Abstract

Cermet coatings with ceramic and metal characteristics will play an increasingly important role in extending the service life of critical components in harsh service environments. In this paper, CoCrAlTaY-30Al2O3 (wt.%) cermet coating was prepared by air plasma spraying technique. The effect of powder feeding rate on the microstructure and mechanical properties of the coating and its high-temperature oxidation behavior was investigated. The results showed that the CoCrAlTaY-30Al2O3 spraying powder mainly consisted of Al5Co2, α-Al2O3, Co, Cr7C3, and TaC in five phases. The microstructure of cermet coating was uniform and its porosity was relatively low. The coating was mainly composed of Al5Co2, Cr, and Al2O3 phases, and the change of powder feeding rate had no obvious effect on the phase composition of the coating. When the powder feeding rate was 32 g/min, the minimum porosity of the coating was (3.68 ± 0.86)%, and the maximum Vickers hardness and binding strength were (664.9 ± 55.9) HV0.3 and (78.6 ± 6.6) MPa, respectively. The oxidation rate constant kp1 of the coating at 1050 °C was 0.066 mg2∙cm−4∙h−1, and the fitted curve R2 value was 0.99547. In the oxidization initial stages, the alloy elements Co, Al, and Cr in the cermet coating were rapidly oxidized to form CoO, Al2O3, and Cr2O3. Then Al2O3 and Cr2O3 reacted with CoO to form Co(Al,Cr)2O4 spinel oxides. The θ-Al2O3 phase was formed after initial oxidation while the θ-Al2O3 phase was completely transformed into α-Al2O3 after 200 h. The oxide film mainly contained Co(Cr,Al)2O4, Cr2O3, and α-Al2O3 phases.

1. Introduction

With the rapid development of the modern manufacturing industry, high-temperature coating technology plays an increasingly important role in various fields. For example, hard particles can scour the surface of the tube in the boiler at high temperatures, which easily leads to continuous thinning of the tube wall and pipe explosion accidents [1,2]. The high-temperature furnace roller as the key metallurgical part of the continuous annealing line has serious wear, oxidation, and nodulation phenomenon at about 1000 °C, which significantly affects the quality of billet strip steel [3,4]. At the same time, high-temperature oxidation corrosion and wear is an important factor that affects the life of key parts of an aero-engine. Therefore, in order to adapt to the special requirements of high-temperature resistance, wear resistance, corrosion resistance, oxidation resistance, high strength and hardness, it is vital to develop a multi-functional high-temperature protective coating for the surface strengthening treatment of key parts, so they are more suitable for aerospace, metallurgy, energy equipment, petrochemical, and other industries in harsh working conditions.

Among high-temperature coatings that both resist oxidation and wear, cermet coating is composed of a metal bond phase and ceramic reinforcing phase, which is a kind of high-temperature protective coating with potential applications. It has the advantages of high bonding strength, superior toughness, good thermal shock resistance, good wear resistance, and good chemical stability [3,5,6,7,8,9]. Especially, MCrAlY (M=Co, Ni, or Co + Ni) has good oxidation resistance, hot corrosion resistance, and thermal fatigue properties, and is widely used as the binder in cermet coatings, however, its wear resistance is poor [9,10,11,12]. According to the reported literature [7,13,14,15,16], adding Al2O3, ZrO2, TiB2, CrB2, ZrB2, and other ceramic phases to the MCrAlY coating could form an MCrAlY-based cermet coating that significantly improves the nodulation resistance and wear resistance at high temperature while maintaining the high bond strength and good high-temperature oxidation resistance of MCrAlY. Bobzin et al. [15] applied a high-energy ball-milling process to prepare the mixture of NiCoCrAlY and ZrO2-Y2O3 (NiCoCrAlY-YPSZ mechanical alloyed powder), and the wear rate of NiCoCrAlY-5 wt.% YPSZ coating prepared by high-velocity oxygen fuel (HVOF) was 1.75 × 10−4 mm3/N∙m), which was only half of the conventional NiCoCrAlY coating. Wang et al. [16] reported that laser cladding nano-Al2O3 modified NiCoCrAlY coating had excellent wear resistance at 500 °C, and the wear rate of the coating was only 34.0%~64.5% of the NiCoCrAlY coating. Zhou et al. [17] showed that the friction coefficient of laser cladding CoCrAlYTaSi-Al2O3 coating was significantly lower than that of CoCrAlYTaSi coating, and the lowest wear rate of CoCrAlYTaSi-45 wt.% Al2O3 coating was only 0.3 × 10−4 mm3/N∙m. However, laser cladding technology has a serious impact on the heat-affected zone of the substrate, which can change the microstructure and properties of the substrate. Meanwhile, the cladding layer is prone to cracking and spalling. As one of the advanced surface technologies, thermal spraying technology has been widely used in the preparation of high-temperature protective coating due to its high production efficiency, low cost, wide range of coating materials, low thermal impact on the substrate, and it’s green and pollution-free characteristics. Hou et al. [10] prepared the CoCrAlYTaCSi-10%Al2O3 cermet coating by high-velocity oxygen fuel (HVOF) and found that the addition of Al2O3 ceramic could improve the hardness, elastic modulus, and wear resistance of the coating, and the wear rate of the coating at 600 °C and 800 °C was 3.96 × 10−5 mm3/N∙m and 2.58 × 10−6 mm3/N∙m, respectively. Wei et al. [18,19] studied the friction and wear properties of HVOF CoCrAlYTA-10%Al2O3 cermet coating under different loads and temperatures. A smooth tribofilm was formed in the worn area of the coating at 600 °C when the loads were lower than 9 N, while the tribofilms were broken as the load increased to 12 N. The average coefficient of friction of the coating decreased with an increase in temperature from 25 °C to 600 °C, while the wear rate of the coating first increased and then decreased. In addition, with the increasingly complex and harsh service environments of key components in metallurgy, aerospace, and other fields, the need to improve high-temperature oxidation behavior and wear resistance of components is crucial. It is necessary to increase the content of the ceramic phase in cermets to improve the wear resistance of coatings. The HVOF spraying technology can no longer meet the requirements of increasing the content of the high melting point ceramic phase in the coating. In this case, it is necessary to adopt the plasma spraying technology with high flame flow temperature (up to 20,000 K) to prepare a high-temperature protective coating for application in metallurgy, aerospace, and other key components requiring more wear resistance. Tao et al. prepared the Al2O3-Cr2O3/NiCoCrAlYTa coatings by atmosphere plasma spraying (APS) and investigated the dry frictional wear behavior at 500 °C [20]. Currently, there were few studies on the preparation process of plasma-sprayed MCrAlY cermet coatings and its oxidation behavior at higher temperatures.

In this paper, APS 70CoCrAlTaY-30Al2O3 (referred to as “CoCrAlTaY-30Al2O3”, wt.%) cermet protective coating was prepared. The influence of the powder feeding rate on the microstructure, phase composition, and mechanical properties of the coating was investigated. Subsequently, the oxidation behavior of CoCrAlTaY-30Al2O3 coating at 1050 °C was discussed in detail.

2. Experimental Procedure

2.1. Specimen Preparation

The substrate material used in the experiment was 310 s (Cr25Ni20) nickel-chromium austenitic stainless steel, and it was processed into 15 mm × 15 mm × 5 mm sample pieces. The samples were ultrasonically cleaned with alcohol and acetone to remove oil stains and then dried. The sample surface was sandblasted with 24 mesh alumina abrasives before preparation. The NiCrAlY(Ni-20Cr-10Al-0.5Y, wt.%) ultrasonic gas atomized alloy powder (Institute of Metals, Chinese Academy of Sciences) was used for the bond coat, and agglomerated sintered CoCrAlTaY-30Al2O3 powder (produced by Fujimi Incorporated, Kakamigahara, Japan) was used for the top working coat. The chemical composition of CoCrAlTaY alloy phase in CoCrAlTaY-30Al2O3 powder was Co-18.8Cr-5.7Al-6.7Ta-0.6Y-0.5Si-1.4C (wt.%). The bond coat and the top working coat were prepared by the Atmosphere plasma spraying system (UniCoat Pro, Oerlikon Metco AG, Wohlen, Switzerland) with an F4MB-XL spray gun. The process parameters of the plasma-sprayed NiCrAlY/CoCrAlTaY-30Al2O3 coating system are shown in Table 1. The effects of the powder feed rate on the microstructure and mechanical properties were studied in detail to obtain the optimum powder feed rate parameters.

Table 1.

Processing parameters for the plasma-sprayed CoCrAlTaY-30Al2O3/NiCrAlY coating system.

2.2. Characterization

The phase composition of the specimen was analyzed through the Rigaku Ultima IVX-ray diffraction (XRD, Cu target, Kα1 λ = 1.54178 Å) with scanning angles of 10° to 90° and a scanning speed of 10°/min. The microstructure and composition of the specimen were characterized by scanning electron microscope (SEM, Phenom XL, Eindhoven, The Netherlands) with energy disperse spectroscopy (EDS). The Vickers hardness was measured by a Vickers hardness tester (MH-5LD, Shanghai Hengyi Precision Instrument Co., Ltd., Shanghai, China) at a load of 3 N with a dwell time of 15 s. Twelve different points were selected for the test to be averaged to avoid accidental results. According to ISO 14916:1999 and MOD “Determination of tensile bonding strength of thermal spraying”, the adhesive strength test between the coating system and the substrate was tested with the microcomputer-controlled electronic universal testing machine (WDW-5E, Shanghai Zhongyan Instrument Manufacturing Co., Ltd., Shanghai, China). The porosity of the sample was calculated through the microscope images processed by Image J software (version: 1.51). The porosity of the coating was obtained by calculating the average value of 10 isomultiple cross-sectional morphologies of different parts.

The high-temperature oxidation behavior of the specimen was characterized by the isothermal oxidation test. The isothermal oxidation experiment was carried out over 200 h in a GSL-1400X tube furnace (Hefei Kejing Material Technology Co., Ltd., Hefei, China) at 1050 °C. Samples were taken every 10 h before 100 h and every 20 h after 100 h, cooled to room temperature, weighed, and recorded with an analytical balance (accurate to 0.00001 g). Finally, the high-temperature oxidation kinetics curves of the specimen were plotted. Three parallel specimens were taken for weighing at each holding time point of each group of samples in the high-temperature oxidation experiment in order to reduce the experimental error. Before the characterization of the cross-sectional microstructure of the oxidized specimen, it was necessary to protect the oxide film on the specimen surface by electroless nickel plating, then inlay and prepare the specimen, and observe the cross-sectional microstructure of the specimen after the grinding and polishing treatment.

3. Results and Discussion

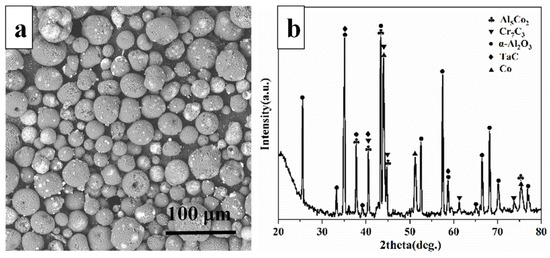

Figure 1 showed the surface morphology and XRD pattern of CoCrAlTaY-30Al2O3 spraying powder. As can be seen from the surface topography, the powder was regularly spherical or nearly spherical with particle sizes in the range of 15~30 μm. There were some pores on the surface of the sprayed powder. The porous structure was conducive to heat transfer to the interior of the powder during plasma spraying, and the uniform particle size of the powder also ensured that the powder particles could be fully melted during heating. CoCrAlTaY-30Al2O3 spraying powder mainly consisted of Al5Co2, α-Al2O3, Co, Cr7C3, and TaC in five phases, as shown in Figure 1b.

Figure 1.

Surface (a) and XRD patterns (b) of CoCrAlTaY-30Al2O3 spraying powder.

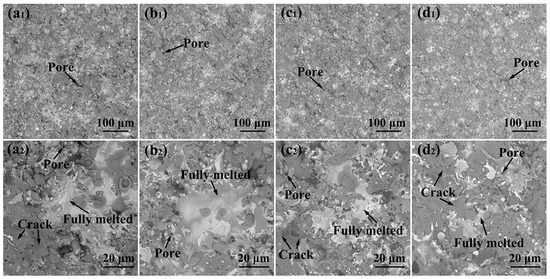

Figure 2 exhibits the surface morphologies of the CoCrAlTaY-30Al2O3 coating with different powder feed rates. There were many pores on the surface of the coating with a 22 g/min powder feed rate (Figure 2(a1,a2)). Owing to the low powder feed rate, the powder particles were overheated by the plasma flame flow and deposited on the surface of the substrate, resulting in more pores. When the powder feed rate was 32 g/min (Figure 2(b1,b2)), the powder particles were fully melted, and the melted particles impacted the substrate surface and spread out evenly. When the powder feeding rate increased to 42 g/min and 52 g/min, more unmelted powder particles could be seen on the surface (as seen in Figure 2(c1,c2,d1,d2)), which would reduce the internal bonding of the coating and adversely affect the compactness and mechanical properties of the coating. Therefore, there was an optimal value of the powder feeding rate. If the powder feeding rate was lower/higher than the optimal value, the powder particles were too few and were overheated or not sufficiently heated so that more pores were formed after deposition on the surface of the substrate. This result was basically consistent with that reported in the literature [21].

Figure 2.

Surface SEM images of CoCrAlTaY-30Al2O3 coatings with different powder feed rates. (a1,a2) 22 g/min; (b1,b2) 32 g/min; (c1,c2) 42 g/min; (d1,d2) 52 g/min.

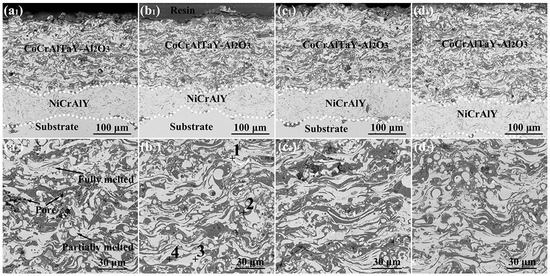

Figure 3 shows the cross-sectional morphologies of the CoCrAlTaY-30Al2O3 coating with different powder feed rates. The thickness of NiCrAlY bond coat was about 70 μm in the whole coating system, and the thickness of the CoCrAlTaY-30Al2O3 working coat was about 190 μm. It was observed that the coating with a powder feed rate of 52 g/min had more pores due to the existence of a large number of unmelted particles. Based on the EDS analysis result (Table 2), the main elements of light bright white microstructure at point 1 mainly contained Ta and C elements. A small amount of carbon elements may be from the CoCrAlTaY spray powder. The main elements of the dark areas in points 2 and 4 were the Al and O elements. This phase was possibly the Al2O3 ceramic phase in the coating. The gray area was rich in Co, Cr, Al, and Ta elements, indicating that the gray microstructure might be a Co-based binder phase. The Co-based binder phase mainly played an important role in bonding, oxidation resistance, and hot corrosion resistance in the coating [22]. By comprehensive comparison, the coating surface with a powder feeding rate of 32 g/min was more smooth and dense, and the microstructure of the coating was more uniform (Figure 3(b1,b2)).

Figure 3.

Cross-sectional SEM images of CoCrAlTaY-30Al2O3 coatings with different powder feed rates. (a1,a2) 22 g/min; (b1,b2) 32 g/min; (c1,c2) 42 g/min; (d1,d2) 52 g/min.

Table 2.

EDS results of cross-sectional CoCrAlTaY-30Al2O3 coating in Figure 3(b2).

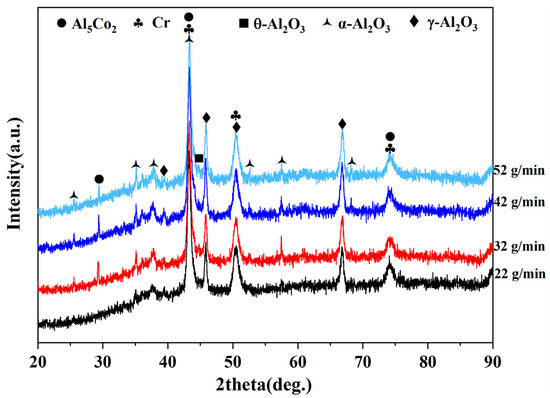

The XRD patterns of the plasma-sprayed CoCrAlTaY-30Al2O3 coating with different powder feed rates are shown in Figure 4. The coating was composed of Al5Co2, Cr, α-Al2O3, θ-Al2O3, and γ-Al2O3 phases, and the phase composition of four different powder feed rates was basically consistent. Dissimilarly, the intensity of diffraction peaks of the AlCo2 phase at about 29° and the α-Al2O3 phase were very low when the powder feeding rate was 22 g/min. With the increase of the powder feeding rate, the intensity of the diffraction peaks of the AlCo2 phase and α-Al2O3 phase in the coating became more obvious. The possible reason for this phenomenon was that the powder particles were overheated by plasma flame flow because of the low powder feed rate. At this time, the Al5Co2 alloy phase decomposed and evaporated excessively in the high-temperature plasma flame, resulting in the decrease of Al5Co2 phase content in the coatings. At the same time, the Al2O3 phase in the coating was too hot to change into the α-Al2O3 phase at room temperature, which preserved the γ-Al2O3 phase at high temperature. This is consistent with the phenomenon reported in the literature [23].

Figure 4.

XRD patterns of plasma-sprayed CoCrAlTaY-30Al2O3 coatings with different powder feed rates.

Table 3 showed the porosity, Vickers hardness, and adhesive strength of CoCrAlTaY-30Al2O3 coatings with different powder feed rates. The porosity and adhesive strength of the coating firstly decreased and then increased with the increase of the powder feed rate, while the variation trend of Vickers hardness was the opposite. The increase in porosity led to a decrease in the adhesive strength of the coating. The Vickers hardness and adhesive strength of the coating reached a maximum value and the porosity reached a minimum value with a 32 g/min powder feed rate. When the powder feed rate was 22 g/min, the powder was fully melted but was easily oxidized and ablated due to the small number of powder particles passing through the flame flow per unit time. In this case, the coating quality was also reduced due to the inclusion of smoke and dust in the process of spraying. However, when the powder feed rate was 42 g/min or 52 g/min, some powder particles were unmelted or partially melted. Based on the above results, the coating with a powder feed rate of 32 g/min had optimal comprehensive performance, including the lowest porosity, highest hardness and adhesive strength. Subsequently, the CoCrAlTaY-30Al2O3 coating was prepared with a powder feeding rate of 32 g/min under the condition that other process parameters remained unchanged, and the high-temperature oxidation behavior of the coating with a 32 g/min powder feeding rate was studied at 1050 °C.

Table 3.

Porosity, Vickers hardness, and adhesion strength of plasma-sprayed CoCrAlTaY-30Al2O3 coatings with different powder feed rates.

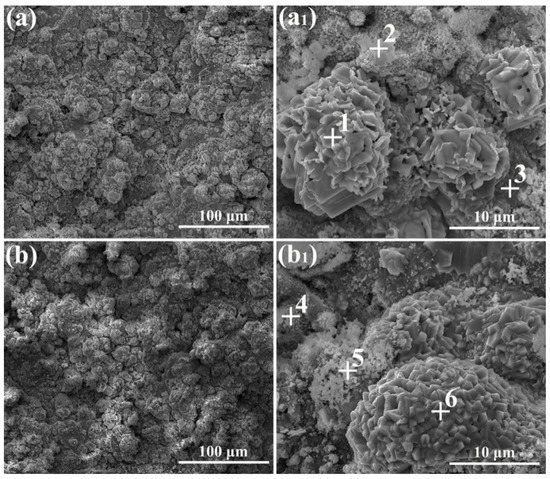

Figure 5 presents surface morphologies of the plasma-sprayed CoCrAlTaY-30Al2O3 coating after oxidation at 1050 °C for 100 and 200 h. As shown in Figure 5, a large number of fine grains were generated on the surface of the coating. The porosity of the coating obviously increased when the oxidation time was extended to 200 h, which may be due to the further oxidation of Cr2O3 in the oxidation product to produce the volatile CrO3. The volatilization of CrO3 caused holes in the oxide film, which destroyed the continuity of the oxide film. Then, oxygen in the air was easy to enter through the holes and continued to react with the alloy elements in the coating, eventually making the oxide film lose its effective protection. Cauliflower-shaped grains appeared on the surface of the coating and grew in a step-by-step way, as seen in Figure 5(a1). According to the EDS results of point 1 (Table 4), the cauliflower-shaped grains contained Co, Cr, and O elements with an atomic ratio of approximately 1:2:4, which might be CoCr2O4 spinel oxide. There were some small white grains on the coating surface (point 2), and the EDS results indicated that the white grain was a mixed oxide of Co, Cr, and Al. In point 3, dark grey grains contained Co, Al, and O elements with an atomic ratio of approximately 1:2:4, which might be CoAl2O4 spinel oxide. With the further oxidation, cauliflower-shaped grains still existed after oxidation at 1050 °C for 200 h, and a small amount of bright white grains (point 5) were generated on the surface of the coating (Figure 5(b1)). The cauliflower-shaped grains still contained Co, Cr, and O elements with an atomic ratio of 1:2:4, which proved that it was also CoAl2O4 spinel oxide (point 6). Compared with the EDS analysis results at points 4 and 5, the bright white grains contained the same elements including Co, Cr, Al, and O. Furthermore, the content of Co and O were very close, only the content of Al and Cr were different, indicating that there were mixed oxides or spinel oxides. In the initial stage of oxidation, Co alloy was rapidly oxidized to CoO, while Al and Cr were gradually oxidized to form Cr2O3 and Al2O3 protective oxides. Then CoO reacted with Al2O3 and Cr2O3 to form CoAl2O4 and CoCr2O4 spinel oxides.

Figure 5.

Surface morphologies of CoCrAlTaY-30Al2O3 coatings after oxidation at 1050 °C. for (a,a1) 100 h and (b,b1) 200 h.

Table 4.

EDS results of the corresponding points on the surface of CoCrAlTaY-30Al2O3 coatings after oxidation at 1050 °C in Figure 5.

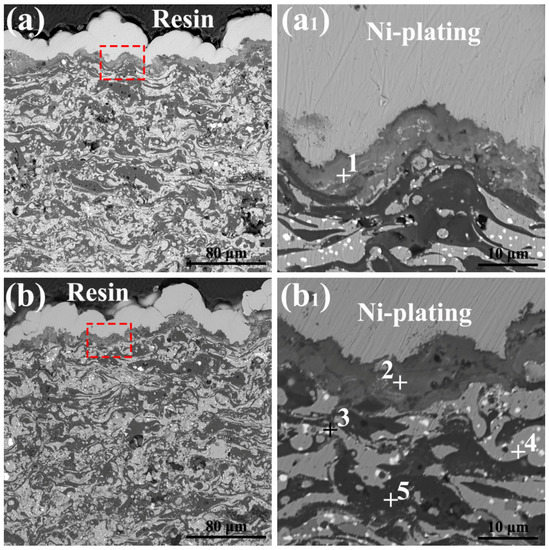

Figure 6 showed the cross-sectional morphologies of the plasma-sprayed CoCrAlTaY-30Al2O3 coating after oxidation at 1050 °C for 100 h and 200 h. The thickness of oxide films for 100 h and 200 h were 6.73 μm and 9.08 μm, respectively. The interface between oxide film and coating was tightly bonded, and no other defects were found. The EDS results of the corresponding points on the cross-sectional surface of CoCrAlTaY-30Al2O3 coatings after oxidation at 1050 °C in Figure 6 was shown in Table 5. In point 1, the main elements were Co, Cr, Al, and O, and the atomic ratio of Co and O was close to 1:4, indicating that it might be CoCr2O4 spinel oxide which does not meet the stoichiometric ratio. Moreover, Co, Cr, Al, and O were also contained at point 2, and the atomic ratio of Co, Al, and O was close to 1:2:4, indicating that CoAl2O4 spinel oxide was included in the oxide film. The main oxides generated by the CoCrAlTaY-30Al2O3 coating after oxidation at 1050 °C were CoCr2O4 and CoAl2O4 spinel oxides. Spinel oxide has a relatively dense structure with low oxygen diffusion, but its combination with the coating was not as stable as the Al2O3 oxide film. Hence, the coating continued to oxidize at 1050 °C with the oxidation time rising. Fortunately, EDS analysis of points 3, 4, and 5 inside the coating showed that the internal composition of the coating was not significantly affected after oxidation at 1050 °C for 200 h.

Figure 6.

Cross-sectional morphologies of plasma-sprayed CoCrAlTaY-30Al2O3 coatings after oxidation at 1050 °C for (a,a1) 100 h and (b,b1) 200 h.

Table 5.

EDS results of the corresponding points on the cross-sectional surface of CoCrAlTaY-30Al2O3 coatings after oxidation at 1050 °C in Figure 6.

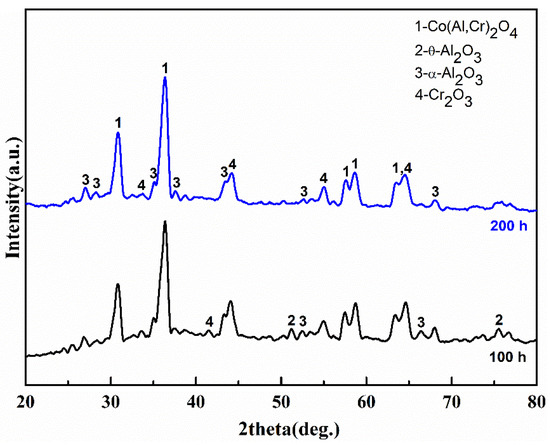

The XRD patterns of the plasma-sprayed CoCrAlTaY-30Al2O3 coating after oxidation at 1050 °C for 100 h and 200 h are shown in Figure 7. The oxide film of the coating was composed of Cr2O3, α-Al2O3, θ-Al2O3, and Co(Al,Cr)2O4 spinel oxide phases after oxidation at 1050 °C for 100 h. In the initial stage of oxidization, the alloy elements Co, Al, and Cr in the coating were rapidly oxidized to form CoO, Al2O3, and Cr2O3. Then Al2O3 and Cr2O3 reacted with CoO to form Co(Al,Cr)2O4 spinel oxides. It can be seen in Figure 7 that the diffraction peak intensity of alumina and chromium oxide was almost the same. The diffraction peak intensity of Co(Al,Cr)2O4 spinel phase after oxidation for 200 h was obviously higher than that after oxidation for 100 h. Therefore, it was basically inferred that with the increase of oxidation time from 100 h to 200 h, the content of Co(Al,Cr)2O4 spinel phase on the surface of the oxidized coating might slightly increase. In addition, the θ-Al2O3 phase still existed in the coating after oxidation for 100 h, while the diffraction peak of the θ-Al2O3 phase disappeared after 200 h, indicating that the θ-Al2O3 phase in the coating was completely transformed into α-Al2O3, accompanied by a significant increase in the diffraction peak intensity of the α-Al2O3 phase.

Figure 7.

XRD patterns of the plasma-sprayed CoCrAlTaY-30Al2O3 coating after oxidation at 1050 °C for 100 h and 200 h.

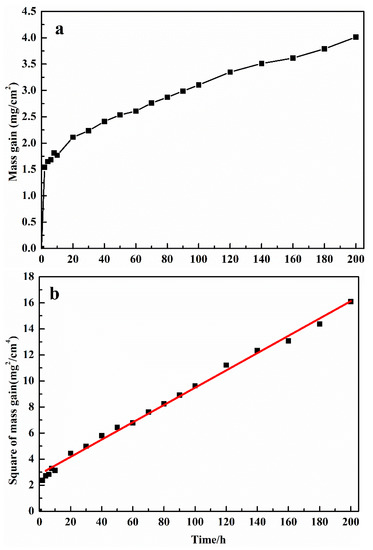

Figure 8 presents the oxidation kinetic curve and oxidation rate curve of the plasma-sprayed CoCrAlTaY-30Al2O3 coating at 1050 °C. As can be seen from Figure 8, the oxidation weight gain of the CoCrAlTaY-30Al2O3 coating was fast in the first 10 h. With the rise of oxidation time, the weight gain of the coating continued to increase at 1050 °C, but the growth rate slowed down. On the basis of Wagner’s high-temperature oxidation theory [24,25]:

where ∆W is the weight gain of the coating (mg); A is the reaction surface area (cm2); kp is the parabolic rate constant (mg2∙cm−4∙h−1), that is, the oxidation rate constant; t is the oxidization time (h), and C is the oxidation weight gain constant. After calculation, the oxidation rate constant kp1 of the coating at 1050 °C was 0.066 mg2∙cm−4∙h−1, and the fitted curve R2 value was 0.99547. The fitting curve was approximately a straight line, indicating that the oxidation kinetic curves of the coating basically conformed to the parabolic law. In the initial stage of oxidation, a dense, continuous protective oxide film had not been formed on the surface. Oxygen was rapidly adsorbed and ionized on the surface of the coating and reacted with metal ions in the coating to form oxides at higher temperatures. At this stage, the oxidation rate of the reaction was controlled by the formation reaction on the surface, so the oxidation rate was very fast, and the weight gain of the coating was obvious within 20 h. As oxidation continued, a dense oxide film as a diffusion barrier was formed on the coating surface. Further oxidation was carried out by the outward diffusion of metal cations or the inward diffusion of oxygen ions. The oxidation rate at this stage was controlled by the reaction rate and ion transmission of the interface between the coating and the oxide and the interface between the oxide film and the gas phase. Thus, the oxidation rate was obviously decreased and the weight gain of the coating was slow at this stage.

Figure 8.

Oxidation kinetic curves (a) and linear fitted curves (b) of plasma-sprayed CoCrAlTaY-30Al2O3 coatings at 1050 °C.

4. Conclusions

- (1)

- The CoCrAlTaY-30Al2O3 coating was successfully fabricated by air plasma spraying. The coating had a relatively uniform microstructure and was composed of Al5Co2, Cr, and Al2O3 in three phases, which was slightly different from its spraying powder.

- (2)

- The change of powder feed rate had no obvious influence on phase composition. When the powder feeding rate was 32 g/min, the CoCrAlTaY-30Al2O3 coating had excellent mechanical properties and low porosity.

- (3)

- The oxidation rate constant of the plasma-sprayed CoCrAlTaY-30Al2O3 coating at 1050 °C was 0.066 mg2∙cm−4∙h−1, which was consistent with the parabolic oxidation law. In the initial stage of oxidation, the alloy elements Co, Al, and Cr in the coating were rapidly oxidized to form CoO, Al2O3, and Cr2O3. Subsequently, Al2O3 and Cr2O3 reacted with CoO to form Co(Al,Cr)2O4 spinel oxides, which slowed down the oxidation in the later stage. The oxide film was composed of Cr2O3, Al2O3, and Co(Al,Cr)2O4 spinel phases.

Author Contributions

Investigation, Data curation, Writing—Original draft preparation, Z.Z.; Investigation, Methodology, W.H.; Investigation, Funding acquisition, Supervision, Z.X. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Anhui Provincial Key Research and Development Program (Grant No. 201904a05020010) and the Natural Science Foundation of Anhui Province (Grant No. 1908085QE219).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge Haoliang Tian for Methodology, Language polishing.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Padmini, B.V.; Bhosale, D.G.; Niranjan, H.B. A study of T11 boiler steel protection by cold sprayed Inconel 738 coating against high temperature erosion. Surf. Interfaces 2021, 23, 101002. [Google Scholar] [CrossRef]

- Singh, J.; Vasudev, H.; Singh, S. Performance of different coating materials against high temperature oxidation in boiler tubes—A review. Mater. Today Proc. 2020, 26, 972–978. [Google Scholar] [CrossRef]

- Huang, T. Effect of Mn on the Formation of Oxide Buildups Upon HVOF-Sprayed MCrAlY-Ceramic-Type Cermet Coatings. J. Therm. Spray Technol. 2011, 20, 447–455. [Google Scholar] [CrossRef]

- Huang, J.; Wang, L.; Wang, W.; Hu, D.; Zhang, K.; Wang, T. Failure analysis of a furnace roller in continuous annealing line after long-term service at high temperatures. Eng. Fail. Anal. 2020, 107, 104057. [Google Scholar] [CrossRef]

- Ham, G.S.; Kreethi, R.; Kim, H.; Yoon, S.-H.; Lee, K.-A. Effects of different HVOF thermal sprayed cermet coatings on tensile and fatigue properties of AISI 1045 steel. J. Mater. Res. Technol. 2021, 15, 6647–6658. [Google Scholar] [CrossRef]

- Xie, X.; Yin, F.; Wang, X.; Ouyang, X. Corrosion Resistance to Molten Zinc of a Novel Cermet Coating Deposited by Activated Combustion High-Velocity Air Fuel (AC-HVAF). J. Therm. Spray Technol. 2019, 28, 1252–1262. [Google Scholar] [CrossRef]

- Hu, Z.; Li, W.; Zhao, Y. The Effect of Laser Power on the Properties of M3B2-Type Boride-Based Cermet Coatings Prepared by Laser Cladding Synthesis. Materials 2020, 13, 1867. [Google Scholar] [CrossRef] [Green Version]

- Bazhin, P.M.; Titov, N.V.; Zhidovich, A.O.; Avdeeva, V.V.; Kolomeichenko, A.V.; Stolin, A.M. Features of the carbo-vibroarc surfacing in the development of multicomponent cermet wear-resistant coatings. Surf. Coat. Technol. 2021, 429, 127952. [Google Scholar] [CrossRef]

- Demian, C.; Denoirjean, A.; Pawłowski, L.; Denoirjean, P.; El Ouardi, R. Microstructural investigations of NiCrAlY + Y2O3 stabilized ZrO2 cermet coatings deposited by plasma transferred arc (PTA). Surf. Coat. Technol. 2016, 300, 104–109. [Google Scholar] [CrossRef]

- Hou, G.; An, Y.; Zhao, X.; Zhou, H.; Chen, J. Effect of alumina dispersion on oxidation behavior as well as friction and wear behavior of HVOF-sprayed CoCrAlYTaCSi coating at elevated temperature up to 1000 °C. Acta Mater. 2015, 95, 164–175. [Google Scholar] [CrossRef]

- Cai, J.; Li, C.; Yao, Y.; Lyu, P.; Guan, Q.; Li, Y.; Lu, J. Microstructural modifications and high-temperature oxidation resistance of arc ion plated NiCoCrAlYSiHf coating via high-current pulsed electron beam. Corros. Sci. 2021, 182, 109281. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.; Chen, Y.; Zhao, X.; Guo, F.; Xiao, P. Effect of microstructure of a NiCoCrAlY coating fabricated by high-velocity air fuel on the isothermal oxidation. Corros. Sci. 2019, 159, 108126. [Google Scholar] [CrossRef]

- Zhao, L.; Parco, M.; Lugscheider, E. Wear behaviour of Al2O3 dispersion strengthened MCrAlY coating. Surf. Coat. Technol. 2004, 184, 298–306. [Google Scholar] [CrossRef]

- Zheng, X.F.; Kang, Y.L.; Zhou, J. Influence of coating and dew point on hearth roll pickup. J. Iron Steel Res. Int. 2019, 26, 647–652. [Google Scholar] [CrossRef]

- Matthews, S.; James, B. Review of thermal spray coating applications in the steel industry: Part 1-hardware in steel making to the continuous annealing process. J. Therm. Spray Technol. 2010, 19, 1267–1276. [Google Scholar] [CrossRef]

- Wang, H.; Zuo, D.; Wang, M.; Sun, G.-F.; Miao, H.; Sun, Y.-L. High temperature frictional wear behaviors of nano-particle reinforced NiCoCrAlY cladded coatings. Trans. Nonferrous Met. Soc. China 2011, 21, 1322–1328. [Google Scholar] [CrossRef]

- Zhou, W.T.; Kong, D.J. Influence of Al2O3 mass fractions on microstructure, oxidation resistance and friction–wear behaviors of CoCrAlYTaSi coatings. Surf. Coat. Technol. 2019, 379, 125058. [Google Scholar]

- Wei, Z.; Wu, Y.; Yang, W.; Hong, S.; Qiao, L.; Cheng, J. Effects of loads on high-temperature wear properties of HVOF sprayed CoCrAlYTa-10%Al2O3 and Cr3C2-NiCr coatings. Mater. Res. Express 2019, 6, 106541. [Google Scholar] [CrossRef]

- Wei, Z.; Wu, Y.; Hong, S.; Qiao, L.; Cheng, J. Effects of temperature on wear properties and mechanisms of HVOF sprayed CoCrAlYTa-10%Al2O3 coatings and H13 steel. Metals 2019, 9, 1224. [Google Scholar] [CrossRef] [Green Version]

- Tao, C.; Wang, L.; Song, X. High-temperature frictional wear behavior of MCrAlY-based coatings deposited by atmosphere plasma spraying. Int. J. Miner. Metall. Mater. 2017, 24, 222–228. [Google Scholar] [CrossRef]

- Pakseresht, A.; Ghasali, E.; Nejati, M.; Shirvanimoghaddam, K.; Javadi, A.H.; Teimouri, R. Development empirical-intelligent relationship between plasma spray parameters and coating performance of Yttria-Stabilized Zirconia. Int. J. Adv. Manuf. Technol. 2014, 76, 1031–1045. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, C.; Lan, H.; Du, L.; Zhang, W. Oxidation and hot corrosion behavior of plasma-sprayed MCrAlY–Cr2O3 coatings. J. Therm. Spray Technol. 2016, 25, 1208–1216. [Google Scholar] [CrossRef]

- Deng, W.; Li, S.; Hou, G.; Liu, X.; Zhao, X.; An, Y.; Zhou, H.; Chen, J. Comparative study on wear behavior of plasma sprayed Al2O3 coatings sliding against different counterparts. Ceram. Int. 2017, 43, 6976–6986. [Google Scholar] [CrossRef]

- Cheng, T.; Wen, Y.; Hawk, J. Diffuse-Interface Modeling and Multiscale-Relay Simulation of Metal Oxidation Kinetics-With Revisit on Wagner’s Theory. J. Phys. Chem. C 2014, 118, 1269–1284. [Google Scholar] [CrossRef]

- Liu, L.; Wu, S.; Chen, Y.; Lu, S. Oxidation Resistance of a Co-Base Superalloy Improved by Pre-Oxidation Heat Treatment. J. Electrochem. Soc. 2016, 163, 282–288. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).