Abstract

Ni–Co coatings have gained widespread attention due to their potential in replacing hard chromium deposits (which have traditionally utilized toxic and corrosive chromic acid baths). A major challenge is to lower the high coefficient of friction of coated surfaces against steel, under dry sliding conditions. In this research, low friction Ni–Co/WS2 nanocomposite coatings have been prepared by a convenient, one-pot electrodeposition from aqueous Ni–Co plating baths containing WS2 particles. The embedment of the WS2 lubricants is found to reduce the friction coefficient of coating significantly, and an ultra-low friction coefficient of 0.16 is obtained for the coating having a WS2 content of 7.1 wt.%. Morphology and composition characterization of wear tracks reveal that the formation of a WS2-rich lubricating tribofilm on the contact surfaces is beneficial to a low friction coefficient and good oxidation resistance. The wettability of electrodeposited coatings was also investigated. Compared to pure Ni-Co coating, the Ni–Co/7.1 wt.% WS2 coating has an excellent hydrophobicity with a high water contact angle (WCA) of 157°, due to a rough surface with dual scale protrusions and the low surface energy of WS2.

1. Introduction

As one of the most promising alternatives for replacement of hard-chromium coatings, Ni–Co coatings have numerous advantages, including high hardness, good adhesion, superior wear and corrosion resistance. These deposits have been widely used in tribological applications [1,2,3]. A favored method for the preparation of Ni–Co alloy/composite coatings is electrodeposition, which is facile, reproducible, readily controlled and suitable for industrial scale-up [4]. Over the last three decades, considerable research studies have focused on tailoring the microstructure and tribological properties of Ni–Co coating via control of the electrolyte composition, electrodeposition conditions and heat treatment temperature [5,6,7,8].

A coating offering low friction against a steel counterpart can reduce the emission of long-lived greenhouse gases, including carbon dioxide (CO2), nitrogen oxides (N2O and NO2) and methane (CH4). The attempt to produce such a coating has attracted increasing attention in both fundamental research and industrial practice. Ni based metallic coatings, however, possess a range of high friction coefficients (in the range of 0.4 to 0.7) against steel under dry friction conditions, which cannot fulfil economic expectations and meet the rising demands for environmental protection. Composite coatings of solid lubricants in a metallic matrix, for example, CNTs [9,10], graphite [11,12], MoS2 [13], WS2 [14] and reduced graphene oxide [15], have been widely developed to provide enhanced tribological properties (i.e., low friction, chemical inertness, good wear and corrosion resistance).

As a distinct solid lubricant, WS2 has a very low coefficient of friction (approx. 0.01) owing to the facile shear of weak interlayer bonds (bound by van der Waal’s forces) between layers. Furthermore, it has a good thermal stability up to 594 °C. These characteristics make WS2 very suitable as a friction modifier in metallic coatings. Metal-WS2 composite coatings with low friction coefficient and/or good wear resistance have been intensively prepared via electrodeposition over recent years. Tenne et al. [14] electrodeposited WS2 particle impregnated Ni films on archwires, which showed a reduction in frictional force up to 60% in comparison to uncoated archwires. García-Lecina et al. [16] reported an electrodeposited Ni–WS2 coating with a stable friction coefficient of 0.4 against steel. Tudela et al. [17] further improved the mechanical strength of the electrodeposited Ni–WS2 coating to enhance bath agitation. Das et al. [18] demonstrated that pulse current electrodeposited Ni–WS2 coating showed a very low friction coefficient of 0.12. In a previous study, we investigated the self-lubricating properties of an electrodeposited Ni–P/WS2 composite coating [19]. Research on the promising combination of ceramic WS2 lubricants and Ni–Co coatings is very limited.

Superhydrophobic coatings have wide potential applications in, e.g., self-cleaning, anti-icing, oil/water separation, anti-corrosion, anti-fouling, energy saving, and medical implants. Recently, superhydrophobic WS2 composite surfaces including Ni/WS2 [20] and Ni–P/WS2 [19] have been readily obtained by electrodeposition without the need for expensive equipment or a specialized reaction environment.

In this study, we present work on the fabrication of low friction Ni–Co/WS2 composite coatings via facile, one-pot electrodeposition in a modified Watts Nickel bath. The variations of microstructure, tribological and hydrophobic properties, which are dependent on the WS2 content of the coating, are systematically investigated. In sliding friction studies, the wear tracks are thoroughly characterized and the self-lubricating mechanism is discussed in detail.

2. Experimental Details

2.1. Sample Preparation

Analytical reagents and distilled water were used to prepare the plating solution. The Ni–Co/WS2 composite coating was deposited from an electrolyte bath consisting of NiSO4·6H2O (200 g L−1), NiCl2·6H2O (40 g L−1), CoSO4·7H2O (40 g L−1), boric acid (30 g L−1), saccharin (2 g L−1), cetyltrimethylammonium bromide (CTAB) (0.1 g L−1) and WS2 particles (1, 5, 10, 15, 25 g L−1). The pH value of the solution was maintained at 4. To improve the dispersion, the solution was placed in an ultrasonic water bath for 15 min before electrodeposition.

A TTi QL355T power station (Cambridge, UK) was chosen as the power source. The coatings were deposited at 3 A dm−2 for 45 min. The bath temperature was maintained at 45 °C by a Grant LTD6G water bath (Cambridge, UK). The electrolyte was continuously stirred by a PTFE-coated magnetic stirrer bar (6 mm diameter × 30 mm length) at 1.67 s−1. The anode was a Ni sheet (purity 99.5%) with a thickness of 1 mm, supplied by Goodman Alloys Ltd. (Yorkshire, England). The cathode substrate was 3 mm thick AISI 1020 mild steel supplied by Goodman Alloys Ltd. (Yorkshire, UK) with a hardness of 150 HV. Both the anode and cathode were cut to a size of 80 mm × 10 mm. Before electrodeposition, the surfaces were mechanically polished with 400, 800, and 1200 grade waterproof abrasive paper sequentially and then ultrasonically cleaned with acetone to remove contamination. During deposition, the cathode was held vertical and parallel to the anode with an interelectrode gap of 25 mm.

2.2. Characterization

Linear sweep voltammetry (LSV) measurements were performed with an Autolab PGSTA30 system in conjunction with a conventional, three-electrode glass cell. The working electrode was a rectangular mild steel plate of dimensions 10 and 40 mm, and the counter electrode was a platinum mesh electrode of similar dimensions. All LSV scans were recorded at a scan rate of 10 mV s−1 over the potential range of −0.5 V to −1.2 V vs. saturated calomel electrode (SCE).

The surface morphologies of as-deposited coatings and wear tracks were imaged using a JEOL JSM 6500 SEM (Tokyo, Japan), using an applied voltage of 15 kV and a working distance of 10 mm. Using integrated energy dispersive X-ray spectroscopy (Oxford Instruments, Oxford, UK), EDS, quantitative elemental information on samples was examined by the characteristic X-ray emission. The phase structures of the composite coatings were analyzed using a Bruker GADDS diffractometer with Cu Kα radiation, scanned at 0.02 deg s−1 over the 2θ range from 10° to 90°.

The friction and wear characteristics of the as obtained coatings were assessed using a reciprocating tribometer (Plint and Parners, Ltd., Wokingham, UK, model TE-77). The experiments were conducted at a constant temperature of 25 °C, in the dry sliding condition and at 40% relative humidity. AISI-52100 steel balls (diameter: 6 mm, hardness: 700 HV, Ra: 0.12 µm) were used as the sliding counter faces. The tests were carried out under a sliding frequency of 1 Hz and a sliding stroke of 2.69 mm for 1000 s. The normal contact load is 5 N and the frictional force is recorded automatically by a piezoelectric transducer. Friction tests on samples were repeated twice to ensure reliability.

Water contact angles (WCA) were determined using a commercial instrument Drop Shape Analysis system (KRÜSS, Hamburg, Germany, model DSA100) with a computer-controlled liquid dispensing system. The values of WCA are taken as an average of five measurements made with 6 µL distilled water droplets.

3. Results and Discussions

3.1. Linear Sweep Voltammetric (LSV) Analysis

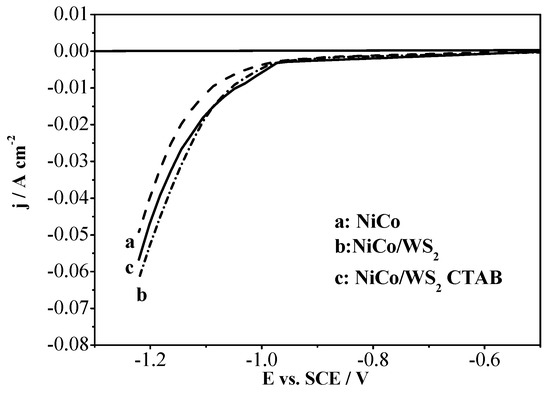

The LSV method was utilized to analyze the mechanism of the coating formation on substrate. Negative direction, cathodic sweep was performed in the range from 500 to −1300 mV which was selected on the basis of the onset of alloy deposition. The cathodic LSV curve in Figure 1 shows that the reduction current density rises quickly as the potential decreases below −0.93 V, which corresponds to rapid simultaneous deposition of cobalt and nickel. After addition of WS2 particles in the electrolyte, the LSV curve shows progressive polarization towards a more negative potential value of −1.01 V although the slope of the curve remains almost unchanged. The delay in electrodeposition is in agreement with results in Ni–Co/C nanotubes reported by Liu et al. [21], and can be attributed to the hindrance effect of WS2 particles adsorbed on the electrode surface. The Ni–Co/WS2 plating system with CTAB addition exhibits polarization towards a more positive potential value. This is due to the adsorption of CTAB cationic surfactant molecules on particles, accelerating the codeposition of WS2 particles into the Ni–Co matrix.

Figure 1.

The current density-cathodic potential curves of (state electrode reactions) in Ni–Co and Ni–Co/WS2 electrolytes.

3.2. Morphology and Structure

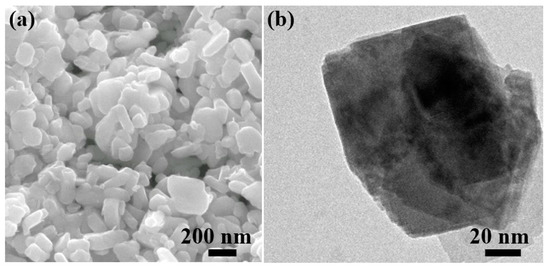

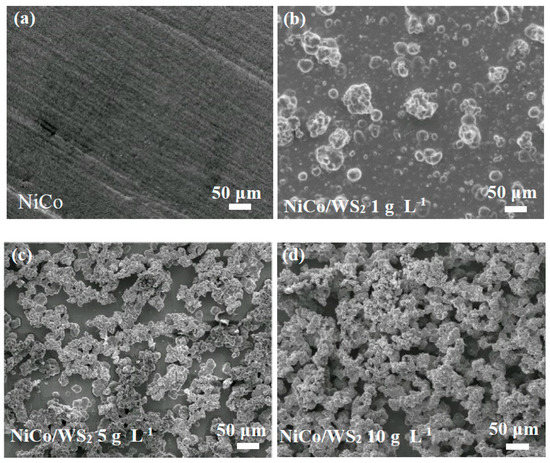

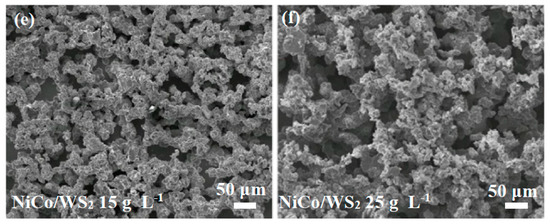

Figure 2 shows the WS2 platelets with an irregular shape, which have diameters in the range of 80–240 nm. Figure 3 shows the surface morphologies of Ni–Co coating and Ni–Co/WS2 coatings deposited from baths with different WS2 concentrations. Compared to the flat morphology of the Ni–Co coating, Ni–Co/WS2 coatings deposited at a WS2 concentration of 1 g L−1 have a rough surface decorated with nodular protrusions. The density and diameter of the nodular protrusions increased at higher WS2 concentration in the bath. During electrodeposition, Ni ions are preferably reduced around WS2 semi conductive particles at the electrode, resulting in a high localized current distribution and the growth of Ni–Co/WS2 bulges on the deposit surface.

Figure 2.

(a) SEM image and (b) TEM image of as-received WS2 particles.

Figure 3.

SEM images of the Ni-Co/WS2 coatings deposited from solutions having controlled WS2 concentrations: (a) 0 g L−1, (b) 1 g L−1, (c) 5 g L−1, (d) 10 g L−1, (e) 15 g L−1 and (f) 25 g L−1.

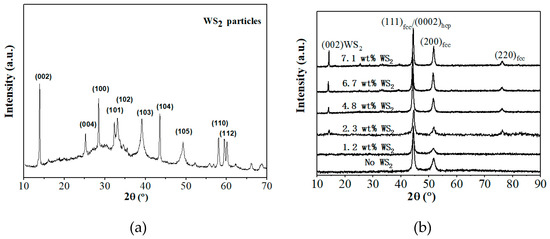

The XRD patterns of WS2 particles, Ni–Co and Ni–Co/WS2 coatings are characterized and summarized in Figure 4. WS2 particles show diffraction peaks at 14°, 33°, 40°, 49° and 58°, which are consistent with the (002), (100), (103), (106) and (110) orientations of hexagonal WS2. Both Ni–Co and Ni–Co/WS2 samples exhibit distinct (0002) hcp/(111) fcc growth orientation with an intense peak at 2θ ≈ 44°. The Ni–Co/WS2 sample also has an obvious peak at 2θ = 14°, confirming the successful inclusion of WS2 in the coating. Using the Scherrer equation and observed diffraction peak widths, the mean grain sizes of Ni–Co/WS2 7.1 wt.% deposits can be calculated as 14 ± 2 nm.

Figure 4.

XRD patterns of (a) WS2 particles and (b) Ni-Co/WS2 samples with different WS2 contents.

3.3. Compositional Analysis

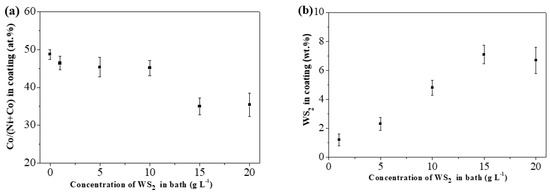

The composition of electrodeposited coatings was examined by EDS. It can be seen in Figure 5 that the obtained coatings show a cobalt percentage in the range 35%–46%, which is much higher than the percentage of Co in the solutions. The trend is in consistence with the results in other Ni–Co electrodeposition systems [22]. The increment of the WS2 particles in bath is found to lower the Co/Ni + Co ratio in coating, which is related to the electrochemical polarization caused by particle adsorption on the electrode [23].

Figure 5.

(a) The mol ratio of Co/(Co + Ni) and (b) the content of WS2 particles in coating versus the concentration of WS2 in solution.

Figure 5b shows that the weight percentage of WS2 particles in coating increases with the increasing of the WS2 concentration in bath, reaching a maximum WS2 content of 7.1 wt.% at a particle concentration of 15 g L−1. There is an optimal particle concentration in this experiment, as a further increase of WS2 concentration leads to particle agglomeration and sedimentation in solution.

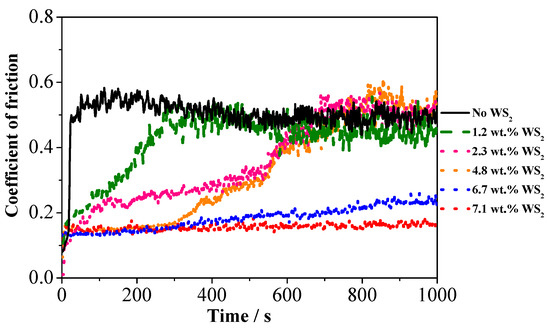

3.4. Tribological Performance

Figure 6 shows the coefficient of friction (COF) versus time for samples having different WS2 contents. The COF of the Ni–Co coating fluctuates within the range of 0.45 to 0.55 during the friction test. In contrast, the Ni–Co/WS2 1.2 wt.% sample exhibits a lower COF of 0.15 in the initial 300 s, but followed by a slow rise to the range of 0.45–0.55 that is close to the COF of pure Ni-Co coating. Notably, the Ni–Co/WS2 7.1 wt.% sample displays a stable low COF value of 0.16 for 1000 s, indicating the effective role of WS2 lubricants on reduction of friction.

Figure 6.

Relationship between friction coefficient and sliding time for the Ni–Co/WS2 with different WS2 contents.

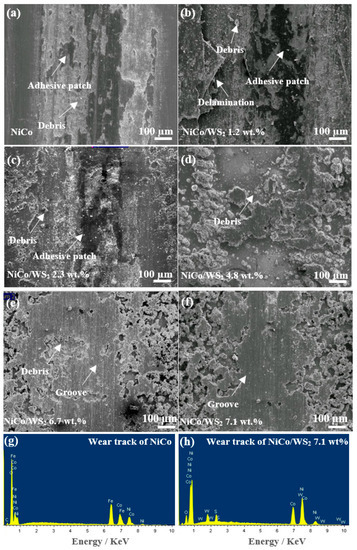

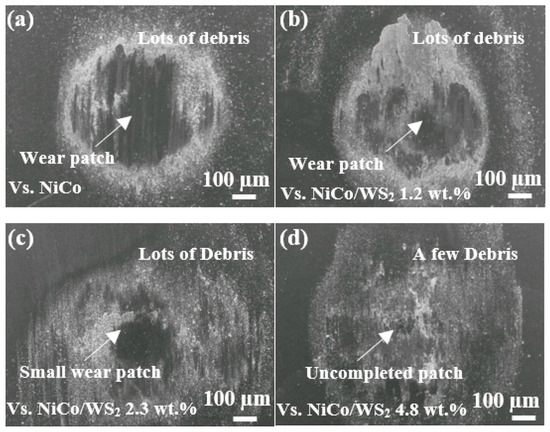

The surface morphology and composition of wear tracks were examined by SEM and EDS respectively. Scoring wear can be found on the pure Ni–Co coating after wear test of 1000 s, as shown in Figure 7. The Ni–Co/WS2 1.2 wt.% composite coating presents a similar wear track surrounded by lots of debris particles. It is worth noting that the surface protrusions of the electrodeposited coating are fragile and easily fractured during the friction process. With the increasing of WS2 content in coating the wear gradually became less severe and finally changed to galling in the case of Ni–Co/WS2 coatings with WS2 content 2.3 wt.% and higher. The wear degree of the Ni-Co/WS2 coating decreases with the increase of WS2 content in coating. The Ni–Co/WS2 7.1 wt.% sample shows only a narrow abrasive wear track with few debris particles. As listed in Table 1, the wear track of Ni–Co coating is composed of 22.1 wt.% Ni, 21.9 wt.% Co, 23.0 wt.% O and 33.0 wt.% Fe. The wear track of the Ni–Co/WS2 7.1 wt.% sample contains a higher WS2 content than that of the resting area on the coating, suggesting that WS2 has a high adhesion ability to the sliding surface. The wear track of the Ni–Co/WS2 7.1 wt.% sample shows a smaller oxygen content of 1.8 wt.% compared to that of pure Ni–Co coating. On the one side, the release of WS2 from the coating matrix reduces frictional heat on the mating surfaces, and on the other, the formation of compact WS2 rich tribofilm separates the coating from the air. These two effects lead to a low degree of oxidation.

Figure 7.

(a–f) SEM images of the wear tracks on various Ni–Co/WS2 coatings; (g–h) EDS spectra of the wear tracks on Ni–Co coating and Ni–Co/WS2 7.1 wt.% coating.

Table 1.

Composition of wear tracks on Ni-Co and Ni-Co/WS2 coatings after friction testing.

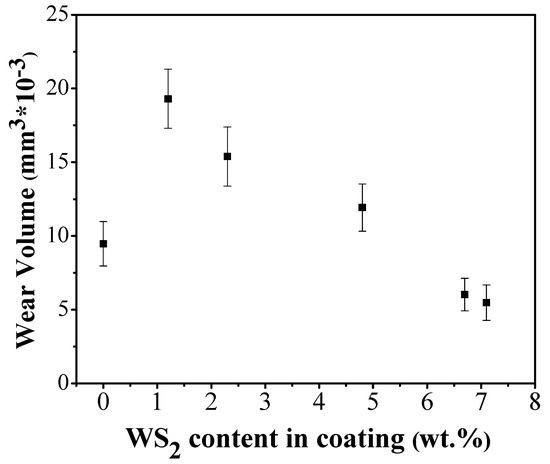

Figure 8 shows a comparison between Ni–Co coating and Ni–Co/WS2 coating in the wear volume in the friction test. Ni–Co coating has a wear volume of 9.5 × 10−3 mm−3. The wear volume of the Ni–Co/WS2 1.2 wt.% coating is as high as 2.0 × 10−2 mm−3 which is related to delamination failure. It is evident that the amount of codeposited WS2 particles is important for improving the wear resistance of the Ni-Co coating when sliding against the steel ball, as indicated by lower volume of 6.0 × 10−3 mm−3 and 5.5 × 10−3 mm−3 for the Ni–Co/WS2 6.7 wt.% and Ni–Co/WS2 7.1 wt.% coatings.

Figure 8.

Comparison of wear volumes of Ni–Co coating and Ni–Co/WS2 coatings with different WS2 contents.

A proper run-in period is vital to the friction and wear performance of the electrodeposited coatings. Due to lack of sufficient solid lubricants, Ni–Co, Ni–Co/WS2 1.2 wt.% and Ni–Co/WS2 2.3 wt.% are not well run-in when sliding against the counter steel ball. For the Ni–Co/WS2 coatings with WS2 content 6.7 wt.% and higher, solid lubricants are reserved within the Ni–Co matrix and gradually released to the friction surfaces for lubrication, resulting in fast run-in and low friction and fundamentally inhibiting excessive operating temperatures and scuffing damage especially at high speeds.

Figure 9 the surface morphologies of counter steel balls after sliding tests. A clear wear scar is observable on the wear track of the steel ball after sliding against Ni–Co coating. Lots of wear debris is observed on the counter ball after sliding against the Ni–Co/WS2 1.2 wt.% coating, which derives from the breakdown of the nodular microstructures in the coating. In contrast, there is a smooth wear track on the counterpart ball after friction against the Ni–Co/WS2 7.1 wt.% coatings, suggesting effective lubrication by WS2 from the coating.

Figure 9.

SEM images of counter balls after friction tests against (a) Ni–Co coating and Ni–Co/WS2 coatings with different WS2 contents: (b) 1.2 wt.%, (c) 2.3 wt.%, (d) 4.8 wt.%, (e) 6.7 wt.% and (f) 7.1 wt.%.

For the Ni–Co coating, the adhesion force between the counterpart ball and the Ni–Co alloy surface is strong; debris particles generated during the friction test are crushed and piled up along the wear scar, i.e., not over-rolled. The wear particles slide firmly on the surface and turn into incomplete tribofilm during a long sliding time.

Due to the lamellar structure of WS2, the inclusion of WS2 particles into the Ni–Co coating significantly reduces the shear force (τ) causing a decrease in the friction coefficient, especially when a smooth lubricating layer is produced. The reconditioning and self-lubricating processes of Ni–Co/WS2 coating is proposed as follows. Once friction starts, the movement of the counterpart ball will impose high shear stress on the contact area, resulting in severe deformation in the coating surface. Then the embedded WS2 nanoparticles in the coating can release from their fixed positions to enter the sliding surfaces. Some WS2 lamellae will be exfoliated into fine particles, which are easily accumulated in the wear crevices or attached to the metal surface to form a densely packed super-lubricating layer. The lubricating layer not only firmly attaches to the coating surface, but also transfers to the counterpart, thus contributing to the excellent tribological properties such as low friction coefficient, good wear resistance and high oxidation resistance under dry sliding conditions without oil or grease.

3.5. Wettability

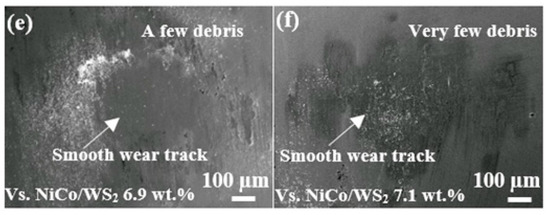

The wetting properties of electrodeposited surfaces are determined by the water contact angle test. As seen in Figure 10, the pure Ni–Co coating has a low WCA of 85°. With the WS2 content increasing, the WCA of the Ni–Co/WS2 coating significantly increases. The Ni–Co/WS2 7.1 wt.% coating shows an excellent superhydrophobicity as indicated by a high WCA of 156.9 deg.

Figure 10.

The variation in contact angle of water on the electrodeposited Ni–Co/WS2 coatings against the concentrations of WS2 in solution.

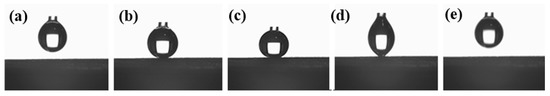

Figure 11 illustrates that the water droplet suspended on a needle tip is difficult to deposit on the coating even though it has been severely deformed. The water droplet rolls to one side when the needle tip approaches the sample surface, but can remain attached to the tip as the needle leaves the sample. This phenomenon indicates that the electrodeposited Ni–Co/WS2 coating has a very low surface energy.

Figure 11.

(a–e) Photographs illustrating water droplet does not adhere to the Ni–Co/WS2 7.1 wt.% surface: (a) a needle with suspended water droplet is set on the top of the Ni–Co/WS2 coating; (b) the water droplet touches the surface of the coating with a low approaching velocity; (c) the water droplet become rounder as the needle further approach; (d) the water droplet is deformed heavily when the needle is separating from surface; (e) the water droplet is away from the coating after separation.

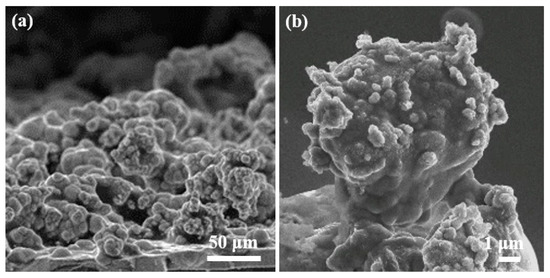

As well known, surface wettability is determined by chemical composition and surface structure, and can be described by either the Wenzel [24] or Cassie–Baxter model [25]. The Ni–Co surface has a WCA below 90° and is intrinsically hydrophilic. According to Wenzel’s model, the wettability of intrinsic hydrophilic surface should be enhanced as the roughness increases, which is obviously not applicable for the electrodeposited Ni–Co/WS2 coatings. Cassie–Baxter’s model is commonly used to predict the hydrophobicity when air is trapped between the solid surface and the liquid droplet. The Ni–Co/WS2 surfaces have a double-rough structure consisting of submicron asperities on micron-scale protrusions as illustrated in Figure 12; therefore, when these coatings are subjected to a liquid droplet, air bubbles are trapped and retained within asperities on the surface, maintaining the hydrophobic Cassie–Baxter state. The dual scale roughness has already been applied as the most commonly used criterion for superhydrophobic solid surface in the Cassie–Baxter state [26].

Figure 12.

(a) Low- and (b) high- magnification SEM images of the cross-section of a Ni–Co/WS2 7.1 wt.% coating.

4. Conclusions

Ni–Co/WS2 nanocomposite coatings have been successfully fabricated using a rapid one-pot electrodeposition route. The increase of the WS2 content plays an important role in lowering the friction coefficient of the electrodeposited coating against steel to 0.16. The analysis of the morphology and composition of wear scars reveal that WS2 strongly adheres to the sliding interfaces for effective lubrication rather than being squeezed out. Adequate levels of WS2 in the coating could enable the formation of a compact, WS2-rich tribofilm on the sliding interfaces that accounts for the ultra-low friction coefficient and high oxidation resistance. Moreover, the hierarchical rough Ni–Co/WS2 composite coating exhibits excellent superhydrophobicity with a high WCA of 158°.

Author Contributions

Conceptualization, Y.H. and S.W.; Methodology, Y.H.; Investigation, Y.H. and W.S.; Formal Analysis, Y.H. and S.W.; Writing–Original Draft Preparation, Y.H.; Writing–Review and Editing, Y.H., S.W., W.S., P.A.S.R. and F.C.W.; Supervision, S.W., P.A.S.R. and F.C.W.; Project Administration, Y.H.; Funding Acquisition, Y.H.

Funding

This research was funded by National Natural Science Foundation of China (No. 11802077).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tian, L.; Xu, J.; Xiao, S. The influence of pH and bath composition on the properties of Ni–Co coatings synthesized by electrodeposition. Vacuum 2011, 86, 27–33. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Y.; Xue, Q.; Liu, H.; Xu, T. Microstructure and tribological properties of electrodeposited Ni–Co alloy deposits. Appl. Surf. Sci. 2005, 242, 326–332. [Google Scholar] [CrossRef]

- Go, E.; Ramirez, J.; Valle, E. Electrodeposition of Co–Ni alloys. J. Appl. Electrochem. 1998, 28, 71–79. [Google Scholar]

- He, Y.; Wang, S.C.; Walsh, F.C.; Li, W.S.; He, L.; Reed, P.A.S. The monitoring of coating health by in situ luminescent layers. RSC Adv. 2015, 5, 42965–42970. [Google Scholar] [CrossRef]

- Correia, A.N.; Machado, S.A.S. Electrodeposition and characterisation of thin layers of Ni–Co alloys obtained from dilute chloride baths. Electrochim. Acta 2000, 45, 1733–1740. [Google Scholar] [CrossRef]

- Qiao, G.; Jing, T.; Wang, N.; Gao, Y.; Zhao, X.; Zhou, J.; Wang, W. High-speed jet electrodeposition and microstructure of nanocrystalline Ni–Co alloys. Electrochim. Acta 2005, 51, 85–92. [Google Scholar] [CrossRef]

- Hibbard, G.D.; Aust, K.T.; Erb, U. Thermal stability of electrodeposited nanocrystalline Ni–Co alloys. Mater. Sci. Eng. A 2006, 433, 195–202. [Google Scholar] [CrossRef]

- Ma, C.; Wang, S.C.; Walsh, F.C. Electrodeposition of nanocrystalline nickel–cobalt binary alloy coatings: A review. Trans. IMF 2015, 93, 104–112. [Google Scholar] [CrossRef]

- Chen, W.X.; Tu, J.P.; Wang, L.Y.; Gan, H.Y.; Xu, Z.D.; Zhang, X.B. Tribological application of carbon nanotubes in a metal-based composite coating and composites. Carbon 2003, 41, 215–222. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Alipour, S.; Safarzadeh, A.; Kim, H.S. Wear and friction behavior of self-lubricating hybrid Cu-(SiC + xCNT) composites. Compos. Part B Eng. 2019, 158, 92–101. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, L.; Hu, W.; Shen, B. Friction and wear behavior of Ni–graphite composites prepared by electroforming. Mater. Des. 2007, 28, 1374–1378. [Google Scholar] [CrossRef]

- Sun, W.C.; Zhang, P.; Zhao, K.; Tian, M.M.; Wang, Y. Effect of graphite concentration on the friction and wear of Ni–Al2O3/graphite composite coatings by a combination of electrophoresis and electrodeposition. Wear 2015, 342, 172–180. [Google Scholar] [CrossRef]

- He, Y.; Wang, S.C.; Walsh, F.C.; Chiu, Y.L.; Reed, P.A.S. Self-lubricating Ni-P-MoS2 composite coatings. Surf. Coat. Technol. 2016, 307, 926–934. [Google Scholar] [CrossRef]

- Redlich, M.; Gorodnev, A.; Feldman, Y.; Kaplanashiri, I.; Tenne, R.; Fleischer, N.; Genut, M.; Feuerstein, N. Friction reduction and wear resistance of electro-co-deposited inorganic fullerene-like WS2 coating for improved stainless steel orthodontic wires. J. Mater. Res. 2008, 23, 2909–2915. [Google Scholar] [CrossRef]

- Mai, Y.J.; Zhou, M.P.; Ling, H.J.; Chen, F.X.; Lian, W.Q.; Jie, X.H. Surfactant-free electrodeposition of reduced graphene oxide/copper composite coatings with enhanced wear resistance. Appl. Surf. Sci. 2018, 433, 232–239. [Google Scholar] [CrossRef]

- García-Lecina, E.; García-Urrutia, I.; Díez, J.A.; Fornell, J.; Pellicer, E.; Sort, J. Codeposition of inorganic fullerene-like WS2 nanoparticles in an electrodeposited nickel matrix under the influence of ultrasonic agitation. Electrochim. Acta 2013, 114, 859–867. [Google Scholar] [CrossRef]

- Tudela, I.; Zhang, Y.; Pal, M.; Kerr, I.; Cobley, A.J. Ultrasound-assisted electrodeposition of thin nickel-based composite coatings with lubricant particles. Surf. Coat. Technol. 2015, 276, 89–105. [Google Scholar] [CrossRef]

- Roy, D.; Das, A.K.; Saini, R.; Singh, P.K.; Kumar, P.; Hussain, M.; Mandal, A.; Dixit, A.R. Pulse current co-deposition of Ni–WS2 nano-composite film for solid lubrication. Mater. Manuf. Proc. 2017, 32, 365–372. [Google Scholar] [CrossRef]

- He, Y.; Sun, W.T.; Wang, S.C.; Reed, P.A.S.; Walsh, F.C. An electrodeposited Ni–P/WS2 coating with combined super-hydrophobicity and self-lubricating properties. Electrochim. Acta 2017, 245, 872–882. [Google Scholar] [CrossRef]

- Zhao, G.; Xue, Y.; Huang, Y.; Ye, Y.; Walsh, F.C.; Chen, J.; Wang, S. One-step electrodeposition of a self-cleaning and corrosion resistant Ni/WS2 superhydrophobic surface. RSC Adv. 2016, 6, 439–443. [Google Scholar] [CrossRef]

- Shi, L.; Sun, C.F.; Gao, P.; Zhou, F.; Liu, W.M. Electrodeposition and characterization of Ni–Co–carbon nanotubes composite coatings. Surf. Coat. Technol. 2006, 200, 4870–4875. [Google Scholar] [CrossRef]

- Golodnitsky, D.; Yu, R.; Ulus, A. The role of anion additives in the electrodeposition of nickel–cobalt alloys from sulfamate electrolyte. Electrochim. Acta 2003, 47, 2707–2714. [Google Scholar] [CrossRef]

- Gómez, E.; Pané, S.; Vallés, E. Electrodeposition of Co–Ni and Co–Ni–Cu systems in sulphate–citrate medium. Electrochim. Acta 2006, 51, 146–153. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Shirtcliffe, N.J.; McHale, G.; Newton, M.I.; Chabrol, G.; Perry, C.C. Dualscale roughness produces unusually water repellent surfaces. Adv. Mater. 2004, 16, 1929–1932. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).