DEM Simulation and Experimental Investigation of Draft-Reducing Performance of Up-Cutting Subsoiling Method Inspired by Animal Digging

Abstract

1. Introduction

2. Materials and Methods

2.1. The Principle of Soil-Breaking Inspired by Animal Digging

2.2. DEM Simulation of Up-Cutting Tools

2.2.1. DEM Modeling

2.2.2. Experimental Design of the DEM Simulation

2.2.3. Measurements in the DEM Simulation

- (1)

- Tool Force and Soil Disturbance

- (2)

- Particle Velocity Distribution

- (3)

- Deformation and Movement Patterns

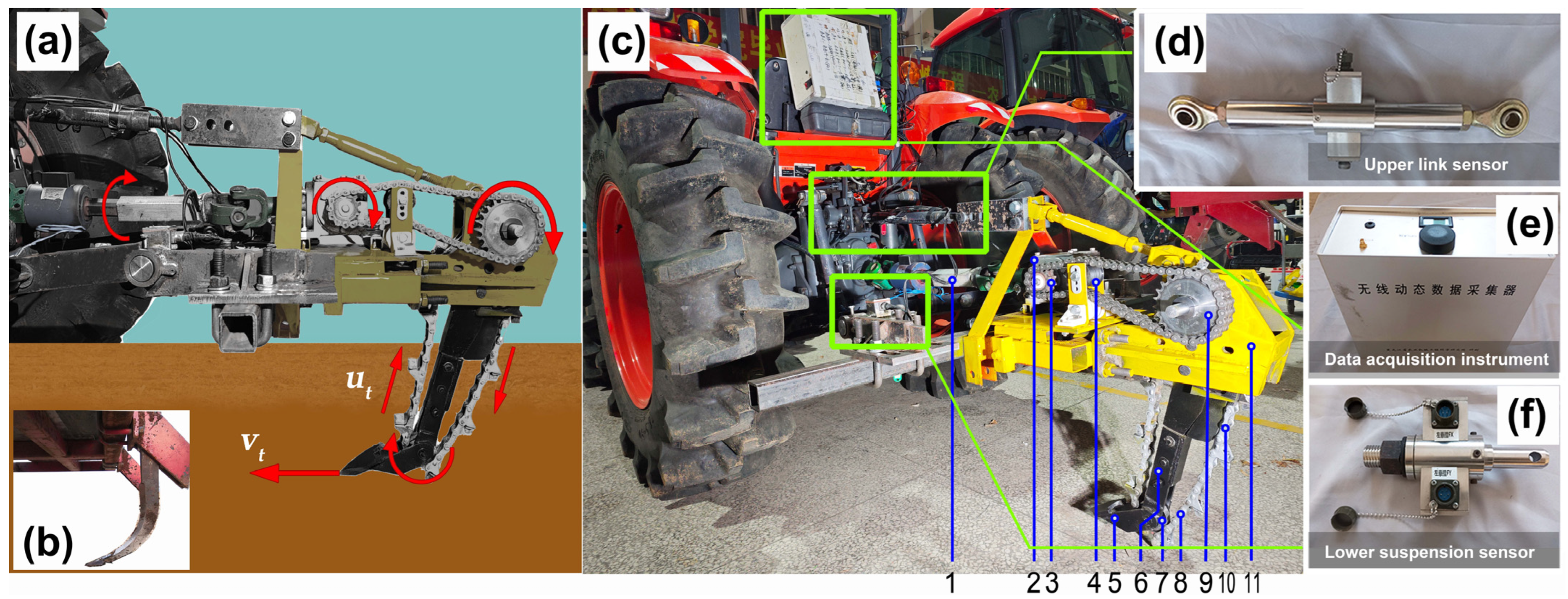

2.3. Field Test

2.3.1. Site and Equipment

2.3.2. Experimental Design of the Field Test

2.3.3. Measurements in the Field Test

- (1)

- Tillage Force Measurement

- (2)

- Furrow Profile Mapping

3. Results

3.1. Results of the DEM Simulation

3.1.1. The Effects of the Rake Angle and Up-Cutting Motion

3.1.2. The Effects of Advancement Velocity and Up-Cutting Motion

3.1.3. The Effects of Up-Cutting Velocity

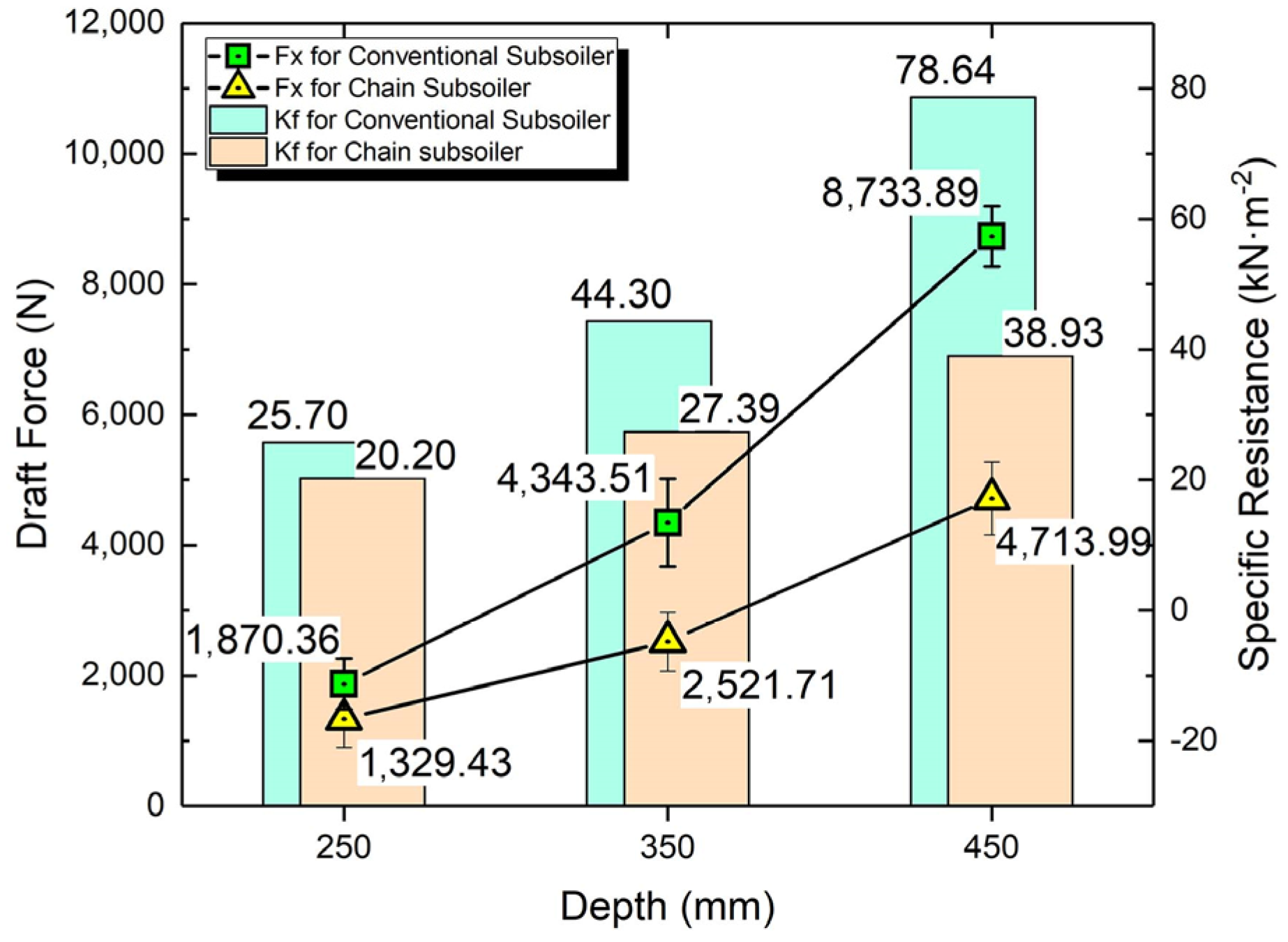

3.2. Results of Field Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DEM | Discrete Element Method |

| OFAT | One Factor At a Time |

| ECS | Earth Coordinate System |

| ICS | Implement Coordinate System |

References

- Gill, W.R.; Vanden Berg, G.E. Soil dynamics in tillage and traction. In Agricultural Handbook No. 316; Agricultural Research Service, United States Department of Agriculture: Washington, DC, USA, 1968; pp. 340–429. [Google Scholar]

- Manuwa, S. Performance evaluation of tillage tines operating under different depths in a sandy clay loam soil. Soil Tillage Res. 2009, 103, 399–405. [Google Scholar] [CrossRef]

- Hemami, A. Motion trajectory study in the scooping operation of an LHD-loader. IEEE Trans. Ind. Appl. 2002, 30, 1333–1338. [Google Scholar] [CrossRef]

- Araya, K. Soil failure caused by subsoilers with pressurized water injection. J. Agric. Eng. Res. 1994, 58, 279–287. [Google Scholar] [CrossRef]

- Larson, D.; Clyma, H. Electro-osmosis effectiveness in reducing tillage draft force and energy requirements. Trans. ASAE 1995, 38, 1281–1288. [Google Scholar] [CrossRef]

- Salokhe, V.; Gee-Clough, D. Technology showcase applications of enamel coating in agriculture. J. Terramechanics 1989, 26, 275–286. [Google Scholar] [CrossRef]

- Tong, J.; Lu, X.; Chen, Y.; Ren, L.; Chen, B. Soil adhesion and abrasive wear of PTFE-matrix composites. Trans. Chin. Soc. Agric. Eng. 1990, 6, 13. [Google Scholar]

- Tong, J.; Ren, L.; Chen, B.; Qaisrani, A. Characteristics of adhesion between soil and solid surfaces. J. Terramechanics 1994, 31, 93–105. [Google Scholar] [CrossRef]

- Ren, L.; Han, Z.; Li, J.; Tong, J. Effects of non-smooth characteristics on bionic bulldozer blades in resistance reduction against soil. J. Terramechanics 2002, 39, 221–230. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Ma, Y.; Tong, J.; Zhang, Z. DEM simulation of bionic subsoilers (tillage depth> 40 cm) with drag reduction and lower soil disturbance characteristics. Adv. Eng. Softw. 2018, 119, 30–37. [Google Scholar] [CrossRef]

- Tong, J.; Wu, B.; Song, Z.; Gao, Z.; Sun, J.; Ma, Y.; Zhuang, J. Research on the drag reduction mechanism of antlion (Myrmeleon sagax) larvae nonsmooth structural surface. Microsc. Res. Tech. 2020, 83, 338–344. [Google Scholar] [CrossRef]

- Niyamapa, T.; Salokhe, V. Force and pressure distribution under vibratory tillage tool. J. Terramechanics 2000, 37, 139–150. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, D.; Yang, L.; Cui, T.; Jing, H.; Zhong, X. Modeling the interaction of soil and a vibrating subsoiler using the discrete element method. Comput. Electron. Agric. 2020, 174, 105518. [Google Scholar] [CrossRef]

- Bandalan, E.; Salokhe, V.; Gupta, C.; Niyamapa, T. Performance of an oscillating subsoiler in breaking a hardpan. J. Terramech. 1999, 36, 117–125. [Google Scholar] [CrossRef]

- Makanga, J.; Salokhe, V.; Gee-Clough, D. Effects of tine rake angle and aspect ratio on soil reactions in dry loam soil. J. Terramech. 1997, 34, 235–250. [Google Scholar] [CrossRef]

- Godwin, R.; Spoor, G.; Leeds-Harrison, P. An experimental investigation into the force mechanics and resulting soil disturbance of mole ploughs. J. Agric. Eng. Res. 1981, 26, 477–497. [Google Scholar] [CrossRef]

- Hettiaratchi, D.; Reece, A. Boundary wedges in two-dimensional passive soil failure. Geotechnique 1975, 25, 197–220. [Google Scholar] [CrossRef]

- Harrison, H. Soil reactions from laboratory studies with an inclined blade. Trans. ASAE 1982, 25, 7–0012. [Google Scholar] [CrossRef]

- Hettiaratchi, D. Theoretical soil mechanics and implement design. Soil Tillage Res. 1988, 11, 325–347. [Google Scholar] [CrossRef]

- Reece, A.; Hettiaratchi, D. A slip-line method for estimating passive earth pressure. J. Agric. Eng. Res. 1989, 42, 27–41. [Google Scholar] [CrossRef]

- Eldridge, D.J. Mounds of the American badger (Taxidea taxus): Significant features of North American shrub-steppe ecosystems. J. Mammal. 2004, 85, 1060–1067. [Google Scholar] [CrossRef]

- Lagaria, A.; Youlatos, D. Anatomical correlates to scratch digging in the forelimb of European ground squirrels (Spermophilus citellus). J. Mammal. 2006, 87, 563–570. [Google Scholar] [CrossRef]

- Camin, S.; Madoery, L.; Roig, V. The burrowing behavior of Ctenomys mendocinus (Rodentia). Mammalia 1995, 59, 9–18. [Google Scholar] [CrossRef]

- Gasc, J.; Renous, S.; Casinos, A.; Laville, E.; Bou, J. Comparison of diverse digging patterns in some small mammals. Fortschritte Der Zool. 1985, 30, 35–38. [Google Scholar]

- Jarvis, J.U.; Sale, J.B. Burrowing and burrow patterns of East African mole-rats Tachyoryctes, Heliophobius and Heterocephalus. J. Zool. 1971, 163, 451–479. [Google Scholar] [CrossRef]

- Van Wassenbergh, S.; Heindryckx, S.; Adriaens, D. Kinematics of chisel-tooth digging by African mole-rats. J. Exp. Biol. 2017, 220, 4479–4485. [Google Scholar] [CrossRef] [PubMed]

- Hann, M.; Giessibl, J. Force measurements on driven discs. J. Agric. Eng. Res. 1998, 69, 149–157. [Google Scholar] [CrossRef]

- Upadhyay, G.; Raheman, H. Comparative analysis of tillage in sandy clay loam soil by free rolling and powered disc harrow. Eng. Agric. Environ. Food 2019, 12, 118–125. [Google Scholar] [CrossRef]

- Nalavade, P.P.; Salokhe, V.M.; Niyamapa, T.; Soni, P. Performance of free rolling and powered tillage discs. Soil Tillage Res. 2010, 109, 87–93. [Google Scholar] [CrossRef]

- Mellor, M. Mechanics of Cutting and Boring. Part 3. Kinematics of Continuous Belt Machines; Cold Regions Research and Engineering Lab: Hanover, NH, USA, 1976. [Google Scholar]

- Mellor, M. Mechanics of Cutting and Boring. Part VIII, Dynamics and Energetics of Continuous Belt Machines; Cold Regions Research and Engineering Lab: Hanover, NH, USA, 1978. [Google Scholar]

- Sitorus, P.E.; Ko, J.H.; Kwon, O.S. Parameter study of chain trenching machines of Underwater Construction Robots via analytical model. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016; pp. 1–6. [Google Scholar]

- Vu, M.T.; Choi, H.-S.; Kim, J.-Y.; Ji, D.-H.; Lee, Y.-J.; Choi, D.-H. A study on underwater track vehicle system. In Proceedings of the 2015 15th International Conference on Control, Automation and Systems (ICCAS), Busan, Republic of Korea, 13–16 October 2015; pp. 253–257. [Google Scholar]

- Gao, P.; Li, J.; Qi, H.; Liu, X.; Ma, Y. Simulation of draught reduction performance of subsoiling with upcutting belt motion using discrete element method. Appl. Sci. 2024, 14, 1313. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.Q.; Zhou, C.H.; Xu, S.C. Simulation of dynamic behavior of soil ahead of the bulldozing plates with different surface configurations by discrete element method. Trans. Chin. Soc. Agric. Eng. 2007, 23, 13–19. [Google Scholar]

- Zhang, R.; Chen, B.; Li, J.-q.; Xu, S.-c. DEM simulation of clod crushing by bionic bulldozing plate. J. Bionic Eng. 2008, 5, 72–78. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. 3D DEM tillage simulation: Validation of a hysteretic spring (plastic) contact model for a sweep tool operating in a cohesionless soil. Soil Tillage Res. 2014, 144, 220–227. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y.; Zhang, X. Modelling the interaction of a deep tillage tool with heterogeneous soil. Comput. Electron. Agric. 2017, 143, 130–138. [Google Scholar] [CrossRef]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Hirasawa, K.; Kataoka, T.; Kubo, T. Prediction and evaluation for leveling performance in rotary tiller. IFAC Proc. Vol. 2013, 46, 315–320. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, W.; Ma, Y.; Tong, J.; Liu, X.; Sun, J. DEM and soil bin study on a biomimetic disc furrow opener. Comput. Electron. Agric. 2019, 156, 209–216. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Discrete element modelling of tillage forces and soil movement of a one-third scale mouldboard plough. Biosyst. Eng. 2017, 155, 44–54. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C. Simulation of tillage forces and furrow profile during soil-mouldboard plough interaction using discrete element modelling. Biosyst. Eng. 2020, 190, 58–70. [Google Scholar] [CrossRef]

- Tong, J.; Jiang, X.-H.; Wang, Y.-M.; Ma, Y.-H.; Li, J.-W.; Sun, J.-Y. Tillage force and disturbance characteristics of different geometric-shaped subsoilers via DEM. Adv. Manuf. 2020, 8, 392–404. [Google Scholar] [CrossRef]

- Wang, X.; Li, P.; He, J.; Wei, W.; Huang, Y. Discrete element simulations and experiments of soil-winged subsoiler interaction. Int. J. Agric. Biol. Eng. 2021, 14, 50–62. [Google Scholar] [CrossRef]

- Ebensperger, L.A.; Bozinovic, F. Energetics and burrowing behaviour in the semifossorial degu Octodon degus (Rodentia: Octodontidae). J. Zool. 2000, 252, 179–186. [Google Scholar] [CrossRef]

- Heth, G. Burrow patterns of the mole rat Spalax ehrenbergi in two soil types (terra-rossa and rendzina) in Mount Carmel, Israel. J. Zool. 1989, 217, 39–56. [Google Scholar] [CrossRef]

- Hildebrand, M. Chapter 6. Digging of quadrupeds. In Functional Vertebrate Morphology; Harvard University Press: Cambridge, MA, USA, 1985; pp. 89–109. [Google Scholar]

- Blouin, S.; Hemami, A.; Lipsett, M. Review of resistive force models for earthmoving processes. J. Aerosp. Eng. 2001, 14, 102–111. [Google Scholar] [CrossRef]

- Hettiaratchi, D. The development of a powered low draught tine cultivator. Soil Tillage Res. 1993, 28, 159–177. [Google Scholar] [CrossRef]

- Reece, A. Soil mechanics of agricultural soils. Soil Sci. 1977, 123, 332–337. [Google Scholar] [CrossRef]

- Hettiaratchi, D. The present state of the theory of soil cutting. J. Terramech. 1965, 2, 63–76. [Google Scholar] [CrossRef]

- Salokhe, V.; Pathak, B. Effect of aspect ratio on soil failure pattern generated by vertical flat tines at low strain rates in dry sand. J. Agric. Eng. Res. 1992, 53, 169–180. [Google Scholar] [CrossRef]

- Hang, C.; Gao, X.; Wang, B.; Yuan, M.; Huang, Y.; Zhu, R. Optimization of the wing parameters for a winged subsoiler. Appl. Eng. Agric. 2017, 33, 313. [Google Scholar] [CrossRef]

- McKyes, E.; Ali, O. The cutting of soil by narrow blades. J. Terramech. 1977, 14, 43–58. [Google Scholar] [CrossRef]

- Shmulevich, I.; Asaf, Z.; Rubinstein, D. Interaction between soil and a wide cutting blade using the discrete element method. Soil Tillage Res. 2007, 97, 37–50. [Google Scholar] [CrossRef]

- Hettiaratchi, D. A critical state soil mechanics model for agricultural soils. Soil Use Manag. 1987, 3, 94–105. [Google Scholar] [CrossRef]

- Coetzee, C.J. The Modelling of Granular Flow Using the Particle-in-Cell Method; University of Stellenbosch: Stellenbosch, South Africa, 2004. [Google Scholar]

- Karmakar, S.; Kushwaha, R.L.; Stilling, D. Propagation of soil failure front associated with various agricultural tillage tools. In Proceedings of the 2003 ASAE Annual Meeting, Las Vegas, NV, USA, 27–30 July 2003; p. 1. [Google Scholar]

| Category | Parameter | Value |

|---|---|---|

| Particle | Radius/mm | 3 |

| Material | Density of particle/(kg·m−3) | 2620 |

| Poisson’s ratio of soil | 0.33 | |

| Shear modulus of soil/Pa | 1.02 × 108 | |

| Density of steel/(kg·m−3) | 7850 | |

| Poisson’s ratio of steel | 0.3 | |

| Shear modulus of steel/Pa | 7.9 × 1010 | |

| Interaction | Coefficient of restitution, soil–soil | 0.53 |

| Coefficient of static friction, soil–soil | 0.63 | |

| Coefficient of rolling friction, soil–soil | 0.42 | |

| Coefficient of restitution, soil–steel | 0.27 | |

| Coefficient of static friction, soil–steel | 0.54 | |

| Coefficient of rolling friction, soil–soil | 0.28 | |

| Bond Normal Stiffness/(N·m−3) | 5 × 107 | |

| Bond Shear Stiffness/(N·m−3) | 5 × 107 | |

| Bond Normal Strength/(Pa) | 21,680 | |

| Bond Shear Strength/(Pa) | 21,680 | |

| Bonded Disk Scale | 0.5 |

| Level | Factor | ||

|---|---|---|---|

| Rake Angle (α)/° | Advancement Velocity (vt)/m·s−1 | Up-Cutting Velocity (ut)/m·s−1 | |

| Low | 45 | 0.5 | 0.5 |

| Medium | 60 | 1 | 1 |

| High | 75 | 1.5 | 1.5 |

| Type | Depth (mm) | Transversal Area (m2) | Disturbed Width (mm) | Uplift Height (mm) |

|---|---|---|---|---|

| Conventional Subsoiler | 250 | 0.0727 | 490.99 | 86.62 |

| 350 | 0.0780 | 513.33 | 93.32 | |

| 450 | 0.1110 | 502.47 | 94.88 | |

| Chain Subsoiler | 250 | 0.0658 | 532.86 | 112.35 |

| 350 | 0.0921 | 487.93 | 108.98 | |

| 450 | 0.1211 | 526.64 | 120.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, P.; Liu, X.; Xu, Z.; Wang, S.; Qu, M.; Ma, Y. DEM Simulation and Experimental Investigation of Draft-Reducing Performance of Up-Cutting Subsoiling Method Inspired by Animal Digging. Agriculture 2025, 15, 2046. https://doi.org/10.3390/agriculture15192046

Gao P, Liu X, Xu Z, Wang S, Qu M, Ma Y. DEM Simulation and Experimental Investigation of Draft-Reducing Performance of Up-Cutting Subsoiling Method Inspired by Animal Digging. Agriculture. 2025; 15(19):2046. https://doi.org/10.3390/agriculture15192046

Chicago/Turabian StyleGao, Peng, Xuanting Liu, Zihe Xu, Shuo Wang, Mingzi Qu, and Yunhai Ma. 2025. "DEM Simulation and Experimental Investigation of Draft-Reducing Performance of Up-Cutting Subsoiling Method Inspired by Animal Digging" Agriculture 15, no. 19: 2046. https://doi.org/10.3390/agriculture15192046

APA StyleGao, P., Liu, X., Xu, Z., Wang, S., Qu, M., & Ma, Y. (2025). DEM Simulation and Experimental Investigation of Draft-Reducing Performance of Up-Cutting Subsoiling Method Inspired by Animal Digging. Agriculture, 15(19), 2046. https://doi.org/10.3390/agriculture15192046