Abstract

The performance degradation of sodium-ion batteries (SIBs) in extremely low-temperature conditions has faced significant challenges for energy storage applications in extreme environments. This review systematically establishes failure mechanisms that govern the performance of low-temperature SIBs, including significantly increased electrolyte viscosity, lattice distortion and adverse phase transitions in electrodes, and sluggish desolvation kinetics at the solid electrolyte interface. Herein, we specifically summarize a series of multi-scale optimization strategies to address these low-temperature challenges: (1) optimizing low-freezing-point solvent components and regulating solvation structures to increase ionic diffusion conductivity; (2) enhancing the hierarchical structure of electrodes and optimizing electron distribution density to improve structural stability and capacity retention at low temperatures; and (3) constructing an inorganic-rich solid electrolyte interphase to induce uniform ion deposition, reduce the desolvation barrier, and inhibit side reactions. This review provides a comprehensive overview of low-temperature SIB applications coupled with advanced characterization and first-principles simulations. Furthermore, we highlight solvation-shell dynamics, charge transfer kinetics, and metastable-phase evolution at the atomic scale, along with the critical pathways for overcoming low-temperature limitations. This review aims to establish fundamental principles and technological guidelines for deploying advanced SIBs in extreme low-temperature environments.

1. Introduction

As global energy transitions accelerate, large-scale energy storage technologies are gaining strategic importance [1,2]. Sodium-ion batteries (SIBs) have emerged as a promising solution in this field, making full use of abundant sodium resources (2.64% of Earth’s crust abundance) and unique technical strengths. Their electrode potential (−2.71 V vs. SHE) is similar to that of lithium-ion batteries (LIBs) [3,4], while sharing the same “rocking-chair” ion diffusion mechanism [5]. This similarity allows partial reuse of LIB production equipment, cutting technology conversion costs. Notably, SIBs outperform LIBs in cold environments. Although sodium ions are slightly larger than lithium ions (0.102 nm vs. 0.076 nm), their smaller solvated size and optimized low-viscosity electrolytes enable faster ion transport below −20 °C. Combined with sodium’s lower reactivity reducing thermal runaway, ensuring enhanced safety and adaptability in cold climates.

On the contrary, although LIBs occupy a dominant position in the current energy storage field by virtue of their proven technology system [6], they face bottlenecks such as uneven distribution of lithium resources, high cost, and poor low-temperature adaptability, which make it difficult for them to satisfy the strict requirements of economy and environmental tolerance in large-scale energy storage scenarios [7]. Based on this, SIBs with significant advantages in resources, technology, performance, and safety, are fully capable of serving as an effective complement [8] and are widely used in large-scale energy storage, contributing to building a more economical, environmentally adaptable, and safe energy storage system in low-temperature conditions. It is worth mentioning that, when deployed in extreme environments such as deep-sea exploration, polar energy systems, and aerospace equipment [9,10,11], traditional energy storage devices suffer more severe challenges such as extreme low temperatures. However, even SIBs have remarkable low-temperature performance but inevitably suffer from significant performance degradation in more severe low-temperature environments (<−20 °C). This phenomenon stems from a significant increase in the macroscopic viscosity of the electrolyte system, which in turn triggers a sharp increase in impedance at the electrode/electrolyte interface; at the microscopic level, the charge transfer kinetics at the solid/liquid interface exhibits hysteresis characteristics, along with a degradation of the nanoscale structure of the Solid Electrolyte Interphase (SEI) and Chemical/Electrochemical Interface (CEI). Fundamental challenges arise from the synergistic effect of electrolyte stability degradation and electrode material phase structure decline, triggering a multiscale failure mechanism at the electrode/electrolyte interface, which ultimately leads to catastrophic capacity degradation, a shortened cycle life, and power density collapse.

SIBs are mainly composed of electrodes, electrolytes, and the interface between these components. The performance of each part directly determines the performance of the batteries. In order to improve the low-temperature performance of SIBs, the optimization of electrolyte components, the solventation structure, the electrode structure design, and the electrode/electrolyte modulation are expected to play an important role. The development of low-temperature SIBs essentially relies on the in-depth synergistic regulation of the electrolyte solvation structure, electrode material surface-interface properties, and desolvation kinetic processes. The solvated sheath structure [12] in the electrolyte, as a medium for ion transport, directly determines the migration number (t+) and ionic conductivity (σ) of sodium ions, and reorganization energy of solvation shell and desolvation energy barriers have a significant influence on the charge transfer reaction rate. The crystal structure of the electrode material as well as the surface interface engineering [13,14,15,16] determine the number of storage sites for sodium ions and the degree of optimization of the insertion and extraction pathways [17,18]. The electrochemical kinetics of the crucial desolvation [19] process, which acts as a bridge connecting the electrolyte to the electrode, is directly correlated to the charge transfer resistance (Rct), as well as the interfacial stability. At low temperatures, the ordering of solvent molecular orientation is enhanced, resulting in an increase in the desolvation barrier of solvated ions, which in turn triggers an intensification of the electrode/electrolyte interface (EEI) side reactions and the formation of a loose and porous SEI/CEI film, further deteriorating the cycling performance of the battery.

The breakthrough direction of future research should focus on building a systematic electrolyte design theory system, focusing on the following dimensions: at the basic mechanism level, it is necessary to deepen the multidimensional synergistic mechanism study of “solvation structure–electrode intrinsic properties–interfacial reaction” [20] and to systematically analyze the relationships between solvation coordination numbers, ion migration paths, and the electrode crystal structure through the linkage of theoretical calculations and in situ characterization techniques [21,22]. Additionally, it is important to establish the dynamic matching law of key parameters and establish the dynamic matching law of key parameters. At the methodological innovation level, we should break through the limitations of traditional single-component optimization and construct a universal regulation strategy based on the multidimensional parameters of solvent polarity, viscosity, and coordination ability [23]. Furthermore, developing a multiscale synergistic solvation structure control method is necessary. At the level of theoretical construction, it is urgent to promote the shift of the electrolyte design paradigm from empirical trial-and-error to theory-driven and to establish a systematic design framework across the micro-mechanism and macro-performance by integrating the whole-process prediction models of solvated structure evolution, interfacial film dynamics, and device performance [24,25,26]. This research paradigm not only provides a systematic solution for the optimization of the low-temperature performance of SIBs but also establishes a universal theoretical basis for the electrolyte design of new energy storage systems.

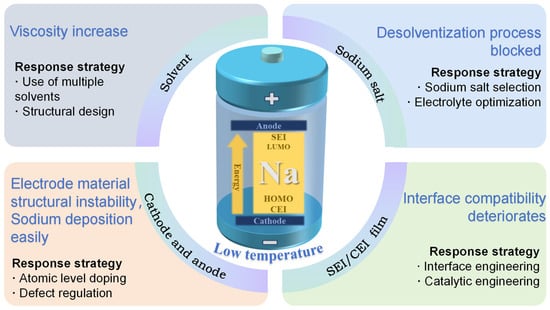

This review focuses on the key scientific issues of SIBs in extreme low-temperature environments, thoroughly investigates the failure mechanisms and reveals the intrinsic correlation mechanisms, and puts forward a targeted regulation strategy to carry out a systematic review (Figure 1), aiming to provide theoretical support and a technical pathway for the development of high-performance batteries. This is of great significance to promoting the technological breakthrough of SIBs within the field of large-scale energy storage.

Figure 1.

Solvation structure and interface engineering synergy in low-temperature sodium-ion batteries: advances and prospects.

2. Failure Mechanisms

Under low-temperature conditions, the performance decline and even failure of SIBs result from the combined effects of multiple factors. At low temperatures, the viscosity of the electrolytes increases, which reduces their ionic conductivity. As a result, the transfer rate of sodium ions slows down, making the desolvation process difficult and weakening the battery’s kinetic performance. Secondly, electrolyte freezing or salt precipitation worsens battery performance. Additionally, for electrode materials at low temperatures, the ionic diffusion rate in cathode materials slows down, affecting their structural stability. Anode materials tend to experience issues like sodium deposition and unstable interface films. These problems break the electrical contact between internal components/structures of the battery, leading to performance degradation. The structure of the direct interface between electrodes and electrolytes also plays a key role. Under low-temperature conditions, the compatibility between the electrolyte and electrode materials decreases, increasing charge transfer resistance, which leads to severe polarization during charging/discharging, harming its efficiency and cycle stability, and ultimately reducing its capacity. The detailed failure mechanisms are summarized in Table 1.

Table 1.

Summary of failure mechanisms of SIBs under low-temperature conditions.

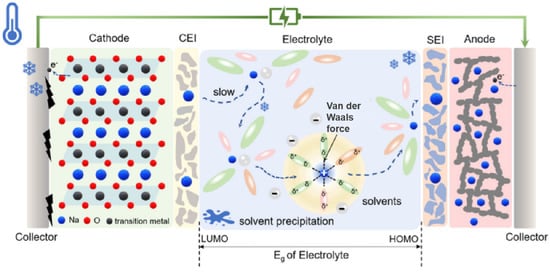

The specific failure mechanism is shown in Figure 2. This process involves the diffusion of Na+ in the electrode bulk, the electrolyte, and SEI, as well as the charge transfer of Na+ and electrons (e−) at the electrode/electrolyte interface [27,28,29,30].

Figure 2.

Schematic diagram of low-temperature deterioration mechanisms. Copyright 2024 Wiley [30].

2.1. Electrolyte

2.1.1. SIB Electrolyte Types and Low-Temperature Working Characteristics

The current electrolyte system for SIBs is mainly based on organic solvents, including esters and ethers. Ester electrolytes, such as ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), diethyl carbonate (DEC), ethyl methyl carbonate (EMC), and methyl propionate (MP), can offer advantages such as a high dielectric constant, adjustable viscosity, and specific interfacial film-forming ability, and hence have become the main commercial electrolyte for SIBs at present. During this process, molecular structures of ester solvents, including the viscosity, donor number (DN) values, the highest occupied molecular orbital (HOMO), and lowest unoccupied molecular orbital (LUMO) energy levels, significantly determine the ionic conductivity, interfacial stability, electrochemical window, and temperature adaptability of SIB electrolytes. Different ester organic solvent molecules can form clusters with unique solvation structures with sodium ions, and the sodium ion intercalation process requires a desolvation process, which is significantly influenced by the desolvation energy barriers of clusters. The properties of different ester solvent molecules are significant. Their DN values and HOMO/LUMO energy levels influence the competitive coordination ability with sodium centers and solvation structures, which can play a key role in the formation of the electrode/electrolyte interface and further determine the voltage window, cyclic performance, low-temperature properties, and stability of SIBs. Rationally blending different solvents by matching the conjugated structure, DN values, and molecular orbital can comprehensively optimize the performance of electrolytes, promoting the practical application of SIBs in terms of energy density, cycle life, and the low-temperature capacity retention ratio.

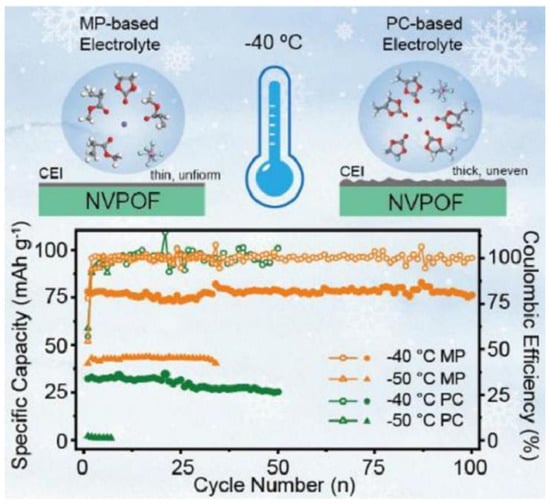

Among the common carboxylic acid ester solvents, methyl propionate (MP) has a significant advantage over similar solvents due to its low viscosity, low melting point, and good compatibility with both cathode and anode materials [31,32]. Liu et al. [33] developed an MP-based electrolyte system for SIBs, which is made possible by adding fluoroethylene carbonate (FEC) as a film-forming additive. The electrolyte combines a low melting point, sufficient ionic conductivity, and high electrochemical stability under low-temperature environments, and the relevant performance indexes are significantly better than those of traditional carbonate electrolytes. When the designed carboxylate-based electrolyte is matched with the high-voltage cathode material Na3V2(PO4)2O2F(NVPOF), the battery system shows excellent ultra-low temperature resistance. At the extreme low temperature of −50 °C, the battery not only operates stably but also forms a robust and homogeneous CEI and maintains a high Na+ migration efficiency at the electrode/electrolyte interface. Due to the synergistic effect of interfacial chemistry modulation and kinetic enhancement effect, the capacity retention of the Na||NVPOF half-cell was about 89% after 500 cycles at 1 C multiplicity in a −25 °C environment, as shown in Figure 3.

Figure 3.

The charge/discharge mechanism and cycling performance of the Na||NVPOF battery. Copyright 2024 Elsevier [33].

Moreover, ether-based electrolytes such as tetrahydrofuran (THF) and triphenyl phosphate (TPP) have raised attention in recent years due to their low viscosity, strong Na+ coordination ability, and satisfactory compatibility with hard-carbon anodes. Therefore, ether-based solvents possess irreplaceable advantages in SIB systems under low-temperature conditions. In a SIB, ether solvents greatly increase ion transport efficiency, improve interface stability, and enhance cycle performance, making them more suitable for severe environments and exhibiting high energy density, large charge/discharge rates, and long cycle life at low temperatures [34,35].

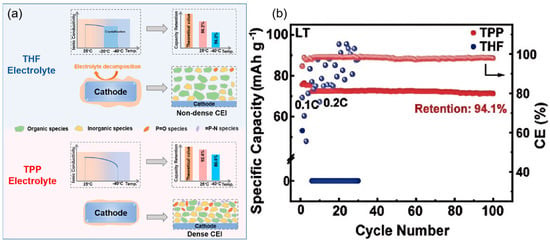

However, practical applications of ether-based electrolyte in extreme environments are still deficient, which is caused by the problem of slow ion diffusion kinetics at low temperatures [36,37,38]. To solve this problem, researchers have tried to develop low-temperature SIB electrolytes based on mixed ether solvents due to their relatively low melting point and viscosity [39,40,41,42]. Ether solvents can be mainly classified into two types, cyclic ethers and linear ethers: linear ether solvents represented by 1,2-dimethoxyethane and diethylene glycol dimethyl ether have high chemical stability, but the strong solvation of solvent molecules with sodium ions will hinder ion transport, which will limit their performance under low-temperature conditions [43,44]. In contrast, cyclic ether solvents such as THF show better low-temperature performance due to their weaker solvation with sodium ions [45,46]. Yin et al. [47] developed a novel sodium-ion battery electrolyte with ether as the main solvent, and the assembled Na2/3Mn2/3Ni1/3O2||Na battery achieved 97.2% capacity retention after 140 cycles at 25 °C and a 2.5–4.0 V voltage interval, while the THF-based electrolyte failed after only 30 cycles under the same conditions. This performance enhancement mainly originates from the CEI of phosphorus-rich and fluorine-rich components formed on the anode surface in the TPP electrolyte. When the temperature was lowered to −40 °C, the high ionic conductivity of the TPP electrolyte over a wide temperature range enabled the Na2/3Mn2/3Ni1/3O2||Na battery to maintain a high capacity retention rate of 94.1% after 100 cycles (as shown in Figure 4), which demonstrates the mechanism of the two electrolytes in the Na2/3Mn2/3Ni1/3O2 positive electrode: the THF electrolyte will crystallize at −20 °C, leading to electrolyte failure, while the TPP electrolyte is able to maintain a high ionic conductivity over a wide range of temperatures, which ensures that the battery still has a high-capacity output under −40 °C. In addition, THF electrolyte continues to decompose during cycling at 25 °C, facilitating the formation of a superior CEI layer with a large number of organic components that cannot effectively protect the electrode surface; in contrast, TPP electrolyte forms a thin and dense CEI layer during cycling, with inorganic components that can stabilize the electrode interface and safeguard the efficiency of sodium ion transport.

Figure 4.

Schematic illustration of failure mechanism. (a) Schematic illustration of the working mechanism of selected electrolyte in the MN cathode. (b) Cycling performance of MN cathode in TPP and THF electrolytes at −40 °C.Copyright 2023 American Chemical Society [47].

2.1.2. High Viscosity at Low Temperatures Decreases the Ionic Transport Efficiency

In a low-temperature environment, the electrolyte viscosity increases significantly, which leads to a sharp decrease in the ion migration kinetics. Taking the charging process as an example, the transport of Na+ in the electrolyte consists of three key steps. First, the process of sodium ions undergoing a solvation process with the organic ligands in the electrolyte when embedded from the electrode. Subsequently, the solvated Na clusters undergo diffusive migration in the electrolyte. Finally, the solvated Na+ cluster requires a desolvation process at the surface of the electrode. During these processes, the viscosity of the electrolyte directly determines the macroscopic performance of the battery, among which ionic conductivity is an important parameter affecting the low-temperature application of SIBs. For organic solvent systems, the solvent viscosity increases sharply as the temperature drops, which is attributed to the sluggish ion diffusion conductivity for solvated clusters. To reveal quantitative relationships between the ionic diffusion coefficient, temperature, and solvent viscosity, the Stokes–Einstein equation [30] (Equation (1)) has been established as follows:

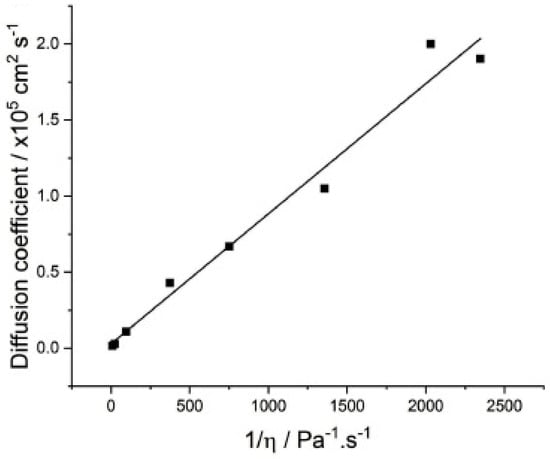

where represents the diffusion coefficient, is the Boltzmann constant, denotes the temperature, is the solvent viscosity, and is the radius of the solvated molecule. The equation shows that higher temperatures and smaller radii of solvated molecules accelerate the diffusion rate, while the opposite occurs at low temperatures [48]. In traditional electrolytes, the diffusion coefficient of ferrocene is 1.9 ± 0.2 × 10−5 cm2 s−1, which aligns with values reported in the literature for similar solutions (2 × 10−5 cm2 s−1). As the concentration approaches the high-concentration region, diffusion decreases rapidly due to the formation of contact ion pairs (CIP) and aggregate (AGG) complexes, which increases viscosity. The diffusion coefficient of Fc is plotted against fluidity in Figure 5 [49]. Logan et al. [50] evaluated electrolyte systems with the addition of a variety of ester co-solvents by measuring viscosity and ionic conductivity, using temperature as a variable, with the aim of exploring their suitability for high-rate application scenarios. The results of the study showed that regardless of the type of additives used, the electrolyte exhibited a tendency of increasing viscosity and decreasing ionic conductivity with decreasing temperature, a pattern that suggests the relative stability of the physical properties of the electrolyte during temperature changes.

Figure 5.

Stokes–Einstein relation with the experimental data. Copyright 2024 ELSEVIER [49].

2.1.3. Low Temperatures Increase the Desolvation Energy Barrier

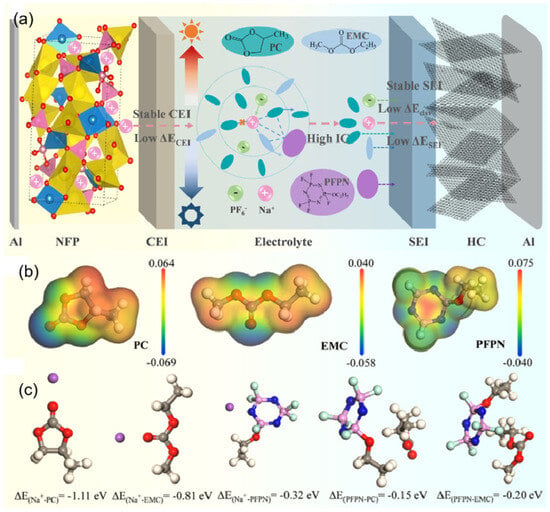

At extremely low temperatures, the interaction between solvent molecules and sodium ions is enhanced, and the desolvation process is blocked, which makes solvent-encapsulated clusters more difficult to release Na+ and become embedded in the electrode, further increasing the interfacial charge transfer resistance. During the charged process, Na+ ions are removed from the cathode and interact with solvent molecules in the electrolyte to form a solvated Na+ cluster. Subsequently, they migrate to the anode surface in the presence of an electric field, exit from the solvated molecules, cross the SEI, and finally embed themselves in the anode (an anodic embedding reaction as an example) [51,52]. The low temperature leads to an increase in electrolyte viscosity and a decrease in ionic conductivity, which reduces the rate of Na+ shuttling through the electrolyte and makes the subsequent desolvation process difficult. This ultimately deteriorates the reaction process and leads to a severe reduction in cell kinetics [30]. Li et al. [53] used PC, which has a high dielectric constant and a wide liquid range, as the main solvent of the electrolyte, enabling the electrolyte to remain liquid under extreme conditions and contain more free ions, thus ensuring the fast migration ability of ions in the electrolyte. Then, two co-solvents with significantly different sodium ion solvation capabilities, EMC and perfluoropropyl nitrile (PFPN), were selected to synergistically regulate the first and second solvation shells of sodium ions, reconstruct the solvation structure of sodium ions, reduce the desolvation energy barrier of sodium ions, and improve the conductivity and electrode/electrolyte interface properties (Figure 6). In the theoretical calculation process, the binding energy (ΔEb) of sodium ions with different solvent molecules is calculated as follows: ΔEb = E(complex) − E(A) − E(Na+), where E(complex) is the energy of the whole system after coordination, E(A) is the energy of a single molecule that constitutes the complex, and E(Na+) is the energy of a single Na+ [54].

Figure 6.

(a) The schematic diagram of the NFP||HC cell considers the effect of electrolytes on the transport of Na+ from cathode to anode and the formation of SEI/CEI; (b) ESP of PC, EMC, and PFPN; (c) binding energies of Na+-PC, Na+-EMC, Na+-PFPN, PFPN-PC, and PFPN-EMC. Copyright 2024 ELSEVIER [53].

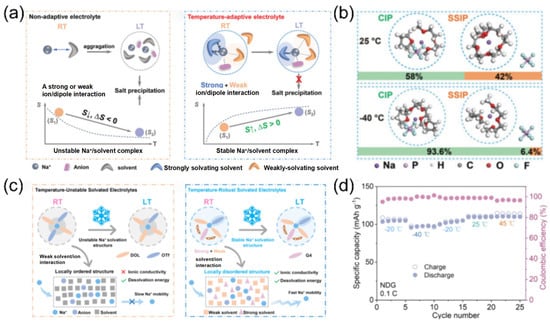

2.1.4. The Weakening of the Entropy Effect at Low Temperatures

In recent years, regulating the solvation structure of electrolytes in SIBs by the introduction of high-entropy design strategies has emerged as an innovative direction for enhancing battery electrochemical performance. As a core parameter of the second law of thermodynamics, entropy was first proposed by Rudolf Clausius to characterize the degree of disorder in a system. It holds important physical significance in the process of energy conversion and storage. As a universal thermodynamic criterion, Gibbs free energy () can quantitatively evaluate the thermodynamic stability of any electrolyte system, and its expression is (Equation (2)):

In the equation, is the enthalpy change, is the temperature, and is the entropy change. For electrolytes, entropy mainly refers to configurational entropy (), where the introduction of multiple components increases local disorder, thereby enhancing (Equation (3)):

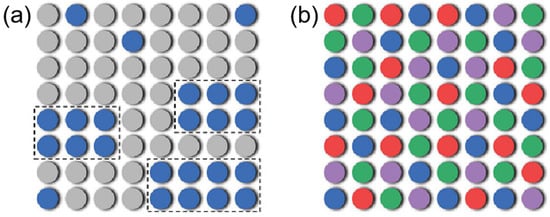

where is the ideal gas constant and is the mole fraction of the -th component. The increase in Scoff enhances the mobility of ions, enabling them to rapidly adapt to changes in the electric field, thereby accelerating the rate of ion transport. In conventional electrolytes with a small number of components, the solubility of the solute is determined by the competition between (a positive value leads to lower solubility) and (a larger value increases solubility) [55]. When the solubility limit is exceeded under specific conditions, the solute precipitates, forming a heterogeneous system, which conceptually resembles spinodal decomposition in solids (Figure 7a). Therefore, introducing multiple components to increase the mixing entropy () in principle represents a strategy to promote the formation of a homogeneous liquid solution (Figure 7b) [56].

Figure 7.

(a) Schematic diagram of compositional structure and energy in heterogeneous solution with precipitation of a component due to a limited solubility. (b) Schematic diagram of compositional structure and energy in a homogeneous solution by mixing more components to increase the entropy of mixing. Copyright 2023 Springer Nature [56].

Therefore, can serve as a tool to analyze specific solvation structures in electrolytes. The exploration of high-entropy electrolytes has opened a new pathway for rational electrolyte design. Multi-component electrolytes offer significant disorder and diverse solvation configurations, substantially enhancing battery performance. For instance, Yang’s team [55] demonstrated that adjusting strong solvation interactions in SIBs enables spontaneous structural reorganization of solvation configurations under low-temperature conditions, thereby avoiding salt precipitation. High-performance electrolytes generally exhibit exceptional chemical/electrochemical stability and stable ion transport capabilities. Notably, binary electrolytes often display higher ionic conductivity compared to single-component systems.

2.2. Sodium Salts Precipitation at Low Temperature

At low temperatures, some sodium salts show a decrease in the degree of dissociation. The low-temperature environment reduces the solubility of sodium salts, which makes the high-concentration electrolyte prone to salt precipitation. Adjusting the concentration of sodium salts in the electrolyte can optimize its stability and electrochemical performance at low temperatures. To increase the concentration of sodium salts can reduce the viscosity and freezing point of the electrolyte. However, an excessively high concentration of sodium salts will lead to the precipitation of an excessive amount of crystals at low temperatures, which will damage the contact between the interfaces in the battery and further cause the decline of the battery capacity or even lead to its failure.

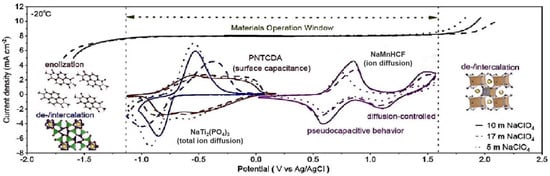

For instance, for the most commonly used sodium salt electrolyte, sodium perchlorate (NaClO4), its freezing point decreases significantly as the concentration of sodium perchlorate increases. Han et al. [57] assessed electrode/electrolyte compatibility; we measured the electrochemical stability windows of three electrolytes and recorded the cyclic voltammetry (CV) curves of three electrodes in NaClO4-based electrolytes using three-electrode cells. Notably, only a minor oxygen evolution reaction (OER) occurred during the charging process of 5 NaClO4 at −20 °C, reducing the likelihood of battery failure under low-temperature conditions (as shown in Figure 8).

Figure 8.

Comparison of different cathode/electrolyte battery systems. Copyright 2024 American Chemical Society [57].

At low temperatures, sodium salts participate in electrode interface reactions, ref. [30], affecting the composition and stability of the SEI membrane at the solid electrolyte interface. At the negative electrode, the reduction in hydrated Na+ in the electrolyte at a low concentration generates an ice-containing SEI membrane, which is loose in structure and poor in conductivity, while NaClO4 crystals precipitate in the electrolyte at high concentrations, leading to a local rupture of the SEI membrane, which triggers the continuous decomposition of the electrolyte. On the anode side, ClO4− will be enriched on the cathode surface at high voltage, forming a high-impedance salt deposition layer, such as in the 17 m NaClO4 electrolyte, where the salt coverage on the cathode surface is more than 40% after charging at −30 °C, which hinders the de-embedding of Na+. This “selective interfacial blockage” mechanism of anode ice accumulation and cathode salt deposition is the core cause of low-temperature battery failure [57]. Among them, selective interfacial blocking refers to the phenomenon in battery or electrochemical systems where a specific material or interfacial layer can selectively hinder the passage of certain substances (such as solvent molecules, large-sized ions, or impurities) across the electrode/electrolyte interface, while allowing target ions (such as lithium ions and sodium ions) to migrate unimpeded.

2.3. Cathode and Anode Materials

2.3.1. Structural Stability of Cathode Materials Is Affected at Low Temperatures

Current SIB cathode materials are mainly focused on polyanion materials (Na3V2(PO4)3, NVP), layered transitional metal oxide materials (TMOs), and Prussian blue analogs (PBAs). At low temperatures, the ion diffusion rate among the electrodes significantly slows down, and structural stability is also affected. The comparative table of polyanion materials, layered transition metal oxide materials, and Prussian blue analogs tested under low-temperature conditions is shown in Table 2.

Table 2.

A comparison table of polyanionic materials, layered transition metal oxides, and Prussian blue analogs at low-temperature conditions.

Polyanionic materials occupy an important position in the research of low-temperature cathode materials due to their unique three-dimensional backbone structure. This structure consists of polyhedral anionic units, which endow the material with strong covalent bonding while constructing stable sodium ion diffusion channels, enabling the material to maintain a long cycle life even under high potential conditions. However, the large anionic groups are an obstacle to the improvement of their performance, limiting the electronic conductivity of the material itself and resulting in a low specific capacity, which makes it more difficult to achieve the desired energy density target at low temperatures [58,59,60]. NASICON-type polyanionic compounds are typical representatives of this, with the general formula Na3M2(XO4)3, where M covers elements such as V, Fe, Ni, Mn, Ti, etc., and X contains elements such as P, S, and Si. The three-dimensional open migration path of sodium ions possessed by such compounds gives them a unique advantage at low temperatures [28,61,62]. Na3V2(PO4)3, as a much talked about cathode material in the NASICON group of compounds, has a stable three-dimensional open framework consisting of a combination of angle-sharing PO4 tetrahedra and VO6 octahedra, which provides sufficient sodium ion migration space [63].

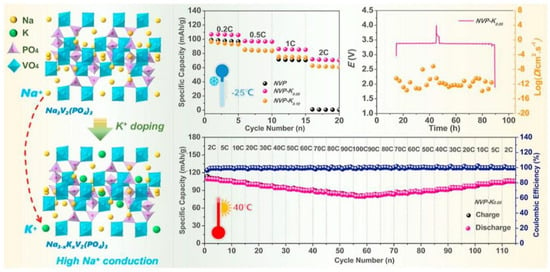

Shen et al. [64] have achieved a K+-ion-doped NVP cathode via a rational approach, which increased the unit cell volume and widened the migration channels for Na+ ions. The schematic diagram of the specific structure is shown in Figure 9. When tested at a low temperature of −25 °C, the capacity of the undoped NVP electrode dropped sharply to zero at the current density of 2 C, while the capacity of NVP-K0.05 could still be maintained at around 72 mAh g−1. This mainly benefitted from the introduction of an appropriate amount of potassium (K) atoms that can not only keep the structural stability of NVP frameworks but also provide suitable migration channels for Na+ ions. The rate performance of the NVP-K0.05 cathode material is comparable to that of the state-of-the-art NVP in SIBs. Among all the Na3-xKxV2(PO4)3 electrode materials, the NVP-K0.05 electrode sample has the best Na migration kinetics, with a Na+ diffusion coefficient value that can reach 10−11 cm2 s−1, which is significantly superior to that of NVP.

Figure 9.

The schematic illustration of the structural stabilization of NVP electrode materials by doping K ions into the Na sites, along with the rate capability plots and cycling plots of the NVP sample. Copyright 2023 Elsevier [64].

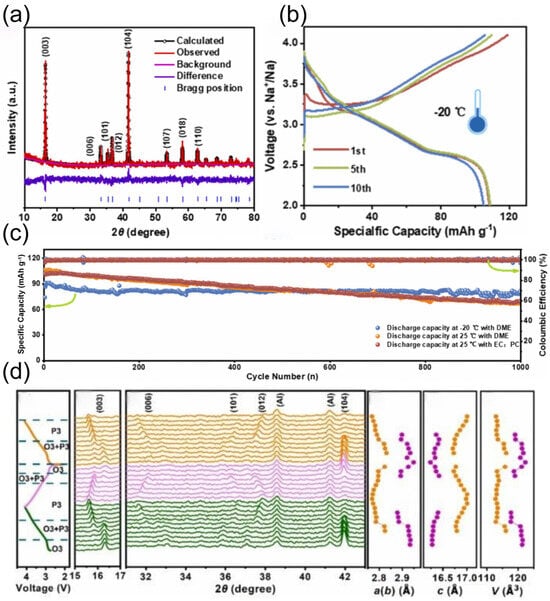

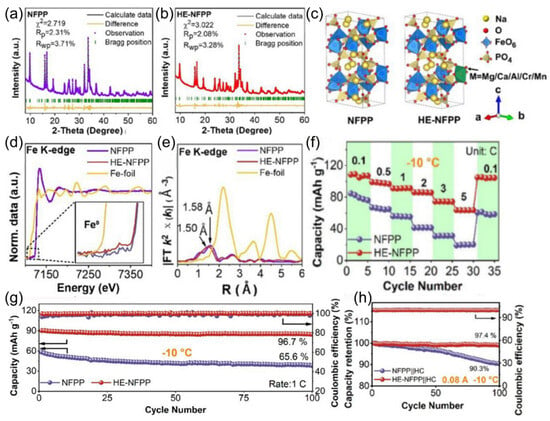

TMO cathode materials can be divided into two categories based on the arrangement of sodium ions and transition metal layers: the P-type and the oxygen-type (O-type). In the P-type cathode structure, sodium ions occupy a prismatic position, while in the O-type cathode, sodium ions are in an octahedral position. Currently, the chemically stable P2-type and O3-type layered materials have attracted much attention, which have the stacking characteristics of ABBA and ABCABC, respectively, and occupy an important position in the research field by virtue of their excellent electrochemical properties [65]. However, these layered materials suffer from significant drawbacks. In the highly depolarized state, they undergo irreversible structural phase transitions, such as P2-OP4 or P2-O2 phase transitions. At the same time, intracrystalline cracks and phase transitions can cause volume changes of up to 23% in the material, which in turn leads to the collapse of the layered structure and severely affects the capacity retention and cycling performance of the material [66,67]. Researchers have actively explored improvement strategies. Liu et al. [68] synthesized a P2-type Na0.696Ni0.329Mn0.671O2 material with highly superior Na+ ion occupied locations, which achieved stable cycling at low temperatures down to −30 °C. The material is also suitable for the production of electrodes in the solid phase. In addition, adjusting the morphology and structure of the cathode material and reducing the grain size to the nanoscale can effectively shorten the diffusion distance of sodium ions in the solid phase and enhance the electrochemical reaction kinetics. Hwang et al. [69] proposed an innovative method to prepare high-density spherical particles consisting of radially assembled columnar structures. The chemical composition of the particles showed a gradient, with a high nickel (Ni) content NaNi0.75Co0.02Mn0.23O2 in the inner core and a Ni0.58Co0.06Mn0.36O2 shell with low Ni and Mn concentrations. This unique structure promotes the redox reaction of Ni2+/3+/4+ to take place mainly inside the material, which reduces the contact resistance at the cathode/electrolyte interface and effectively inhibits unnecessary side reactions, and demonstrates excellent cycling stability at low temperatures of −20 °C.

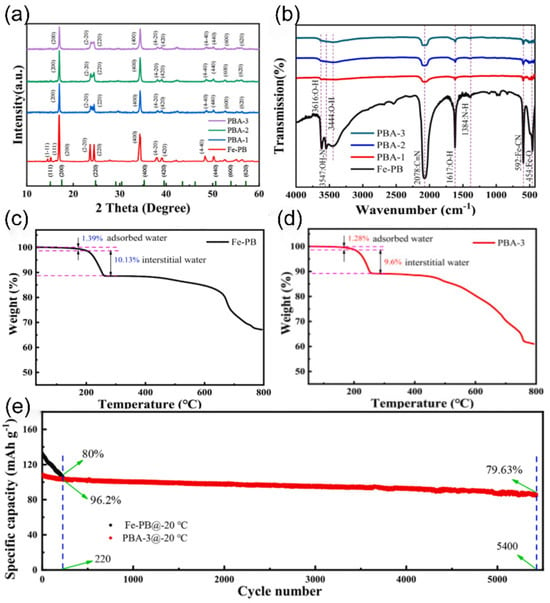

Prussian blue analogues (PBAs) have been widely studied in the field of cathode materials for SIBs by virtue of the significant advantages of an easy preparation process and possession of high capacity. However, all three common cathode materials have obvious performance shortcomings, and the presence of a large number of crystal defects and interstitial water limits their performance in low-temperature environments [70,71,72]. To solve this problem, researchers have explored optimized strategies. Zhang et al. [73] successfully prepared low-defect and sodium-rich PBA materials by using chelator- and sodium-assisted co-precipitation crystallization. Their synthesized Co0.7Ni0.3-hydrofluoric acid can achieve a capacity of 109 mAh g−1 at −30 °C without an activation process, which provides a new research direction for the performance enhancement of PBAs in low-temperature applications.

2.3.2. The Lattice Instability of Anode Materials at Low Temperatures

Under the low-temperature environment, the anode materials of SIBs face the problems of sodium precipitation and unstable interfacial film. According to the sodium storage mechanism, the current anode materials are mainly divided into three categories, including intercalation type, alloying type, and conversion type.

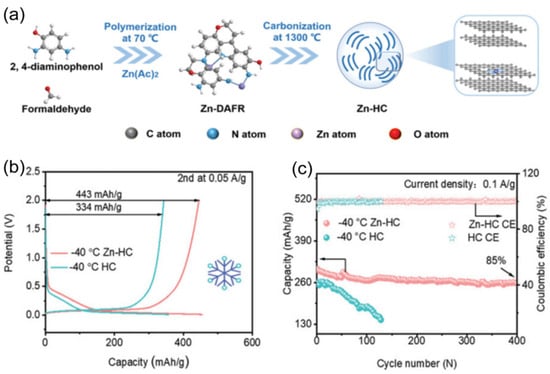

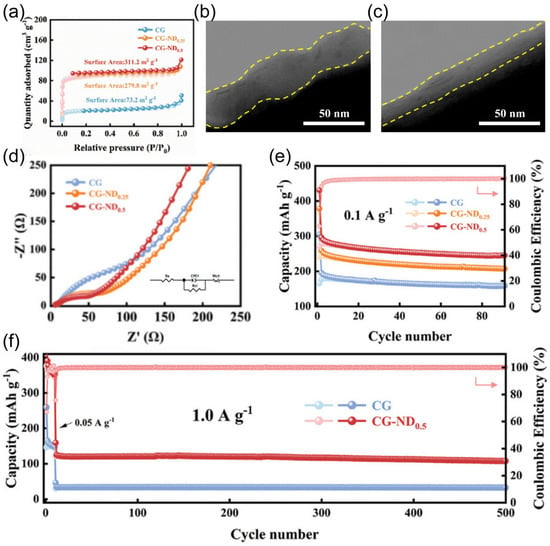

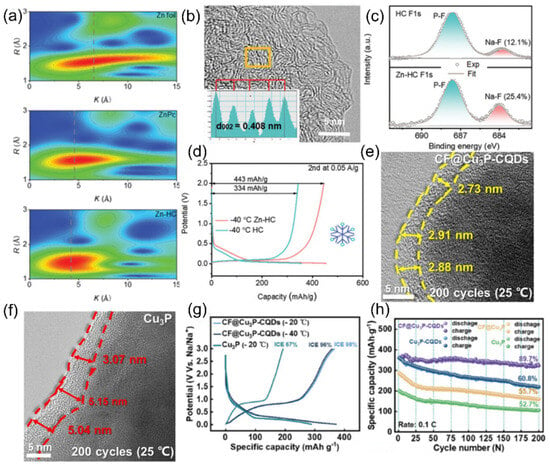

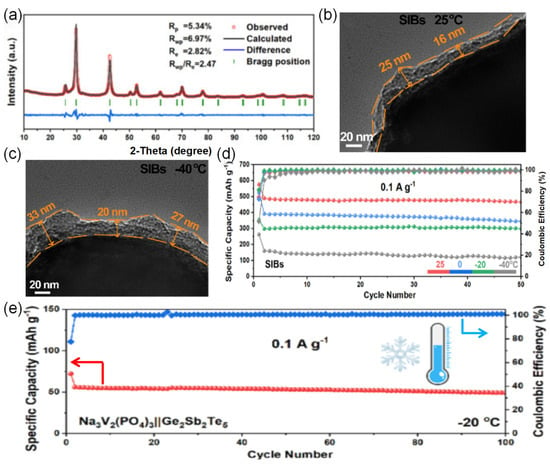

Non-graphitized hard carbon (HC) has become a typical material for carbon-based sodium storage anodes by virtue of its moderate layer spacing and abundant sodium storage sites [74,75]. Its porous structure endows the material with a large active surface area, but it also leads to an overconsumption of the active sodium source during the first charging to form the SEI film, making the initial efficiency low [30]. To address this issue, Hou et al. [76] prepared paper-like HC with an ordered fibrous structure using a pre-oxidation process, which improved the initial Coulombic efficiency of the material to 91.2%. The material showed excellent low-temperature cycling performance by maintaining a capacity retention rate higher than 80% after 1000 cycles at −15 °C and 500 mA g−1. In addition, the surface carbon coating technology can effectively inhibit the surface side reaction between HC and electrolyte and improve the initial efficiency, enabling conventional HC to achieve a high reversible capacity of 265 mAh g−1 at −15 °C and 0.1 C. The surface carbon coating technology can also effectively inhibit the surface side reaction between HC and electrolytes and improve the initial efficiency. However, HC materials suffer from the shortcoming of poor multiplication performance at low temperatures. It was found by Ponrouch et al. [77] that the introduction of heteroatoms such as nitrogen, phosphorus, sulfur, and oxygen can significantly improve the multiplicity performance and specific capacity by modulating the defects and layer spacing. A zinc single atom-regulated hard-carbon (Zn-HC) composite developed by Lu’s team [78], which combines monoatomic zinc with HC, possesses extended layer spacing (d(002) = 0.408 nm), a highly developed nanopore structure, and fewer defects. These properties not only guarantee a high initial Coulombic efficiency but also accelerate the sodium ion storage process. Of particular interest is that the Zn-N4-C structure in the material can act as a catalyst to promote the rapid decomposition of NaPF6 and the formation of a thin and inorganic-rich SEI film, which further enhances the kinetics of sodium ion storage at the interface. After comprehensive electrochemical optimization, the Zn-HC material can maintain a capacity of 140 mAh g−1 at a high charging current of 0.05 A g−1, and its specific capacity is still as high as 443 mAh g−1 even at the extreme low temperature of −40 °C. After 400 cycles, the specific capacity of the Zn-HC material can be maintained at a high charge current of 0.05 A g−1, and the specific capacity is still as high as 443 mAh g−1 after 400 cycles, and the capacity retention rate is up to 85% after 400 cycles (as shown in Figure 10).

Figure 10.

(a) Schematic illustration of the synthesis of Zn-HC. (b) The galvanostatic charge/discharge (GCD) curves (the second cycle). (c) Cycling stabilities. Copyright 2023 Wiley [73].

Zinc has a high crustal abundance (approximately 78 ppm), and its price is significantly lower than scarce metals like lithium and cobalt (the current zinc price is about USD 2.5/kg, less than 1/20th of the price of lithium carbonate). Additionally, the amount of zinc used in the doping process is typically low (atomic ratio of 5–15%), controlling material costs from the source. In cost-sensitive large-scale energy storage fields (such as grid peak regulation and low-speed electric vehicles), the zinc-doped hard carbon’s balance between capacity retention (>85% after 1000 cycles) and cost gives it greater promotion potential compared to high-priced silicon-based anodes. However, in high-end 3C products, attention must be paid to the long-term impact of zinc residues on interfacial stability to avoid hidden costs due to cyclic degradation. In summary, the cost competitiveness of zinc-doped hard carbon stems from elemental abundance and process adaptability, but its practical application requires optimization based on the performance-cost threshold of specific scenarios.

The research on alloying-type anode materials mainly focuses on the elements of germanium (Ge), stannum (Sn), and plumbum (Pb) belonging to the IVA group of the periodic table, and P, antimony (Sb), and bismuth (Bi) in the VA group, which can be prepared by the chemical reaction of forming sodium alloy phases, such as NaGe, Na15Sn4, Na15Pb4, Na3P, Na3Sb, Na3Bi, and so on [79,80]. In comparison to the insertion-type negative electrode materials, the alloy anode has many significant advantages: its theoretical specific capacity is more than 400 mAh g−1, the working potential is in the suitable interval of 0.2–0.6 V, and not only is the conductivity good, but also the raw material source is widely available. Based on these characteristics, alloy anodes have great potential for development in the field of anode materials for low-temperature SIBs [81,82,83]. In practical research and application, many research teams have achieved a series of results. Huang et al. [84] prepared layer-stacked Sb@graphene (LS-Sb@G) micro- and nano-composites using the solvent-thermal method, in which Sb nanoparticles were uniformly adhered to the graphene substrate and embedded in the intercalation to form a dense layered micro- and nanostructure. The capacity retention rate of this material was maintained at 63.7% after 100 cycles at −20 °C. Chen et al. [85] successfully prepared Sb composite-coated three-dimensional porous carbon microspheres by applying a salt-template-guided spray-drying strategy, in which the N/S-co-doped porous shell structure was able to effectively confine antimony nanocrystals, which enables the material to maintain excellent high-fold cycling performance even at a low temperature of 5 °C.

Currently, research on negative electrode materials for conversion reactions focuses on transition metal sulfides (TMSs), phosphides, and selenides, which have attracted much attention for research in low-temperature environments by virtue of their higher electronic conductivity and faster reaction kinetic [86,87,88]. Unlike conventional carbon-based materials, these anode materials for conversion reactions rely on a unique reversible redox reaction to achieve sodium ion storage, which provides the advantage of higher theoretical capacity and energy density. However, they suffer from a similar problem to alloy anodes in that they undergo significant volume changes during cycling, leading to material fracture and disruption of the electrode contact, which in turn results in rapid capacity degradation [89,90]. Researchers have carried out in-depth studies to address the above problems and achieved results. Jiang et al. [91] took MoSe2 as the object of study, and after analyzing its basic chemical reaction process, it was found that the reversibility of the conversion reaction depended on whether Mo, the discharge product of MoSe2, could react with Na2Se to achieve the regeneration of MoSe2. Based on this, the reversible reaction is promoted by modulating the structural strain of the Mo2 material to change the activities of the transformation products molybdenum (Mo) and Na2Se. Among them, the TS-MoSe2 material with tensile confinement exhibits highly reversible sodium ion storage performance even at the extreme low temperature of −30 °C. After 100 cycles at a current density of 0.1 A g−1, the reversible capacity of TS-MoSe2 was still as high as 380 mAh g−1. Fan et al. [92] used a solvent-thermal method to design micro- and nanostructured FeS spheres (FeS@ g-C) coated with thin graphitic carbon (g-C), which is similar to the design idea of the alloying reaction of carbon composites; g-C coating enhances the temperature resistance of porous gradient FeS sphere composites by virtue of short ionic diffusion paths and high conductivity. The FeS@ g-C composites reach a reversible capacity of 311 mAh g−1 after 80 cycles at −25 °C and 0.05 A g−1.

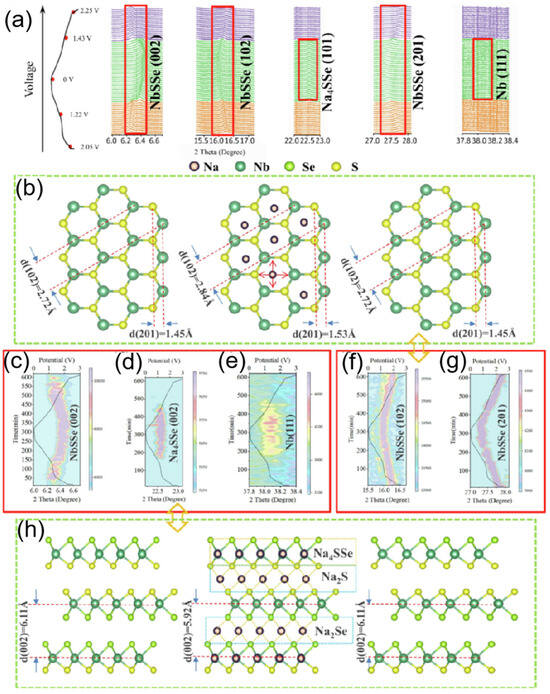

To deeply investigate the sodium ion intercalation behavior and conversion reactions, in situ synchrotron X-ray diffraction (XRD) was conducted to monitor the reaction process, as shown in Figure 11a. For the intercalation and deintercalation reactions, the process is continuous across the entire voltage range, with corresponding reactions occurring between the lattice layers of NbSSe. Taking the (102) and (201) crystal planes as examples (as shown in Figure 11b,f,g), the NbSSe structure gradually changes along with sodium ion intercalation/deintercalation throughout the charge/discharge process. After charging, according to Bragg’s law, the lattice spacing of the (102) plane increases from 2.72 Å to 2.84 Å. Taking the conversion mechanism as an example (illustrated in Figure 11c–e,h), when the voltages are <1.22 V (discharge) and >1.45 V (charge), the reaction kinetics are mainly governed by the synergistic driving of thermodynamics and kinetics. During the continuous charge/discharge process, when the voltage is between 1.22 V and 1.45 V, conversion reactions occur, accounting for <37% of the total capacity (as shown in Figure 11d,e). The formation energies of Na2S, Na2Se, and Na2SSe are −1.292 eV, −1.069 eV, and −1.176 eV, respectively. As schematically shown in Figure 11h, considering the influence and proximity of formation energies, the binding force of forming Na2S and Na2Se (due to interlayer sodium ions capturing partial S or Se atoms) causes the (002) lattice plane spacing to decrease [93,94].

Figure 11.

(a) Synchrotron X-ray powder diffraction was used, and superimposed voltage distribution plots are shown. (b) Schematic diagrams of changes in NbSSe. (c,f,g). The selected 2θ ranges for NbSSe. (d,e) The selected 2θ ranges for Na4SSe and Nb, respectively. (h) Schematic diagrams of changes in the NbSSe (002) lattice planes. Copyright 2022 Elsevier [93].

2.4. Electrode/Electrolyte Interface

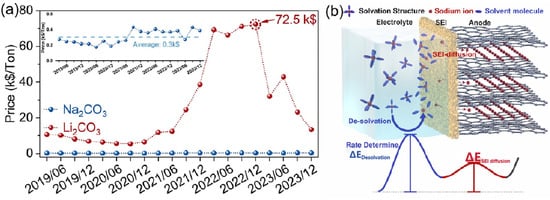

In a low-temperature environment, the interfacial compatibility between the electrolyte and electrode materials decreases significantly, resulting in an increase in charge transfer resistance and an increase in the polarization phenomenon of the battery during charging and discharging, which seriously affects the charging and discharging efficiency and cycling stability and ultimately leads to a decrease in the capacity of the battery. The formation of an SEI film at the interface between the electrode and electrolyte plays a decisive role in battery performance. A stable SEI film can effectively prevent the continuous decomposition of the electrolyte, optimize the ion transport process, and inhibit the growth of dendrites, thus significantly improving the cycle stability and safety of the battery. The solvated structure and composition of the electrolyte are the key factors affecting the formation of SEI film. High-concentration electrolytes and localized high-concentration electrolytes are capable of forming anion-rich solvated structures, which contribute to the formation of inorganic-rich SEI films on the surface of sodium metal anodes. In addition, weakly solvated electrolytes and dilute weakly interacting electrolytes are also conducive to the generation of stable SEI films. Taking the low-temperature-adapted electrolyte as an example, the anion-rich solvated structure can promote the formation of a uniform and continuous SEI film on the surface of a hard-carbon anode, which significantly improves the low-temperature performance of the battery [95,96]. The diffusion process of Na+ ions at the interface (mainly the SEI film) consumes energy, and an excessively thick SEI film on the anode surface can severely limit the kinetic performance of the battery in low-temperature environments, as shown in Figure 12. Therefore, electrolytes that can form a thin interfacial layer are more advantageous in low-temperature applications and help to improve the overall performance of the battery [97].

Figure 12.

(a) Metric ton price trend of sodium carbonate and battery-grade lithium carbonate; the inset is the enlarged price trend of sodium carbonate. (b) Schematic illustration of sodium-ion behavior during charging in the sodium-ion full-cell and the energy changes (color online). Copyright 2024 Springer Nature Link [97].

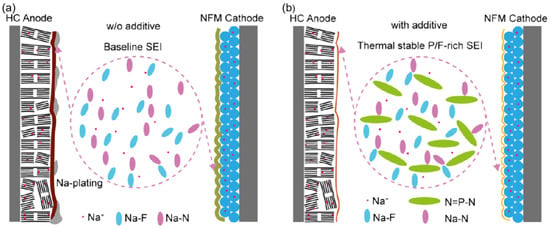

Studies focus on using fluorinated additives to precisely tailor the composition of SEI films, thereby further improving the cycling stability and safety of SIBs, especially under low-temperature conditions. Zhang et al. [98] demonstrated that a Na0.98Ni0.5Fe0.2Mn0.3O2 (NFM) hard-carbon (HC) pouch cell with 10 wt.% ethoxy (pentafluoro) cyclotriphosphazene (PFPN) exhibits an 85% capacity retention after 450 cycles at a 0.2 C rate and 0 °C, showing about a 4% increase in capacity compared to the baseline electrolyte (81.33%). At 0.5 C and 30 °C, the capacity retention remains 84% after 600 cycles. These results indicate that the addition of PFPN leads to the formation of a unique SEI structure during long-term cycling, with the electrode surface enriched in P and N elements. This structure effectively enhances the battery’s kinetic performance and suppresses sodium precipitation, as shown in Figure 13. Thus, during electrochemical cycling, PFPN facilitates the formation of a distinct SEI layer rich in phosphorus and nitrogen, thereby improving the battery’s kinetic characteristics.

Figure 13.

Schematic of the electrode SEI structure. (a) Without additives. (b) With additive. Copyright 2025 American Chemical Society [98].

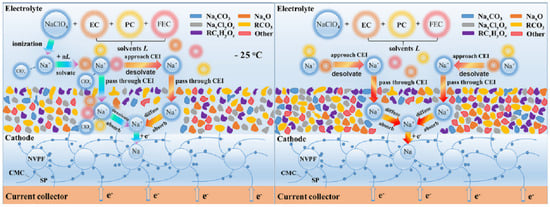

During the operation of SIBs, the electrolyte reacts with the surface of the cathode to form a CEI film. The performance of CEI film has a crucial impact on the overall performance of the battery. A suitable electrolyte can induce the cathode surface to generate a thin and strong CEI layer, which is a protective film that can effectively prevent the electrode material from coming into direct contact with the electrolyte. This protective film can effectively avoid direct contact between the electrode material and the electrolyte, thus improving the cycle life of the battery at low temperature conditions [99]. The specific mechanism is shown in Figure 14.

Figure 14.

Different behavior of Na+ across the CEI layer. Copyright 2022, Elsevier [99].

3. Strategy

3.1. Strategies for Improving the Low-Temperature Performance of SIB Electrolytes

As the primary medium connecting the cathode and anode, the electrolyte dictates the Coulombic efficiency, energy density, and cycle life of the battery system. To ensure the normal operation and performance of batteries at low temperatures, the electrolyte needs to exhibit excellent electrical conductivity, superior fluidity, and strong polarization resistance. These characteristics are of significance for enhancing the rate capability and fast-charging performance of SIBs under extremely cold conditions. The main strategies for optimizing the electrolyte include the selection of sodium salts, the addition of additives, and the utilization of multiple solvents to form a more favorable SEI [97]. These strategies optimize the electrochemical stability and ionic conductivity of the electrolyte, reduce its viscosity, and enhance the ion mobility and diffusion coefficient, thereby maintaining high power output and cycling stability at low temperatures. However, the selection of appropriate sodium salts requires a delicate balance among their solubility, ionic conductivity, and chemical stability to ensure the optimal performance of the electrolyte. Although the addition of additives is beneficial for adjusting the properties of the electrolyte, it increases complexity and necessitates careful management of their types and concentrations to prevent undesirable side reactions. Additionally, while the adoption of multi-solvent systems enhances the capabilities of the electrolyte, it may increase the weight and cost of the battery system. A thorough assessment of compatibility between the various solvents is also required to reduce the risk of phase separation, which could compromise the overall efficiency and reliability of the battery. Nevertheless, the significance of the solvation structure within the electrolyte must not be overlooked [100].

3.1.1. Solvent Component Regulation

The coordination ability of solvent molecules with cations fundamentally determines the desolvation process. This means that the ability of solvent molecules to effectively interact and coordinate with cations determines the efficiency with which these cations are stripped of their solvent shell layers. Strong coordination may lead to co-intercalation of cation/solvent complexes, inevitably damaging the structure of electrode materials and exacerbating side reactions in the solid phase. In the study conducted by Wang et al. [101], the co-solvent 1,3-dioxolane (DOL) optimizes the solvated structure of the electrolyte due to its low melting point and low solvation energy. This co-solvent enhances the participation of more PF6− anions in the formation of contact-ion pairs (CIPs) and reduces the desolvation energy of Na+. The electrolyte remains in a stable liquid state with good ionic conductivity at −40 °C, which facilitates the formation of a stable NaF-rich SEI membrane and improves the low-temperature performance of SIBs. At the same time, extremely weak interactions between cations and solvents impede ion migration during the charging and discharging processes. Therefore, mixing multiple solvents and adjusting their proportions can optimize the solvation structure, thereby achieving optimal electrochemical performance. In low-temperature and high-rate scenarios, the properties of SIBs are limited by the kinetic and thermodynamic properties of sodium ions. Therefore, the precise regulation of electrolyte solvation structures has emerged as a pivotal approach to overcoming performance bottlenecks. Li et al. [53] innovatively proposed a “hierarchical doping” strategy [102], using PC as the main solvent and introducing EMC and 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether (PFPN) as an additive. EMC can penetrate into the first solvation layer of sodium ions (Figure 15a,b), reducing the desolvation energy barrier and dispersing the electrolyte. PFPN resides in the second solvation layer, weakening the interaction between ions and solvents through a “tug-of-war effect” and participating in the formation of a stable interfacial film. The designed Na button battery containing the PC, EMC, and PFPN mixed solvent electrolyte (PEMP) electrolyte rebuilds the solvation structure of sodium ions, enhancing ionic conductivity (Figure 15c) and the diffusion rate within the electrolyte (Figure 15d). Notably, the Na3Fe2(PO4)P2O7 (NFP)||Na coin cell with this electrolyte exhibits outstanding performance at −20 °C, maintaining a capacity retention rate of over 99% after 500 cycles at 5C (Figure 15e). After cycling the same number of times in the blank electrolyte and the PEMP electrolyte, the CEI and SEI formed in the PEMP electrolyte are thinner and more uniform (Figure 15f). This design, for the first time from the perspective of hierarchical regulation of solvation structures, demonstrates the feasibility of multi-component solvent synergistic optimization in enhancing the transport efficiency of sodium ions.

Figure 15.

(a,b) The coordination number and FTIR spectra of different electrolytes. (c) The Ea,ct analyzed by Arrhenius. (d) Ionic conductivity of different electrolytes. (e) GCD curve of the NFP||Na battery at 5C at 0 °C. (f) HR-TEM images of the NFP cathode and HC anode surfaces of the NFP||HC battery surface after cycling in blank and PEMP electrolytes. Copyright 2024 Elsevier [53].

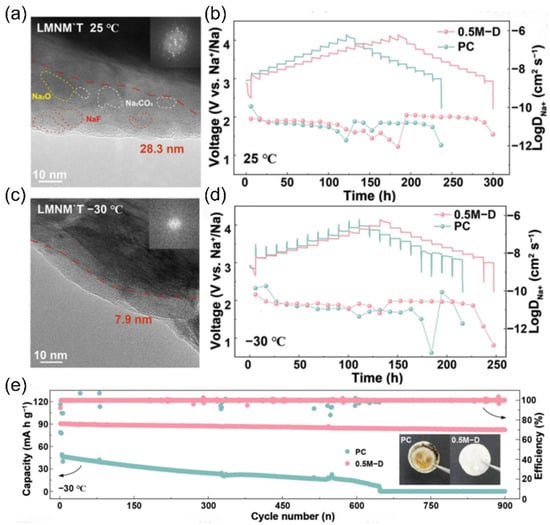

Following the concept of the dynamic regulation of solvation structures, researchers have discovered that the combination of strong and weak solvation properties in ether-based mixed solvents can endow electrolytes with temperature-adaptive characteristics. The Yang team [103] designed a temperature-adaptive electrolyte. Taking diglyme (DIG) and THF as examples, these solvents have similar dielectric constants and donor numbers. When mixed, the solvation structure can spontaneously transform at low temperatures, preventing salt precipitation (Figure 16a). As the temperature decreases, more THF participates in the solvation process (Figure 16b), stabilizing the sodium ion/solvent complexes and increasing the entropy of the system. Similarly, Huang et al. [99] designed an electrolyte with a temperature-robust solvation structure. The mixed solvent of tetraethylene glycol dimethyl ether (G4) and 1,3-dioxolane (DOL) forms a temperature-robust solvation structure through intermolecular forces anchoring (Figure 16c). The Na3V2(PO4)3||Na full battery demonstrates a reversible capacity of 95.9 mAh g−1 at −40 °C, which is 87.6% of its room-temperature capacity (Figure 16d). This marks a technological upgrade of solvation structures for electrolytes, maintaining robust temperature stability rather than volatility.

Figure 16.

(a) Schematic illustration showing the low-temperature electrolyte design strategy. (b) The representative solvation structures; the bottom shows the percentage of each solvation configuration. Copyright 2023 Elsevier [103]. (c) Schematic illustration of temperature-unstable solvation structures and temperature-robust solvation structures. (d) Charge/discharge capacities at various temperatures. Copyright 2025 American Chemical Society [104].

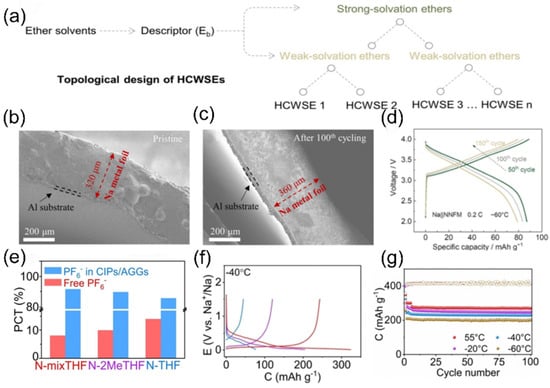

For the extreme condition of ultra-low temperature (below −60 °C), two complementary strategies have further expanded the boundary of solvation structure regulation. First, the Wang team [105] introduced strong solvation ether additives into the weak solvation system through topological design (Figure 17a) [106]. Cross-sectional SEM images of the pristine Na metal anode (Figure 17b) and after 100 cycles (Figure 17c) illustrate structural stability. The voltage profiles of the Na||NNFM cell at 0.2 C at −60 °C are shown in (Figure 17d). Second, Fang et al. [107] introduced 2-methyltetrahydrofuran (2MeTHF), which has weak solvating ability, into THF to construct a weakly solvating electrolyte. This weakens the Na+-solvent/dipole interaction, prompting more anions to participate in the solvation sheath (Figure 17e) and form a low-resistance SEI film with rich NaF. As a result, hard carbon electrodes achieve reversible capacities of 243.2 mAh g−1 and 205.4 mAh g−1 at −40 °C and −60 °C (Figure 17f,g). Although these two approaches differ in methodology, they jointly verify the universal principle of optimizing low-temperature mass transfer and interfaces by regulating the strength of ion/solvent interactions.

Figure 17.

(a) Schematic diagram of the topological design. (b,c) Cross-sectional SEM images of a Na metal anode and the one after 100 cycles. (d) Voltage profiles of the Na||NNFM cell at −60 °C. Copyright 2025 American Chemical Society [106]. (e) Coordinated structures. (f) Charge/discharge curves of HC at 50 mA g−1 at −40 °C. From right to left, N-mixTHF, N-2MeTHF, and NTHF. (g) Cycling performance at different temperatures. Copyright 2024 Wiley [107].

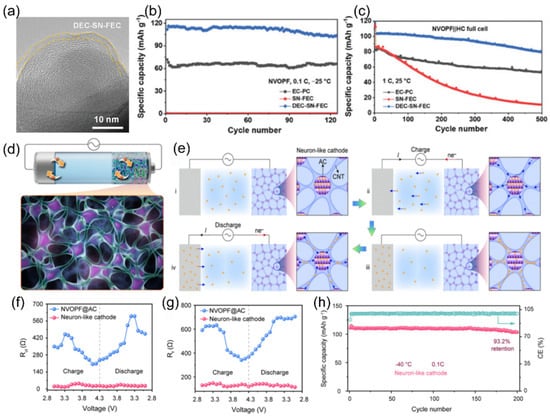

With the deepening understanding of solvation structure regulation, researchers have turned their attention to a broader range of battery systems. Although LIBs differ from SIBs in ionic properties, there are similarities in the underlying logic of electrolyte optimization. The Mo team [108] applied a moderately fluorinated ethyl difluoroacetate (EDFA) solvent to balance weak binding energy and high ionic conductivity, promoting the formation of a low-resistance inorganic SEI film on the graphite anode. This enabled a reversible capacity of 279 mAh g−1 and 6 C fast charging at −40 °C. Gao et al. [109] utilized a synergistic system of methyl propionate and methyl pentafluoropropionate. By adjusting the Li+ solvation sheath through hydrogen bonding, they weakened the Li+-solvent interaction and facilitated rapid desolvation at the interface. As a result, the LiFePO4 (LFP)||graphite battery maintained 81.2% of its room-temperature capacity at −30 °C, and a 1 Ah pouch battery still had a discharge capacity of 0.85 Ah at −20 °C, demonstrating the potential of synergistic optimization of non-fluorinated and fluorinated solvents.

The cutting-edge explorations in solvation structure design and interfacial chemistry regulation of low-temperature LIBs have provided valuable technical inspirations for low-temperature SIBs. Strategies such as the synergistic regulation of ion/solvent interactions through strong/weak solvents [110] and the promotion of low-resistance inorganic interfacial film formation via fluorination modification essentially revolve around the common goal of “reducing the desolvation energy barrier of ions and enhancing bulk phase transport and interfacial stability”. SIBs can draw on these molecular-level design concepts. By regulating the dielectric constant, donor number, and degree of fluorination of solvents, the solvation structure of Na+ can be optimized, and the formation of a stable interfacial layer rich in NaF can be promoted. This approach enables the enhancement of ionic conductivity and interfacial compatibility at low temperatures at the same time, offering a cross-system technical pathway to overcome the kinetic limitations of sodium ions.

In the recent past, aqueous low-temperature solid-state SIBs have gained some traction. Gui et al. [111] have built a bendable quasi-solid aqueous low-temperature solid-state SIB with the help of a glycol–polyacrylamide–sodium perchlorate hydrogel electrolyte. This innovative design inhibits icing through hydrogen bonding between glycol and water molecules, enabling the battery to maintain 64% of its room-temperature energy density and achieve an ionic conductivity up to 2.5 mS cm−1 at −30 °C. Additionally, the battery exhibits excellent mechanical toughness, allowing it to be bent while reliably supplying power to electronic devices.

In the future, based on the molecular design of polymer electrolytes and the synergistic optimization strategy of composite interfacial layers, we anticipate the development of a high-performance SIB system adapted to a wide temperature range. This research focuses on the design of polymer chain segment polarity, the construction of ion conduction networks within the interfacial layer, multicomponent synergistic interfacial engineering, and the development of novel composite electrolytes. It systematically investigates multidimensional approaches to optimize the interfacial dynamics of the batteries and enhance ion transport in low-temperature environments. By regulating the microscopic interactions of the electrolyte and the multiscale structure of the interface, this research provides a solid theoretical foundation and practical framework for overcoming the core challenges of interfacial impedance accumulation and ion migration hysteresis under extreme operating conditions. Furthermore, it facilitates the extensive application of SIBs in scenarios requiring high cold resistance, high power, and flexibility.

3.1.2. Efficient Dissociation of Sodium Salts

In SIBs, the optimization of electrolyte formulations is highly dependent on the properties of the selection of sodium salts. Sodium salts such as sodium hexafluorophosphate (NaPF6), sodium tetrafluoroborate (NaBF4), sodium perchlorate (NaClO4), sodium bis(trifluoromethanesulfonyl)imide (NaTFSI), sodium fluoro–bis(trifluoromethanesulfonyl)imide (NaFTFSI), and sodium fluorosulfonylimide (NaFSI) play a crucial and multi-dimensional role in the electrochemical performance of the batteries. The development of novel sodium salts with appropriate anion structures and properties can improve the solvation state of sodium ions and facilitate desolvation. For example, the design and synthesis of sodium salts with larger anion volumes and more stable structures can make the solvation shell around sodium ions looser and facilitate desolvation. Additionally, optimizing the concentration of sodium salts also impacts the desolvation process. Appropriately increasing the salt concentration can increase the number of ion pairs in the electrolyte, altering the solvation structure and promoting desolvation to a certain extent. However, excessively high salt concentrations may lead to increased electrolyte viscosity and hindered ion migration, necessitating the identification of an optimal concentration balance. In the work of Guo et al. [112], the localized high concentration electrolyte (LHCE) facilitates the exchange of anion/solvent molecules within the solvated sheaths of sodium ions and organic cations through the introduction of an ionic liquid. This process reduces the size of the solvated clusters and enhances sodium/anion coordination, which in turn promotes rapid ionic dynamics both in the liquid phase and at the interface. As a result, this enables longer-lasting low-temperature sodium deposition and contributes to the development of a shuttle-effect-free 0.5 Ah sodium–sulfur flexible-pack battery. As the core conductive substances, the Na+ ions dissociated from these sodium salts upon dissolution serve as the primary charge carriers that shuttle between the cathode and anode electrodes during charging and discharging. The regulation of their concentration directly affects the ionic conductivity of the electrolyte. By maintaining ion balance between the cathode and anode electrodes, polarization can be effectively suppressed, internal resistance can be reduced, and rapid ion migration can be promoted. Sodium salts are also deeply involved in the formation of the SEI. The anions dissociated from sodium salts collaborate with solvent molecules to construct an ion-selective SEI film, which not only blocks electron transfer to inhibit side reactions but also provides an efficient transport pathway for Na+ ions, directly determining the interface stability and the cycle life of the battery. Moreover, the electrochemical window of the sodium salt anions needs to encompass the redox potential ranges of both the cathode and anode electrodes to ensure the battery’s thermodynamic stability. In terms of thermal stability, common sodium salts exhibit a decreasing trend as follows: NaClO4 > NaBF4 > NaTFSI > NaPF6 > NaFTFSI > NaFSI [113]. Although NaClO4 demonstrates excellent thermal stability due to the high oxidation state of chlorine, its strong oxidizing property makes it prone to triggering violent oxidation reactions, thus limiting its practical application. Conversely, while NaPF6 has relatively lower thermal stability, it has become the current mainstream choice due to its lowest oxidation potential and highest electrical conductivity. These property disparities underscore that the formulation design of electrolytes for SIBs requires a precise balance among ionic conduction efficiency, interface stability, and thermal safety to meet the high-performance requirements of diverse occasions [114].

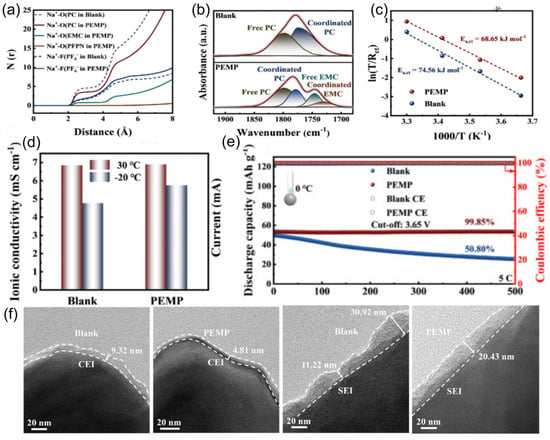

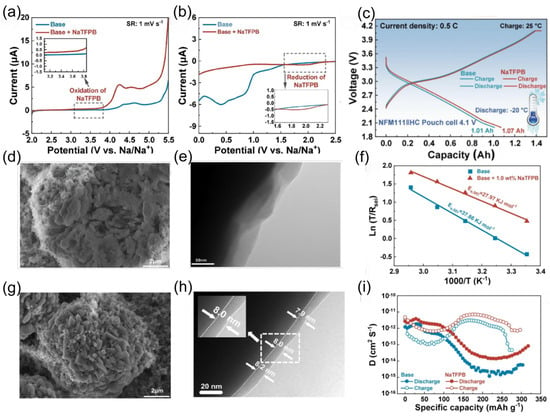

Hu et al. [115] added the sodium salt sodium tetrakis(pentafluorophenyl)borate (NaTFPB) to the basic electrolyte. Through theoretical simulations and experimental studies, they found that NaTFPB can regulate the structure of the first solvation shell of Na+ [116], and preferential redox reactions (Figure 18a,b) occurred on the electrode surface, forming stable CEI and SEI layers rich in NaF and boron compounds. This effectively inhibits the decomposition of the electrolyte and the dissolution of transition metals, improves ion transport kinetics, and provides the battery with good discharge capability at −20 °C (Figure 18c). As shown in the SEM and Transmission Electron Microscope (TEM) images of the NaNi0.33Fe0.33Mn0.33O2 (NFM111) cathode after cycling in different electrolytes (Figure 18d,e,g,h), these layers effectively inhibited the decomposition of the electrolyte and the dissolution of transition metals. Analysis of the activation energy of Na+ transport through the SEI (Figure 18f) revealed that the addition of NaTFPB reduced the activation energy and facilitated ion transport. In addition, the Galvanostatic Intermittent Titration Technique (GITT) curves and diffusion coefficients of the alkali + NaTFPB electrolyte (Figure 18i) further indicated that the ion diffusion performance was improved.

Figure 18.

(a,b) LSV spectra of base and base+NaTFPB electrolytes at 1 mV s−1. (c) The discharge comparison at a low temperature of −20 °C. (d,e,g,h) SEM and TEM images of the NFM111 cathode after cycling in a base electrolyte and a NaTFPB-containing electrolyte. (f) The activation energies for the Na+ transport through the SEI. (i) GITT curves and diffusion coefficients of base + NaTFPB electrolytes. Copyright 2025 Elsevier [115].

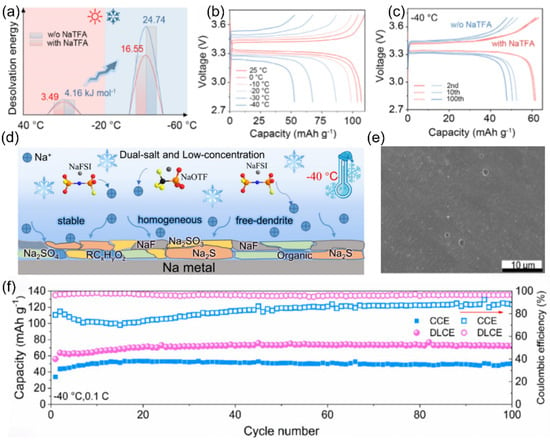

To address the severe capacity loss in SIBs caused by slow interfacial dynamics at low temperatures, the Li’s team [117] introduced the trifluoroacetate (TFA−) anion with ultra-high electron-donating ability into a diglyme (G2)-based electrolyte to regulate the solvation structure of sodium ions. Experimental results and theoretical calculations demonstrate that TFA− can enhance its coordination with sodium ions, enabling more hexafluorophosphate anion (PF6−) anions and fewer G2 molecules to occupy the inner solvation sheath, thereby reducing the desolvation energy (Figure 19a). As a result, the Na||Na3V2(PO4)3 battery can retain 60.2% of its room-temperature capacity at −40 °C (Figure 19b) and 99.2% capacity retention after 100 cycles (Figure 19c).

Figure 19.

(a) Schematic of desolvation energy at a wide temperature. (b) Charge/discharge curves in the electrolyte with NaTFA. (c) Charge/discharge curves at 100 mA g−1 at −40 °C. Copyright 2024 PANS [117]. (d) Schematic diagram of the synthesis process. (e) SEM images of electrolytes after cycling. (f) Cycling performance of the Na||Na3V2(PO4)3 full-cells. Copyright 2025 American Chemical Society [118].

Yang et al. [118] innovatively dissolved two sodium salts, sodium trifluoromethanesulfonate (NaOTf) and sodium hexafluorophosphate (NaPF6), in diglyme (G2) (Figure 19d) to prepare a weakly solvated electrolyte [119] with a small amount of additive. In the low-temperature environment of −40 °C, owing to the weak Na+-G2 interaction in the weakly solvated electrolyte, the surface of sodium metal remains smooth during cycling (Figure 19e) without dendrite formation. This good surface condition ensures the electrochemical performance of the battery. The half-cell has a high Coulombic efficiency of 99.2% after 100 cycles at −40 °C and 0.1 C, while being able to maintain a capacity of 70.5 mAh g−1 (Figure 19f).

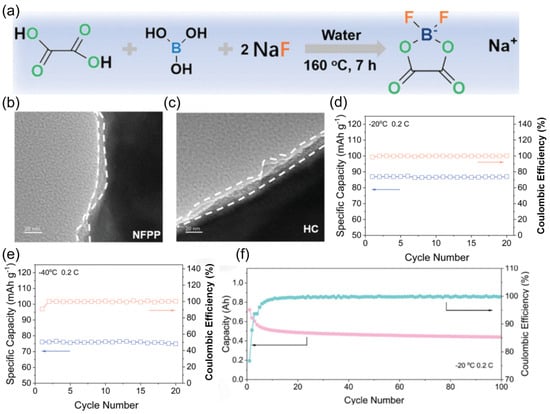

Aiming at the shortcomings of commonly used sodium salts, the Xia team [120] developed a low-cost and easy-to-prepare sodium salt: sodium difluoro(oxalato)borate (NaDFOB) (Figure 20a). The synergistic effect of the oxalic acid root and fluorine atoms in its molecular structure forms a dense composite film of NaF/Na2B4O7 on the electrode surface (Figure 20b,c). The Na4Fe3(PO4)2P2O7 (NFPP) electrode exhibits excellent performance in the electrolyte containing NaDFOB, with a capacity retention rate of 92.7% at −20 °C and 84.8% at −40 °C (Figure 20d,e). For the HC//NFPP pouch full battery at −20 °C, with an initial capacity of 0.8 Ah, the capacity tends to stabilize after a certain number of cycles, and the final capacity is approximately 0.4 Ah, with the final Coulombic efficiency approaching 100% (Figure 20f), demonstrating the potential of the novel sodium salt in practical devices.

Figure 20.

(a) A schematic illustration of the synthesis of NaDFOB. (b,c) TEM images of NFPP and HC electrodes after cycling. (d,e) Cycling performance of Na//NFPP half-cells at −20 °C and −40 °C. (f) Cycling performance of the HC//NFPP pouch at low temperature. An arrow to the left indicates that the curve corresponds to the left vertical axis, and the same is true to the right. Copyright 2024 Wiley [120].

Furthermore, although a 2 m dual-salt sulfolane (TMS)/ethyl acetate (EA)-based local high-concentration electrolyte (LHCE) [121] has been designed, its outstanding low-temperature performance offers novel insights for further electrolyte design. In the future, through the synergistic effects of solvents and salts, it may be possible to develop similar low-temperature sodium salt materials. These studies, ranging from the screening of anion types to the regulation of solvation shell structures, interfacial film engineering, and the synthesis of novel sodium salts, systematically reveal the performance optimization pathways for low-temperature SIBs. They provide extensive theoretical and experimental support for overcoming the bottlenecks of energy storage technologies in extreme environments.

3.1.3. Additives

In the electrolytes of low-temperature SIBs, additives form a multidimensional regulation system through functional differentiation and synergistic effects. In terms of composition, they can be classified into four major categories: solvent type, film-forming type, conductivity-enhancing type, and stability type. These categories, respectively, undertake core functions of lowering the freezing point, inducing the formation of interfacial films, optimizing ion transport, and suppressing side reactions.

The underlying mechanisms of their actions essentially involve reconstructing the Na+ solvation sheath [122] through coordination chemistry, improving the low-temperature viscosity of the electrolyte via the eutectic effect [123], and directionally constructing nanoscale dense interfacial films on the surfaces of cathode and anode electrodes through redox reactions. Meanwhile, with the help of chemical adsorption of functional groups containing phosphorus, sulfur, or cyano groups, or filling with nanoparticles, the mechanical properties of the interface are enhanced, and the growth of sodium dendrites and hydrofluoric acid (HF) corrosion are inhibited [124,125,126,127,128].

These mechanisms work in concert to enable the ionic conductivity of the electrolyte to reach the ideal value at low temperatures and promote a capacity retention rate of the battery in extreme low-temperature environments exceeding 90%, thus becoming a key technical factor in breaking through the low-temperature performance bottleneck of SIBs.

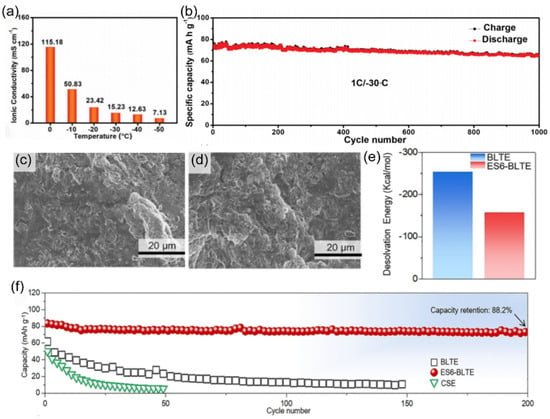

When traditional aqueous electrolytes encountered the challenge of ion conduction failure at −50 °C, Zhu et al. [129] prepared a new low-temperature electrolyte by adding calcium chloride (CaCl2) as an antifreeze additive to a 1m NaClO4 aqueous electrolyte. At −50 °C, ionic conductivity reached a remarkable 7.13 mS cm−1 (Figure 21a), far exceeding the 0.11 mS cm−1 of the NaClO4 electrolyte with dimethyl sulfoxide (DMSO) addition. This breakthrough enabled the Na2CoFe(CN)6-activated carbon full-cell to exhibit outstanding performance at low temperatures. At −30 °C, the specific discharge capacity of the cell reached 74.5 mAh g−1, and after 1000 cycles, the discharge capacity remained at 64.6 mAh g−1, with a capacity retention rate of 86.7% (Figure 21b).

Figure 21.

(a) The ionic conductivity of CaCl2 + NaClO4 electrolyte at different temperatures. (b) Cyclic performances of the full-cell under −30 °C. Copyright 2023 Wiley [121] (c,d) SEM images of Na anodes with BLTE and ES6-BLTE electrolytes after cycling. (e) The desolvation energy of BLTE and ES6-BLTE electrolytes obtained from DFT calculations. (f) Cyclability of the Na||NVP cells with BLTE and ES6-BLTE electrolytes at 0.1 C. Copyright 2023 WILEY [130].

Zhong’s team [130] identified the kinetic bottleneck in the sodium ion desolvation process and aimed to enhance the low-temperature performance of SIBs by regulating the solvation structure with additives. They designed a carbonate-based electrolyte, 1.0 M NaFSI in EC/PC/DEC (1/1/4, v/v/v), containing 6% ethylene sulfate (ES6BLTE). As the core additive, ES optimized the solvation structure through molecular engineering, reducing the coordination between Na+ and solvent molecules. This led to a significant decrease in the Na+ desolvation energy from −253.1 kcal mol−1 in the baseline low-temperature electrolyte of 1.0 M NaFSI in EC/PC/DEC (1/1/4, v/v/v) (BLTE) electrolyte to −157.5 kcal mol−1 (Figure 21e), remarkably reducing the interfacial reaction resistance. This microscopic coordination reconstruction brought about a macroscopic performance leap. SEM images of Na anodes with BLTE (Figure 21c) and ES6BLTE electrolytes (Figure 21d) after cycling reveal structural differences. The Na||Na3V2(PO4)3 full-cell achieved a capacity retention rate of 88.2% after 200 cycles at 0.1 C (Figure 21f).

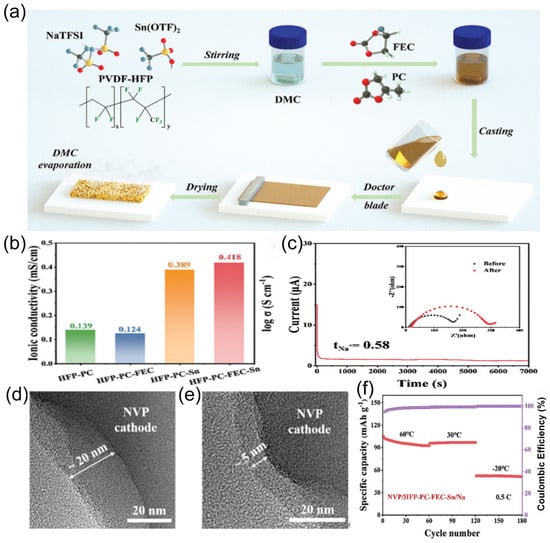

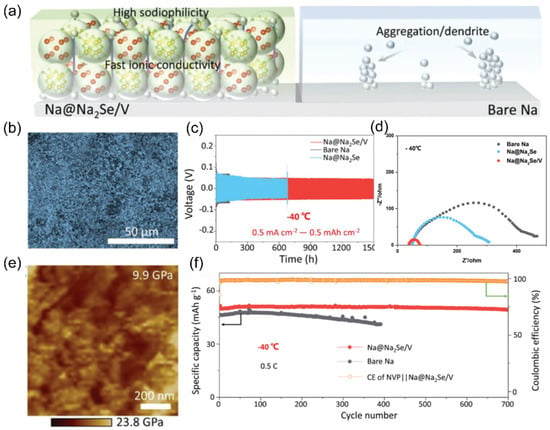

Yang et al. [131] combined a fluoroethylene carbonate (FEC) and tin trifluoromethanesulfonate (Sn(OTf)2) into the poly(vinylidenefluoride-co-hexafluoropropylene) (PVDF-HFP) and NaTFSI polymer matrix with a Sn(OTf)2 catalytic system and introduced PC and FEC into DMC solvent to construct a quasi-solid-state electrolyte (QSPE) with both high conductivity and interfacial stability (Figure 22a). Sn(OTf)2 catalyzes the ring-opening reaction of PC, reducing the transport barrier and enhancing sodium ion transport, endowing the prepared QSPE with an ionic conductivity of 0.42 mS cm−1 and a sodium ion transference number of 0.58 (Figure 22b,c). The reduction in desolvation energy remarkably reduced the interfacial reaction resistance. SEM images of Na anodes with BLTE (Figure 22d) and ES6-BLTE electrolytes (Figure 22e) after cycling revealed structural differences. When this electrolyte is applied to pouch batteries, it demonstrates stable performance at −20 °C (Figure 22f), not only inheriting the safety advantages of solid-state electrolytes but also compensating for the conduction defects of traditional solid-state materials through catalytic reactions.

Figure 22.

(a) Schematic illustration of HFP-PC-FEC-Sn QSPE. (b) Ionic conductivity of QSPEs. (c) Chronoamperometry curve of Na/HFP-PC-FEC-Sn/Na cells. The inset shows Nyquist plots before and after polarization. (d,e) TEM images of CEI film on an NVP cathode after 100 cycles. (f) Long cycling performance of NVP/HFP-PC-FEC-Sn/Na at 0.5 C. Copyright 2024 WILEY [131].

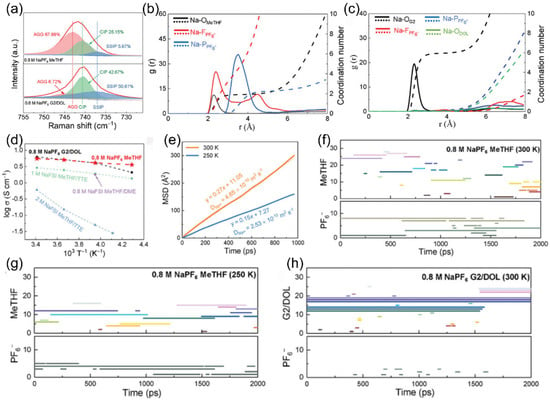

Ge team’s [132] diluted electrolyte with 2-methyltetrahydrofuran (MeTHF) as a key additive demonstrated ultra-high Coulombic efficiency for sodium plating/stripping at −25 °C and −40 °C (Figure 23a). Through a variety of characterization methods, it was found that the MeTHF additive induced the electrolyte to form an anion-π interaction-dominated solvation structure (Figure 23b,c). This structure not only endows anode-free sodium metal batteries (AFSMBs) with excellent ionic conductivity and charge conduction efficiency at low temperatures (Figure 23d,e), but also ensures the continuous and efficient operation of the charge transport network under low-temperature conditions through the stable architecture of ion conduction channels (Figure 23f–h).

Figure 23.

(a) Fitted Raman spectra of PF6− anions, (b,c) Na+ RDF and coordination number, and (d) temperature-dependent ionic conductivity in the MeTHF and G2/DOL electrolytes. (e) The mean-squared displacements of Na+ in MeTHF at 25 and −25 °C. (f–h) Evolution of the Na-ion solvation environment in the MeTHF and G2/DOL. Copyright 2024 Wiley [132].