Abstract

In the past few years, offshore site investigations have extensively utilized full-flow penetrometers like the Ball and T-bar penetrometers to assess penetration resistance and subsequently analyze the strength characteristics of marine clay. The relationship between penetration rate and the measured resistance to penetration and shear strength in clays has been extensively documented through full-flow penetration tests. Although previous studies have shown empirical correlations between undrained shear strength and penetration resistance, the resistance factor utilized in these correlations is typically suggested for cohesive soils that are overconsolidated or normally consolidated, rather than underconsolidated soils. The effects of penetration rate undrained penetration resistances in underconsolidated marine clay are investigated in this study by considering the outcomes of variable rate penetration testing and twitch penetration testing using full-flow penetrometers in laboratory model tests. The discussion focuses on penetration resistances depending on the normalized velocity of the full-flow penetrometers (Ball and T-bar).

1. Introduction

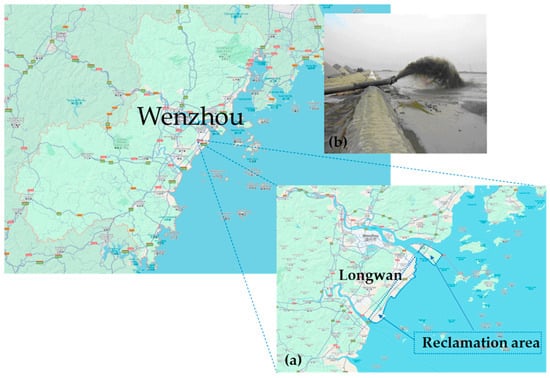

Over the past few decades, the scarcity of urban land resources has become more noticeable due to the growth and expansion of coastal cities in numerous nations [1]. Coastal reclamation has become an effective way to solve the problem of land resource shortage [2]. At present, the cumulative area of coastal reclamation in China has exceeded 11,000 km2, resulting in the continuous emergence of a mass of coastal new cities’ reclamation area. Among the regions of reclamation in Zhejiang Province, China, most of them are by hydraulic fill. The Wenzhou Oufei Project is the largest single reclamation project in China, with a total area of 326.67 km2 [3]. The Wenzhou Oufei Project holds the distinction of being China’s biggest reclamation project to date. The position of the view of the Wenzhou Oufei Project reclamation area and the photo of the dredger fill in the field are shown in Figure 1a,b, respectively. The coastal reclamation projects mainly rely on the reclamation of nearshore clay sediment as the dredger fill material, and generally use the preloading method for drainage and consolidation treatment [4,5]. Consequently, construction and building on the new dredger fill is inevitable.

Figure 1.

The Oufei project reclamation site, Longwan, in Wenzhou, China. (a) The position of the view; (b) The photo of the dredger fill in the field.

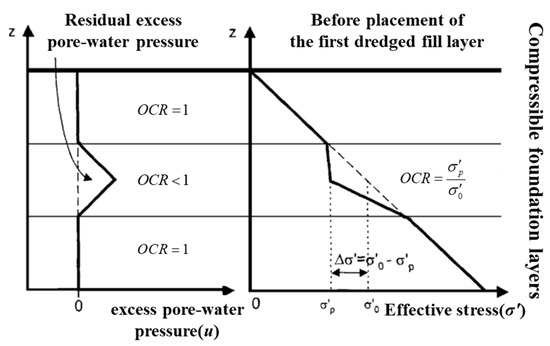

Nevertheless, due to the limited permeability of soft marine clay, the foundation treatment only results in the formation of a solid soil layer on top, while the underlying layer of soft marine clay remains incompletely consolidated, referred to as an underconsolidated condition [1,6,7,8,9,10,11,12,13]. During the consolidation of a compressible foundation layer under consolidation, residual excess pore water pressures are present, which result from previous loads or self-weight. This means the primary consolidation of the compressible foundation has not been completed, and the residual excess pore water pressures equal the reduction of the initial overburden pressures. As the average overconsolidation ratio (OCR) in the underconsolidated case is less than unity, the preconsolidation effective stress, (less than the effective overburden pressure, ), becomes the new initial overburden pressure in the middle, as shown in Figure 2 [9]. The dredger fill foundation is characterized by high water content, high compressibility, and low strength [3]. A mass of civil engineering projects, such as buildings, roads, bridges, ports, and docks projects, have been built or are under construction on the underconsolidated soft soil foundation in the reclamation area. How to accurately obtain the geotechnical design parameters of the underconsolidated soft soil foundation in the reclamation area where these structures are located during the engineering survey process has become a key issue in engineering design and construction. Typically, the new manual fills sites, making sampling and laboratory evaluation difficult. Geotechnical in situ tests have become an effective method for determining geotechnical design parameters [14,15].

Figure 2.

Distribution of residual excess pore -water pressure and effective overburden pressure to reflect underconsolidated compressible foundation material [9].

Recently, the full-flow penetration testing technique has gained popularity as a novel in situ testing method for onshore and offshore engineering projects. It is commonly employed to measure undrained soft clay sediments, both onshore and offshore, using instruments like Ball and T-bar penetrometers [16]. In comparison to conventional piezocone penetration testing, full-flow penetration testing offers several benefits. The penetrometer compels the soil to flow around it, excluding the small drill string area, resulting in equal pressure above and below the probe, which reduces the importance of overburden correction. In soft sediments, the full-flow penetrometers have a larger projected area compared to traditional CPTu, enabling them to test larger volumes of soil and provide more precise measurement outcomes. A plastic solution and numerical model have been created for the flow of soil around the penetrometer [17]. Furthermore, the ball overcomes the susceptibility to the potential eccentric loading of the T-bar, increasingly becoming prevalent owing to its inherent merits over the T-bar penetrometer. Full-flow penetration testing is a more efficient method than vane shear test (VST) as it enables continuous analysis of undrained strength instead of analyzing at discrete depths. Both T-bar and Ball penetrometers possess equal projected areas. The projected areas of both the full-scale T-bar and Ball penetrometers are equal (100 cm2). There is no conclusive comparison between the T-bar and Ball penetrometers because both are still evolving, and there are limited test data on the full-flow penetrometer. It is recommended that one of the full-flow penetrometers (T-bar or Ball) is used for a site investigation based on the project requirements, the soil conditions likely to be encountered, and the geotechnical problems to be addressed. Table 1 summarizes the relative merits of both T-bar and Ball penetrometers.

Table 1.

Advantages and disadvantages of Ball and T-bar penetrometers.

Prior research has indicated that the tip resistance acquired through CPTu in loosely packed soil differs considerably from the composition of the normally consolidated clay stratum. According to Tanaka et al. [18], the mid-depths of the clay stratum in an underconsolidated clay exhibit the lowest levels of both penetration resistance and pore water pressure, as observed through CPTu. In the case of normally consolidated clay, the tip resistance and pore water pressure both exhibit a linear increase as depth increases. According to Karakouzian et al. [19], the Nkt value obtained from VST data in underconsolidated clay is greater than that of normally consolidated clays at a specific location when estimating the in situ shear strength using CPTu values. On the contrary, according to the study conducted by Lunne et al. [20], it was found that the Nkt value remains consistent for both underconsolidated clay and normally consolidated clay.

The result of CPTu and laboratory tests have effectively showcased the correlation between penetration rate and the recorded penetration resistance and undrained shear strength in clay [20]. The penetration resistance of full-flow penetrometers is also influenced by the rate of penetration. Nevertheless, prior research on the influence of penetration rate on penetration resistance in full-flow penetration testing has primarily concentrated on normally consolidated and overconsolidated clay [21,22,23]. This article introduces data on underconsolidated clay (new dredged fill) in laboratory modeling tests. The authors examined and deliberated on the outcomes of penetration tests conducted at different rates and using both twitch penetration tests and full-flow penetrometers. The objective was to explore how the rate of penetration impacts the resistance encountered in underconsolidated marine clay.

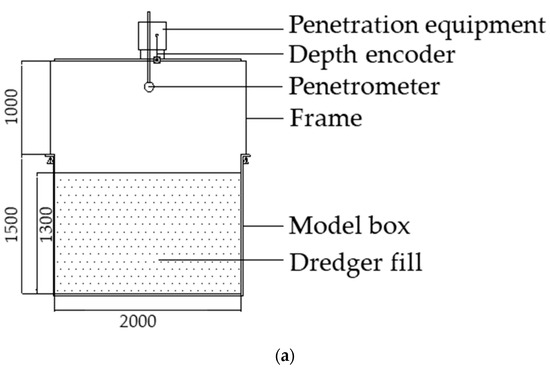

2. Model Box Testing System

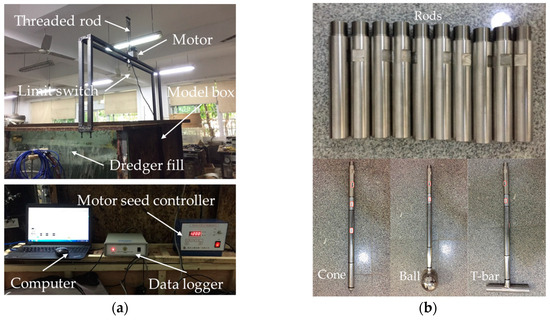

The apparatus used for the test primarily included a model box, penetration equipment, depth encoder, penetrometer, and adaptable support frame, as Figure 3 shows.

Figure 3.

Schematic diagram testing apparatus. (a) Penetration actuator assembly; (b) Testing layout (unit in mm).

2.1. Model Box and Penetration Equipment

The model box is made of stainless steel, and it has 200 cm of length and width, 150 cm of height, and 1.25 cm of thickness. Figure 4 displays the system designed for the penetrometer to penetrate the soil at a predetermined velocity. This adjustable support frame system consisted of two channeled metal frames 100 cm high, with a width of 250 cm, braced with crossbars. Two bushes were located in the middle of the crossbars to facilitate the linear movement of the penetrometer. The penetrometer is driven by a TCH-1 electrical machinery drive (Nanjing Soil Instrument Factory Co., Ltd., Nanjing, China). The movement of the penetrometer was recorded using a displacement sensor that had a travel distance of 50 cm. To stop the penetrometer from penetrating beyond the base of the clay bed, limit switches were positioned on the supporting frame, ensuring a 10 cm gap. In this test, the penetration was conducted using equipment that allowed for adjustable speed. The penetration rate range designed for the test was 0 to 50 mm/s, which determined the five required penetration rates for the variable speed test: 2 mm/s, 5 mm/s, 10 mm/s, 20 mm/s, and 40 mm/s. The penetration equipment is capable of causing different drainage conditions of penetrometers in the clay ranging from partial drainage to undrained conditions by adjusting the rate of penetration. The encoder of depth connects the penetrometer to the steel frame. A wireline potentiometer was used to record measurements of the depth meter.

Figure 4.

Testing equipment. (a) Penetration and data acquisition equipment; (b) Penetrometers and rods.

2.2. Penetrometers and Rods

These tests utilized a piezocone, a Ball, and T-bar full-flow penetrometers. Piezocone penetration tests were conducted by using a standard cone with a 60° tip angle and 35.7 mm diameter. The cone is depicted in Figure 4b, which installed a high-density polypropylene filter element, measuring u2, with a thickness of 1.5 mm, positioned behind the cone shoulder that is 5 mm in height. In this study, the T-bar and Ball penetrometers with the projected areas of 100 cm2 and the area ratios, AR, of 10:1 (AR = Ap/As) were used. The T-bar penetrometer has a length of 250 mm and a diameter of 40 mm, while the Ball has a diameter of 113 mm. To guarantee a coarse interface, the penetrometers’ surfaces underwent a gentle sandblasting process. The load cell is positioned directly behind the penetrometer, aligned with the rods, and was specifically engineered to account for flexing and variations in temperature. Table 2 presents the detailed parameters of the cone and full-flow penetrometers. A set of rods consists of 10 stainless steel short rods with a 180 mm length, including a 30 mm thread length, which means the effective length after tightening is 150 mm.

Table 2.

Summary of parameters for cone and full-flow penetrometers.

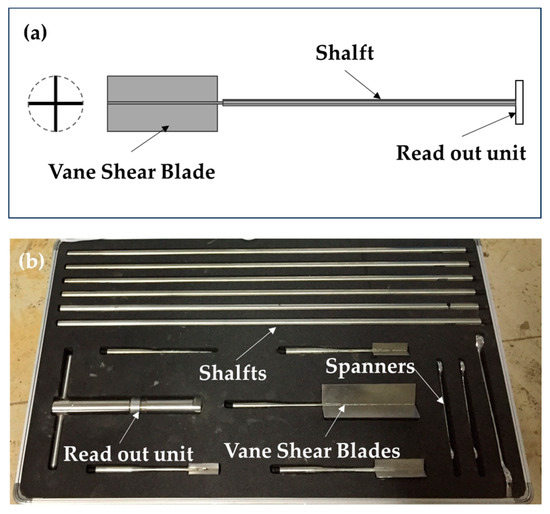

2.3. Vane

The high-precision portable laboratory vane shear test apparatus (PS-VST-P, PENESON, Guangzhou, China) was used to conduct tests on all VSTs. This apparatus, as depicted in Figure 5, offered a vane with a shear strength resolution of 0.8125 kPa.

Figure 5.

Portable laboratory vane. (a) Vane construction view; (b) Actual photo of the vane.

2.4. Sample Preparation

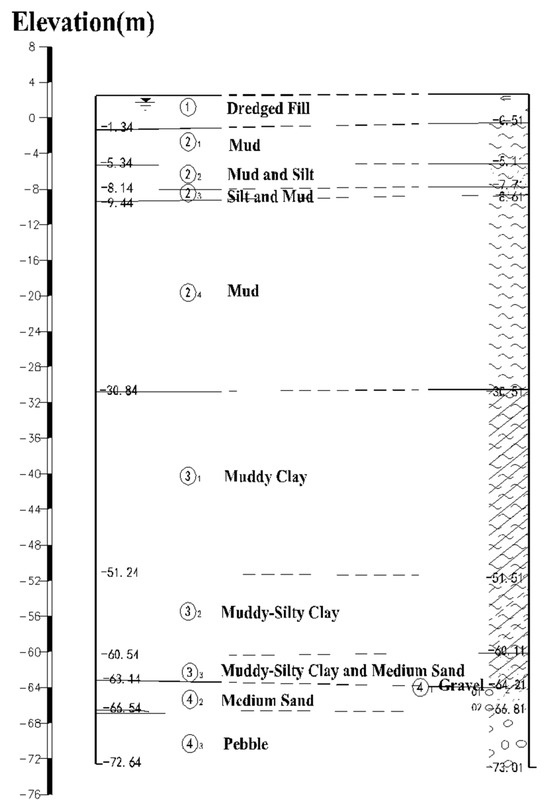

Tests were performed on clay samples obtained from the Oufei project site, Longwan, in Wenzhou, China, and the reclamation site is shown in Figure 1b. The clay samples were acquired through hydraulic filling after dredging of the sediment. Fill material for land reclamation projects is generally dredged from the nearby seabed. Dredged soil can reach a depth of five meters. Figure 6 plots the geological profile of soil in a typical reclamation site of this project.

Figure 6.

Geological profile of soil in the Wenzhou Oufei project site.

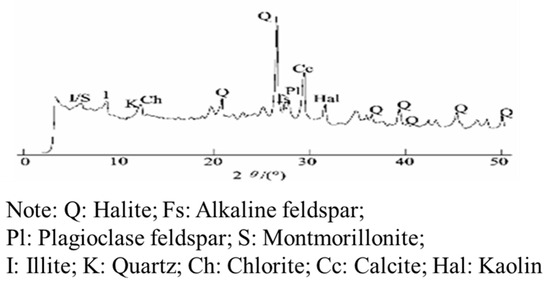

The X-ray diffraction (XRD) technique was served as the analytical method for determining the mineral composition of the clay in the dredged silt samples collected from the Wenzhou Oufei Project. To ascertain the material composition of the blown silt with precision, XRD was employed to generate the mineral composition diffractograms (Figure 7). These diffractograms were analyzed against the standard mineral diffraction patterns of XRD, revealing that halite predominates the mineral composition of the clay, succeeded by illite, with lesser amounts of quartz, an illite–smectite mixed layer, and chlorite. The analytical results, presented in Table 3, indicate a significant presence of clay minerals in the blown silt, with halite comprising 32% of the clay minerals’ weight, illite 17%, quartz 16%, an illite–smectite mixed layer 11%, and chlorite 9%.

Figure 7.

The XRD patterns of dredged silts from Wenzhou Oufei Project.

Table 3.

Classification and statistics of mineral composition in dredged silts.

Laboratory tests were conducted to determine the soil characteristics, as shown in Table 4. The clay had a high-water content of 109.4%, with a liquid limit of 56%, a plastic limit of 27%, and a specific gravity of 2.73. A Rowe cell oedometer test was conducted to determine the consolidation properties of the soil. As the vertical effective stress level (σv′) rises from 12.5 kPa to 100 kPa, the coefficient of consolidation (cv) also rises, ranging from 3.09 to 7.37 × 10−3 cm2/s. Other properties are provided in Table 4. At the time of the test, it had been nearly two years since the soil sample was obtained, and the soil sample had been naturally deposited in the model box, which has certain structural characteristics. Self-weight consolidation of newly placed fill has not yet been completed. The clay samples were ensured to be submerged completely under water during tests. The presence of free water on the surface of clay samples had a profound impact on the penetration resistance [24].

Table 4.

Summary of dredged soil properties.

3. Test Methodology

Newly placed fill was used to conduct penetration tests on the underconsolidated clay specimens. To examine the impact of two significant factors, namely, shape (for determining resistance factor N) and penetration rate on penetration resistance in underconsolidated clay, each location underwent multiple penetrations using the three penetrometers (cone, Ball, and T-bar). To investigate the impact of the tip shape, the researchers penetrated the cone with a diameter of 35.7 mm, the Ball with a diameter of 113 m, and the T-bar with a diameter of 40 mm and a length of 250 mm (D × L).To examine the impact of the penetration rate, the penetrometers were penetrated at various speeds, namely, 2 mm/s, 20 mm/s, and 40 mm/s. Lastly, the twitch penetrations were performed with three differently shaped penetrometers to examine the drainage conditions’ effect. Following the completion of all penetration tests, vane shear tests were conducted at ten varying depths ranging from 10 cm to 100 cm with increments of 10 cm. VSTs were conducted at two distinct positions within the plane. The vane was spun at a rate of approximately 2.0° per second until the clay’s strength was completely activated to determine the undrained shear strength of both intact and remolded samples. Various penetration tests were conducted on the underconsolidated clay samples in the model container specified in Table 5. The locations of the penetration test are indicated in Figure 3b. To monitor the soil’s pore water pressure, electric miniature piezometers were placed at depths of 20 cm, 40 cm, 60 cm, 80 cm, and 100 cm. At each location of the laboratory model, piezometer data were collected simultaneously from the pore water pressure acquisition instrument.

Table 5.

Summary of vane shear tests and penetrometer tests.

3.1. Vane Shear Test (VST)

In order to ascertain the undrained strength characteristics, a total of four laboratory vane shear experiments were conducted on samples of dredger fill in the model box. These tests encompassed two undisturbed and remolded undrained shear tests, which were carried out at four distinct positions within the plane. The VSTs were conducted at 10 depths within every 100 mm. To ensure undrained conditions during the shearing process, the rotation rate recommended in ASTM D2573 (2002) was used for all the VSTs [25,26]. The VSTs were carried out inside the model box, where the available test space is more than five times the diameter of the vane shear blade. It can be expected to avoid boundary effects and ensure enough distance from the container’s edges and bottom, as well as between each measurement [27]. To prevent the buildup of excessive pore water pressure, the vane was carefully inserted into the soil sample at a rate of less than 1 mm per second [28].

3.2. Piezocone Penetration Test (CPTu)

- Correction of measured cone tip resistance

The calculated value of cone tip resistance, qt, is determined using the following relationship [20]:

where qc is the cone tip resistance, u2 is the pore water pressure measured behind the shoulder of the cone, and a is the area ratio of the cone. The ratio of the cone area is approximately equal to the ratio between the load cell or shaft’s cross-sectional area and the cone’s projected area. The calculation of u2(1−a) determines the pore water pressure that adds to cone resistance, taking into account the tip shape. According to the research by Lunne et al. [20], the range is valued at approximately 0.55 to nearly 0.9. In the study, a cone penetrometer with a net area ratio of 0.75 was adopted. The pore water pressure behind the shoulder of the cone, u2, is determined by utilizing the measured pore water pressure values on the cone, u1, according to the relationship:

where u0 is the in situ pore water pressure at time 0 (before inserting the cone), u1 is the pore water pressure measured on the piezocone, and K is the adjustment factor. Karakouzian et al. [19] indicated that the recommended values of the adjustment factor, K, for underconsolidated clay in CPTu were dependent on the stress history of the soil deposit and soil type. In this study, the adjustment value, K, of 0.75, was adopted to calculate u2. For all these corrections, the in situ pore water pressure has been taken as hydrostatic with a water table about 1 cm above the ground surface, and the average unit weight for the soil was 14.43 kN/m3 below the water table. The net tip resistance of the piezocone is calculated as below:

where qt is the corrected tip resistance by the pore water pressure, σv0 is the total overburden stress, γ is the unit weight, and h is the soil thickness.

- 2.

- Calculation of undrained shear strength from CPTu

In clays, an estimate of undrained shear strength, Su is calculated according to the equation [29]:

where qt is the corrected tip resistance by pore water pressure, σvo is the total overburden stress, and Nkt is cone resistance factor. For practical use, errors in determining qt from the measured tip resistance, qc, and in estimating σvo and Nkt lead to quite large inaccuracies, particularly for soft clay [29].

3.3. Full-Flow Penetrometer Tests

- Correction of measured penetration resistance

For the full-flow penetrometer, correction is required for the net penetration resistance observed by the load cell due to the effects of measured pore water pressure and overburden stress. The net resistance of the full-flow penetrometer, a relationship suggested by Chung et al. [29], is as follows:

where qm is the measured penetration resistance, σv is the total vertical overburden stress, u2 is the measured pore water pressure, and α is the load cell area ratio. As is the projected areas of the push rod and Ap is the projected area of the penetrometer.

In practice, σv0 is often uncharted, and the measurement of u2 in real-time is challenging and rarely conducted during experiments. Chung et al. [29] made a few minor alterations to the aforementioned equation, which did not lead to substantial changes in the calculations and removed the need for precise measurement of u2 in the full-flow penetrometer. As Nanda et al. [30] reported, there is no need to correct for pore water pressure when using the improved full-flow penetrometer. Only the overburden correction is necessary, resulting in the following modified equation:

where qm is the measured penetration resistance, σv0 is the in situ total vertical overburden stress, As is the projected area of the push rod, and Ap is the projected area of the penetrometer.

- 2.

- Evaluation of undrained shear strength by the full-flow penetrometer test

The estimation of undrained shear strength, su, can be obtained by dividing the net penetration resistance, qnet, by the resistance factor, N [29]:

where NT-bar and NBall are the resistance factors for the T-bar and Ball, respectively.

- 3.

- Influence of penetration rate

In general, the shear strength increases with increasing strain rate, which is dependent on factors such as stress history and soil type. The consolidated undrained triaxial compression (CK0UC) experiments in resedimented Boston Blue Clay indicated an increased effect at lower OCR values, which is pertinent to the soils examined [31]. The literature has previously reported studies on the strain-rate effect using full-flow penetrometers [21,24,32,33,34,35,36,37,38]. Strain-rate effects can be studied under two conditions based on the rate of penetration of full-flow penetrometers: partial drainage and undrained conditions [39]. The dissipation of partial pore water at very slow penetration rates increases the soil strength and penetration resistance as well as the subsequent consolidation of the soil. From a very slow penetration rate, penetration resistance gradually decreases until fully undrained conditions are reached. As the rate of penetration increases from fully undrained conditions, the penetration resistance increases largely as a result of penetration rate effects. Generally, when the value of the normalized speed parameter, V, is greater than 20 for the full-flow penetrometers, fully undrained conditions will be predominant [40]. In terms of the dimensionless speed parameter, V, it is possible to define it as follows:

where v is the rate of the penetrometer, d is the diameter of the penetrometer, and cv is the coefficient of consolidation.

For both normally consolidated and overconsolidated soft clays with intact strengths, various relationships have been proposed: the hyperbolic sine equation [30,34], the semi-logarithmic equation [21], and the power law. Based on the reference penetration rate, all of these relationships are fitted with parameters. Most previous works assume a penetration rate of 2 cm/s for full-flow penetrometer testing. Table 6 summarizes the reported relationships between rate and strength for normally consolidated and overconsolidated soft clays.

Table 6.

Reported relationships of the rate–strength for soft clays.

These types of relationships are generally interpreted using hyperbolic sine, semilogarithmic, and power functions. It is usually necessary to fit the testing results with nondimensional parameters to interpret the results. In general, there are no clear guidelines for determining which function to use, but it largely depends on the type of soil and penetrometers used [30]. Schlue et al. [28] indicated that both a semilogarithmic and a power law can be used to describe the relationship between peripheral velocity in the VSTs and measured shear strength of dredged harbor mud, and the semi-logarithmic function produces a slightly better curve. In this article, the soil sample was also obtained by hydraulic fill after dredging. Accordingly, the following semi-logarithmic equation was adopted to fit the penetration resistance, qin, with the penetration rates:

where a is the intercept factor, μ is the rate factor, v/d is the normalized penetrometer velocity, and (v/d)ref is the reference normalized penetrometer velocity.

4. Results and Discussion

4.1. Vane Shear Test (VST)

The uniform underconsolidated marine clay in the model box has a rising undrained shear strength of 4.9 kPa near the surface to 22.5 kPa at the bottom of the clay bed. The sensitivity range is from 1.5 to 2.5. Table 7 provides the result of the undrained shear strength (intact and remolded strength, su and sur) and sensitivity values of soil at ten various depths, which is based on the average of the two vane shear tests.

Table 7.

Undrained shear strength (intact and remolded strength, su and sur) over depth by the VST.

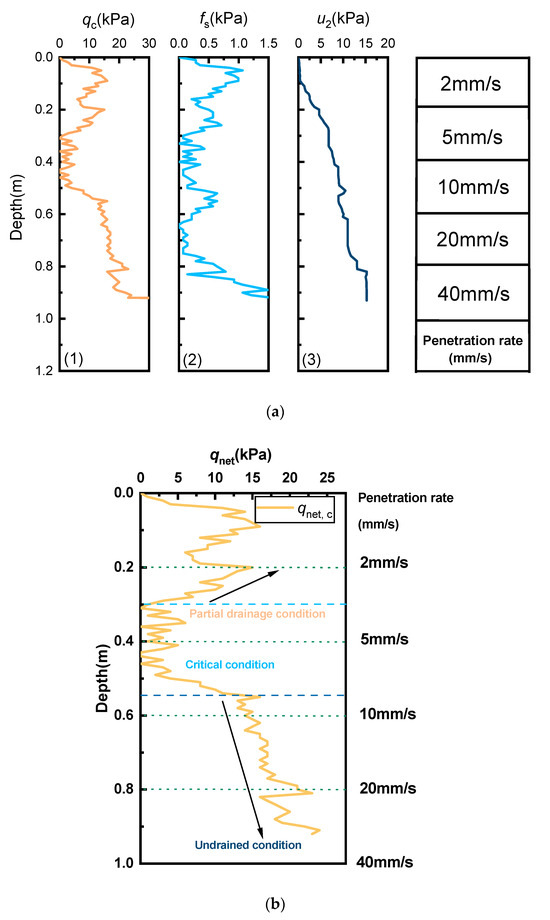

4.2. Piezocone Penetration Test (CPTu) in Underconsolidated Clay

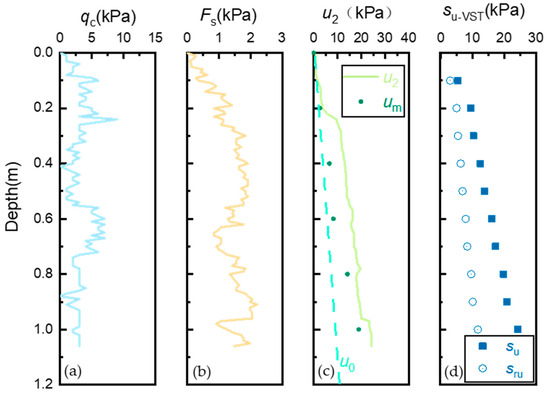

Test profiles of CPTu including cone tip resistance (qt), sleeve friction (fs), pore water pressure (u2), and intact and remolded undrained shear strength (su and sur) from VST are presented in Figure 8. Also shown in Figure 8c are the pore water pressure readings at five different depths from the electric piezometers in the soil.

Figure 8.

Piezocone penetration test (CPTu) profiles of underconsolidated clay in laboratory model from Wenzhou Bay (Oufei project site). (a) Cone tip resistance profiles; (b) Sleeve friction profiles; (c) Pore water pressure profiles (u2 measured by piezocone and um measured by electric piezometers); (d) Vane shear test data.

Figure 8c displays that the pore water pressure in the soil is higher than the corresponding hydrostatic pressure. The calculation of hydrostatic pressure is equal to the unit weight of pore water multiplied by the depth below the water table as the dashed straight line in Figure 8c shows. This indicates that the remaining excess pore water pressure resulting from the consolidation of dredger fill due to its self-weight has not completely dissipated, indicating that the clay is still in an underconsolidated condition [19]. The mineral analysis of XRD also indicates that the material composition of the dredged silt is characterized by a high proportion of viscous mineral particles, adversely affecting the self-settling behavior of the silt.

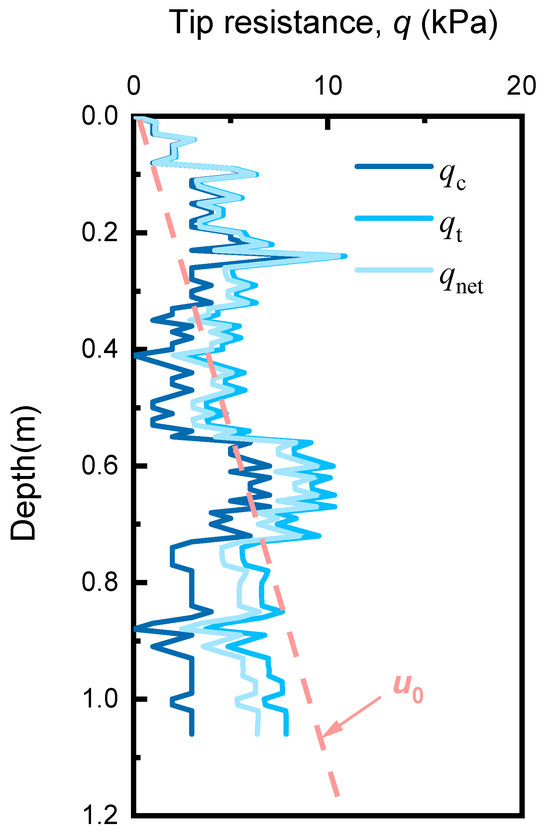

Figure 9 shows the measured cone tip resistance (qc), the corrected cone tip resistance (qt), and net cone tip resistance (qn) profiles by piezocone penetration tests. The corrected cone tip resistance (qt) is used in Equation (1) and the net cone tip resistance (qn) is calculated by Equation (3). The test results of CPTu show that cone tip resistance (qt) is less than 10kPa and sleeve friction (fs) is less than 5kPa. Accordingly, corrections need to be applied to the raw measured cone tip resistance. As may be seen in Figure 9, the correction of tip resistance for the cone is significant. This is mainly because the measured tip resistance is relatively small, and hence, increases the weight of the pore water pressure (u2) and overburden stress. The errors in determining qt from the measured resistance, qc, lead to quite large inaccuracies, particularly for soft clay of low strength. Obviously, the strength of underconsolidated clay in the model box is too low to be measured accurately by conventional piezocone. In addition, as seen in Figure 8d, intact and remolded undrained shear strength of soil shows a consistent rise with depth. This trend was similar to self-weight consolidation clays.

Figure 9.

Correction of cone tip resistance data (cone tip resistance, qc, corrected cone tip resistance, qt, and net tip resistance, qnet).

4.3. Full-Flow Penetrometer Tests in Underconsolidated Clay

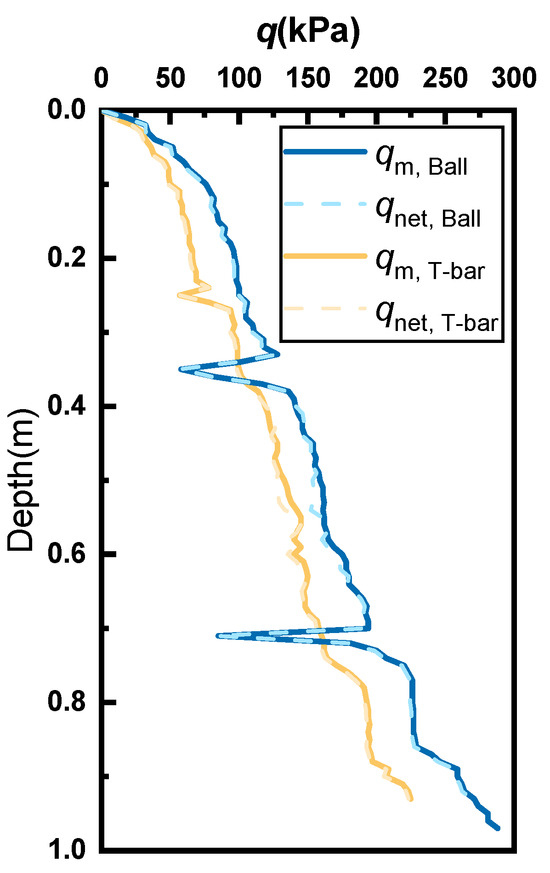

As may be seen in Figure 10, the profiles of penetration resistances for the full-flow penetrometers (T-bar and Ball) were corrected by Equation (5), as the penetrometers have a significantly larger projected area than the shaft, rendering the correction insignificant [29]. Both the T-bar and Ball penetrometers exhibit comparable resistance profiles, with the T-bar indicating lesser penetration resistance compared to the Ball. Low et al. [41] and DeJong et al. [42] also observed similar results in field tests. The penetration resistance of the Ball exhibits roughly 20% greater penetration resistance compared to the T-bar at the bottom of the clay bed as Figure 10 shows. It is necessary to mention that two sharp drops exhibited in the Ball resistance profile are not seen in the T-bar resistance profile. This occurred due to their immediate suspension, which is an unintentional incident that happened during continuous penetration tests.

Figure 10.

Correction of Ball and T-bar net penetration resistance profile.

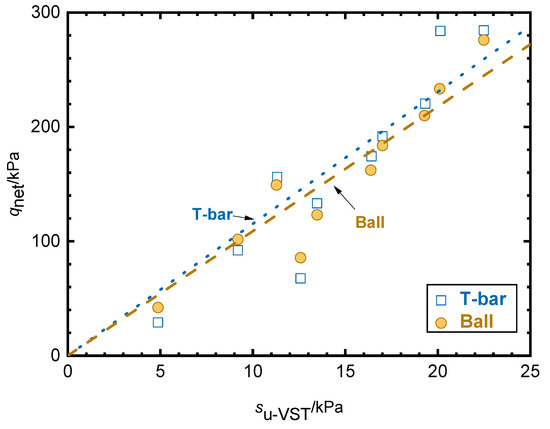

- Determination of resistance factors N of full-flow penetrometers in underconsolidated clay using strength data of VST

To determine the values of penetration factors N for underconsolidated clay from Wenzhou Bay, China, the VSTs were conducted 1 m around the penetration point. The resistance factor N for a specific site can be approximated by determining the slope of undrained shear strength, su (reference strength from VST data) versus net penetration resistance, qnet, as Figure 11 shows. This estimation is based on the fact that the reference strengths increase uniformly with depth. The averages calculated for the resistance factor NBall and NT-bar of the spot, as determined by the VST data, are 10.9 and 12.0, correspondingly; both are within the recommended value range of normally consolidated clay.

Figure 11.

Relationship between net penetration resistance, qin, and undrained shear strength, su, for underconsolidated clay at Wenzhou.

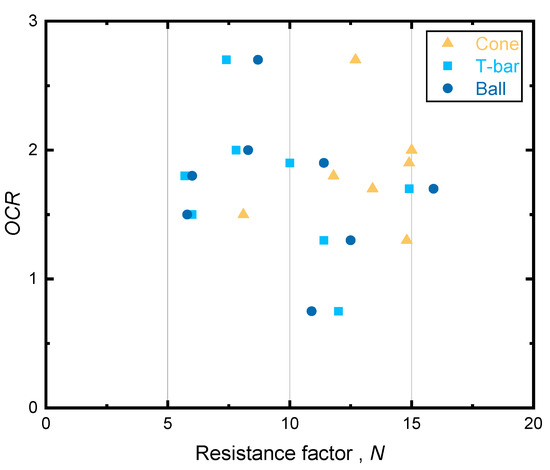

DeJong et al. [42] reported that four highly characterized soft sediment sites (from No. 1 to 4) were all overconsolidated soil with overconsolidation ratio, OCR, from 1.5 to 2.7 [42]. The mean resistance factors (N) with different OCR from four sites for each profile based on reference strength from VST are shown in Figure 12 and Table 8. The resistance factors Nkt for the CPTu range from 8.1 to 15.0. The resistance factors NBall for Ball range from 5.8 to 15.9. The resistance factors NT-bar for T-bar range from 5.7 to 14.9. The No. 5 site is a reclamation site using dredged material. Consolidation of the dredged marine clay at Craney Island has been occurring since 1955. For underconsolidated marine clays, the Nkt value of 15 is adopted to estimate in situ undrained shear strength using the results of CPTu and VST [19,43]. Therefore, it is critically important to ascertain the suitable Nkt value for a specific site if CPT values will be used to evaluate the undrained shear strength in the field. The most desirable approach involves directly calibrating the N using the empirical relationship between reference strength from laboratory or VST data and net tip resistance from CPT data of specific sites [19,43]. When using VST data as the reference strength, the recommended values of the penetration factors N for full-flow penetrometer in underconsolidated clay are average values of range in overconsolidated clay reported by the previous in situ full-flow testing data.

Figure 12.

Range of measured resistance factors (N) with overconsolidation ratio (OCR) for cone, Ball, and T-bar [19,21,42].

Table 8.

Values of resistance factor N for normally consolidated and underconsolidated clay [19,21,42].

- 2.

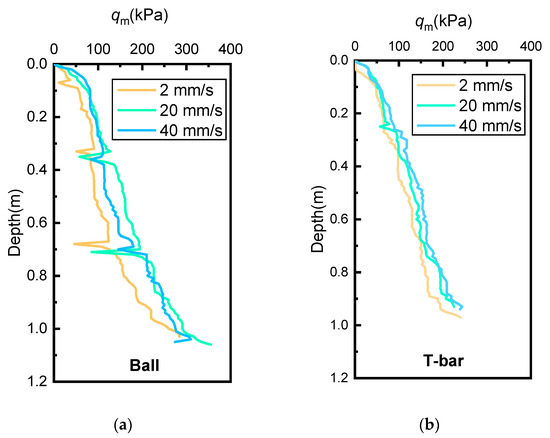

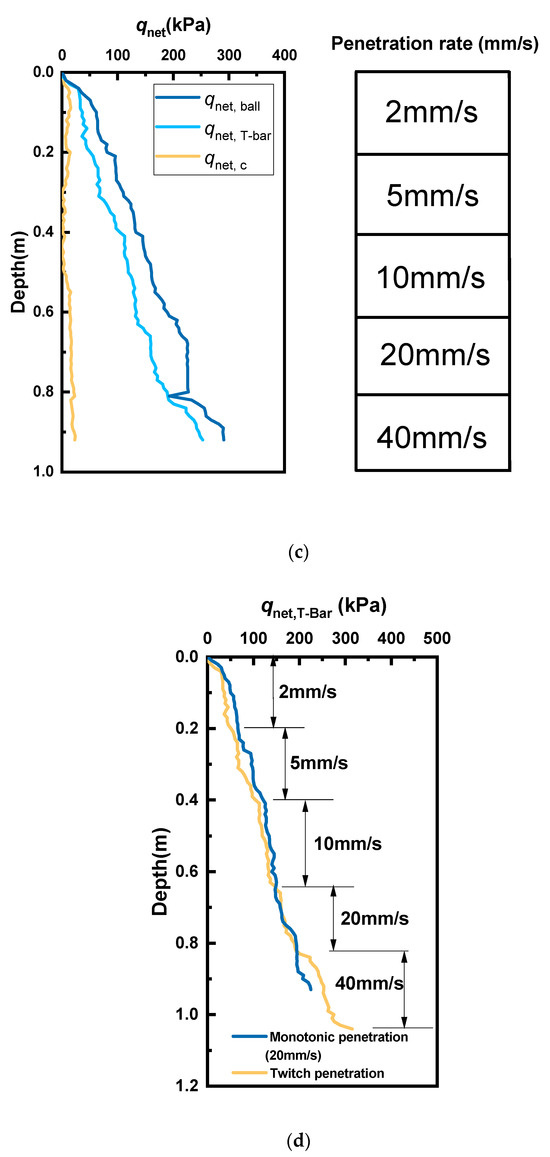

- Variable rate monotonic penetration testing

For both the Ball and T-bar penetrometer, the penetration resistance profiles at three different velocities of 2 mm/s, 20 mm/s, and 40 mm/s are drawn in Figure 13. The test result shows that the qm at the rates of 20 mm/s and 40 mm/s was significantly greater than that at 2 mm/s. The profile of the penetration resistance remains relatively unchanged and is similar at both shallow and deep embedment in the monotonic penetration test, despite the change in penetration rate from 20 mm/s to 40 mm/s, which is under an order of magnitude.

Figure 13.

Penetration resistance profiles of different constant velocities for the full-flow penetrometers. (a) Ball; (b) T-bar.

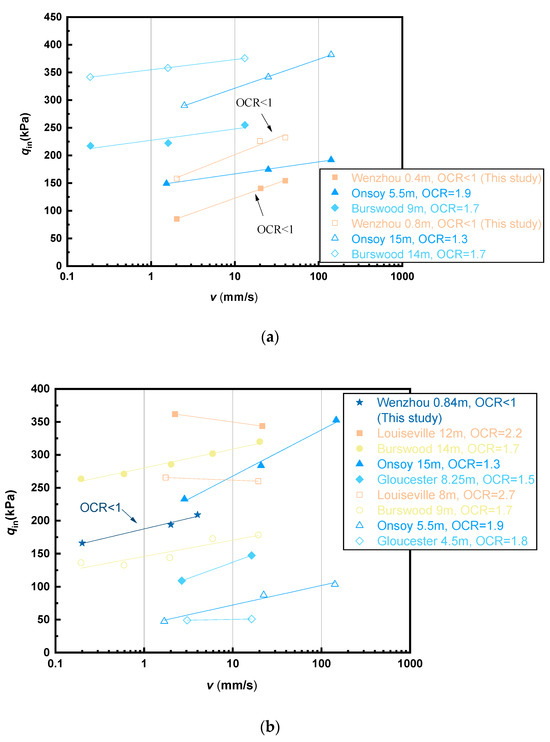

This study extends the field research of Yafrate et al. [21] by examining the rate dependence with the full-flow penetrometers (Ball and T-bar) in underconsolidated soil, considering the effect of the consolidation condition. Table 9 shows that the testing results presented by Yafrate et al. [21] and DeJong et al. [42] were four high-quality in situ test data with different overconsolidation ratios, OCR, and sensitivities, st. The author compared and analyzed the field data of four sites with the monotonic penetration test result at three different penetration rates. As Figure 14 shows, the penetration resistance in the underconsolidated clay increases with the increase in the penetration rate at rates from 2 mm/s to 40 mm/s. The relationship between the penetration resistance and the velocity is presented as Figure 14 shows. The plots demonstrate a consistent pattern of higher penetration resistance as the penetration velocity increases for the underconsolidated clay, resembling the findings for the normally and overconsolidated clay presented by Yafrate et al. [21] except for one test site in Louiseville, Norway. That site is likely an accidental event.

Table 9.

Summary of normally consolidated and overconsolidated clay test site data (Adapted from Yafrate et al. [21] and DeJong et al. [42]).

Figure 14.

Penetration resistance (qin) versus penetration velocity (v). (a) Ball; (b) T-bar.

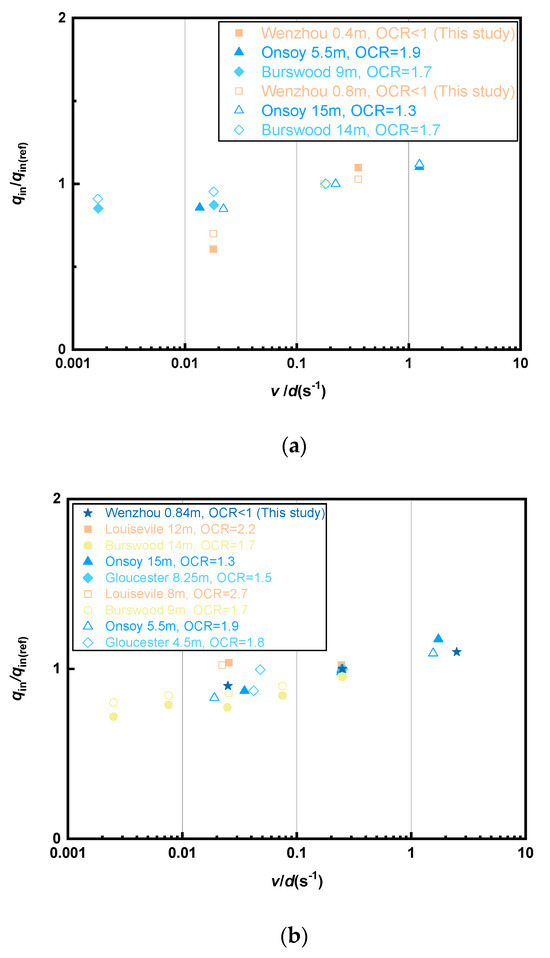

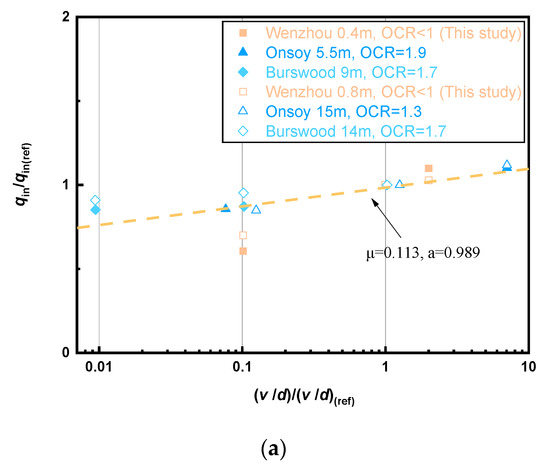

In order to combine the Ball and T-bar penetrometer testing data, the penetration velocity, v, was normalized by dividing it by the diameter of the penetrometer, d, which was 40 mm and 113 mm, respectively. Comparing the resistance values at different depths is possible by normalizing the intact penetration resistance qin with a reference standard penetration resistance qin(ref) at a velocity of 20 mm/s. Figure 15 illustrates a consistent pattern of higher penetration resistance as the velocity increases.

Figure 15.

Normalized penetration resistance (qin/qin(ref)) versus normalized penetration velocity (v/d). (a) Ball; (b) T-bar.

Yafrate et al. [21] presented the values of the velocity parameters μ for Ball and T-bar as 0.14 and 0.12, respectively (Table 10), which is based on Equation (9). The testing results of the full-flow penetrometers in underconsolidated clay are subsequently compared to the stress conditions at the site and the characteristics of the soft clay to deduce the following semi-logarithmic relationships for interpretation over the underconsolidated, normally consolidated, and overconsolidated clay:

where qin,Ball is the intact penetration resistance of Ball, qin(ref),Ball is the reference intact penetration resistance of Ball, v/d is the normalized penetrometer velocity, (v/d)ref is reference normalized penetrometer velocity, qin,T-bar is the intact penetration resistance of T-bar, and qin(ref),T-bar is the reference intact penetration resistance of T-bar.

Table 10.

Reported rate effect parameters for Equation 9 (Adapted from Yafrate et al. [21]).

The rate factors for penetration resistance shown in Figure 16 are slightly lower than the rate factor presented by Yafrate et al. [21] for both Ball and T-bar penetrometer variable penetration rate testing for the field data. The difference could be that they reported the rate parameter for a rate of different consolidation conditions, whereas a rate factor of 0.113 and 0.117, respectively, seems to be more appropriate for the underconsolidated clay from the Gulf of Wenzhou with weak structure behavior.

Figure 16.

Relationship normalized penetration resistance versus normalized penetration velocity. (a) Ball; (b) T-bar.

Meanwhile, the rate factors for the intact penetration resistance of Ball, qin,Ball, are lower than those for the intact penetration resistance of T-bar, qin,T-bar, which is consistent with the results presented by Low et al. [44]. A lower rate parameter implies Wenzhou Bay clay is slightly less rate-dependent than both normally consolidated and overconsolidated clay, which has implications for the penetration of the full-flow penetrometer in newly dredger fill.

- 3.

- Twitch penetration testing

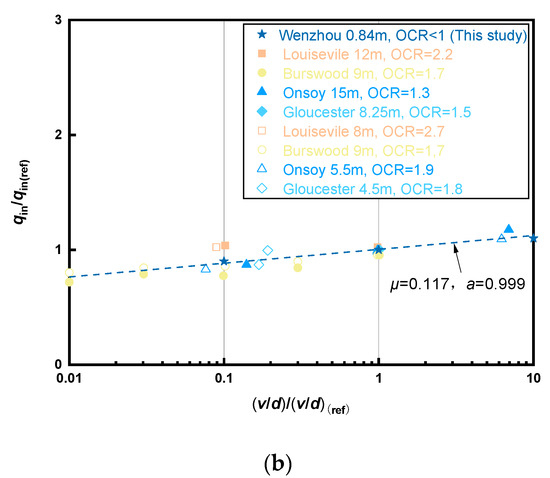

Twitch penetration testing for the full-flow penetrometers, namely, the penetration rate is gradient-varying during penetration with the order of magnitude changes, which improved the efficiency of investigating the rate effect on penetration resistance [34]. The accelerated twitch penetration testing methodology was applied in this paper, where the velocity of penetration is gradually increased throughout a single penetration test. The penetrometers were driven into the underconsolidated clay at a velocity that varied from 2 mm/s, 5 mm/s, 10 mm/s, 20 mm/s to 40 mm/s. The results of the twitch penetration tests for the differently shaped penetrometers (cone, Ball, and T-bar) are as Figure 17 shows.

Figure 17.

Twitch penetration tests: (a) Profiles of twitch tests for piezocone; (b) Tip resistance profiles for piezocone; (c) Penetration resistance profiles of for cone, Ball, and T-bar; (d) Comparison between twitch test and constant rate penetration test (20 mm/s) for T-bar.

Figure 17a shows the testing profiles of tip resistance (qt), sleeve friction (fs), and pore water pressure (u2), from the twitch penetration tests of the piezocone. Figure 15(a3) shows the total pore water pressure measurement during the twitch penetration test. Pore water pressure measurements at the cone’s shoulder have recorded the development of pore water pressure during twitch penetration. When penetrating at a velocity of 2 mm/s, the excess pore water pressure escalates uniformly as the depth increases. Following the elevation of the penetration velocity to 20 mm/s, the pore water pressure persists in its ascent, albeit at a diminished pace. After a further increase in the penetration velocity to 40 mm/s, the measured pore water pressure u2 remains relatively stable, indicating that the dissipation rate of pore water pressure is equivalent to the generation rate [23].

The net tip resistance for the piezocone in twitch penetration testing has been corrected by Equation (3), as Figure 17b shows. As the velocity is increased during penetration, there was a transformation from the partially drained condition to the undrained condition, implying that the given normalized penetration rate range experienced critical normalized velocity (transition point), which leads to a decrease firstly and an increase subsequently of penetration resistance [45].

According to Figure 17c, the penetration resistance of the T-bar penetrometer is slightly lower at 15% than that of the Ball penetrometer. The causes can be ascribed to the geometry and flow behavior of the penetrometers, and the fact that consolidation under conditions of axial symmetry happens at a faster rate compared to plane strain [46].

Figure 17d compares the penetration resistance of the T-bar penetrometer measured in twitch penetration testing with the penetration resistance measured in constant penetration rate testing performed at a velocity of 2 mm/s. It may be seen that the T-bar twitch penetration testing initially exhibits a similar trend of penetration resistance to the monotonic penetration testing at a velocity of 2 mm/s up to a velocity of 20 mm/s from where the twitch penetration testing begins to exhibit resistance, raising more greatly with depth than the monotonic penetration testing. In the final step, with the rate of 40 mm/s, the twitch test shows approximately 25% greater resistance than the constant test.

5. Conclusions

This paper has presented the results of the variable rate monotonic penetration testing and twitch penetration testing conducted in the laboratory model box for differently shaped penetrometers (cone, Ball, and T-bar). The effects of penetration rate on the penetration resistance in underconsolidated clay have been discussed, considering the effect of the consolidation condition of clay:

- The strength of underconsolidated clay is too low to be measured accurately by conventional piezocone. The Ball penetrometer produces slightly greater penetration resistance (10–20%) than that of the T-bar penetrometer in the underconsolidated clay, and the correction for the Ball and T-bar both are far less significant than that for the cone, which is similar to that in normally consolidated clay.

- Using VST data as the reference strength, the values of the penetration resistance factors, N, for full-flow penetrometer in underconsolidated clay, are recommended as values of 10.9, and 12.0, respectively, for Ball and T-bar penetrometer, which both are within the recommended value range of normally consolidated clay;

- Under undrained conditions, like in normally consolidated and overconsolidated clay, there was a general trend of increasing penetration resistance with increasing penetration rate in underconsolidated clay. Considering the influence of the consolidation state of the soil, one modified semi-logarithmic equation relating the penetration rate to the resistance penetration is applied, and the rate factor, μ, for Ball and T-bar penetrometer with this test condition is 0.113 and 0.117, respectively, with the relatively minor influence of rate-dependency behavior;

- The rate effect on penetration resistance for full-flow penetrometer in underconsolidated clay is lower than that in overconsolidated clay, which has implications for the penetration of the full-flow penetrometer in newly dredger fill. Therefore, caution should be exercised when extrapolating the penetration resistance of the full-flow penetrometer in underconsolidated clays for direct application in design.

In this paper, we have solely evaluated the rate effect on the penetration resistance of the full-flow penetration test in underconsolidated clay. However, the impact of the rate effect on penetration resistance of the full-flow penetrometers in underconsolidated clays with different degrees of consolidation is unclear. Moreover, due to limitations in speed control of the penetration equipment, the full-flow penetration test in this study was primarily conducted under undrained conditions. In future work, we will carry out the parameter sensitivity analysis of the penetration resistance rate effect in underconsolidated soils with varying degrees of consolidation. We will also involve extending the magnitudes of penetration rates and further study the characteristics of the rate effect on penetration resistance under both drained and partially drained conditions with the full-flow penetration test.

Author Contributions

Writing—original draft preparation, H.Q. and P.P.; conceptualization, P.P.; supervision and writing—review and editing, H.H.; investigation, X.L.; data curation and providing language, R.Z.; investigation—performing the experiments and data collection, Z.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Project of Jiangsu Province Transportation Engineering Construction Bureau, grant number CX-2019GC02, National Natural Science Foundation of China for Distinguished Young Scholars (Grant No. 42225206), and National Natural Science Foundation of China (Grant No. 42072299).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liang, F.; Zhao, M.; Qin, C.; Jia, Y.; Wang, Z.; Yue, G. Centrifugal test of a road embankment built after new dredger fill on thick marine clay. Mar. Georesources Geotechnol. 2020, 38, 114–121. [Google Scholar] [CrossRef]

- Wang, W.; Liu, H.; Li, Y.; Su, J. Development and management of land reclamation in China. Ocean Coast. Manag. 2014, 102, 415–425. [Google Scholar] [CrossRef]

- Cai, Y.; Qiao, H.; Wang, J.; Geng, X.; Wang, P. Experimental tests on effect of deformed prefabricated vertical drains in dredged soil on consolidation via vacuum preloading. Eng. Geol. 2017, 222, 10–19. [Google Scholar] [CrossRef]

- Wang, J.; Fang, Z.; Cai, Y.; Chai, J.; Wang, P.; Geng, X. Preloading using fill surcharge and prefabricated vertical drains for an airport. Geotext. Geomembr. 2018, 46, 575–585. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Z.; Fu, H.; Ding, G.; Cai, Y.; Geng, X.; Shi, C. Effect of surcharge loading rate and mobilized load ratio on the performance of vacuum–surcharge preloading with PVDs. Geotext. Geomembr. 2019, 47, 121–127. [Google Scholar] [CrossRef]

- Zheng, J.; Hu, X.; Gao, S.; Wu, L.; Yao, S.; Dai, M.; Liu, Z.; Wang, J. Undrained cyclic behavior of under-consolidated soft marine clay with different degrees of consolidation. Mar. Georesources Geotechnol. 2022, 42, 176–183. [Google Scholar] [CrossRef]

- Zhu, W.; Wang, J.; Zhuang, H. Influence of cyclic deviator stress and consolidation degree on permanent strain of “under-consolidated” marine sediment. Mar. Georesources Geotechnol. 2023, 41, 764–773. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.-R.; Jee, S.-H. Cover Placement on Dredged Marine Clay Reclaimed Deposit. Mar. Georesources Geotechnol. 2014, 32, 38–61. [Google Scholar] [CrossRef]

- Stark, T.D.; Choi, H.; Schroeder, P.R. Settlement of dredged and contaminated material placement areas. I: Theory and use of primary consolidation, secondary compression, and desiccation of dredged fill. J. Waterw. Port Coast. Ocean Eng. 2005, 131, 43–51. [Google Scholar] [CrossRef]

- Stark, T.D.; Choi, H.; Schroeder, P.R. Settlement of dredged and contaminated material placement areas. II: Primary consolidation, secondary compression, and desiccation of dredged fill input parameters. J. Waterw. Port Coast. Ocean Eng. 2005, 131, 52–61. [Google Scholar] [CrossRef]

- Gu, C.; Wang, J.; Cai, Y.; Sun, L.; Wang, P.; Dong, Q.Y. Deformation characteristics of overconsolidated clay sheared under constant and variable confining pressure. Soils Found. 2016, 56, 427–439. [Google Scholar] [CrossRef]

- Rotte, V.M.; Sutar, A.A.; Patel, A.; Patel, A. Effect of various parameters on electrokinetic dewatering of saturated clay. In Proceedings of the Indian Geotechnical Conference 2019: IGC-2019, Surat, Gujarat, 19–21 December 2019; Volume III, pp. 183–194. [Google Scholar]

- Flora, A.; Gargano, S.; Lirer, S.; Mele, L. Effect of electro-kinetic consolidation on fine grained dredged sediments. Procedia Eng. 2016, 158, 3–8. [Google Scholar] [CrossRef]

- Cavallaro, A. The use of Cone Penetration Tests (CPT) for the study of the dynamic characteristics of the soils. In Proceedings of the IMEKO TC4 International Conference on Metrology for Archaeology a Cultural Heritage, Trento, Italy, 22–24 October 2020; pp. 242–247. [Google Scholar]

- Cavallaro, A. Dynamic characteristics of the soils by Cone Penetration Tests (CPT). In Proceedings of the 5th International Symposium on Cone Penetration Testing, CPT22, Bologna, Italy, 8–10 June 2022; pp. 311–316. [Google Scholar]

- Qiao, H.; Liu, L.; He, H.; Liu, X.; Liu, X.; Peng, P. The Practice and Development of T-Bar Penetrometer Tests in Offshore Engineering Investigation: A Comprehensive Review. J. Mar. Sci. Eng. Geol. 2023, 11, 1160. [Google Scholar] [CrossRef]

- Einav, I.; Randolph, M.F. Combining upper bound and strain path methods for evaluating penetration resistance. Int. J. Numer. Methods Eng. 2005, 63, 1991–2016. [Google Scholar] [CrossRef]

- Tanaka, Y.; Sakagami, T. Piezocone testing in underconsolidated clay. Can. Geotech. J. 1989, 26, 563–567. [Google Scholar] [CrossRef]

- Karakouzian, M.; Avar, B.B.; Hudyma, N.; Moss, J.A. Field measurements of shear strength of an underconsolidated marine clay. Eng. Geol. 2003, 67, 233–242. [Google Scholar] [CrossRef]

- Lunne, T.; Powell, J.J.; Robertson, P.K. Cone Penetration Testing in Geotechnical Practice; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Yafrate, N.J.; DeJong, J.T.; DeGroot, D.J. The influence of full-flow penetrometer area ratio on penetration resistance and undrained and remoulded shear strength. Proceedings of Offshore Site Investigation and Geotechnics: Confronting New Challenges and Sharing Knowledge, London, UK, 11–13 September 2007. [Google Scholar]

- Taukoor, V.; Rutherford, C. Displacement rate effects during T-bar cycling in remoulded Gulf of Mexico clay. Géotechnique 2017, 67, 553–557. [Google Scholar] [CrossRef]

- Mahmoodzadeh, H.; Boylan, N.; Randolph, M.; Cassidy, M. The Effect of Partial Drainage on Measurements by a Piezoball Penetrometer. Proceedings of 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; pp. 1007–1016. [Google Scholar]

- Ganesan, S.A.; Bolton, M.D. Characterisation of a high plasticity marine clay using a T-bar penetrometer. Underw. Technol. 2013, 31, 179–185. [Google Scholar] [CrossRef]

- Blight, G. A note on field vane testing of silty soils. Can. Geotech. J. 1968, 5, 142–149. [Google Scholar] [CrossRef]

- Matsui, T.; Abe, N. Shear mechanisms of vane test in soft clays. Soils Found. 1981, 21, 69–80. [Google Scholar] [CrossRef][Green Version]

- Flaate, K. Factors influencing the results of vane tests. Can. Geotech. J. 1966, 3, 18–31. [Google Scholar] [CrossRef]

- Schlue, B.F.; Moerz, T.; Kreiter, S. Influence of shear rate on undrained vane shear strength of organic harbor mud. J. Geotech. Geoenviron. Eng. 2010, 136, 1437–1447. [Google Scholar] [CrossRef]

- Chung, S.; Randolph, M. Penetration resistance in soft clay for different shaped penetrometers. In Proceedings of the 2nd International Conference on Site Characterization, Porto, Portugal, 19–22 September 2004; pp. 671–677. [Google Scholar]

- Nanda, S.; Sivakumar, V.; Hoyer, P.; Bradshaw, A.; Gavin, K.; Gerkus, H.; Jalilvand, S.; Gilbert, R.; Doherty, P.; Fanning, J. Effects of strain rates on the undrained shear strength of kaolin. Geotech. Test. J. 2017, 40, 951–962. [Google Scholar] [CrossRef]

- Sheahan, T.C.; Ladd, C.C.; Germaine, J.T. Rate-dependent undrained shear behavior of saturated clay. J. Geotech. Eng. 1996, 122, 99–108. [Google Scholar] [CrossRef]

- Lunne, T.; Andersen, K.H.; Low, H.E.; Randolph, M.F.; Sjursen, M. Guidelines for offshore in situ testing and interpretation in deepwater soft clays. Can. Geotech. J. 2011, 48, 543–556. [Google Scholar] [CrossRef]

- Lehane, B.; O’loughlin, C.; Gaudin, C.; Randolph, M. Rate effects on penetrometer resistance in kaolin. Géotechnique 2009, 59, 41–52. [Google Scholar] [CrossRef]

- Chung, S.F.; Randolph, M.F.; Schneider, J.A. Effect of penetration rate on penetrometer resistance in clay. J. Geotech. Geoenviron. Eng. 2006, 132, 1188–1196. [Google Scholar] [CrossRef]

- Guo, X.; Liu, X.; Zhang, H.; Shan, Z.; Sun, M. Improved predictive model for the strength of fluidized seabed sediments with rate effect characteristics by full-scale spherical penetrometer tests. Comput. Geotech. 2023, 161, 105535. [Google Scholar] [CrossRef]

- Sespeñe, S.M.; Choo, Y.W. Empirical factors for miniature cone and T-bar penetrometers for kaolin clay. KSCE J. Civ. Eng. 2019, 23, 4675–4686. [Google Scholar] [CrossRef]

- Mahmoodzadeh, H.; Randolph, M.F. Penetrometer testing: Effect of partial consolidation on subsequent dissipation response. J. Geotech. Geoenviron. Eng. 2014, 140, 04014022. [Google Scholar] [CrossRef]

- Zhu, B.; Dai, J.; Kong, D. Assess the effects of loading rate and interface roughness on T-bar penetration resistance. Soils Found. 2020, 60, 266–273. [Google Scholar] [CrossRef]

- Randolph, M.; Hope, S. Effect of cone velocity on cone resistance and excess pore pressures. In Proceedings of the Engineering Practice and Performance of Soft Deposits, Osaka, Japan, 1 January 2004; pp. 147–152. [Google Scholar]

- House, A.; Oliveira, J.; Randolph, M. Evaluating the coefficient of consolidation using penetration tests. Int. J. Phys. Model. Geotech. 2001, 1, 17–26. [Google Scholar] [CrossRef]

- Low, H.; Lunne, T.; Andersen, K.; Sjursen, M.; Li, X.; Randolph, M. Estimation of intact and remoulded undrained shear strengths from penetration tests in soft clays. Géotechnique 2010, 60, 843–859. [Google Scholar] [CrossRef]

- DeJong, J.T.; Yafrate, N.J.; DeGroot, D.J. Evaluation of undrained shear strength using full-flow penetrometers. J. Geotech. Geoenviron. Eng. 2011, 137, 14–26. [Google Scholar] [CrossRef]

- Cai, G.; Liu, S.; Tong, L.; Du, G. Field evaluation of undrained shear strength from piezocone penetration tests in soft marine clay. Mar. Georesources Geotechnol. 2010, 28, 143–153. [Google Scholar] [CrossRef]

- Low, H.; Randolph, M.; DeJong, J.; Yafrate, N. Variable rate full-flow penetration tests intact and remoulded soil. In Proceedings of the Geotechnical and Geophysical Site Characterization, London, UK, 1 January 2009; pp. 1087–1092. [Google Scholar]

- Bemben, S.; Myers, H. The influence of rate of penetration on static cone resistance in Connecticut river valley varved clay. In Proceedings of the European Symposium on Penetration Testing, Stockholm, Sweden, 5–7 June 1974; pp. 33–43. [Google Scholar]

- Davis, E.H.; Poulos, H. Rate of settlement under two-and three dimensional conditions. Geotechnique 1972, 22, 95–114. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).