Multiscale Wear Simulation in Textured, Lubricated Contacts

Abstract

1. Introduction

2. Materials and Methods

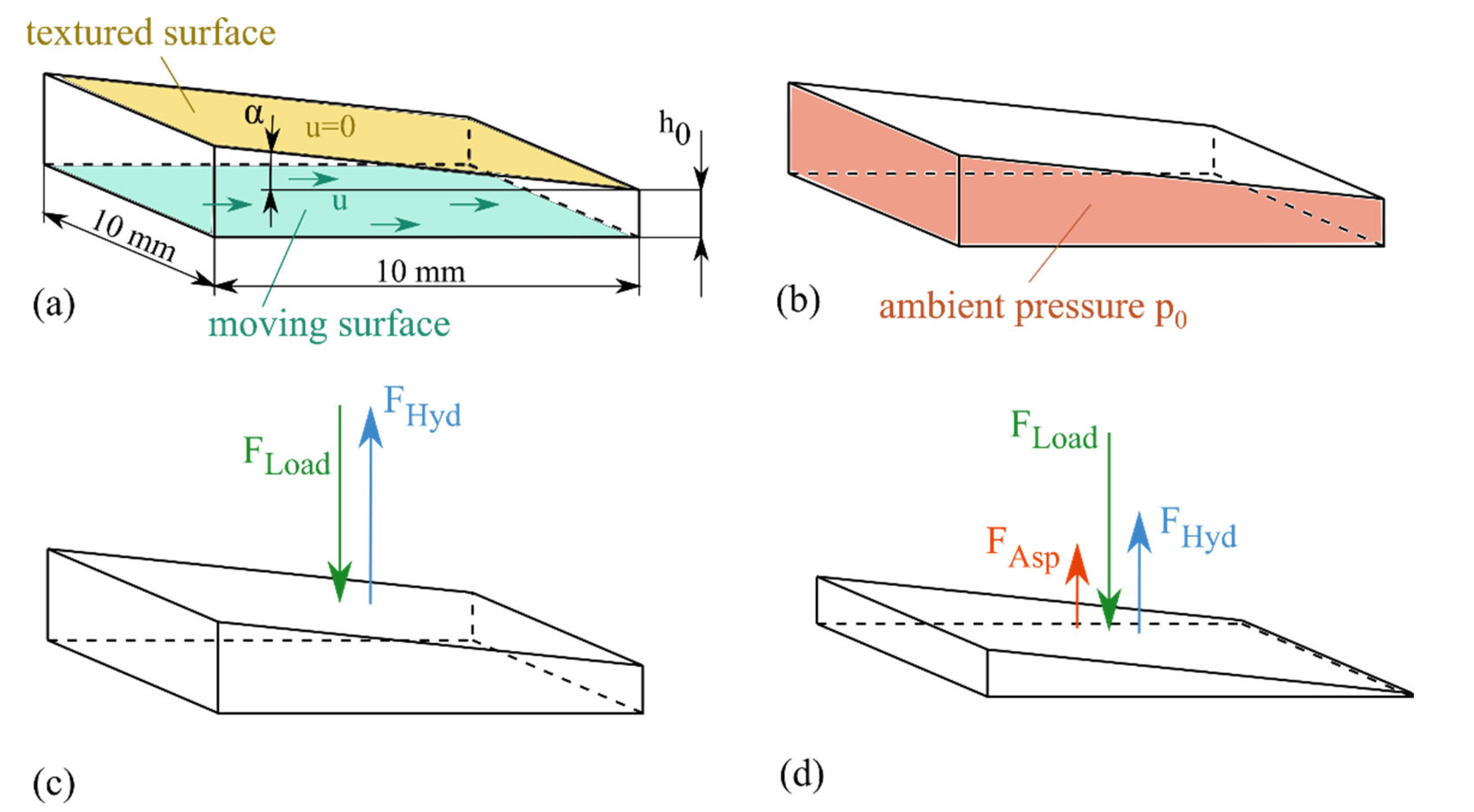

2.1. Macro Model

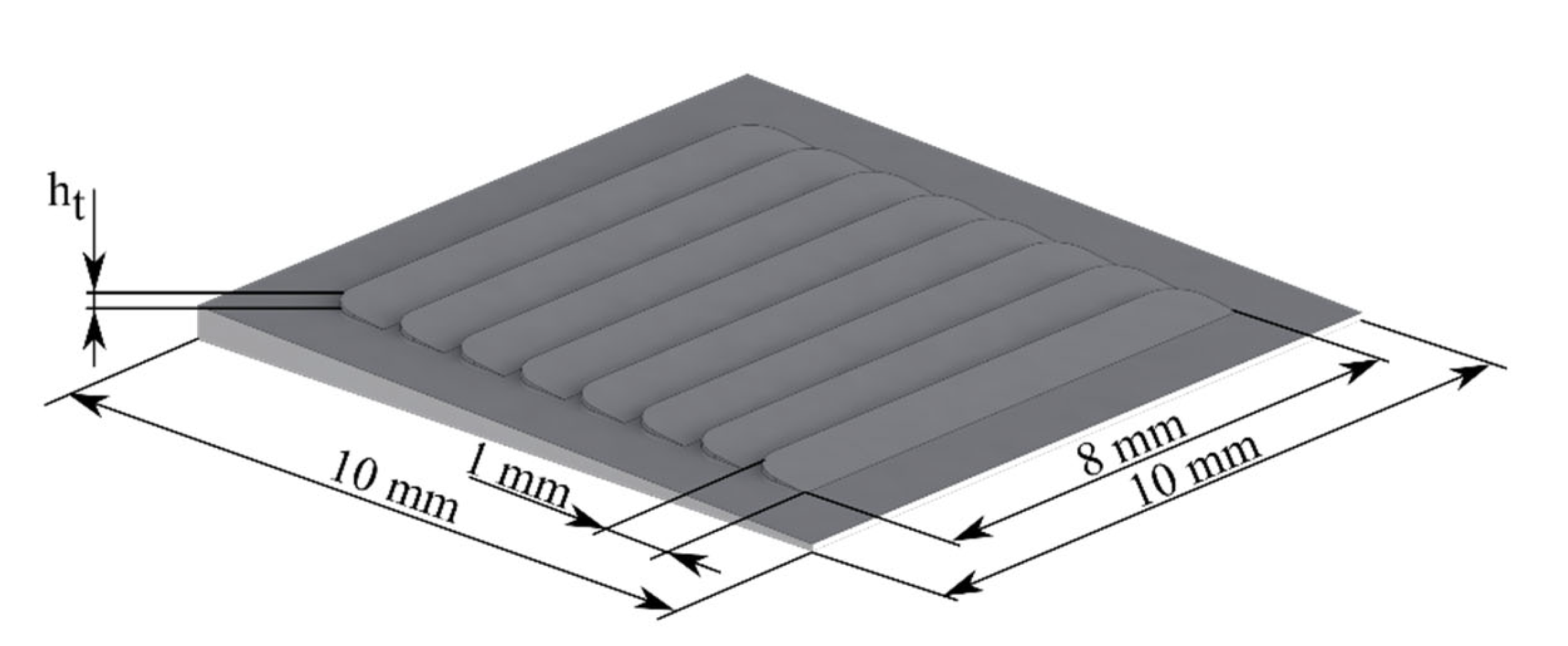

2.2. Micro Model

2.3. Wear

3. Results

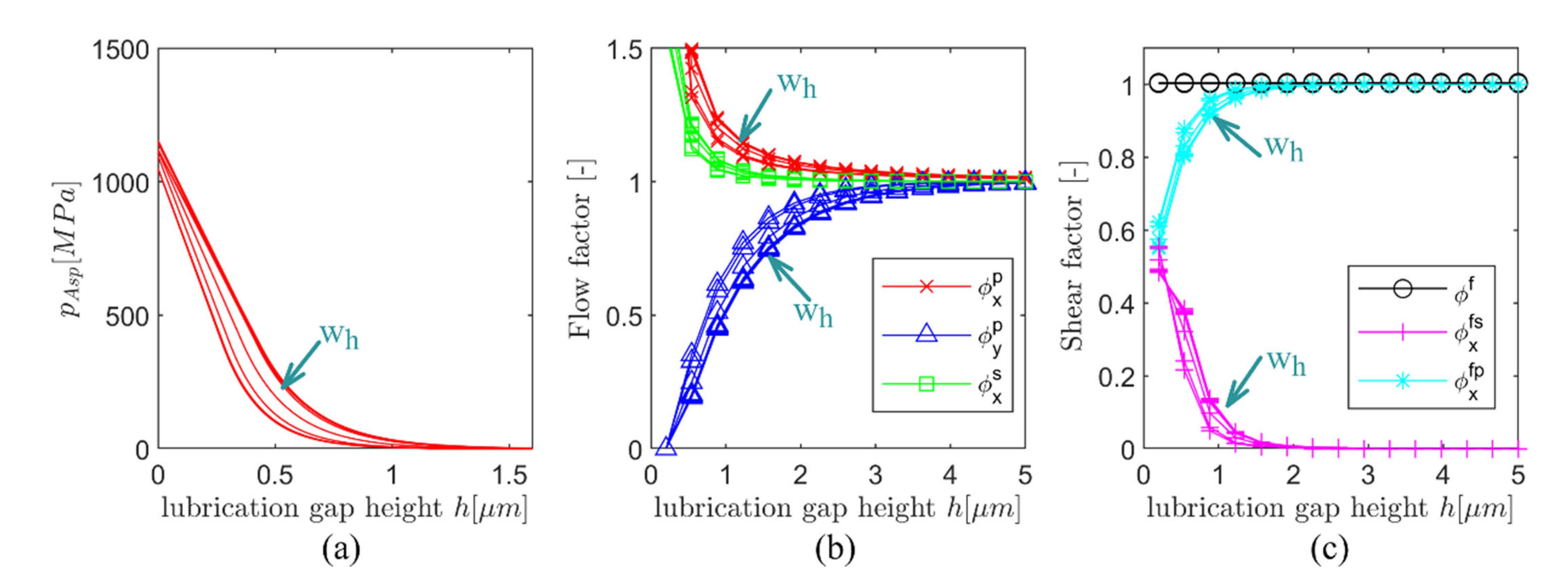

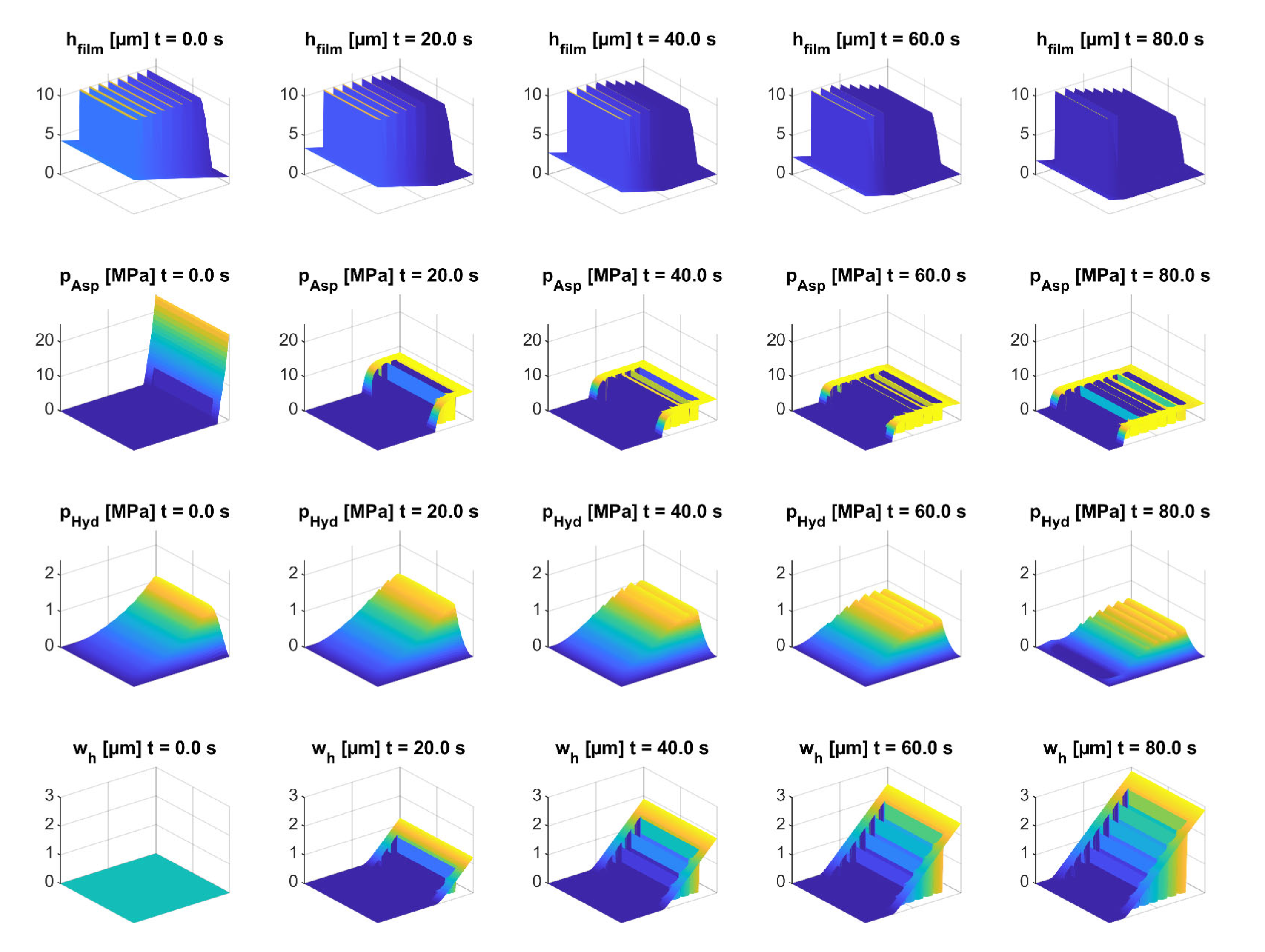

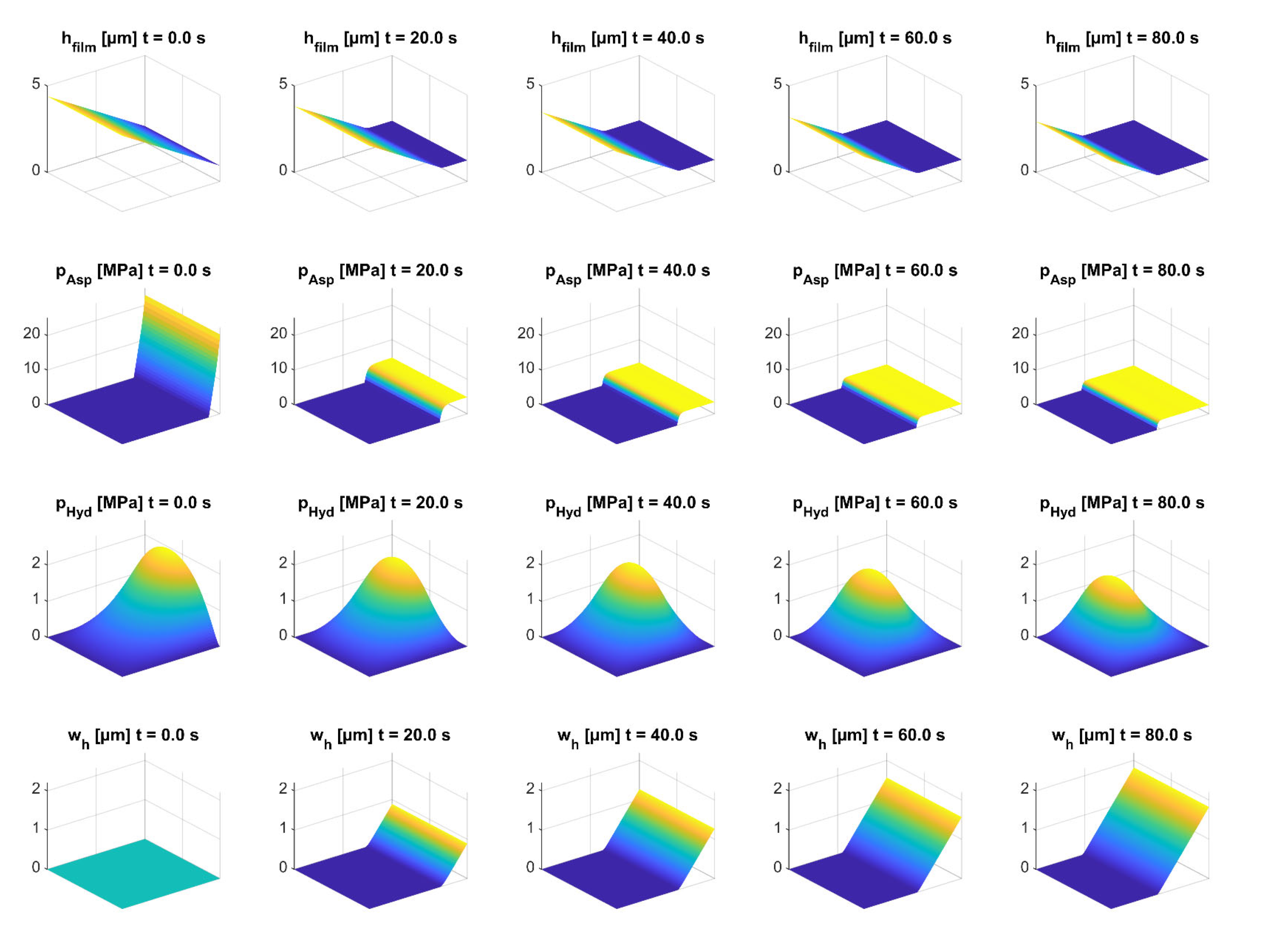

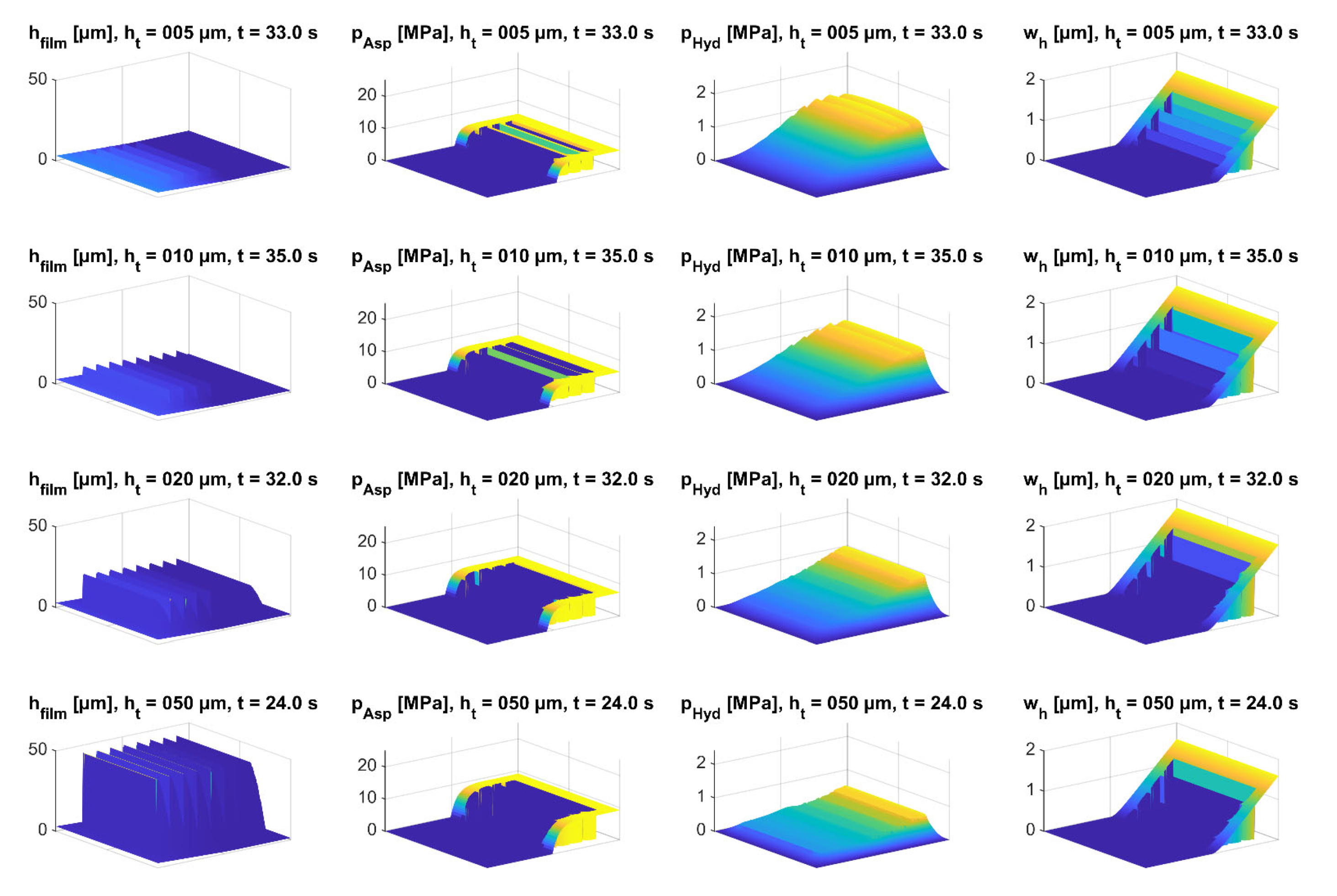

3.1. Micro Model

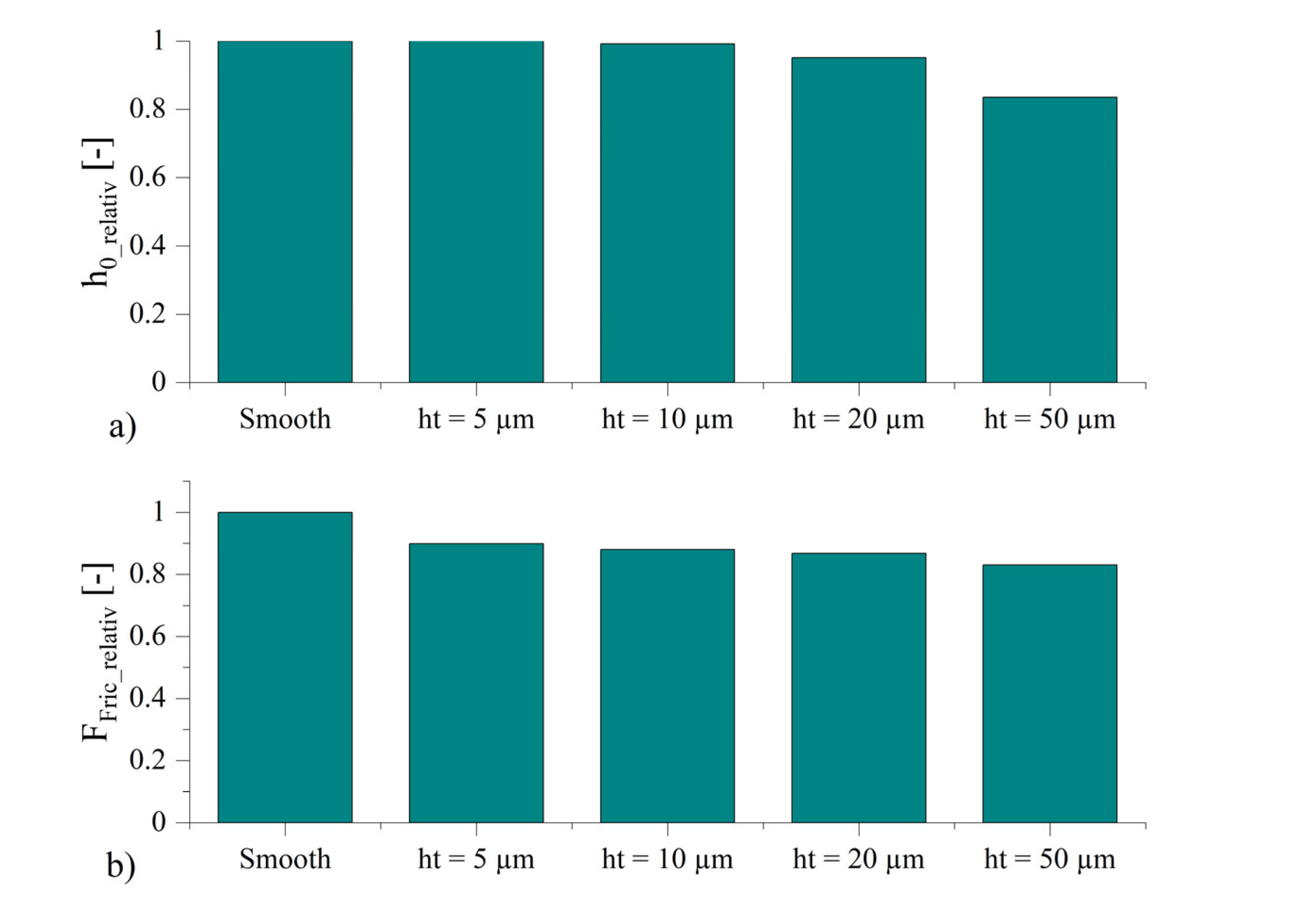

3.2. Hydrodynamic Simulation

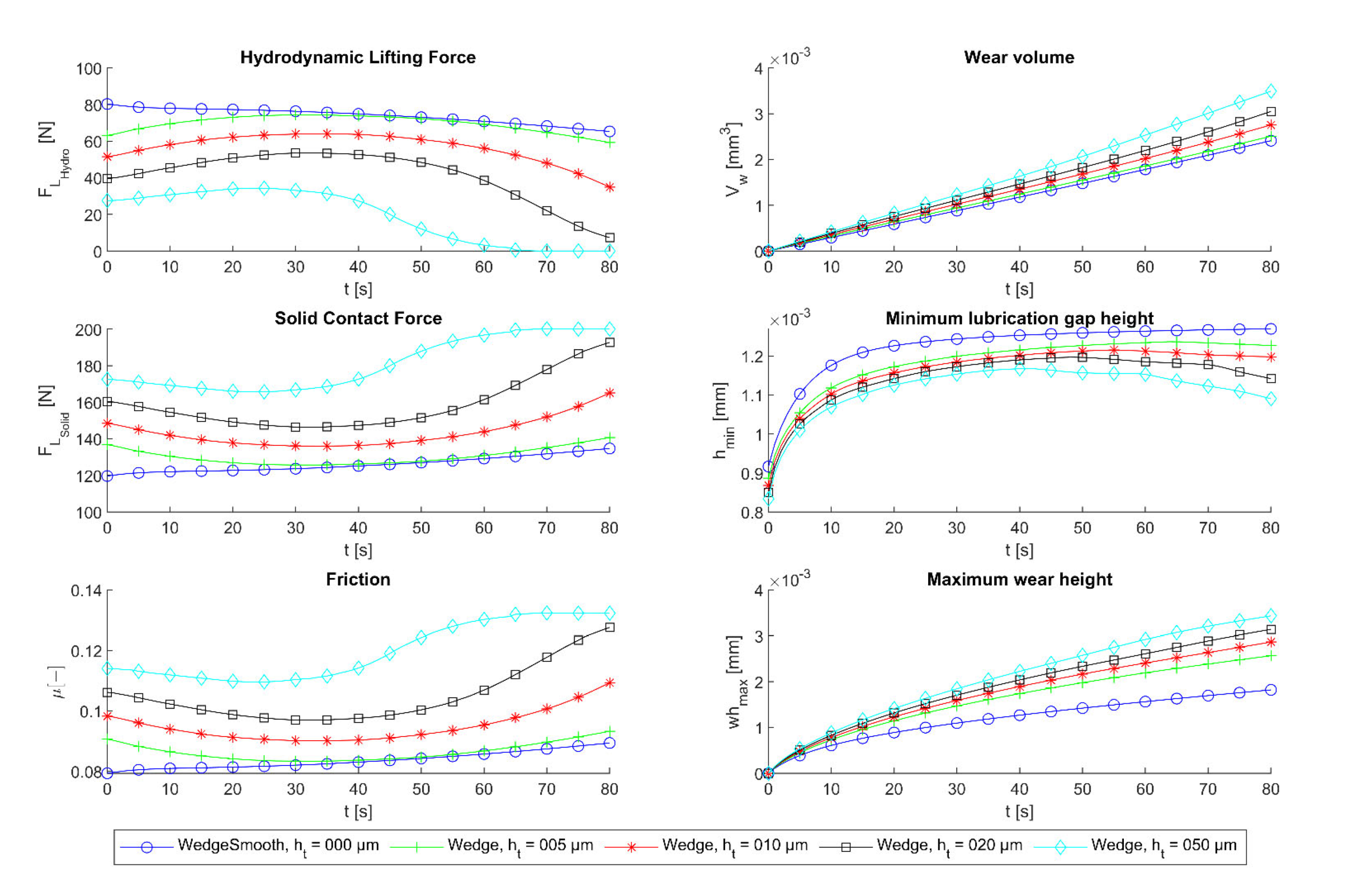

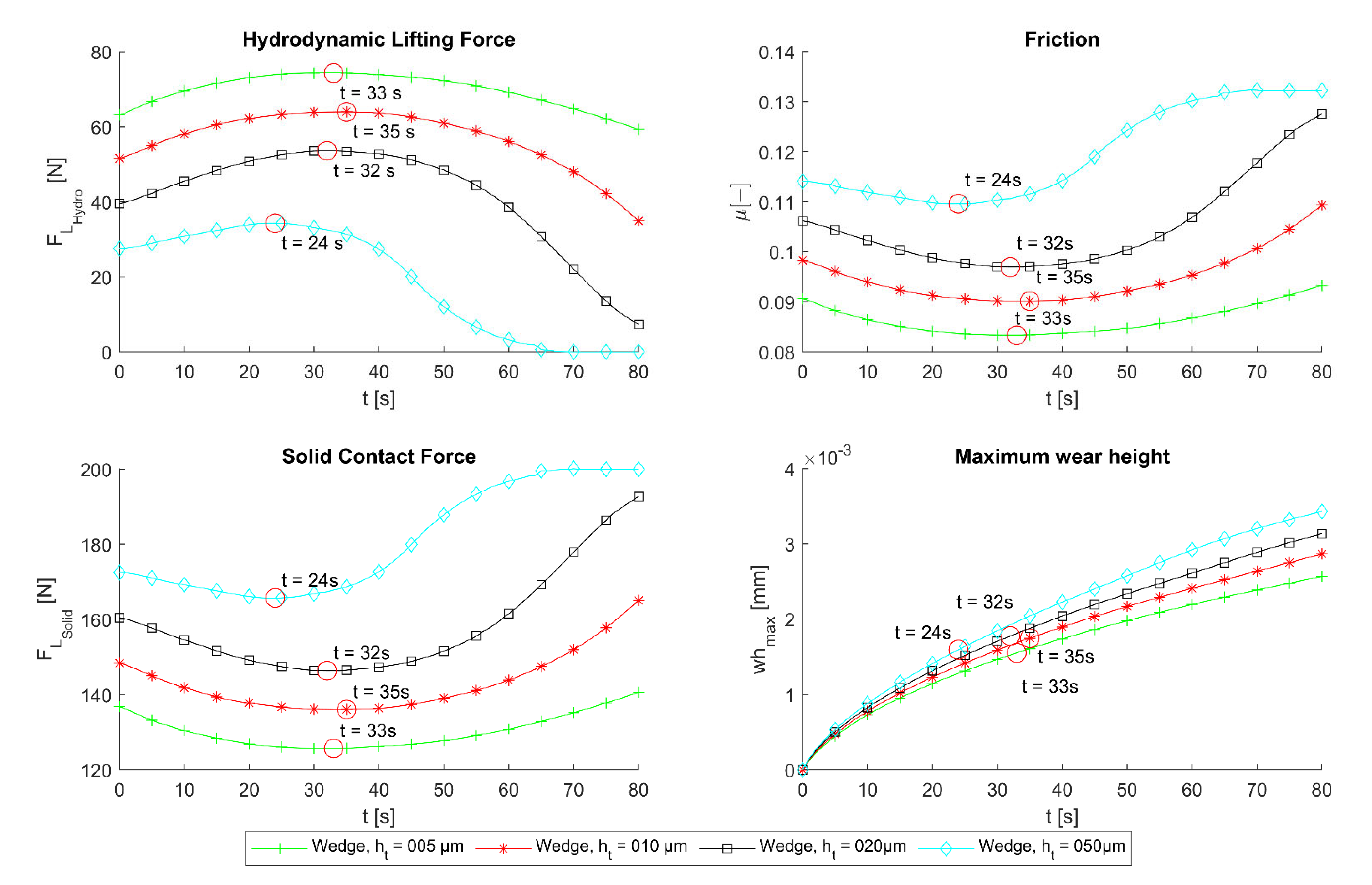

3.3. Wear Simulation

4. Discussion

5. Conclusions

- Surface textures show the potential to positively affect the performance of lubricated contacts in the hydrodynamic lubrication regime in terms of reduced friction and increased lifting force.

- For a given texture shape, the texture height ht has a significant influence on the operating performance.

- A specific texture geometry, which has a positive effect on tribological performance in a specific operating point in the hydrodynamic lubrication regime, is not inevitably associated with lower wear values. Hence, it can be inferred that a certain texture geometry only improved the tribological performance within the range of a certain operating point.

- With increasing wear, an intermediate improvement in the tribological performance for the textured surfaces could be observed. From a reversal point, which occurred for all considered textured heights at a maximum wear height of ~1.6 µm, respectively, a convergence ratio of K ~1.5, the tribological performance deteriorated again, which corresponded to the observations regarding the coefficient of friction for different convergence ratios of another author [42].

- In the present study, the ability to trap wear particles in the texturing dimples was not modeled. This mechanism can improve the wear behavior, therefore, the obtained simulation results should be interpreted as relative values. The presented simulation model is intended to provide a better understanding of the contact conditions, particularly the asperity contact pressure, in the lubricated and textured contacts and considering the wear dependent surfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, Y.; Yuan, L.; Li, J.; Wang, J. Boundary layer drag reduction research hypotheses derived from bio-inspired surface and recent advanced applications. Micron 2015, 79, 59–73. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Wang, J.; Luo, G.; Wang, S.; Qu, J.; Fan, X.; Liu, C. Study on the Drag Reduction Characteristics of the Surface Morphology of Paramisgurnus dabryanus Loach. Coatings 2021, 11, 1357. [Google Scholar] [CrossRef]

- Zhang, M.; Feng, S.; Wang, L.; Zheng, Y. Lotus effect in wetting and self-cleaning. Biotribology 2016, 5, 31–43. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Dobrica, M.B.; Fillon, M.; Pascovici, M.D.; Cicone, T. Optimizing surface texture for hydrodynamic lubricated contacts using a mass-conserving numerical approach. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 737–750. [Google Scholar] [CrossRef]

- Mishra, P.; Ramkumar, P. Effect of Micro Texture on Tribological Performance of Piston Ring-Cylinder Liner System under Different Lubrication Regimes. In Proceedings of the International Conference on Advances in Design, Materials, Manufacturing and Surface Engineering for Mobility, SAE International, Chennai, India, 20–21 July 2018. [Google Scholar]

- Morris, N.; Leighton, M.; de La Cruz, M.; Rahmani, R.; Rahnejat, H.; Howell-Smith, S. Combined numerical and experimental investigation of the micro-hydrodynamics of chevron-based textured patterns influencing conjunctional friction of sliding contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 316–335. [Google Scholar] [CrossRef]

- Filho, I.C.M.F.; Bottene, A.C.; Silva, E.J.; Nicoletti, R. Static behavior of plain journal bearings with textured journal-Experimental analysis. Tribol. Int. 2021, 159, 106970. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Fowell, M.; Mattsson, L.; Reddyhoff, T. The effects of laser surface texture applied to internal combustion engine journal bearing shells–An experimental study. Tribol. Int. 2019, 134, 317–327. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Szurdak, A.; König, F.; Jacobs, G.; Hirt, G.; Mücklich, F. From lab to application-Improved frictional performance of journal bearings induced by single- and multi-scale surface patterns. Tribol. Int. 2018, 127, 500–508. [Google Scholar] [CrossRef]

- Bartel, D. Simulation von Tribosystemen: Grundlagen und Anwendungen; Vieweg + Teubner; GWV Fachverlage GmbH: Wiesbaden, Germany, 2010. [Google Scholar]

- Dobrica, M.B.; Fillon, M. About the validity of Reynolds equation and inertia effects in textured sliders of infinite width. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 69–78. [Google Scholar] [CrossRef]

- Jackson, R.L.; Green, I. A statistical model of elasto-plastic asperity contact between rough surfaces. Tribol. Int. 2006, 39, 906–914. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally flat surfaces. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Tripp, J.H. The contact of two nominally flat rough surfaces. Proc. Inst. Mech. Eng. 1970, 185, 625–633. [Google Scholar] [CrossRef]

- Kogut, L.; Etsion, I. A Finite Element Based Elastic-Plastic Model for the Contact of Rough Surfaces. Tribol. Trans. 2003, 46, 383–390. [Google Scholar] [CrossRef]

- Maier, M.; Pusterhofer, M.; Summer, F.; Grün, F. Validation of statistic and deterministic asperity contact models using experimental Stribeck data. Tribol. Int. 2021, 165, 107329. [Google Scholar] [CrossRef]

- Waddad, Y.; Magnier, V.; Dufrénoy, P.; de Saxcé, G. Multiscale thermomechanical modeling of frictional contact problems considering wear–Application to a pin-on-disc system. Wear 2019, 426–427, 1399–1409. [Google Scholar] [CrossRef]

- Sugimura, J.; Kimura, Y.; Amino, K. Analysis of the Topographical Changes due to Wear-Geometry of the Running-In Process. Toraibarojisuto J. Jpn. Soc. Tribol. 1986, 31, 813–820. [Google Scholar]

- König, F.; Chaib, A.O.; Jacobs, G.; Sous, C. A multiscale-approach for wear prediction in journal bearing systems–from wearing-in towards steady-state wear. Wear 2019, 426–427, 1203–1211. [Google Scholar] [CrossRef]

- Maier, M.; Pusterhofer, M.; Grün, F. Modelling Approaches of Wear-Based Surface Development and Their Experimental Validation. Lubricants 2022, 10, 335. [Google Scholar] [CrossRef]

- Albers, A.; Reichert, S. On the influence of surface roughness on the wear behavior in the running-in phase in mixed-lubricated contacts with the finite element method. Wear 2017, 376–377, 1185–1193. [Google Scholar] [CrossRef]

- Jarchard, F.; Hirst, W. The wear of metals under unlubricated conditions. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1956, 236, 397–410. [Google Scholar] [CrossRef]

- Põdra, P.; Andersson, S. Simulating sliding wear with finite element method. Tribol. Int. 1999, 32, 71–81. [Google Scholar] [CrossRef]

- Fleischer, G. Zum energetischen Niveau von Reibpaarungen. Schmierungstechnik 1985, 12, 358–363. [Google Scholar]

- Ostovan, F.; Hasanzadeh, E.; Toozandehjani, M.; Shafiei, E.; Jamaludin, K.R.; Amrin, A.B. A combined friction stir processing and ball milling route for fabrication Al5083-Al2O3 nanocomposite. Mater. Res. Express 2019, 6, 65012. [Google Scholar] [CrossRef]

- Ostovan, F.; Azimifar, I.; Toozandehjani, M.; Shafiei, E.; Shamshirsaz, M. Synthesis of ex-situ Al5083 reinforced with mechanically-alloyed CNTs and Fe2O3 nanoparticles using friction stir processing. J. Mater. Res. Technol. 2021, 14, 1670–1681. [Google Scholar] [CrossRef]

- Netgen/NGSolve Finite Element Tool. 2023. Available online: https://docu.ngsolve.org/latest/index.html (accessed on 10 January 2023).

- Michael Dawson-Haggerty. Trimesh. 2023. Available online: https://trimsh.org/trimesh.html (accessed on 10 January 2023).

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Application of Average Flow Model to Lubrication Between Rough Sliding Surfaces. J. Lubr. Technol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Jakobsson, B.; Floberg, L. The Finite Journal Bearing, Considering Vaporization: (Das Gleitlager von Endlicher Breite mit Verdampfung); Gumperts: Göteborg, Germany, 1957. [Google Scholar]

- Boussinesq, J. Application des Potentiels à L'étude de L'équilibre et du Mouvement des Solides Élastiques, Principalement au Calcul des Déformations et des Pressions Que Produisent, Dans Ces Solides, des Efforts Quelconques Exercés sur Une Petite Partie de Leur Surface ou de Leur Intérieur: Mémoire Suivi de Notes Étendues sur Divers Points de Physique Mathématique et d'Analyse; Gauthier-Villars: Paris, France, 1885. [Google Scholar]

- Maier, M.; Pusterhofer, M.; Grün, F. Wear simulation in lubricated contacts considering wear-dependent surface topography changes. Mater. Today Proc. 2023, 96, 173. [Google Scholar] [CrossRef]

- Bergmann, P.; Grün, F.; Gódor, I.; Stadler, G.; Maier-Kiener, V. On the modelling of mixed lubrication of conformal contacts. Tribol. Int. 2018, 125, 220–236. [Google Scholar] [CrossRef]

- Sander, D.E.; Allmaier, H.; Priebsch, H.H.; Witt, M.; Skiadas, A. Simulation of journal bearing friction in severe mixed lubrication–Validation and effect of surface smoothing due to running-in. Tribol. Int. 2016, 96, 173–183. [Google Scholar] [CrossRef]

- Mokhtar, M.O.A.; Howarth, R.B.; Davies, P.B. Wear Characteristics of Plain Hydrodynamic Journal Bearings During Repeated Starting and Stopping. ASLE Trans. 1977, 20, 191–194. [Google Scholar] [CrossRef]

- Pusterhofer, M.; Summer, F.; Gódor, I.; Grün, F. Cumulative damage assessment of tribological durability limits. Wear 2020, 456–457, 203318. [Google Scholar] [CrossRef]

- König, F.; Sous, C.; Jacobs, G. Numerical prediction of the frictional losses in sliding bearings during start-stop operation. Friction 2020, 71, 22. [Google Scholar] [CrossRef]

- Awasthi, R.K.; Jain, S.C.; Sharma, S.C. A Simulation Study of Running-in Wear Effect and Its Influence on Average Flow Factors. Tribol. Trans. 2006, 49, 427–438. [Google Scholar] [CrossRef]

- Schiebel, A.; Körner, K. Die Gleitlager (Längs- und Querlager): Berechnung und Konstruktion; Springer: Berlin/Heidelberg, Germany, 1933. [Google Scholar]

- Rosenkranz, A.; Costa, H.L.; Profito, F.; Gachot, C.; Medina, S.; Dini, D. Influence of surface texturing on hydrodynamic friction in plane converging bearings-An experimental and numerical approach. Tribol. Int. 2019, 134, 190–204. [Google Scholar] [CrossRef]

- Azami, B.; Torabi, A.; Akbarzadeh, S.; Esfahanian, M. Experimental Investigation of Textured Surfaces in Line and Point Mixed Lubrication Contact. J. Stress Anal. 2022, 6, 59–65. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. Combined friction and wear reduction in a reciprocating contact through laser surface texturing. Wear 2016, 358–359, 51–61. [Google Scholar] [CrossRef]

- Liu, S.; Sai, Q.; Wang, S.; Williams, J. Effects of Laser Surface Texturing and Lubrication on the Vibrational and Tribological Performance of Sliding Contact. Lubricants 2022, 10, 10. [Google Scholar] [CrossRef]

- Schnell, G.; Müller, T.; Seitz, H. Tribological effects of different scaled chevron-shaped microstructures on the Stribeck curve of parallel contacts under unidirectional friction. Tribol. Int. 2023, 178, 108099. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Load | FLoad = 200 N |

| Velocity | u = 5 m/s |

| Density | ρ = 819.63 kg/m3 |

| Dynamic viscosity | η = 0.01021 Pas |

| Parameter | Value |

|---|---|

| Load | Fload = 200 N |

| Velocity | u = 0.124 m/s |

| Density | ρ = 819.63 kg/m3 |

| Dynamic viscosity | η = 0.01021 Pas |

| Wear coefficient | C = 3.72 × 10−14 m3/Nm |

| Static friction coefficient | µ0 = 0.132 |

| E-Modulus upper body | Eupper = 77,590 N/mm2 |

| E-Modulus lower body | Elower = 210,000 N/mm2 |

| Poisson’s ratio upper body | νupper = 0.3 |

| Poisson’s ratio lower body | νlower = 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maier, M.; Pusterhofer, M.; Grün, F. Multiscale Wear Simulation in Textured, Lubricated Contacts. Coatings 2023, 13, 697. https://doi.org/10.3390/coatings13040697

Maier M, Pusterhofer M, Grün F. Multiscale Wear Simulation in Textured, Lubricated Contacts. Coatings. 2023; 13(4):697. https://doi.org/10.3390/coatings13040697

Chicago/Turabian StyleMaier, Michael, Michael Pusterhofer, and Florian Grün. 2023. "Multiscale Wear Simulation in Textured, Lubricated Contacts" Coatings 13, no. 4: 697. https://doi.org/10.3390/coatings13040697

APA StyleMaier, M., Pusterhofer, M., & Grün, F. (2023). Multiscale Wear Simulation in Textured, Lubricated Contacts. Coatings, 13(4), 697. https://doi.org/10.3390/coatings13040697