Abstract

This paper generalizes the results of our research, which was aimed at the development of adaptive cutting tool coatings for high speed dry cutting, from the inception of the idea to complex multilayer coatings for processing tough metals. Typically, the streams of external energy and matter during high speed cutting are causing damage to the tool materials and to the hard, protective coatings through multiple mechanical and chemical processes including oxidation, however these oxidation processes could be used to improve the tools’ lifetime. The structure and the phase transformations on the wear surface in the nanostructured single layer and nanolaminated multilayer PVD coatings were investigated by a set of electron spectroscopy methods. The dynamics of the secondary phase formation on the various stages of tool life is demonstrated. The obtained results show that the enhancement of non-equilibrium processes during friction leads to a dominating formation of protective triboceramics on a base of sapphire-like, tungsten, and niobium polyvalent oxides with a structure which decisively improves the wear performance. The mechanisms of the formation of non-equilibrium protective oxides at high speed dry cutting and the non-equilibrium thermodynamics approaches for the tribooxidation description are discussed. Polyvalent metals and multilayer coatings provide a wider set of protective oxide nanofilms.

1. Introduction

The present series of researches were aimed at increasing the wear resistance of tools operating at severe tribological conditions of high speed dry cutting, with temperatures of up to 1000 °С, high local stresses in the “tool-chip” contact area, the interaction of the tool surface with processing material, and atmosphere. The most common approach to prolong the lifetime of cutting tools is linked with the application of coatings with ultra-high hardness (DLC coatings [1,2,3,4]), low heat conductivity, and high heat resistance, together with a low friction coefficient: Al2O3 [5,6,7], ZrO2 [8], oxinitride [9,10,11], or a complex multilayer oxide-nitride [12,13,14].

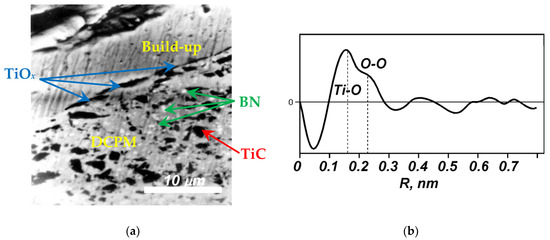

The studies of wear processes and transformations of surface composition and structure in the deformed compacted powder material (DCPM) 6W5Mo5Co HSS + 20% TiC + 2% BN [15,16] at cutting C45 steel (HB 180–200) have demonstrated the formation of secondary non-equilibrium non-stoichiometric amorphous oxide films on the tools surface: TiC and BN were transformed to simple and complex oxides on the wear hollow surface as a result of tribooxidation. These processes were developed at a depth less than 0.5 µm. Figure 1a demonstrates the thin films of TiOx that were generated by the simultaneous oxidation and deformation of TiC particles. The atomic coordination in these oxides that was revealed by Extended Electrons Energy Losses Fine Structure Spectroscopy (EELFS) [17] is presented in Figure 1b. One can clearly see the lack of long range order in the atomic coordination, which evidences the amorphous structure of oxide films.

Figure 1.

(a) The formation of non-equilibrium Ti oxides on the wear surface of DCPM through the oxidation of TiC particles (SEM); (b) atomic coordination in the oxide film (EELFS).

The system “cutting tool-processing material-environment” can be treated as an open one with intensive energy and matter exchange within the environment. The processes on the cutting tools’ surface are very far from equilibrium conditions due to high speeds and high contact loads, so we can use some non-equilibrium thermodynamics approaches as guidelines for the development of coatings that are able to improve their protective properties during operation.

So, energy and matter fluxes of high power during cutting allow us to use another protection way: active wear resistance requiring high hardness and heat resistance of coatings with a moderate thickness (less than 15 µm). Such coatings should be able to generate protective secondary compounds (mainly oxides) on the surface with better tribological properties compared to the coating itself. This paper demonstrates the complication of the composition and the structure of the coatings for increased cutting speeds and hardness of processing materials that generalize the series of our studies.

2. Materials and Methods

The hard-wearing resistant coatings on the tools’ surface for high speed cutting were fabricated by a physical vapor deposition (PVD) process. This method has several advantages compared to chemical vapor deposition (CVD) coating application technology. Firstly, PVD is realized at lower process temperatures (<500 °C), while 1000–1200 °C is typical for CVD. These low temperatures preserve the structure of high speed steel (HSS) substrate [18,19]. Secondly, PVD coatings better fit the shape of the tools’ cutting edge. This method provides useful compressive stresses in coatings and excludes the reaction with a substrate. Arc-PVD technology provides a wide range of opportunities for the formation of single- and multilayered composite coatings with nanoscale structures based on single phase and multiphase nitrides, oxides, and borides, doped by the elements of IV–VI refractory metals, including alloys with various elements (Al, Si, Cu, etc.) to improve its structure and properties [20].

The details of the coatings deposition and cutting test conditions were presented in our papers which discussed the correspondent coatings [21,22,23,24,25,26].

Electron spectroscopy methods are well suited to investigations of transformation in very thin surface layers because their typical analysis depth is 5–10 atomic layers. The determination of the chemical composition, electronic, and atomic structure of the tool worn surface was performed using ESCALAB Mk2 (VG) electron spectroscopy laboratory using the following techniques: X-ray photoelectron spectroscopy (XPS), Al Kα monochromatic source, hν = 1486.6 eV, spot 2 × 8 mm2, FWHM on Au 4f7/2 line = 0.6 eV; Auger spectroscopy (AES) including Auger microscopy, E0 = 0.5–4 keV, LEG-200 source, spot diameter ≥ 200 nm, magnification to ×20,000, image resolution up to 4096 × 4096 pixels; High resolution electron energy losses spectroscopy (HREELS), EMU-50 source (VG, UK), E0 = 0.5–100 eV; FWHM = 17 meV; Electrons energy losses fine structure analysis (EELFS) for the determination of the atomic coordination on the surface [17]; secondary ions mass spectroscopy (SIMS), SQ-300 quadrupole mass analyzer (VG, UK), Ar+ source AG-6 with E0 = 0.5–5 keV, spot diameter ≥ 10 µm, and mass range 0–300 amu (atomic mass unit) Carbon 1 s photoelectron peak with binding energy 285.0 eV was used as an internal reference to precisely determine the energy positions of the other spectral lines. Prior to the analysis, the samples were sputter cleaned using Ar+ ions in the preparation chamber of the spectrometer at a pressure of 10−5 Pa, an accelerating voltage of 5 kV, and a current of 20 µA. The spectrometer settings were selected in a way to provide maximal resolution, together with a good “signal/noise” ratio.

3. Results and Discussion

The tendency of the sophistication of elemental composition and the architecture of coatings for high speed dry cutting is connected with the increased cutting speeds and the need to process hard-to-cut materials, such as quenched steels, Al and Ti alloys, Ni-Al alloys, etc. These severe cutting conditions require complex protective coatings with high hardness and fracture toughness, low thermal conductivity and friction coefficients, adhesion compatibility with matrix, and minimal formation of build-up. The same requirements should also be applied to secondary oxide over-coatings that are generated on the coatings’ surface.

3.1. Single Layer Adaptive Coatings

Further development of TiN-based coatings was directed based on the complication of their chemical composition. TiAlN nitride coatings were tested on hard-to-cut material (H13 steel, 50 HRC; TiAl6V4; Waspalloy) machining [21,22,23], with the expectation of better mechanical and tribological properties of alumina compared to the non-equilibrium TiOx.

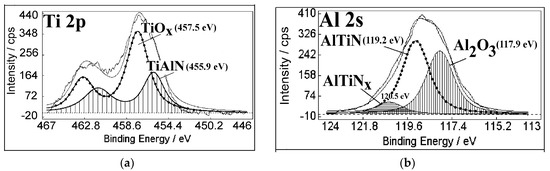

The XPS studies of the wear surface of the coatings (Figure 2) demonstrate the simultaneous formation of Ti and Al oxides.

Figure 2.

The fine structure of XPS lines from the wear hollow on the TiAlN coating surface: (a) Ti 2p1/2–2p3/2 line; (b) Al 2s line.

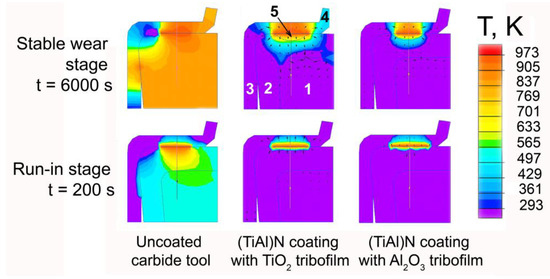

Soft titanium oxides were dynamically removed from the wear surface, while alumina remained on the surface, protecting the underlayers of the coating from thermal and mechanical damages. Alumina has good protective properties, possessing high hardness, low coefficients of friction, and thermal conductivity. The finite elements method (FEM) of modeling the temperature fields distribution at cutting, which is presented in Figure 3, demonstrates that Al2O3 tribofilm reduces the thermal influence depth which decreases the heating of the coating and the whole cutting tool. The properties of the components used in the model are listed in Table S1. It is necessary to emphasize that alumina has a negative temperature dependence of the thermal conductivity coefficient, protecting the initial coating from heat damage.

Figure 3.

FEM analysis of temperature distribution in “cutting tool–chip” systems with Ti and Al secondary oxides on the surface. 1—K10 carbide tool; 2—(TiAl)N coating; 3—medium carbon steel; 4—chip; 5—tribooxide.

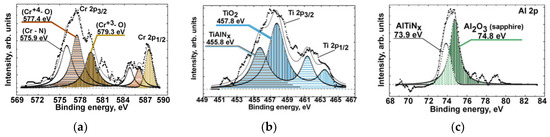

So, such promising tribological properties of secondary alumina films are stipulating increased Al content in the TiAlN coating. On the other hand, a high content of aluminum changes the structure of a complex nitride from a cubic (hard) to a hexagonal (soft) one. It is required to bind excess aluminum in the complex nitride coating. The addition of Cr to the TiAlN coating composition was used to stabilize the cubic lattice. Our results presented in [22] demonstrate that the Cr in the complex nitride is significantly changing its phase composition. CrAl7 nanoclusters are formed in the matrix of non-equilibrium (TiCrAl)N. The increased solubility of AlN leads to the growth of the coating’s resistibility to oxidation, and the formation of the Al2O3 films with sapphire-like structure develop on the wear surface, together with the TiO2 and a mixture of Cr3+ and Cr4+ oxides (Figure 4). As a hard compound, Cr2O3 also plays a positive role in a wear resistant oxide film. These tribo-oxides have some lubricious properties and could improve the wear behavior, acting in synergy with the protective alumina-based films. We can summarize that the tribofilms that formed during the wear of TiAlN and (TiCrAl)N coatings, consist of protective sapphire-like tribooxides, polyvalent lubricious tribooxides of Al and Cr, and some amount of non-protective (at elevated temperatures) rutile-like tribofilms.

Figure 4.

The fine structure of XPS lines from the wear hollow on the TiAlCrN coating surface: (a) Cr 2p1/2–2p3/2; (b) Ti 2p1/2–2p3/2 line; (c) Al 2s line.

It is necessary to emphasize that the above-mentioned oxides do not exist as separate phases, but that these Ti–O, Cr–O, Al–O chemical bonds are found in the non-equilibrium solid solution.

The optimal Cr amount in the (TixAlyCrz)N coating with low (0.05 < х < у, х/у < 1) Ti content could be described as:

z = (1/7 ÷ 1/5) × (x − y),

Such a relationship between Ti, Cr, and Al content provides the formation of a hard cubic phase in the coating, instead of a softer hexagonal one.

The further improvement of the coatings for high speed dry cutting led to experiments with nanocrystalline adaptive Ti0.2Al0.55Cr0.2Si0.03Y0.02N PVD coating [23]. According to XPS and EELFS data, the mullite-like structure of the oxide films, which have very good protective properties, was detected on the surface.

3.2. Multilayer Adaptive Coatings with Polyvalent Metals (NbN, WN)

It is possible to control the tribooxidation process by increasing the degrees of freedom of an open thermodynamic system. Basing on this assumption, the wear-resistant coatings were formed on the basis of polyvalent metal nitrides: chromium, niobium, and tungsten. These polyvalent metals provide a large range of different tribooxides. Some of them could perform a protective function, while others with a lower strength of interatomic bonds are removed from the wear zone.

The addition of Nb and W could occur in nanolaminate multilayer architecture. The nanolaminate structure has several preferences compared to the single layer coating, with the same thickness:

- Optimal crystalline structure of individual layers which provides the best wear resistance.

- Their oxidation dynamics are equal to a multicomponent single layer system due to very short diffusion paths and high operation temperatures.

- The microaccumulation of cracks and other damages could be blocked on multiple interfaces. This useful behavior of multilayer coatings compared to a single layer one was approved during the data processing of the impact fatigue fracture resistance tests [27].

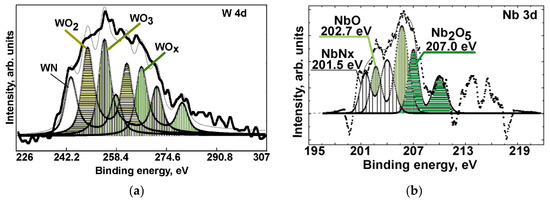

XPS studies of the wear hollow composition on multilayer nanolaminate coatings (Ti25Al65Cr10)N/WN and (Ti25Al65Cr10)N/NbN on the steady wear stage [24] are demonstrating the formation of the sets of W or Nb oxides of various valences (Figure 5a,b, correspondingly), together with the set of Cr, Ti, and Al oxides, which are similar to those presented in Figure 4. All of these oxides are localized in a very thin (less than 10 nm) surface layer, because metal -N bonds are observed on the XPS spectra. Evidently, all of these oxides have different strengths of interatomic bonds, so their relative quantities are changed during the wear test time. The strongest oxides are enriching the surface, while the weaker ones are erased by a chip stream. The protective properties of oxide film are improved in such a way.

Figure 5.

The fine structure of XPS lines from the wear hollow on the (TiAlCr)N/WN and (TiAlCr)N/NbN coatings surface: (a) W 4d group; (b) Nb 3d group.

The evolution of the chemical composition and the atomic coordination of the secondary protective oxides on the surface of nanolaminate (Ti20Al55Cr20Si3Y2)N/(Ti25Al65Cr10)N coating on the various stages of wear from run-in to catastrophic wear was studied in [27]. The wear behavior of such coatings were analyzed in [26].

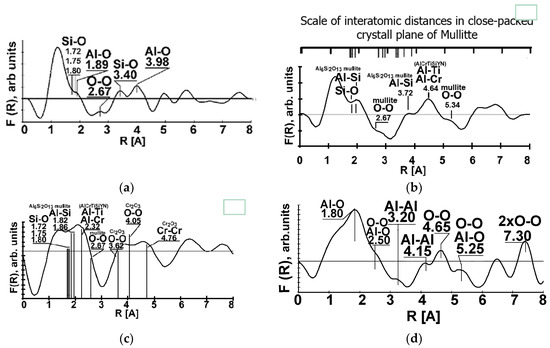

It was reported in [27] that separate islands of non-equilibrium nitrides and oxides are formed during the initial wear stage. The oxides thickness was about 1.8 nm, and they had an amorphous structure according to EELFS data (Figure 6a). Only the nearest coordination spheres with distances up to 0.4 nm form peaks. During this stage, the first portions of secondary oxides are formed at high contact pressures.

Figure 6.

The evolution of the atomic coordination in the secondary oxide films after different cutting lengths: (a) 5 m of cutting; (b) 15 m; (c) 30 m; (d) 60 m. Figures (b,c) were published as Figure 5 in [27].

One can see on Figure 6b–d that a mixture of Al and Si oxides with a mullite-like structure is formed after 15 m of cutting. After a 30 m cutting length, the process of oxide formation provides an increased variety of oxides on the worn surface. The sapphire-like Al2O3 and Cr2O3, with a high level of structure defects, were observed. The thickness of the tribofilm was grown from 1.8 to 6 nm.

So, at the end of the run-in stage and during the stable stage, the oxide film covered all of the “tool-chip” contact area. Due to the very good mechanical and protective properties of the oxide films, their wear velocity was very low, and the high temperatures of high speed dry cutting made the recrystallization processes in the oxides available.

Further studies have demonstrated that after 100 m of cutting (near the end of the steady wear stage), the atomic structure of the tool surface starts to change again: EELFS at a small (less than 1 µm) beam size reveals areas with an amorphous structure similar to the one presented in Figure 6a, together with well-ordered areas of alumina (Figure 6d). The long-range order in tribofilms disappears and their structure becomes amorphous again.

The reason for the formation of the amorphous zones during this stage is associated with the increased wear velocity due to the accumulation of damages in the coating and local peeling of the “old” oxides. Fresh amorphous oxides are formed on the open nitride surface, similarly to the nitrides’ oxidation during the beginning of cutting.

It is necessary to emphasize that the application of the above-mentioned coatings for high speed dry cutting is limited by the heat resistance of the substrate. So, high speed steels operate at temperatures below 650 °C [28], while WC-based tools allow heating to 1000 °C [29,30]. Higher operating temperatures require ceramic tools [31,32].

4. Conclusions

Nanostructured, and especially nanolaminate coatings that are based on complex nitrides, demonstrate a very good operability during the high speed dry cutting of well processed materials such as C45 (1045) steel, as well as hard-to-machine materials (tool steels with hardness 55–60 HRC, austenite stainless steels, and Ni-Al alloys for jet turbine blades). Such improved wear resistance is stipulated by the adaptation processes that are associated with the formation of protective tribooxides as “over-coatings” in the thin surface layers of nitride coatings.

It is necessary to emphasize that these adaptive coatings are optimized for definite processing materials and cutting modes. As expected, better operating properties in the pre-given conditions correspond to lower versatility, not only for processing other materials, but also for the deviation of cutting parameters from predefined values.

Observations of the wear mechanisms on the coatings’ surface allow us to conclude that the composition of the coating shall contain minimal amounts of elements that are similar to the processing metal base to minimize the adhesive wear of the coating.

Supplementary Materials

The following are available online at http://www.mdpi.com/2079-6412/8/6/223/s1, Table S1: Physical properties of the components in the FEM model.

Author Contributions

Conceptualization, D.W. and A.K.; Methodology, A.K.; Investigation, D.W. and A.K.; Writing-Original Draft Preparation, D.W.; Writing-Review & Editing, D.W. and A.K.; Visualization, D.W. and A.K.

Funding

The research was carried out with the partial financial support of RSF project No. 14-12-00170.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dai, M.; Zhou, K.; Yuan, Z.; Ding, Q.; Fu, Z. The cutting performance of diamond and DLC-coated cutting tools. Diam. Relat. Mater. 2000, 9, 1753–1757. [Google Scholar] [CrossRef]

- Wu, T.; Cheng, K. Micro milling performance assessment of diamond-like carbon coatings on a micro-end mill. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 1038–1046. [Google Scholar] [CrossRef]

- Aslantas, K.; Hopa, H.E.; Percin, M.; Ucun, İ.; Çicek, A. Cutting performance of nano-crystalline diamond (NCD) coating in micro-milling of Ti6Al4V alloy. Precis. Eng. 2016, 45, 55–66. [Google Scholar] [CrossRef]

- Lei, X.; Wang, L.; Shen, B.; Sun, F. Microdrill with variations in thickness of diamond coating. Surf. Eng. 2016, 32, 165–171. [Google Scholar] [CrossRef]

- Ljungberg, B.; Lenander, A. Oxide Coated Cutting Tool. U.S. Patent 5,487,625, 30 January 1996. [Google Scholar]

- Åstrand, M.; Selinder, T.I.; Fietzke, F.; Klostermann, H. PVD-Al2O3-coated cemented carbide cutting tools. Surf. Coat. Technol. 2004, 188–189, 186–192. [Google Scholar] [CrossRef]

- Lindahl, E.; Engqvist, J. CVD Coated Cutting Tool with Textured k-Al2O3 Layer. U.S. Patent Appl. 15/637308, 4 January 2018. [Google Scholar]

- Schulz, H.; Dörr, J.; Rass, I.J.; Schulze, M.; Leyendecker, T.; Erkens, G. Performance of oxide PVD-coatings in dry cutting operations. Surf. Coat. Technol. 2001, 146–147, 480–485. [Google Scholar] [CrossRef]

- Pilkington, A.; Dowey, S.J.; Toton, J.T.; Doyle, E.D. Machining with AlCr-oxinitride PVD coated cutting tools. Tribol. Int. 2013, 65, 303–313. [Google Scholar] [CrossRef]

- Makino, Y.; Nose, M.; Tanaka, T.; Misawa, M.; Tanimoto, A.; Nakai, T.; Kato, K.; Nogi, K. Characterization of Ti(NxOy) coatings produced by the arc ion plating method. Surf. Coat. Technol. 1998, 98, 934–938. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, X.W.; Li, G.Z.; Li, G.Y. Microstructure and mechanical properties of reactively sputtered Ti(O,N) coatings. Int. J. Refract. Met. Hard Mater. 2008, 26, 461–464. [Google Scholar] [CrossRef]

- Nohava, J.; Dessarzin, P.; Karvankova, P.; Morstein, M. Characterization of tribological behavior and wear mechanisms of novel oxynitride PVD coatings designed for applications at high temperatures. Tribol. Int. 2015, 81, 231–239. [Google Scholar] [CrossRef]

- Ciftci, I. Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 2006, 39, 565–569. [Google Scholar] [CrossRef]

- Raab, R.; Koller, C.M.; Kolozsváric, S.; Ramm, J.; Mayrhofer, P.H. Interfaces in arc evaporated Al-Cr-N/Al-Cr-O multilayers and their impact on hardness. Surf. Coat. Technol. 2017, 324, 236–242. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Kovalev, A.I.; Shuster, L.S.; Bokiy, Y.F.; Dosbayeva, G.K.; Wainstein, D.L.; Mishina, V.P. Characteristic features of alloying HSS-based deformed compound powder materials with consideration for tool self-organization at cutting. 1. Characteristic features of wear in HSS-based deformed compound powder materials at cutting. Wear 1997, 206, 214–220. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Kovalev, A.I.; Shuster, L.S.; Bokiy, Y.F.; Dosbayeva, G.K.; Wainstein, D.L.; Mishina, V.P. On characteristics features of alloying HSS-based deformed compound powder materials with consideration for tool self-organization at cutting 2. Cutting tool friction control due to the alloying of the HSS-based deformed compound powder material. Wear 1998, 214, 279–286. [Google Scholar] [CrossRef]

- Wainstein, D.L.; Kovalev, A.I. Fine determination of interatomic distances on surface using extended energy-loss fine structure (EELFS) data: Peculiarities of the technique. Surf. Interface Anal. 2002, 34, 230–233. [Google Scholar] [CrossRef]

- Mrkvica, I.; Neslušan, M.; Čep, R.; Sléha, V. Properties and comparison of PVD coatings. Tehnički Vjesnik 2016, 23, 569–574. [Google Scholar] [CrossRef]

- Merkleina, M.; Schradera, T.; Engela, U. Wear behavior of PVD-coatings. Tribol. Ind. 2012, 34, 51–56. [Google Scholar]

- Vereschaka, A.А.; Volosova, M.A.; Batako, A.D.; Vereshchaka, A.S.; Mokritskii, B.Y. Development of wear-resistant coatings compounds for high-speed steel tool using a combined cathodic vacuum arc deposition. Int. J. Adv. Manuf. Technol. 2016, 84, 1471–1482. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Weatherly, G.C.; Dodonov, A.I.; Kovalev, A.I.; Veldhuis, S.C.; Shuster, L.S.; Dosbaeva, G.K.; Wainstein, D.L. Nano-crystalline FAD (filtered arc deposited) TiAlN PVD coatings for high-speed machining application. Surf. Coat. Technol. 2004, 177–178, 800–811. [Google Scholar] [CrossRef]

- Kovalev, A.I.; Wainstein, D.L.; Rashkovskiy, A.Y.; Fox-Rabinovich, G.S.; Yamamoto, K.; Veldhuis, S.; Aguirre, M.; Beake, B.D. Impact of Al and Cr alloying in TiN-based PVD coatings on cutting performance during machining of hard to cut materials. Vacuum 2010, 84, 184–187. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Veldhuis, S.C.; Dosbaeva, G.K.; Yamamoto, K.; Kovalev, A.I.; Wainstein, D.L.; Gershman, I.S.; Shuster, L.S.; Beake, B.D. Nanocrystalline coating design for extreme applications based on the concept of complex adaptive behavior. J. Appl. Phys. 2008, 103, 083510. [Google Scholar] [CrossRef]

- Kovalev, A.; Wainstein, D.; Fox-Rabinovich, G.; Veldhuis, S.; Yamamoto, K. Features of self-organization in nanostructuring PVD coatings on base of polyvalent metal nitrides under severe tribological conditions. Surf. Interface Anal. 2008, 40, 881–884. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Kovalev, A.; Veldhuis, S.; Yamamoto, K.; Endrino, J.L.; Gershman, I.S.; Rashkovskiy, A.; Aguirre, M.H.; Wainstein, D.L. Spatio-temporal behaviour of atomic-scale tribo-ceramic films in adaptive surface engineered nano-materials. Sci. Rep. 2015, 5, 8780. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.; Beake, B.D.; Yamamoto, K.; Bose, B.; Aguirre, M.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Improvement of wear performance of nano-multilayer PVD coatings under dry hard end milling conditions based on their architectural development. Coatings 2018, 8, 59. [Google Scholar] [CrossRef]

- Kovalev, A.I.; Rashkovsky, A.Y.; Fox-Rabinovich, G.S.; Veldhuis, S.; Beake, B.D. Regularities of tribooxidation and damageability at the early stage of wear of single-layer (TiAlCrSiY)N and multilayer (TiAlCrSiY)N/(TiAlCr)N coatings in the case of high-speed cutting. Prot. Met. Phys. Chem. Surf. 2016, 52, 315–323. [Google Scholar] [CrossRef]

- Roberts, G.; Krauss, G.; Kennedy, R. Tool Steels, 5th ed.; ASM International: Materials Park, OH, USA, 1998. [Google Scholar]

- Oberg, E.; Jones, F.D.; Horton, H.L.; Ryffel, H.H. Machinery’s Handbook, 25th ed.; Green, R.E., McCauley, C.J., Eds.; Industrial Press: New York, NY, USA, 1996. [Google Scholar]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and wear of cutting tools in high-speed machining of Inconel 718 and Ti6Al6V2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- El-Wardany, T.I.; Mohammed, E.; Elbestawi, M.A. Cutting temperature of ceramic tools in high speed machining of difficult-to-cut materials. Int. J. Mach. Tool Manuf. 1996, 36, 611–634. [Google Scholar] [CrossRef]

- Tian, X.; Zhao, J.; Qin, W.; Gong, F.; Wang, Y.; Pan, H. Performance of ceramic tools in high-speed cutting iron-based superalloys. Mach. Sci. Technol. 2017, 21, 279–290. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).