Abstract

Enhanced demand for the development of sustainable materials has generated significant research interest in products containing biomass-derived fibers, such as the fibers extracted from the energy crop Sida hermaphrodita (SH). Green chemicals and green methods, such as microwave treatment, have been used for the isolation of fibers from biomass waste. In this study, long extracted fibers were used as a reinforcement of the PLA matrix to give them high strength, which is required for high-performance biocomposites. To enable composite usage in automotive industry, several additives were applied to enhance their mechanical, thermal, and antimicrobial properties. Therefore, vegetable drying oil, montmorillonite nanoclay (MMT), and milled cork were used to improve their mechanical and thermal properties. Zinc oxide (ZnO) was applied to enhance the biocomposite’s antimicrobial properties, which were confirmed through significant bacterial reduction across all tested biocomposite variants, particularly in samples functionalized with ZnO, cork, and montmorillonite. Additionally, X-ray microtomography provided detailed insight into fiber dispersion and internal structural heterogeneity, which is crucial for evaluating mechanical performance and flame-retardant behavior. All characterization methods, including mechanical ones, lead to the conclusion that green and sustainable biocomposites based on PLA and Sida hermaphrodita fibers treated with antimicrobial (AM) and flame-retardant (FR) agents can be successfully applied for a wide variety of antimicrobial and flame-retardant products.

1. Introduction

Sustainable development encompasses the entire impact of the economy on the environment and is based on renewable energy sources. Among them, the highest percentage, approx. 65%, refers to biomass, which can be converted into different forms of energy using various technologies [1]. Modern technologies enable substantial, commercially profitable renewable energy production from biomass, which has numerous additional, positive effects. These include, above all, investments in the development of rural areas and local communities, as well as new jobs. Additionally, due to the negative energy balance, the EU aims to use its own energy sources and ensure the stability of market supply [2].

Therefore, the focus of our research was the development of a sustainable, and preferably biodegradable, biomass-derived natural fiber-reinforced composite. In order to develop a biocomposite product, both parts, the matrix and its reinforcement, must be made from sustainable sources, so the biodegradable polymeric PLA matrix was reinforced with biomass-derived natural fibers isolated from the energy crop Sida hermaphrodita (Figure 1).

Figure 1.

Sida hermaphrodita (SH): (a) illustration created by Sara Strgačić; (b) plant grown at the premises of University of Zagreb Faculty of Agronomy.

Sida hermaphrodita, or Virginia mallow, is naturally spread across the prairies of North America. It grows on sandy or stony soils with a small amount of organic matter and produces relatively large amounts of biomass on light soils with low fertility [3]. It is grown for its lignocellulosic fibers, as fodder for livestock, and as a honey plant [4]. The content of the lignocellulosic composition of Virginia mallow biomass is very similar to Spartium junceum L., approx. 20%–40% cellulose, 25%–35% hemicellulose, and 20%–25% lignin, while the lower calorific value is around 17 MJ/kg [5].

To isolate the fibers from the plant stem and to separate the bundles of fibers from the cuticularized epidermis and cells of the woody core, alkaline treatment is most often applied. It is usually carried out with sodium hydroxide (NaOH) for faster removal of pectin, lignin, and hemicellulose. On the other hand, stem fibers show some disadvantages that hinder their usage in the production of targeted products. For example, natural fibers are flammable, so they must be processed at a lower temperature (lower than 200 °C) due to the possible degradation of the fibers. Natural fibers exhibit high moisture absorption due to their hydrophilic nature, as well as incompatibility with most hydrophobic polymers. These problems are well known, so a lot of research targets the reduction of these negative characteristics [6].

If biomass-derived fibers without any additional treatment are used as reinforcement in the production of composite materials, they will show poor interfacial properties with the polymer matrix. Due to their hydrophilic nature and poor interfacial properties of natural fiber/polymer matrix systems, stem fibers will not achieve their full potential as a reinforcing agent for composite systems without chemical modifications [7]. Chemicals can activate hydroxyl groups or introduce new moieties that can efficiently bond with the matrix. The most common methods of natural fibers modifications are alkalization, acetylation, oxidation treatments with peroxide, benzoylation, silane treatments, grafting, cross-linking with various agents and nanoparticle addition [8]. In the current era of sustainable development, scientists and engineers are turning again to the use of biomaterials and biopolymers based on natural, renewable raw materials such as, for example, vegetable oil or corn starch, hoping to reach similar properties as petroleum-based plastics, but with environmental benefits [9]. This opens a new area within composite materials, i.e., ecodesign of sustainable biocomposites [10]. Such green composites are produced under the strict limitations for usage of green methods, such as microwave radiation, and green agents for all processes, including the functional finishing, e.g., flame retardant (FR) and/or antimicrobial (AM) ones.

1.1. Adition of Antimicrobial Agents

Antimicrobial composites are materials designed to inhibit the growth of microorganisms, thereby simultaneously improving the material’s protective properties, so as materials longevity. Most often methods used are coating with antimicrobial agents or functionalization of surfaces to diminish the adhesion of microorganisms to the surfaces, or to reduce biofilm formation [11].

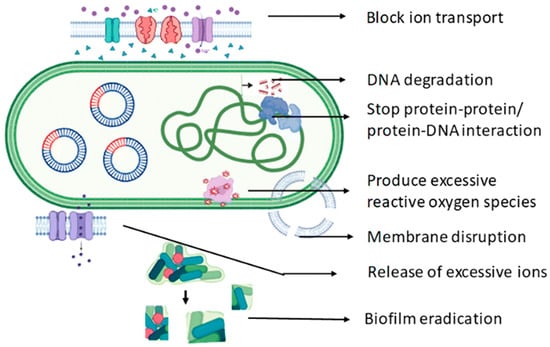

Key groups of antimicrobial agents used are (1) metal-based antimicrobials (e.g., ZnO), (2) organic antimicrobials (e.g., linseed oil), and (3) inorganic antimicrobials (e.g., MMT) [12]. The group of metal-based antimicrobials, which include zinc oxide (ZnO), silver (Ag), and copper (Cu) agents, is widely used [13]. Possible applications range from UV absorbers for textiles, fillers for rubber industry, powders or creams for cosmetics to sensors, and solar cells for electronics industry [14]. The mechanism of their behavior is in killing bacteria through microbial membrane disruption by producing reactive oxygen species (ROS). ROS can irreversibly oxidize and damage cellular components of pathogens, including lipids, proteins, and DNA. Due to the mechanism of action, antibacterial materials should be used with caution and their possible cyto/geno-toxicity properties must be evidenced. The potent antibacterial activity of ZnO is widely recognized and attributed to the generation of reactive oxygen species (ROS) and their disruption of bacterial cell membranes. However, despite its efficacy, the potential cytotoxic and genotoxic effects of ZnO nanoparticles have raised concerns, particularly regarding their application in biomedical and food-related fields. Studies have reported that ZnO nanoparticles can induce oxidative stress, DNA damage, and cellular apoptosis at high concentrations or prolonged exposure, necessitating a balanced evaluation of their antibacterial benefits and cytotoxic risks [15,16]. Therefore, in this research, authors have used micro sized ZnO particles which show sufficient antimicrobial properties with low cytotoxicity [17]. Additionally, low ZnO concentrations, according to the Mitjans, M. et al., does not have an impact on acute toxicity [18].

Inorganic nanoparticles can be generated directly on to the material’s surface or by additional pre-functionalization of different chemical groups (i.g., hydroxy or carboxy) for enhancement of their attachments [19]. Montmorillonite (MMT) is a naturally abundant, non-toxic clay that can support nanoparticles which are often added for targeted functionality. MMT-based composites have shown potential for overcoming toxicity issues, enhancing antimicrobial activity, and improving thermal and mechanical stability. Additionally, cork has shown inherent antibacterial activity, particularly effective against Gram-positive bacteria like S. aureus. In the study performed by Goncalves et al., cork inhibits bacterial reduction of almost 100%, measured after 90 min of bacteria incubation [20].

Combining different antimicrobial agents can create synergistic effects, making the composites more effective than intrinsic PLA. Additionally, higher antibacterial activity has been observed in the case of nanocomposites incorporating nanoparticles, in comparison to their bulk counterparts. The reason lies in their higher surface-to-volume ratio which improves contact with microorganisms, so as their effectiveness [21].

Possible ways of nanoparticles antimicrobial activities to fight against pathogens are presented in Figure 2. Usual antibacterial tests include nonpathogenic bacterial strains like E. coli and S. aureus, but most of the novel recommendations suggest usage of other bacterial pathogens, due to the increased antibiotic resistance [22].

Figure 2.

Bactericidal effect of nanoparticles and their modes of action. Reproduced from [21] with permission from the Royal Society of Chemistry.

Despite their potential, antimicrobial composites face challenges such as cytotoxicity, biocompatibility, and environmental impact. Ongoing research aims to optimize the synthesis of these materials to balance their antimicrobial properties with safety and sustainability.

1.2. Addition of Flame-Retardant (FR) Agents

Primarily, the goal of flame-retardant biocomposites is the enhancement of fire resistance while maintaining environmental sustainability. Recent advancements include the incorporation of nanomaterials and bio-based flame retardants [23,24]. Green techniques, such as plasma, laser treatments, as well as layer-by-layer deposition [25], have been applied for surface treatments and are showing promising results. Different modes of action of FR agents and their classification are presented in Table 1.

Table 1.

Classification of FR additives according to their methods of action.

Another classification of FR agents is according to their structure: (1) halogen-based FRs, (2) phosphorous-based FRs, (3) nitrogen-based FRs, and (4) inorganic FRs [23]. For this research, the choice of FR agents was directed toward inorganic MMT, due to its additional antimicrobial performance.

2. Materials and Methods

2.1. Materials for Fiber Isolation and Composite Formation

The biomass was collected from the experimental field of the University of Zagreb Faculty of Agriculture located at Maksimir park, Zagreb. NaOH pellets (Sodium hydroxide) of ≥97% purity and surface modified montmorillonite nanoclay of ≥70% purity were purchased from Sigma-Aldrich Inc., Gillingham, Dorset, UK. ZnO (Zinc oxide) of ≥99% purity, p.a., with particles under 5 µm, was purchased from Kemika d.d., Zagreb, Croatia, while PLA polymer 6201D was obtained from Nature Works LLC, Plymouth, MA, USA. The cork was milled in a cryogenic mill 6875, SPEXSamplePrep LLC, Metuchen, NJ, USA, during five cycles for 3 min each. PLA sheets were prepared in vacuum oven VO 49, Memmert, Nuremberg, Germany at 180 °C, 700 mbar, and 5 min. Composite components such as fibers, PLA, MMT, ZnO, and milled cork-C were absolutely dried at 100 °C for 24 h before the composite production process. Slurries composed of linseed oil (LO, 10 wt.%), montmorillonite nanoclay (MMT, 1 wt.%), Zinc oxide (ZnO, 1 wt.%), and cork (C, 1 wt.%) were made with laboratory Vortex Mixer MX-S, DLAB, Beijing, China until the homogeneous mixture.

Fibers (20 wt.%) were combed and parallelized before being coated with the slurry. The sandwiched structure, consisting of treated fibers manually laid in one direction between two PLA sheets (Specimens’ legend is presented in Table 2), was placed inside the square aluminum mold, which had a size of 80 cm × 80 mm × 3 mm. Such an assembly was pressed in the laboratory compression-molding press LAB 100 C, Pinette PEI, Chalon-sur-Saône, France at 190 °C, and 30 kN pressure for 3 min with a 30 s degassing cycle.

Table 2.

Specimens’ legend.

2.2. Methods

2.2.1. Antimicrobial Activity

The samples for antimicrobial (AM) testing were cut using a laser cutter, FabCore FC21-MK3, FabCreator, The Netherlands, to dimensions of 1 × 1 cm. Antimicrobial activity was tested on two types of bacteria, Gram-positive Staphylococcus aureus (ATCC 25923) and Gram-negative Klebsiella pneumoniae (ATCC 11296). As a control, a microscopic glass slide was used. The testing procedure followed the ASTM E2180-18 method [26], where 1 mL of bacterial suspension in Tryptic Soy Broth (of 108 CFU/mL concentration) is inoculated in an agar slurry adjusted to a temperature of 45 °C. The slurry was prepared by autoclaving 3 g/L of bacteriological agar in 0.85% NaCl solution. Previously sterilized biocomposite samples (under 105 °C for 6 h in a dry oven) were placed in a sterile plastic Petri dish, and the surface was moistened with a sterile swab stick soaked with sterile 0.85% NaCl.

A 0.25 mL of slurry with bacteria was inoculated onto the upper surface of the samples, which resulted in a slurry layer of approximately 1 mm in thickness, the so-called pseudo-biofilm. When the slurry on the samples settled, the samples were incubated for 24 h at 37 °C. To avoid drying of the slurry, the Petri dishes were tightly wrapped with parafilm before the incubation.

After the specified contact time of 24 h, the surviving bacteria were recovered via elution of the agar slurry in a sterile NaCl. Samples were transferred to a sterile falcon-type plastic tube containing 10 mL of NaCl solution and vigorously shaken on a mechanical shaker for 3 min at highest frequency (50 Hz). Shaking detaches and completely disperses the slurry, so still-viable cells remain dispersed in the supernatant. From the supernatant, serial dilutions were made and inoculated onto Tryptic Soy Agar plates. After the incubation (24 h/37 °C), the grown colonies were counted and expressed as CFU per sample. Antibacterial activity was expressed as log reduction of the initial number of bacteria after 24 h of incubation.

2.2.2. X-Ray Microtomography

To examine in detail the inner structure of the manufactured composites at micron scale, X-ray microtomography was performed [27], and scans of the composite samples cut to 10 × 10 mm were obtained. Imaging of samples P and PSLMZC was performed using a laboratory tomograph manufactured by RX Solutions (Annecy, France) equipped with a Hamamatsu X-ray source (Hamamatsu City, Japan) and a Varian flat panel detector (Varian Medical Systems, Salt Lake City, UT, USA). Each sample was irradiated with an X-ray beam (generated with a 100 kV 100 μA electron beam on a tungsten target) for 1400 angular projections equally spaced over 360°. In the next step, the 2D radiographs were converted into 3D datasets using a filtered back projection algorithm. The chosen pixel size was set to 10 μm, as it allows for the visualization and differentiation of biomass fibers.

To resolve the fine structural details between fiber reinforcements and the surrounding matrix, sample PSL was scanned by high-sensitivity synchrotron radiation microimaging. This technique offers enhanced contrast based on differences in the X-ray refractive indices of the dissimilar constituents. Imaging was conducted on a 150-m-long ID19 beamline at the European Synchrotron Radiation Facility (ESRF), utilizing a partially spatially coherent beam to perform high-resolution microtomography through propagation-based phase-contrast imaging. A pink beam with approximately 3% bandwidth, generated by the third harmonic of a short-period undulator (λ = 17 mm), was used. Lower harmonics were attenuated using a series of copper and aluminum filters to tune impinging radiation to a peak energy of 53 keV. The detection system consisted of a pco.edge 5.5 camera (PCO AG, Germany) coupled with a 2× tandem lens setup (210:100, Hasselblad, Sweden), yielding an effective pixel size of 3.1 μm.

The detector was placed 0.7 m downstream of the sample to provide sufficient propagation distance for phase-contrast enhancement, improving edge definition between dissimilar materials. An off-center rotation axis was employed to accommodate for the fact that sized exceeded the field of view (7.7 × 6.5 mm2, H × V), over a full 360° rotation. A total of 6000 projections were acquired with an exposure time of 25 ms per frame, resulting in a total acquisition time of under 3 min.

Tomographic reconstruction was performed using the in-house software Nabu 2024.2.0 [28], implementing a forward single-distance phase retrieval algorithm with an assumed δ/β ratio of 200, followed by filtered back projection. Post-processing steps, including ring artefact removal and signal filtering, were carried out using a custom-developed script suite. The scans were analyzed using Image software ImageJ Fiji 1.54, which was also used for image editing.

2.2.3. Morphology Analysis

For better understanding of the morphological characteristics of biocomposites and the properties closely related to morphology, a Scanning Electron Microscope (SEM), Vega LMS, Tescan, Brno, Czech Republic and stereo microscope SZX7, Olympus, Tokyo, Japan have been applied for the analysis. Measurements with optical microscope were conducted using 40× magnification. Samples measured with the SEM were polished using Minitech 250 SP1, Presi, Eybens, France polishing machine, and coated on Q150T ES, Quorum Technologies, Laughton, UK sputter coater with metal layer prior to the examination in order to prevent a charging effect and achieve better conductivity of the samples. The magnification used for SEM microscopy was 250×.

2.2.4. Microscale Combustion Calorimetry

Microscale combustion calorimetry (MCC) was used to investigate the heat of combustion the gases evolved during the controlled heating of the specimens in a non-flaming test. The test has been conducted on a device for microscale combustion calorimetry (MCC -2, Concept Equipment, Poling, UK). Standard ASTM D7309-21a (Method A) was used for the combustion of data calculations based on three replicates measurements of the heat release rate (HRR) curves [29].

2.2.5. Mechanical Properties

Standard EN ISO 527-5:2021 was used for the tensile properties’ determination [30] on universal testing machine UTM 1445, Zwick, Ulm, Germany, with a force of 10 kN. The test was conducted at room temperature with a testing speed and gauge length of 3 mm/min and 50 mm, respectively. Tensile tests were carried out in five repetitions for each sample, and the average results and standard deviation were subsequently calculated. Load, elongation, stress, strain, and Young’s modulus of the specimens were measured for determination of mechanical properties.

3. Results and Discussion

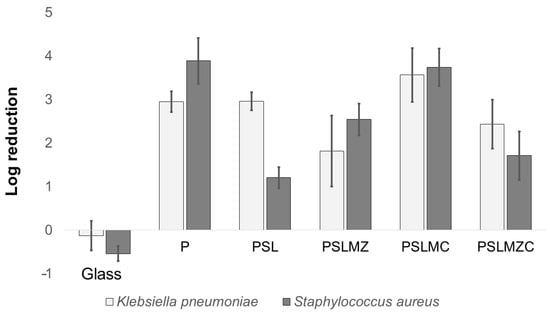

3.1. Antimicrobial Activity

The ASTM method for antimicrobial activity determination defines the material antibacterial activity as a calculation of % reduction of bacteria from treated versus untreated samples. However, in our experiment, even the untreated sample (P) showed almost 100% bacteria reduction. Therefore, the results in Figure 3 are presented as the log reduction of the number of bacteria at the start and after 24 h of contact with the tested materials. To validate the results, the same test was performed on a glass slide (non-antibacterial), and on it the bacteria actively multiplied (Figure 3). All the materials, including the control pristine PLA specimen, exhibited high reduction of bacterial numbers, which in the case of P and PSLMC were almost being reduced to zero from the starting number of bacteria.

Figure 3.

The Log reduction of bacterial numbers calculated as the ratio of starting number of bacteria, and the number of bacteria after 24 h of contact with the tested material. LogCFU-START (K. pneumoniae) = 3.9 ± 0.17, LogCFU-START (S. aureus) = 4.3 ± 0.2.

The ZnO-containing sample (PSLMZ) demonstrated substantial bacterial reduction, supporting the mechanism of microbial membranes disruption by ROS. Moreover, the PSLMC sample, which is additionally functionalized with cork, exhibits the highest antimicrobial activity. This aligns with previous findings that cork possesses intrinsic antibacterial properties, especially against S. aureus, likely due to its suberin and phenolic content. The synergistic effect of suberin, phenolic compounds, and waxes causes disruption of bacterial membranes, particularly effective against Gram-positive bacteria [20]. Additionally, montmorillonite (MMT) can contribute to antimicrobial activity by serving as a carrier for metal ions or nanoparticles, enhancing their dispersion and contact with microbes, and can adsorb microbial cell wall components, leading to membrane destabilization and inhibition of microbial growth [11].

The antibacterial test results demonstrated significant activity across all composite variants with a notable reduction in viable bacterial counts for both K. pneumoniae and S. aureus. The synergistic antimicrobial performance was expected especially of the PSLMZC sample, which combined ZnO, MMT, and cork. However, this was not confirmed, since even the neat PLA matrix (sample P) showed strong antibacterial effect, which could be attributed to the sample’s surface properties, including low surface roughness and potential residuals from the molding process that might inhibit the bacterial adhesion. The incorporation of antimicrobial agents neither disturbs the antimicrobial activity nor contributes to its further enhancement, when compared to the control PLA sample.

As stated in a review paper by Shao et al. [31], the PLA does not possess inherent antibacterial properties. However, a study by Zhao et al. [32] also reported significant antibacterial activity of PLA samples that was not enhanced with any of the bactericidal substances. They utilized electrospun stereo-complexed PLA (sc-PLA) fibers, which reduced numbers of E. coli by 69% and S. aureus by 99.9% and attributed this effect to the formation of a mildly acidic environment during the PLA degradation, inhibiting bacterial growth. Our PLA samples were prepared by hot pressing and probably lack the structural characteristics observed in electrospun sc-PLA, such as micropores, which could potentially influence bacterial adhesion [31,32]. Interestingly, Gong et al. also reported an approx. 60%–70% reduction in the bacterial numbers of S. aureus and E. coli whilst testing the electrospun PLA [33]. The effect has also contributed to possible acidity of lactic acid.

It seems necessary to perform further and thorough in-depth analyses of the surface properties of PLA composites and include pH measurements during the antibacterial testing to clarify the observed antimicrobial effects of PLA samples.

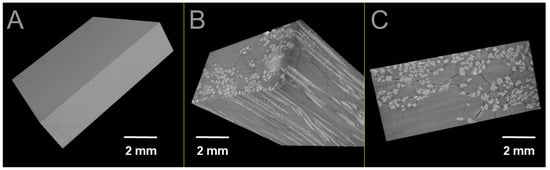

3.2. X-Ray Microtomography

The X-ray microtomography analysis provided valuable insights into the internal architecture of the composite samples. The 3D reconstructions clearly revealed a heterogeneous dispersion of fibers, with localized areas of higher fiber density and regions with lack of fibers. In addition, cracking of the material throughout the entire sample interior was observed in Figure 4. This non-uniform distribution is most likely a result of manual layering during composite assembly and can influence the mechanical performance by generating anisotropic stress distribution under load. The internal fracturing observed within the sample is most likely a result of the sample preparation process itself, rather than the consequence of any subsequently applied mechanical stress.

Figure 4.

X-ray microtomography of PLA composites reinforced with Sida hermaphrodita fibers. (A)—control PLA sample with uniform matrix structure scanned at laboratory tomograph. (B,C)—synchrotrone data on composite sample PSL showing heterogeneous fiber dispersion.

In addition to fiber clustering, several air pockets and voids were detected within the polymer matrix, particularly around fiber-rich zones (Figure 5). These voids are likely formed during the compression-molding process due to incomplete compaction or trapped air during the slurry coating. Such defects are of concern as they may function as stress concentrators, leading to mechanical weakness or crack initiation under the strain. Moreover, from a thermal perspective, the presence of voids can negatively affect the formation of uniform char layers, which are critical for flame retardancy [34].

Figure 5.

X-ray microtomography of composite sample PSLMZC (PLA+SH+LO+MMT+ZnO+C) revealing air voids (black color, (A)), and localized clustering (B), scanned at laboratory tomograph.

Despite these imperfections, the micro-CT data also showed evidence of relatively good fiber orientation in many regions, suggesting that even a partially aligned fiber layout may still contribute to reinforcement effects. For future work, a more controlled fiber laying or pre-impregnation technique will minimize the void formation and improve fiber homogeneity across the composite volume.

The X-ray microtomography analysis confirmed that manual layering introduced heterogeneity in fiber dispersion, contributing to the formation of voids and localized stress concentration zones. These structural imperfections likely influence both mechanical performance and flame-retardant behavior, which is evident from the reduced char-forming efficiency in fiber-rich, porous regions. Similar effects of structural non-uniformity on composite performance have been previously reported in fiber-reinforced systems [35].

Despite these drawbacks, partial fiber alignment observed in some areas may enhance load distribution and compensate for defects to some extent. Improvements in processing, such as controlled pre-impregnation or vacuum molding, are likely to enhance both mechanical and thermal behavior.

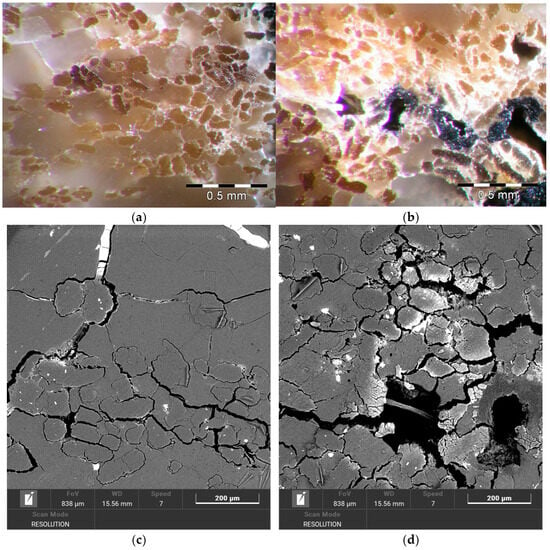

3.3. Morphology Analysis

An analysis of the biocomposite cross-section surface performed with an optical microscope and a scanning electron microscope confirms the X-ray microtomography data. Figure 6b,d present the PSLMZC sample, in which voids and cracks are visible throughout the cross-section surface. Sample PSLMC shows better morphology properties, indicating enhanced adhesion between polymer matrix and natural fibers. The absence of zinc oxide in the formulation of the PSLMC sample might be the reason for better interfacial adhesion between the main components (polymer and fibers). According to Thipperudrappa, S. et al. [36], the presence of ZnO particles induces a reduction in active locations where bonds between matrix and fibers could be formed, which results in a decrease in tensile strength.

Figure 6.

Morphology analysis of PLA composites reinforced with the SH fibers with the addition of MMT and cork, including (a) optical microscope image of cross-section surface of PSLMC sample, (b) optical microscope image of cross-section surface of PSLMZC sample, (c) SEM micrograph of cross-section surface of PSLMC sample, and (d) SEM micrograph of cross-section surface of PSLMZC sample.

Kovačević, Z. et al. [37], in their research, pointed to the significantly larger lumen of SH fibers, which is not visible in Figure 6 due to the mechanical interlocking of polymer adhesive into the fiber central cavity. The filling of fiber lumen with polymer often shows improved properties, such as resistance of water absorption and hindering of crack propagation within the composite material [38]. SH fibers, like other natural fibers, show surface roughness, which is responsible for the mechanical interlocking of fibers and hydrophobic polymers. The hydrophobicity of the composite’s surface could be the reason for antimicrobial efficiency [39]. The reduced contact area between bacteria and composites influences bacteria adhesion to the material’s surface. Furthermore, hydrophobic surfaces can compromise bacterial cell membranes, leading to their collapse [40]. However, despite the above-mentioned interlocking, the samples investigated show structural non-uniformity and a tendency of crack propagation, which will be improved by optimizing composite-processing parameters in our future research.

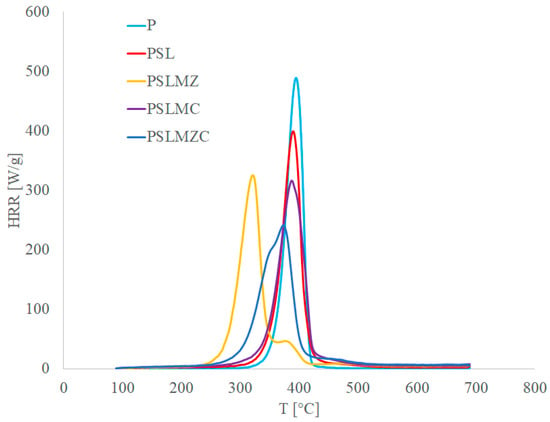

3.4. Microscale Combustion Calorimetry (MCC)

Figure 7 presents MCC curves of SH-reinforced composites compared to neat PLA (Specimen P), which has the highest heat release rate (HRR) value of 500.00 W/g. Our results confirmed the previous findings of Murad et al. [24] that the addition of nanoparticles improves char formation and causes a decrease in HRR values. In our research, the sole addition of 1 wt.% of MMT leads to an HRR decrease within the range 325.17–241.42 W/g. It is noticeable that MMT-treated specimens (specimens PSLMZ, PSLMC, and PSLMZC) exhibit lower heat release values than other tested specimens pointing to lower flammability of these specimens. Heat release rate (W/g) of specimens containing MMT decreased by 34.97% (PSLMZ), 36.57% (PSLMC), and 51.72% (PSLMZC), in comparison to neat PLA.

Figure 7.

MCC results of SH-reinforced composites.

Therefore, it can be noted that the influence of linseed oil, without the addition of MMT, is insufficient and causes only slight decrease of HRR value. A more pronounced influence on flame retardancy was caused with the addition of ZnO and cork as additives. The main influence of ZnO additive is in its catalyzation of char layer formation, which has a direct impact on the reduction of flammable gases release and suppression of smoke which might occur during the combustion [41].

Previous findings revealed that cork requires higher ignition temperature, and therefore it was added for further enhancement of the composite fire and smoke resistance [42]. Our results revealed an additional decrease in HRR values of 25.76% when the cork is added into the coating slurry. Furthermore, according to the literature, cork has low thermal conductivity, which is giving an advantage of excellent insulation properties and guiding its usage towards heat insulation materials.

Another important parameter of MCC analysis is the yield of pyrolysis (yp). After exposure to 750 °C, those specimens containing MMT have a more pronounced yield of pyrolysis, ranging from 4.96% for specimen PSLMC, 6.05% for specimen PSLMZ, and up to 10.2% in the case of the PSLMZC specimen. Those results indicate the lowest decomposition of composites containing all additives after the finalization of pyrolysis stage.

Overall, the combination of MMT, cork, and ZnO in composites results with synergistic effect that enhances the flame retardancy via mechanism of protective char layers. The reduction in heat release was up to 50%, and therefore significant improvement of composite thermal stability was accomplished.

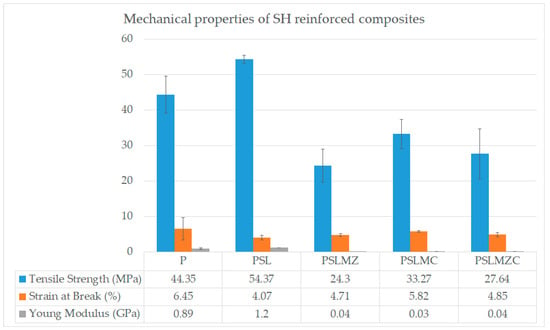

3.5. Mechanical Properties

Composites reinforced with Sida hermaphrodita fibers exhibit notable mechanical properties, as presented at Figure 8. Research has shown significant enhancement of the tensile strength when SH fibers were applied for the reinforcement. Addition of linseed oil (PSL specimen) caused enhancement of tensile strength for 22.59% and Young Modulus for 34.83% in comparison to neat PLA (P specimen) which exhibits tensile strength of 44.35 MPa and Young modulus of 0.89 GPa. This positive trend is extremely important for the design of composite materials, since it directly influences composite stiffness, contributing to the enhancement of load bearings and consequently to less pronounced deformations.

Figure 8.

Mechanical properties of composites reinforced with Sida hermaphrodita.

On the other side, composites reinforced with SH fibers coated with MMT, ZnO, and milled cork additives revealed lower values of tensile strengths, ranging from 24.3 MPa for the PSLMZ specimen to a slightly better 33.27 MPa for the PSLMC specimen, where cork was added instead of the ZnO. The results of strain at break showed a less pronounced decrease caused by the addition of AM and FR agents. In general, the strain at break of fiber-reinforced composites will present a less pronounced decrease in the case when a good fiber–matrix adhesion through strong bonding between the fibers and the matrix is obtained. The load is then effectively transferred from the matrix to the fibers, which will cause stress reduction and diminish premature failures. Equally important is the fiber orientation, since alignment of fibers in the same direction with applied load can enhance the composite’s ability to withstand strain, since fibers can carry more load without breaking. Therefore, ensuring an even distribution of fibers within the matrix helps in uniform distribution of stress, which can prevent localized failure and maintain a higher strain at break [43]. Part of our results (PSL) confirmed an even distribution of fibers within the composite, leading to sufficient capability of developed composites to withstand strain. Although the tested materials (PSLMZ, PSLMC, and PSLMZC) show poor mechanical properties in comparison to composites reinforced with untreated fibers, their purpose can be directed towards the development of packaging materials in agriculture where enhanced antibacterial activity, mechanical weakness, and biodegradability are desirable properties of composites whose presence in the soil would not have an negative effect on the plants’ growth [44].

4. Conclusions

To be able to characterize the final product, such as textile fiber or fiber-reinforced composite, as sustainable and green, it is not enough to choose raw materials that meet the required conditions. The entire production process should be managed in a sustainable way to have the lowest negative impact on the environment. Therefore, the accent of our paper is on the sole application of environmentally friendly agents, procedures, and devices and on the complete utilization of applied raw materials and production side streams, which is in accordance with the requirements of the circular economy.

Since applied energy crop Sida hermaphrodita is a renewable source, the isolation and application of its fibers for PLA matrix reinforcement is in line with current EU guidelines for circular economy and reduction of carbon footprint. Despite all these positive trends, natural fibers have well-known drawbacks, such as uneven properties, compared to synthetic fibers, which we try to substitute in this research. Therefore, antimicrobial and flame-retardant additives were applied with the aim to enhance composite mechanical, thermal, and functional properties. The ZnO, MMT, and cork acted synergistically in enhancing antimicrobial functionality. The developed composites exhibited markable antimicrobial activity against both Gram-positive and Gram-negative bacteria, even in the absence of added antimicrobial agents, suggesting a contribution of surface properties and natural components to microbial inhibition.

Unfortunately, the incorporation of FRs into composites has complex and often conflicting effects on their mechanical properties. Our results revealed that applied additives may lead to a reduction in tensile strength and a less pronounced decrease in strain at break. The addition of linseed oil has shown the potential to enhance mechanical performance, while the other additives caused a decrease in mechanical properties and therefore need to be replaced or optimized in further research. The X-ray microtomography analysis confirmed that structural imperfections, such as fiber clustering and voids, may affect composite performance but also revealed partial fiber alignment, which supports the reinforcement. These findings emphasize the need for optimized processing techniques to improve fiber distribution and maximize both antimicrobial efficacy and mechanical integrity.

On the other hand, the applied inorganic FR agent enhanced the thermal stability of composites by increasing the amount of residue, preventing molten materials from dripping during the combustion, and encouraging the char formation, which has consequently improved the fire resistance. Therefore, developed biocomposites mostly meet required characteristics for applications in automotive and construction industries via their availability, energy efficiency, sufficient mechanical resistance, stability of the material, and a high degree of protection against burning and microorganisms, with complete biodegradability of composite parts, fibers, and the matrix.

Author Contributions

Conceptualization, S.B. and T.I.; methodology, S.B. and Z.K.; software, Z.K.; validation, Z.K. and S.B.; formal analysis, Z.K., T.B., S.R.d.R., B.L. and T.I.; investigation, Z.K. and T.B.; resources, S.B. and T.I.; data curation, Z.K.; writing—original draft preparation, S.B.; writing—review and editing, T.I. and Z.K.; visualization, Z.K.; supervision, T.I. and Z.K.; project administration, S.B.; funding acquisition, S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was performed using equipment purchased by projects K.K.01.1.1.02.0024 Modernization of Textile Science Research Centre Infrastructure (MI-TSRC) and KK.01.1.1.04.0091 Design of Advanced Biocomposites from Sustainable Energy Sources (BIOCOMPOSITES), both funded by European Regional Development Fund, Operational Programme Competitiveness and Cohesion. The 3SR is part of LabEx Tec 21—ANR-11-LABX-0030 and of Institut Carnot PolyNat (ANR16-CARN-0025). B.L. acknowledges funding from the EPSRC (EP/W003333/1).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

More data related to this study can be accessed upon a request to the corresponding author.

Acknowledgments

The authors would like to acknowledge the contribution of the ESRF for providing in-house research beamtime under proposal IHMA530.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- El Bassam, N. Handbook of Bioenergy Crops. A Complete References to Species, Development and Applications, 1st ed.; Routledge: London, UK, 2010; pp. 1–544. [Google Scholar] [CrossRef]

- Guarascio, D.; Reljic, J.; Zezza, F. Energy vulnerability and resilience in the EU: Concepts, empirics and policy. J. Ind. Bus. Econ. 2025, 1–44. [Google Scholar] [CrossRef]

- Leto, J.; Bilandžija, N. Applied Energy Crops. In Sustainable Development of Biocomposites and Biofuels from Renewable Energy Sources; Bischof, S., Ed.; University of Zagreb Faculty of Textile Technology: Zagreb, Croatia, 2023; pp. 19–45. ISBN 978-953-8418-09-9. [Google Scholar]

- Borkowska, H.; Styk, B. Virginia fanpetals (Sida hermaphrodita L. Rusby): Cultivation and Utilization. Monograph, 2nd ed.; WAR; University of Life Sciences: Lublin, Poland, 2006. [Google Scholar]

- Šurić, J.; Šic Žlabur, J.; Peter, A.; Brandić, I.; Voća, S.; Dujmović, M.; Leto, J.; Voća, N. Energy vs. Nutritional Potential of Virginia Mallow (Sida hermaphrodita L.) and Cup Plant (Silphium perfoliatum L.). Plants 2022, 11, 2906. [Google Scholar] [CrossRef] [PubMed]

- Derval dos Santos, R.; Lenz, D.M. Biocomposites: Influence of Matrix Nature and Additives on the Properties and Biodegradation Behaviour. In Biodegradation—Engineering and Technology; Chamy, R., Ed.; InTech Open: Rijeka, Croatia, 2013; pp. 433–475. [Google Scholar]

- Zhou, Y.; Fan, M.; Chen, L. Interface and bonding mechanisms of plant fibre composites: An overview. Compos. Part B Eng. 2016, 101, 31–45. [Google Scholar] [CrossRef]

- Huo, S.; Thapa, A.; Ulven, C.A. Effect of surface treatments on interfacial properties of flax fiber-reinforced composites. Adv. Compos. Mater. 2013, 22, 109–121. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Vujasinović, E.; Pavunc Samaržija, M. Biocomposites-Materials of the future. In Sustainable Development of Biocomposites and Biofuels from Renewable Energy Sources; Bischof, S., Ed.; University of Zagreb Faculty of Textile Technology: Zagreb, Croatia, 2023; pp. 113–152. ISBN 978-953-8418-09-9. [Google Scholar]

- Bustamante-Torres, M.; Arcentales-Vera, B.; Estrella-Nuñez, J.; Yánez-Vega, H.; Bucio, E. Antimicrobial Activity of Composites-Based on Biopolymers. Macromol 2022, 2, 258–283. [Google Scholar] [CrossRef]

- Budimir, A.; Bischof Vukušić, S.; Flinčec Grgac, S. Study of antimicrobial properties of cotton textiles treated with citric acid for medical purposes. Cellulose 2012, 19, 289–296. [Google Scholar] [CrossRef]

- Bischof Vukušić, S.; Gaan, S. Antimicrobial Protective Textiles. In Functional Protective Textiles; Bischof Vukušić, S., Ed.; University of Zagreb Faculty of Textile Technology: Zagreb, Croatia, 2012; pp. 101–144. ISBN 978-953-7105-45-7. [Google Scholar]

- Abebe, B.; Zereffa, E.A.; Tadesse, A.; Ananda Murthi, H.C. A Review on Enhancing the Antibacterial Activity of ZnO: Mechanisms and Microscopic Investigation. Nanoscale Res. Lett. 2020, 15, 190. [Google Scholar] [CrossRef]

- Singh, S. Zinc oxide nanoparticles impacts: Cytotoxicity, genotoxicity, developmental toxicity, and neurotoxicity. Toxicol. Mech. Methods 2019, 29, 300–311. [Google Scholar] [CrossRef]

- Keerthana, S.; Kumar, A. Potential risks and benefits of zinc oxide nanoparticles: A systematic review. Crit. Rev. Toxicol. 2020, 50, 47–71. [Google Scholar] [CrossRef]

- del Campo, A.; de Lucas-Gil, E.; Rubio-Marcos, F.; Arrieta, M.P.; Fernandez-Garcia, M.; Fernandez, J.F.; Munoz-Bonilla, A. Accelerated disintegration of compostable Ecovio polymer by using ZnO particles as filler. Polym. Degrad. Stab. 2021, 185, 109501. [Google Scholar] [CrossRef]

- Mitjans, M.; Marics, L.; Bilbao, M.; Maddaleno, A.S.; Piñero, J.J.; Vinardell, M.P. Size Matters? A Comprehensive In Vitro Study of the Impact of Particle Size on the Toxicity of ZnO. Nanomaterials 2023, 13, 1800. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Shafiq, M.; Ma, M.; Chen, H. Synthesis and Surface Engineering of Inorganic Nanomaterials Based on Microfluidic Technology. Nanomaterials 2020, 10, 1177. [Google Scholar] [CrossRef]

- Gonçalves, F.; Correia, P.; Silva, S.P.; Almeida-Aguiar, C. Evaluation of antimicrobial properties of cork. FEMS Microbiol. Lett. 2016, 363, fnv231. [Google Scholar] [CrossRef]

- Mondal, S.K.; Chakraborty, S.; Manna, S.; Mandal, S.M. Antimicrobial nanoparticles: Current landscape and future challenges. RSC Pharm. 2024, 1, 388–402. [Google Scholar] [CrossRef]

- Warangkar, S.C.; Desphande, M.D.; Totewad, N.D.; Singh, A.A. Antibacterial, Antifungal and Antiviral Nanocomposites: Recent Advances and Mechanisms of Action. In Biocomposites: Recent Advances; Elnashar, M.M., Karakus, S., Eds.; InTech Open: Rijeka, Croatia, 2022; Chapter 5. [Google Scholar] [CrossRef]

- Madyaratri, E.V.; Ridho, M.R.; Aristri, M.A.; Lubis, M.A.R.; Iswanto, A.H.; Nawawi, D.S.; Antov, P.; Kristak, L.; Majlingova, A.; Fatriasari, W. Recent Advances in the Development of Fire-Resistant Biocomposites—A Review. Polymers 2022, 14, 362. [Google Scholar] [CrossRef]

- Murad, M.S.; Hamzat, A.K.; Asmatulu, E.; Asmatulu, R. Flame-retardant fiber composites: Synergistic effects of additives on mechanical, thermal, chemical, and structural properties. Adv. Compos. Hybrid. Mater. 2025, 8, 31. [Google Scholar] [CrossRef]

- Magovac, E.; Jordanov, I.; Grunlan, J.C.; Bischof, S. Environmentally-Benign Phytic Acid-Based Multilayer Coating for Flame Retardant Cotton. Materials 2020, 13, 5492. [Google Scholar] [CrossRef]

- ASTM E2180-18; Standard Test Method for Determining the Activity of Incorporated Antimicrobial Agent(s) in Polymeric or Hydrophobic Materials. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Ivankovic, T.; Rajic, A.; Ercegovic Razic, S.; Rolland du Roscoat, S.; Skenderi, Z. Antibacterial properties of non-modified wool, determined and discussed in relation to ISO 20645:2004 standard. Molecules 2022, 27, 1876. [Google Scholar] [CrossRef]

- Payno, H.; Paleo, P.; Nemoz, C.; Cloetens, P.; Di Michiel, M.; Rack, A.; Tafforeau, P.; Solé, V.A.; Viganò, N.R. Overcoming the data processing challenges of unifying tomography techniques at ESRF. J. Phys. Conf. Ser. 2022, 2380, 012106. [Google Scholar] [CrossRef]

- ASTM D7309-21a; Standard Test Method for Determining Flammability Characteristics of Plastics and Other Solid Materials Using Microscale Combustion Calorimetry. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- EN ISO 527-5:2021; Plastics—Determination of tensile properties, Part 5: Test conditions for unidirectional fibre-reinforced plastic composites. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2021.

- Shao, L.; Xi, Y.; Weng, Y. Recent Advances in PLA-Based Antibacterial Food Packaging and Its Applications. Molecules 2022, 27, 5953. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Ke, H.; Yang, T.; Peng, Q.; Ge, J.; Yao, L.; Xu, S.; Zhirong, D.; Pan, G. Enhanced Thermal and Antibacterial Properties of Stereo-Complexed Polylactide Fibers Doped With Nano-Silver. Front. Mater. 2022, 9, 775333. [Google Scholar] [CrossRef]

- Gong, H.; Li, L.; Li, N.; Tian, L.; Zhang, T.; Zhang, L.; Jiao, T. Preparation and Antibacterial Properties of PLA-Based Composite Nanofiber Membrane Material Loaded with Cationic Antibacterial Agent by Electrospinning. Coatings 2023, 13, 1686. [Google Scholar] [CrossRef]

- Davis, T.; Healy, D.; Bubeck, A.; Walker, R. Stress concentrations around voids in three dimensions: The roots of failure. J. Struct. Geol. 2017, 102, 193–207. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Liang, S.-D.; Li, Y.-L.; Guo, Y.-C.; Shan, G.-Y. Compressive behavior of FRP-confined elliptical concrete-filled high-strength steel tube columns. Compos. Struct. 2021, 266, 113808. [Google Scholar] [CrossRef]

- Thipperudrapa, S.; Kini, U.A.; Hiremath, A. Influence of zinc oxide nanoparticles on the mechanical and thermal responses of glass fiber-reinforced epoxy nanocomposites. Polym. Compos. 2020, 41, 174–181. [Google Scholar] [CrossRef]

- Kovačević, Z.; Pilipović, A.; Meheš, M.; Bischof, S. Zero Waste Concept in Production of PLA Biocomposites Reinforced with Fibers Derived from Wild Plant (Spartium junceum L.) and Energy Crop (Sida hermaphrodita (L.) Rusby). Polymers 2025, 17, 235. [Google Scholar] [CrossRef]

- Richely, E.; Durand, S.; Melelli, A.; Kao, A.; Magueresse, A.; Dhakal, H.; Gorshkova, T.; Callebert, F.; Bourmaud, A.; Beaugrand, J.; et al. Novel Insight into the Intricate Shape of Flax Fibre Lumen. Fibers 2021, 9, 24. [Google Scholar] [CrossRef]

- Le, B.H.; Phuong Thi, H.B.; Nguyen Thi Thanh, B.; Quang Van, T.; Vu, H.D.; Xuan, H.L. Influence of hydrophobicity on the antimicrobial activity of helical antimicrobial peptides: A study focusing on three mastoparans. Mol. Divers. 2024, 1–8. [Google Scholar] [CrossRef]

- Zhao, L.; Huang, Y.; Gao, S.; Cui, Y.; He, D.; Wang, L.; Chen, Y.X. Comparison on effect of hydrophobicity on the antibacterial and antifungal activities of α-helical antimicrobial peptides. Sci. China Chem. 2013, 56, 1307–1314. [Google Scholar] [CrossRef]

- Nageswara Rao, T.; Manohra Naidu, T.; Soo Kim, M.; Parvatamma, B.; Prashanthi, Y.; Heun Koo, B. Influence of Zinc Oxide Nanoparticles and Char Forming Agent Polymer on Flame Retardancy of Intumescent Flame Retardant Coatings. Nanomaterials 2020, 10, 42. [Google Scholar] [CrossRef] [PubMed]

- Van den Bulcke, J.; Defoirdt, N.; Van Acker, J.; Pereira, H. Thermal behaviour of cork and cork components. Thermochim. Acta 2014, 582, 94–100. [Google Scholar] [CrossRef]

- Ma, L.; Liu, F.; Liu, D.; Liu, Y. Review of Strain Rate Effects of Fiber-Reinforced Polymer Composites. Polymers 2021, 13, 2839. [Google Scholar] [CrossRef]

- Smola-Dmochowska, A.; Lewicka, K.; Macyk, A.; Rychter, P.; Pamula, E.; Dobrzynski, P. Biodegradable Polymers and Polymer Composites with Antibacterial Properties. Int. J. Mol. Sci. 2023, 24, 7473. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).