Abstract

In this study, the life cycle assessment (LCA) was used to compare the environmental performances of a conventional bulk carrier (baseline vessel) and a wind-energy-optimised bulk carrier equipped with modern on-board technologies working in synergy (future vessel). Fossil fuels was used for the baseline vessels, whereas the future vessel used liquefied biogas (LBG) and hydrotreated vegetable oil (HVO) as marine fuels. The entire life cycle phases of the vessels, namely, construction, operation, maintenance, and end-of-life, were included. The results showed that the future vessel could reduce 31.23% energy consumption, compared to the baseline model. Furthermore, the significant reduction in CO2 (48.6%), NOX (88.6%), SOX (100.0%), and black carbon (94.0%) in the tank-to-wake phase was achieved owing to energy-saving technologies working in synergy and alternative fuels. This study emphasizes the vital role of energy efficiency, technologies, and alternative fuels to achieve the zero-emission ambition of the maritime industry. Furthermore, the impacts of ship construction, maintenance, and end-of-life need to be fully considered in order to decarbonize vessel from a life cycle perspective.

1. Introduction

GHG emissions from the shipping industry currently account for nearly 3% of global GHG emissions [1]. Without prompt action, these emissions are projected to increase by up to 130% of the 2008 levels by 2050 [2]. At MEPC80 in July 2023, the International Maritime Organization (IMO) revised the decarbonisation strategy for the shipping industry, with the aim of achieving “net-zero GHG emissions by or around 2050” [3]. This action demonstrates the maritime industry’s commitment to mitigating its environmental impact.

To mitigate the environmental impact of the shipping industry, it is essential to effectively utilize energy-saving technologies and alternative fuels. In project CHEK (deCarbonising sHipping by Enabling Key technology symbiosis on real vessel concept designs) [4], it is acknowledged that there is no “silver bullet” solution that can single-handedly support the maritime industry’s decarbonisation efforts, especially in achieving the highly ambitious targets set by the IMO [3]. A series of technologies designed to work in synergy, along with the exploration of alternative fuels like LBG and HVO, have been investigated with the goal of reducing emissions from ships. These innovative technologies have been optimized right from the ship’s design phase and have been successfully applied to a bulk carrier.

Some energy-saving technologies can be listed as air-lubrication systems, gate rudders, ultrasound antifouling, waste heat recovery, wing sails, weather routing, etc. To avoid compromises with an increasingly fluctuating engine load profile, the concept comprises a scalable, hybrid 4-stroke engine power plant. These technologies are designed to enhance efficiency and reduce environmental impacts.

The utilization of alternative fuels and technologies, regarding their environmental benefits, requires careful consideration [5]. To assess the true impacts of shipping, it is crucial to employ a systematic tool. The LCA method provides such a systematic tool for evaluating the environmental impacts of a product or service throughout its entire life cycle. The LCA framework typically comprises four stages: (i) goal and scope definition, (ii) life cycle inventory, (iii) impact assessment, and (iv) interpretation [6]. Consequently, LCA is essential for measuring the carbon footprint and assessing the environmental impacts throughout a ship’s life cycle.

In the shipping industry, the application of LCA is gaining importance [7]. LCA finds various applications in the maritime sector, including assessments for fuels, propulsion systems (considering both fuels and engines), and the LCA of vessels [8,9,10]. The readers are referred to see the recent literature reviews on the application of LCA in the shipping industry in references [8,9,10]. Additionally, IMO has issued guidelines on GHG emissions, which provide instructions for calculating the life cycle impacts of fuels [11].

In this study, the LCA method was used to validate the environmental benefits of the technologies working in synergy together with the use of alternative fuels, applied to a bulk carrier. This paper proceeds as follows: after the introductory section, Section 2 presents the LCA method utilized in this work, following instructions from ISO14040 [6]. Section 3 presents the life cycle emissions results, uncertainty, and parameter variation analyses.

2. Method

2.1. Goal and Scope Definition

In project CHEK, new conceptual vessel designs are generated as a synthesis of efficient design and operation, innovative technologies, and sustainable fuels. This study investigated the comparative LCA of two versions of Kamsarmax-sized bulk carriers, namely, baseline and future vessels. The baseline vessel was actually a digital prototype rather than a real vessel, and all performance data were simulated using digital models. The designed future vessel aims to reduce on-board energy consumption and is equipped with a combination of energy efficiency technologies working in synergy. The synergy of technologies was demonstrated by including in the vessels WindWings technology, air lubrication system, gate rudder, ultrasound antifouling system, waste heat recovery, and automated route optimisation.

Even though the new ship concepts are developed digitally, existing vessels are also studied in the project to validate the modelling and as a reference, and some of the studied and developed technologies in project CHEK are tested on-board existing ships. For instance, Figure 1 illustrates a Kamsarmax-sized vessel with two WindWing sails. A Kamsarmax-sized vessel without any specific energy saving technologies was chosen as a reference vessel for the LCA calculation.

Figure 1.

Reference bulk carrier (source: https://www.cargill.com/static/assets/images/Pyxis-ocean/Hero_Pyxis_Ocean_Aug_2023.jpg).

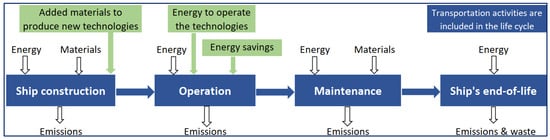

Figure 2 shows the system boundary of the LCA work, including four main phases, namely, ship construction, operation, maintenance, and end-of-life. The green colour denotes the contribution of added technologies to the future vessel. In the construction and maintenance phases, material and energy consumption as well as emissions emitted from typical activities in shipyards were taken into account. The transportation of material from still mills to the shipyards was also considered in the vessel’s life cycle. In the ship operation, well-to-tank (WTT) and tank-to-wake (TTW) emissions of fuels were collected from Ecoinvent database version 3.8 [12], Sphera’s database [13], and IMO’s 4th GHG report [2]. Section 2.2 presents the data used in this study.

Figure 2.

System boundary of the vessel’s life cycle.

The function of a bulk carrier is to transport bulk cargo by sea over its lifetime; therefore, the chosen functional unit in this work was “the transport of one ton bulk cargo by the bulk carrier (one ton* nautical mile) by the sea over 25 years”. This functional unit ensured a fair comparison between the baseline and the future vessels.

In line with the strategy of IMO reducing the GHG emissions in the upcoming years, GWP100 [14] was chosen as the environmental indicator. Furthermore, typical emissions from the shipping industry were also investigated, such as CO2, CO, PM10, PM2.5, CH4, NOX, N2O, NMVOC, SOX, and BC. LCA-FE software application version 10.7.1.28 [13] was used in order to obtain results.

Due to the uncertainty of the input data, some parameters were chosen in the uncertainty analysis (see Section 3.2). Some assumption and limitations were made as follows:

- The lifetime of vessels is 25 years. After 25 years, the vessels will be retired, and the materials will be recycled.

- Waste generation and management during the ship’s life cycle, labour, and economic factors are ignored.

- Malfunction of engines, equipment, and system are also ignored in the ship’s life cycle.

- Both baseline and future vessels have the same maintenance plan. The maintenance phase will affect the transportation work amount due to the idle status of the vessel at this time.

- The difference in the transportation work and cargo capacity between the baseline vessel and future vessel are considered in the uncertainty analysis.

- The data for transportation work of the reference vessel are used to estimate the total transportation work in the entire life cycle.

2.2. Life Cycle Inventory

2.2.1. Data for Vessels’ Life Cycle Phases

Table 1 presents the data of the ship construction, maintenance, and end-of-life that were used for the study.

Table 1.

Life cycle inventory description.

Table 2.

Hull’s material components [12,15].

In the ship operation, the fuel consumption data were taken from the digital model, which is presented in the following section. Table 3 presents the WTT carbon factors, whereas Table 4 presents TTW emission factors of marine fuels used in this study.

Table 3.

Well-to-tank carbon factors (unit: kg CO2 eq./kg of fuel).

Table 4.

TTW emission factors (unit: kg of CO2 equiv. emission/1 kg of fuel) [2].

2.2.2. Digital Model

Project CHEK includes digital model development in several modelling generations. This study is based on the second round of modelling called “digital master”. The digital ship includes new hull, and the modelling of the ship propulsion power was based on a realistic operational profile including the impact of weather on typical routes. The vessel fuel consumption is obtained from a system-level energy model “DeltaKey”, where the propulsion profile is combined to the ship’s other energy consumers. The ship fuels, machinery concept, and other available technologies are included in the energy model, including their main interactions. The propulsion power modelling, the “digital master” simulations, and the model’s main parameters are described in [30,31]. Table 5 presents the fuel consumption results obtained from the digital master model.

Table 5.

Fuel consumption data from digital master model in the vessels’ lifetime (unit: ton).

2.2.3. Uncertainty Analysis and Parameter Variation Description

Uncertainty analysis is a critical component of LCA, which is used to evaluate the robustness and reliability of LCA results [32]. Uncertainty arises due to variability in the input data of energy consumption in the shipyard; electricity consumption of the materials used, e.g., steel; fuel types of consumption; cargo capacity; and emission factors.

Uncertainty analysis can be used to improve the robustness and reliability of LCA studies by identifying the most important parameters and ensuring that the results are not overly sensitive to minor variations or uncertainties [33]. It can also help to identify areas where more data or research is needed to reduce the uncertainty in the LCA model. Table 6 shows the sensitivity analysis description that was deployed in this study.

Table 6.

Uncertainty analysis description.

3. Results and Discussion

3.1. Life Cycle Emissions and GWP

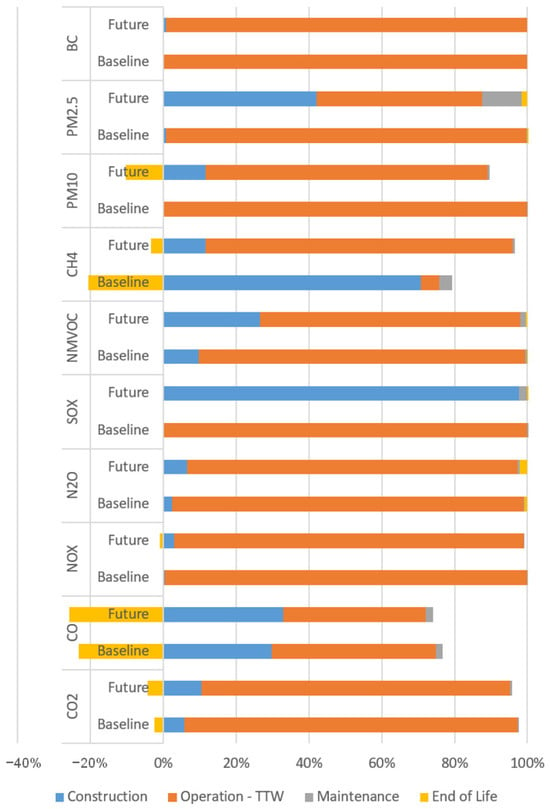

Figure 3 shows the share of the life cycle phases of the baseline and future bulk carrier in emissions. Unsurprisingly, the operation phases have a greater contribution to the impacts on most emissions and GWP100. This is because a high amount of marine fuels is consumed in this phase during the entire life cycle (Table 5). The operation phase accounts for 95.9% and 79.7% of the total GWP100 for baseline and future vessels, respectively.

Figure 3.

Contribution of life cycle phases of baseline and future bulk carriers to the emissions and GWP100.

The use of VLSFO and LBG, which contain a low/or zero sulphur content, leads to the negligible contribution of the operation phase to the amount of SOX, compared to the ship construction and maintenance phases. The results also show that the construction phase has a considerable amount of CO emissions for both vessels. Furthermore, the future vessel has a higher contribution in construction and maintenance than the baseline vessel. It is suggested that, in order to decarbonize the entire life cycle of a vessel, the impacts of ship construction, maintenance, and end-of-life should be carefully investigated.

The energy-saving technologies working in synergy can reduce the total energy consumption from 5.613 × 109 to 3.86 × 109 MJ, equal to a 31.23% reduction (Table 5). Table 7 presents the emissions reduction of the future vessels in the operation phase and from the entire life cycle. It is clear that the future vessel could significantly cut down the global warming impact as well as CO2 (48.6%), NOX (88.6%), SOX (100.0%), and BC (94.0%) emissions in the TTW phase.

Table 7.

Comparison (unit: kg CO2 eq./ton·nm).

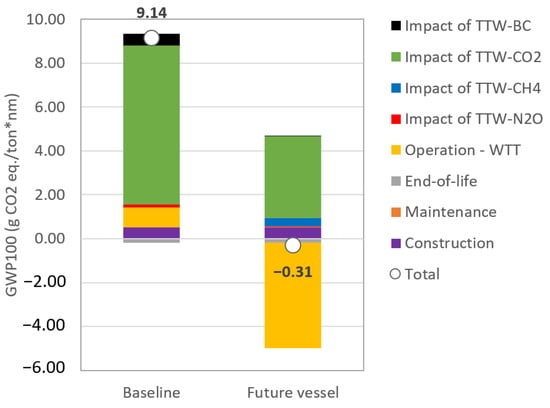

Figure 4 presents the GWP100 values for the baseline and future vessels. The baseline vessel emits 9.140 g of CO2 eq. per ton·nm. In contrast, the introduction of biofuels such as LBG and HVO in the future vessel could markedly lower the life cycle’s environmental impact, reducing it to −0.31 g of CO2 eq. per ton·nm. Nonetheless, it is crucial to note that these results depend heavily on the WTT phase, which is the fuel production stage.

Figure 4.

GWP100 per functional unit of baseline and future vessels.

3.2. Sensitivity Analysis and Parameter Variation

Table 8 shows the changes in the GWP100 results in percentage due to the uncertainty of some parameters. The changes in parameters in ship construction and maintenance could cause a slight variation in the results, with the highest change of 0.47% of GWP100 for electricity consumption in shipyards. The lifetime and the cargo weight of the vessel are also important factors that affect the environmental performance. The pilot fuel rate can also affect the results considerably, depending on the type of fuel and production pathway.

Table 8.

Uncertainty analysis results.

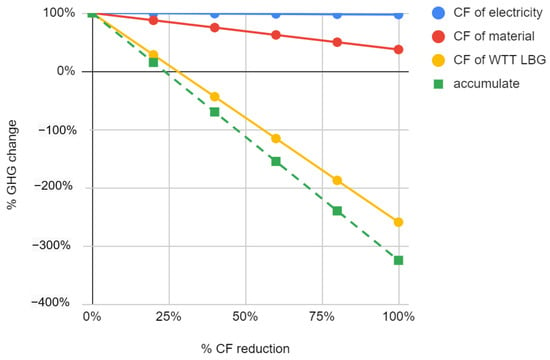

Figure 5 illustrates the effects of carbon factors (CFs) on the WTT of fuels, materials to build the vessels, and electricity (for the future vessel). From the LCA perspective, the reduction in the CF effects on the (i) electricity in the shipyards, (ii) materials used to build the vessels, and (iii) WTT phase of fuels are considered the potential trend to cut down the life cycle emissions. It is assumed that the CFs will be decreased from 0% to 100% (horizontal axis). The vertical axis shows the % change in the LCA results of the future vessel. A 100% value on the vertical axis is equivalent to the current GWP value of the future bulk carriers.

Figure 5.

Parameter variation.

The impact of electricity and energy in the shipyard can be considered to reduce the environmental impacts of the construction phases. Green material can also be used to build the vessel. In order to explore further reductions in GHG associated with the use of LBG, it may be considered to implement a bioenergy with a carbon capture and storage approach, by which, at least, the CO2 co-produced during the production of biogas could be captured at the source and geologically sequestered to reduce the overall climate impact from LBG use. Typically, the production of biogas involves the formation of at least 25% CO2 on a molar basis [34]. This means that for 1 kg of bio-LNG, at least 0.916 kg of biogenic CO2 could potentially be sequestered.

4. Conclusions

This study used the LCA method to investigate the life cycle emission and GWP100 of bulk carriers with the data adopted from a digital master model. The LCA work followed the instructions from ISO14040, and the results were obtained by using the LCA-FE software application. The results showed that the future vessel, which uses LBG as marine fuel and is equipped with modern technologies working in synergy, can significantly lower environmental impacts and achieve energy savings of up to 31.23%. Additionally, during the TTW phase, the future vessel has the potential to reduce CO2 emissions by 48.6%, NOX by 88.6%, SOX by 100%, and BC by 94%.

The limitation of this study is due to the lack of data related to the material used to produce the technologies, the effect of new technologies on the maintenance phase, and the cargo capacity or cargo weight changes when the new technologies are applied. Several concluding remarks can be listed as follows:

- The use of energy-saving techniques working in synergy and alternative fuels plays a crucial role in reducing the impacts on the environment. In order to reach zero or near-zero impact from a life cycle perspective, more technologies on-board vessels and upstream of marine fuels’ production need to be investigated and studied. Furthermore, energy-saving technologies ensure lower costs for alternative marine fuels in a ship’s operation phase.

- The use of alternative fuels could reduce the impact of ship operation and the contribution of ship construction, maintenance, and end-of-life. Therefore, the role of these phases should be considered adequately soon.

- The LCA methodology should be used as a credible tool to support maritime decarbonisation. A credible framework and guideline should be established which consider all the life cycle phases of the vessels, not the life cycle of marine fuels only. In summary, this LCA study underscores the vital importance of adopting a holistic approach to maritime sustainability, encompassing innovative technologies, alternative fuels, and a comprehensive understanding of the entire life cycle of bulk carriers. By embracing these principles, the industry can strive towards a more environmentally responsible and sustainable future.

Author Contributions

T.D.: Conceptualization, Methodology, Software, Data curation, Writing. S.B.: Conceptualization, Methodology, Software, Data curation, Writing. M.E.: Conceptualization, Methodology, Data curation, Writing—original draft. A.S.: Conceptualization, Methodology, Data curation, Writing—original draft. A.I.Ö.: Conceptualization, Methodology, Reviewing, Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This project received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 955286. The content of this report reflects only the authors’ view and the European Commission is not responsible for any use that may be made of the information it contains.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

Authors S.B. and M.E. were employed by the company Deltamarin Finland. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bodansky, D. Regulating Greenhouse Gas Emissions from Ships: The Role of the International Maritime Organization. In Ocean Law Debates: The 50-Year Legacy and Emerging Issues for the Years Ahead; Scheiber, H., Oral, N., Kwon, M., Eds.; BRILL: Leiden, The Netherlands, 2016. [Google Scholar]

- IMO. Fourth IMO GHG Study 2020; IMO: London, UK, 2020; Available online: https://www.imo.org/en/ourwork/Environment/Pages/Fourth-IMO-Greenhouse-Gas-Study-2020.aspx (accessed on 16 November 2023).

- IMO. 2023 IMO Strategy on Reduction of GHG Emissions from Ships. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/annex/MEPC%2080/Annex%2015.pdf (accessed on 27 September 2023).

- CHEK. Decarbonizing Shipping. Available online: https://www.projectchek.eu/ (accessed on 11 November 2023).

- Dong, D.T.; Cai, W. Life-cycle assessment of ships: The effects of fuel consumption reduction and light displacement tonnage. P. I. Mech. Eng. M-J. Eng. 2019, 234, 143–153. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Chatzinikolaou, S.D.; Ventikos, N.P. Holistic framework for studying ship air emissions in a life cycle perspective. Ocean Eng. 2015, 110, 113–122. [Google Scholar] [CrossRef]

- Mondello, G.; Salomone, R.; Saija, G.; Lanuzza, F.; Gulotta, T.M. Life Cycle Assessment and Life Cycle Costing for assessing maritime transport: A comprehensive literature review. Marit. Policy Manag. 2021, 50, 198–218. [Google Scholar] [CrossRef]

- Mio, A.; Fermeglia, M.; Favi, C. A critical review and normalization of the life cycle assessment outcomes in the naval sector. Bibliometric analysis and characteristics of the studies. J. Clean. Prod. 2022, 371, 133268. [Google Scholar] [CrossRef]

- Istrate, I.; Iribarren, D.; Dufour, J.; Ortiz Cebolla, R.; Arrigoni, A.; Moretto, P.; Dolci, F. Quantifying Emissions in the European Maritime Sector; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- IMO. MEPC 80-WP.7—Report of the Fifteenth Meeting of the Intersessional Working Group on Reduction of GHG Emissions; IMO: London, UK, 2023. [Google Scholar]

- Ecoinvent. Ecoinvent Database. 2023. Available online: https://ecoinvent.org/the-ecoinvent-database/ (accessed on 10 October 2023).

- LCA for Experts (GaBi), Stuttgart. 2023. Available online: https://sphera.com/life-cycle-assessment-lca-software/ (accessed on 10 November 2023).

- IPCC. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2021. [Google Scholar]

- Jain, K.P.; Pruyn, J.F.J.; Hopman, J.J. Quantitative assessment of material composition of end-of-life ships using onboard documentation. Resour. Conserv. Recycl. 2016, 107, 1–9. [Google Scholar] [CrossRef]

- Johnsen, T.; Fet, A.M. Screening Life Cycle Assessment of M/V Color Festival; HiÅ10/B101/R-98/009/00; Aalesund College: Ålesund, Norway, 1998. [Google Scholar]

- Kameyama, M.; Hiraoka, K.; Tauchi, H. Study on Life Cycle Impact Assessment for Ships; National Maritime Reseach Institute: Tokyo, Japan, 2007.

- National Pollutant Inventory. Emission Estimation Technique Manual for Shipbuilding Repair and Maintenance. Available online: http://www.npi.gov.au/resource/emission-estimation-technique-manual-shipbuilding-repair-and-maintenance (accessed on 27 October 2018).

- The National Shipbuilding Research Program. Particulate Emission Factors for Blasting Operations and Other Potential Sources. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA447602.pdf (accessed on 10 November 2023).

- Harish, C.; Sunil, S.K. Energy Consumption and Conservation in Shipbuilding. Int. J. Innov. Res. Dev. 2015, 4, 26–31. Available online: https://api.semanticscholar.org/CorpusID:108931394 (accessed on 21 October 2023).

- Kumar, R. Ship Dismantling—A Status Report on South Asia; Euroconsult Mott MacDonald and WWF-India: New Delhi, India, 2011. [Google Scholar]

- Aage Bjørn, A.; Erik, B.; Terje, S. Decommissioning of Ships. Environmental Standards; NO. 2000-3158; Det Norske Veritas: Høvik, Norway, 2000. [Google Scholar]

- Young Power in Social Action. Ship Breaking in Bangladesh. Environmental Pollution. Available online: http://www.shipbreakingbd.info/Environment.html (accessed on 16 April 2019).

- The European Parliament and the Council of the European Union. Directive (eu) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). Available online: https://eur-lex.europa.eu/eli/dir/2018/2001/oj (accessed on 18 November 2023).

- Wärtsilä. LNG Plants—Mini and Small Scale Liquefaction Technology; Wärtsilä: Helsinki, Finland, 2016; Available online: https://cdn.wartsila.com/docs/default-source/product-files/ogi/lng-solutions/brochure-o-ogi-lng-liquefaction.pdf (accessed on 11 January 2024).

- Lehtoranta, K.; Kuittinen, N.; Vesala, H.; Koponen, P. Methane Emissions from a State-of-the-Art LNG-Powered Vessel. Atmosphere 2023, 14, 825. [Google Scholar] [CrossRef]

- Albin, K.; Simon, A.; Tomas, R. Well-to-Wheel LCI Data for HVO Fuels on the Swedish Market. 2019. Available online: https://f3centre.se/app/uploads/f3-23-17_2019-04_Källmén-et-al_Rev_190508_FINAL.pdf (accessed on 11 January 2024).

- Brian, P.; Jens, E. HVO Fuel Proven to be Effective for Diesel Generator Sets. 2019. Available online: https://www.mtu-solutions.com/content/dam/mtu/technical-article/2022/hvo-fuel-proven-to-be-effective-for-diesel-generator-sets/WP_HVO_Proven_Effective_Diesel_Gensets_FINAL.pdf/_jcr_content/renditions/original./WP_HVO_Proven_Effective_Diesel_Gensets_FINAL.pdf (accessed on 11 January 2024).

- Pechout, M.; Kotek, M.; Jindra, P.; Macoun, D.; Hart, J.; Vojtisek-Lom, M. Comparison of hydrogenated vegetable oil and biodiesel effects on combustion, unregulated and regulated gaseous pollutants and DPF regeneration procedure in a Euro6 car. Sci. Total Environ. 2019, 696, 133748. [Google Scholar] [CrossRef] [PubMed]

- Arun, K.; Tomasz, H.; Grzegorz, M. Bulk carrier with rigid sails—Combined effects of realistic weather conditions. In Proceedings of the 23rd Hydronav 2023—International Symposium on Hydrodynamics in Ship Design, Safety, Manoeuvring and Operation, Sopot, Poland, 24–26 May 2023; pp. 44–52. [Google Scholar]

- Annika, S.; Mia, E.; Bogdan, M.; Arun, K.; Ville, W. Development in CII Performance of a Bulk Carrier, Transitioning from Today’s State of the Art to Net-Zero Design. In Proceedings of the 15th Symposium on High-Performance Marine Vehicles HIPER’23, Bernried, Germany, 18–20 September 2023; pp. 234–247. Available online: http://data.hiper-conf.info/Hiper2023_Bernried.pdf (accessed on 11 January 2024).

- Barahmand, Z.; Eikeland, M.S. Life Cycle Assessment under Uncertainty: A Scoping Review. World 2022, 3, 692–717. [Google Scholar] [CrossRef]

- Saltelli, A.; Annoni, P.; Azzini, I.; Campolongo, F.; Ratto, M.; Tarantola, S. Variance based sensitivity analysis of model output. Design and estimator for the total sensitivity index. Comput. Phys. Commun. 2010, 181, 259–270. [Google Scholar] [CrossRef]

- Selvaraj, R.; Nasir, K.T.A.; Vasa, N.J.; Nagendra, S.M.S. Monitoring of CO2 and CH4 composition in a biogas matrix from different biomass structures. Sens. Actuators B Chem. 2017, 249, 378–385. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).