Abstract

Graphene oxide–titanium (GO-Ti) composite materials were fabricated using GO as a precursor and then anchoring nano titanium (Nano-Ti) particles on GO sheets with the help of a silane coupling agent. Then, the coating samples were prepared by dispersing GO, Nano-Ti particles, and GO-Ti in an epoxy resin at a low weight fraction of 1 wt %. The GO-Ti composites were investigated by X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and transmission electron microscopy (TEM). The dispersibility and anti-corrosion mechanism of the coatings were studied by sedimentation experiments, electrochemical impedance spectroscopy (EIS), SEM, and salt spray tests. The mechanical properties of the coatings were analyzed by friction and wear tests. The results showed that the Nano-Ti particles were successfully loaded on the GO surface by chemical bonds, which made GO-Ti composites exhibit better dispersibility in the epoxy than GO. Compared with Nano-Ti particles and GO, the GO-Ti composite exhibited significant advantages in improving the corrosion resistance of epoxy coatings at the same contents, which was attributed to the excellent dispersibility, inherent corrosion resistance, and sheet structure. Among the different proportions of composite materials, the GO-Ti (2:1) material exhibited the best dispersibility and corrosion resistance. In addition, the composite material also greatly improved the wear resistance of the coating.

1. Introduction

Metal corrosion has become a very serious problem, which also causes enormous losses to human society. According to statistics, the annual metal equipment and materials scrapped by corrosion in the world are equivalent to 10% of the annual metal production [1,2]. Among various metal anti-corrosion methods, organic coating is one of the most economical, effective, and common methods [3]. Epoxy resin (EP) is widely used in organic anti-corrosive coatings due to its good corrosion resistance, strong adhesion to metal substrate, and low cost [4,5]. However, epoxy resin has a high brittle character, which usually results in cracks on the coating surface [6,7]. In addition, during the curing process of the resin, the volatilization of the diluent leads to the appearance of micropores in the resin, which further leads to the deterioration of the shielding performance and the anti-corrosion performance of the resin.

As a sheet structural material, graphene has the advantages of high specific surface area, excellent barrier properties, high chemical stability, and good electrical conductivity, which can significantly improve the comprehensive performance of anti-corrosive coatings [8,9,10]. However, the researchers have found that the high conductivity of graphene exacerbates the electrochemical corrosion rate of metal surfaces, resulting in more severe corrosion [11,12,13]. Similar to graphene, graphene oxide (GO) has a sheet-like structure, which is one of the most important graphene derivatives. The surface of GO contains a large number of reactive functional groups (carboxyl groups, hydroxyl groups, and epoxy groups). These functional groups make GO particularly easy to be modified, and they can form a composite with other polymers firmly by the action of some functional groups [8]. However, due to the strong van der Waals force and π–π effect between the sheets, GO tends to exhibit a strong polymerization tendency, which is very detrimental to the dispersion of GO in the coating [14]. Therefore, how to achieve a good dispersion of GO in the polymer is the key to the practical application of GO in the anti-corrosion field.

Nanoparticles have been widely used as resin fillers to block micropores and improve the corrosion resistance and mechanical properties of the resins due to the special characteristics such as small size effect and surface effect [15,16]. The researchers have found that loading inorganic nanoparticles on the surface of GO is a way to effectively increase the dispersion of GO sheets and reduce aggregation [17,18,19,20]. Titanium (Ti) has some excellent characteristics, such as non-toxicity, low density, high strength, and extremely strong corrosion resistance, which has attracted great attention in the coating field [21]. Nano-Ti particles can improve the anti-corrosion performance of the coating as a filler, which has been widely verified by experiments [22,23]. It is of great interest to explore the uniform loading of Nano-Ti particles on the surface of GO to improve its dispersion properties, so as to develop a new nano GO-Ti composite that combines the superior properties of both nanosheet materials and nanoparticles.

Therefore, in this study, GO and Nano-Ti particles were respectively modified by a chemical modification method to obtain functionalized graphene oxide (f-GO) and functionalized Nano-Ti particles (f-Ti). Then, a nano GO-Ti composite material with excellent dispersibility was prepared, which was finally added to the epoxy resin to improve the corrosion resistance. The experimental results show that the GO-Ti composite material can effectively improve the corrosion resistance and wear resistance of the coating, which is due to the sheet structure, excellent mechanical properties, and lubrication and cross-linking buffering function. Therefore, the GO-Ti/EP coating is suitable for environments that require both corrosion protection and wear resistance, such as coal conveying equipment. Consequently, this study is of great significance for the practical application of GO in the field of anti-corrosion.

2. Experimental

2.1. Materials

Expanded graphite, 98% concentrated sulfuric acid (H2SO4), potassium permanganate (KMnO4), sodium nitrate (NaNO3), 30% hydrogen peroxide (H2O2), N, N-dimethylformamide (DMF), absolute ethanol (analytical grade), 37% hydrochloric acid (HCl), sodium chloride (NaCl), 3-aminopropyltriethoxysilane (APTES), and 3-glycidoxypropyltrimethoxysilane (GPTMS) were purchased from Sinopharm Chemical Reagent Co., Ltd., China (Shanghai, China). Nano-Ti particles (60 nm) were purchased from Aladdin Reagent (China) Co., Ltd., (Shanghai, China) Epoxy resin (CYD 014) and its hardener (P54) were supplied by Baling Chemical (China) Co., (Yueyang, China) Q235 steel sheets were purchased from Biuged in Guangzhou Province, (China) Co., (Guangzhou, China).

2.2. Preparation of GO

GO was synthesized using the Hummers method [24]. Firstly, 1 g of expanded graphite was added to 30 mL of 98% H2SO4 in an ice bath environment. Thereafter, 1 g of NaNO3, and 6 g of KMnO4 were added under magnetic stirring. After 1 h of reaction, the mixture was stirred at 38 °C for 2 h in an oil bath environment. After that, 46 mL of deionized water was slowly added to the mixture at 98 °C. After stirring for 1.5 h, 100 g of a 10% H2O2 solution was slowly added to the mixed solution, followed by washing several times with a 37% aqueous HCl solution and deionized water. Finally, the resulting solid was obtained by drying in a vacuum oven at 60 °C for 24 h and grinding.

2.3. Preparation of f-GO and f-Ti

First, 0.15 g of GO and 3 g of GPTMS were added to 135 g of absolute ethanol, followed by ultrasonic dispersion for 30 min. After that, the mixture was magnetically stirred at 80 °C for 4 h, and 12 g of deionized water was slowly added dropwise during the reaction. Then, the mixture was suction filtered and washed repeatedly five times with ethanol and deionized water. Finally, the reaction product was dried in a vacuum at 60 °C for 24 h, followed by grinding to obtain f-GO. The method for the synthesis of f-Ti was similar to the method for preparing f-GO except that the coupling agent used was APTES.

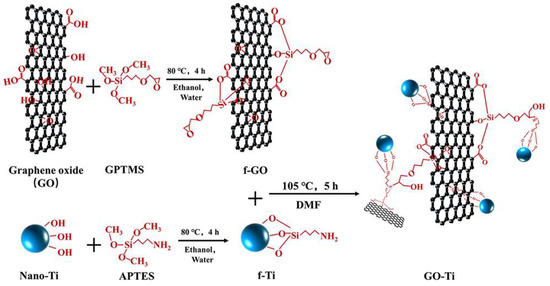

2.4. Preparation of GO-Ti

GO-Ti composites with different material weight proportions (GO:Ti = 1:1, 2:1, and 3:1) were prepared. Taking GO:Ti = 3:1 as an example, 0.15 g of f-GO was dispersed in 75 mL of DMF solution and ultrasonically dispersed for 30 min; then 0.05 g f-Ti was added, and it was ultrasonically dispersed for 30 min. After that, the mixture was reacted in an oil bath at 105 °C for 5 h, and then washed repeatedly five times with ethanol and deionized water. Finally, the GO-Ti composites were obtained after drying the reaction products under 60 °C for 24 h and grinding. The synthesis procedure for GO-Ti composites is illustrated in Figure 1.

Figure 1.

Synthesis procedure for graphene oxide–titanium (GO-Ti) composites.

2.5. Preparation of GO/EP, Ti/EP, and GO-Ti /EP Composite Coatings

GO, Nano-Ti particles, and GO-Ti composites with different proportions were respectively added to the epoxy resin in an amount of 1 wt %, mechanically stirred for 24 h, and then ultrasonically dispersed for 0.5 h to prepare the composite coatings. Afterwards, the above coatings were thoroughly mixed with a certain proportion of curing agent. In order to make the viscosity of coatings suitable for spraying, an appropriate amount of thinner was added to the coatings. A Q235 steel substrate was mechanically polished by sand papers of 400, 800, and 1200 grades. The coatings were uniformly sprayed on the surface of the steel plate, cured at room temperature for 24 h, and then baked at 80 °C for 1 h to obtain the composite coatings of GO/EP, Ti/EP, and GO-Ti/EP layer samples. A pure resin coating was also prepared by the above method as a comparative example. For the accuracy of the subsequent experiments, the film thickness was measured on the composite coating samples using a film thickness meter, and the coating samples with 110 μm thickness were selected for subsequent testing.

2.6. Measurements

Infrared spectra tests of f-GO, f-Ti, and GO-Ti in the region of 4000–500 cm−1 were recorded by an Fourier transform infrared spectroscopy (FTIR) spectrometer (IR Nicolet 6700, Shimadzu, Kyoto, Japan). The GO-Ti composites were tested by X-ray photoelectron spectroscopy (ESCALAB250XI, Thermo Fisher Scientific, Waltham, USA) with an Al Ka X-ray source. Moreover, SEM (6700F, JEOL, Tokyo, Japan), TEM (TECNAI F20, FEI, Hillsboro, USA), and XRD (RigakuUltima IV, Tokyo, Japan) were employed to characterize the physical structure and morphology of the GO-Ti composites and composite coatings.

Electrochemical impedance spectroscopy (EIS) was measured at the German electrochemical workstation Zahner to study the electrochemical performance and corrosion resistance of different coatings (EP, GO/EP, Ti/EP, GO-Ti(1:1)/EP, GO-Ti(2:1)/EP, and GO-Ti(3:1)/EP). The mixture was performed using a three-electrode system in a 3.5 wt % NaCl solution. The steel plates coated with different coatings were used as the working electrode with a test area of 1.5 cm2. A saturated calomel electrode (SCE) was used as a reference electrode, and platinum electrode was used as an auxiliary electrode. The frequency range of electrochemical impedance experiment was 105–10−2 Hz, and the amplitude of the sinusoidal disturbance signal was 20 mV. Before the test, the samples were immersed in a 3.5 wt % NaCl solution for 2 h to obtain a stable open circuit voltage. The experimental data were analyzed by ZSimpWin (Version 3.60).

The salt spray test (BGD 881, BIUGED, China) was carried out in 5 wt % NaCl solution to further explore the corrosion resistance of different coatings. In addition, a sedimentation experiment was conducted to investigate the dispersibility of the composites.

The friction and wear tests (HSR-2M, Lanzhou Zhongke Kaihua, Lanzhou, China) were used to investigate the effect of composites on the mechanical properties of coatings. The friction coefficient was measured under a sliding velocity of 1 Hz, a load of 2 N with a test duration of 1200 s, and a wear track length of 5 mm. The friction pair was 316 L steel balls.

3. Results and Discussions

3.1. Structure and Morphology of GO-Ti Composites

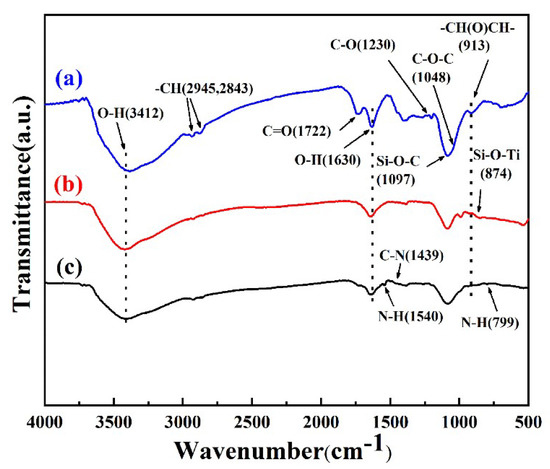

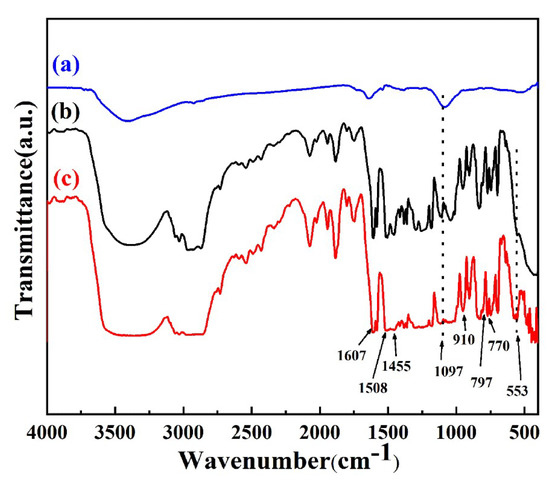

FTIR analysis is performed to investigate the bonding between Nano-Ti particles and GO. Figure 2 shows the infrared spectra of f-GO, f-Ti, and GO-Ti. There is a broad and intense peak centered at 3412 cm−1, which is due to the stretching vibration of O-H. The peaks at 2945 and 2843 cm−1 are the characteristic absorption peaks of the –CH bond, and the peaks at 1097 and 874 cm−1 are the characteristic absorption peaks of Si–O–C and Si–O–Ti, respectively [20,25], which indicates that GPTMS and APTES have successfully functionalized GO and Nano-Ti particles, respectively. The O-H bending peak at 1630 cm−1 is attributed to the deformation vibration of the water, indicating that GO, f-Ti, and GO-Ti contain a small amount of adsorbed water [26,27]. The characteristic absorption peaks at 1722, 1230, 1048, and 913 cm−1 belong to C=O, C–O, C–O–C, and –CH(O)CH–, respectively [20,28,29], indicating the presence of a large number of oxygen-containing groups on the surface of f-GO. In the infrared spectra of GO-Ti, new peaks appear at 1540, 799, and 1439 cm−1, corresponding to the secondary amide N–H– bending, N-H rocking, and C–N stretching [30], respectively, and the –CH(O)CH– absorption peak at 913 cm−1 disappears, which proves that the epoxy group of f-GO reacts with the amino group of f-Ti [31]. This conclusion is further proved in the subsequent XPS test.

Figure 2.

Fourier transform infrared spectroscopy (FTIR) spectra of (a) functionalized graphene oxide (f-GO), (b) functionalized Nano-Ti particles (f-Ti), and (c) GO-Ti composites.

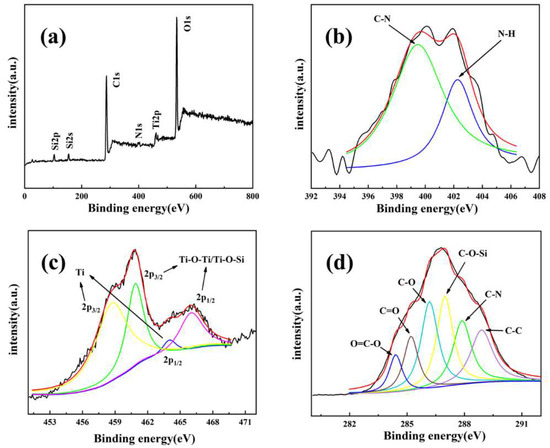

The chemical bonds and elemental composition of GO-Ti composites are further studied by XPS. Figure 3a shows the XPS measurement of GO-Ti. The Si and N elements are derived from GPTMS and APTES, which preliminarily indicates that GO and Nano-Ti particles have been covalently functionalized by silane coupling agents. Figure 3b shows that the high-resolution XPS spectra of the N 1s region of GO-Ti. The N 1s spectrum is separated into N-H (402.2 eV) and C-N (399.5 eV) [17], which can prove that the epoxy group of f-GO reacts with the amino group of f-Ti. Figure 3c shows the high-resolution XPS spectra of the Ti 2p region of GO-Ti. The Ti2p spectrum is related to Ti–O–Ti/Ti–O–Si (460.8 eV and 466.5 eV) and Ti (458.7 eV and 464 eV). From Figure 3d, it can be seen that the C 1s signals are fitted into six peaks of C–C (284.4 eV), C–N (285.2 eV), C–O–Si (286.2 eV), C–O (286.9 eV), C=O (287.9 eV), and O=C–O (288.9 eV). Based on the results of FTIR and XPS, it can be inferred that there is a covalent bond between f-Ti and f-GO.

Figure 3.

XPS spectra of GO-Ti: (a) Survey spectrum, (b) High-resolution spectra of N 1s, (c) High-resolution spectra of Ti 2p, (d) High-resolution spectra of C 1s.

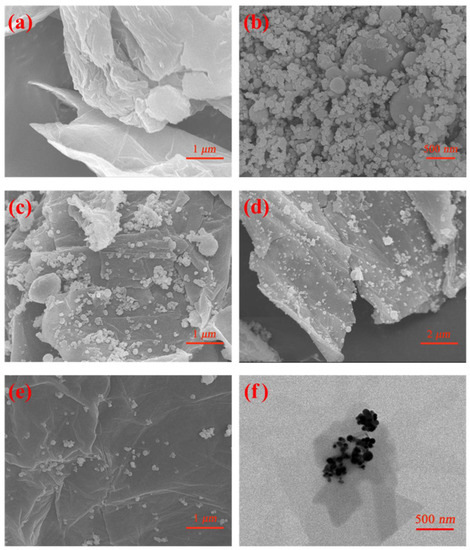

Figure 4a–e shows the SEM images of GO, Nano-Ti particles, and GO-Ti composites with different weight proportions of 1:1, 2:1, and 3:1. Figure 4f shows TEM images of GO-Ti (2:1). The wrinkles and folds of GO can be clearly seen from Figure 4a, which are the characteristics of GO [28]. In addition, a large number of GO sheets are gathered together due to the effect of van der Waals forces, which makes it difficult to disperse GO in the polymer. In Figure 4b, Nano-Ti particles present a state of severe aggregation. As shown in Figure 4c–e, different amounts of Nano-Ti particles are loaded on the surface of GO after the composite reaction, and the aggregation of GO and Nano-Ti particles is obviously reduced in the composite nanosheets. At the same time, the sheet structure of GO is not destroyed, which is critical to the anti-penetration ability. It is worth noting that the dispersity of Nano-Ti particles on the surface of GO is related to the composite proportions of Nano-Ti particles and GO. As shown in Figure 4c, the aggregation of Nano-Ti particles in the GO-Ti (1:1) is the most serious, which may be due to the high proportion of Nano-Ti particles to GO. In the GO-Ti (2:1) shown in Figure 4d,f, it can be seen that the Nano-Ti particles are uniformly distributed on the GO surface. In the GO-Ti (3:1) shown in Figure 4e, the Nano-Ti particles on the surface of GO are too rare, which may be due to the insufficient reaction amount of the Nano-Ti particles. Therefore, it can be inferred that when the proportion of GO-Ti is 2:1, the sheets of composite will be dispersed to the greatest extent, which will further lead to better dispersion of the composite in epoxy resin. This inference is further confirmed by XRD and settlement experiments.

Figure 4.

SEM images of (a) GO, (b) Nano-Ti particles, (c) GO-Ti(1:1), (d) GO-Ti(2:1), and (e) GO-Ti(3:1) composites. TEM image of (f) GO-Ti(2:1) composite.

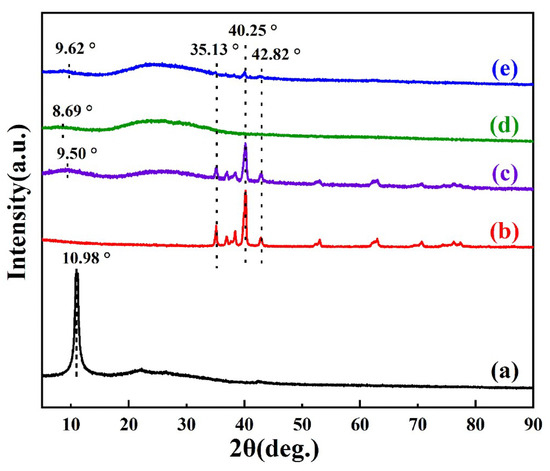

XRD is employed to obtain the detailed structural information of GO and GO-Ti composites. As shown in Figure 5, the characteristic diffraction peak of GO is at 10.98°, which corresponds to the (002) plane [32]. The diffraction peaks of 35.13°, 40.25°, and 42.82° are the characteristic peaks of Ti, corresponding to the (100), (002), and (101) planes, respectively [33]. It can be clearly seen that the characteristic peaks of Ti are still observed in the pattern of GO-Ti composite material, which indicates that the Nano-Ti particles have been successfully anchored on the GO surface. The position of the diffraction peak of Ti has not changed, but the intensity of the diffraction peak is significantly reduced, indicating that the crystallinity of the Ti powder in the composite is reduced. In addition, the characteristic peak of GO in the composite material is significantly weakened and shifted to the left by varying degrees.

Figure 5.

XRD pattern of (a) GO, (b) Ti, (c) GO-Ti (1:1), (d) GO-Ti (2:1), and (e) GO-Ti (3:1) composites.

According to Bragg’s law:

where n is the diffraction hierarchy, λ is the represent X-ray wavelength, d is the d-spacing, and θ is the diffraction angle. According to the calculation, the d-spacing of the GO nanosheet is 0.81 nm. In contrast, the d-spacing of the GO-Ti(1:1), GO-Ti(2:1), and GO-Ti(3:1) composites increase to 0.93, 1.02, and 0.92 nm, respectively, which indicates that the load f-Ti on GO sheets changes the structure of GO, making the GO change from multilamellar accumulation to a loose structure. By combining the results of FTIR, XPS, SEM, and XRD analysis, it can be confirmed that Nano-Ti particles are successfully loaded on the GO surfaces, and GO-Ti composites are successfully prepared.

nλ = 2dsinθ

3.2. The Properties of GO-Ti/EP Composite Coatings

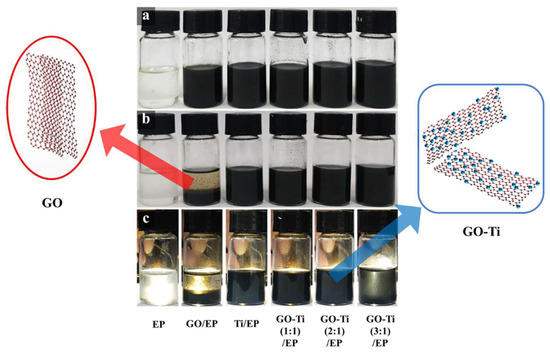

The dispersion of GO, Nano-Ti particles, and GO-Ti composites in epoxy resin is investigated by sedimentation experiments. Figure 6 shows the sedimentation experiment images of GO/EP, Ti/EP, GO-Ti (1:1)/EP, GO-Ti (2:1)/EP, and GO-Ti (3:1)/EP. On the 14th day of the sedimentation experiment, it is found that GO/EP completely settles. This is mainly due to the high van der Waals force between GO sheets which causes GO to aggregate and settle, and ultimately results in poor dispersion of GO in epoxy resin. On the other hand, several composite coatings (GO-Ti(1:1)/EP, GO-Ti(2:1)/EP, and GO-Ti(3:1)/EP) still exhibit excellent dispersion, which indicates that the loading of Nano-Ti particles on the GO sheets reduces the van der Waals force. After 70 days of experimentation, it is observed under the illumination that the composite coatings still have no sedimentation phenomenon except for GO-Ti(3:1)/EP. This is because the content of Nano-Ti particles is too low to effectively disperse the GO sheets. These results are also consistent with the observations of XRD and SEM.

Figure 6.

Settlement experiment of different composite coatings at different times: (a) 0 days, (b) 14 days, and (c) 70 days.

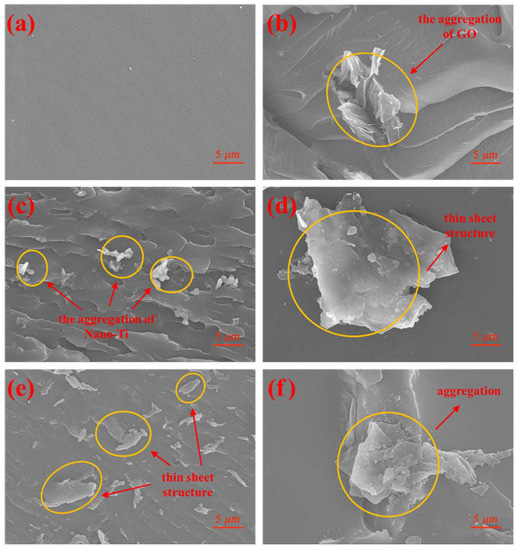

Scanning electron microscope is used to further investigate the dispersibility and state of GO, Ti, and GO-Ti in epoxy resin. Figure 7a–f display the fracture morphology of EP, GO/EP, Ti/EP, GO-Ti(1:1)/EP, GO-Ti(2:1)/EP, and GO-Ti(3:1)/EP, respectively. According to Figure 7a, the fracture surface of EP shows very smooth characteristics. After dispersing different nanofillers in the epoxy resin, the morphology of the epoxy resin has changed greatly. It can be clearly seen in Figure 7b that the GO sheet layers severely aggregate in the resin, indicating that a strong van der Waals force prevents the GO from being sufficiently dispersed in the resin. Similarly, for the Nano-Ti in Figure 7c, aggregation is also the biggest resistance to its dispersion. In Figure 7c,d, it is worth noting that after dispersing GO-Ti(1:1) and GO-Ti(2:1) in the epoxy resin, the GO-Ti composites still maintain the thin sheet structure, showing their excellent dispersibility. In contrast, GO-Ti(3:1) still clusters in the epoxy resin and shows poor dispersion, which is consistent with the results obtained in the settlement experiment. From the results, the composite process improves the dispersibility of GO-Ti in epoxy resin at the appropriate composite ratio. The dispersibility is closely related to the anticorrosive performance, which can be verified in subsequent experiments.

Figure 7.

Fracture surface of (a) epoxy resin (EP), (b) GO/EP, (c) Ti/EP, (d) GO-Ti (1:1)/EP, (e) GO-Ti (2:1)/EP, and (f) GO-Ti (3:1)/EP.

FTIR analysis is performed to further investigate the state of the GO-Ti composite in the coating. Figure 8 shows the infrared spectra of the GO-Ti composite, EP, and GO-Ti/EP coating. As shown in Figure 8, epoxy resins contain a large number of functional groups, such as aromatic rings vibration (1607, 1508, and 1455 cm−1) and epoxy group stretch (910, 797, and 770 cm−1) [34]. It is worth noting that after the addition of composite materials, the new peaks appear at 1097 and 553 cm−1, which correspond to Si–O–C and Ti–O–Ti bonds, respectively. These peaks come from the GO-Ti composite. Combining with the results of fracture surface SEM, it can be concluded that the structure of the composite is not damaged.

Figure 8.

FTIR spectra of (a) GO-Ti composite, (b) EP, and (c) GO-Ti/EP coating.

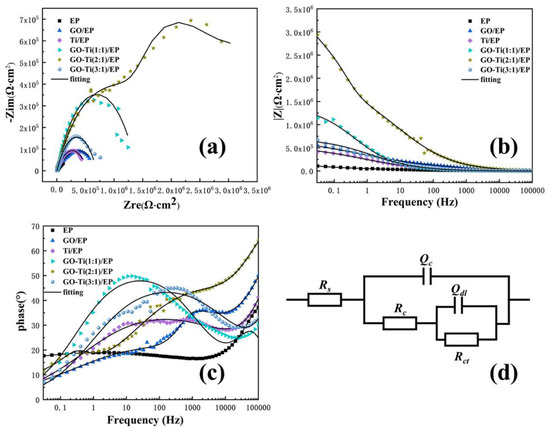

Electrochemical impedance spectroscopy is used to analyze the corrosion resistance of coatings. Figure 9a shows Nyquist plots of different coatings at different times, while Figure 9b,c display Bode plots. Generally, the corrosion of the coating process of the coating is divided into several periods. In the early corrosion solution, the solution penetrates into the interior of the coating through the surface micropores. With the increase of immersion time, the corrosion enters the mid-period, as indicated by the characteristics of two-time constant in the impedance spectrum [35,36]; meanwhile, the solution penetrates and diffuses into the interface between the coating and the substrate, but the coating still has a protective effect. The corrosion process will enter the next period in a very short time and exhibit low impedance due to the poor anti-corrosion performance. Therefore, the corrosion resistance of the coating can be discriminated by the corrosion period transition time. In order to investigate the corrosion period of anti-corrosion coating, the impedance spectrum data is fitted by ZSimpWin software. Figure 9d shows the equivalent circuit diagram. In the figure, Rs is the solution resistance, Qc is the coating capacitance, Rc is the coating resistance, Qdl is the double-layer capacitance, and Rct is the electron transfer resistance. The electrochemical parameters are given in Table 1.

Figure 9.

(a) Nyquist plots of coatings, (b,c) Bodes plots of coatings after soaking for 72 h (EP, Ti/EP), 96 h (GO/EP), 120 h (GO-Ti(1:1)/EP, GO-Ti (3:1)/EP) and 192 h (GO-Ti(2:1)/EP) and (d) The equivalent circuit model used for fitting the EIS measurements.

Table 1.

The electrochemical parameters extracted from electrochemical impedance spectroscopy (EIS) data of the EP, GO/EP, Ti/EP, and GO from Table 1. GO-Ti(3:1)/EP and GO-Ti(2:1)/EP samples immersed in 3.5 wt % NaCl solution for different times.

As illustrated in Figure 9a, the order of impedance arc radius for different coatings is GO-Ti(2:1)/EP>GO-Ti(1:1)/EP>GO-Ti(3:1)/EP>GO/EP>Ti/EP>EP. The size of the radius determines the size of impedance, so the GO-Ti(2:1) /EP coating has the highest impedance. As shown in Figure 9b,c, EP and Ti/EP coatings are in the mid-period of corrosion after 72 h of immersion. Due to the good corrosion resistance of Ti, the low-frequency impedance modulus value (|Z|0.01Hz) of Ti/EP is higher than that of EP. After 96 h, the GO/EP coating is in the mid-period of corrosion, and the |Z|0.01Hz increases slightly compared to the former, which is due to the sheet structure of GO effectively blocking the coating of micropores. After 120 h, GO-Ti(1:1)/EP and GO-Ti(3:1)/EP coatings are in the middle of corrosion, and the |Z|0.01Hz has a great improvement compared with the EP and Ti/EP coatings. After 192 h, the GO-Ti(2:1)/EP coating is still in the middle of corrosion, and it presents the largest |Z|0.01Hz, which is 26.5 times that of the EP coating and 5.4 times that of the GO/EP coating. This is because the composite material has a sheet-like structure, which has the inherent corrosion resistance of GO and Ti, as well as excellent dispersibility, thereby improving the efficiency of the corrosion resistant medium, and finally improving the corrosion resistance of the epoxy resin coating. According to Table 1, the Rc values of coatings with GO-Ti are higher than those without GO-Ti, and GO-Ti(2:1)/EP has the highest Rc values. The larger value of Rct at GO-Ti/EP is a result of the great chemical stability of GO-Ti.

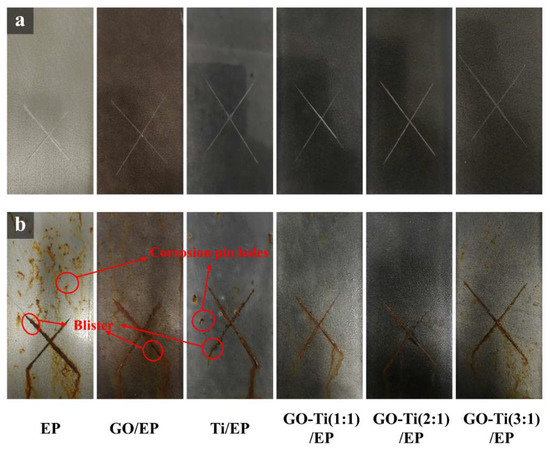

The salt spray test is carried out to further explore the properties of the composite coating. As shown in Figure 10a, scratches are made on the surface of the coating before the experiment to facilitate the observation of corrosion. Figure 10b shows the photographs of different coating samples (EP, GO/EP, Ti/EP, GO-Ti (1:1)/EP, GO-Ti (2:1)/EP, and GO-Ti (3:1)/EP) after 168 h of a salt spray test. It can be seen that after 168 h of the salt spray experiment, pure EP, GO/EP, and Ti/EP coatings show a lot of blisters on both sides of the scratch, the depth of rust is severe in the range of 2 mm, and pitting corrosion occurs in the unscratched area. On both sides of the scratch of GO-Ti (1:1)/EP, GO-Ti (2:1)/EP, and GO-Ti (3:1)/EP composite coatings, corrosion only occurs within 1 mm. No blister and corrosion spot are observed at the unscratched area of the GO-Ti (2:1)/EP coating sample. The results show that the addition of a GO-Ti composite can enhance the shielding performance of the coating. Furthermore, the coating of the GO-Ti (2:1) composite has the best anti-corrosion performance, which is consistent with the EIS results.

Figure 10.

Photographs of different coating salt spray tests: (a) Before the salt spray test, (b) 168 h after the salt spray test.

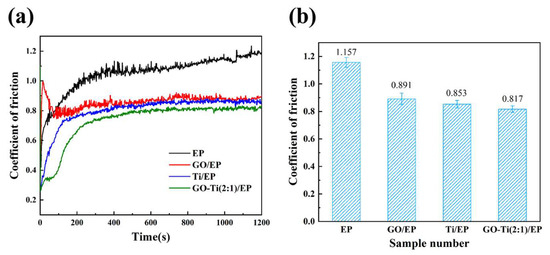

In addition, we make an inquiry into the mechanical properties of composite coatings. The change of the friction coefficient of the coatings is shown in Figure 11. Epoxy resin has the disadvantages of being hard and brittle, having low breaking energy, and demonstrating poor wear resistance. During the friction process, the EP undergoes an oxidation reaction, the surface macromolecular chains are twisted under the action of shear stress, and the chemical bonds and hydrogen bonds within the molecular chain and between the chains are broken [37]. Therefore, the friction coefficient of EP is very high. After adding GO, Nano-Ti, and GO-Ti composites to the EP, the friction coefficient decreased significantly. This can be attributed to two reasons. On one hand, the nanofillers use their own hardness to restrict the movement of the surrounding epoxy macromolecules, constrain the movement of the polymer chain, and play a supporting role under the load. On the other hand, the nanofillers can play a lubricating role in the resin, so that the friction between the coating and the friction pair mainly occurs between the solid lubricant film layers. It is worth noting that the addition of the GO-Ti (2:1) composite makes the friction coefficient of the coating the lowest, which shows that the degree of dispersion of GO also has an important impact on the improvement of wear resistance.

Figure 11.

(a) Friction coefficient versus time and (b) average friction coefficient of EP, GO/EP, Ti/EP, and GO-Ti(2:1)/EP.

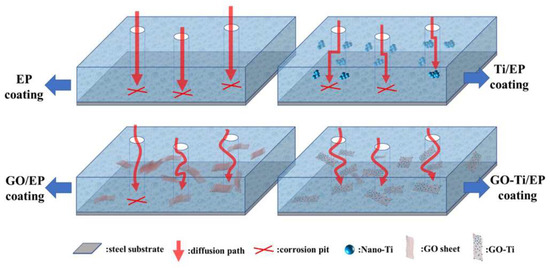

Based on the above results, the anti-corrosive mechanism of composite materials can be inferred, as shown in Figure 12. Due to the volatilization of the diluted solvent, EP is easy to produce micropores during the curing process, which makes it easier for the corrosive medium to contact the substrate surface. Although GO and Nano-Ti alone can block micropores to a certain extent, they cannot effectively disperse in the resin and cannot effectively shield the corrosive medium. By combining GO with Nano-Ti, the composite exhibits excellent dispersion performance. Due to the sheet structure, good dispersion, and interfacial compatibility of composites, a "maze effect" can be formed to prevent the penetration of corrosive media, prolong the penetration path of corrosive media in the coating, and ultimately delay the occurrence of corrosion.

Figure 12.

The anti-corrosion mechanisms of GO-Ti /EP composite coatings.

4. Conclusions

Compared with the previous related research, the present study selected Nano-Ti particles with excellent anti-corrosion and mechanical properties to decorate GO, so that not only the dispersibility of GO is improved, but also GO can synergistically improve the coating performance with nanoparticles. In addition, the optimal composite ratio between Nano-Ti particles and GO was explored. FTIR, XRD, XPS, SEM, and TEM were used to study GO-Ti composites. Through a settlement experiment, EIS, SEM, and salt spray test, the dispersion of the composites in the coatings and the anti-corrosion mechanism of the coatings are studied. The mechanical properties of the coatings are analyzed by friction and wear tests. The obtained results are summarized as follows:

- Nano-Ti particles are successfully uniformly loaded on the GO sheets, and the best composite ratio of GO and Nano-Ti is 2:1. The GO-Ti sheet spacing is increased to 1.02 nm at most, and the composites have good compatibility with epoxy resin.

- The |Z|0.01Hz of GO-Ti/EP is higher than that of GO/EP, showing an excellent anti-corrosion effect. This is because the composites exhibit the sheet structure that blocks the micropores and hinders the invasion of corrosive medium.

- The addition of GO-Ti effectively improves the wear resistance of the coatings, mainly because the composites can play a lubricating and cross-linking buffering role in the coating.

Author Contributions

Conceptualization, X.O.; Investigation, B.L.; Methodology, H.Y. and P.W.; Writing—original draft, H.Y. and H.X.; Writing—review and editing, F.Q., N.Z., and B.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Nature Science Foundation of China (51701172), Guangdong Province Key Area R&D Program (2019B090909002), National Natural Science Foundation Joint Fund Key Project (U1865206), National Science and Technology Major Project (2017-VII-0012-0107), National Defense Science and Technology Key Laboratory Fund (614220207011802), Postdoctoral Science Foundation of China (2018M632977), and Natural Science Foundation of Hunan Province (2018JJ3504), National Natural Science Foundation of China (11605149).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bian, J.; Wang, W.; Cuan, C. Metal Corrosion and Progress in Anti-Corrosion Organic Coatings. J. Mater. Sci. Eng. 2003, 5, 769–772. (In Chinese) [Google Scholar]

- Ma, H.; Cui, C.; Chen, T. Brief Introduction to Metal Corrosion and Protection. Electrochemistry 2011, 3, 55–58. [Google Scholar]

- Nazeer, A.A.; Madkour, M. Potential use of smart coatings for corrosion protection of metals and alloys: A review. J. Mol. Liq. 2018, 253, 11–22. [Google Scholar] [CrossRef]

- Sugiman, S.; Putra, I.K.P.; Setyawan, P.D. Effects of the media and ageing condition on the tensile properties and fracture toughness of epoxy resin. Polym. Degrad. Stab. 2016, 134, 311–321. [Google Scholar] [CrossRef]

- Park, S.-J.; Heo, G.-Y.; Jin, F.-L. Cure behaviors and thermal stabilities of tetrafunctional epoxy resin toughened by polyamideimide. Macromol. Res. 2015, 23, 320–324. [Google Scholar] [CrossRef]

- Paluvai, N.R.; Mohanty, S.; Nayak, S.K. Fabrication and evaluation of acrylated epoxidized castor oil-toughened diglycidyl ether of bisphenol A nanocomposites. Can. J. Chem. Eng. 2015, 93, 2107–2116. [Google Scholar] [CrossRef]

- Yahyaie, H.; Ebrahimi, M.; Tahami, H.V.; Mafi, E.R. Toughening mechanisms of rubber modified thin film epoxy resins. Prog. Org. Coat. 2013, 76, 286–292. [Google Scholar] [CrossRef]

- Smith, A.T.; Lachance, A.M.; Zeng, S.; Liu, B.; Sun, L. Synthesis, properties, and applications of graphene oxide/reduced graphene oxide and their nanocomposites. Nano Mater. Sci. 2019, 1, 31–47. [Google Scholar] [CrossRef]

- Wang, J.; Jin, X.; Li, C.; Wang, W.; Wu, H.; Guo, S. Graphene and graphene derivatives toughening polymers: Toward high toughness and strength. Chem. Eng. J. 2019, 370, 831–854. [Google Scholar] [CrossRef]

- Ding, R.; Chen, S.; Lv, J.; Zhang, W.; Zhao, X.-D.; Liu, J.; Wang, X.; Gui, T.-J.; Li, B.-J.; Tang, Y.-Z.; et al. Study on graphene modified organic anti-corrosion coatings: A comprehensive review. J. Alloys Compd. 2019, 806, 611–635. [Google Scholar] [CrossRef]

- Wu, Y.; Zhu, X.; Zhao, W.; Wang, Y.; Wang, C.; Xue, Q. Corrosion mechanism of graphene coating with different defect levels. J. Alloys Compd. 2019, 777, 135–144. [Google Scholar] [CrossRef]

- Sun, W.; Wang, L.; Wu, T.; Wang, M.; Yang, Z.; Pan, Y.; Liu, G. Inhibiting the Corrosion-Promotion Activity of Graphene. Chem. Mater. 2015, 27, 2367–2373. [Google Scholar] [CrossRef]

- Schriver, M.; Regan, W.; Gannett, W.J.; Zaniewski, A.M.; Crommie, M.F.; Zettl, A. Graphene as a Long-Term Metal Oxidation Barrier: Worse Than Nothing. ACS Nano 2013, 7, 5763–5768. [Google Scholar] [CrossRef] [PubMed]

- Niu, L.; Coleman, J.N.; Zhang, H.; Shin, H.; Chhowalla, M.; Zheng, Z. Production of Two-Dimensional Nanomaterials via Liquid-Based Direct Exfoliation. Small 2016, 12, 272–293. [Google Scholar] [CrossRef] [PubMed]

- Fankhänel, J.; Arash, B.; Rolfes, R. Elastic interphase properties of nanoparticle/epoxy nanocomposites: A molecular dynamics study. Compos. Part B Eng. 2019, 176, 107211. [Google Scholar] [CrossRef]

- Jamkhande, P.G.; Ghule, N.W.; Bamer, A.H.; Kalaskar, M.G. Metal nanoparticles synthesis: An overview on methods of preparation, advantages and disadvantages, and applications. J. Drug Deliv. Sci. Technol. 2019, 53, 101174. [Google Scholar] [CrossRef]

- Di, H.; Yu, Z.; Ma, Y.; Li, F.; Lv, L.; Pan, Y.; Lin, Y.; Liu, Y.; He, Y. Graphene oxide decorated with Fe3O4 nanoparticles with advanced anticorrosive properties of epoxy coatings. J. Taiwan Inst. Chem. Eng. 2016, 64, 244–251. [Google Scholar] [CrossRef]

- Yu, Z.; Di, H.; Ma, Y.; Lv, L.; Pan, Y.; Zhang, C.; He, Y. Fabrication of graphene oxide–alumina hybrids to reinforce the anti-corrosion performance of composite epoxy coatings. Appl. Surf. Sci. 2015, 351, 986–996. [Google Scholar] [CrossRef]

- Das, M.R.; Sarma, R.K.; Borah, S.C.; Kumari, R.; Saikia, R.; Deshmukh, A.B.; Shelke, M.V.; Sengupta, P.; Szunerits, S.; Boukherroub, R. The synthesis of citrate-modified silver nanoparticles in an aqueous suspension of graphene oxide nanosheets and their antibacterial activity. Colloids Surf. B Biointerfaces 2013, 105, 128–136. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Yu, M.; Li, S.; Zhao, K.; Xue, B.; Zu, H. Silane modification of titanium dioxide-decorated graphene oxide nanocomposite for enhancing anticorrosion performance of epoxy coatings on AA-2024. J. Alloys Compd. 2018, 744, 728–739. [Google Scholar] [CrossRef]

- Yan, S.; Song, G.-L.; Li, Z.; Wang, H.; Zheng, D.; Cao, F.; Horynova, M.; Dargusch, M.S.; Zhou, L. A state-of-the-art review on passivation and biofouling of Ti and its alloys in marine environments. J. Mater. Sci. Technol. 2018, 34, 421–435. [Google Scholar] [CrossRef]

- Zhang, X. Effects of Nano-sized Titanium Powder on the Anti-corrosion Property of Epoxy Coatings on Steel. Kem. u Ind. 2014, 63, 317–322. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F.; Du, Y. Effect of nano-sized titanium powder addition on corrosion performance of epoxy coatings. Surf. Coat. Technol. 2007, 201, 7241–7245. [Google Scholar] [CrossRef]

- William, S.H.; Richard, E.O. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar]

- Ahmadi-Moghadam, B.; Sharafimasooleh, M.; Shadlou, S.; Taheri, F. Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater. Des. 2015, 66, 142–149. [Google Scholar] [CrossRef]

- Xu, L.; Feng, J.; Li, J.; Liu, X.; Jiang, S. Graphene oxide bonded fused-silica fiber for solid-phase microextraction-gas chromatography of polycyclic aromatic. J. Sep. Sci. 2012, 35, 93–100. [Google Scholar] [CrossRef]

- Bruun, S.W.; Kohler, A.; Adt, I.; Sockalingum, G.D.; Manfait, M.; Martens, H. Correcting Attenuated Total Reflection—Fourier Transform Infrared Spectra for Water Vapor and Carbon Dioxide. Appl. Spectrosc. 2006, 60, 1029–1039. [Google Scholar] [CrossRef]

- Muniyalakshmi, M.; Sethuraman, K.; Silambarasan, D. Synthesis and characterization of graphene oxide nanosheets. Mater. Today Proc. 2019, in press. [Google Scholar] [CrossRef]

- Alrashed, M.M.; Soucek, M.D.; Jana, S.C. Role of graphene oxide and functionalized graphene oxide in protective hybrid coatings. Prog. Org. Coat. 2019, 134, 197–208. [Google Scholar] [CrossRef]

- Di, H.; Yu, Z.; Ma, Y.; Pan, Y.; Shi, H.; Lv, L.; Li, F.; Wang, C.; Long, T.; He, Y. Anchoring calcium carbonate on graphene oxide reinforced with anticorrosive properties of composite epoxy coatings. Polym. Adv. Technol. 2016, 27, 915–921. [Google Scholar] [CrossRef]

- Sbirrazzuoli, N.; Mititelu-Mija, A.; Vincent, L.; Alzina, C. Isoconversional kinetic analysis of stoichiometric and off-stoichiometric epoxy-amine cures. Thermochim. Acta 2006, 447, 167–177. [Google Scholar] [CrossRef]

- Amrollahi, S.; Ramezanzadeh, B.; Yari, H.; Ramezanzadeh, M.; Mahdavian, M. In-situ growth of ceria nanoparticles on graphene oxide nanoplatelets to be used as a multifunctional (UV shield/radical scavenger/anticorrosive) hybrid compound for exterior coatings. Prog. Org. Coat. 2019, 136, 105241. [Google Scholar] [CrossRef]

- Kalsoom, U.-I.; Bashir, S.; Ali, N. SEM, AFM, EDX and XRD analysis of laser ablated Ti in nonreactive and reactive ambient environments. Surf. Coat. Technol. 2013, 235, 297–302. [Google Scholar] [CrossRef]

- Liu, X.; Shao, Y.; Zhang, Y.; Meng, G.; Zhang, T.; Wang, F. Using high-temperature mechanochemistry treatment to modify iron oxide and improve the corrosion performance of epoxy coating–I. High-temperature ball milling treatment. Corros. Sci. 2015, 90, 451–462. [Google Scholar] [CrossRef]

- Liu, X.; Xiong, J.; Lv, Y.; Zuo, Y. Study on corrosion electrochemical behavior of several different coating systems by EIS. Prog. Org. Coat. 2009, 64, 497–503. [Google Scholar] [CrossRef]

- Zhu, C.; Xie, R.; Xue, J.; Song, L. Studies of the impedance models and water transport behaviors of cathodically polarized coating. Electrochim. Acta 2011, 56, 5828–5835. [Google Scholar] [CrossRef]

- Shi, G.; Zhang, M.Q.; Rong, M.Z.; Wetzel, B.; Friedrich, K. Friction and wear of low nanometer Si3N4 filled epoxy composites. Wear 2003, 254, 784–796. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).