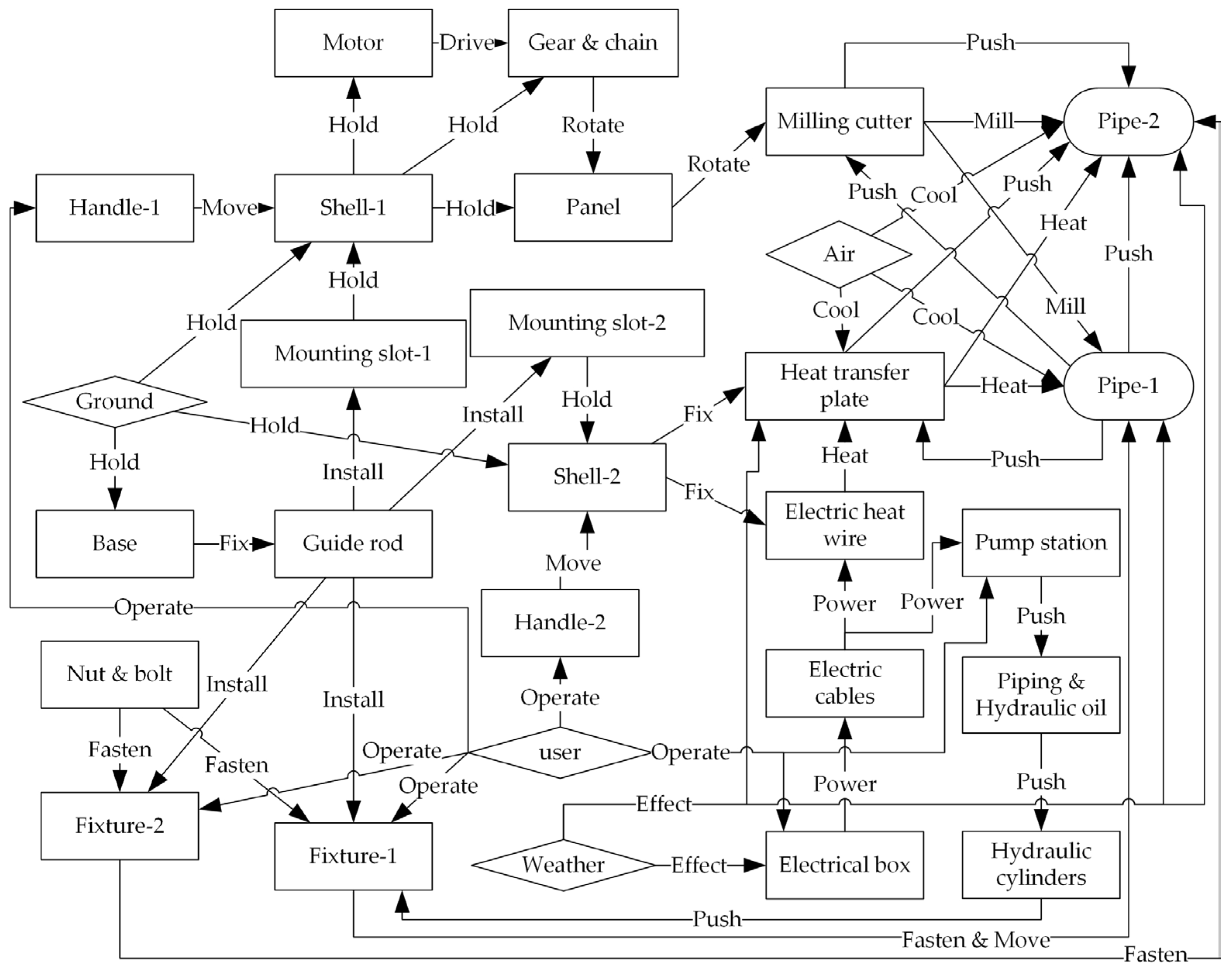

3.3. Typical Product Scenario Construction

4. Proposed Method

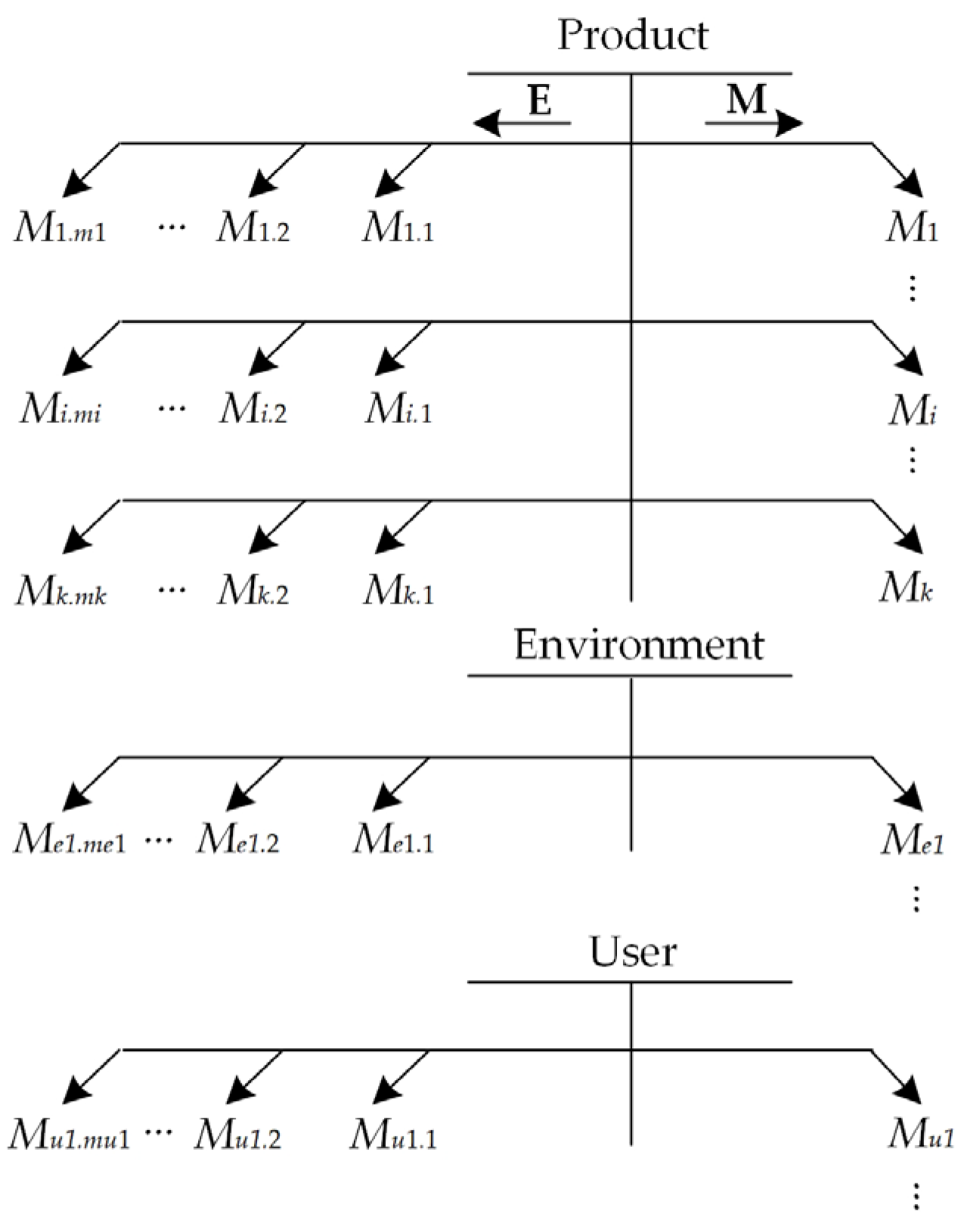

4.1. The Target Scenario Elements for Extension

4.2. Methods for Extending Target Scenario Elements

4.2.1. Scenario Elements Extension Rules

4.2.2. Scenario Elements Extension Strategies

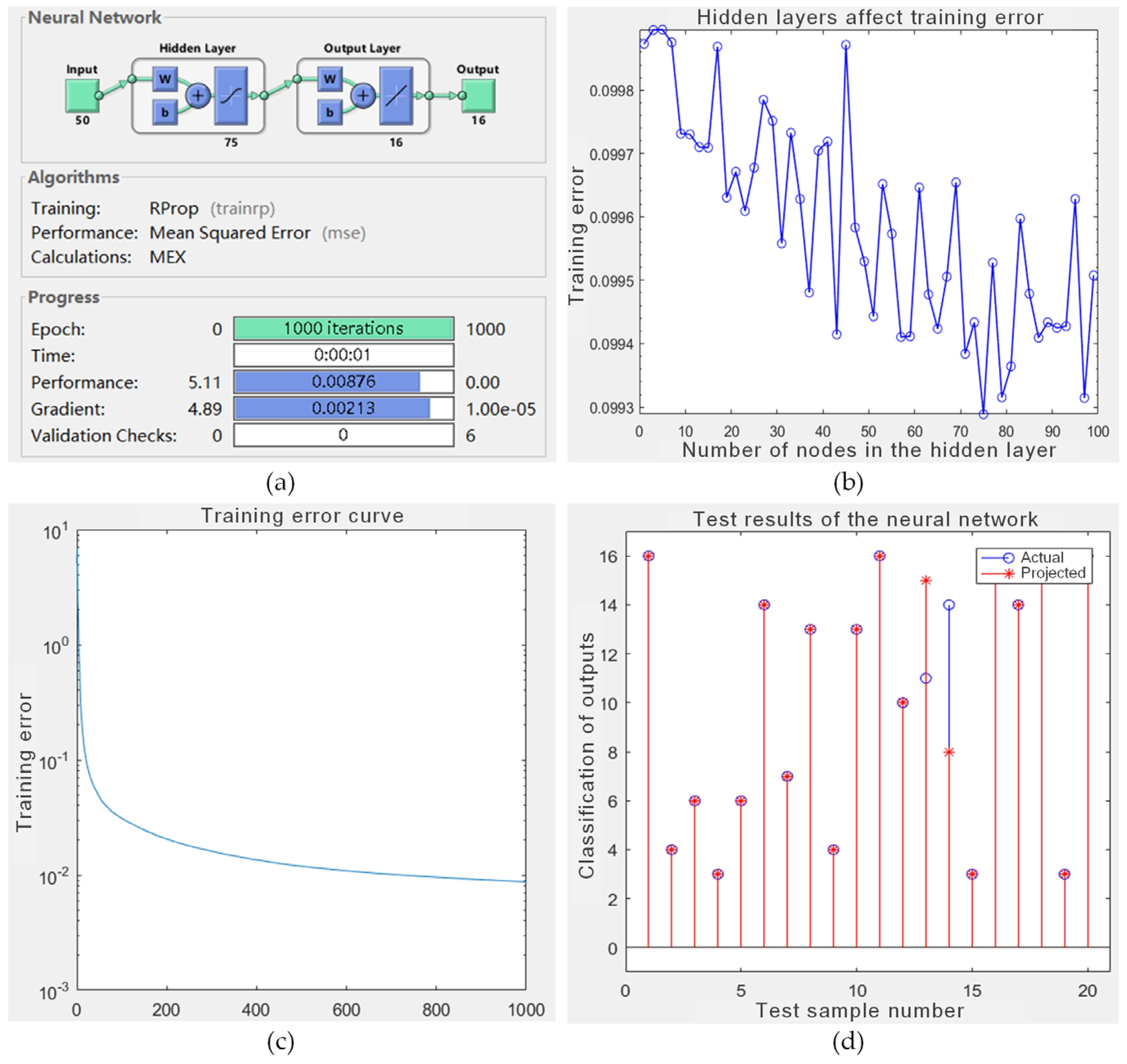

4.2.3. Selection Strategies for Extending Scenario Elements

4.3. New Scenario Element Sets Construction and Innovation Opportunity Identification

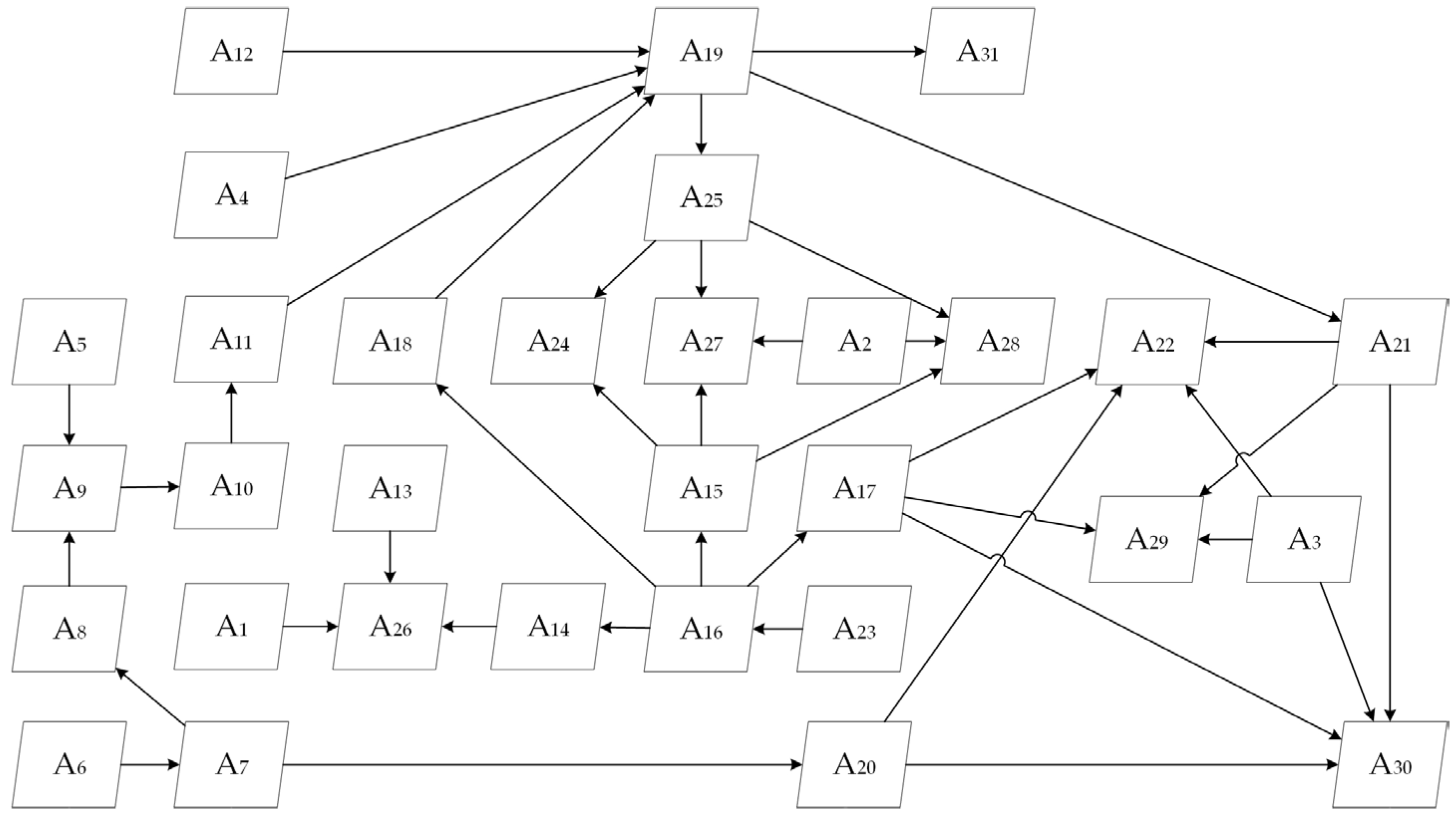

4.3.1. Innovation Opportunity Generation Process

4.3.2. Innovation Opportunity Evaluation

4.4. Summary

5. Case Study

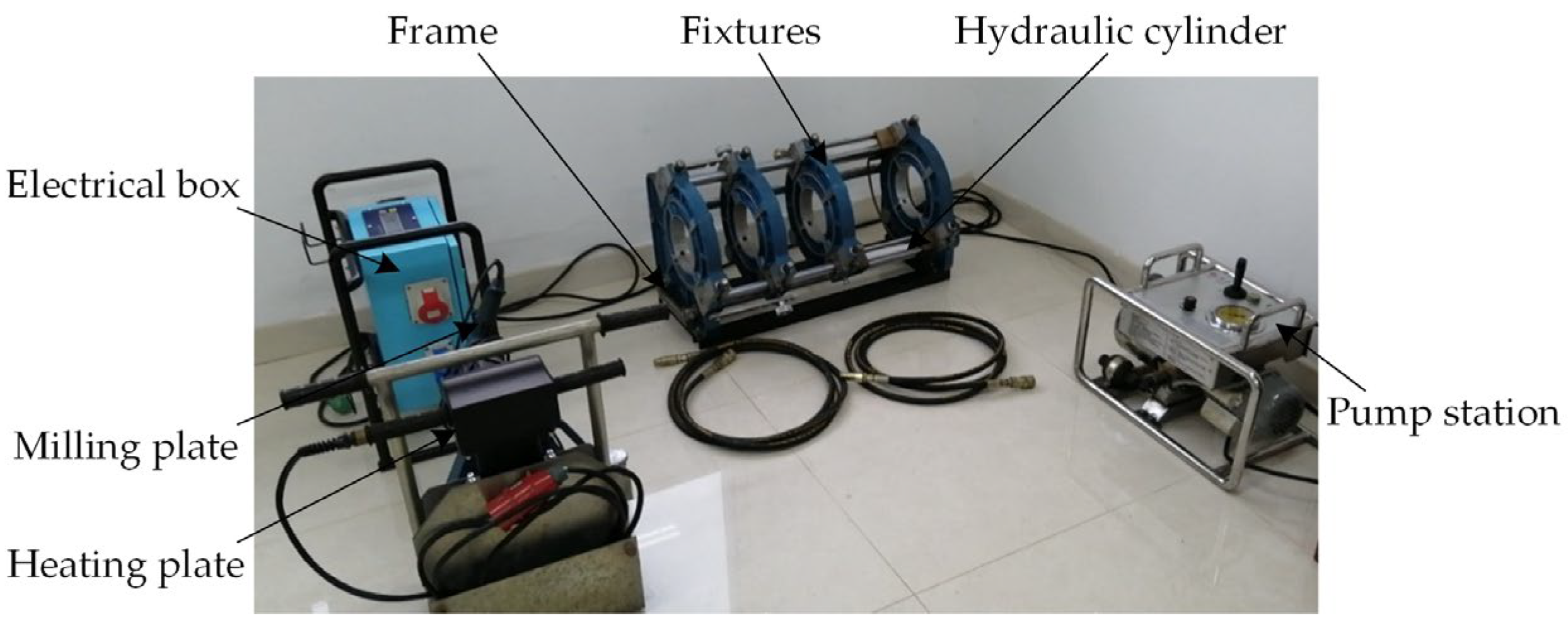

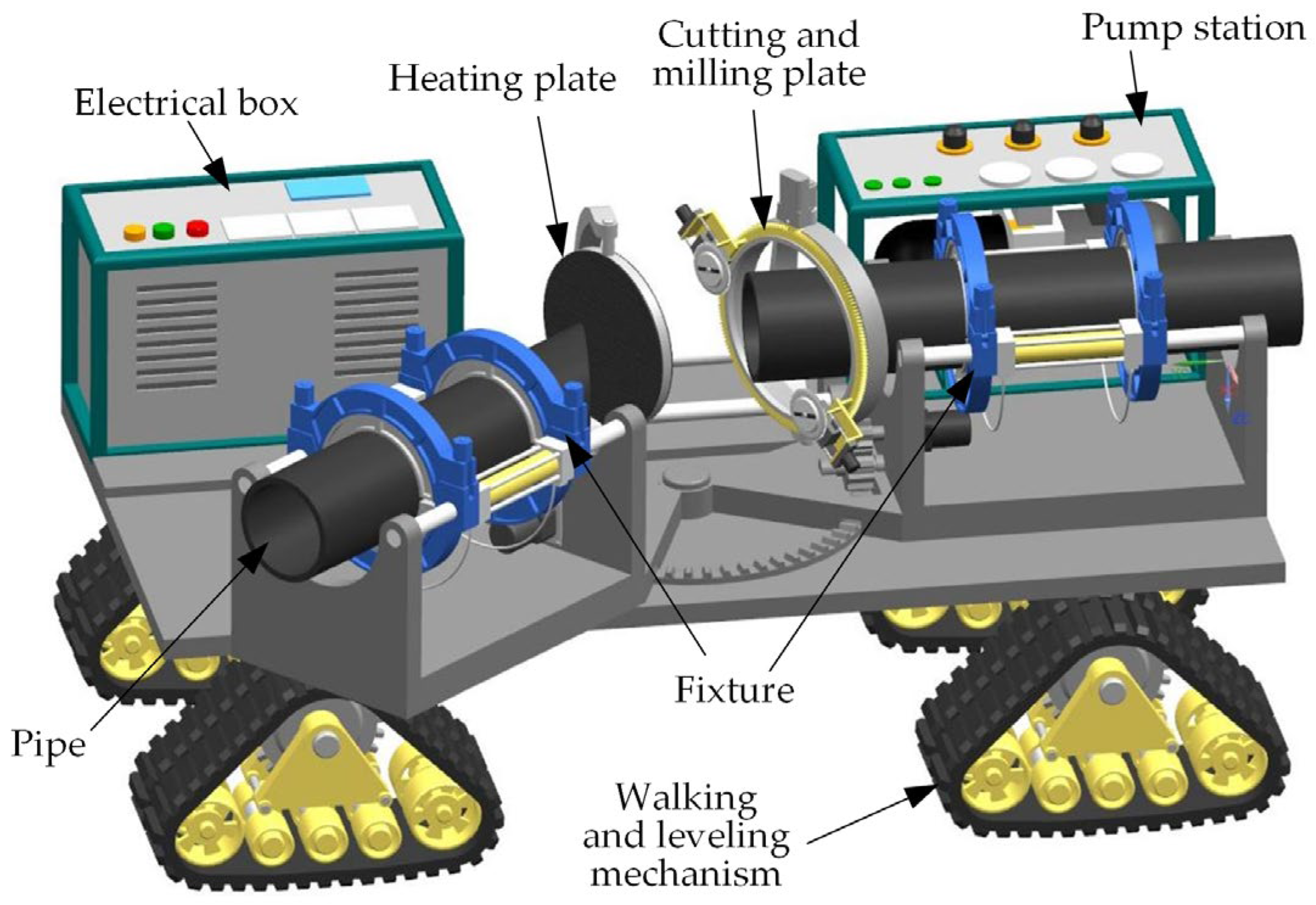

5.1. Product Scenario of PE-WM

5.2. PE-WM’s Target Extension Scenario Elements

5.3. Selection of Element Extension Strategies

5.4. New Scenario Element Sets and Innovation Opportunities

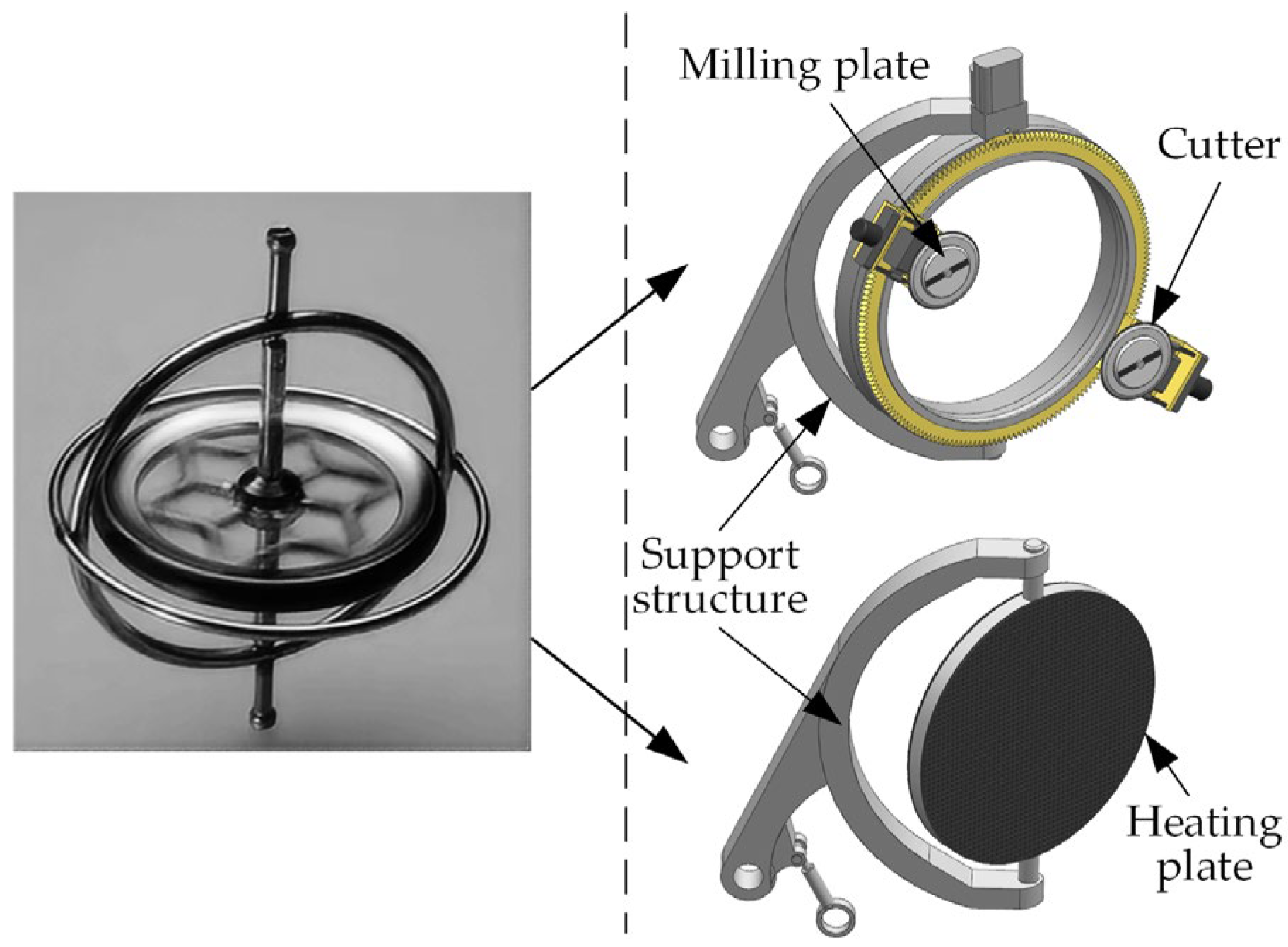

5.5. Innovative Design Scheme of PE-WM

5.6. Solution Evaluation and Comparison

6. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | m1(E1) | m2(E2) | m3(E3) | No. | m1(E1) | m2(E2) | m3(E3) | No. | m1(E1) | m2(E2) | m3(E3) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | A1 | 0.00 | 0.15 | 0.11 | A12 | 0.10 | 0.03 | 0.09 | A22 | 0.62 | 0.74 | 0.69 |

| H2 | 0.44 | 0.32 | 0.15 | 0.14 | 0.17 | 0.36 | 0.33 | 0.21 | 0.20 | |||

| H3 | 0.54 | 0.52 | 0.72 | 0.75 | 0.78 | 0.53 | 0.04 | 0.01 | 0.07 | |||

| Θ | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.02 | 0.01 | 0.04 | 0.04 | |||

| H1 | A2 | 0.20 | 0.06 | 0.13 | A13 | 0.10 | 0.03 | 0.09 | A23 | 0.68 | 0.50 | 0.71 |

| H2 | 0.23 | 0.28 | 0.27 | 0.14 | 0.17 | 0.36 | 0.26 | 0.25 | 0.22 | |||

| H3 | 0.55 | 0.65 | 0.59 | 0.75 | 0.78 | 0.53 | 0.04 | 0.14 | 0.00 | |||

| Θ | 0.02 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 | 0.11 | 0.07 | |||

| H1 | A3 | 0.20 | 0.06 | 0.13 | A14 | 0.01 | 0.06 | 0.06 | A24 | 0.74 | 0.38 | 0.52 |

| H2 | 0.23 | 0.28 | 0.27 | 0.11 | 0.21 | 0.15 | 0.12 | 0.36 | 0.31 | |||

| H3 | 0.55 | 0.65 | 0.59 | 0.87 | 0.71 | 0.78 | 0.10 | 0.20 | 0.08 | |||

| Θ | 0.02 | 0.01 | 0.01 | 0.01 | 0.02 | 0.01 | 0.04 | 0.06 | 0.09 | |||

| H1 | A4 | 0.00 | 0.15 | 0.11 | A15 | 0.15 | 0.01 | 0.03 | A25 | 0.17 | 0.09 | 0.18 |

| H2 | 0.44 | 0.32 | 0.15 | 0.17 | 0.06 | 0.21 | 0.43 | 0.68 | 0.70 | |||

| H3 | 0.54 | 0.52 | 0.72 | 0.67 | 0.92 | 0.74 | 0.37 | 0.21 | 0.11 | |||

| Θ | 0.02 | 0.01 | 0.02 | 0.01 | 0.01 | 0.02 | 0.03 | 0.02 | 0.01 | |||

| H1 | A5 | 0.08 | 0.15 | 0.09 | A16 | 0.00 | 0.01 | 0.00 | A26 | 0.16 | 0.03 | 0.15 |

| H2 | 0.18 | 0.20 | 0.20 | 0.04 | 0.09 | 0.07 | 0.71 | 0.81 | 0.59 | |||

| H3 | 0.72 | 0.63 | 0.70 | 0.95 | 0.89 | 0.92 | 0.11 | 0.15 | 0.24 | |||

| Θ | 0.02 | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.01 | 0.02 | |||

| H1 | A6 | 0.13 | 0.02 | 0.10 | A17 | 0.15 | 0.01 | 0.03 | A27 | 0.74 | 0.38 | 0.52 |

| H2 | 0.17 | 0.09 | 0.21 | 0.17 | 0.06 | 0.21 | 0.12 | 0.36 | 0.31 | |||

| H3 | 0.69 | 0.88 | 0.67 | 0.67 | 0.92 | 0.74 | 0.10 | 0.20 | 0.08 | |||

| Θ | 0.01 | 0.01 | 0.02 | 0.01 | 0.01 | 0.02 | 0.04 | 0.06 | 0.09 | |||

| H1 | A7 | 0.06 | 0.02 | 0.11 | A18 | 0.01 | 0.06 | 0.06 | A28 | 0.17 | 0.09 | 0.18 |

| H2 | 0.28 | 0.19 | 0.24 | 0.11 | 0.21 | 0.15 | 0.43 | 0.68 | 0.70 | |||

| H3 | 0.65 | 0.78 | 0.63 | 0.87 | 0.71 | 0.78 | 0.37 | 0.21 | 0.11 | |||

| Θ | 0.01 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 0.03 | 0.02 | 0.01 | |||

| H1 | A8 | 0.09 | 0.03 | 0.05 | A19 | 0.17 | 0.30 | 0.14 | A29 | 0.26 | 0.18 | 0.22 |

| H2 | 0.16 | 0.09 | 0.23 | 0.66 | 0.55 | 0.84 | 0.44 | 0.72 | 0.62 | |||

| H3 | 0.74 | 0.86 | 0.71 | 0.07 | 0.11 | 0.01 | 0.27 | 0.09 | 0.14 | |||

| Θ | 0.01 | 0.02 | 0.01 | 0.10 | 0.04 | 0.01 | 0.03 | 0.01 | 0.02 | |||

| H1 | A9 | 0.14 | 0.11 | 0.01 | A20 | 0.03 | 0.05 | 0.11 | A30 | 0.62 | 0.74 | 0.69 |

| H2 | 0.19 | 0.16 | 0.24 | 0.20 | 0.11 | 0.16 | 0.33 | 0.21 | 0.20 | |||

| H3 | 0.65 | 0.72 | 0.74 | 0.76 | 0.82 | 0.72 | 0.04 | 0.01 | 0.07 | |||

| Θ | 0.02 | 0.01 | 0.01 | 0.01 | 0.02 | 0.01 | 0.01 | 0.04 | 0.04 | |||

| H1 | A10 | 0.14 | 0.29 | 0.26 | A21 | 0.26 | 0.18 | 0.22 | A31 | 0.75 | 0.54 | 0.63 |

| H2 | 0.58 | 0.46 | 0.51 | 0.44 | 0.72 | 0.62 | 0.14 | 0.27 | 0.29 | |||

| H3 | 0.26 | 0.23 | 0.22 | 0.27 | 0.09 | 0.14 | 0.10 | 0.17 | 0.07 | |||

| Θ | 0.02 | 0.02 | 0.01 | 0.03 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | |||

| H1 | A11 | 0.23 | 0.13 | 0.02 | ||||||||

| H2 | 0.52 | 0.74 | 0.71 | |||||||||

| H3 | 0.24 | 0.11 | 0.26 | |||||||||

| Θ | 0.01 | 0.02 | 0.01 |

| No. | Probability | No. | Probability | ||||||

|---|---|---|---|---|---|---|---|---|---|

| H1 | H2 | H3 | Θ | H1 | H2 | H3 | Θ | ||

| A1 | 0.0016758 | 0.1049519 | 0.8933560 | 0.0000163 | A17 | 0.0003267 | 0.0059875 | 0.9936817 | 0.0000041 |

| A2 | 0.0086795 | 0.0817900 | 0.9095224 | 0.0000081 | A18 | 0.0002148 | 0.0086208 | 0.9911605 | 0.0000039 |

| A3 | 0.0086795 | 0.0817900 | 0.9095224 | 0.0000081 | A19 | 0.0347296 | 0.9639804 | 0.0011889 | 0.0001012 |

| A4 | 0.0016758 | 0.1049519 | 0.8933560 | 0.0000163 | A20 | 0.0007000 | 0.0097226 | 0.9895732 | 0.0000042 |

| A5 | 0.0048121 | 0.0262057 | 0.9689708 | 0.0000113 | A21 | 0.0556322 | 0.9241654 | 0.0201771 | 0.0000253 |

| A6 | 0.0011553 | 0.0095234 | 0.9893167 | 0.0000046 | A22 | 0.9455432 | 0.0537319 | 0.0006827 | 0.0000422 |

| A7 | 0.0007650 | 0.0425621 | 0.9566673 | 0.0000056 | A23 | 0.9170105 | 0.0800972 | 0.0024681 | 0.0004242 |

| A8 | 0.0006209 | 0.0093461 | 0.9900288 | 0.0000042 | A24 | 0.8642412 | 0.1101873 | 0.0246789 | 0.0008926 |

| A9 | 0.0010156 | 0.0237232 | 0.9752559 | 0.0000053 | A25 | 0.0171186 | 0.9376036 | 0.0452532 | 0.0000246 |

| A10 | 0.0746915 | 0.8354868 | 0.0897994 | 0.0000223 | A26 | 0.0032816 | 0.9821718 | 0.0145359 | 0.0000108 |

| A11 | 0.0035949 | 0.9671421 | 0.0292563 | 0.0000067 | A27 | 0.8642412 | 0.1101873 | 0.0246789 | 0.0008926 |

| A12 | 0.0017379 | 0.0313047 | 0.9669459 | 0.0000116 | A28 | 0.0171186 | 0.9376036 | 0.0452532 | 0.0000246 |

| A13 | 0.0017379 | 0.0313047 | 0.9669459 | 0.0000116 | A29 | 0.0556322 | 0.9241654 | 0.0201771 | 0.0000253 |

| A14 | 0.0002148 | 0.0086208 | 0.9911605 | 0.0000039 | A30 | 0.9455432 | 0.0537319 | 0.0006827 | 0.0000422 |

| A15 | 0.0003267 | 0.0059875 | 0.9936817 | 0.0000041 | A31 | 0.9487290 | 0.0454473 | 0.0058167 | 0.0000070 |

| A16 | 0.0000012 | 0.0004963 | 0.9995012 | 0.0000012 | |||||

| No. | Carrier | Act | Object | No. | Carrier | Act | Object |

|---|---|---|---|---|---|---|---|

| A1 | User | Operate | Fixture-2 | A17 | Guide rod | Install | Heating plate |

| A2 | User | Operate | Milling plate | A18 | Guide rod | Install | Fixture-1 |

| A3 | User | Operate | Heating plate | A19 | Fixture-1 | Fasten and Move | Pipe-1 |

| A4 | User | Operate | Fixture-1 | A20 | Cabel | Power | Heating plate |

| A5 | User | Operate | Pump station | A21 | Pipe-1 | Push | Heating plate |

| A6 | User | Operate | Electrical box | A22 | Heating plate | Heat | Pipe-1 |

| A7 | Weather | Effect | Electrical box | A23 | Ground | Hold | Base |

| A8 | Cable | Power | Pump station | A24 | Milling plate | Mill | Pipe-1 |

| A9 | Pump station | Push | Piping and Hydraulic oil | A25 | Pipe-1 | Push | Milling plate |

| A10 | Piping and Hydraulic oil | Push | Hydraulic cylinder | A26 | Fixture-2 | Fasten | Pipe-2 |

| A11 | Hydraulic cylinder | Push | Fixture-1 | A27 | Milling plate | Mill | Pipe-2 |

| A12 | Nut and bolt | Fasten | Fixture-1 | A28 | Milling plate | Push | Pipe-2 |

| A13 | Nut and bolt | Fasten | Fixture-2 | A29 | Heating plate | Push | Pipe-2 |

| A14 | Guide rod | Install | Fixture-2 | A30 | Heating plate | Heat | Pipe-2 |

| A15 | Guide rod | Install | Milling plate | A31 | Pipe-1 | Push | Pipe-2 |

| A16 | Base | Fix | Guide rod |

References

- Ferreira, J.J.M.; Fernandes, C.I.; Ferreira, F.A.F. To be or not to be digital, that is the question: Firm innovation and performance. J. Bus. Res. 2019, 101, 583–590. [Google Scholar] [CrossRef]

- Suchek, N.; Fernandes, C.I.; Kraus, S.; Filser, M.; Sjögrén, H. Innovation and the circular economy: A systematic literature review. Bus. Strategy Environ. 2021, 30, 3686–3702. [Google Scholar] [CrossRef]

- Jeong, B.; Yoon, J.; Lee, J.M. Social media mining for product planning: A product opportunity mining approach based on topic modeling and sentiment analysis. Int. J. Inf. Manag. 2019, 48, 280–290. [Google Scholar] [CrossRef]

- Hock-Doepgen, M.; Clauss, T.; Kraus, S.; Cheng, C.F. Knowledge management capabilities and organizational risk-taking for business model innovation in SMEs. J. Bus. Res. 2021, 130, 683–697. [Google Scholar] [CrossRef]

- He, J.; Ortiz, J. Sustainable business modeling: The need for innovative design thinking. J. Clean. Prod. 2021, 298, 126751. [Google Scholar] [CrossRef]

- Liu, A.; Lu, S. Functional design framework for innovative design thinking in product development. CIRP J. Manuf. Sci. Technol. 2020, 30, 105–117. [Google Scholar] [CrossRef]

- Kudrowitz, B.M.; Wallace, D. Assessing the quality of ideas from prolific, early-stage product ideation. J. Eng. Des. 2013, 24, 120–139. [Google Scholar] [CrossRef]

- Holmén, M.; Magnusson, M.; McKelvey, M. What are innovative opportunities? Ind. Innov. 2007, 14, 27–45. [Google Scholar] [CrossRef]

- Kifetew, F.M.; Perini, A.; Susi, A.; Siena, A.; Muñante, D.; Morales-Ramirez, I. Automating user-feedback driven requirements prioritization. Inform. Softw. Technol. 2021, 138, 106635. [Google Scholar] [CrossRef]

- Huang, C.; Chen, Y. How to enhance the green innovation of sports goods? Micro- and macro-level evidence from China’s manufacturing enterprises. Front. Environ. Sci. 2022, 9, 809156. [Google Scholar] [CrossRef]

- Shen, S.; Venaik, S.; Zhu, Y. A dynamic model of internationalization and innovation in emerging market enterprises: Knowledge exploration, transformation, and exploitation. Manag. Int. Rev. MIR J. Int. Bus. 2023, 63, 561–610. [Google Scholar] [CrossRef] [PubMed]

- Dean, T.; Zhang, H.; Xiao, Y. The role of complexity in the valley of death and radical innovation performance. Technovation 2022, 109, 102160. [Google Scholar] [CrossRef]

- Hagspiel, V.; Huisman, K.J.M.; Kort, P.M.; Lavrutich, M.N.; Nunes, C.; Pimentel, R. Technology adoption in a declining market. Eur. J. Oper. Res. 2020, 285, 380–392. [Google Scholar] [CrossRef]

- Lin, F.; Evans, R.D.; Kharel, R.; Williams, R.A. Competitor intelligence and product innovation: The role of open-mindedness and interfunctional coordination. IEEE Trans. Eng. Manag. 2022, 69, 314–328. [Google Scholar] [CrossRef]

- Lu, C.; Gu, T.; Chen, J.; Liu, Z. Will internet market newness improve performance? An empirical study on the internet market Innovation of Offline Retailers in China. Sustainability 2021, 13, 12619. [Google Scholar] [CrossRef]

- Restuccia, M.; de Brentani, U.; Legoux, R.; Ouellet, J.F. Product life-cycle management and distributor contribution to new product development. J. Prod. Innov. Manag. 2016, 33, 69–89. [Google Scholar] [CrossRef]

- Yoruk, E.; Jones, P. Firm-environment alignment of entrepreneurial opportunity exploitation in technology-based ventures: A configurational approach. J. Small Bus. Manag. 2023, 61, 612–658. [Google Scholar] [CrossRef]

- Rossiter, J.R.; Lilien, G.L. New “brainstorming” principles. Aust. J. Manag. 1994, 19, 61–72. [Google Scholar] [CrossRef]

- Chen, J. The Using of Mind Map in Concept Design. In Proceedings of the 2008 9th International Conference on Computer-Aided Industrial Design and Conceptual Design, Kunming, China, 22–25 November 2008; pp. 1034–1037. [Google Scholar]

- Boonpracha, J. SCAMPER for creativity of students’ creative idea creation in product design. Think. Ski. Creat. 2023, 48, 101282. [Google Scholar] [CrossRef]

- Ilevbare, I.M.; Probert, D.; Phaal, R. A Review of TRIZ, and its benefits and challenges in practice. Technovation 2013, 33, 30–37. [Google Scholar] [CrossRef]

- Mann, D.L. Better Technology forecasting using systematic innovation methods. Technol. Forecast. Soc. 2003, 70, 779–795. [Google Scholar] [CrossRef]

- Huang, J.Y.; Siao, S.T. Development of an integrated bionic design system. J. Eng. Des. Technol. 2016, 14, 310–327. [Google Scholar] [CrossRef]

- Jia, L.; Peng, Q.; Tan, R.; Zhu, X. Analogical stimuli retrieval approach based on R-SBF ontology model. J. Eng. Des. 2019, 30, 599–624. [Google Scholar] [CrossRef]

- McLafferty, I. Focus group interviews as a data collecting strategy. J. Adv. Nurs. 2004, 48, 187–194. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Ming, X.; He, L.; Zheng, M.; Xu, Z. A TRIZ-based trimming method for patent design around. Comput. Aided Des. 2015, 62, 20–30. [Google Scholar] [CrossRef]

- Canfora, G.; Di Penta, M. New Frontiers of Reverse Engineering. In Proceedings of the Future of Software Engineering (FOSE ′07), Minneapolis, MN, USA, 23–25 May 2007; pp. 326–341. [Google Scholar]

- Huizingh, E.K.R.E. Open innovation: State of the art and future perspectives. Technovation 2011, 31, 2–9. [Google Scholar] [CrossRef]

- Bradfield, R.; Wright, G.; Burt, G.; Cairns, G.; Van Der Heijden, K. The origins and evolution of scenario techniques in long range business planning. Futures 2005, 37, 795–812. [Google Scholar] [CrossRef]

- Cornelius, P.; Van De Putte, A.; Romani, M. Three decades of scenario planning in Shell. Calif. Manag. Rev. 2005, 48, 92–109. [Google Scholar] [CrossRef]

- Huss, W.R.; Honton, E.J. Scenario planning—What style should you use? Long Range Plann. 1987, 20, 21–29. [Google Scholar] [CrossRef]

- Godet, M. The art of scenarios and strategic planning: Tools and pitfalls. Technol. Forecast. Soc. 2000, 65, 3–22. [Google Scholar] [CrossRef]

- Spaniol, M.J.; Rowland, N.J. Defining scenario. Futures Foresight Sci. 2019, 1, e3. [Google Scholar] [CrossRef]

- Sardar, Z. The namesake: Futures; futures studies; futurology; futuristic; foresight—what’s in a name? Futures 2010, 42, 177–184. [Google Scholar] [CrossRef]

- Yu, X.; Wan, K.; Du, Q. The power of knowledge: Basic research and technological innovation–evidence from within and across industries in China. Appl. Econ. 2023; published online: 30 May 2023. [Google Scholar]

- Rao, S.K.; Prasad, R. Impact of 5G technologies on industry 4.0. Kluw. Commun. 2018, 100, 145–159. [Google Scholar] [CrossRef]

- Mirtalaie, M.A.; Hussain, O.K.; Chang, E.; Hussain, F.K. A decision support framework for identifying novel ideas in new product development from cross-domain analysis. Inform. Syst. 2017, 69, 59–80. [Google Scholar] [CrossRef]

- Hensen, A.H.R.; Dong, J.Q. Hierarchical business value of information technology: Toward a digital innovation value chain. Inf. Manag. 2020, 57, 103209. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Yung, I.-S.; Lai, M.-H. Dynamic Capabilities in New Product Development: The Case of Asus in Motherboard Production. Total Qual. Manag. Bus. Excell. 2012, 23, 1125–1134. [Google Scholar] [CrossRef]

- Buganza, T.; Dell’Era, C.; Verganti, R. Exploring the Relationships between Product Development and Environmental Turbulence: The Case of Mobile TLC Services. J. Prod. Innov. Manag. 2009, 26, 308–321. [Google Scholar] [CrossRef]

- Nieto, M.; Quevedo, P. Absorptive Capacity, Technological Opportunity, Knowledge Spillovers, and Innovative Effort. Technovation 2005, 25, 1141–1157. [Google Scholar] [CrossRef]

- Wang, C.; Geng, H.; Sun, R.; Song, H. Technological Potential Analysis and Vacant Technology Forecasting in the Graphene Field Based on the Patent Data Mining. Resour. Policy 2022, 77, 102636. [Google Scholar] [CrossRef]

- Shibata, N.; Kajikawa, Y.; Takeda, Y.; Matsushima, K. Detecting Emerging Research Fronts Based on Topological Measures in Citation Networks of Scientific Publications. Technovation 2008, 28, 758–775. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, C.; Huang, L.; Porter, A. Empirically Informing a Technology Delivery System Model for an Emerging Technology: Illustrated for Dye-Sensitized Solar Cells. RD Manag. 2012, 42, 133–149. [Google Scholar] [CrossRef]

- Érdi, P.; Makovi, K.; Somogyvári, Z.; Strandburg, K.; Tobochnik, J.; Volf, P.; Zalányi, L. Prediction of Emerging Technologies Based on Analysis of the US Patent Citation Network. Scientometrics 2013, 95, 225–242. [Google Scholar] [CrossRef]

- You, H.; Li, M.; Hipel, K.W.; Jiang, J.; Ge, B.; Duan, H. Development Trend Forecasting for Coherent Light Generator Technology Based on Patent Citation Network Analysis. Scientometrics 2017, 111, 297–315. [Google Scholar] [CrossRef]

- Higham, K.; Contisciani, M.; De Bacco, C. Multilayer Patent Citation Networks: A Comprehensive Analytical Framework for Studying Explicit Technological Relationships. Technol. Forecast. Soc. Chang. 2022, 179, 121628. [Google Scholar] [CrossRef]

- Verspagen, B.; De Loo, I. Technology Spillovers between Sectors. Technol. Forecast. Soc. 1999, 60, 215–235. [Google Scholar] [CrossRef]

- Karki, M.M.S. Patent Citation Analysis: A Policy Analysis Tool. World Pat. Inf. 1997, 19, 269–272. [Google Scholar] [CrossRef]

- Yoon, B.; Magee, C.L. Exploring Technology Opportunities by Visualizing Patent Information Based on Generative Topographic Mapping and Link Prediction. Technol. Forecast. Soc. Chang. 2018, 132, 105–117. [Google Scholar] [CrossRef]

- Lee, C.; Kwon, O.; Kim, M.; Kwon, D. Early Identification of Emerging Technologies: A Machine Learning Approach Using Multiple Patent Indicators. Technol. Forecast. Soc. Chang. 2018, 127, 291–303. [Google Scholar] [CrossRef]

- Shen, Y.-C.; Wang, M.-Y.; Yang, Y.-C. Discovering the Potential Opportunities of Scientific Advancement and Technological Innovation: A Case Study of Smart Health Monitoring Technology. Technol. Forecast. Soc. 2020, 160, 120225. [Google Scholar] [CrossRef]

- Seo, W.; Yoon, J.; Park, H.; Coh, B.; Lee, J.-M.; Kwon, O.-J. Product Opportunity Identification Based on Internal Capabilities Using Text Mining and Association Rule Mining. Technol. Forecast. Soc. Chang. 2016, 105, 94–104. [Google Scholar] [CrossRef]

- Jun, S.; Sung Park, S.; Sik Jang, D. Technology Forecasting Using Matrix Map and Patent Clustering. Ind. Manag. Data Syst. 2012, 112, 786–807. [Google Scholar] [CrossRef]

- Son, C.; Suh, Y.; Jeon, J.; Park, Y. Development of a GTM-Based Patent Map for Identifying Patent Vacuums. Expert Syst. Appl. 2012, 39, 2489–2500. [Google Scholar] [CrossRef]

- Lee, C.; Kim, J.; Kwon, O.; Woo, H.-G. Stochastic Technology Life Cycle Analysis Using Multiple Patent Indicators. Technol. Forecast. Soc. 2016, 106, 53–64. [Google Scholar] [CrossRef]

- Cammarano, A.; Varriale, V.; Michelino, F.; Caputo, M. Employing Online Big Data and Patent Statistics to Examine the Relationship between End Product’s Perceived Quality and Components’ Technological Features. Technol. Soc. 2023, 73, 102231. [Google Scholar] [CrossRef]

- Zhou, T.; Lu, Y.; Wang, B. The Relative Importance of Website Design Quality and Service Quality in Determining Consumers’ Online Repurchase Behavior. Inform. Syst. Manag. 2009, 26, 327–337. [Google Scholar] [CrossRef]

- Morel, L.; Boly, V. New Product Development Process (NPDP): Updating the Identification Stage Practices. Int. J. Prod. Dev. 2006, 3, 232–251. [Google Scholar] [CrossRef]

- Jang, H.; Park, S.; Yoon, B. Exploring Technology Opportunities Based on User Needs: Application of Opinion Mining and SAO Analysis. Eng. Manag. J. 2023, 35, 209–222. [Google Scholar] [CrossRef]

- Ozcan, S.; Suloglu, M.; Sakar, C.O.; Chatufale, S. Social media mining for ideation: Identification of sustainable solutions and opinions. Technovation 2021, 107, 102322. [Google Scholar] [CrossRef]

- Yakubu, H.; Kwong, C.K.; Lee, C.K.M. A multigene genetic programming-based fuzzy regression approach for modelling customer satisfaction based on online reviews. Soft Comput. 2021, 25, 5395–5410. [Google Scholar] [CrossRef]

- Sardesai, S.; Stute, M.; Kamphues, J. A methodology for future scenario planning. In Next Generation Supply: A Roadmap for Research and Innovation; Springer: Cham, Switzerland, 2021; pp. 35–59. [Google Scholar]

- Weimer-Jehle, W. Cross-Impact Balances: A system-theoretical approach to cross-impact analysis. Technol. Forecast. Soc. 2006, 73, 334–361. [Google Scholar] [CrossRef]

- Bottero, M.; Assumma, V.; Caprioli, C.; Dell’Ovo, M. Decision making in urban development: The application of a hybrid evaluation method for a critical area in the city of Turin (Italy). Sustain. Cities Soc. 2021, 72, 103028. [Google Scholar] [CrossRef]

- Von Wirth, T.; Wissen Hayek, U.; Kunze, A.; Neuenschwander, N.; Stauffacher, M.; Scholz, R.W. Identifying urban transformation dynamics: Functional use of scenario techniques to integrate knowledge from science and practice. Technol. Forecast. Soc. 2014, 89, 115–130. [Google Scholar] [CrossRef]

- Strengers, Y.; Dahlgren, K.; Pink, S.; Sadowski, J.; Nicholls, L. Digital Technology and energy imaginaries of future home life: Comic-strip scenarios as a method to disrupt energy industry futures. Energy Res. Soc. Sci. 2022, 84, 102366. [Google Scholar] [CrossRef]

- Andersen, P.D.; Hansen, M.; Selin, C. Stakeholder inclusion in scenario planning—A review of european projects. Technol. Forecast. Soc. 2021, 169, 120802. [Google Scholar] [CrossRef]

- Schuh, G.; Schultze, W.; Schiffer, M.; Rieger, A.; Rudolf, S.; Lehbrink, H. Scenario-based determination of product feature uncertainties for robust product architectures. Prod. Eng. 2014, 8, 383–395. [Google Scholar] [CrossRef]

- Kurakawa, K. A Scenario-driven conceptual design information model and its formation. Res. Eng. Des. 2004, 15, 122–137. [Google Scholar] [CrossRef]

- Randt, N.P. An Approach to product development with scenario planning: The case of aircraft design. Futures 2015, 71, 11–28. [Google Scholar] [CrossRef]

- Shin, J.E.; Sutcliffe, A.G.; Gregoriades, A. Scenario advisor tool for requirements engineering. Requir. Eng. 2005, 10, 132–145. [Google Scholar] [CrossRef]

- Liu, F.; Li, X.; Shi, Y. Scientific breakthrough study of extenics. Procedia Comput. Sci. 2016, 91, 526–531. [Google Scholar] [CrossRef]

- Li, W.; Song, Z.; Mao, E.; Suh, S. Using extenics to describe coupled solutions in axiomatic design. J. Eng. Des. 2019, 30, 1–31. [Google Scholar] [CrossRef]

- Fulton Suri, J.; Marsh, M. Scenario building as an ergonomics method in consumer product design. Appl. Ergon. 2000, 31, 151–157. [Google Scholar] [CrossRef] [PubMed]

- Sheu, D.D.; Hou, C.T. TRIZ-based systematic device trimming: Theory and application. Procedia Eng. 2015, 131, 237–258. [Google Scholar] [CrossRef]

- Pahl, G.; Wallace, K.; Blessing, L. Engineering Design: A Systematic Approach, 3rd ed.; Springer: London, UK, 2007; ISBN 978-1-84628-318-5. [Google Scholar]

- Liu, F.; Zhao, Q.; Yang, Y. An approach to assess the value of industrial heritage based on dempster—Shafer theory. J. Cult. Herit. 2018, 32, 210–220. [Google Scholar] [CrossRef]

- Dong, Y.; Tan, R.; Zhang, P.; Peng, Q.; Shao, P. Product redesign using functional backtrack with digital twin. Adv. Eng. Inform. 2021, 49, 101361. [Google Scholar] [CrossRef]

- Yang, C. Extension Innovation Method, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Wang, K.; Tan, R.; Peng, Q.; Sun, Y.; Li, H.; Sun, J. Radical innovation of product design using an effect solving method. Comput. Ind. Eng. 2021, 151, 106970. [Google Scholar] [CrossRef]

- Zhang, P.; Nie, Z.; Dong, Y.; Zhang, Z.; Yu, F.; Tan, R. Smart concept design based on recessive inheritance in complex electromechanical system. Adv. Eng. Inform. 2020, 43, 101010. [Google Scholar] [CrossRef]

- Bartini, R.O.D. Relations between physical constants. Prog. Phys. 2005, 3, 34–40. [Google Scholar]

| Level | m1(E1) | m2(E2) | m3(E3) | ms |

|---|---|---|---|---|

| H1 | p11 | p12 | p13 | ms1 |

| H2 | p21 | p22 | p23 | ms2 |

| H3 | p31 | p32 | p33 | ms3 |

| {H1, H2, H3} | pΘ1 | pΘ2 | pΘ3 | msΘ |

| No. | Name | Explanation | Symbolic |

|---|---|---|---|

| Rule 1 | Same-object multi-characteristic extension | Increasing the involvement or importance of different characteristics that have not been attended to, thus changing the original scenario elements. | |

| Rule 2 | Same-characteristic divergence | Changing the type of object while keeping the characteristics unchanged. Usually, this operation also changes the value of the characteristics and the type of scenario elements. | |

| Rule 3 | Same-characteristic and same-value divergence | Exploring different objects with the same characteristics and values to discover diverse scenario elements with the same characteristics. | |

| Rule 4 | Same-object and same-characteristic divergence | Change the value of a characteristic to change the category of an object or to increase the diversity of a characteristic. | |

| Rule 5 | Change of correlation | There are six types of changes: disappearance or addition of correlation, stronger or weaker correlation, and exchange of linear and non-linear correlation. | |

| Rule 6 | Extension by implication relations | Discover new scenario elements from the context of the scenario elements based on their implication relationships. | |

| Rule 7 | Combination extension | Combine two or more scenario elements into a new scenario element through combination. | |

| Rule 8 | Replication | This rule can be considered a special case of combination extension, which is the combination of multiple scenario elements that are the same or similar. | |

| Rule 9 | Delete | This is the reverse of combination extension, where deleting some or all of the decomposed values, characteristics, or objects can change the original scenario element. |

| No. | NEC | Suggested Extension Rules | Cases |

|---|---|---|---|

| 1 | Adapting to changes in parameters within the product. | Rule 1, Rule 4, Rule 5 | Car cooling fan adjusts speed according to engine temperature. |

| 2 | Function execution time is dynamic. | Rule 1, Rule 4, Rule 5 | Solar concentrator rotates with the sun. |

| 3 | Function execution space is dynamic. | Rule 1, Rule 2, Rule 3, Rule 4, Rule 5 | Electromagnetic suspension adjusts the height and stiffness of the chassis according to the road surface. |

| 4 | Product structure in space and time is dynamic. | Rule 5, Rule 7, Rule 8, Rule 9 | Structural changes of a laptop computer when used on a desktop and when transported in a backpack. |

| 5 | Adapting product functions to environment parameters. | Rule 1, Rule 5 | Air conditioner compressor speed adjusted to room temperature. |

| 6 | Precise targeting of users. | Rule 1, Rule 5, Rule 6, Rule 9 | Change of user age of clothes to 0–3 years old to get baby and toddler clothes. |

| 7 | Reducing human involvement. | Rule 5, Rule 9 | A light-sensitive energy-saving lamp that automatically switches on and off according to light intensity. |

| 8 | Replication of product functions. | Rule 7, Rule 8, Rule 9 | A large number of small LED screens forming a large LED screen. |

| 9 | Integration of needs in different environments. | Rule 2, Rule 3, Rule 6 | Integrated dual-use drone for underwater and airborne use. |

| 10 | Integration of different user needs. | Rule 1, Rule 2, Rule 3, Rule 4 | A foldable smart phone that can satisfy both large and small-screen users. |

| 11 | Integration of functions with different needs. | Rule 1, Rule 3, Rule 6, Rule 7 | Integration of beer bottle opener and lighter. |

| 12 | Integration of functions with opposite needs. | Rule 6, Rule 7 | Integration of eraser and pencil. |

| 13 | Reducing harmful effects on users. | Rule 2, Rule 3, Rule 5, Rule 7, Rule 9 | Anti-blue-light coating for eyeglass lenses. |

| 14 | Reducing harmful effects on the environment. | Rule 2, Rule 3, Rule 5, Rule 7, Rule 9 | Electrical enclosures made from recycled waste. |

| 15 | Reducing harmful effects on the product. | Rule 2, Rule 3, Rule 5, Rule 7, Rule 9 | Surface carburizing of metal parts. |

| 16 | Improving the quality of needs. | Rule 2, Rule 3, Rule 7, Rule 9 | Upgrading of mercury thermometers to infrared thermometers. |

| No. | Predecessor Product | Next Generation Product | LT Dimension (Input) | NEC (Output) |

|---|---|---|---|---|

| 1 | Mercury thermometer | Electronic thermometer | #37, #48 | 13 |

| 2 | Integrated air conditioner | Split air conditioner | #16, #24, #48 | 13 |

| 3 | Ground-level garage | Three-dimensional garage | #41 | 8 |

| 4 | Naturally aspirated engine | Turbocharged engine | #9, #28, #48 | 16 |

| 5 | Cell phone holder | Handheld gimbal | #29, #42, #44 | 4 |

| No. | Indicators | Score |

|---|---|---|

| 1 | Changing of basic scenario element value | 1 |

| 2 | Changing of basic scenario element characteristic | 2 |

| 3 | Changing of basic scenario element object | 3 |

| 4 | Changing of relationship scenario element | 1 |

| No. | Function | No. | Function | No. | Function |

|---|---|---|---|---|---|

| A1 | Operate fixtures | A12 | Maintain clamping force | A23 | Increase stability |

| A2 | Load and unload milling plate | A13 | Maintain clamping force | A24 | Flattens solid surface |

| A3 | Load and unload heating plate | A14 | Constrain solid’s movement direction | A25 | Increase contact surface pressure |

| A4 | Operate fixtures | A15 | Stabilize position | A26 | Fixed pipe position |

| A5 | Connect fluid | A16 | Fix guide rod | A27 | Flattens solid surface |

| A6 | Switch on the power | A17 | Stabilize position | A28 | Increase contact surface pressure |

| A7 | Transmit current | A18 | Constrain solid’s movement direction | A29 | Increase contact area |

| A8 | Convert electricity | A19 | Change solid’s position | A30 | Increase solid temperature |

| A9 | Increase liquid’s pressure | A20 | Increase solid temperature | A31 | Combine solids |

| A10 | Drive hydraulic cylinder | A21 | Increase contact area | ||

| A11 | Move solid linearly | A22 | Input electric energy |

| Target | LT Dimension Numbers | NEC | Suggested Extension Rules |

|---|---|---|---|

| Heating plate | #37, #41, #23, #29, #11 | 11 | Rule 1; Rule 3; Rule 6; Rule 7 |

| Pipe-1 | #15, #24, #33, #25, #11, #19, #37 | 9 | Rule 2; Rule 3; Rule 6 |

| Ground | #15, #24, #19 | 15 | Rule 2; Rule 3; Rule 5; Rule 7; Rule 9 |

| Base | #33, #11, 19 | 3 | Rule 1; Rule 2; Rule 3; Rule 4; Rule 5 |

| Milling plate | #16, #24, #32, #11, #41, #19, #35, #48, #28, #29 | 4 | Rule 5; Rule 7; Rule 8; Rule 9 |

| Pipe-2 | #15, #24, #33, #11, #19, #37 | 14 | Rule 2; Rule 3; Rule 5; Rule 7; Rule 9 |

| No. | Heating Plate | Rule | No. | New Scenario Elements |

|---|---|---|---|---|

| M3 | Rule 1 | M3-1 | ||

| Rule 2 | M3-2 | |||

| M3-3 | ||||

| M3-4 | ||||

| M3-5 | ||||

| Rule 3 | M3-7 | |||

| M3-7 | ||||

| Rule 4 | M3-8 | |||

| M3-9 |

| No. | Pipe-1 | Rule | No. | New Scenario Elements |

|---|---|---|---|---|

| M6.1 | Rule 2 | M6.1-1 | ||

| M6.1-2 | ||||

| M6.1-3 | ||||

| Rule 3 | M6.1-4 | |||

| M6.1-5 |

| No. | Ground | Rule | No. | New Scenario Elements |

|---|---|---|---|---|

| Me1 | Rule 2 | Me1-1 | ||

| Me1-2 | ||||

| Me1-3 | ||||

| Rule 3 | Me1-4 | |||

| Rule 5 | Me1-5 | |||

| Me1-6 | ||||

| Me1-7 | ||||

| Me1-8 | ||||

| Me1-9 |

| No. | Base | Rule | No. | New Scenario Elements |

|---|---|---|---|---|

| M1.1 | Rule 1 | M1.1-1 | ||

| Rule 4 | M1.1-2 | |||

| M1.1-3 |

| No. | Milling Plate | Rule | No. | New Scenario Elements |

|---|---|---|---|---|

| M2 | Rule 5 | M2-1 | ||

| M2-2 | ||||

| M2-3 | ||||

| Rule 7 | M2-4 | |||

| M2-5 | ||||

| Rule 8 | M2-6 | |||

| M2-7 |

| No. | Pipe-2 | Rule | No. | New Scenario Elements |

|---|---|---|---|---|

| M6.2 | Rule 2 | M6.2-1 | ||

| M6.2-2 | ||||

| M6.2-3 | ||||

| M6.2-4 | ||||

| Rule 3 | M6.2-5 | |||

| M6.2-6 | ||||

| Rule 5 | M6.2-7 |

| IIO | Expected Novelty | Expected Value | Total Score |

|---|---|---|---|

| IIO-1 | 3 + 2 + 2 + 1 + 1 + 1 + 1 = 11 | 6 | 17 |

| IIO-2 | 3 + 2 + 2 + 3 + 1 = 11 | 10 | 21 |

| IIO-3 | 3 + 2 + 2 + 1 + 3 + 1 + 1 + 1 = 14 | 11 | 25 |

| Product name: New PE-WM | Overall function: Connect the pipes |

| Key input: Two separated PE pipes | Key output: A connected complete PE pipe |

| Important assistant functions: Adjusting the base, Walking, Loading and unloading milling and heating plates, Cutting pipes, Adjusting pipes | |

| Performance requirements: | The angle of the pipe after welding is 90° to 180°; Adjusting the base to keep the machine level; Automatic loading and unloading of the milling and heating plates by means of hydraulic cylinders; Pipe cutting device and milling plate can be adjusted in angle; Clamps can be rotated and moved; |

| Environmental characteristics: | The working place is outdoors in a non-flat area; Sunny weather; Power supply is available; Temperature and humidity are normal; |

| User Characteristics: | Physically active adults engaged in pipeline construction; Have some specialized knowledge; Normal mobility; |

| Available Resources: | Air, atmospheric pressure, power, manpower, power provided by motors and hydraulics, etc.; |

| Design Constraints: | Cost should be kept under USD1500; Operation should not be too complicated; Pipe O.D. range from 100 to 4000 mm; Pipe wall thickness less than 30 mm. |

| Type | Patent | Advantage | Disadvantage |

|---|---|---|---|

| Joint | CN218719619U: Novel electric fuse connecting pipe fitting for household interface of heat-resistant polyethylene heat supply pipe network | 1. Ease of construction. 2. Low cost. 3. No complicated equipment required. 4. Can be connected at 90 degrees. 5. Can connect complex shaped joints. 6. Can connect pipes of different materials. 7. Increase structural load bearing capacity. | 1. Requires prefabricated parts. 2. Angle cannot be adjusted. 3. Low construction tolerance. 4. Difficulty in ensuring quality of joints. 5. Joints are not universal. |

| CN218645023U: Leakage-proof PE (polyethylene) electric smelting 90-degree elbow | |||

| CN218582583U: Electrothermal fusion welding structure of pipeline joint coating sleeve after seamless thermal shrinkage | |||

| CN215721591U: Pipeline connecting structure | |||

| Automatic (semi-automatic) | CN219405477U: A PE drainage pipe thermal welding equipment | 1. Highly automated. 2. High efficiency. 3. High versatility. 4. Controllable welding quality. 5. High welding quality. | 1. Unable to connect pipes of different materials. 2. Unable to connect pipes of different sizes. 3. Unable to connect pipes with angles. 4. Not easy to transport. 5. Cannot be moved by itself. |

| CN219007064U: PE pipeline hot melting connection fixing device | |||

| CN218804090U: A PE pipe hot-melt welding equipment with good supporting effect | |||

| CN218366577U: Polyethylene gas pipe hot melting butt joint pipe fitting | |||

| CN217862856U: Electric melting welding device for high-density polyethylene pipeline |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Tan, R.; Peng, Q.; Wang, K.; Dong, Y. Identification of Innovative Opportunities Based on Product Scenario Evolution. Systems 2023, 11, 572. https://doi.org/10.3390/systems11120572

Wang F, Tan R, Peng Q, Wang K, Dong Y. Identification of Innovative Opportunities Based on Product Scenario Evolution. Systems. 2023; 11(12):572. https://doi.org/10.3390/systems11120572

Chicago/Turabian StyleWang, Fanfan, Runhua Tan, Qingjin Peng, Kang Wang, and Yafan Dong. 2023. "Identification of Innovative Opportunities Based on Product Scenario Evolution" Systems 11, no. 12: 572. https://doi.org/10.3390/systems11120572

APA StyleWang, F., Tan, R., Peng, Q., Wang, K., & Dong, Y. (2023). Identification of Innovative Opportunities Based on Product Scenario Evolution. Systems, 11(12), 572. https://doi.org/10.3390/systems11120572