Abstract

This study focuses on a comparative analysis of AlCrXN (X = Mo or V) coatings with the reference AlCrN coating via arc ion plating technique (AIP). The XRD and XPS results showed that the AlCrXN coatings were mainly composed of fcc-(Cr,Al)N solid solution phases. Both the AlCrMoN and AlCrVN coatings exhibited much higher hardness and adhesive strength than the AlCrN coating. The addition of Mo or V decreased the coefficient of friction (COF) and wear rate, which was due to the formation of lubricant oxides containing Mo or V on the coating surfaces. The cutting results showed that abrasive wear, adhesive wear, and oxidation wear were the main wear mechanisms for the coated tools at the cutting speeds of 60 m/min and 94 m/min. The addition of Mo or V dramatically improved the cutting performance of AlCrXN-coated tools by increasing the anti-wear ability due to the high hardness and the formed lubricant VOx or MoOx films.

1. Introduction

During the past few decades, transitional metal nitride coatings such as TiN, TiCN, CrN, CrCN, and TiAlN [1] prepared by physical vapor deposition (PVD) have been extensively applied as a protective coatings to enhance the lifetime and machining performance of the machining tools. The CrAlN system has also been recognized as an improved coating system in aspect of their higher hardness, wear resistance, excellent thermal stability, and high temperature oxidation resistance [2]. In the fields of cutting, application of nitrides coatings as a protective layer has shown significant potential because of their higher hardness and wear resistance, excellent thermal stability and oxidation resistance. However, the assessment of the PVD nitride coatings was sophisticated and confronted with some problems, which have not been solved until now. The cutting tools are usually performed under different machining conditions for which the service temperature could reach up to 600–800 °C. This high temperature accelerated the adhesion and wear between the tool and chip, shortening the service life of the coated tools [3]. In addition, it seemed difficult to obtain both the large toughness and high hardness of the tool coatings at elevated temperatures, which was very important for the cutting application. Recently, the multilayer coatings such as AlTiN/MoN, AlTiN/CrAlTiN [4], AlCrN/TiAlSiN [5], AlCrN/VN [6], AlCrN/AlCrON [7] have also been extensively investigated because of their superior tribological and mechanical properties under elevated temperatures. These multilayer nitride coatings have also demonstrated great ability to enhance the high-speed machining performance [8,9]. Besides, it was also known that the coatings with lower friction coefficient could reduce the adhesive wear, which was usually reported in the worn rake face of the cutter. Therefore, a modified coating was required that could form thin lubricious oxide films at elevated temperatures. The addition of self-lubricating elements such as molybdenum and vanadium various nitride coating created a new path for high speed machining by improving friction properties and boosting the service tool life. Lower coefficient of friction and higher wear resistance were observed in numerous V and Mo-alloyed based nitride coatings, such as CrN/Mo2N, TiAlN/MoN [10], CrN/MoN [11], and TiAlN/MoN [12]. The coefficient of friction and anti-wear of these coatings could be improved especially at high temperatures by the formation of lubricant oxides of MoO3 and V2O5 [13]. Numerous metal oxide has also been used as wear-resistant coatings of various systems prepared by different methods such as PVD [14], electroexplosive spraying etc., [15,16,17]. Although the AlCrVN and AlCrMoN coatings have been widely investigated in term of the microstructure, hardness, and wear resistance, the cutting performance of the AlCrVN- and AlCrMoN-coated cutters, especially the high-speed steel (HSS) cutter such as gear hob, broach, and complex shaped tools, has not yet been concerned.

In this work, the AlCrXN (X = Mo or V) coatings were prepared by arc ion plating (AIP). The main objective of the present article is to explore the effects of self-lubricating elements such as Mo or V on the phase structures, mechanical properties, tribological behavior, and cutting performance of the AlCrXN coatings. Moreover, the wear mechanism of the AlCrXN-coated HSS cutters was also discussed in detail.

2. Materials and Methods

2.1. Deposition of Coating Technique

The AlCrN, AlCrMoN, and AlCrVN coatings were deposited on the polished cemented carbide (CC) substrate (15 mm × 15 mm × 4.5 mm) for the tribological test, high-speed steel substrates (HSS) (10 mm × 10 mm × 3 mm) for the examinations of SEM, XRD, XPS, and adhesion and hardness and M2 straight shank vertical milling cutters (with the diameter of 10 mm for cutting experiment) by using arc ion plating technique (Fade, Pro 1200, China). The used cemented carbides were WC-Co 8 at.%, and the chemical composition of used HSS substrates were C 0.85%, Cr 4%, Mo 5%, W 6%, V 2%. First, the substrates were polished to an average surface roughness of ~0.05 μm by using diamond paste and ultrasonically cleaned in a solution of acetone and ethanol for 30 min. The HSS end mills (diameter = 10 mm) were preferred for coated tools. In this work, three different types of target materials were used. One was AlCr alloy target (Al70Cr30 at.%, purity of 99.95%), and the others were CrV and CrMo alloy targets (Cr70V30 and Cr70Mo30 with the purity of 99.8%). The N2 environment was applied during deposition. The deposition process was incorporated with four steps: heating, glow discharging, ion etching, and deposition. Substrates were heated at 450 °C by using a radiant heater located inside the chamber. First, AlCrN coating was deposited on all substrates as adhesion layer and the thickness was about 800 nm, and Al70Cr30 target current was used at 120A. When depositing the AlCrVN coatings, both the Al70Cr30 and Cr70V30 targets were opened, and the currents of Al70Cr30 and Cr70V30 were 120 A and 130 A, respectively. Also for AlCrMoN coatings, both the Al70Cr30 and Cr70M30 targets were opened, and the currents of Al70Cr30 and Cr70M30 were 120 A and 130 A, respectively. The deposition parameters are also listed in Table 1.

Table 1.

Deposition parameters of the coatings by physical vapor deposition (PVD) process.

2.2. Coating Characterization Methods

The cross-sectional and surface morphology of AlCrN, AlCrVN, and AlCrMoN coatings were analyzed by using Phenom scanning electron microscopy (SEM JSM-6490LV, JEOL, Nieuw-Vennep, the Netherlands). Phase structures of coatings were characterized by X-ray diffractometer (Bruker D8 advance XRD, Karlsruhe, Germany). Binding energies of these coatings were observed by XPS (Thermo ESCALAB 250, Dreieich, Germany) with an Al-Kα (hv = 1486.6 eV) radiation source recorded at 150 W. Nano-indenter (Agilent Nano Indenter G200, Santa Clara, CA, USA) was used to examine the hardness (H) and elastic modulus (E) with an indentation depth of 400 nm and a maximum load of 500 mN. The duration is 10 s. For each sample, ten indentation tests were carried out for each coating to obtain the average value. Rockwell C indenter method was used to analyze the adhesion of the coatings, and the indention morphology was analyzed under Zeiss AxioLab.A1 microscopy (manufactured by Berlin, Germany). The coefficient of friction test was examined by (CSM HT-1000, Monroe, LA, USA), Al2O3 ball with a diameter of 6 mm was used for the friction test. The test was performed under 5 N of a load, 6 mm of diameter of wear tracks, 350 r/min of speed, 0.0732 m/s of sliding speed, room temperature (~25 °C), and 3600 s of total time. The wear rate was calculated by using the formula, , where L is the load (N), Wv is the wear volume (m3), S is the distance per circle, and d is the number of circles.

Milling test of HSS cutters was carried out by CNC (VMC-85 Hoton, Beijing, China) machine to examine the cutting performance with cutting edges. 20CrMo workpiece material with the hardness of 200 HB and M2 straight shank vertical milling cutters (Φ 10 mm) was used for cutting test. Two parameters were employed: (1) 60 m/min linear speed (Vc), 1910 rpm spindle speed, 0.2 mm/r of feed per tooth (fn), 2 mm axial depth (ae) and 2 mm axial depth (ap); (2) 94 m/min linear speed (Vc), a 3000 rpm spindle speed, 0.2 mm/r of feed per tooth (fn), 0.2 mm axial depth (ae) and 2 mm axial depth(ap). The wear standard VB was chosen as 0.15 mm for the cutting tools.

3. Results and Discussion

3.1. Cross-Sectional and Surface Morphologies

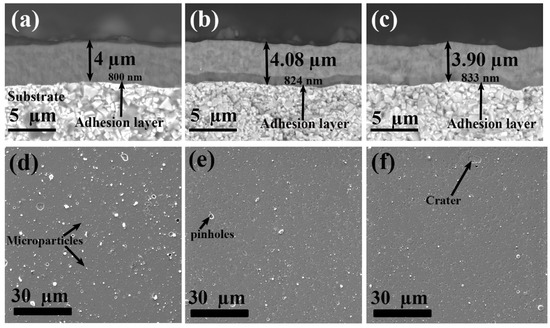

Figure 1a–c exhibited the cross-sectional images of AlCrN, AlCrMoN, and AlCrVN coatings. All these coatings were well adherent to the substrate with the dense and homogeneous structure. The AlCrN coating showed the thickness of 4.00 μm, while AlCrMoN and AlCrVN coatings showed the thickness of 4.08 μm and 3.96 μm, respectively. Also, AlCrN adhesion layer with a thickness of 800 nm was used to enhance the adhesion strength of the AlCrMoN and AlCrVN coatings as shown in Figure 1b,c. The surface morphologies of coatings were given in Figure 1d–f and all the coatings consisted of micro-particle and pinholes. It could be found that the surface of AlCrN coating (Figure 1d) contained more pinholes and micro-particles. However, the surface of AlCrVN coating (Figure 1f) was much smoother and exhibited smaller pinhole and micro-particles than other two coatings. The creation of micro-particle, pinhole, and craters on the coating surface was a typical characteristic by using arc ion plating (AIP) method, which could be explained in reference [18].

Figure 1.

Cross-sectional on coated cemented carbide (CC) substrates and surface morphology on the coated high-speed steel (HSS) substrates (a,d) AlCrN coating (b,e) AlCrMoN coating, and (c,f) AlCrVN coating.

3.2. Structure Analysis by XRD and XPS

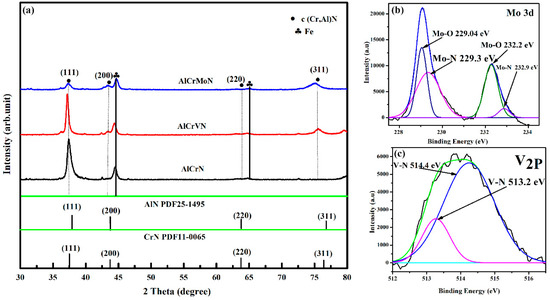

Typical X-ray diffraction (XRD) patterns of the as-deposited AlCrN, AlCrVN, and AlCrMoN coatings are given in Figure 2a. The results revealed that the fcc-(Cr, Al)N phase existed in the three coatings, in which the main phase were centered at the (111), (200), and (220) planes. The presence of the fcc-(Cr, Al)N solid-solution phase and shift of diffraction peaks toward a lower angle were due to that the smaller Cr atoms were substituted by larger Al atoms in the CrN lattice [19]. In this work, broadening peaks were also found in AlCrMoN coating. However, the VN and MoN phases were not detected from the XRD pattern [20,21]. XPS experiment was performed to examine the binding states of as-deposited coatings. From Figure 2b, it could be deduced that AlCrMoN coating was recognized to two binding states of Mo 3d5/2 (B.E = 229.04 eV, 232.2 eV) and Mo 3d3/2 (B.E = 229.9 eV, 232.3 eV), which corresponded to the Mo-N and Mo-O bonds [22]. For the AlCrVN, the V 2p spectrum was established two peaks at 514.4 eV and 513.2 eV (Figure 2c), which corresponded to the V 2p3/2 and V 2p1/2 energy levels of V-N binding as reported in reference [23].

Figure 2.

(a) X-ray diffraction (XRD) spectrum of the three coatings coated HSS substrates and XP-spectrum of (b) AlCrMoN coating coated HSS substrates, (c) AlCrVN coating coated HSS substrates.

3.3. Mechanical Property Analysis

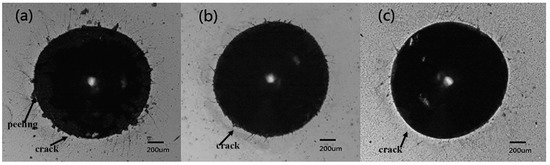

The adhesion of all deposited coatings was examined by using the Rockwell indentation test and the indentation morphologies are shown in Figure 3. The AlCrN coating exhibited some radial cracks and peels around the indentation (see in Figure 3a), which could be regarded as the grade of HF2 [24]. However, the AlCrVN and AlCrMoN coatings revealed no external cracks and delamination around the indentation and showed the better adhesion (Figure 3b,c), which could be classified as HF1 grade. Hardness (H) and elastic modulus (E) of the as-deposited coatings were examined by nano-indentation test, and the results are given in Table 2. The results indicated that the hardness and elastic modulus of AlCrMoN coating are 29 GPa and 400 GPa. However, the AlCrVN coating showed an increase in hardness and elastic modulus of 33 GPa and 446 GPa than the other two coatings. This increase in hardness might be attributed to the solid solution strengthening [25,26] caused by the solution of V in (Al, Cr)N that the formed lattice distortion restrained the mobility of the dislocations, resulting in the enhancement of hardness.

Figure 3.

Rockwell morphologies of the coatings on coated HSS substrates (a) AlCrN coating, (b) AlCrVN coating, and (c) AlCrMoN coating.

Table 2.

Adhesion, coefficient of friction, wear rate, hardness and elastic modules of the as-deposited coatings on HSS substrates.

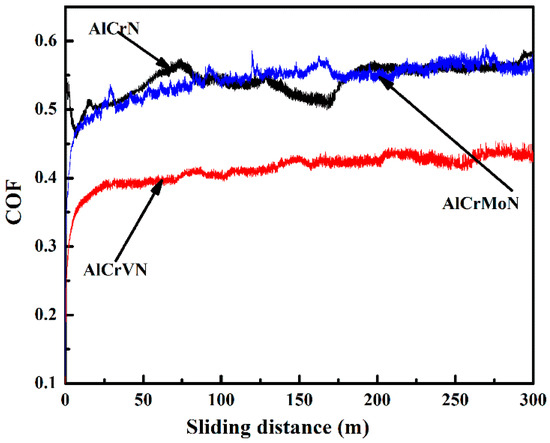

3.4. Tribological Property

Variation in coefficient of friction versus sliding distance of the as-deposited coatings is given in Figure 4 and all the curves exhibited the similar evolution trend. For the AlCrVN and AlCrMoN coatings, the coefficient of friction achieved a steady state with a slight fluctuation during the friction process. The average friction coefficients of AlCrN and AlCrMoN coatings are observed as 0.51 and 0.50, respectively. While the friction coefficient for AlCrVN coating decreased to 0.42, which was relatively lower than the other two coatings.

Figure 4.

Friction coefficients of the coatings on coated CC substrates.

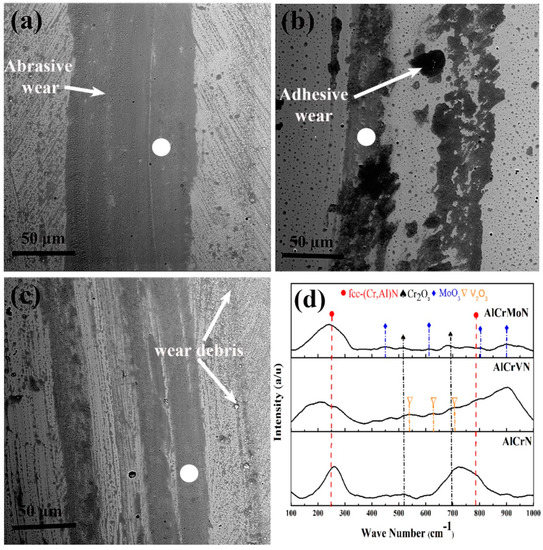

Worn surfaces of the coatings after wear test were analyzed by SEM and the results are presented in Figure 5. The worn tracks on AlCrVN and AlCrMoN coatings exhibit shallower grooves compared with the AlCrN coating (Figure 5b,c), which is due to the formation of Mo and V rich oxides (Magneli type oxides) [27]. From the previous reports [28], it was well established that Mo- and V-containing coatings usually could react with oxygen to form MoO3 and V2O5 phase during the friction process. The Raman spectroscopy (Figure 5d) on the worn tracks confirmed the formation of MoO3 and V2O5.

Figure 5.

Typical scanning electron microscopy (SEM) micrographs of worn track morphologies on coated CC substrates (a) AlCrN coating, (b) AlCrVN coating, (c) AlCrMoN coating, and (d) Raman spectroscopy on the worn track.

The specific wear rates of the all coatings are shown in Table 2. The AlCrVN coating showed the lowest wear rate (1.52 × 10−15 m3/(N·m) was due to the highest hardness and the formed lubricative oxides (VOx). Thus the high enough hardness of AlCrVN coating could effectively resist to the abrasive wear. Moreover, the AlCrMoN coating exhibited the higher wear rate of 2.42 × 10−15 m3/(N·m) than AlCrVN coating, although AlCrMoN coating possessed the lowest friction coefficient. The AlCrN coating possessed the highest friction coefficient and wear rate (3.60 × 10−15 m3/(N·m)) because of the lowest hardness among the other deposited coatings. As a result, the AlCrMoN and AlCrVN coatings showed the formation of thin tribo-films comprising lubricious phases such as VOx and MoOx oxides, which was probably responsible for the excellent friction and wear performance.

3.5. Cutting Performance of the Coated Cutters

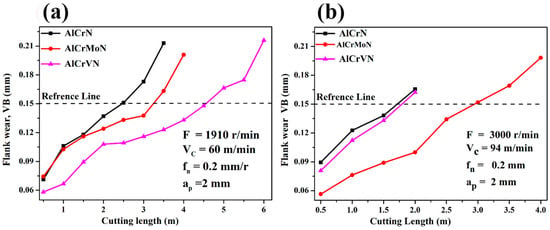

Figure 6a,b presented the cutting life curves of the AlCrN, AlCrMoN, and AlCrVN coatings under different cutting speeds. When the cutting speed was 60 m/min and the VB was set as 0.15 mm, the cutting length of the AlCrN coated end mill was 2.51 m as shown in Figure 6a. While the cutting length of AlCrMoN- and AlCrVN-coated tools were extended to 3.25 m and 4.58 m, respectively. When the cutting speed increased to 94 m/min (Figure 6b), the cutting lengths of the AlCrN and AlCrVN coated tools were significantly reduced to 1.71 m and 1.78 m (VB was 0.15 mm). However, the AlCrMoN-coated tools showed a slight decrease in cutting length of 2.97 m (VB = 0.15 mm). From the results of cutting life curves, it could be found that both the cutting length decreased with increasing the cutting speed. The higher cutting speed resulted in the increase of temperature, wear rate, and the reduction in cutting tool life [29,30]. It also could be found that the AlCrVN coating showed the higher cutting length at the low cutting speed, while the AlCrMoN coating showed the higher cutting length at the high cutting speed.

Figure 6.

Cutting life curves of the coated HSS straight shank end milling cutter under different speeds (a) 60 m/min and (b) 90 m/min.

Worn micrographs on flank surfaces of the coated straight shank end milling cutter under the cutting speed of 60 m/min were examined through the combination of SEM and EDS and the results are presented in Figure 7. It was clearly seen that the worn morphologies were composed of three different areas: peeled off area (substrate), worn area (coating delamination), and the partial worn area. According to the EDS results, the main elements in the coating peeled areas were Co, Fe, W, N, O, etc., which corresponded to the HSS tool. During the milling process, the abrasive wear occurred on the end mill flank surface was the typical characteristic of the wear between the workpiece and chip on the surface of the tool. In case of the AlCrN coated tool (Figure 7a,b), the sharp chipping edge and large peeled area on the surface edge were observed. However, the AlCrVN (Figure 7d,e) and AlCrMoN (Figure 7g,h) coated tools showed less peeled off area as compared with the AlCrN coating. That was due to the large hardness and adhesion, low COF and lubricant oxides formed on the surface, which was beneficial to remove the chips effectively and also reduced the abrasive and adhesive wear [31,32]. In Figure 7f,i, the main elements in delamination and partially worn coating area were Al, Cr, V, N and Al, Cr, Mo, N, which were related to the AlCrVN and AlCrMoN coatings, respectively, indicating that the coatings did not completely wear out.

Figure 7.

Worn micrographs on flank surfaces of the coated HSS straight shank end milling cutter under the 60 m/min speed: (a–c) AlCrN coating; (d–f) AlCrMoN coating; (g–i) AlCrVN coating.

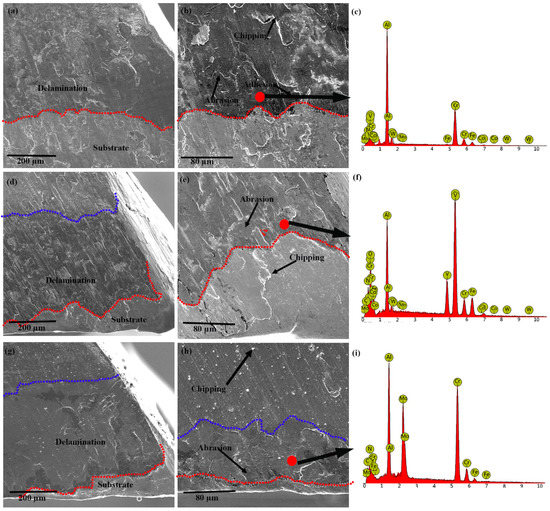

Similarly, the worn micrographs on flank surfaces of the coated straight shank end milling cutter under the speed of 94 m/min are also shown in Figure 8a–i. Generally, the wear between the cutting edge and work-piece becomes more serious at the higher and higher cutting speed. As a result, the cutting temperature increased in cutting zone which played a crucial role in failure of coated tools. From Figure 8, it was obvious that chipping area increased in all the coatings. The main failure mechanism of coated tools at the high cutting speed was the strong plastic deformation due to the large strain rates at the contact areas between the work-pieces and coated tools [32,33]. The decrease of cutting life of AlCrN (Figure 8a,b) and AlCrVN (Figure 8d,e) coated tools was due to the abrasive and adhesive wear which could be found on the worn flank face. However, the cutting life of the AlCrMoN coating decreased less than other two coatings, revealing that the Mo-based coatings showed comparatively much better potential at the high cutting speeds. This might be that the formed MoO3 oxides could provide stable lubricants at high temperatures as reported by Stone et al. [34]. From the cutting results, it could be concluded that abrasive wear, adhesive wear, and oxidation wear were the main wear mechanism for the coated tools. The addition of Mo and V improved the cutting performance of AlCrXN-coated tools as increasing the anti-wear ability because of the high hardness and the lubricant VOx and MoOx films.

Figure 8.

Worn micrographs on flank surfaces of the coated HSS straight shank end milling cutter under the 90 m/min speed: (a–c) AlCrN coating; (d–f) AlCrMoN coating; (g–i) AlCrVN coating.

4. Conclusions

In this study, the AlCrN and AlCrXN (X = Mo or V) coatings were deposited by multi arc-ion plating technology. Phase-structures, hardness, adhesion, tribological, and mechanical properties were investigated by XRD, XPS, ball-on-disc tribometer, and nano-indentation. The results showed that AlCrXN(X = Mo or V) coatings possessed the solid solution fcc-(Cr,cAl)N phase with orientations of (111), (200), (220), and (311). Both the AlCrMoN and AlCrVN coatings exhibited higher hardness and adhesive strength than the AlCrN coating. Addition of Mo or V also decreased the coefficient of friction (COF) and wear rate because of the formation of lubricative Mo or V containing oxides on the coating surfaces. Under the cutting speeds of 60 m/min and 94 m/min, the main wear mechanism for the coated tools were abrasive wear, adhesive wear, and oxidation wear. The addition of Mo or V improves the cutting performance and wear resistance of AlCrXN-coated tools due to higher hardness and the formation of lubricant VOx and MoOx films. Moreover, the MoO3 oxides could provide stable lubricants at high temperatures, which was further contributed to the cutting performance of the AlCrMoN-coated tool under the high cutting speed.

Author Contributions

Conceptualization, S.I. and F.C.; methodology, S.I.; data curation, S.I., J.W., J.Z., F.A. and J.L.; Writing—S.I.; Writing—review and editing, F.C.; Supervision, F.C. and S.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Science Foundation of Anhui Province, grant number 1808085QE131 and Key research and development plan of Anhui Province, grant number 1804b06020370.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jindal, P.; Santhanam, A.; Schleinkofer, U.; Shuster, A. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Berger, O. The correlation between structure, multifunctional properties and application of PVD MAX phase coatings. Part. III. Multifunctional applications. Surf. Eng. 2019, 36, 303–325. [Google Scholar] [CrossRef]

- Willmann, H.; Mayrhofer, P.; Hultman, L.; Mitterer, C. Thermal stability and age hardening of supersaturated AlCrN hard coatings. Int. Heat Treat. Surf. Eng. 2007, 1, 75–79. [Google Scholar] [CrossRef]

- Xiao, B.; Li, H.; Mei, H.; Dai, W.; Wu, Z.; Wang, Q.; Zuo, F. A study of oxidation behavior of AlTiN-and AlCrN-based multilayer coatings. Surf. Coat. Technol. 2018, 333, 229–237. [Google Scholar] [CrossRef]

- Chen, W.; Lin, Y.; Zheng, J.; Zhang, S.; Liu, S.; Kwon, S. Preparation and characterization of CrAlN/TiAlSiN nano-multilayers by cathodic vacuum arc. Surf. Coat. Technol. 2015, 265, 205–211. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhang, S.; Lee, J.-W.; Li, B.; Wang, Y.; Zhao, D. Self-lubricating CrAlN/VN multilayer coatings at room temperature. Appl. Surf. Sci. 2013, 279, 189–196. [Google Scholar] [CrossRef]

- Raab, R.; Koller, C.; Kolozsvári, S.; Ramm, J.; Mayrhofer, P. Interfaces in arc evaporated Al-Cr-N/Al-Cr-O multilayers and their impact on hardness. Surf. Coat. Technol. 2017, 324, 236–242. [Google Scholar] [CrossRef]

- Pogrebnyak, A.D.; Shpak, A.P.; Azarenkov, N.A.; Beresnev, V.M. Structures and properties of hard and superhard nanocomposite coatings. Uspekhi Fiz. Nauk 2009, 179, 35–64. [Google Scholar] [CrossRef]

- Kindlund, H.; SanGiovanni, D.; Martínez-De-Olcoz, L.; Lu, J.; Jensen, J.; Birch, J.; Petrov, I.; Greene, J.E.; Chirita, V.; Hultman, L. Toughness enhancement in hard ceramic thin films by alloy design. APL Mater. 2013, 1, 042104. [Google Scholar] [CrossRef]

- Yousaf, M.; Pelenovich, V.; Yang, B.; Liu, C.; Zou, C. Influence of substrate rotation speed on the structure and mechanical properties of nanocrystalline AlTiN/MoN coatings synthesized by cathodic arc ion-plating. Surf. Coat. Technol. 2015, 265, 117–124. [Google Scholar] [CrossRef]

- Lisovenko, M.; Bondar, O.; Opielak, M.; Beresnev, V.; Konarski, P.; Sakenova, R.; Konstantinov, S.; Komarov, F.F. Structure and properties of nanoscale MoN/CrN multilayered coatings. In Proceedings of the 2017 IEEE 7th International Conference Nanomaterials: Application & Properties (NAP), Odesa, Ukraine, 10–15 September 2017. [Google Scholar]

- Han, B.; Wang, Z.; Devi, N.; Kondamareddy, K.K.; Wang, Z.; Li, N.; Zuo, W.; Zou, C.; Liu, C. RBS Depth Profiling Analysis of (Ti, Al)N/MoN and CrN/MoN Multilayers. Nanoscale Res. Lett. 2017, 12, 161. [Google Scholar] [CrossRef] [PubMed]

- Ju, H. High-Temperature Self-Lubricating Metal Nitride-Based Nanostructure Composite Films. In Friction, Lubrication and Wear; IntechOpen: London, UK, 2019. [Google Scholar]

- Pradhan, S.; Nouveau, C.; Vasin, A.; Djouadi, M.-A. Deposition of CrN coatings by PVD methods for mechanical application. Surf. Coat. Technol. 2005, 200, 141–145. [Google Scholar] [CrossRef]

- Romanov, D.; Moskovskii, S.; Konovalov, S.; Sosnin, K.; Gromov, V.; Ivanov, Y. Improvement of copper alloy properties in electro-explosive spraying of ZnO-Ag coatings resistant to electrical erosion. J. Mater. Res. Technol. 2019, 8, 5515–5523. [Google Scholar] [CrossRef]

- Romanov, D.; Moskovskii, S.; Martusevich, E.; Gayevoy, E.; Gromov, V. Structural-phase state of the system “CdO-Ag coating/copper substrate” formed by electroexplosive method. Metalurgija 2018, 57, 299–302. [Google Scholar]

- Romanov, D.; Gromov, V.; Glezer, A.; Panin, S.; Semin, A. Structure of electro-explosion resistant coatings consisting of immiscible components. Mater. Lett. 2017, 188, 25–28. [Google Scholar] [CrossRef]

- Jokar, K.; Elmkhah, H.; Fattah-Alhosseini, A.; Babaei, K.; Azolriasatein, A. Comparison of the wear and corrosion behavior between CrN and AlCrN coatings deposited by Arc-PVD method. Mater. Res. Express 2019, 6, 116426. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, W.; Chen, W.; Yang, S. Structural optimisation and synthesis of multilayers and nanocomposite AlCrTiSiN coatings for excellent machinability. Surf. Coat. Technol. 2015, 277, 23–29. [Google Scholar] [CrossRef]

- Yoon, C.S.; Kim, K.H.; Kwon, S.H.; Park, I.W. Syntheses and Properties of Cr-Al-Mo-N Coatings Fabricated by Using a Hybrid Coating System. J. Korean Phys. Soc. 2009, 54, 1237–1241. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, J.-W.; Duh, J.-G. Mechanical strengthening in self-lubricating CrAlN/VN multilayer coatings for improved high-temperature tribological characteristics. Surf. Coat. Technol. 2016, 303, 12–17. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, G.; Xu, X.; Yang, G.; Liu, M.; Shao, Z. Enhancing electrocatalytic activity for hydrogen evolution by strongly coupled molybdenum Nitride@Nitrogen-Doped carbon porous nano-octahedrons. ACS Catal. 2017, 7, 3540–3547. [Google Scholar] [CrossRef]

- Achour, A.; Islam, M.; Ahmad, I.; Saeed, K.; Solaymani, S. Electrochemical stability enhancement in reactive magnetron sputtered VN films upon annealing treatment. Coatings 2019, 9, 72. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, G.-J.; Jiang, B. Comparison in mechanical and tribological properties of CrTiAlMoN and CrTiAlN nano-multilayer coatings deposited by magnetron sputtering. Appl. Surf. Sci. 2016, 363, 217–224. [Google Scholar] [CrossRef]

- Endrino, J.; Derflinger, V. The influence of alloying elements on the phase stability and mechanical properties of AlCrN coatings. Surf. Coat. Technol. 2005, 200, 988–992. [Google Scholar] [CrossRef]

- Li, Z.; Raabe, D. Strong and ductile non-equiatomic high-entropy alloys: Design, processing, microstructure, and mechanical properties. JOM 2017, 69, 2099–2106. [Google Scholar] [CrossRef] [PubMed]

- Fateh, N.; Fontalvo, G.A.; Gassner, G.; Mitterer, C. The beneficial effect of high-temperature oxidation on the tribological behaviour of V and VN coatings. Tribol. Lett. 2007, 28, 1–7. [Google Scholar] [CrossRef]

- Mei, H.; Zhao, S.; Wu, Z.; Dai, W.; Wang, Q. Effect of nitrogen partial pressure on microstructure and mechanical properties of Mo-Cu-V-N composite coatings deposited by HIPIMS. Surf. Coat. Technol. 2017, 329, 68–76. [Google Scholar] [CrossRef]

- Chen, R. Principle of Metal Cutting; China Machine: Beijing, China, 1992. [Google Scholar]

- Fu, Y.; Li, H.; Ji, L.; Liu, X.; He, N.; Zhou, H.; Chen, J. Preparation and high-temperature tribological properties of CrAlVYN-Ag nanocomposite coatings. Mater. Manuf. Process. 2016, 32, 409–415. [Google Scholar] [CrossRef]

- Olovsjö, S.; Wretland, A.; Sjöberg, G. The effect of grain size and hardness of wrought Alloy 718 on the wear of cemented carbide tools. Wear 2010, 268, 1045–1052. [Google Scholar] [CrossRef]

- Li, A.; Zhao, J.; Hou, G. Effect of cutting speed on chip formation and wear mechanisms of coated carbide tools when ultra-high-speed face milling titanium alloy Ti-6Al-4V. Adv. Mech. Eng. 2017, 9, 1687814017713704. [Google Scholar] [CrossRef]

- Yue, Q.-B.; He, H.-B.; Li, H.-Y.; Zhang, J.; Li, Y.-M.; Ma, L. Research on friction characteristics of AlCrN and TiAlSiN coatings and properties of coated tools. Int. J. Precis. Eng. Manuf. 2019, 20, 1581–1589. [Google Scholar] [CrossRef]

- Stone, D.; Liu, J.; Singh, D.; Muratore, C.; Voevodin, A.A.; Mishra, S.; Rebholz, C.; Ge, Q.; Aouadi, S. Layered atomic structures of double oxides for low shear strength at high temperatures. Scr. Mater. 2010, 62, 735–738. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).