Tribooxidation as a Way to Improve the Wear Resistance of Cutting Tools

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

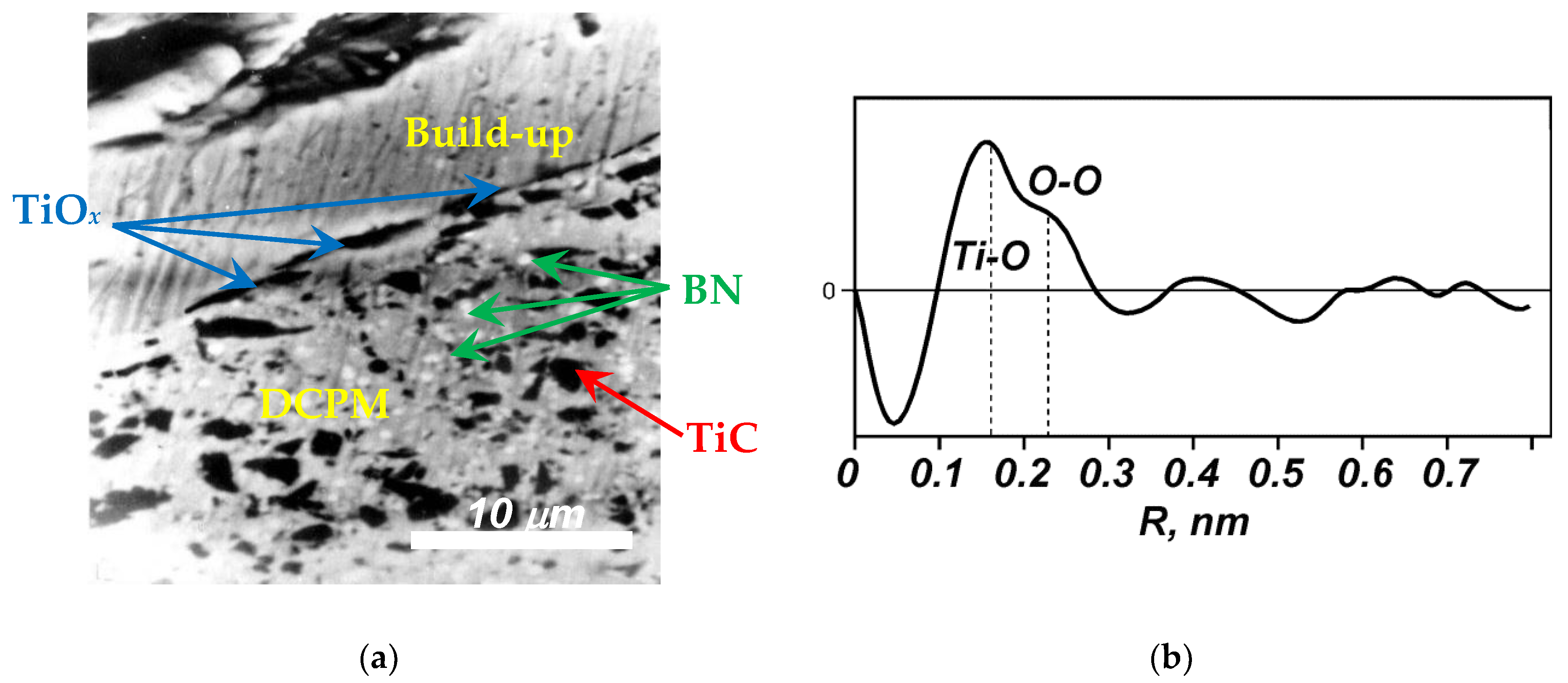

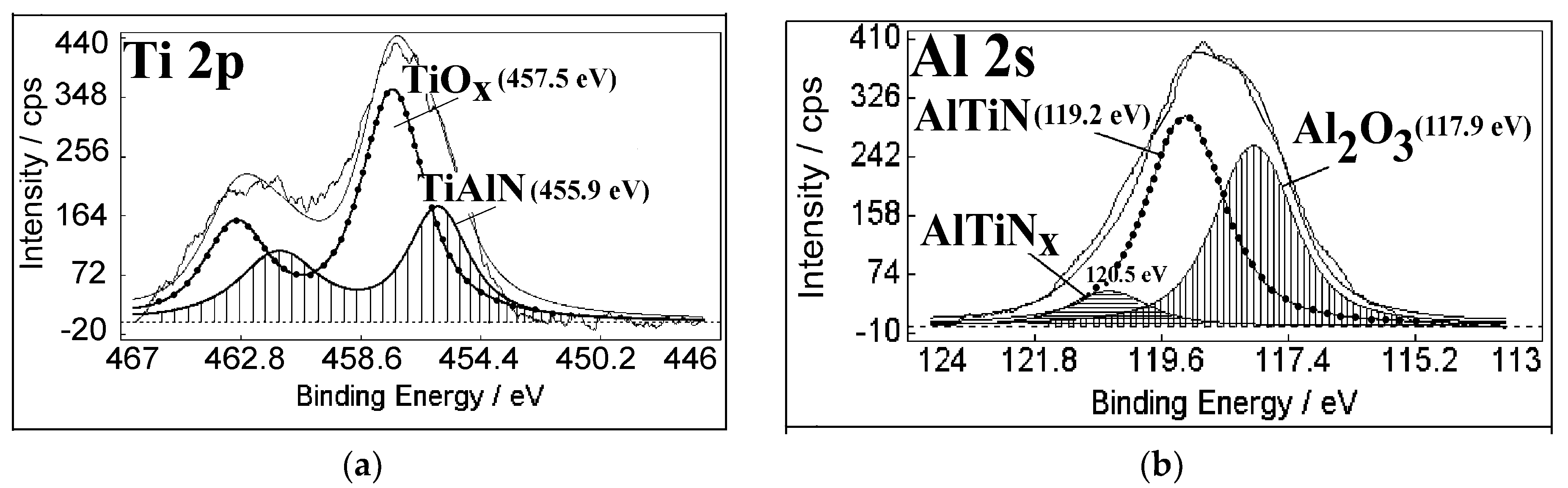

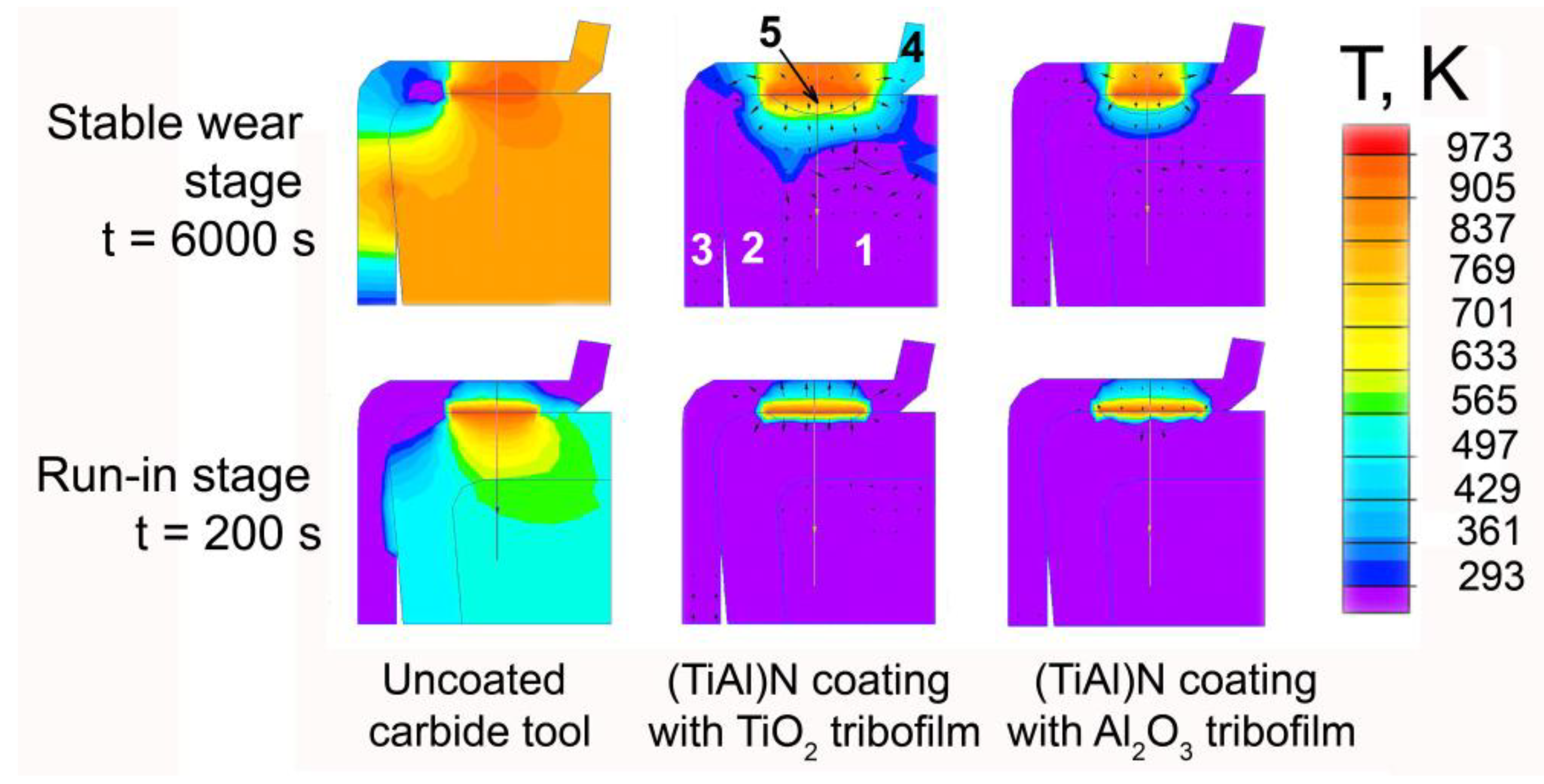

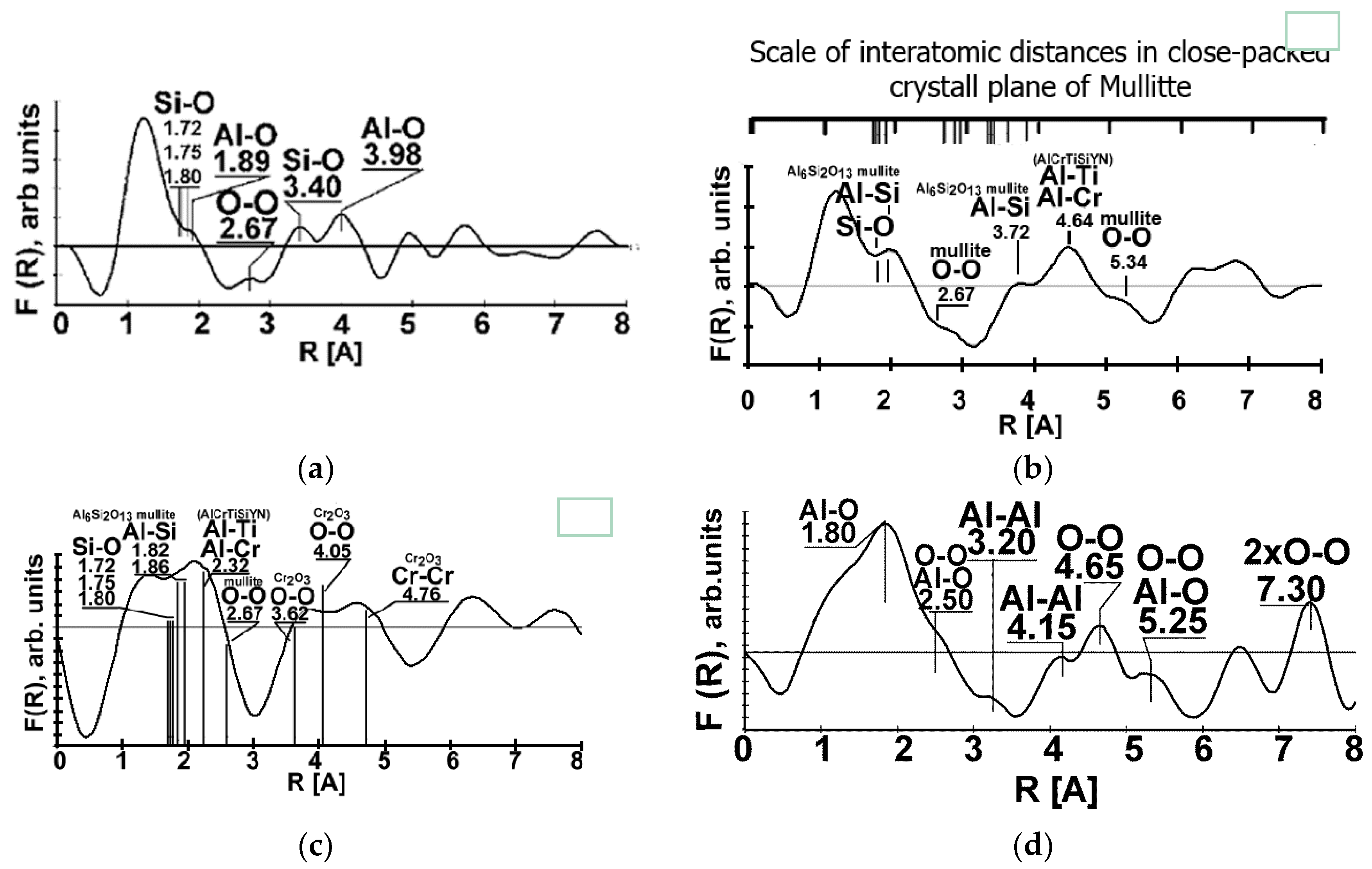

3.1. Single Layer Adaptive Coatings

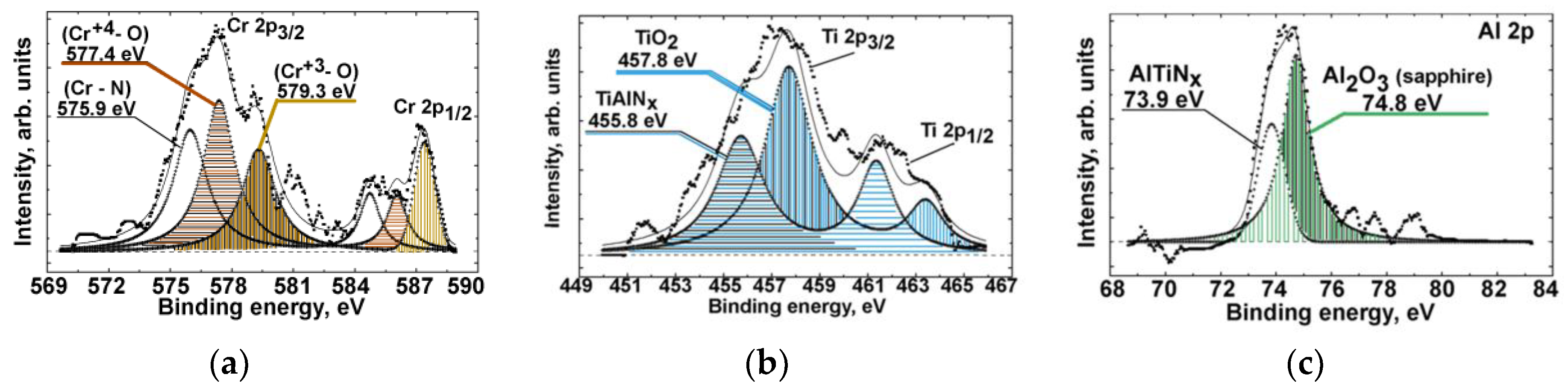

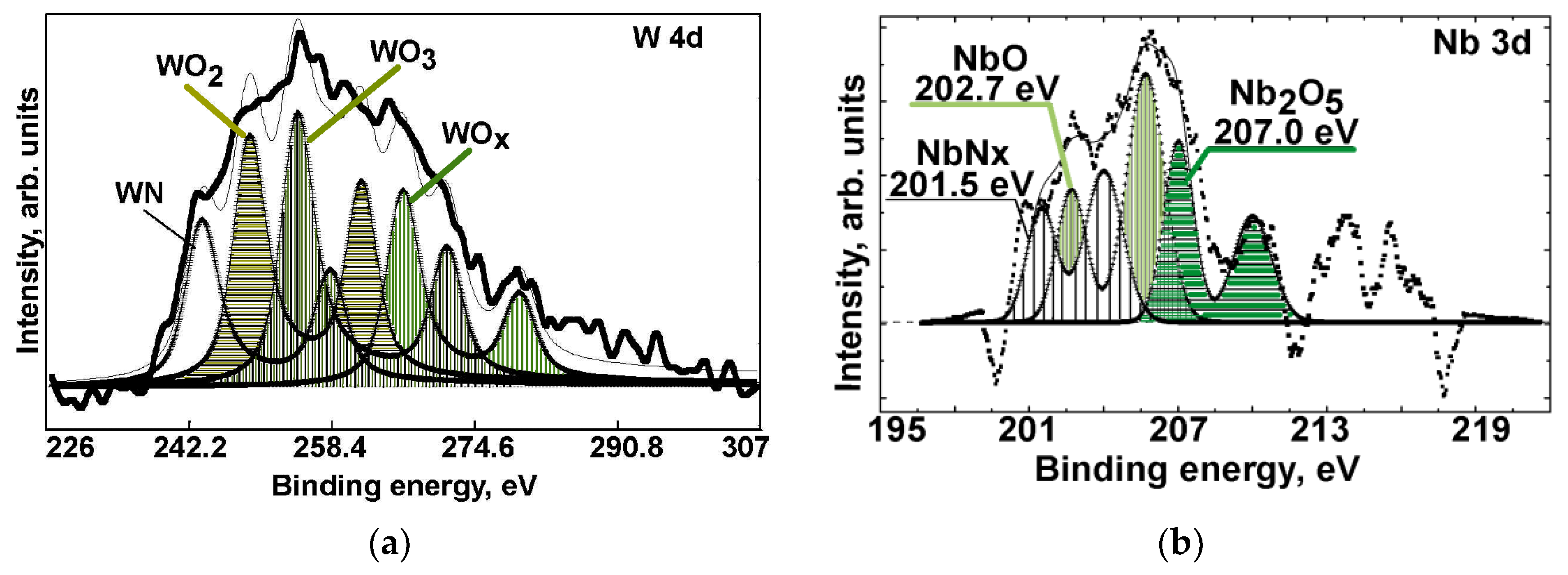

3.2. Multilayer Adaptive Coatings with Polyvalent Metals (NbN, WN)

- Optimal crystalline structure of individual layers which provides the best wear resistance.

- Their oxidation dynamics are equal to a multicomponent single layer system due to very short diffusion paths and high operation temperatures.

- The microaccumulation of cracks and other damages could be blocked on multiple interfaces. This useful behavior of multilayer coatings compared to a single layer one was approved during the data processing of the impact fatigue fracture resistance tests [27].

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Dai, M.; Zhou, K.; Yuan, Z.; Ding, Q.; Fu, Z. The cutting performance of diamond and DLC-coated cutting tools. Diam. Relat. Mater. 2000, 9, 1753–1757. [Google Scholar] [CrossRef]

- Wu, T.; Cheng, K. Micro milling performance assessment of diamond-like carbon coatings on a micro-end mill. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 1038–1046. [Google Scholar] [CrossRef]

- Aslantas, K.; Hopa, H.E.; Percin, M.; Ucun, İ.; Çicek, A. Cutting performance of nano-crystalline diamond (NCD) coating in micro-milling of Ti6Al4V alloy. Precis. Eng. 2016, 45, 55–66. [Google Scholar] [CrossRef]

- Lei, X.; Wang, L.; Shen, B.; Sun, F. Microdrill with variations in thickness of diamond coating. Surf. Eng. 2016, 32, 165–171. [Google Scholar] [CrossRef]

- Ljungberg, B.; Lenander, A. Oxide Coated Cutting Tool. U.S. Patent 5,487,625, 30 January 1996. [Google Scholar]

- Åstrand, M.; Selinder, T.I.; Fietzke, F.; Klostermann, H. PVD-Al2O3-coated cemented carbide cutting tools. Surf. Coat. Technol. 2004, 188–189, 186–192. [Google Scholar] [CrossRef]

- Lindahl, E.; Engqvist, J. CVD Coated Cutting Tool with Textured k-Al2O3 Layer. U.S. Patent Appl. 15/637308, 4 January 2018. [Google Scholar]

- Schulz, H.; Dörr, J.; Rass, I.J.; Schulze, M.; Leyendecker, T.; Erkens, G. Performance of oxide PVD-coatings in dry cutting operations. Surf. Coat. Technol. 2001, 146–147, 480–485. [Google Scholar] [CrossRef]

- Pilkington, A.; Dowey, S.J.; Toton, J.T.; Doyle, E.D. Machining with AlCr-oxinitride PVD coated cutting tools. Tribol. Int. 2013, 65, 303–313. [Google Scholar] [CrossRef]

- Makino, Y.; Nose, M.; Tanaka, T.; Misawa, M.; Tanimoto, A.; Nakai, T.; Kato, K.; Nogi, K. Characterization of Ti(NxOy) coatings produced by the arc ion plating method. Surf. Coat. Technol. 1998, 98, 934–938. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, X.W.; Li, G.Z.; Li, G.Y. Microstructure and mechanical properties of reactively sputtered Ti(O,N) coatings. Int. J. Refract. Met. Hard Mater. 2008, 26, 461–464. [Google Scholar] [CrossRef]

- Nohava, J.; Dessarzin, P.; Karvankova, P.; Morstein, M. Characterization of tribological behavior and wear mechanisms of novel oxynitride PVD coatings designed for applications at high temperatures. Tribol. Int. 2015, 81, 231–239. [Google Scholar] [CrossRef]

- Ciftci, I. Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 2006, 39, 565–569. [Google Scholar] [CrossRef]

- Raab, R.; Koller, C.M.; Kolozsváric, S.; Ramm, J.; Mayrhofer, P.H. Interfaces in arc evaporated Al-Cr-N/Al-Cr-O multilayers and their impact on hardness. Surf. Coat. Technol. 2017, 324, 236–242. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Kovalev, A.I.; Shuster, L.S.; Bokiy, Y.F.; Dosbayeva, G.K.; Wainstein, D.L.; Mishina, V.P. Characteristic features of alloying HSS-based deformed compound powder materials with consideration for tool self-organization at cutting. 1. Characteristic features of wear in HSS-based deformed compound powder materials at cutting. Wear 1997, 206, 214–220. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Kovalev, A.I.; Shuster, L.S.; Bokiy, Y.F.; Dosbayeva, G.K.; Wainstein, D.L.; Mishina, V.P. On characteristics features of alloying HSS-based deformed compound powder materials with consideration for tool self-organization at cutting 2. Cutting tool friction control due to the alloying of the HSS-based deformed compound powder material. Wear 1998, 214, 279–286. [Google Scholar] [CrossRef]

- Wainstein, D.L.; Kovalev, A.I. Fine determination of interatomic distances on surface using extended energy-loss fine structure (EELFS) data: Peculiarities of the technique. Surf. Interface Anal. 2002, 34, 230–233. [Google Scholar] [CrossRef]

- Mrkvica, I.; Neslušan, M.; Čep, R.; Sléha, V. Properties and comparison of PVD coatings. Tehnički Vjesnik 2016, 23, 569–574. [Google Scholar] [CrossRef]

- Merkleina, M.; Schradera, T.; Engela, U. Wear behavior of PVD-coatings. Tribol. Ind. 2012, 34, 51–56. [Google Scholar]

- Vereschaka, A.А.; Volosova, M.A.; Batako, A.D.; Vereshchaka, A.S.; Mokritskii, B.Y. Development of wear-resistant coatings compounds for high-speed steel tool using a combined cathodic vacuum arc deposition. Int. J. Adv. Manuf. Technol. 2016, 84, 1471–1482. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Weatherly, G.C.; Dodonov, A.I.; Kovalev, A.I.; Veldhuis, S.C.; Shuster, L.S.; Dosbaeva, G.K.; Wainstein, D.L. Nano-crystalline FAD (filtered arc deposited) TiAlN PVD coatings for high-speed machining application. Surf. Coat. Technol. 2004, 177–178, 800–811. [Google Scholar] [CrossRef]

- Kovalev, A.I.; Wainstein, D.L.; Rashkovskiy, A.Y.; Fox-Rabinovich, G.S.; Yamamoto, K.; Veldhuis, S.; Aguirre, M.; Beake, B.D. Impact of Al and Cr alloying in TiN-based PVD coatings on cutting performance during machining of hard to cut materials. Vacuum 2010, 84, 184–187. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Veldhuis, S.C.; Dosbaeva, G.K.; Yamamoto, K.; Kovalev, A.I.; Wainstein, D.L.; Gershman, I.S.; Shuster, L.S.; Beake, B.D. Nanocrystalline coating design for extreme applications based on the concept of complex adaptive behavior. J. Appl. Phys. 2008, 103, 083510. [Google Scholar] [CrossRef]

- Kovalev, A.; Wainstein, D.; Fox-Rabinovich, G.; Veldhuis, S.; Yamamoto, K. Features of self-organization in nanostructuring PVD coatings on base of polyvalent metal nitrides under severe tribological conditions. Surf. Interface Anal. 2008, 40, 881–884. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Kovalev, A.; Veldhuis, S.; Yamamoto, K.; Endrino, J.L.; Gershman, I.S.; Rashkovskiy, A.; Aguirre, M.H.; Wainstein, D.L. Spatio-temporal behaviour of atomic-scale tribo-ceramic films in adaptive surface engineered nano-materials. Sci. Rep. 2015, 5, 8780. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.; Beake, B.D.; Yamamoto, K.; Bose, B.; Aguirre, M.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Improvement of wear performance of nano-multilayer PVD coatings under dry hard end milling conditions based on their architectural development. Coatings 2018, 8, 59. [Google Scholar] [CrossRef]

- Kovalev, A.I.; Rashkovsky, A.Y.; Fox-Rabinovich, G.S.; Veldhuis, S.; Beake, B.D. Regularities of tribooxidation and damageability at the early stage of wear of single-layer (TiAlCrSiY)N and multilayer (TiAlCrSiY)N/(TiAlCr)N coatings in the case of high-speed cutting. Prot. Met. Phys. Chem. Surf. 2016, 52, 315–323. [Google Scholar] [CrossRef]

- Roberts, G.; Krauss, G.; Kennedy, R. Tool Steels, 5th ed.; ASM International: Materials Park, OH, USA, 1998. [Google Scholar]

- Oberg, E.; Jones, F.D.; Horton, H.L.; Ryffel, H.H. Machinery’s Handbook, 25th ed.; Green, R.E., McCauley, C.J., Eds.; Industrial Press: New York, NY, USA, 1996. [Google Scholar]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and wear of cutting tools in high-speed machining of Inconel 718 and Ti6Al6V2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- El-Wardany, T.I.; Mohammed, E.; Elbestawi, M.A. Cutting temperature of ceramic tools in high speed machining of difficult-to-cut materials. Int. J. Mach. Tool Manuf. 1996, 36, 611–634. [Google Scholar] [CrossRef]

- Tian, X.; Zhao, J.; Qin, W.; Gong, F.; Wang, Y.; Pan, H. Performance of ceramic tools in high-speed cutting iron-based superalloys. Mach. Sci. Technol. 2017, 21, 279–290. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wainstein, D.; Kovalev, A. Tribooxidation as a Way to Improve the Wear Resistance of Cutting Tools. Coatings 2018, 8, 223. https://doi.org/10.3390/coatings8060223

Wainstein D, Kovalev A. Tribooxidation as a Way to Improve the Wear Resistance of Cutting Tools. Coatings. 2018; 8(6):223. https://doi.org/10.3390/coatings8060223

Chicago/Turabian StyleWainstein, Dmitry, and Anatoly Kovalev. 2018. "Tribooxidation as a Way to Improve the Wear Resistance of Cutting Tools" Coatings 8, no. 6: 223. https://doi.org/10.3390/coatings8060223

APA StyleWainstein, D., & Kovalev, A. (2018). Tribooxidation as a Way to Improve the Wear Resistance of Cutting Tools. Coatings, 8(6), 223. https://doi.org/10.3390/coatings8060223