1. Introduction

Surface treatment requires the use of physical, chemical, or mechanical methods to alter the surface characteristics of a material—for example, to change the surface crystal microstructure, increase the surface hardness, or add a coating to increase corrosion resistance—and thereby endow the material with multiple characteristics. The initial purpose of surface treatment is mostly to enhance the material’s appearance through alterations such as anodizing, electrolytic polishing, and so on. Another goal may be to improve the material’s functionality, such as with powder-coating, hot-dip galvanizing, and electroless nickel plating. Surface treatment technology can be roughly divided into two major types [

1]: (1) dry surface treatment and (2) wet surface treatment. Dry surface treatment can be subdivided into physical vapor deposition and chemical vapor deposition. Workpiece processing is usually performed in a vacuum and has drawbacks: the workpiece is limited by the size of the cabin, and the equipment is very expensive. Wet surface treatment is subdivided into electrochemical reactions and chemical reactions. Usually, the workpiece is processed in an aqueous solution. A large workpiece can be processed, but water pollution is a huge problem.

Plasma was initially discovered by Crookes [

2] in 1879. Subsequent research yielded plasma electrolytic treatment and glow–discharge electrolysis [

3,

4,

5]. Gupta et al. [

6] published a review paper on plasma electrolytic technology. In 2010, Aliofkhazraei et al. [

7] integrated plasma electrolytic technology into a specialist book. Practically, plasma electrolytic technology can be divided into two categories: anodic plasma electrolytic (APE) and cathodic plasma electrolytic (CPE) technology. The application of anodic plasma electrolytic technology can be classified as either the oxidation of metals or the fabrication of nanostructures [

7]. This technology is mainly used for the treatment of light metals or the special treatment of metals. With regard to metal oxidation, Gu et al. [

8] discussed the deposition of aluminum compound coating on a steel plate using a comprehensive method of arc spraying and plasma electrolytic oxidation. Lukiyanchuk et al. [

9] applied plasma-electrolytic oxidation technology to coat Fe and Cu on an aluminum alloy. Parfenov et al. [

10] summarized plasma electrolytic technology and proposed a theoretical model to further observe the reaction process. Wu et al. [

11] employed anodic plasma electrolytic technology to coat a hardened oxide layer on medium carbon steel, conferring wear resistance.

Cathodic plasma electrolytic technology can also be applied to achieve nanocrystalline coatings, cleaning, the fabrication of nanostructures, and heat treatment. Nanocrystalline coatings and cleaning are the most common uses. In 2009, Aliofkhazraei et al. [

12] studied the relationship between nanostructure and corrosion resistance in a composite coating on stainless steel 316 and discussed the parameters for forming nanostructural layers on CP–Ti using plasma electrolytic technology. In a subsequent study, Aliofkhazraei et al. [

13] applied CPE techniques to achieve nanocoating on the surfaces of a wide range of metallic substrates. Quan et al. [

14] proposed a novel cobalt coating on stainless steel 304 using CPE technology. Wang et al. [

15] used CPE deposition technology to fabricate an Al

2O

3 ceramic coating on a TiAl alloy. Lopes et al. [

16] studied the influence of different parameters in the formation of TiO

2 thin films on stainless steel using a cathodic plasma deposition technique, since TiO

2 has high anti-corrosive properties.

Silver is known to have antibacterial characteristics. For example, in 2004 Kim et al. [

17] used self-synthesized nanosilver particles as an antibacterial agent to test its antibacterial effect on

Escherichia coli; their results showed that nanosilver particles could significantly increase the permeability of the cell wall and eventually cause cell death. Jeon et al. [

18] mixed silver with antibacterial properties into silica materials using a sol-gel method. The resulting silica film mixed with silver was used as an antibacterial glass. Other researchers [

19,

20] synthesized pure titanium and titanium alloy plates coated with nanosilver particles and analyzed their cell adhesion properties on treated titanium surfaces. Analysis showed that the silver nanoparticles were successfully coated on the surface of the titanium material and had a bactericidal effect.

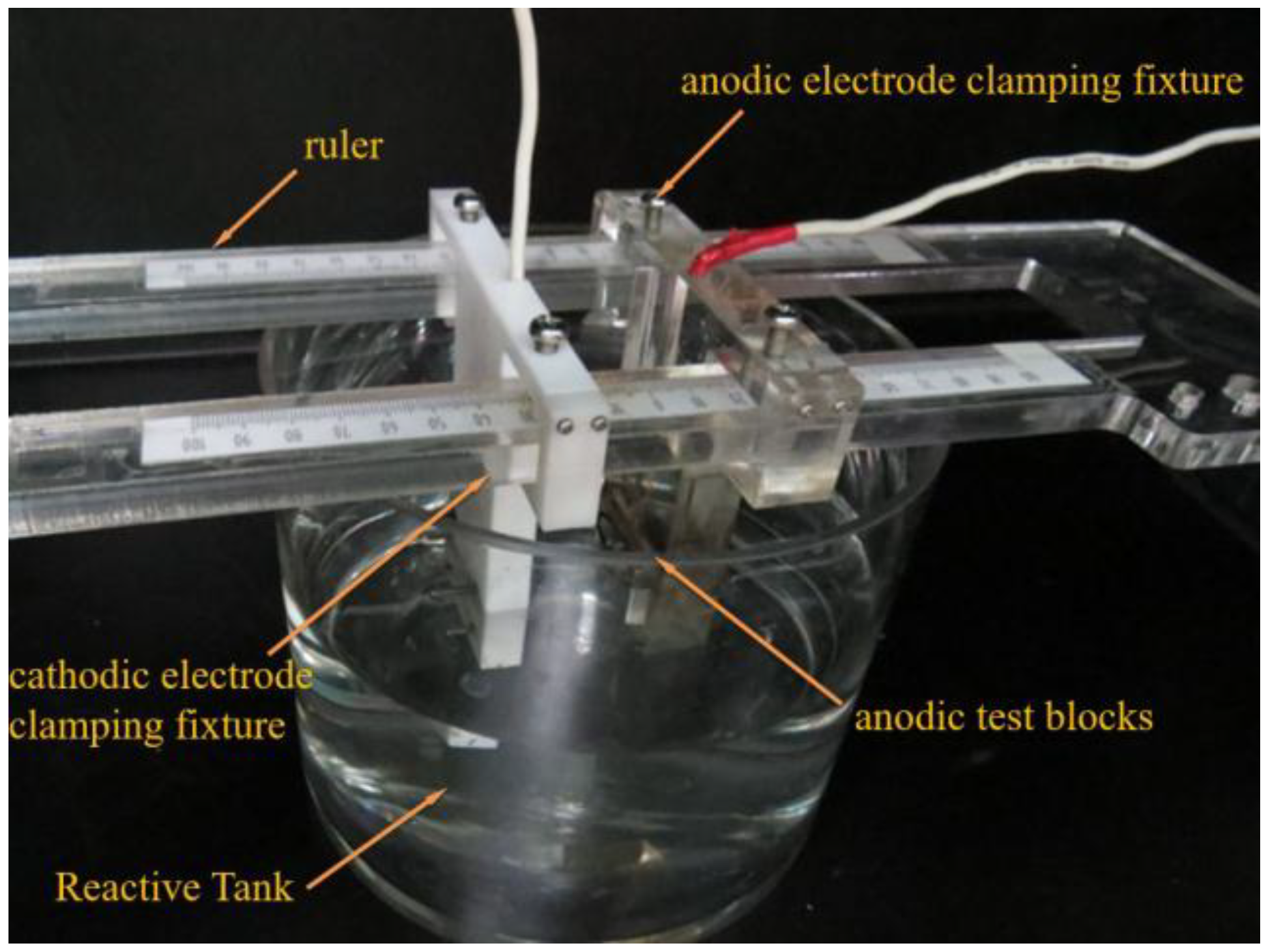

This study uses plasma electrolytic technology to coat a stainless steel surface with nanosilver, yielding stainless steel with antibacterial properties. Based on the one-factor-at-a-time experimental approach, we determined the parameters required to effectively coat nanosilver on stainless steel 316 and achieve a hydrophobic effect on the surface. After treatment with plasma electrolytic technology, the surface appearance of the specimens was observed with field emission gun scanning electron microscopy (FE–SEM), and its compositions were analyzed using an energy dispersive spectrometer (EDS). Finally, the specimens underwent contact angle measurement. The expectation was that a contact angle greater than 100° would yield hydrophobicity.

3. Results and Discussion

These experiments aimed to determine the optimum parameters for coating based on one-factor-at-a-time experimentation, to achieve a specimen surface with hydrophobicity. This section discusses the experiments in three parts. First, we look at the effect of different KNO

3 concentrations on the plasma electrolytic coating. The higher the KNO

3 concentration, the better the electrical conductivity of the solution, which affects the coating deposition speed. Next, we examine the effect of different AgNO

3 concentrations upon the plasma electrolytic coating. Note that AgNO

3 is a precious metal and must be used sparingly. The higher the AgNO

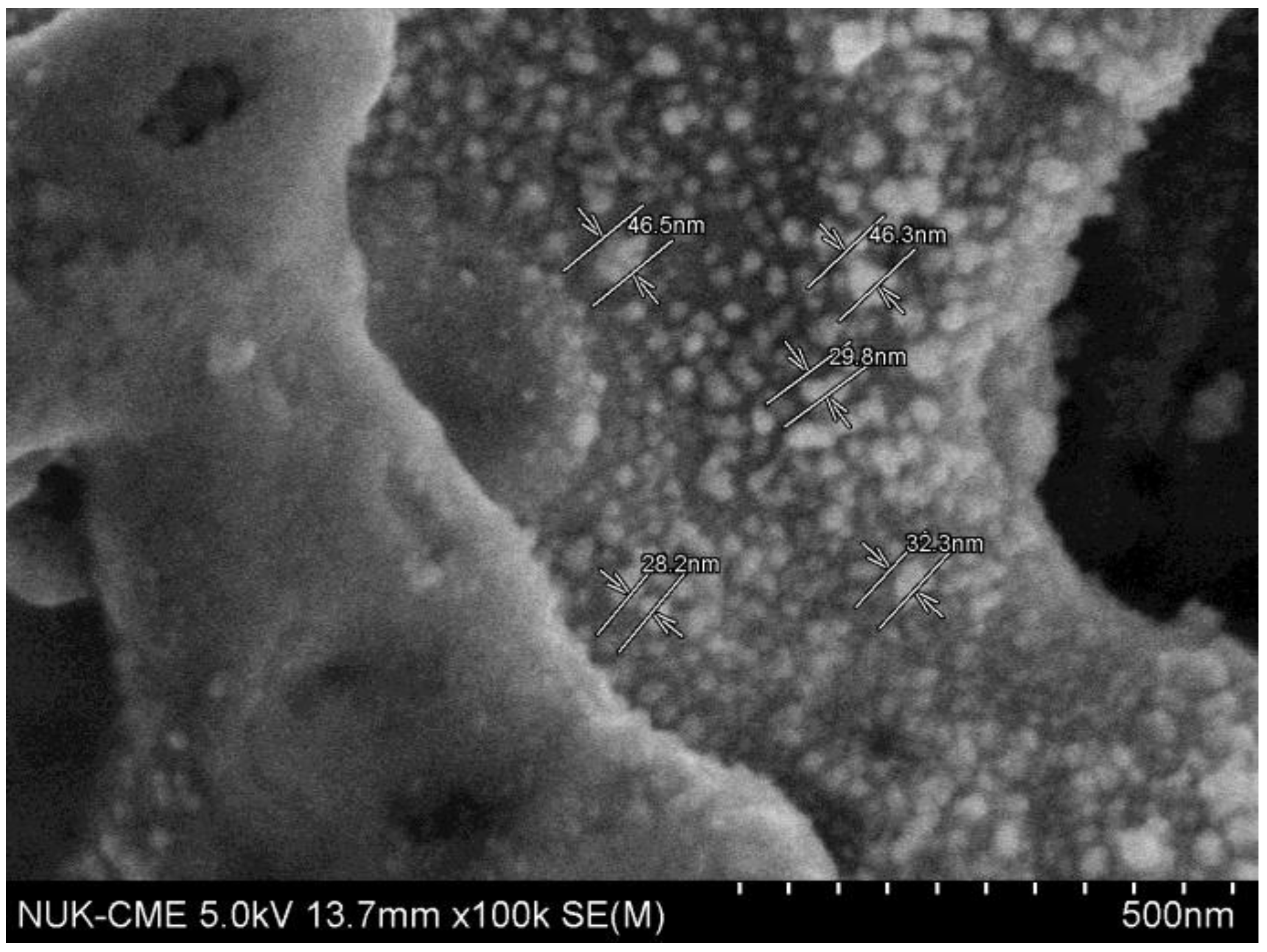

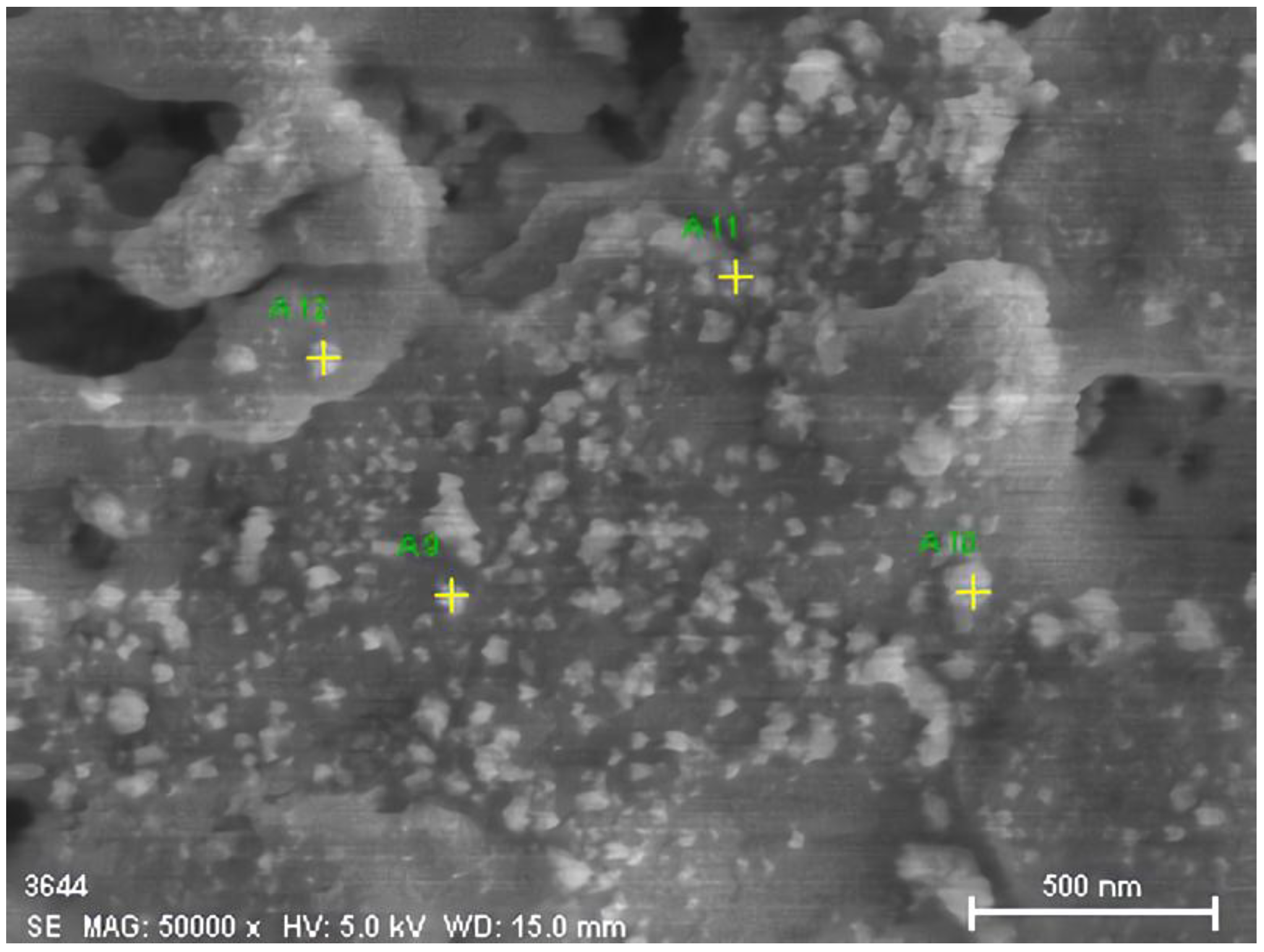

3 concentration, the higher the coating rate; at the same time, the surface hydrophobicity is depressed. Third, we look at the effect of electrode distance on plasma electrolysis. This distance affects the energy consumed in the current flow. It also confirms whether high or low energy will affect the coating weight of silver. Finally, we discuss the effect of surface hydrophobicity after plasma electrolysis. The aim is to measure the contact angle, then determine the change in surface hydrophobicity after treatment. In the experiment, after the material was processed with plasma electrolytic technology, the surface of the specimens was coated by nanosilver particles. The particle size after plasma electrolysis was confirmed to be about 30–50 nm on the surface of the specimen, as shown in

Figure 2, which was within the particle size range of nanosilver. EDS was conducted to analyze the surface composition, as shown in

Figure 3; the main component was silver (see

Table 1).

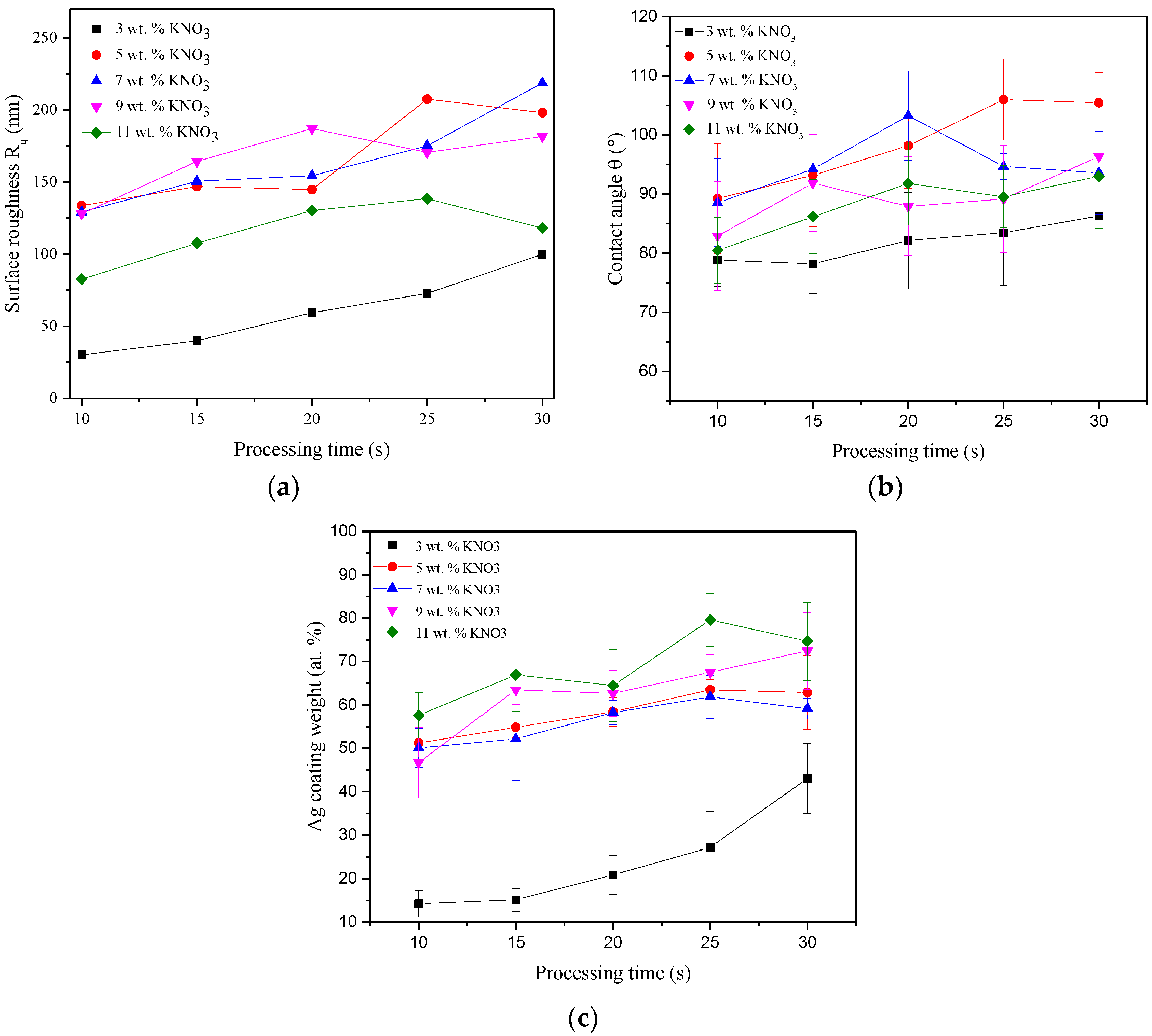

3.1. The Effect of Different KNO3 Concentrations on the Plasma Electrolytic Coating

After plasma electrolytic coating with different KNO

3 concentrations, the cathodic specimen was subjected to SEM, EDS, and contact angle measurement, as shown in

Figure 4. When the KNO

3 concentration was 3 wt.%, the electrical conductivity was small enough that the plasma electrolytic reaction was incomplete and the processing surface was uneven. Achieving an even surface required a processing time of more than 25 s, but the overall surface uniformity was still insufficient. With multiple repeated experiments, we observed that the results were affected by the external ambient temperature. When the ambient temperature was low, normal arcing could not start because the temperature affected the electrical conductivity. That is, lower conductivity resulted from lower temperatures, while higher conductivity was achieved with higher temperatures. In this study, the temperature of the electrolyte is about 25–35 °C during the processing.

When the KNO

3 concentration was increased to 5, 7 and 9 wt.%, the RMS surface roughness (

Rq) peaked and the surface was uniform. As shown in

Figure 4a, the trends of the three curves at 5, 7 and 9 wt.% are quite similar because their differences are within the measurement error since the standard deviation is about 6%. When the processing time was longer, the surface was increasingly rough. When the concentration was increased to 11 wt.%, the surface roughness dramatically declined. We conjecture that the higher the electrical conductivity of the electrolyte, the more violent the plasma electrolytic reaction. This higher electrical conductivity causes the coating deposition speed to be greater than the speed at which holes are created during the plasma electrolytic reaction. This results in fewer holes on the surface of the stainless steel, with some parts being flat and devoid of holes.

The contact angle measurements for different KNO

3 concentrations are presented in

Figure 4b. It was observed that the trends of the three curves at KNO

3 concentrations of 5, 7 and 9 wt.% are almost the same because the diagram clearly shows that the contact angle gradually increased as the treatment time increased. However, a KNO

3 concentration of 5 wt.% is suggested as a better parameter for achieving the desired contact angle because this trend is more consistent.

Figure 4c compares the silver coating weight for different KNO

3 concentrations and processing times. We found that the silver coating weight on the surface gradually increased with time. With the exception of a KNO

3 concentration of 3 wt.%, the remaining four concentrations caused the surface to be coated with more than 60 at.% silver within 30 s. A KNO

3 concentration of 3 wt.% induced low electrical conductivity, so a starting arc was not achieved and hence the Ag coating was not uniform or, in some cases, complete. The above suggests that a KNO

3 concentration of 5 wt.% was optimal for coating Ag on the surface of the stainless steel using plasma electrolysis.

3.2. Effect of Different AgNO3 Concentrations on Plasma Electrolytic Coating

As discussed in

Section 3.1, a KNO

3 concentration of 5 wt.% was found to be optimal and was therefore used during these experiments.

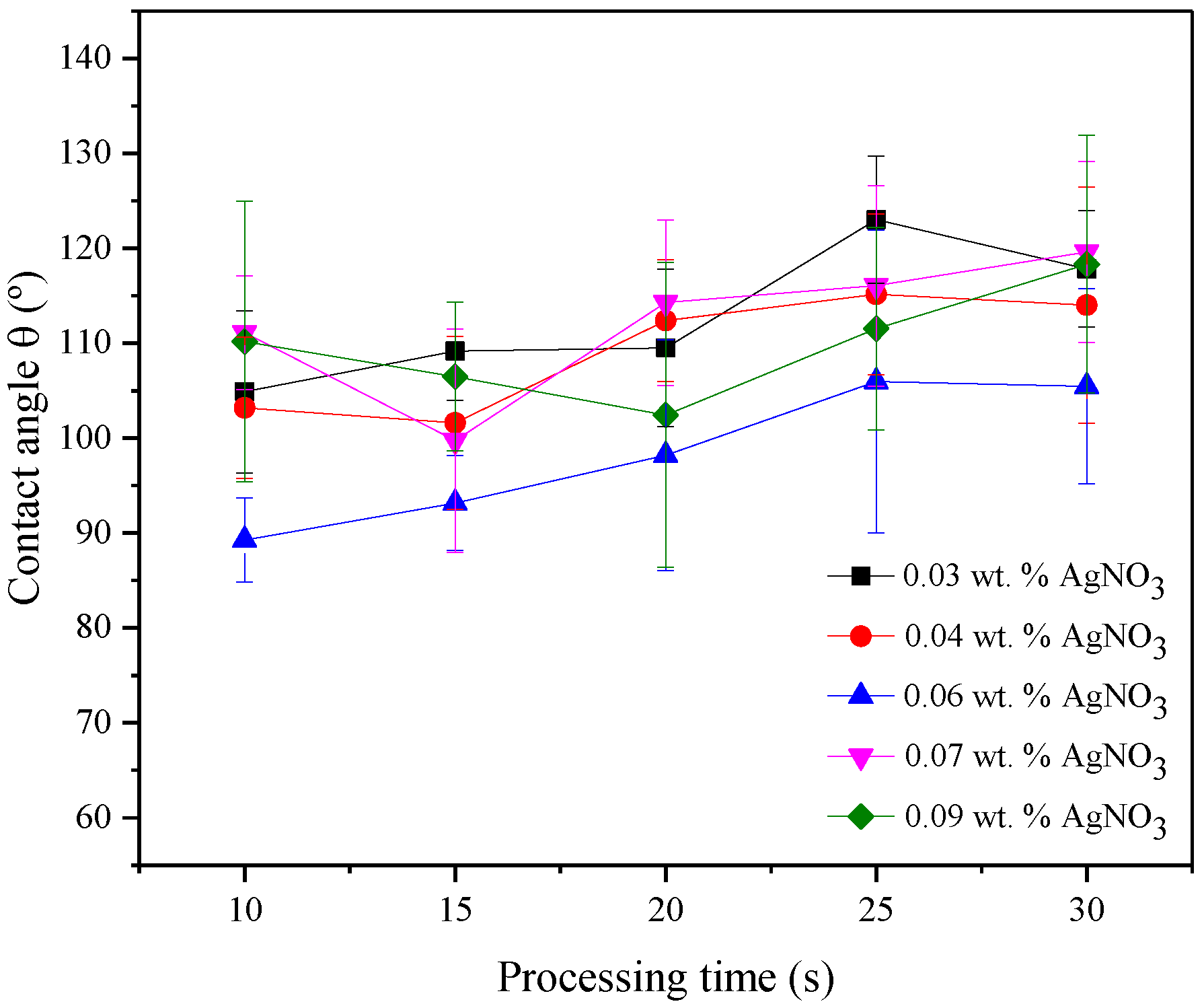

Figure 5 compares the contact angle data for different AgNO

3 concentrations and processing times. When the AgNO

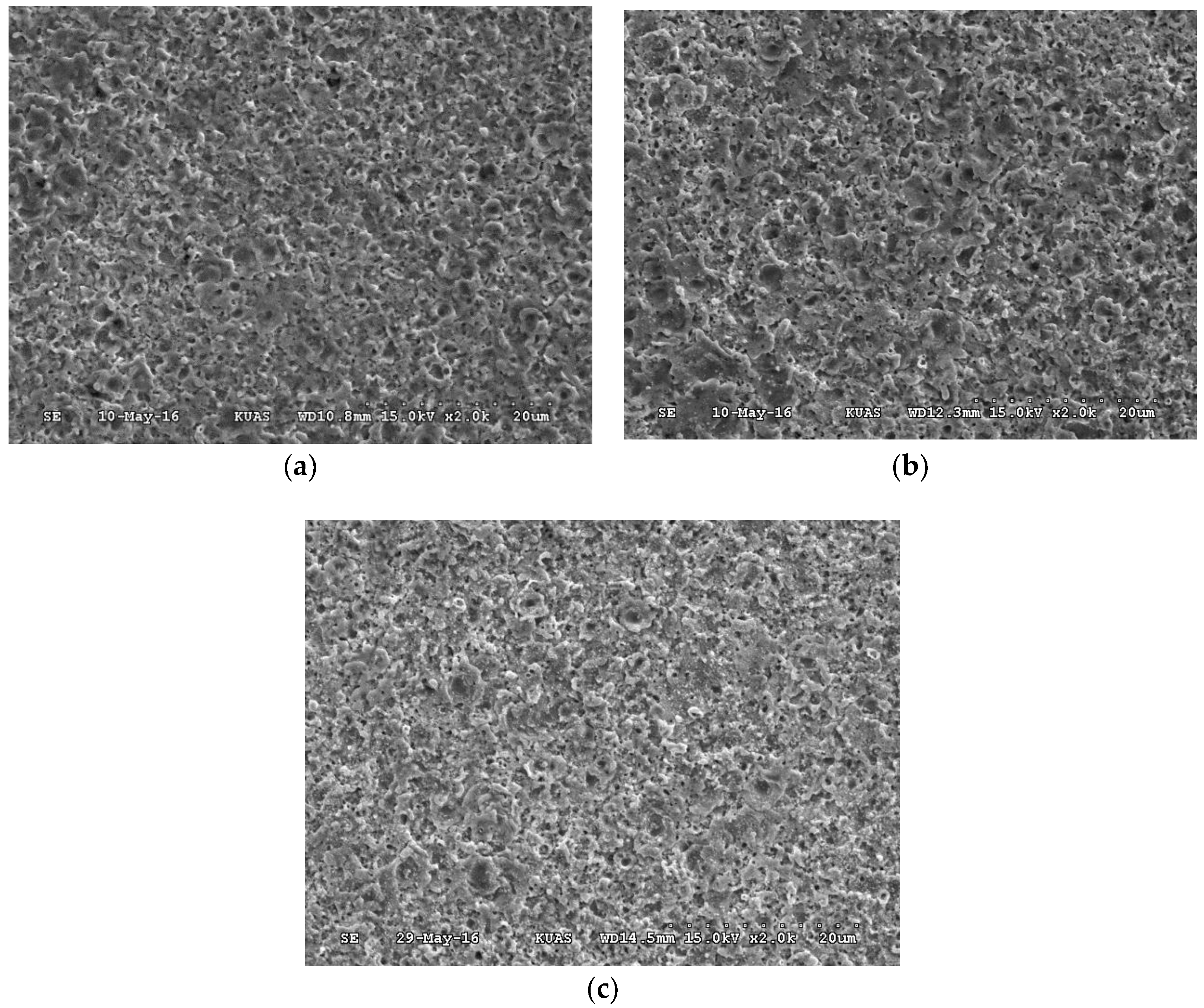

3 concentration was 0.03 wt.% with a processing time from 10 s to 25 s, the contact angle gradually increased from 105° to the widest angle of 123.02°, demonstrating hydrophobicity was achieved. SEM photos of the surface for an AgNO

3 concentration of 0.03 wt.% with different processing times are shown in

Figure 6. It can be observed that the holes at 30 s are larger than those at 10 s and 20 s, and the holes on the material’s surface failed to fully support the drop, causing a decrease in the contact angle. However, when the AgNO

3 concentration was 0.09 wt.%, the water drop contact angle for a processing time of 30 s was close to demonstrating hydrophobicity. Since the standard deviations are average and all within 10%, the trends of the four curves, except 0.06 wt.%, are quite similar. It can be conducted that the variation on the concentration of AgNO

3 has a little influence on contact angle.

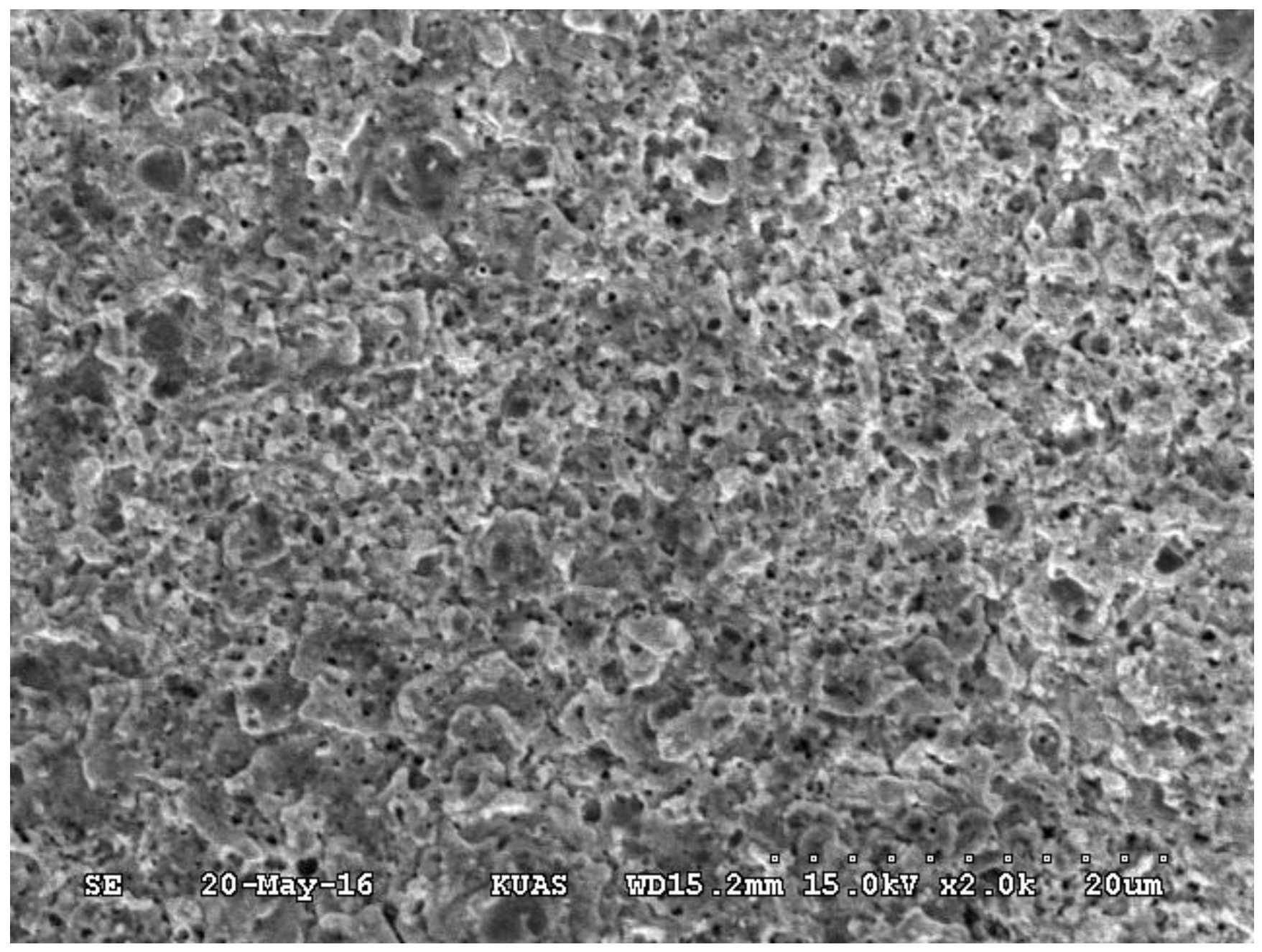

Figure 7 presented that the size of the surface holes for a processing time of 15 s was not uniform; there were some larger holes among the small holes, causing uneven drops on the material surface as well as a narrowing of the contact angle. Therefore, the processing time plays a key effect on contact angle.

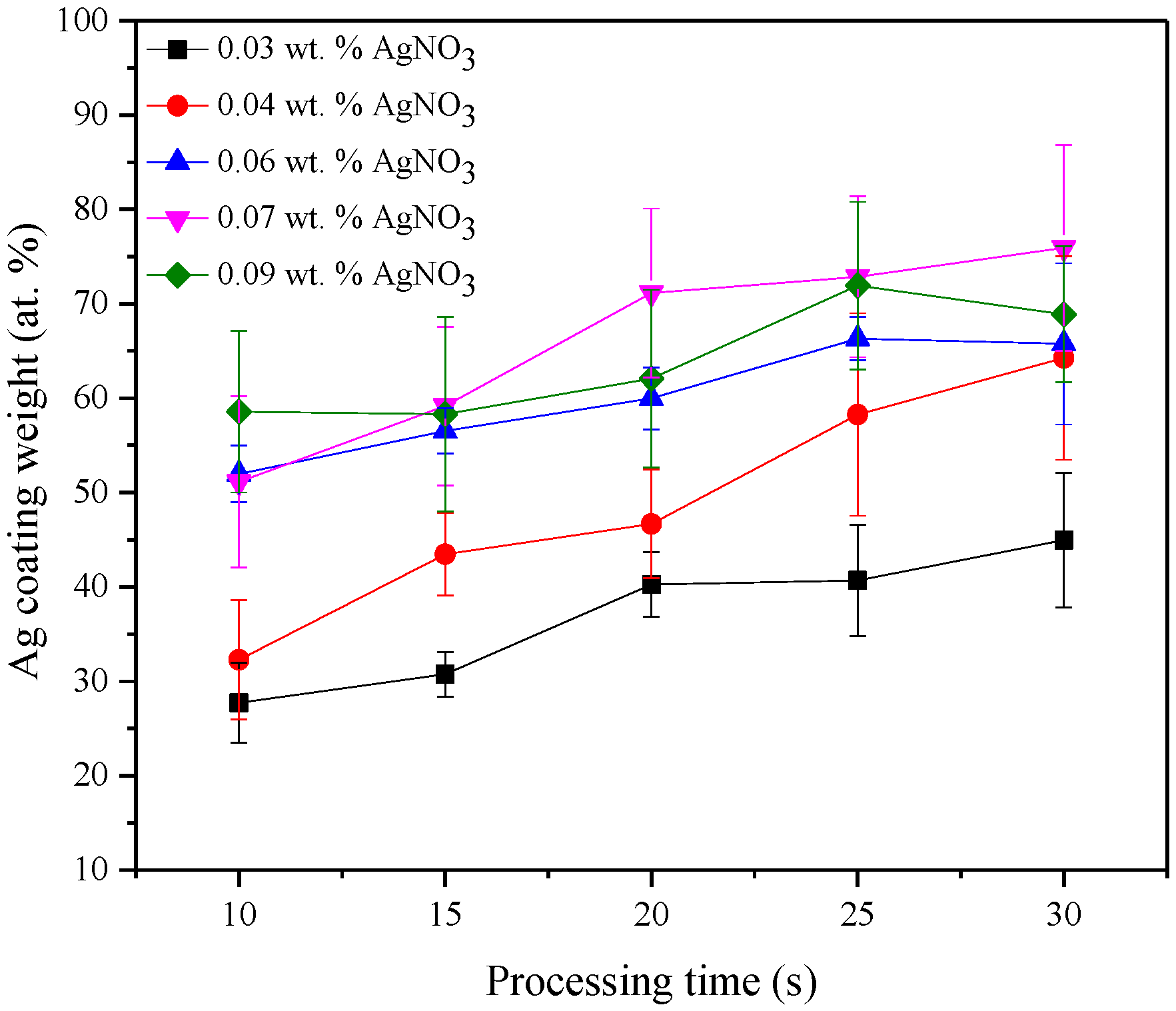

Figure 8 presents the measured mean value and standard deviation of the silver coating weight for different AgNO

3 concentrations and processing times. The silver coating weight gradually increased when the processing time increased for AgNO

3 concentrations of 0.03 wt.%, 0.04 wt.%, 0.06 wt.%, 0.07 wt.%, and 0.09 wt.%. An AgNO

3 concentration of 0.03 wt.% yielded the least silver coating on the surface, followed by an AgNO

3 concentration of 0.05 wt.%, whereas at concentrations of 0.06 wt.%, 0.07 wt.%, and 0.09 wt.%, the difference in coating amount was not significant.

Figure 5 and

Figure 8 suggest that an AgNO

3 concentration of 0.03 wt.% was optimal for getting a water drop contact angle that achieved hydrophobicity and produced the least silver coating on the surface. The thick of Ag coating film is about 600 nm.

3.3. Effect of Different Plate Distances on Plasma Electrolytic Coating

Based on the above discussion, we set the silver KNO

3 concentration at 3 wt.% and the silver nitrate concentration at 0.03 wt.% in the following experiments to determine the effect of varying the electrode distance.

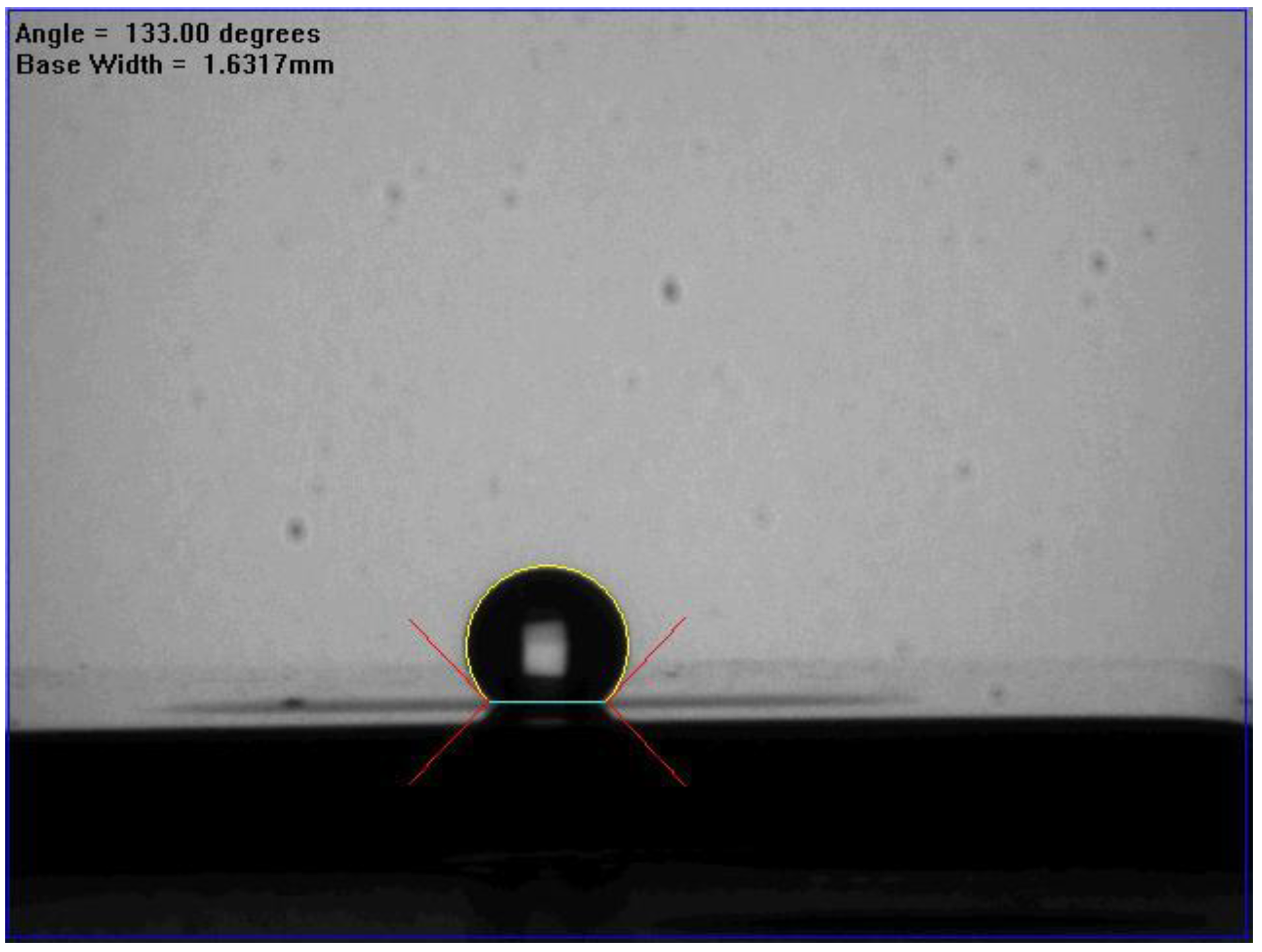

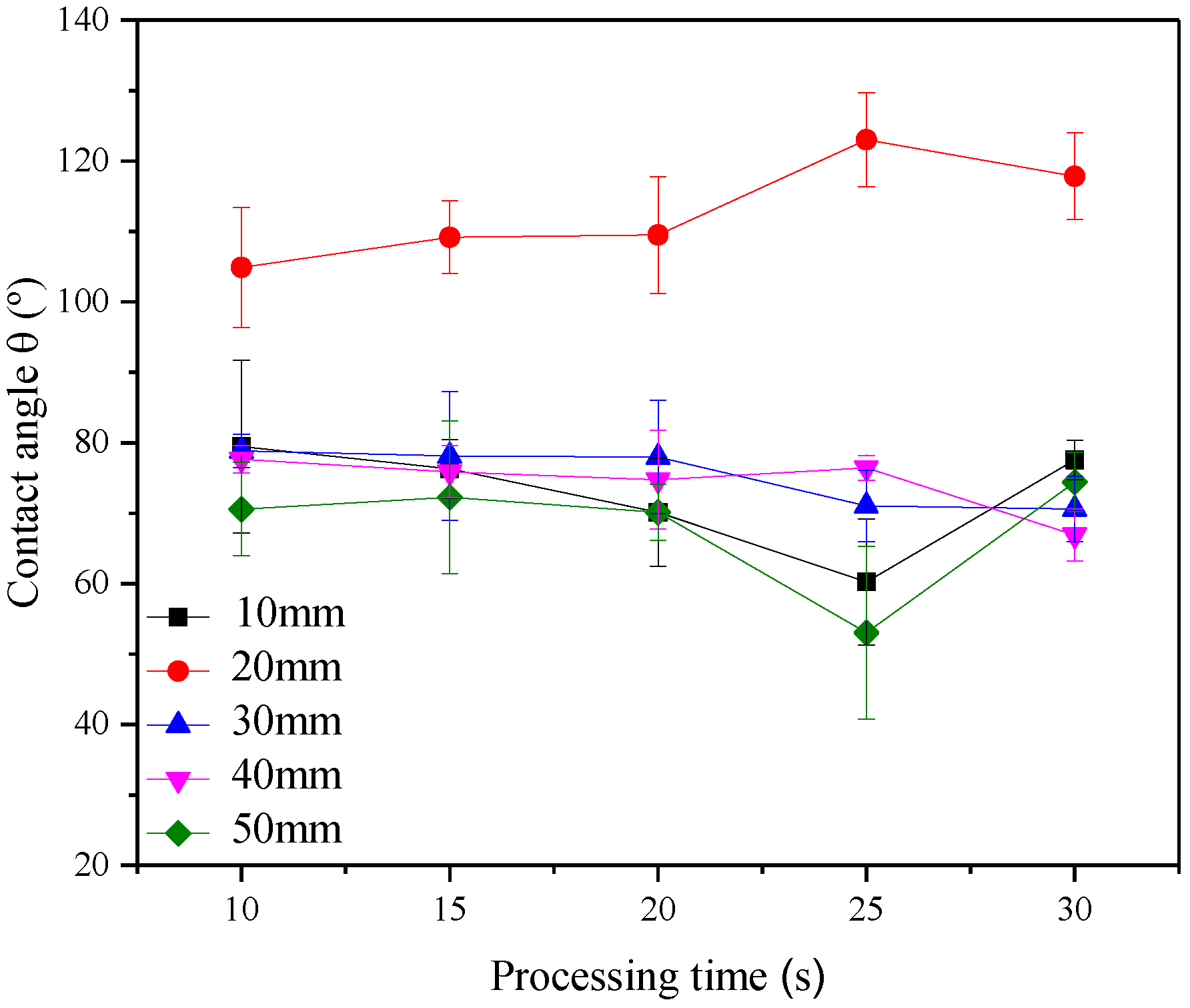

Figure 9 presents photos of contact angle measurement with respect to processing time with an electrode distance of 20 mm, and

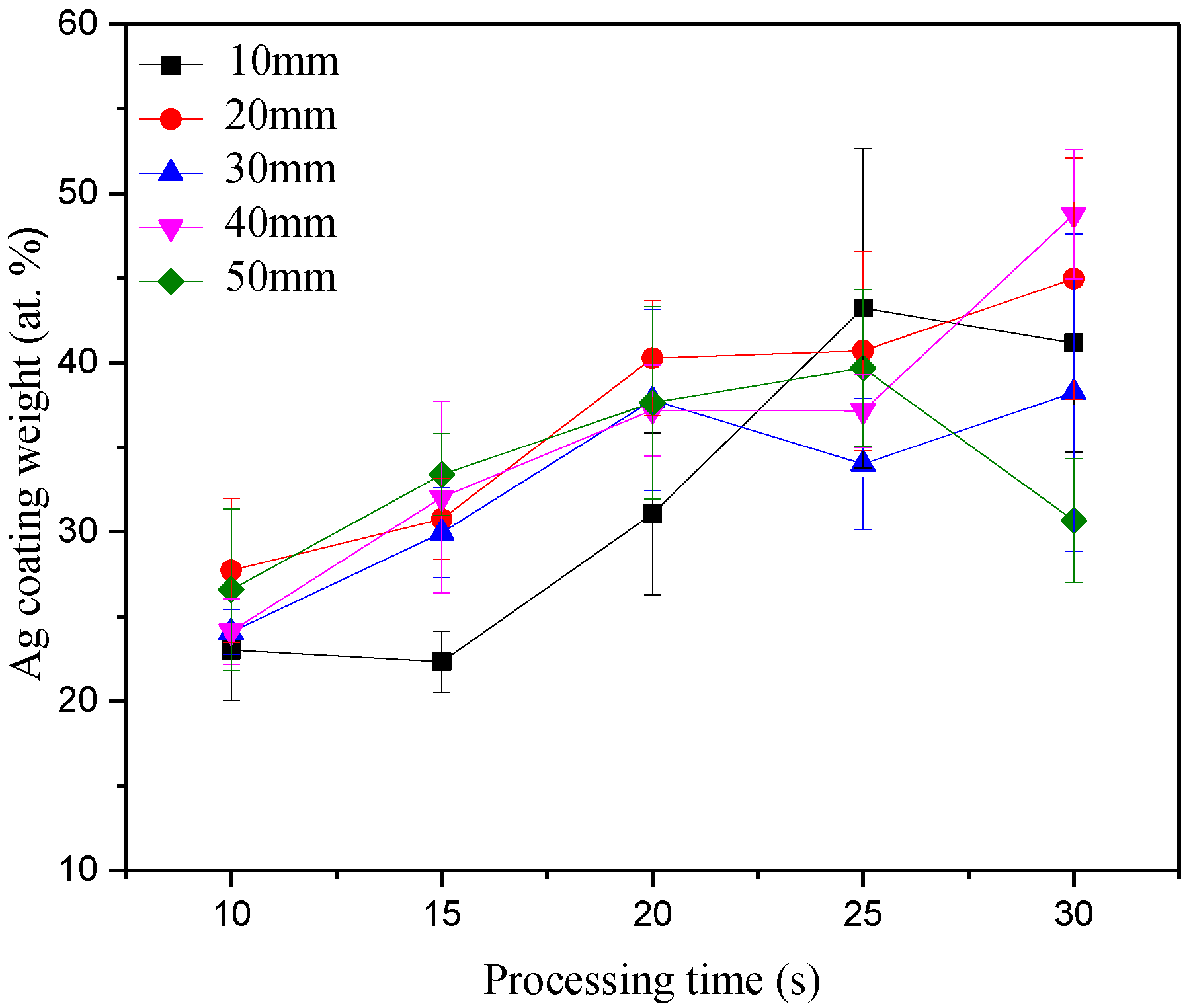

Figure 10 compares the measured mean value and standard deviation of the contact angle for different electrode distances and processing times. From

Figure 10, we see that an electrode distance of 20 mm yielded the best contact angle. For distances of 10 mm, 30 mm, 40 mm, and 50 mm, the dependences of the contact angle was practically coincided and almost the same. The standard deviation range for electrode distances of 10 mm and 50 mm was large, exceeding 10%, whereas for distances of 20 mm, 30 mm, and 40 mm, the standard deviation was within 10%.

Figure 11 compares the measured mean values and standard deviations of the silver-coating weight for different electrode distances and processing times. The longer the processing time, the heavier the silver-coating weight. When the electrode distance was 10 mm, the silver-coating weight was lower than with the other four greater electrode distances. This may have been because when the electrode distance was too small, the electrical resistance dropped and the plasma electrolytic reaction became fiercer, such that the coated silver element was destroyed, creating a new hole. This prevented the silver from completely coating the surface of the material. The above results suggest that the best contact angle and lower coating weight were achieved with an electrode distance of 20 mm.

4. Conclusions

This paper has successfully applied plasma electrolytic technology to coat nanosilver on the surface of stainless steel 316, achieving a relatively uniform distribution. The optimal parameters for KNO3 concentration, AgNO3 concentration, and electrode distance were obtained using the one-factor-at-a-time experimental approach. The KNO3 concentration affects the electrical conductivity, depending on the ambient temperature in the plasma electrolytic reaction system. The experimental results show that a KNO3 concentration of 5 wt.% yields better performance and boosts the contact angle above 100° to achieve hydrophobicity. In terms of AgNO3 concentration, the higher the concentration, the more silver will be deposited on the surface. Therefore, we suggest an AgNO3 concentration of 0.03 wt.% to achieve a larger contact angle and therefore hydrophobicity, as well as a thinner silver coating on the surface with uniform distribution. When the electrode distance is set at 10 mm, the plasma electrolytic reaction is quite violent, since the two electrodes are too close. As a result, the silver cannot be completely coated on the surface, and the contact angle is smaller than in the original material. An electrode distance of 20 mm was found to be optimal for producing a hydrophobic coating. The contact angle of the 316 stainless steel is about 75.75°, producing a hydrophilic material. However, the contact angle of the specimen after the plasma electrolytic silver coating treatment is about 134° ± 10°, yielding a hydrophobic surface. Our experiments show that this silver-coating treatment using plasma electrolytic technology can change the surface of stainless steel from hydrophilic to hydrophobic and make it water-free. In the future, we will explore other properties of nanosilver coatings on stainless steel, such as strength, oxidation resistance, and aging.