Abstract

The modification experiment of waterborne coating was carried out by adding microcapsules. The wall material of the microcapsule was urea-formaldehyde resin and the core material of the microcapsule was epoxy resin. Core material can improve the toughness of the coating and prevent the cracking of the coating. The influences of different contents of microcapsules and the order of adding microcapsules in the coating process on the properties of gloss, color difference and toughness were studied. The results showed that the gloss of the waterborne coating decreased with the increase of microcapsule content. The color difference of coating increased first and then decreased, and when the microcapsule content was 8.0%, the color difference was the largest. The toughness of the coatings also increased first and then decreased. When the content of the microcapsule was 10.0%, the toughness of the coating was significantly enhanced. When the microcapsules with a content of 10.0% were added to the waterborne coating, under the same process, the coating gloss of microcapsules added to the primer was relatively high, and the coating gloss was the highest when the coating process was three-layer primer and two-layer topcoat. The microcapsule had little effect on the color difference of coating in different coating processes. When the coating process was three-layer primer and three-layer topcoat, the coating toughness was the best when microcapsules were added to the topcoats. This study provides a basis for industrial application of waterborne coatings to enhance their toughness.

1. Introduction

In recent years, with the increasing awareness of health and environmental protection, waterborne coatings have become a new type of environmental protection coating [1] for their high safety, low cost and fast drying speed [2]. The most important feature of waterborne coatings is that they do not contain volatile organic compounds [3] and air pollutants, so they are widely used in various fields, such as woodwork processing, in interior decoration materials, housing construction, automobile manufacturing, in aircraft carriers, etc. [4,5], and have broad market application prospects. However, due to the low hardness, non-wear resistance and insufficient toughness of the waterborne coating, accidental damage and cracks often occur during its service life, which limits its practical application [6,7,8]. In view of the above shortcomings, it is necessary to modify the waterborne coating in order to improve the performance.

At present, there are many modification methods for waterborne coatings, such as organosiloxane modification [9], polyurethane modification [10], nanomaterials modification [11] and microcapsules modification [12]. In particular, it was found that adding microcapsules to waterborne coatings can improve the water resistance, wear resistance and the healing properties of coatings [13], which had attracted wide attention [14]. Zhang et al. prepared microcapsule-based self-healing coatings containing epoxy ester as a healing agent [15]. Mirabedini et al. prepared self-healing acrylic latex coatings using novel oil-filled ethyl cellulose microcapsules with enhanced mechanical properties and healing properties of latex coating [16]. Ataei et al. found that the gloss and bond strength of the coatings decreased and the flexural elongation decreased with the increase of the concentration of microcapsules in epoxy coating containing microencapsulated alkyd resin based on coconut oil [17]. These reports focused on improving the water resistance, corrosion resistance and mechanical properties of waterborne coatings, but there are few reports on the toughness enhancement of waterborne coatings [18,19,20,21,22].

In this paper, urea-formaldehyde (the wall material)-coated epoxy (the core material) microcapsules were prepared by two-step in situ polymerization and added to waterborne coatings to study the effects of microcapsules and coating processes on the gloss, chromatic distortion and toughness of waterborne coatings. The main purpose of adding microcapsule was to improve the toughness of the coating and prevent the cracking of the coating. The effects of adding microcapsules in different coating processes on the performance of coatings were compared, which laid a foundation for the application of waterborne coatings in engineering.

2. Materials and Methods

2.1. Test Materials

Waterborne wood coating, F. mandshurica veneer (uniform material color, 40 mm × 40 mm × 3 mm), glass substrates (75 mm × 25 mm × 1 mm) and aluminum substrates (50 mm × 40 mm × 1 mm) were supplied by Yihua Lifestyle Technology Co., Ltd., Shantou, China. Waterborne wood coating consisted of acrylic copolymers supported by water (the content was 90.0%), dipropylene glycol methyl ether (the content was 2.0%) and dipropylene glycol butyl ether (the content was 8.0%). The solid content of the coating is about 26.5%. Urea (Mw: 60.06 g/mol, CAS No.: 57-13-6), 37% formaldehyde solution (Mw: 30.03 g/mol, CAS No.: 50-00-0), epoxy resin (Mw: 375.86 g/mol, CAS No.: 61788-97-4), sodium dodecyl benzene sulfonate (Mw: 348.48 g/mol, CAS No.: 25155-30-0), citric acid monohydrate (Mw: 210.14 g/mol, CAS No.: 5949-29-1), anhydrous ethanol (Mw: 46.07 g/mol, CAS No.: 64-17-5) and triethanolamine (Mw: 149.19 g/mol, CAS No.: 102-71-6) were supplied by Xilong Chemical Co., Ltd., Guangzhou, China.

2.2. Preparation of Microcapsules

Urea-formaldehyde-coated epoxy microcapsules were prepared by in situ polymerization. A mixture of 20.0 g urea and 34.0 g 37% formaldehyde solution was added into the beaker. The system was mixed evenly. The triethanolamine was added to the mixture slowly, and the pH value of the solution was adjusted to 8.0–9.0 by triethanolamine. The mixture was stirred continuously for 1 h in a constant temperature water bath at 70 °C to prepare the wall material solution and was cooled at room temperature. 1.95 g sodium dodecylbenzene sulfonate was added in 193.05 g deionized water to dissolve completely, and a 1.0% sodium dodecylbenzene sulfonate aqueous solution was obtained. Twenty-five g epoxy resin was added to the sodium dodecylbenzene sulfonate aqueous solution. A stable core material emulsion was obtained by stirring at a speed of 1200 r/min for 30 min in a 60 °C water bath. Then the wall material solution was added into the core material emulsion and stirred to make it evenly mixed. The citric acid monohydrate was added to the above mixture, and the pH value was adjusted to 2.5–3.0. The system was reacted at 70 °C for 3 h. After several rinses with deionized water and absolute ethanol, the product was put into the oven and dried at 80 °C for 4 h. The final white powder was the required urea-formaldehyde-coated epoxy microcapsules.

2.3. Preparation of Coatings

The coatings were sprayed on F. mandshurica veneer, glass substrates and aluminum substrates. The incorporation of the microcapsules into the coating was done at room temperature. The specific steps were as follows: The microcapsules were added into the waterborne wood coating according to the mass fraction of microcapsule mass to total mass of liquid coatings (the sum of microcapsule mass and waterborne coatings mass) of 0%, 1.0%, 3.0%, 5.0%, 8.0%, 10.0% and 12.0%. The waterborne coatings were sprayed onto the F. mandshurica veneer, glass substrates and aluminum substrates by an airbrush (Guangzhou Zhongtian Electrical Equipment Co., Ltd., Guangzhou, China). The coating was naturally dried for 3 h and then the waterborne coating was sanded using 1000 grit sandpaper, and a dry cloth was used to wipe off the dust. The spray process needed to be repeated twice. The thickness of the waterborne coating was about 40 μm. After the coatings on the glass substrates were dried, they were immersed in water. After the coatings were whitened, the coatings were removed from the glass substrates with an artistic knife, and then dried in an oven at 40 °C for 30 min for elongation at break testing. The coatings sprayed on the aluminum substrates were for the bend testing. The coatings sprayed on the F. mandshurica veneer were for the gloss and chromatic distortion testing.

In the process of waterborne wood coating, in order to fill wood holes, smooth the surface of the whole coating and increase the sealing property of the coating, the layer number of primer and topcoat was set to be 2 and 3, respectively, and the order of adding microcapsules in different coating processes was changed, and all-factor experiments were carried out. The layer number of primer and topcoat applied during the experiment is shown in Table 1. Taking the coating process of two-layer primer and two-layer topcoat when the microcapsules were added to the primers as an example:

Table 1.

Number of primer and topcoat coatings.

Firstly, the microcapsules were added into the waterborne coatings according to the mass fraction of 10.0%. They were evenly dispersed and sprayed once as primer. The coatings were dried naturally for 3 h. Then the waterborne coatings were polished with 1000 grit sandpaper and the dust was wiped off with a dry cloth. Then the above process was repeated once to obtain the two-layer primer.

Secondly, after the two-layer primer was dried, the waterborne coatings were sprayed as the topcoat, and the coatings were dried naturally for 3 h. Then the waterborne coatings were polished with 1000 grit sandpaper and the dust was wiped off with a dry cloth. Then the above process was repeated once to obtain the two-layer topcoat.

2.4. Performance Test

The microstructure of the microcapsules was analyzed using a Quanta 200 environment scanning electron microscope (SEM), FEI Company (Hillsboro, Oregon, USA), and L2800 Biomicroscope, Guangzhou Liss Optical Instrument Co., Ltd., (Guangzhou, China). The dimension of the microcapsules was measured with a L2800 Biomicroscope. The components of the microcapsules were analyzed using a VERTEX 80V infrared spectrum analyzer, Germany BRUKER Co., Ltd., (Karlsruhe, Germany). The HP-2136 chromatic distortion meter (Zhuhai Tianchuang Instrument Co. Ltd., Zhuhai, China) was used to directly measure the lab value of the specimen. A HG268 gloss meter, produced by 3NH Technology Co., Ltd., Shenzhen, China, was used to measure the gloss of the waterborne coatings on the F. mandshurica veneer. The coating flexibility of microcapsule aluminum-based coatings with different mass fractions and aluminum-based coatings with different coating processes containing microcapsules were tested by a coating flexibility tester. Tensile fracture tests of coatings containing microcapsules with different mass fractions were carried out using the Model AG-IC100KN precision electronic universal capability experiment machine, SHIMADZU Co., Ltd., Kyoto, Japan. All the experiments were repeated four times with an error of less than 5.0%.

3. Results and Discussion

3.1. Effect of Microcapsule on the Properties of Waterborne Coatings

3.1.1. Analysis of Gloss of Coating

The prepared microcapsules are shown in Figure 1. The particle size distribution is shown in Figure 2. The prepared microcapsules are spherical, with a particle size of about 3–5 μm and low breakage rate.

Figure 1.

Scanning electron microscope (SEM) of microcapsules: (A) large magnification; (B) small magnification.

Figure 2.

Particle size distribution of microcapsules.

Figure 3 is the infrared spectrum of microcapsules. It can be seen from Figure 3 that there are prominent characteristic absorption peaks of N–H near 3360 cm−1, which indicates that there are many amino groups in the system. The characteristic absorption peaks of the C–H bond at 2966 cm−1, C=O at 1645 cm−1 and C–N at 1556 cm−1 correspond to the chemical bonds in urea-formaldehyde resin, indicating that urea-formaldehyde resin has been synthesized during the preparation of microcapsule powder. The symmetrical vibration absorption peak of the epoxy matrix is 1247 cm−1, which indicates that epoxy resin exists in the prepared microcapsule powder.

Figure 3.

Infrared spectrogram of microcapsules.

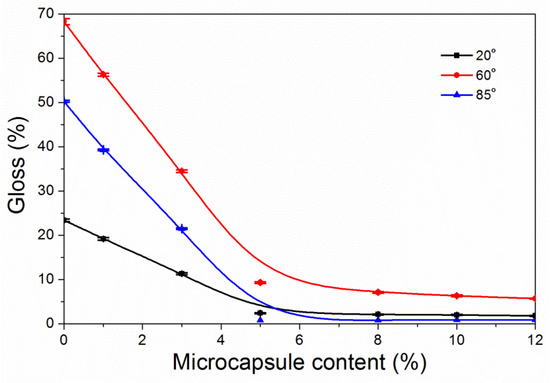

The effect of the change of the mass fraction of microcapsules on the gloss of the coatings was shown in Figure 4. When the visible light was incident at different angles of 20°, 60° and 85°, with the increase of the contents of microcapsules from 0% to 12.0%, the gloss of the coating decreased from 23.4%, 68.3% and 50.3% to 1.8%, 5.7% and 0.9%, respectively. This is because the waterborne coating used in the experiment was a colorless varnish; without adding other substances, the surface is smooth, and the gloss is higher. With the addition of the white powder of microcapsules, the original gloss of the coating was changed so that the surface was not as smooth as before. At the same time, due to the addition of microcapsules, the proportion of waterborne solvents in waterborne coating decreased, the drying time of the coating decreased, and the drying speed became faster, resulting in higher surface roughness and lower gloss of coating. Therefore, the more microcapsules added, the higher the surface roughness and the lower the gloss of the coating.

Figure 4.

The relationship between the contents of microcapsules and the gloss of coating.

3.1.2. Color Difference Analysis of Coating

The color difference of coating refers to the difference in color when the light source is polychromatic light. The results are shown in Table 2. L, a* and b* respectively represent the black-white, red-green and yellow-blue values of a point in the coating. L’, a*’ and b*’ respectively represent the black-white, red-green and yellow-blue values of the rest of the coating [23]. After subtraction, the difference values ΔL, Δa* and Δb*, respectively, are expressed as illumination difference, red-green index difference and yellow-blue index difference. Thus, the color difference ΔE can be obtained according to the formula:

Table 2.

Effect of microcapsules on color difference of waterborne coating.

Table 2 shows the effect of mass fraction of microcapsules on the color difference of the coating. Combined with Figure 5, it can be seen that the variation of the color difference of the coating was as follows: When the microcapsules were added to waterborne wood coating, the color difference of coating also changed with the increase of microcapsule mass fraction. When microcapsule content increased from 0% to 8.0%, the color difference of coating increased from 1.3 to 6.8. When microcapsule content increased from 8.0% to 12.0%, the color difference of coating decreased from 6.8 to 2.0. When the mass fraction of microcapsules was 8.0%, the color difference of coating reached the maximum. Therefore, the addition of microcapsules had a certain effect on the color difference of coatings, and the color difference of the coating increased as compared with that without microcapsules.

Figure 5.

Effect of microcapsule content on color difference of coating.

3.1.3. Flexibility Analysis of Coating

The waterborne wood coating with microcapsules of different mass fractions on the surface of the aluminum sheet was placed on the coating flexibility tester. The coating was upward, and the base material adhered to the steel axis [24]. The coatings were bent in turn according to the diameter of the steel shaft from large to small. The minimum diameter of the steel shaft through which the base material can pass represents the flexibility of the coating. The smaller the diameter of the steel shaft, the higher the flexibility of the coating. After the bending test, it was found that, when bending with a minimum diameter of 0.5 mm, no cracks were found in all the coatings, which proved that the coatings were relatively soft. Through the test of coating flexibility, it was found that the waterborne coating itself was relatively soft. It is difficult to reach a conclusion with the flexibility test method on the effect of adding microcapsules on the flexibility of waterborne coating. It is necessary to further test the tensile fracture of waterborne wood coating modified by microcapsules with different mass fractions.

The coatings were stretched on a precision electronic universal capability experiment machine. The elongation at break of the coating was calculated according to the displacement length of the coating at break and the original length of the coating before stretching. The elongation at break curve of the coating was obtained as shown in Figure 6. With the increase of the content of microcapsules, the elongation at break of the coating first increased and then decreased, that is, the flexibility of the coating first increased and then decreased. When the amounts of microcapsules increased from 0% to 10.0%, the elongation at break increased from 2.67% to 4.91%. When the amounts of microcapsules increased from 10.0% to 12.0%, the elongation at break decreased from 4.91% to 4.11%. The results show that the toughness of the coating was the highest when the amount of microcapsule was 10.0%.

Figure 6.

Effect of amounts of microcapsules added on elongation at break of coating.

Figure 7 was the effect of different mass fractions on infrared spectra of waterborne coatings. It can be seen from the graph that there were absorption peaks representing C=C–H near 810 cm−1, absorption characteristic peaks of C–O–C near 1150 cm−1, absorption peaks representing C=O at 1724 cm−1 and stretching vibration peaks representing CH2 and CH3 near 2950 cm−1. The characteristic peaks of urea-formaldehyde resin and epoxy resin appeared simultaneously in the infrared spectra of waterborne coatings with microcapsules, which indicated that the components of microcapsules existed in the waterborne coatings and were not destroyed.

Figure 7.

Influences of microcapsules on infrared spectrum of coatings.

SEM images of waterborne coatings with different mass fractions of microcapsules are shown in Figure 8. It can be seen that the coating surface was very smooth without microcapsules (Figure 8A). When the microcapsule content was 10.0%, it could be evenly distributed (Figure 8B). But when the microcapsule content increased to 12.0%, there was reunion (Figure 8C). After adding microcapsules, the gloss decreased and the color difference increased due to the unevenness of the coatings. Microcapsule is a core-shell structure of epoxy resin as the core and urea-formaldehyde resin as the shell, which has good elasticity, therefore, the elongation at break and toughness of the coating increases. However, when the content of microcapsules was too high, the agglomeration was more serious in the coating (Figure 8C), which reduced the elongation at break of the coating.

Figure 8.

SEM of waterborne coatings with different contents of microcapsules: (A) 0; (B) 10.0% and (C) 12.0%.

3.2. Effect of Different Coating Processes

3.2.1. Analysis of Gloss of Coating

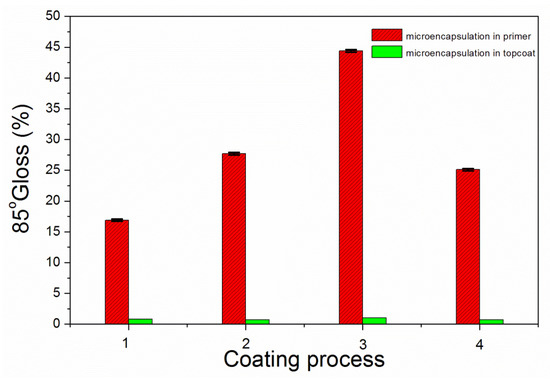

Because the color difference of the coating changed little when the mass fraction of microcapsule was 10.0%, and it had low color difference and good toughness and mechanical properties, the effect of coating process on the performance of the coating was further considered by fixing the mass fraction of microcapsule at 10.0%. The influence of the coating process on the gloss of coating is shown in Figure 9, Figure 10 and Figure 11. It can be seen from the figure that the gloss of the coatings with microcapsules added to primer was higher than that with microcapsules added to topcoat under the same coating process at different incident angles of 20°, 60° and 85°. When the microcapsules were added to the primer and the layer number of topcoat was two, the gloss of coating increased with the increase of the layer number of primer. When the microcapsules were added to the primer and the layer number of topcoat was three, the gloss of coating decreased with the increase of the layer number of primer. When the microcapsules were added in topcoat, the gloss of the coating remained unchanged with the increase of the layer number of topcoat when the layer numbers of primers was 2 and 3. Therefore, adding microcapsules to primers had better gloss; in particular, when the coating process was three-layer primer and two-layer topcoat, the gloss of the coating was the highest.

Figure 9.

Gloss variation of coating at 20° incident angle (samples 1–4 from Table 1).

Figure 10.

Gloss variation of coating at 60° incident angle (samples 1–4 from Table 1).

Figure 11.

Gloss variation of coating at 85° incident angle (samples 1–4 from Table 1).

3.2.2. Color Difference Analysis of Coating

The chromatic distortions of the coatings after adding microcapsules under different coating processes are shown in Table 3 and Table 4. From Table 3, the color difference decreased from 2.4 to 0.9 with the increase in the layer number of primer added with microcapsules when the layer number of topcoat was two. When the layer number of topcoat was three, the color difference increased from 1.1 to 3.7 with the increase of the layer number of primer. From Table 4, it can be observed that the color difference decreased from 3.1 to 1.1 with the increase in the layer number of topcoat with added microcapsules when the layer number of primer was two. When the layer number of primer was three, the color difference increased from 1.1 to 1.5 when the layer number of topcoat increased. In general, adding microcapsules to primer and topcoat had little effect on the color difference of waterborne coating and low fluctuation, respectively. When the microcapsules were added to primer and the coating process was three-layer primer and two-layer topcoat, the color difference of the coating was the smallest, at 0.9. This is because the microcapsule particles are small, and when embedded in the primer, they have little effect on the topcoat.

Table 3.

Effect of microcapsules in primer on color difference of waterborne coating.

Table 4.

Effect of microcapsules in topcoat on color difference of waterborne coating.

3.2.3. Flexibility Analysis of Coating

When the microcapsules were added to the primer and topcoat, the flexibility tester was used to test the coating prepared by different coating processes [25]. After bending, it was found that when bending with the smallest diameter of the steel shaft of 0.5 mm, no cracks appeared in all the coating, which proved that the coating had good flexibility.

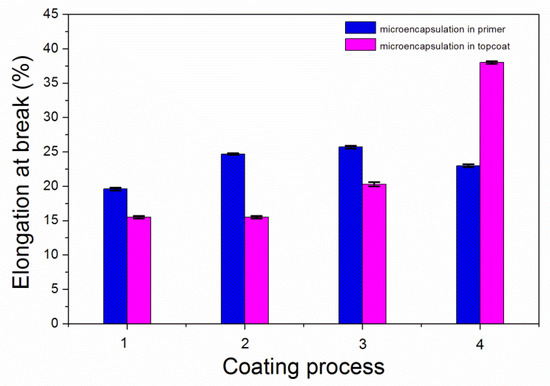

The results of the elongation at break of the coating obtained by placing the coating in the universal capability experiment machine are shown in Figure 12. Except for the coating methods of three-layer primer and three-layer topcoat, the elongation at break of the coatings with microcapsules in the primer was better than that with microcapsules in the topcoat under the same coating process. When the layer number of primer was two, the elongation at break of coating increased from 19.6% to 25.7% with the increase of the layer number of primer added with microcapsules. When the layer number of topcoat was three, the elongation at break of coating decreased from 24.7% to 23.0% with the increase of layer number of primer added with microcapsules. When the microcapsules were added in the topcoat, the elongation at break of the coating did not change significantly when the layer number of primers was two, but when the layer number of primers was three, the toughness of the coating increased with the increase of the layer number of topcoat. When the coating process was three-layer primer and three-layer topcoat, the elongation at break of the coating was the highest when the microcapsules were added to the topcoat.

Figure 12.

Effect of different coating processes on elongation at break of the coating (samples 1–4 from Table 1).

4. Conclusions

The effects of the mass fractions of microcapsules and the sequence of microcapsules on the properties of waterborne coating were studied. The gloss, color difference and flexibility of the modified coating were studied. The results showed that the gloss of the coating decreased with the increase of the mass fractions of microcapsules, and the color difference increased first and then decreased. When the mass fraction of microcapsules was 8.0%, the color difference was the highest, at 6.8. The elongation at break of the coating first increased and then decreased with the mass fractions of microcapsules. When the mass fractions of microcapsules were 10.0%, the toughness of the coating was the best. At the same time, adding 10.0% microcapsule in waterborne coating, under the same coating process, the gloss of the coating with microcapsule in primer was higher, and the gloss of the coating was the highest when the coating process was three-layer primer and two-layer topcoat. Microcapsule had little effect on the chromatic distortion of coating in different coating processes. When adding microcapsule to primer with three-layer primer and two-layer topcoat, the color difference was the lowest of 0.9. When the coating process was three-layer primer and three-layer topcoat and microcapsules were added to the topcoat, the elongation at break and toughness of the coating were the highest. In the coating process of three-layer primer and two-layer topcoat, when the microcapsule content was 10.0% in the primer, the gloss of the waterborne coating was the highest, the color difference was the lowest, the toughness was better and the comprehensive performance was better.

Author Contributions

Formal Analysis, X.Q.; Investigation, X.Y. and L.W.; Data Curation, X.Y.; Writing—Original Draft Preparation, X.Y.

Funding

This research was funded by Natural Science Foundation of Jiangsu Province, grant number BK20150887 and Youth Science and Technology Innovation Fund of Nanjing Forestry University, grant number CX2016018.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xu, J.; Jiang, Y.; Zhang, T.; Dai, Y.; Yang, D.; Qiu, F.; Yu, Z.P.; Yang, P. Synthesis of UV-curing waterborne polyurethane-acrylate coating and its photopolymerization kinetics using FT-IR and photo-DSC methods. Prog. Org. Coat. 2018, 122, 10–18. [Google Scholar] [CrossRef]

- Yan, X.; Qian, X.; Lu, R.; Miyakoshi, T. Synergistic effect of addition of fillers on properties of interior waterborne UV-curing wood coatings. Coatings 2017, 8, 9. [Google Scholar] [CrossRef]

- Xu, H.; Qiu, F.; Wang, Y.; Yang, D.; Wu, W.; Chen, Z.; Zhu, J. Preparation, mechanical properties of waterborne polyurethane and crosslinked polyurethane-acrylate composite. J. Appl. Polym. Sci. 2012, 124, 958–968. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, S.; Qian, J. Synthesis and properties of a novel UV-curable waterborne hyperbranched polyurethane. J. Coat. Tech. Res. 2014, 11, 319–328. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, S.; Zhou, D.; Zhang, Y.; Wang, X.; Yang, R. Biodegradable polyvinyl alcohol nanocomposites made from rice straw fibrils: Mechanical and thermal properties. J. Compos. Mater. 2013, 47, 1449–1459. [Google Scholar] [CrossRef]

- Tong, X.; Zhang, T.; Yang, M.; Zhang, Q. Preparation and characterization of novel melamine modified poly(urea-formaldehyde) self-repairing microcapsules. Coll. Surf. A 2010, 371, 91–97. [Google Scholar] [CrossRef]

- Xu, W.; Wu, Z.; Zhang, J. Compressive creep and recovery behaviors of seat cushions in upholstered. Wood Fiber Sci. 2015, 47, 431–444. [Google Scholar]

- Gu, Y.; Wu, Z.; Zhang, J. Load-deflection behavior of rattan chair seats. Wood Fiber Sci. 2016, 48, 13–24. [Google Scholar]

- Verma, G.; Dhoke, S.K.; Khanna, A.S. Polyester based-siloxane modified waterborne anticorrosive hydrophobic coating on copper. Surf. Coat. Tech. 2015, 221, 1229–1235. [Google Scholar] [CrossRef]

- Jeong, J.; Han, Y.; Yang, J.; Kwak, D.S.; Jeong, H.M. Waterborne polyurethane modified with poly(ethylene glycol) macromer for waterproof breathable coating. Prog. Org. Coat. 2017, 103, 69–75. [Google Scholar] [CrossRef]

- Nikolic, M.; Barsberg, S.; Larsen, F.H.; Lof, D.; Mortensen, K.; Sanadi, A.R. Mechanical characteristics of alkyd binder reinforced by surface modified colloidal nano silica. Prog. Org. Coat. 2016, 90, 147–153. [Google Scholar] [CrossRef]

- Guo, W.; Jia, Y.; Tian, K.; Xu, Z.; Jiao, J.; Li, R.; Wu, Y.; Cao, L.; Wang, H. UV-Triggered self-healing of a single robust SiO2 microcapsule based on cationic polymerization for potential application in aerospace coatings. ACS Appl. Mater. Inter. 2016, 8, 21046–21054. [Google Scholar] [CrossRef]

- Liao, L.; Zhang, W.; Xin, Y.; Wang, H.; Zhao, Y.; Li, W. Preparation and characterization of microcapsule containing epoxy resin and its self-healing performance of anticorrosion covering material. Chin. Sci. Bull. 2011, 56, 439–443. [Google Scholar] [CrossRef]

- Brown, E.N.; White, S.R.; Sottos, N.R. Microcapsule induced toughening in a self-healing polymer composite. J. Mater. Sci. 2004, 39, 1703–1710. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; Zhou, Q. Preparation and characterization of microcapsules based self-healing coatings containing epoxy ester as healing agent. Prog. Org. Coat. 2018, 125, 403–410. [Google Scholar] [CrossRef]

- Mirabedini, S.M.; Dutil, I.; Gauquelin, L.; Yan, N.; Farnood, R.R. Preparation of self-healing acrylic latex coatings using novel oil-filled ethyl cellulose microcapsules. Prog. Org. Coat. 2015, 85, 168–177. [Google Scholar] [CrossRef]

- Ataei, S.; Khorasani, S.N.; Torkaman, R.; Neisiany, R.E.; Koochaki, M.S. Self-healing performance of an epoxy coating containing microencapsulated alkyd resin based on coconut oil. Prog. Org. Coat. 2015, 120, 160–166. [Google Scholar] [CrossRef]

- Nesterova, T.; Dam-Johansen, K.; Pedersen, L.T.; Kiil, S. Microcapsule-based self-healing anticorrosive coatings: Capsule size, coating formulation, and exposure testing. Prog. Org. Coat. 2012, 75, 309–318. [Google Scholar] [CrossRef]

- Wang, H.; Hu, S.; Cai, S.; Yu, F. Preparation and properties of bisphenol a epoxy resin microcapsules coated with melamine-formaldehyde resin. Polyn. Bull. 2014, 71, 2407–2419. [Google Scholar] [CrossRef]

- Safaei, F.; Khorasani, S.N.; Rahnama, H.; Neisiany, R.E.; Koochaki, M.S. Single microcapsules containing epoxy healing agent used for development in the fabrication of cost efficients self-healing epoxy coating. Pro. Org. Coat. 2018, 114, 40–46. [Google Scholar] [CrossRef]

- Sadrabadi, T.E.; Allahkaram, S.R.; Staab, T.; Towhidi, N. Preparation and characterization of durable micro/nanocapsules for use in self-healing anticorrosive coatings. Polym. Sci. Ser. B 2017, 59, 281–291. [Google Scholar] [CrossRef]

- Es-haghi, H.; Mirabedini, S.M.; Imani, M.; Farnood, R.R. Mechanical and self-healing properties of a water-based acrylic latex containing linseed oil filled microcapsules: Effect of pre-silanization of microcapsules’ shell compound. Compos. Part B Eng. 2015, 85, 305–314. [Google Scholar]

- Lu, R.; Wan, Y.; Honda, T.; Ishimura, T.; Kamiya, Y.; Miyakoshi, T. Design and characterization of modified urethane lacquer coating. Prog. Org. Coat. 2006, 57, 215–222. [Google Scholar] [CrossRef]

- Perfetti, G.; Arfsten, J.; Kwade, A.; Wildeboer, W.J.; Meesters, G.M.H. Repeated impacts tests and nanoindentation as complementary tools for mechanical characterization of polymer-coated particles. J. Appl. Polym. Sci. 2010, 118, 790–804. [Google Scholar]

- Ghazali, H.; Ye, L.; Zhang, M. Mode II interlaminar fracture toughness of CF/EP composite containing microencapsulated healing resins. Compos. Sci. Technol. 2017, 142, 275–285. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).