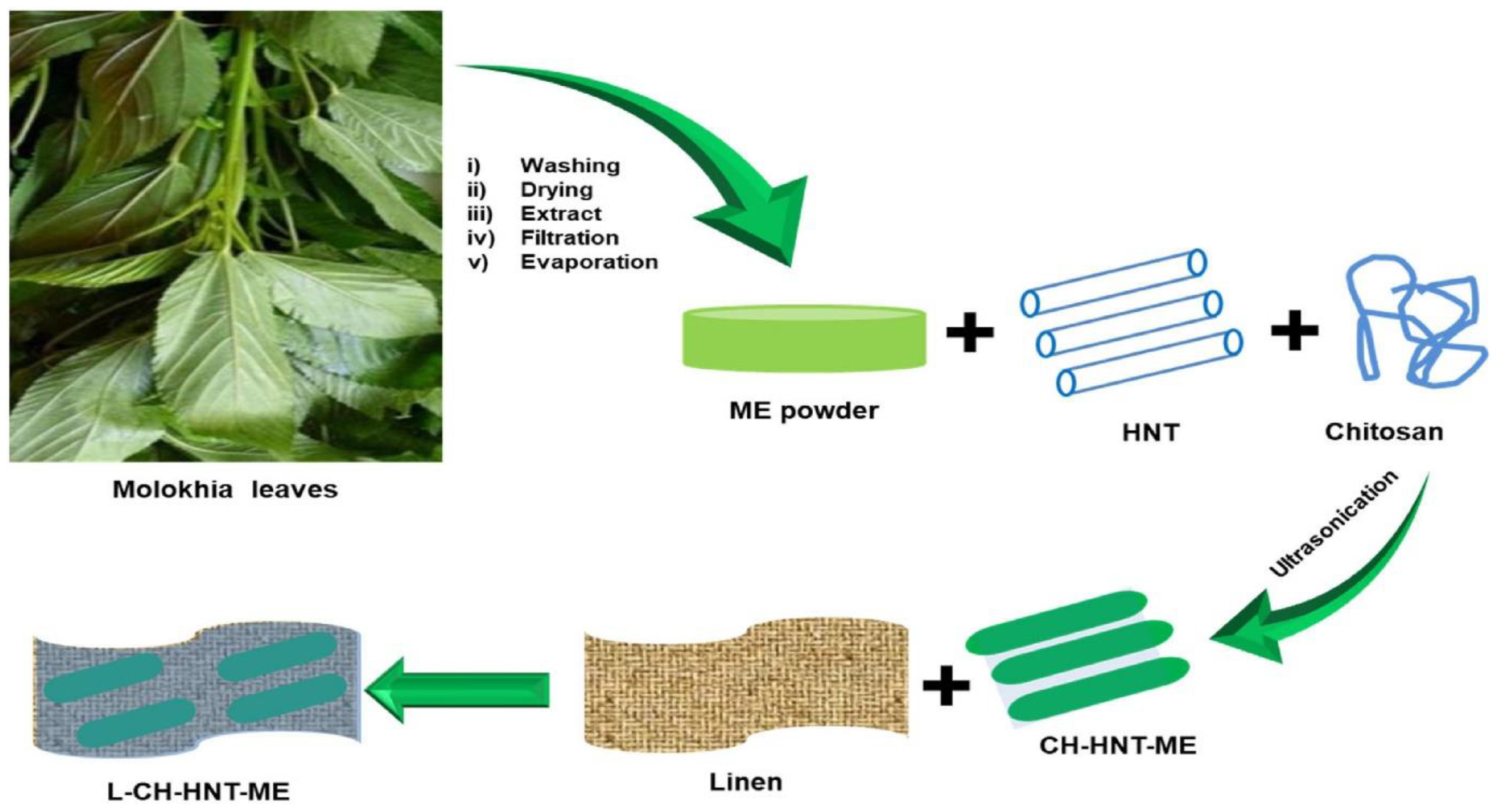

In order to meet the technical requirements, it is necessary to infuse new functions into textile fabrics due to the rapid advancement in the exploitation of textile-based materials in various industrial applications. Although textile fabrics have outstanding mechanical, economical, and light weight capabilities, their organic (natural or synthetic) origin encourages bacterial growth and causes easier combustion. Together with their sensitivity to harmful UV rays, this restricts textile fabric uses and their potential [1,2]. Therefore, there is a pressing need to include a variety of smart functionalities to provide comfort and open up new possibilities for new applications [3]. Thus, textile fabrics have to be treated through coating technology, with smart coating nanocomposites including various sustainable nanomaterials. In this regard, for example, to achieve strong flame retardancy, textile fabrics must be treated with a variety of ingredients, such as halogenated compounds, which are prohibited despite being highly effective flame retardants due to their toxicity and serious environmental issues [4]. The use of phosphorus–nitrogen-based compounds in various forms (organic and/or inorganic) led to good flame retardancy but had a negative impact on mechanical qualities. Following that, flame-resistant nanomaterials of various dimensions were developed, including spherical nanoparticles, graphene nanosheets, and nanofibers [5,6,7]. By adding coatings made of nanomaterial-based flame retardants to textile fabrics, good flame retardancy behaviour was achieved while also strengthening the textile fabrics [8,9,10]. It is interesting to note that complying with the United Nations’ recent recommendations for sustainable development goals, which advise that the creation of coatings should predominantly come from renewable bio-precursors [11,12], Attia et al. reported multipurpose, environmentally friendly, and sustainable textile coating [9]. The discovered coating was produced with naturally occurring halloysite nanotubes and renewable molokhia extract in the presence of chitosan chains. Halloysite nanotubes were encapsulated in molokhia extract, evenly dissolved in chitosan solution, and then coated on the surface of linen textile fibres. The developed coating improved fire safety, UV protection and mechanical properties [9]. This is in addition to promising antibacterial behaviour to textile fabric surfaces as indicated in Figure 1.

Figure 1.

Schematic diagram representing the synthesis of green textile coatings CH-HNT-ME and their linen textile fabrics composite L-CH-HNT-ME, reproduced with permission [9]. Copyright 2022, Elsevier.

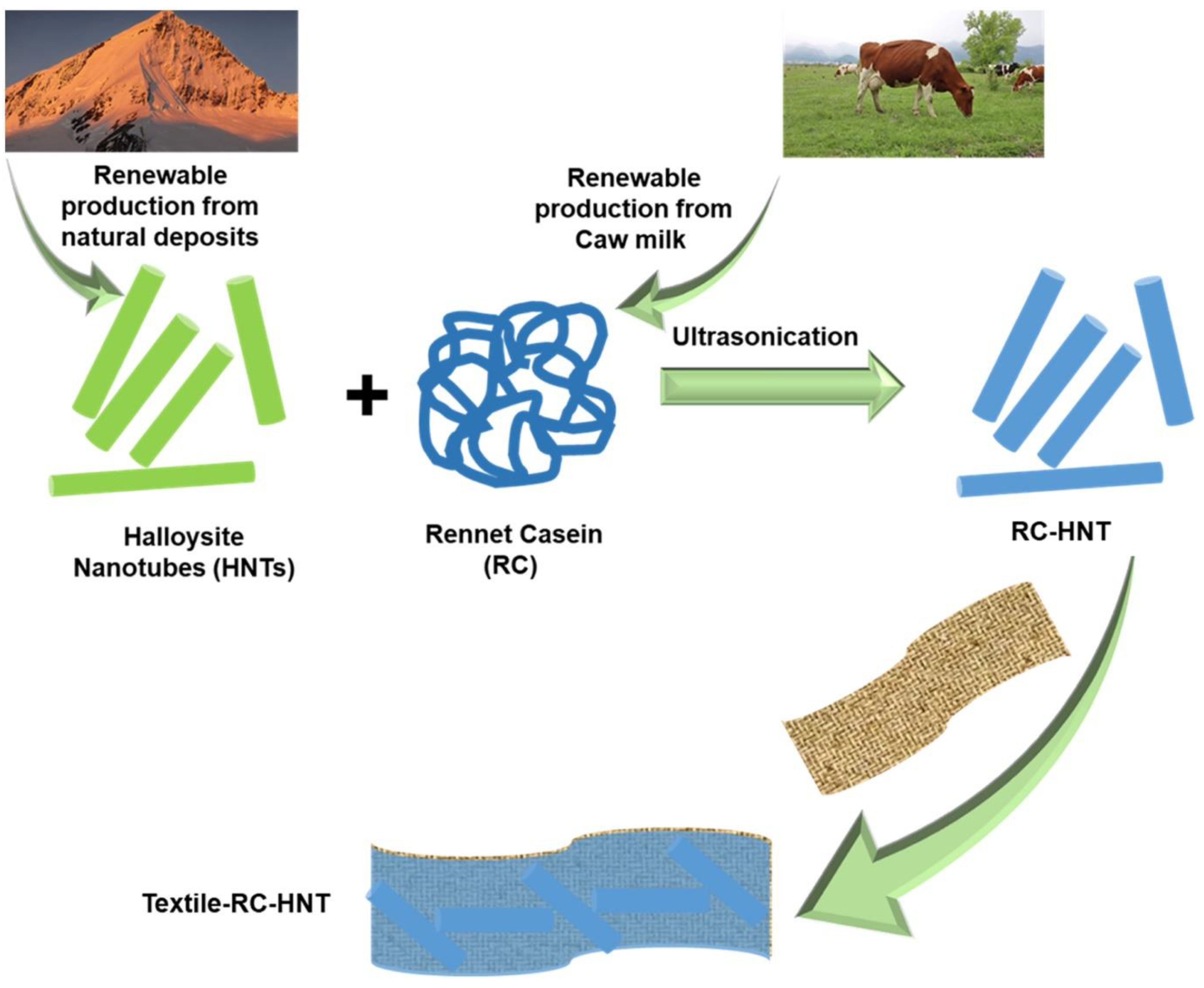

In light of this approach, renewable, effective, and reasonably priced flame retardant, antiviral, strengthened, and antibacterial coating for textile materials has been recently developed and reported based on green synthesis approach as shown in Figure 2. In this sustainable coating, one-dimensional nanocomposite was developed from abundant halloysite nanotubes (HNTs) rennet casein as renewable a biopolymer, simply synthesized from a renewable source of cow’s milk. The coated textile fabrics’ flammability, poisonous gas suppression, reinforcing, antibacterial, and antiviral characteristics were all greatly improved [13]. Recently, textile fabrics have been used as substrate for fabrication of flexible sensor for accurate detection of toxic ions [14]. However, this required the incorporation of electrical conductivity and antibacterial feature to the fabrics used to afford safety and efficient performance. In addition, e-textiles, also referred to as electronic textiles, are composed of cloth but also contain built-in sensing and energy producing capabilities. Applications for e-textiles are numerous and expanding, including in the fields of energy storage, military, construction, automotive, and fashion, as well as in the areas of health monitoring, sports and fitness tracking, and fashion [15,16]. The capacity of a textile to be electrically conductive to transfer information or power is one essential prerequisite for these technologies [17]. Therefore, in this Special Issue, innovative and sustainable coatings for textile fabrics are proposed in order to achieve outstanding fire safety, antibacterial, self-cleaning, UV protection and hydrophobic properties. Additionally, innovation in electrically conductive textiles for electronic and sensor applications are invited, and biocompatible textile coatings for medical application of textile coatings are much appreciated.

Figure 2.

Schematic diagram representing the green synthesis of renewable textile fabrics coatings and their application on textile fabrics, reproduced with permission [13]. Copyright 2022, Elsevier.

Author Contributions

Conceptualization, N.F.A., N.F.A., S.E.A.E. and M.A.-E. writing—original draft preparation, N.F.A., S.E.A.E. and M.A.-E. writing—review and editing, N.F.A.; visualization, S.E.A.E. and M.A.-E. All authors have read and agreed to the published version of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Attia, N.F.; Mousa, M. Synthesis of smart coating for furniture textile and their flammability and hydrophobic properties. Prog. Org. Coat. 2017, 110, 204–209. [Google Scholar] [CrossRef]

- Attia, N.F.; Osama, R.; Elashery, S.E.A.; Abul, K.; Al-Sehemi, A.G.; Algarni, H. Recent advances of sustainable textile fabric coatings for UV protection properties. Coatings 2022, 12, 1597. [Google Scholar] [CrossRef]

- Zeng, F.; Qin, Z.; Chen, Y.; Shan, X. Constructing polyaniline nanowire arrays as efficient traps on graphene sheets to promote compound synergetic effect in the assembled coating for multifunctional protective cotton fabrics. Chem. Eng. J. 2021, 426, 130819. [Google Scholar]

- Attia, N.F.; Elashery, S.E.A.; Zakria, A.M.; Eltaweil, A.S.; Oh, H. Recent advances in graphene sheets as new generation of flame-retardant materials. Mater. Sci. Eng. B 2021, 274, 115460. [Google Scholar] [CrossRef]

- Attia, N.F.; Ebissy, A.A.E.; Morsy, M.S.; Sadak, R.A.; Gamal, H. Influence of textile fabrics structures on thermal, UV shielding, and mechanical properties of textile fabrics coated with sustainable coating. J. Nat. Fibers 2021, 18, 2189–2196. [Google Scholar] [CrossRef]

- Attia, N.F.; Eid, A.M.; Soliman, M.A.; Nagy, M. Exfoliation and decoration of graphene sheets with silver nanoparticles and their antibacterial properties. J. Polym. Environ. 2018, 26, 1072–1077. [Google Scholar] [CrossRef]

- Liu, A.; Hu, X.; Yang, L.; Yang, X.; Dong, J.; Chen, S.; Tan, Y.; Hao, L.; Wang, R. The synergetic modification of surface micro-dissolution and cationization for fabricating cotton fabrics with high UV resistance and conductivity by enriched GO coating. Cellulose 2020, 27, 10489–10500. [Google Scholar] [CrossRef]

- Attia, N.F.; Soliman, M.H.; El-Sakka, S.S. Facile Route for synthesis of novel flame retardant, reinforcement and antibacterial textile fabrics coatings. Coatings 2020, 10, 576. [Google Scholar] [CrossRef]

- Attia, N.F.; Ahmed, H.E.; El Ebissy, A.A.; El Ashery, S.E.A. Green and novel approach for enhancing flame retardancy, UV protection and mechanical properties of fabrics utilized in historical textile fabrics conservation. Prog. Org. Coat. 2022, 166, 106822. [Google Scholar] [CrossRef]

- Shi, Y.M.; Li, L.J. Chemically modified graphene: Flame retardant or fuel for combustion? J. Mater. Chem. 2011, 21, 3277–3279. [Google Scholar] [CrossRef]

- United Nations Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 16 January 2023).

- Attia, N.F.; Asma, M.; Hussein, A.; El-Demerdash, A.M.; Kandil, S. Greener bio-based spherical nanoparticles for efficient multilayer textile fabrics nanocoating with outstanding fire retardancy, toxic gases suppression, reinforcement and antibacterial properties. Surf. Interf. 2023, 36, 102595. [Google Scholar] [CrossRef]

- Attia, N.F.; Asma, M.; Hussein, A.; El-Demerdash, A.M.; Kandil, S. Bio-inspired one-dimensional based textile fabric coating for integrating high flame retardancy, antibacterial, toxic gases suppression, antiviral and reinforcement properties. Polym. Degrad. Stab. 2022, 205, 110152. [Google Scholar] [CrossRef]

- Sweilam, M.N.; Varcoe, J.R.; Crean, C. Fabrication and optimization of fiber-based lithium sensor: A step toward wearable sensors for lithium drug monitoring in interstitial fluid. ACS Sens. 2018, 3, 1802–1810. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, S.; Lin, Y.; Yuan, X.; Liu, L. Silver nanowires coated on cotton for flexible pressure sensors. J. Mater. Chem. C 2016, 4, 935–943. [Google Scholar] [CrossRef]

- Arjmand, M.; Moud, A.A.; Li, Y.; Sundararaj, U. Outstanding electromagnetic interference shielding of silver nanowires: Comparison with carbon nanotubes. RSC Adv. 2015, 5, 56590–56598. [Google Scholar] [CrossRef]

- Maheshwari, N.; Abd-Ellah, M.; Goldthorpe, I.A. Transfer printing of silver nanowire conductive ink for e-textile applications. Flex. Print. Electron. 2019, 4, 025005. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).