Abstract

Seed rope direct-seeding is an advanced precision sowing technique that involves encapsulating seeds within rope materials, adhering to specific spacing and quantity, and then deploying these ropes in the field as an alternative to conventional direct-seeding. This method offers the dual benefits of minimal sprout damage and precise control over row-to-seed spacing. The mechanical properties of the seed rope material and the integrity of the wrapped seeds are critical factors that influence the growth and development of the plants’ root system, which in turn is a key determinant for the optimization of the seed rope automatic seeder. This paper employed uniaxial tensile testing to investigate the mechanical properties and tensile failure characteristics of seed ropes across various materials, seed wrapping techniques, and seed soaking methods. Additionally, scanning electron microscopy was utilized to scrutinize the microstructural features of the tensile fracture surfaces of the seed ropes. The results showed that the tensile strength of paper-based seed ropes ranged from 1.80 to 2.89 N/mm, with elongation at the break between 31.4% and 47.5%, and a critical stress range of 5.67 to 9.06 N. In contrast, non-woven fabric ropes exhibited a tensile strength range of 0.91 to 1.23 N/mm2, an elongation at break range of 160.3 to 284.2%, and a critical stress range of 2.86 to 3.86 N. Electron microscope scanning imagery analysis indicated that the broken fibers were disordered, and the fibers of the soaked ropes showed minor surface damage, which is attributed to the decline in tensile strength observed in soaked ropes. Regarding the phenotypic study of root growth and development, the root growth and development phenotypes of two types of rope materials across four different vegetable varieties were explored; the results indicated that the influence of the seed rope material on the root system was pronounced in the early stages of growth and development. As plants progressed to the middle stage of growth, the trend in root length mirrored that of the early stage, with the seed rope material continuing to significantly impact root system development. In the late stage of growth, the effect of the seed rope material on root growth gradually diminished as the seed rope material decomposed. Interestingly, the root length under non-woven fabric wrapping not only caught up to, but in some instances, surpassed the root length of unwrapped seeds. This research provides valuable theoretical insights and data to support the optimization of the parameters for the automatic seed rope direct-seeder.

1. Introduction

In the plot sowing experiments, the seed quantity for each variety was small, with some barely exceeding a few dozen, demanding heightened precision in sowing. Among the array of innovative sowing methods, seed rope direct-seeding technology stands out for its ability to achieve exact single-seed placement, offering the benefits of no cross-contamination between varieties and minimal sprout damage. However, initial field experiments with the seed rope direct-seeding machinery highlighted the need for manual intervention when making turns at the plot’s boundaries, which involved breaking the seed rope. The constant need to open and turn the seed rope led to operational inefficiencies, with a high risk of slippage that significantly impacted both work efficiency and quality. The current state of automation in seed rope direct-seeding machines is suboptimal, particularly in the areas of rope breaking and other automated functions. Scholars have explored the quantitative mechanisms of seed rope planting, such as employing scissor mechanisms to achieve the cutting of seed ropes. These efforts lack an automatic sowing function post-cutting, necessitating continued manual intervention. There is substantial scope for enhancement in this area. To design an automated seed rope direct-seeding machine, it is imperative to conduct comprehensive mechanical property experiments on various seed rope types, examining how different seed sizes, shapes, and processing methods influence the mechanical properties of seed rope breakage, as well as root growth and development.

The literature on the technology of rope direct-seeding is quite scarce, both within our country and abroad. The earliest recorded development in this field dates back to 1972 in the United States, where a four-line rope direct-seeding machine was introduced. In Japan, advancements have been made with the development of a compact and lightweight vegetable seeder (model PTS-12) that incorporates seed rope sowing technology [1].

Ren was one of the early researchers in the field of direct-seeding technology and equipment, and developed rice rope weaving machines and direct-seeding equipment [2,3,4,5]; Liu and others referred to the agricultural requirements for carrot sowing and the sowing technology characteristics of the seed rope, and designed two rows carrot sowing machine [6]. To enhance the tensile strength and precision of rice spacing and to prevent seed loss, Ren and colleagues have proposed a novel approach involving the application of adhesive to the inclusion material. They have developed a modified corn starch-based adhesive, which serves as a valuable reference for the refinement and design of rice seed rope twisting machinery [7,8]. Zhang delved into the properties of materials used for seed rope encapsulation and their subsequent impact on the growth patterns of rice direct-seeding. The experiments revealed that rice grown from non-woven fabric seed ropes exhibited impressive metrics in terms of germination rates, root system development, and seedling height. Notably, these positive growth indicators were found to be minimally influenced by the twisting tension applied during the seed rope production process [9]; Zhang also conducted a comparative analysis of key technologies, including rope fabrication, rope sowing, trenching, and belt guidance systems. This work offers valuable insights and serves as a reference for the development and research of belt planting technology and associated equipment [10]. Lv conducted an in-depth study on the rice seed rope releasing mechanism and the seed rope conveying channel. They developed a mathematical model to quantify the frictional forces within the motion pair, providing a theoretical foundation for their analysis. Through a comprehensive examination of the sowing mechanism’s structure, an integrated sowing system was designed. Field experiments demonstrated that their mechanism achieved a satisfactory release effect [11]. Zhang carried out an extensive experimental investigation focusing on the number of twists per unit length within the seed rope and the rotational inertia of the seed rope spool, as well as the frictional torque of the bearings. The study revealed that the rotation of the seed rope spool could be effectively driven by the tension of the seed rope itself. This discovery furnishes a solid theoretical foundation for the selection of appropriate seed rope materials and the engineering of seed rope direct-seeding machinery [12]. Xin developed an innovative automatic rope-cutting device for direct-seeding machinery. This device comprises a stationary crossbeam, a scissors-actuated crossbeam, a driving rod, a driving mechanism, and a guidance system. The invention employs a linkage transmission system, working in tandem with the guidance and driving mechanisms, to facilitate the vertical movement of the scissors-actuated crossbeam [13]; Liang has devised a rope-cutting device that encompasses both a cutting mechanism and a pressing mechanism. This invention addresses the prevalent issue of time-consuming and labor-intensive rope cutting [14].

Tensile testing is one of the most prevalent and critical methods for assessing the mechanical properties of materials. Naik has made significant advancements in the traditional drawing technique, specifically for natural fiber composite materials, refining the process to achieve superior results [15]. Bain conducted tensile experiments on ropes made of different materials and analyzed their mechanical properties [16]; Vivek analyzed the influence of fabrics with different elastic contents on their mechanical properties [17]; Fedoko conducted a tensile experiment on smooth conveyor belts to determine their internal structure [18]. McSwain investigated the effect of compressive stress in a concrete matrix on fiber pull-out behavior and plotted typical pull-out curves at three levels [19]; Muna studied the mechanical strength and Young’s modulus of AMUD-CFRP through tensile testing, and investigated the morphology and structure of the surface of additive manufacturing specimens using optical microscopy, scanning electron microscopy (SEM), and digital microscopy [20]; Halabi studied the tensile behavior of popular synthetic fiber ropes made from polyester, polypropylene, and nylon polymer fibers, providing insights into the process structure performance relationship of synthetic fiber ropes [21]. Numerous scholars have delved into the tensile mechanical properties of various rope materials, examining aspects such as loading mechanisms and material weaving techniques. In a series of experiments conducted by Mine and colleagues on polymer fiber materials, it was revealed that the inherent strength and stability of the fibers and the intricacies of the weaving process are pivotal factors that significantly influence the material’s mechanical properties [22]. Mine also studied the surface roughness of cotton fiber materials, proving that roughness is also one of the factors affecting the strength of fiber materials [23]. Midendorf employed a micromechanics model to analyze unidirectional weaving, thereby assessing the elasticity and damage behavior of the material in question. Their approach provided a sophisticated understanding of how these textiles respond under stress and the mechanisms behind their durability [24]. Metzner and colleagues carried out a comparative analysis of composite materials featuring diverse textile structures. Their study aimed to uncover the extent to which the textile structure influences the mechanical properties of these materials, shedding light on the relationship between weave configuration and material performance [25]. Shi conducted an in-depth exploration of the correlation between structural parameters and the tensile properties of composite materials. They provided a detailed analysis of the tensile failure modes, offering valuable insights into how these materials behave under stress and the factors that contribute to their ultimate failure [26]. Cui conducted tensile strength experiments on four types of rope materials and compared them [27].

The current research on the automation mechanism of rope direct-seeding machines can only achieve the use of shear force to break the rope, and manual assistance is still required for rope installation, the degree of automation is not high. In order to design an automatic rope-breaking mechanism that can clamp and pull out the seed rope after being pulled apart by tensile stress, this paper used a universal testing machine to test the critical stress at which the seed rope broke under tensile stress for six different shapes and sizes of seeds, rice, Chinese cabbage, cabbage, lettuce, Indian lettuce, and celery, made of two materials: paper and non-woven fabric. The tensile performance of the seed rope is an important parameter during the laying and breaking process of the seed rope, providing a data basis for the tensile stress range of the automatic rope breaking mechanism. However, the seeds used in this study are all smaller in size. In the future, the critical tensile stress of the seed rope wrapped around larger seeds should be tested to enable the automatic rope breaking mechanism to adapt to the direct seeding of seed ropes for more types of seeds.

The primary objective is to achieve quantitative and directional seeding. The mechanical and physical properties of the materials serve as the essential foundation for precise rope breaking and seed dispensing. Furthermore, the subsequent analysis of plant growth characteristics—especially the impact on crop root systems under this seeding mode—provides the basis for implementing intercropping of different varieties.

1.1. Materials and Methods

1.1.1. Experimental Materials and Equipment

The selected materials for the experiment are paper material (19 mm width and 0.03 mm thickness, made of plant fibers and cut into strips) and non-woven fabric (23 mm width and 0.07 mm thickness, made of polyvinyl acetate). The choice of these two materials is based on their widespread use in the market.

Both of these materials have the ability to degrade or decompose. After being buried in the soil, they quickly decompose and disappear through the action of microorganisms, water, and oxygen, which do not affect the germination of seeds and have no impact on the environment, as shown in Table 1.

Table 1.

The material of seed ropes.

The seeds that were encapsulated within the seed ropes for this study were carefully selected to represent a variety of shapes and sizes, all of which have proven their robust adaptability in the practice of seed rope direct-seeding technology. The selection includes a type of seed with a larger volume: rice seeds; small grain vegetable seeds (with an average diameter of ≤3 mm), comprising two nearly spherical seeds: Lifeng No. 3 cabbage and Zhenbao sweet cabbage heart, and two seeds with a flattened shape: Xindali No. 2 lettuce and Sijixiang sweet pointed oil wheat; and a type of seed with an extremely small particle size and light weight: Ventura celery.

The size data in the table were derived from measuring 100 seeds using a ruler and subsequently calculating the average value.

The shape and dimensions of seeds play a pivotal role in the design and research of agricultural machinery, and the frictional properties of particles, such as the natural angle of repose, are crucial parameters for the design of equipment handling bulk material transport and processing. Consequently, this study involved the measurement and statistical analysis of the length, width, thickness, thousand seed weight, and natural angle of repose of the seeds utilized in the research, as shown in Table 2.

Table 2.

The physical properties of seeds.

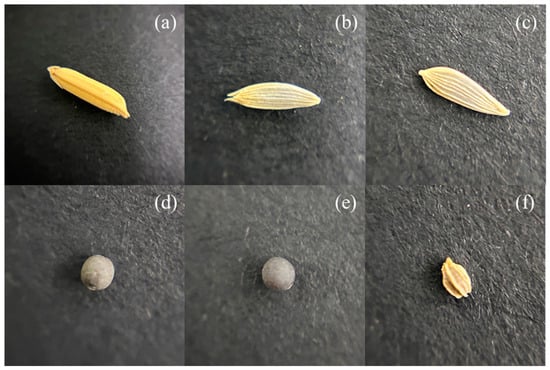

Owing to the diversity in seed shapes and sizes, the contact area between the seeds and the wrapping material after the seed rope is woven differs accordingly. Consequently, when the seed rope is tensioned, there are variations in the force exerted at the interface between the seeds and the wrapping material. Additionally, the thousand-grain weight of seeds influences, to a certain extent, the stress on the fibers of the material encircling the seeds as the seed rope is woven. The natural angle of repose is indicative of the frictional retention and dispersal capabilities of granular materials; an increased angle of repose corresponds to a higher internal friction force within the material and a reduced dispersal performance. Therefore, the seeds selected for this study exhibit substantial variations in shape, three-dimensional dimensions, thousand seed weight, and natural angle of repose. These factors are crucial for a comprehensive assessment of how the physical properties of seeds influence the effectiveness of seed rope direct-seeding techniques. The varying sizes and shapes of seeds were selected to conduct comparative observations on how seed dimensions and contours impact the tensile strength and elongation properties of both paper and non-woven fabric ropes, as shown in Figure 1. This analysis aims to identify the most compatible rope material for different seed types for sowing purposes and to ascertain the critical tensile force required under various seed wrapping conditions, as well as the optimal tensile stress necessary for the automatic breaking mechanism.

Figure 1.

(a) Rice; (b) leaf-used lettuce; (c) lettuce; (d) Chinese cabbage; (e) flowering Chinese cabbage; (f) celery.

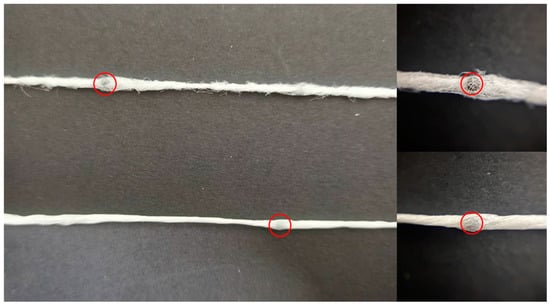

Taking into account the length of the material gripped by the testing machine’s clamps, it has been determined that all rope samples for the tensile experiment should be 200 mm in length and 2 mm in diameter. The following samples have been prepared: six original paper material, six original non-woven fabrics, six paper ropes wrapped around six distinct seeds, six non-woven fabric ropes wrapped around six different seeds, six paper ropes wrapped around six different seeds that have been soaked for 24 h, and six non-woven fabric ropes wrapped around six different seeds that have also been soaked for 24 h. In line with the sowing techniques specific to different seed types, the wrapping distance for the seed rope has been set at 40 mm. Consistent twisting force—quantified by the number of twists between seeds wrapped by the seed rope—is applied to both the paper material and non-woven fabric, with a specified count of five twists, As shown in Figure 2.

Figure 2.

Different materials of seed ropes. (The red circle highlights the seeds positioned on the sowing belt).

The testing equipment adopts the universal testing machine KY-D2103, according to GB/T16825.1-2008 [28]. Inspection of static uniaxial testing machines—Part 1: Inspection and calibration of force measuring systems for tensile and/or compressive testing machines, the accuracy level of the testing machine was determined to be level 0.5, and the fixture range was 1 kN.

1.1.2. Experimental Methods

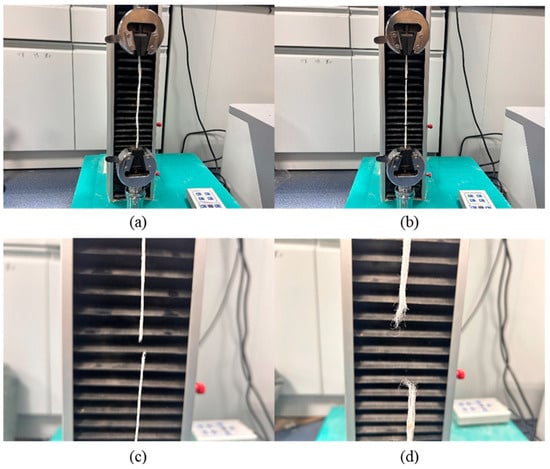

The rope-pulling test should be conducted at room temperature. According to the regulations, prepare the sample materials and divide the two types of rope into two groups. In order to compare the deformation degree of the working section of samples with different thicknesses after being pulled, it is necessary to specify the ratio of the length of the working section to the cross-sectional diameter d. Since the thickness of the original material and the cross-sectional diameter of the rope are both ≤2 mm, the original gauge length is taken as Lo = 100 mm ± 1 mm. Before the experiment, adjust the tightness of the fixtures to ensure that there is no deviation when the two fixtures clamp the seed rope and that the length of the material clamped by the two fixtures is consistent, as shown in Figure 3.

Figure 3.

(a) The planting rope is fixed on the universal testing machine; (b) seed rope during stretching process; (c) the fracture condition of the paper material rope when it is pulled apart; (d) the fracture condition of non-woven fabric rope when pulled apart.

According to GB/T3923.1-2013 [29], (textile fabrics—tensile properties—Part 1: determination of tensile strength and elongation at the break—strip method) and GB/T12914-2018 [30] (determination of tensile strength of paper and paperboard), set the tensile speed. Given that the paper sample has a density of 45 g/m2 and the non-woven sample has a density of 40 g/m2, both of which are less than 200 g/m2, we proceeded with a uniform tensile test for the seed ropes. Once the two ends of the seed rope are secured in the clamps, tensile force F is initiated from 0 N and increased at a consistent rate of 20 mm/min. This longitudinal load is applied uniformly along the length of the seed rope, continuing until the rope ultimately fails, at which point the test is halted. The broken sample is then removed, and a new sample is positioned in the clamps. This sequence is repeated iteratively until all samples have been subjected to the tensile test.

Record the maximum tensile load Fb, the load Fm at the break, displacement values, etc., and take photos to record the fracture of the rope when it is broken. Save the data and curve graph of the testing machine. After removing the broken seed rope, randomly select the test sample of the seed rope, and preserve the broken section of the sample intact for electron microscopy analysis of the fracture section.

1.2. Experimental Results and Analysis

Calculate the ultimate tensile strength based on the stress data obtained during the experimental process [31]:

Calculate the post fracture gauge length by analyzing the displacement data before and after the rope is stretched, and calculate the post fracture elongation rate based on the post fracture gauge length :

Table 3 shows the tensile strength of different types of ropes, with paper material ropes having a higher tensile strength than non-woven fabric ropes.

Table 3.

Tensile strength of different seed belts (N/mm2).

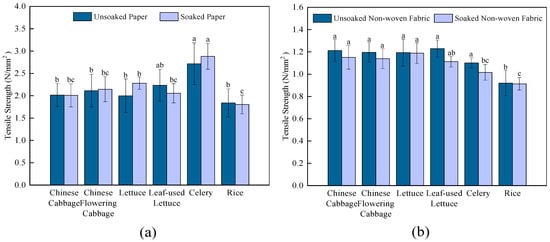

Figure 4 illustrates the tensile strength of various rope types under tension. It is evident that the tensile strength of the ropes fluctuates considerably when they are wrapped around different seeds, with the variation becoming particularly pronounced after a soaking treatment.

Figure 4.

(a) Tensile strength of non-impregnated and impregnated paper material; (b) tensile strength of non-impregnated and impregnated non-woven fabrics. (Where there is a single marked letter, the difference is not significant, and where there are different marked letters, the difference is significant).

The tensile strength of the paper material rope is markedly influenced by the size of the seeds, with the celery rope exhibiting a significantly higher tensile strength compared to other ropes, while the rice rope shows a significantly lower tensile strength than the others. Regardless of whether they undergo a soaking treatment or not, it is observed that the smaller the seed volume, the greater the tensile strength of the paper material, and conversely, the larger the seed volume, the lower the tensile strength of the paper material.

The tensile strength of the non-woven fabric rope is not significantly affected by the size of the seeds; however, the shape of the seeds does have a certain impact. After a soaking treatment, there is a significant difference in tensile strength. The rice seed ropes have a significantly lower tensile strength compared to other seed ropes, followed by the celery seed ropes. The tensile strength of seed ropes enclosing spherical seeds, such as cabbage and cauliflower, is slightly higher than that of those wrapped around irregularly shaped seeds.

Table 4 shows the elongation at the break of different types of ropes. The elongation at break of non-woven fabric ropes mostly exceeds 200%, which is significantly higher than that of paper material ropes. The elongation at break of paper material ropes does not exceed 50%.

Table 4.

Elongation after fracture of different seed belts (%).

Table 5 shows the maximum force required to break different types of ropes during the tensile test. The highest tensile force required to break the paper material rope can reach 9.0600 N, which is significantly greater than the tensile force required to break the non-woven fabric.

Table 5.

Critical stress in the seed belt pull-out test (N).

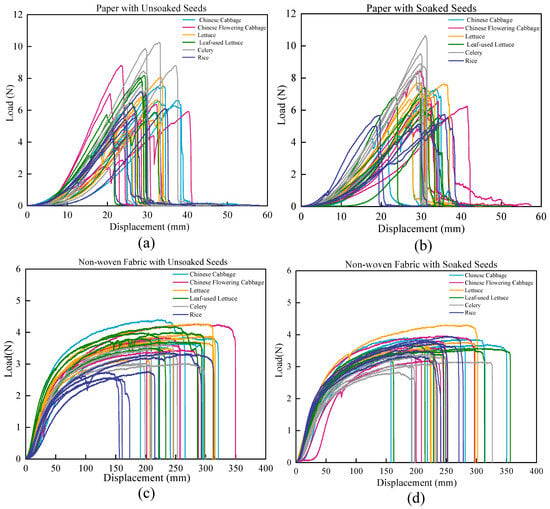

Figure 5 shows the pull-out curves of paper material and non-woven fabric rope under two treatments: non-seed soaking and seed soaking. From a single graph, six repeated experiments were conducted on the seed rope wrapped with the same seed, and there were some differences in the pulling curves of each repetition. This is due to small errors, such as inconsistent elasticity caused by manual twisting, as well as subtle effects caused by the unevenness of the material itself. The celery seeds with the smallest particle size have greater force and displacement in the paper material, while they exhibit the smallest force and displacement in the non-woven fabric.

Figure 5.

(a) Force-displacement diagram of no seed soaking paper material; (b) force-displacement diagram of seed soaking paper material; (c) force-displacement diagram of non-seed soaking and non-woven fabric; (d) force-displacement diagram of non-woven fabric and seed soaking.

The tensile curve of non-woven fabric rope shows low strength but high elongation. The fiber strength and elongation of non-woven fabric rope soaked in seeds are slightly lower than those without seeds, depending on the moisture absorption capacity of the non-woven fabric material itself. The stretching curve of paper material shows high strength but low elongation. After reaching the maximum tensile stress, the paper material fibers were not completely damaged and still had some residual strength.

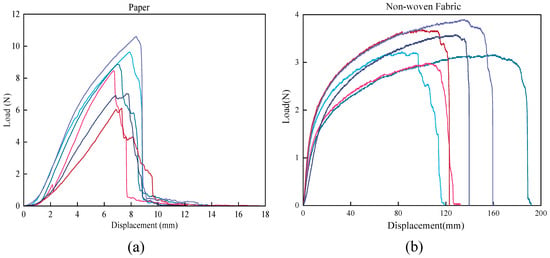

A pull-out test was conducted on paper material and non-woven fabric without wrapped seeds and twisting. Each material was subjected to six repetitions to obtain the initial force-displacement diagram of the paper material and non-woven fabric, as shown in Figure 6. Without any wrapping or twisting, the elongation of paper material and non-woven fabric is small, resulting in poor tensile performance.

Figure 6.

(a) Unpackaged paper material force-displacement diagram; (b) unpackaged non-woven fabric force-displacement diagram.

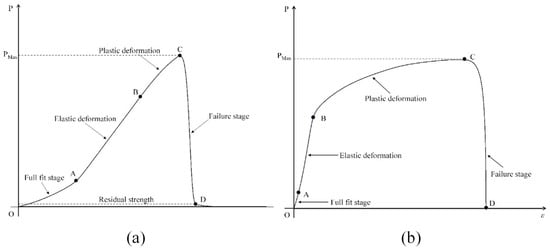

As shown in Figure 7, the comprehensive force-displacement diagram is used to fit the pull-out curves of paper material and non-woven fabric rope, which is helpful for studying the pull-out curves of different seed wrapping situations. Typical drawing curve of paper material and non-woven fabric integration.

Figure 7.

(a) Typical drawing curve of paper material and (b) typical drawing curve of non-woven fabric.

The pull-out test of the rope fibers is divided into four different stages, namely the OA stage, which is the fully extended stage; the AB stage, as elastic deformation stage; the BC stage, as plastic deformation stage; the CD stage, as the destruction stage.

In the first stage, the two ends of the seed rope are clamped on the universal testing machine, and the length of the seed rope is greater than the length between the two fixtures. Therefore, in the initial stage of stretching, the seed rope is in the fully extended stage. As the two end fixtures move, the force on the seed rope gradually increases, and the seed rope fibers are also gradually straightened, entering the second stage, which is the elastic deformation stage. At this time, the strain generated is elastic strain, and the structure of the seed rope fibers has not yet been damaged. As the tensile load further increases, the structure of the seed rope fibers begins to be damaged, and the increase in load decreases while its deformation continues to increase. It then enters the third stage, the plastic deformation stage, where the seed rope fibers gradually suffer from tensile stress failure. After the sample elongates to a certain extent, the load reading gradually decreases, and the tensile load reaches its maximum value at point C. At this point, the cross-sectional area of a certain section of the rope sample significantly shrinks until the rope fibers are completely destroyed. The force on the rope drops rapidly, and the rope is pulled apart, which is the fourth stage, the failure stage.

After the non-woven fabric reaches the maximum tensile stress, all fibers are damaged, and the seed rope is completely broken. However, not all fibers are immediately damaged after the paper material reaches the maximum tensile stress. There are still connected paper fibers, and the residual strength slowly decreases from point D until it is completely broken.

Comparing the force-displacement curves obtained from the tensile test of the seed rope with those of the typical pull-out test, it can be seen that the tensile curves of the two are roughly consistent. However, it can be seen from the tensile curve graph of the test that there are a few curves that are not smooth as a whole, indicating that there is slight unloading during the stretching process. The reason for unloading may be that the seeds wrapped in the seed rope fall out of the seed rope fibers during stretching, or it may be due to errors in the weaving process of the seed rope.

After soaking for 24 h, the woven paper material seed rope wrapped around it has a higher residual strength than the non-soaked paper material after reaching the maximum tensile stress. This may be due to the influence of seed germination on the fiber of the paper material, and its strength trend may be related to the germination potential of the seeds.

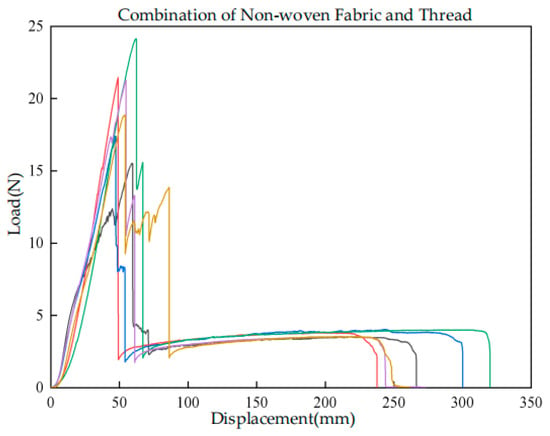

In addition, the seed rope woven with a combination of thread and non-woven fabric was tested for a total of six repetitions, as shown in Figure 8. It can be seen that this method includes two distinct stages of tensile fracture. The thread has a high tensile strength but a low elongation rate, while the non-woven fabric has a relatively weak tensile strength but a high elongation rate. The seed rope woven by combining the two requires strong tension and a longer working time to break.

Figure 8.

Thread with non-woven composite weaving rope force-displacement diagram.

2. Electron Microscopy Scanning Analysis of Tensile Fracture Surface

2.1. Materials and Methods

2.1.1. Experimental Materials and Equipment

Scanning electron microscopy can observe the microstructure of the broken rope under different stress conditions, in order to explore the microscopic changes in different ropes under different stress conditions and further understand the mechanical mechanism of the rope under external forces. Check the state of the fiber surface at the fracture section of the seed rope under shear stress and uniform tensile stress, and compare the differences between the fiber surface of the seed rope with soaked or not. The experimental equipment used was a COXM EM-30A desktop electron scanning microscope from OPTON company (Cheonan, Republic of Korea), and the sample preparation process employed a KAS-2000F ion sputtering instrument from OPTON company to spray gold onto the seed rope fibers.

2.1.2. Experimental Methods

The sample preparation steps for SEM analysis are as follows: take a small section of sheared and stretched seed rope fracture fibers, spray the sample with gold, and then use conductive adhesive to paste it on the sample testing platform for scanning observation, obtaining scanning images at different magnifications.

2.1.3. Result Analysis

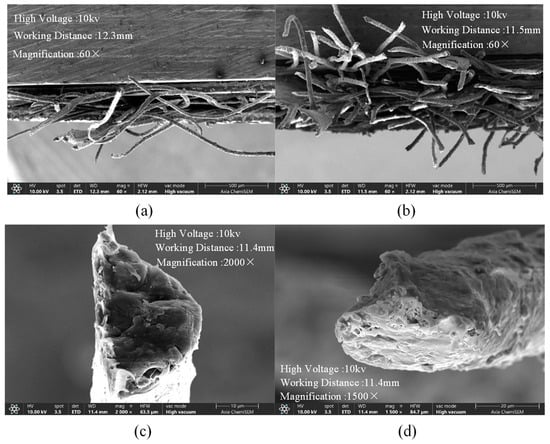

As shown in Figure 9, comparing and observing the non-woven fabric soaked in seeds, it can be seen that under tensile and shear stress, the fracture section is slightly flat. However, the degree of damage to the cross-section of the non-woven fabric after tensile fracture is not consistent, and it is not as smooth as the fracture section after shear.

Figure 9.

(a) Soaked and broken non-woven fabric, (b) soaked and cut non-woven fabric, (c) soaked and broken non-woven fabric, and (d) soaked and cut non-woven fabric.

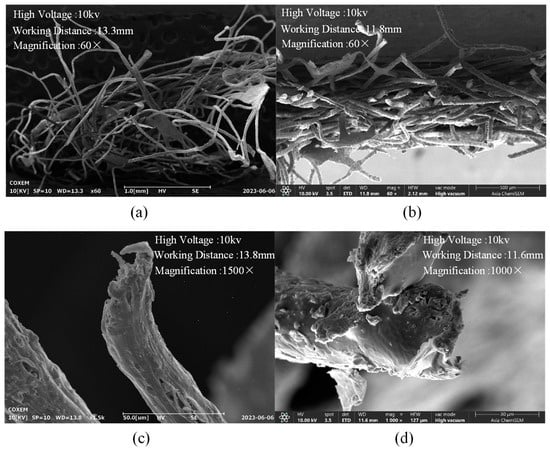

As shown in Figure 10, comparing and observing the non-woven fabric without immersion, it can be seen that there is a significant difference in the fracture surface under tensile stress and shear stress. The degree of fiber elongation on the fracture surface of non-woven fabrics that have not been soaked and pulled apart varies, and the fracture surface is generally messy, while the fibers on the shear fracture section have low fiber alignment. From the cross-section of a single fiber, there is elongation at the fracture point of the stretched fiber, thinning at the fracture surface, and uneven damage; the sheared fibers still exhibit full fiber filaments at the fracture site, and the fracture surface is smooth relatively.

Figure 10.

(a) Not soaked tensile non-woven fabric, (b) not soaked shear non-woven fabric, (c) not soaked tensile non-woven fabric, and (d) not soaked shear non-woven fabric.

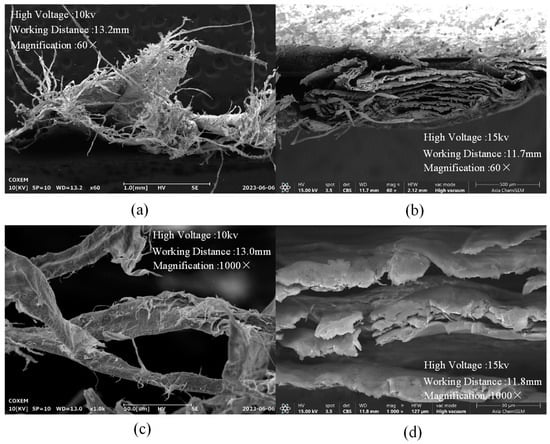

As shown in Figure 11, comparing and observing the unplanted paper material, it can be seen that there are significant differences in the fracture surface under tensile stress and shear stress. The paper material that breaks under tensile stress has different stress conditions for each fiber on the fracture surface, and there are differences in the elongation after fracture. The surface of each fiber filament is damaged to varying degrees, and the high surface roughness; The paper material that breaks under shear stress has a relatively uniform force on each layer of fibers on the fracture surface, and the overall fracture surface is flat and regular.

Figure 11.

(a) Break the paper material, (b) cut the paper material, (c) break the paper material, and (d) cut the paper material.

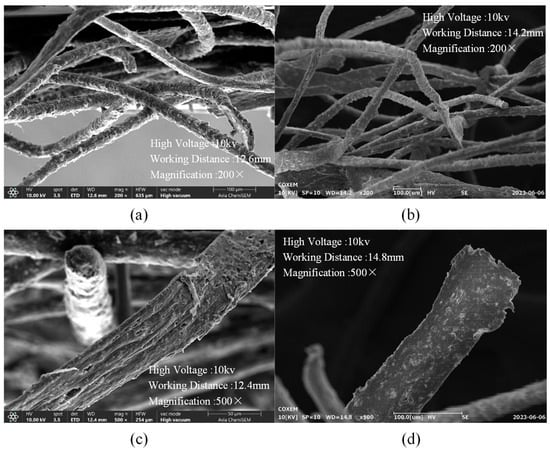

As shown in Figure 12, comparing the non-woven fabrics soaked in seeds and not soaked in seeds, it can be seen that the non-woven fabric fibers soaked in seeds for 24 h have many burrs on the surface, while the non-soaked surface is smooth, indicating that the fiber surface of the non-woven fabric material is partially damaged after soaking in seeds and absorbing water. This is also the reason why the tensile strength of the non-woven fabric rope soaked in seeds decreases.

Figure 12.

(a) Soaked and break non-woven fabric, (b) non-soaked and break non-woven fabric, (c) soaked and broken non-woven fabric, and (d) non-soaked and break non-woven fabric.

3. Phenotypic Study on the Effect of Seed Rope on Root Growth

3.1. Experimental Materials

Paper material (19 mm), the non-woven fabric containing material (23 mm width), transparent plastic flower pot (size 20 × 10.5 × 12 cm), shovel, organic fertilizer, nitrogen phosphorus potassium water-soluble compound fertilizer, through seed germination test, select the seeds with the highest germination rate: Hong Kong sweet cabbage (germination rate 98%), Zhenbao sweet cabbage (germination rate 98%), Lifeng 3 cabbage (germination rate 98%), Huangjing cabbage 1 (germination rate 94%).

3.2. Experimental Methods

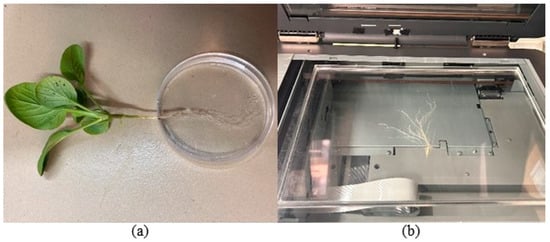

Disinfect the experimental seeds, prepare anhydrous ethanol with a content of 75%, soak the seeds for 2 min, and then rinse them repeatedly with pure water 5–6 times until they are clean and dry for later use. A pneumatic seed rope weaving machine was used to weave the seeds of four varieties separately, and two types of ropes were produced: Wood pulp paper seed rope (WR); Non-woven fabrics seed rope (NR), and another set of seeds without any packaging as blank control (CK). Use transparent flower pots for planting to observe the general process of germination and growth. Before sowing, mix an appropriate amount of organic fertilizer into the soil as base fertilizer. During the cultivation process, nitrogen phosphorus potassium water-soluble compound fertilizer is applied every 10 days, and the fertilization method is spraying. At the same time, use of the PR-3022-TRREC-N01 soil recorder from Pruson Corporation to detect and record the temperature and humidity of the soil in each pot daily, control the amount of watering and sunshine time, and minimize the error in the cultivation environment strictly, As shown in Figure 13.

Figure 13.

(a) Flower pot cultivation and (b) observation of root growth.

3.3. Root Scanning

3.3.1. Experimental Equipment

The experiment conducted surface scanning observation and data analysis on the roots of vegetables grown under different types of rope-wrapping materials. The root scanning equipment used was Epson scanner EPSON Expression 10000XL, Epson, Suwa, Nagano, Japan. and the root data analysis software used was WinRHIZO root image analysis system software (https://regent.qc.ca/assets/winrhizo_about.html, accessed on 10 January 2025).

3.3.2. Experimental Methods

Cultivation is carried out for a total of 30 days, with scanning and observation conducted every 10 days. Due to the fragility of the root system of cabbage and Chinese cabbage, a small soil block is excavated and washed in water during each sampling to avoid damage to the root system. After cleaning the root system multiple times until there is no soil residue, remove the root part and place it on the scanner after the scanner tray is filled with water. Spread the root system and wrap it to reflect the overall shape of the root, then scan the root system, As shown in Figure 14.

Figure 14.

(a) Leaf vegetable root cleaning and (b) root scanning test.

The root morphology indicators are: total root length (mm), root projected area (mm2), root surface area (mm2), root volume (mm3), and number of root tips (pieces).

3.4. Experimental Methods

Scanning and analyzing the root growth of four vegetable varieties within 30 days, the experimental results are as follows. According to the experimental results, different coating materials have a certain impact on the growth of vegetable roots, but their effects on different varieties are also different.

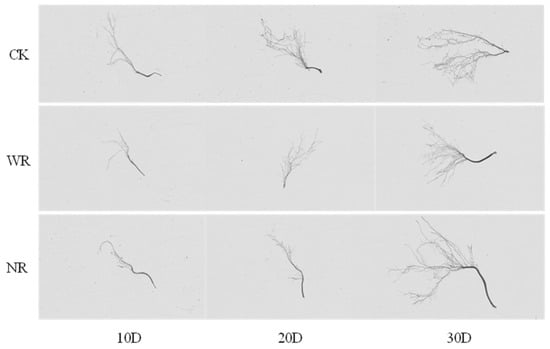

Table 6 shows the root scanning data of Hong Kong sugar beet hearts at different growth stages under different covering materials. The comparison of root scanning is shown in Figure 15.

Table 6.

Hong Kong Chinese flowering cabbage root growth data.

Figure 15.

Hong Kong Chinese flowering cabbage root scan.

Table 7 shows the results of one-way analysis of variance (ANOVA) on the root system data of Hong Kong sugar beet hearts. After testing, all indicators were found to have a significance p > 0.05 when the growth period was 10 days. At this time, the difference in the effect of seed rope material on root growth was not significant. When the growth period is 20 days, only the total root length has a significant p-value < 0.05. At this time, the difference in the effect of the rope material on the total root length is significant, while the differences in other indicators are not significant. When the growth period is 30 days, the significance of all indicators is p > 0.05, which proves the difference in the effect of seed rope material on root growth in the later stage of growth.

Table 7.

Result of one-way ANOVA analysis of Hong Kong Chinese flowering cabbage root data.

Table 8 shows the root scanning data of Zhenbao sugar cabbage at different growth stages under different covering materials. The comparison of root scanning is shown in Figure 16.

Table 8.

Zhen Bao sugar cabbage root growth data.

Figure 16.

Zhen Bao Chinese flowering cabbage root scan.

Table 9 shows the results of a one-way analysis of variance (ANOVA) of the root system data of Baobao sugar beet. After testing, all indicators were found to be significant, with p > 0.05 when the growth period was 10 days. At this time, the difference in the effect of seed rope material on root growth was not significant. When the growth period is 20 days, the four indicators of total root length, root projection area, root surface area, and root volume are significantly less than 0.05, indicating a significant difference in the effect of seed rope material on root growth; When the growth period is 30 days, the significance of all indicators is p > 0.05, indicating that there is no significant difference in the effect of seed rope material on root growth in the later stage of growth.

Table 9.

Result of one-way ANOVA analysis of Zhen Bao Chinese flowering cabbage root data.

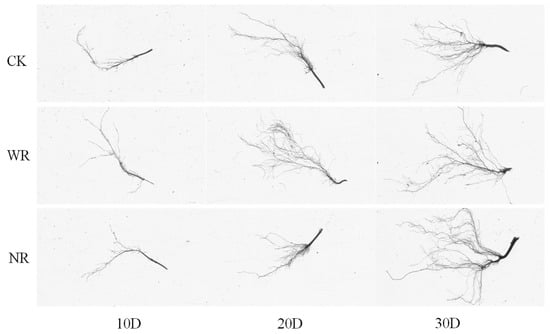

Table 10 shows the root scanning data of Lifeng 3 cabbage at different growth stages under different covering materials. The comparison of root scanning is shown in Figure 17.

Table 10.

Lifeng NO.3 Chinese cabbage root growth data.

Figure 17.

Lifeng NO.3 Chinese cabbage root scan.

Table 11 shows the results of one-way ANOVA of root system data for Chinese cabbage variety Lifeng 3. After testing, only the root tip number had a significant p-value > 0.05 when the growth period was 10 days, indicating a significant difference in the effect of seed rope material on root growth at this time. When the growth period is 20 days and the growth period is 30 days, all indicators are significantly p > 0.05, indicating that there is no significant difference in the effect of seed rope material on root growth in the middle and late stages of Lifeng 3 cabbage.

Table 11.

Result of one-way ANOVA analysis of Lifeng NO.3 Chinese cabbage root data.

Table 12 shows the root scanning data of Huangjing Cabbage No. 1 at different growth stages under different covering materials. The comparison of root scanning is shown in Figure 18.

Table 12.

Huangjing Cabbage No. 1 root growth data.

Figure 18.

Huangjing Cabbage No. 1 root scan.

Table 13 shows the results of one-way ANOVA of root data for Huangjing Cabbage No.1. After testing, it was found that only the root tip number had a significant p-value < 0.05 when the growth period was 10 days and 20 days, indicating that there was no significant difference in the effect of seed rope material on root growth at this time; When the growth period is 30 days, the significance of only the root tip number index becomes p > 0.05, indicating a significant difference in the effect of seed rope material on root growth in the later stage of Huangjing Cabbage No.1. From the above, it can be seen that only the root growth of Huangjing Cabbage No.1 is slightly affected by the material of the seed rope, while the root growth of the other three leafy vegetables is not affected by the material of the seed rope in the later stage of growth.

Table 13.

The result of one-way ANOVA analysis of Huangjing Cabbage No. 1 root data.

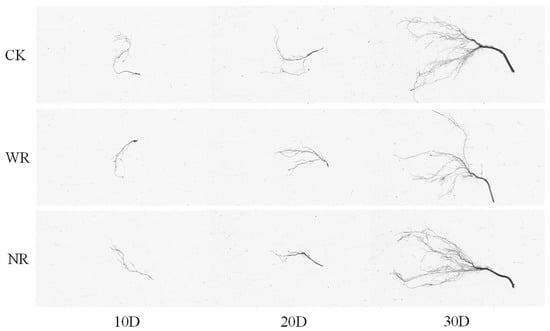

In order to comprehensively investigate the effects of coating materials on various dimensions of root growth indicators, comparative graphs of five indicators, including total root length, root projection area, root surface area, root volume, and root tip number, were drawn as follows.

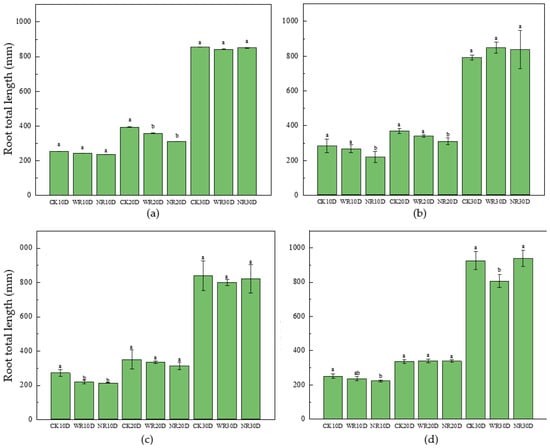

Figure 19 shows a comparison of the total root length growth of four vegetable seeds. It can be seen from the figure that the coating material has a greater impact on the root system in the early stage of growth. The root length grown under non-woven fabric wrapping is the smallest, followed by paper material wrapping. The length of the root system during the mid-growth stage is similar to the trend in the early stage, with no wrapping compared to wrapping with wood pulp paper material and non-woven fabric. In the later stage of growth, it can be clearly observed from the bar chart that the significance of the effect of coating materials on root growth gradually decreases. The total length of vegetable roots planted with both types of ropes increases rapidly, which is similar to the control group sown directly without coating. The root length of Baobao sugar beet hearts wrapped in wood pulp paper material and non-woven fabric even exceeds that of the blank control group without coating.

Figure 19.

Total root length of four kinds of vegetables in different material coating state. (a) Hong Kong sweet cabbage; (b) Zhenbao sweet cabbage; (c) Lifeng 3 cabbage; (d) Huangjing cabbage 1. Note: lowercase letters with different growth cycles indicate significant differences in mean values (p < 0.05).

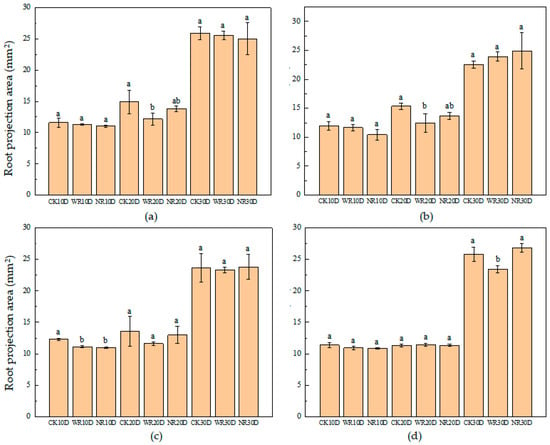

Figure 20 shows a comparison of the root projection areas of four vegetable seeds. It can be seen from the figure that the coating material also has an inhibitory effect on root growth in the early stage of growth, but the degree of influence is not high. The effect becomes more obvious in the middle stage of growth, and the trend is that the control without coating is wrapped in non-woven fabric and wood pulp paper material, which is different from the effect of root length. Only the root projection area of Huangjing Cabbage No.1 is similar under three conditions; The root projection area of the group planted with planting ropes in the later stage of growth also increased significantly, similar to that of direct planting. Some varieties also exceeded the blank control group without wrapping.

Figure 20.

Root projection area of four kinds of vegetables in differrent material coating state. (a) Hong Kong sweet cabbage; (b) Zhenbao sweet cabbage; (c) Lifeng 3 cabbage; (d) Huangjing cabbage 1. Note: lowercase letters with different growth cycles indicate significant differences in mean values (p < 0.05).

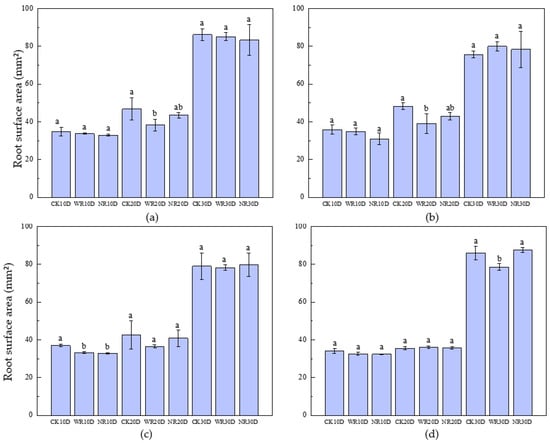

Figure 21 shows a comparison of the root surface area of four vegetable seeds. The variation pattern of this indicator is consistent with the projected area, except for the root surface area size of Baobao Sweet Cabbage in the later stage of growth, which is the comparison of wood pulp paper material wrapped with non-woven fabric wrapped with non-woven fabric without wrapping. It is inconsistent with the projected area pattern, which may be caused by experimental errors. However, the significant effect of the wrapping material on the root surface area in the later stage of growth is not high, and the overall pattern is consistent.

Figure 21.

Root surface area of four kinds of vegetables under different material coating conditions. (a) Hong Kong sweet cabbage; (b) Zhenbao sweet cabbage; (c) Lifeng 3 cabbage; (d) Huangjing cabbage 1. Note: lowercase letters with different growth cycles indicate significant differences in mean values (p < 0.05).

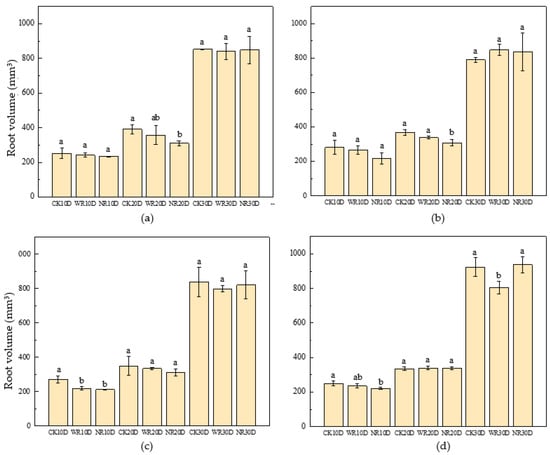

Figure 22 shows the comparison of root volume of four vegetable seeds. The change pattern of indicators is the same: the root volume of the control group without wrapping in the early and middle stages of growth is the largest, while the root volume of vegetables planted with wood pulp paper material and non-woven fabric wrapping is smaller. Except for Huangjing Cabbage No.1, the root volume size of the control group without wrapping is the same as that of the control group wrapped with wood pulp paper material and non-woven fabric wrapping. In the later stage of growth, there is no obvious pattern of change, but it can be seen that the root volume of most groups planted with wrapped ropes is similar to that of the control group without wrapping, and some even exceed the control group without wrapping.

Figure 22.

Root volume of four kinds of vegetables in different material coating state. (a) Hong Kong sweet cabbage; (b) Zhenbao sweet cabbage; (c) Lifeng 3 cabbage; (d) Huangjing cabbage 1. Note: lowercase letters with different growth cycles indicate significant differences in mean values (p < 0.05).

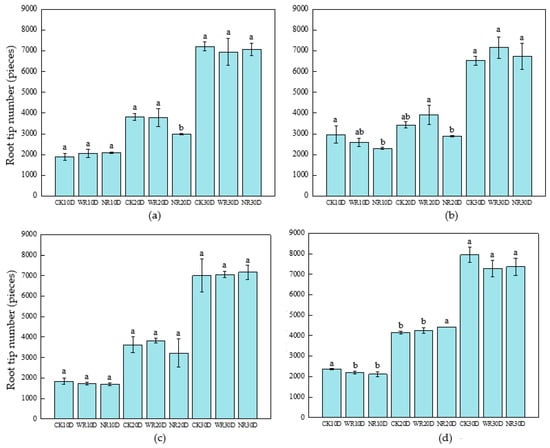

Figure 23 shows the comparison of root tip numbers of four vegetable seeds. Similarly to other research factors, the root tip numbers of the control group without wrapping were relatively higher in the early and middle stages of growth. In the later stages, the root tip numbers were similar under the three wrapping conditions, and some of the rope wrapped planting groups had more root tip numbers than the non wrapping control group. The effect of wrapping materials on root tip numbers was not significant. However, there are differences in the cyclic variation in root tip number, and the trend of root tip number affected by the wrapping material is irregular at different stages. The growth situation of different varieties is also different.

Figure 23.

The number of root tips of four kinds of vegetables in different material coating state. (a) Hong Kong sweet cabbage; (b) Zhenbao sweet cabbage; (c) Lifeng 3 cabbage; (d) Huangjing cabbage 1. Note: lowercase letters with different growth cycles indicate significant differences in mean values (p < 0.05).

Different seed rope materials have a certain impact on the growth of vegetable roots, but the degree of impact varies for different varieties. The influence of seed rope materials on the root system is significant in the early stage of growth, with roots grown under non-woven fabric wrapping having the smallest length, followed by those wrapped with paper material; The length of the root system in the middle stage of growth is similar to the trend in the early stage; The effect of seed rope materials on root growth gradually weakens in the later stage of growth, and the length of roots wrapped in non-woven fabric has gradually caught up with or even exceeded that of roots without any wrapping.

4. Discussion

- In order to observe the microstructure of the broken rope under different stress conditions, explore the microscopic changes in different ropes under tensile stress and shear stress, and further understand the mechanical mechanism of the rope under external forces, the cross-sections of the broken ropes under two stress conditions were scanned and observed by electron microscopy. We obtained the overall situation diagram and single fiber diagram of the fracture section of ropes of different materials under different stress conditions, and observed the differences in the degree of disorder of the failure surface and the degree of fiber surface damage.

- A tensile test was conducted on the seed rope woven with a combination of thread and non-woven fabric, and it can be seen that its tensile curve is divided into two distinct stages. In the future, more different rope weaving methods can be explored to enhance the adaptability of the automatic rope breaking mechanism.

- Current research on rope direct-seeding machines can only automate rope breaking using shear force, still requiring manual rope installation. To design an automatic rope-breaking mechanism that can clamp and pull out the seed rope after tensile stress, this study used a universal testing machine to measure the critical tensile stress for breaking seed ropes containing six types of seeds (rice, Chinese cabbage, cabbage, lettuce, Indian lettuce, and celery) made from paper and non-woven fabric. The tensile performance of the seed rope is key for laying and breaking processes, providing data for the automatic mechanism’s stress range. However, only small seeds were tested. Future research should focus on larger seeds to expand the mechanism’s applicability for direct-seeding more seed types.

5. Conclusions

This article studies the stress situation of the seed rope under different conditions, and conducts electron microscopy scanning on the microscopic damage of its cross-section after fracture failure. Comparative analysis was conducted on the tensile properties and changes in fiber structure of the rope. The main conclusions are as follows:

- The tensile strength range of the paper material seed rope is approximately 1.80–2.89 N/mm 2, the elongation at break range is approximately 31.4–47.5%, and the critical stress range is approximately 5.67–9.06 N. The tensile strength range of non-woven fabric rope is approximately 0.91–1.23 N/mm 2, the elongation at break range is approximately 160.3–284.2%, and the critical stress range is approximately 2.86–3.86 N. The results show that during the operation of the automatic rope-breaking mechanism in the rope direct-seeding machine, the stress required to break the paper material rope was slightly higher than that of the non-woven fabric rope, but its elongation rate was lower, resulting in a shorter operating time of the mechanism. For the seed rope woven with a combination of thread and non-woven fabric, high tension is required when breaking the rope, and it also requires a long running time.

- By analyzing the electron microscope scanning images of the fracture cross-sections of various types of ropes under different materials, stresses, and processing conditions, it was found that under tensile stress, the fracture cross-sections of all types of ropes were more disordered and the damage was stronger than under shear stress. In addition, the fiber surface of the seed rope soaked for 24 h showed slight damage, resulting in a slight decrease in the critical tensile stress value of the seed rope after soaking.

The results of this study provide reference for the structural design and usage methods of seed rope direct-seeding machines, and have guiding significance for selecting suitable seed rope materials and optimizing seed rope processing conditions. However, further exploration should be conducted on other properties of the seed rope to better meet practical application needs.

This article investigates the stress conditions of seed ropes under various circumstances. Electron microscopy scanning is performed on the microscopic damage of their cross-sections after fracture failure, and a comparative analysis is conducted on the tensile properties and changes in fiber structure of the ropes. The main conclusions are as follows:

In the future, we will expand the scope of seed testing, test the critical tensile stress of seed ropes for large-sized seeds, and optimize the adaptability of the automatic rope-breaking mechanism. We will also study the tensile conditions of more seed rope weaving methods to enhance the adaptability of the automatic upper rope-breaking mechanism. Furthermore, we will conduct in-depth investigations into other properties of seed ropes, such as durability and corrosion resistance, so as to meet the requirements of practical applications.

Author Contributions

Conceptualization, B.W.; methodology, Y.S.; software, Y.S.; validation, Y.N.; formal analysis, Y.S.; investigation, Y.S.; resources, B.W.; data curation, L.W.; writing—original draft preparation, Y.N. and L.W.; writing—review and editing, Y.S.; visualization, X.S.; project administration, B.W.; funding acquisition, B.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Hainan Provincial Natural Science Foundation of China, grant number 323RC415; Nanhai nova project in Hainan province, grant number: NHXXRCXM202308.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

We would like to thank the Innovation and Utilization team of tropical meloncrop genetic germplasm, Hainan University.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sun, L. Power farming. Rope seeding. Grain Oil Process. Food Mach. 1973, 8–9. [Google Scholar] [CrossRef]

- Han, D.; Ren, E.; Liu, C. Design and Experimental Study of Hand held Rice Seed Rope Livestreaming Machine. Agric. Mech. Res. 2019, 41, 144–148+164. [Google Scholar]

- Han, S.; Ren, W.; Li, G. Improvement Design and Finite Element Analysis of Main Working Components of Rice Seed Rope Livestreaming Machine. Agric. Mech. Res. 2016, 38, 62–65+75. [Google Scholar]

- Xu, Y.; Ren, W.; Huang, W.; Lv, P.; Zhang, Y.; Zhang, B. Design and Experimental Study on Key Components of Rice Direct-seeding Machine. J. Shenyang Agric. Univ. 2016, 47, 687–694. [Google Scholar]

- Wentao, R.; Xiaorong, L.; Aiju, K.; Benhua, Z.; Hongguang, C.; Yi, Y. Design of Rice Seed Rope Livestreaming Machine. J. Shenyang Agric. Univ. 2009, 40, 62–66. [Google Scholar]

- Liu, S.; Yang, R.; Wang, J.; Yin, B.; Zhang, M.; Ma, Y.; Pan, S. Design and experiment of a carrot seeder with one row and two rows based on the planting rope mode. Agric. Mech. Res. 2023, 45, 88–93. [Google Scholar]

- Ren, W.; Dai, L.; Cui, H. The Effect of Modified Corn Starch Adhesive on the Quality of Seed Rope Twisting. J. Agric. Eng. 2010, 26, 164–169. [Google Scholar]

- Ren, W.; Che, Z.; Liu, J. Experimental study on the effect of paddy field mud on the adhesion of agricultural paper film. J. Agric. Eng. 2011, 27, 129–133. [Google Scholar]

- Zhang, B. Design and Experimental Study of a Small Rice Seed Rope Livestreaming Machine; Shenyang Agricultural University: Shenyang, China, 2018. [Google Scholar]

- Zhang, B.; Liu, D.; Xi, X.; Zhang, Y.; Chen, C.; Qu, J.; Dong, H.; Zhang, R. The Analysis of the Applications of Crop Seed Material Sowing Technology and Equipment: A Review. Appl. Sci. 2021, 11, 11228. [Google Scholar] [CrossRef]

- Lv, X.; Ren, W.; Lv, X. Design of the playback mechanism for rice seed rope player. Agric. Mech. Res. 2008, 96–98. [Google Scholar] [CrossRef]

- Zhang, Y. Development and Experimental Study of Rice Seed Rope Livestreaming Machine; Shenyang Agricultural University: Shenyang, China, 2006. [Google Scholar]

- Xin, M.; Ren, W.; Song, Y.; Wu, L.; Cui, H.; Kong, A.; Liu, C.; Wang, Y. Automatic Rope Cutting Device for Rope Direct-Seeding Machine. ZL201410101111, 6 April 2016. [Google Scholar]

- Liang, Z. Rope Cutting Device and Crop Sowing Machine. ZL202121398332, 14 December 2021. [Google Scholar]

- Naik, D.L.; Sharma, A.; Chada, R.R.; Kiran, R.; Sirotiak, T. Modified pullout test for indirect characterization of natural fiber and cementitious matrix interface properties. Constr. Build. Mater. 2019, 208, 381–393. [Google Scholar] [CrossRef]

- Bain, C.; Davies, P.; Bles, G.; Marco, Y.; Barnet, J. Influence of bedding-in on the tensile performance of HMPE fiber ropes. Ocean Eng. 2020, 203, 107144. [Google Scholar] [CrossRef]

- Shaw, V.P.; Mukhopadhyay, A. Behaviour of Stretch Denim Fabric under Tensile Load. Fibers Polym. 2022, 23, 295–302. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnár, V.; Michalik, P.; Dovica, M.; Kelemenová, T.; Toth, T. Failure analysis of conveyor belt samples under tensile load. J. Ind. Text. 2019, 48, 1364–1383. [Google Scholar] [CrossRef]

- McSwain, A.C.; McSwain, A.C.; Berube, K.A.; Cusatis, G.; Landis, E.N. Confinement effects on fiber pullout forces for ultra-high-performance concrete. Cem. Concr. Compos. 2018, 91, 53–58. [Google Scholar] [CrossRef]

- Muna, I.I.; Mieloszyk, M.; Rimasauskiene, R.; Maqsood, N.; Rimasauskas, M. Thermal Effects on Mechanical Strength of Additive Manufactured CFRP Composites at Stable and Cyclic Temperature. Polymers 2022, 14, 4680. [Google Scholar] [CrossRef] [PubMed]

- Halabi, Y.; Xu, H.; Yu, Z.; Alhaddad, W.; Dreier, I. Experimental-based statistical models for the tensile characterization of synthetic fiber ropes: A machine learning approach. Sci. Rep. 2023, 13, 17768. [Google Scholar] [CrossRef] [PubMed]

- Akgun, M.; Becerir, B.; Alpay, H.R. Assessing the relationship among fabric constructional parameters, fractional reflectances and cover factors of polyester fabrics by experimental and mathematical methods. Fibers Polym. 2010, 11, 291–302. [Google Scholar] [CrossRef]

- Akgun, M.; Becerir, B.; Alpay, H.R. Reflectance prediction of colored polyester fabrics by a novel formula. Fibers Polym. 2014, 15, 126–137. [Google Scholar] [CrossRef]

- Middendorf, P.; Van Den Broucke, B.; Gessler, A.; Maidl, F.; Metzner, C. Material characterization of non-crimp braided CFRP for aeronautic applications. In Proceedings of the 9th International Conference on Textile Composites, Newark, NJ, USA, 13–15 October 2008. [Google Scholar]

- Metzner, C.; Gessler, A.; Weimer, C.; Beier, U.; Middendorf, P. Performance assessment on unidirectional braided CFRP materials. In Proceedings of the SEICO Conference, Paris, France, 10–11 March 2014. [Google Scholar]

- Shi, L.; Yang, Y.; Yan, J. Research on the tensile properties of two-dimensional biaxial unidirectional woven layered composite materials. Compos. Sci. Eng. 2018, 63–67. [Google Scholar] [CrossRef]

- Cui, H. Development and Experimental Study of Rice Seed Rope Twisting Machine; Shenyang Agricultural University: Shenyang, China, 2012. [Google Scholar]

- GB/T16825.1-2008; Inspection of static uniaxial testing machines—Part 1: Inspection and calibration of force measuring systems for tensile and/or compressive testing machines. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008.

- GB/T3923.1-2013; Textiles—Tensile properties of fabrics—Part 1: Determination of tensile strength and elongation at break—Strip method. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2013.

- GB/T12914-2018; Measurement of Tensile Strength of Paper and Paperboard. State Administration for Market Regulation: Beijing, China, 2018.

- Shu, D. Mechanical Properties of Engineering Materials; Machinery Industry Press: Beijing, China, 2007. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).