Abstract

Water is the primary limiting factor in dryland crop production, therefore emerging approaches for preserving rainwater to be more accessible to plants, for extended periods of time, can significantly improve agricultural system efficiency. Furrow diking, a method involving compartmentalizing micro-basins to increase infiltration and soil water storage is one of the most promising water conservation solutions, particularly for sloping terrain. Moreover, furrow diking is associated with water conservation practices and regenerative agriculture as adaptive to dryland crop production. The present research study aims at improving the process of building soil compartmentalized segments using furrow diking technology, by designing and testing optimal geometries for the active soil modeling component. Three new constructive designs of a furrow diking active subassembly were built and tested in comparison with the standard version. In accordance with the considered quality indicators, the most efficient constructive shape was the curved rotor blade due to the higher volume of managed soil and fewer soil losses. Furthermore, the technology applied on three non-irrigated sunflower experimental crops grown on sloping land showed very good effectiveness with respect to the studied climatic and pedological conditions in southern Romania. When compared with non-compartmentalized crops, the most efficient rotor geometry design increased seed production by 11–13%. Water storage efficiency contributed the most to the yield increase, with moisture retention from the root zone improving by an average of 20%.

1. Introduction

The main factor affecting agricultural productivity in arid and semi-arid lands, particularly on sloping terrain is water shortage. Since climate change has the potential to affect agriculture through changes in temperature and rainfall, current forecasts anticipate that climate change would aggravate the water deficit in many European agricultural regions [1]. This issue highlights the need for developing an integrated technology to improve rainwater usage efficiency, while also supporting soil and environmental quality, resulting in increased agricultural production at reduced costs.

Supplemental irrigation is frequently required during extended periods of drought throughout the crop growing season to avoid water stress and yield limitations. Current agricultural water concerns, as well as the need to reduce input costs in farming operations, underline the importance of developing smart watering techniques for optimal water allocation, natural resource conservation, and increased profitability [2]. At present, the performance of furrow dike irrigation systems is influenced by rainfall factors, soil parameters, as well as the specific cropping and tillage practices employed in each particular location.

Increased rainwater retention enhances water efficiency and lowers irrigation and other input costs, maximizing the profit margin at farm level. Moreover, heavy rains can generate water accumulations on soils, particularly on those presenting low permeability or an increased slope, causing an important risk of productivity losses [3]. These issues highlight the need for integrating improved technologies, which are capable of enhancing rainwater usage efficiency, while also supporting soil and environment quality, resulting in increased agricultural production at minimum costs. Several techniques have been developed to allow for the achievement of better use of limited rainfall for the agriculture sector in arid and semi-arid environments. Furrow diking is the practice of installing earth dams at regular intervals across furrows between crop rows, resulting in a series of micro-basins. These reservoirs retain and hold precipitations, providing more time for water to infiltrate into the soil and reduce runoff [4]. Some studies associate this technology with regenerative agriculture [5,6], since furrow diking is a type of conservation tillage practice that has proved highly effective in preventing soil loss, which is caused by agricultural land wash-out.

The technology may not be suitable for all types of crops, cultivation technologies, nor for all climatic areas [7]. Therefore, evaluations are performed on different types of soils to show important differences. A research study evaluated crop response to furrow diking [8] conducted to determine cotton (Gossypium hirsutum L.), peanut (Arachis hypogaea L.), and corn (Zea mays L.) yields following compartmentalized furrow in conventional and strip tillage systems. The study concluded that peanut and corn may be nonresponsive to furrow diking on coarse-textured soils, while cotton responded favorably to furrow diking.

There is limited relevant research on furrow diking applied to sunflower crops, since in the past there was no focus on conservative technologies and on saving groundwater. Furthermore, to be cost-effective with the technology, the crop has to be established on difficult terrain, on a slope, with the risk of soil washing or landslides.

Furrow diking equipment is typically operated shortly after the establishment of the culture and under ideal conditions may improve productivity. However, maintaining a constant protection effect of micro-basins in varied environmental conditions is sometimes difficult. Several studies have examined how rainfall and slope affect furrow diking durability and conservation efficiency [9,10]. Simulated rainfall studies involving four intensities and three slopes were undertaken to investigate the effects of precipitation intensity and slope on soil compartmentalized structures and on water runoff formation. The experiment indicated that furrow diking reservoirs may face severe drainage overtopping when the rainfall intensity and slope increased, resulting in damaging and collapsing of the soil structures. During the process, runoff and soil loss accelerated at a quick rate, and severe water erosion emerged on dams, resulting in the loss of furrow diking’s capacity to absorb rainwater and sediment, as well as substantial reduction in water and soil conservation efficiency.

Extensive periods of drought during the crop vegetative stage require the use of supplemental irrigation to avoid yield-limiting water stress. To assess retaining and erosional capabilities of furrow diking, researchers examined runoff and soil loss from furrow diked and non-furrow diked tilled systems [11]. The study showed a cost-effective management technique for Southeastern United States producers that supports natural resource conservation, as well as increases producer profit margins and environmental quality.

Due to technological limitations, weed pressure, inconsistent crop yield responses, conservation tillage adoption, and intensely chemicalized treatment, furrow diking was abandoned. However, the technology attracted considerable attention again, since it can be successfully integrated into regenerative agriculture as a soil and water conservation method, particularly in the summer when runoff potential is highest. Increased surface depressional storage, rainfall/irrigation capture, infiltration, and reduced runoff and soil loss are among its main advantages that can bring important strengths to the principles of regenerative agriculture [12,13,14]. Improving water usage efficiency is an important reaction to the rising water shortages, which include the necessity to leave appropriate freshwater in rivers and lakes to support ecosystems, while also fulfilling the growing needs of cities and businesses [15]. Water use efficiency may be defined as the amount of carbon assimilated as biomass or the grain produced per unit of water used by the crop [16]. The current focus of water productivity has evolved, and now includes the benefits and costs of water used for agriculture. In addition, it expresses the goal of providing more food, income, employment, and environmental benefits at a lower social and environmental cost per unit of water utilized [17].

Furrow diking systems could improve the overall yield potential and profit margins by allowing farmers to make greater use of natural rainfall and/or irrigation, while also extending the time between supplemental watering [18]. Experiments performed over long periods of time [19] showed that furrow diking has the capacity to retain between 25 and 30 mm of runoff each year, with maximum exceptional results of over 100 mm per year. Several studies used rainfall simulators to provide runoff predictions with basin and reservoir tillage [20,21,22]. However, the properties of rainwater (intensity, application duration, and volume of water applied) may differ significantly from those of a linear move sprinkler irrigation. Therefore, the actual effect of water on earth dams must be studied.

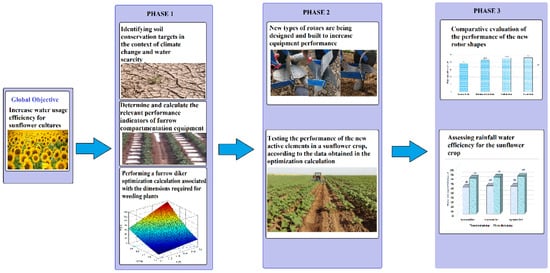

Our overall goal is to identify new techniques for increasing water usage efficiency, which can be applied to sunflower cultures, particularly for lands presenting some difficulties, such as high angle of inclination, low water retention level or with desertification tendencies. The present article addresses the technology of maintaining humidity in the soil using the compartmentation furrow system (furrow diking). Starting from the standard furrow diking equipment, the active elements of the equipment were calculated and improved, then new constructive shapes that can be associated with this technology were tested. Next, we evaluated and compared the obtained results to identify which constructive variant provides the most promising results in association with rainfall water efficiency for sunflower crops. A diagram describing the experimental design is presented in Figure 1.

Figure 1.

Case under consideration: Increasing water usage efficiency using new rotor designs associated with furrow diking technology.

2. Materials and Methods

2.1. Research Approach and Expected Output

In this section, our goal is to identify economical and reliable techniques aimed at enhancing water use efficiency to balance the unfavorable effects of climate change on agricultural productivity, among several vulnerable European regions. Fast and unexpected temperature changes and unpredictable hydrological cycles could be managed by improving agricultural mechanical processes and systems with new and more efficient designs [23,24,25,26]. The worsening of water scarcity is expected in coming years due to climate change, population pressure, and industrial development [27], which may have serious implications for agricultural sustainability and long-term food security [28].

Furrow diking is a mechanical soil-working technique that provides good results in creating segmented watering gutters with the goal of optimizing the quantity of water received by a crop. However, the compact earth dams used to capture small pools of stored water are typically highly sensitive and break down during heavy rains. Herein, this problem is addressed through the use of a new type of specially designed equipment, which eliminates some of the existing flaws of this technology. In addition to mitigating the effects of climate change, we aim to address the principles of regenerative agriculture to design technologies that reduce the use of chemicals in agriculture and restore soil quality.

Starting from the widely used equipment for furrow compartmentation, calculations were performed to optimize the shape of the active tillage component (the rotor). Based on the calculations, three new different geometric options of the blades that make up the rotor were selected (optimized straight blade, inclined blade, and curved blade). To objectively differentiate the constructive variants, a series of performance indicators were selected, associated with the shape of micro-basins and their resistance. The three types of blades were tested on experimental sunflower crops for field evaluation. The evaluated experimental crops were selected in difficult agricultural areas, where the phenomenon of soil washing and water runoff occurs frequently due to the high slopes. The crops were not irrigated, and the furrow diking operation has been applied in the weeding phase.

The promotion of furrow diking technology using the improved equipment for modeling the soil for sunflower crop allowed us to achieve the following long-term objectives:

- Improved water conservation in the soil, as well as reduced evaporation in the root zone;

- Prevention of the performance of a second mechanical plow, which is required in classical technologies;

- Highly effective control measure for weeds in the area between the plants;

- Increased agricultural production by more than 10%, as well as increased efficiency of precipitation capitalization by more than 1.4 kg/ha, per mm of precipitation;

- Improved soil quality through the reduction of topsoil migration due to strong winds;

- Reduced soil loss on sloping terrain caused by rainfall.

2.2. Working Conditions and Environmental Characteristics

Sunflower (Helianthus annuus L.) is commonly grown as a dryland crop due to its drought tolerance. In addition, it reacts well on irrigation, with production increases of up to 200% on droughty soils and in severely dry years. The sunflower planted hybrid is characterized by early flowering and maturity and medium yield potential, which is sown in Ilfov County (Romania) on a crop totaling 50 ha. The three experimental lots were selected in areas with the highest level of inclination (6%) on alluvial chernozem soil on 15 April 2021 and harvested on 28 June 2021. The experiment included an assessment on the impact of the furrow diking technology on three plots, while an additional plot with conventionally managed technology has been considered as the control. In the autumn prior to sampling for this study, the land had been plowed to a depth of 30 cm. Meanwhile, in the spring, the preparation of the germination bed was carried out with the combinator and the sowing with an SPC-6 type seeder. The experiments were performed when the height of the sunflower plants was between 42–46 cm, on an area of 30 rows with length of 866 m and working width of 3.5 m, covering a total surface on a single passage of 0.3031 ha/passage. The analysis was performed in three different areas, which represented the repetitions of the experiment, while the arithmetic mean was considered for the calculations. The distance between the sunflower rows was 70 cm, the density of plants was 50,000 plants/ha, the slope of the land was 6%, the average soil moisture was 12%, and the tractor used was 65 hp U-650 M on wheels, with a working speed of 3.2 km/h.

The following measurements and control devices were used to test the equipment under operational conditions: A portable soil moisture meter (HH2 used in conjunction with ThetaProbe ML2× precision sensor; accuracy ±1%); digital electronic penetrometer with field scout cone (SC-900); a furrow meter; professional chronometer (accuracy class 2); and several fixed bars.

2.3. Determination of Agricultural Soil Characteristics

Determination of the geographic variability of physical soil characteristics is important due to the geological and pedological soil-forming processes that cause soil properties to vary spatially within a region. Farming techniques, such as tillage, crop rotation, and irrigation management impact the geographical diversity of soil parameters. Furthermore, determination of the degree of soil crushing, compaction level, temperature, and soil type was performed with dedicated equipment prior to testing the process of furrow diking, as presented in Figure 2.

Figure 2.

Analysis of soil characteristics and climatic conditions of the area prior to testing the performance indicators of the equipment.

Soil compaction has been determined with the Field-Scout SC-900 Soil Compaction Meter, while the temperature and moisture have been determined using the Field-Scout TDR-350 Soil Moisture Meter. Soil granulation was determined using perforated sieves, and the meteorological conditions were obtained from the National Meteorology Agency records.

2.4. Description of the Equipment Used for Modeling Soil Compartmentalized Furrows

The equipment is designed to operate on weeds in crops, which are sown at distances between rows of 70–80 cm, on lands with a maximum slope of up to 5%, in soils with light, medium or heavy texture, and a relative humidity that does not allow easy adherence to the active organ. The best solutions for accumulating water from precipitation and creating a consistent water distribution on the soil surface are currently explored. A minimum depth of at least 250 mm is required. Improvements in this water management technology consist of the construction of compartmentalized (interrupted) furrows, so-called furrow diking. The work of opening water furrows (thinning works) is carried out using dedicated equipment that operates in aggregate with an agricultural tractor.

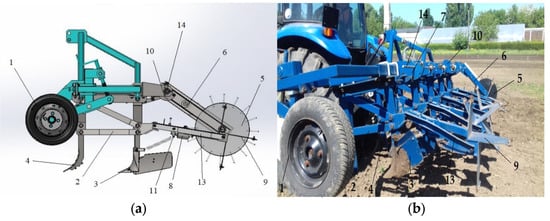

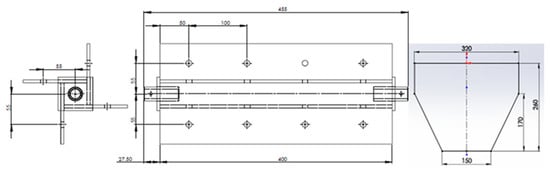

The equipment is composed of the following main subassemblies: A gripping triangle for opening the irrigation channel, a section for conducting compartmentalized furrows, and two arrow-type knives for hoeing. The detailed description of the equipment is depicted in Figure 3a,b.

Figure 3.

Equipment for opening and partitioning water furrows. (a) Equipment overview. (b) Simplified technical scheme consisting of: 1—support wheel, 2—supporting frame, 3—gripping triangle, 4—arrow knife for hoeing, 5—spur wheel for driving the compartmenting mechanism, 6—chain drive, 7—camshaft support, 8—locking element, 9—vane rotor, 10—camshaft, 11—ground pressing mechanism, 12—lever, 13—rotor support, 14—camshaft axle.

The soil loosening elements are attached to the front frame using flanges and specific sleeves. The front working organs are chisel-shaped and may penetrate the soil to a depth of up to 20 cm. The knife may glide on a vertical axis and may be adjusted to fit different plant sizes. Screws are used to secure the knifes at certain depths. The gripping triangle is mounted at variable distances behind the loosening knives, depending on the furrow arrangement. In addition, it consists of a removable knife, a holder, two handrails, and a vertical support. The support bracket adjusts the penetration angle into the soil and is also the safety element for overloading. The penetration angle can be adjusted by rotating the subassembly holder into the vertical support. When working with the equipment, the plants should not exceed 60 cm in height to prevent damaging by the movement of the equipment. The active parts (the loosening knives and the tip) are hardened for increased strength and the edges are capable of self-sharpening during operation.

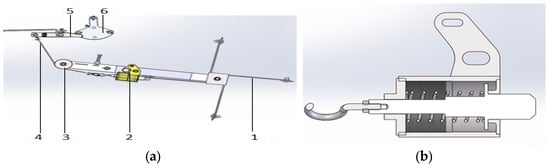

The furrow diking subassembly (furrow compartmentation equipment) is mounted on the rear frame, and consists of a camshaft mechanism for transmitting the motion to the bolts, as shown in Figure 4.

Figure 4.

Detail of the subassembly used for opening and partitioning water furrows. (a) Furrow diking control system subassembly detailed diagram: 1—rotor with blades, 2—locking element, 3—roller, 4—cable, 5—lever, 6—rotor with spurs for setting the distance between dams. (b) Furrow diking control system locking element.

The rotational movement of the wheel is transmitted by a chain drive to a shaft positioned parallel to the second square bar, with the cams positioned in front of each working section. The device ensures the modeling of compartmentalized watering furrows in two ways: Alternatively or consecutively, depending on the sowing scheme, the type of soil, and the root areas of plant. The adjustment of the furrow diking mechanism allows for the construction of soil dams along the furrow at distances of 1.5, 3 or 6 m. During the operation, the equipment simultaneously loosens the soil, opens the furrows, settles the slope, and prepares the furrow bottom.

The rotor consists of four pentagonal blades disposed on a shaft, with the angle between the two adjacent blades at 90°. The vertical position on the outer side of the blade facilitates its approach to the row of plants along the working section, without any damage to the plants. The ground spring of the scraper vane is mounted by means of a steel rod between the rotor support fork and the bar provided on the vertical support.

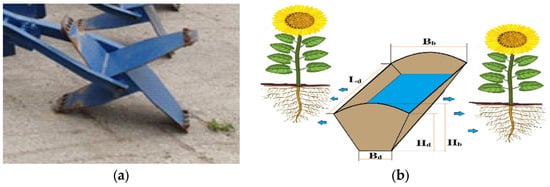

2.5. Modeling of the Working Process for the Working Surface with the Blade-Type Active Surface–Blade

The active component in furrow diking systems is a rotor, which is composed of four blades that process the soil, as shown in Figure 5a. When the equipment moves, a layer of soil accumulates in front of the blade, which rises on its working surface (driven by crawling) and forms a prismatic cavity. Figure 5b presents the main characteristics of the compartmented furrow, which are elements that help in the determination of the qualitative working indices.

Figure 5.

Furrow diking technology in detail with the active component, consisting of a soil modeling rotor (a) that shapes the earth into prismatic patterns (b).

Qualitative working indices which are currently evaluated include the depth of watering ditch, Hd; the width of the bottom, Bd; the upper width of the ditch, Bb; dam height, Hb; and distance between dams, Ld. The absolute mean (1), the mean square deviation (2), and the variation index (3) were calculated for all indices.

- -

- The absolute mean, Vma, is calculated with the relation:where vi is the measured value and n is the number of measurements performed.

- -

- The mean square deviation, σa, is calculated with the relation:

- -

- Variation index, Va, is calculated with the relation:

The resistance force Rp encountered on a straight blade during the working movement of the blade is:

where R1—is the resistance of displacement (by dragging); R2—is the resistant force of displacement of the ground on the blade; μ is the average coefficient of friction; b—is the working width of the blade, (m); ρ—is the density of the soil, (kg/m3); and g—is gravitational acceleration, (m/s2).

In the case of a curved blade, the force of displacement of the material layer on the blade can be determined using relation (5), where s is replaced by the value of the length of the active spring of the blade. In this case, the relationship is:

2.6. Optimization of the Equipment for Opening and Compartmenting Furrows for Sunflower Crop

The aim of this study was to optimize the active element of the furrow diking system, namely the rotor blades, for the sunflower crops. An algorithm selection, by efficiently sampling the search space and identifying the right potential solution, is required for the optimization function. Herein, the random search method was used to oppress the partitioning blades. In addition, these techniques are stochastic approaches that rely entirely on the random sampling of a succession of points in the problem’s feasible region, in accordance with a predetermined probability distribution or sequence of probability distributions. This method is successful as no assumptions are made concerning the objective function of the structure. Moreover, it can be useful in clarifying issues with a substantial knowledge base, which could impact or influence the optimization technique used in finding non-intuitive solutions.

The random search method determines the global minimum of a n-variable function and is based on generating a group of random numbers in a predefined domain. The values of the variables, in which the function is defined, are selected using random numbers. In this sense, at each iteration of the minimization process, a sequence of random numbers is generated with the uniform probability density in the allowed variation range. With the use of these random numbers, the values for the variables of the objective function are established. In addition, for all these vectors, the objective function values are determined and the vector with the minimum function value is retained. Next, the field is narrowed around the minimum point and the process is repeated for a new iteration.

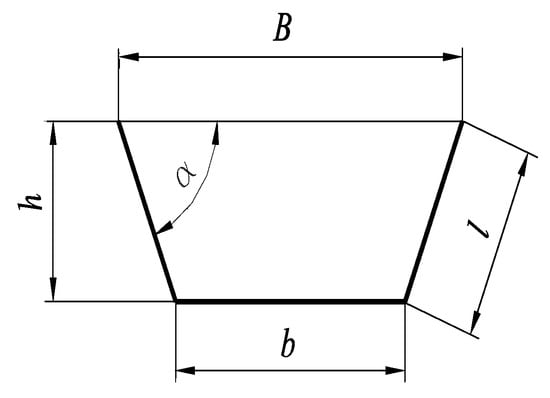

The cross-sectional shape of the watering channel has an isosceles trapezoidal shape, as shown in Figure 6. In this case, the area of the trapezoid must be maximized at a particular perimeter to achieve the lowest expenses. In practice, the perimeter of the trapezoid that remains embossed in the soil will be determined only by the two oblique sides and the small base.

Figure 6.

Determination of the cross-sectional shape of the watering channel.

To express the purpose of the function, in relation to the parameters of the problem, the following mathematical relations (6)–(13) are used:

is the angle between the large base B and the side l.

If in the relation of the trapezoidal surface the replacements are carried out, then the result is:

Resulting in the expression of the cross-sectional area of the watering channel:

Therefore, for optimization, it is necessary to determine the size of side l and angle α for the section of the trapezoid to be maximum.

The initial conditions of the optimization problem are as follows:

is the channel perimeter (dimensionless);

n = 2 is the number of parameters;

;

;

NRA = 100, the accepted number of function calls within one iteration;

ITER = 2000, the number of iterations allowed, in the process of finding the optimal function.

The results of the calculations are:

For a given perimeter , the two variables are:

and the maximum section is:

In the case of the watering channel for sunflower crops, h = 0.17 m, therefore

The optimal width of the watering channel for sunflower crops sown at a distance between rows of 0.6 m is 0.4 m, to not affect the roots of the plants.

2.7. Design and Testing of Rotor Blades in Accordance with Optimization Calculations

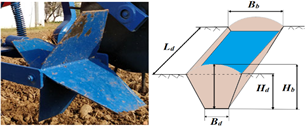

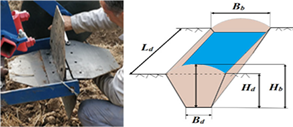

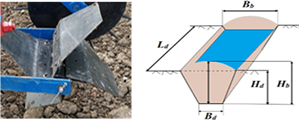

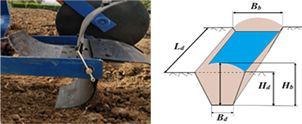

The testing started with the use of a furrow dike equipped with standard rotary blades, and then three new optimized variants were designed and investigated. The design was aimed at optimizing the dimensions of straight active blades as well as inclined and curved blades. Figure 7 presents the standardized version of the blade, while Figure 8, Figure 9 and Figure 10 present the optimized versions.

Figure 7.

Overview of the dimensions of a standard rotor equipped with the furrow compartmenting system.

Figure 8.

Design and construction of a straight optimized blade equipped with the furrow compartmenting system rotor.

Figure 9.

Design and construction of an inclined optimized blade equipped with the furrow compartmenting system rotor.

Figure 10.

Design and construction of a curved optimized blade equipped with the furrow compartmenting system rotor.

In accordance with the objectives, the theoretical calculations aimed at optimizing the shape and characteristics of the blade were evaluated in another scientific article, which is associated with the same research project.

2.8. Evaluation Method of Rainfall Water Efficiency for the Sunflower Crop

The primary objective in this study is to enhance water storage in the soil root zone, while reducing deep percolation and surface runoff to fulfill crop necessities. The soil water storage efficiency measures how well the system utilizes the available capacity of the root zone storage to satisfy crop requirements. As a result, enhancing the storage of the water resource is beneficial. The ratio of the amount of water stored in the root zone to the volume of water necessary to fill the root zone to near field capacity is known as soil water storage efficiency (Es), as shown below:

where is the soil water storage efficiency (%); is the volume of water stored in the soil root zone, (acre-inch); is the volume capacity at field level in the crop root zone (acre-inch); and is the volume of water in the soil root zone prior to the watering event (acre-inch).

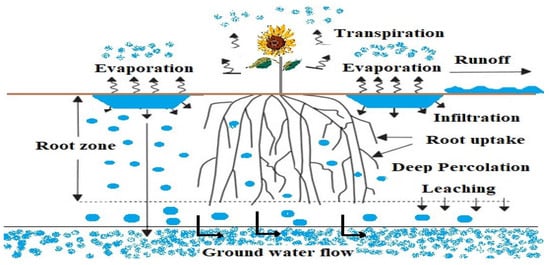

Water losses for sunflower cultivation include surface evaporation, transpiration, deep percolation, and surface runoff, as presented in Figure 11. Primarily percolation and runoff losses have been considered when comparing the storage efficiency of furrow diking technology versus conventional technology for sunflower cultivation.

Figure 11.

The main water losses for sunflower cultivation.

Crop water use efficiency is used to describe irrigation effectiveness in terms of crop yield (productivity). Water productivity and water use efficiency indexes were determined to evaluate the productivity of irrigation and evapotranspiration in the treatments. Water productivity indexes for seed yield were calculated using the following equations:

where WUE(Y) denotes water use efficiency for seed yield (kg mm−1); YLD denotes the seed yield (kg); and ETa is the actual crop evapotranspiration amount (mm).

3. Results

3.1. Determination of Soil Characteristics

The soil characteristics and local climatic patterns are highly significant for the level of performance of furrow diking technology, particularly if the land is not irrigated.

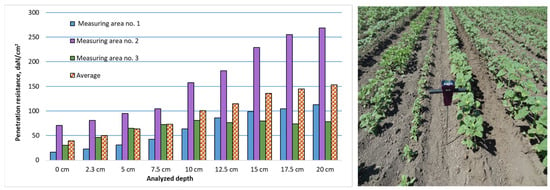

Determination of Penetration Resistance

Soil penetration resistance is a strong indicator of soil physical quality and creates opposition to the penetration of a rigid body. In addition, as the soil moisture increases, the resistance decreases, as shown in Figure 12.

Figure 12.

Evaluation of soil penetration resistance in a sunflower culture (between rows).

The results obtained were corroborated by the main classes of resistance to soil penetration, suggesting that the evaluated soils are highly compact due to the sunflower crop requirements of a large number of mechanical operations.

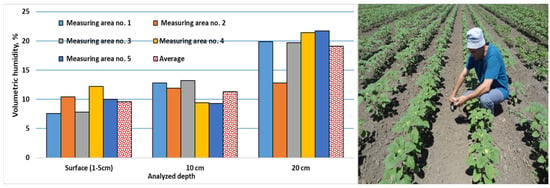

Moreover, the average humidity of the soil at a depth of 20 cm was determined as 19.1%, which is within the agrotechnical parameters for sunflower culture, as shown in Figure 13.

Figure 13.

Evaluation of volumetric soil moisture data as a function of depth.

3.2. Determination of Qualitative Indices for the Equipment for Creating Compartmentalized Furrows

Qualitative indicators during the furrow compartmentation process include fuel consumption, compartment size indicators, and rainwater storage indicators, as shown in Figure 14.

Figure 14.

Modeling compartmentalized segments in the furrow diking system for sunflower culture.

3.2.1. Determination of Quality Indices for Equipment Equipped with Standard Rotor with Straight Blades

The minimal amounts of water that should be retained in the soil for sunflower cultivation have been determined based on local multiannual records of weather conditions and soil characteristics. The dimensions of the micro-basins (Hb, total height of the dam; Hd, useful height of the dam; Bb, width of the dam at the top; Bd, width of the dam at the bottom; Ld, length of the basins) have been used as quality indicators for the rotor operation, based on this information and the equipment’s optimization calculation.

The results of this experimental research are presented in Table 1, Table 2, Table 3 and Table 4, while Figure 15, Figure 16, Figure 17 and Figure 18 depict the operation of each type of blade (standardized straight blade, optimized straight blade, inclined blade, and curved blade).

Table 1.

Qualitative indices for evaluating the rotor of a furrow compartmenting equipment that has been equipped with the standard blade.

Table 2.

Qualitative indices for evaluating the rotor of a furrow compartmenting equipment that has been equipped with the optimized straight blades.

Table 3.

Qualitative indices for evaluating the rotor of a furrow compartmenting equipment that has been equipped with the optimized inclined blades.

Table 4.

Qualitative indices for evaluating the rotor of a furrow compartmenting equipment that has been equipped with the optimized curved blades.

Figure 15.

Testing the furrow diking system equipped with the standard rotor blades. (a) Testing the equipment performance on difficult soils. (b) Evaluation of the equipment wear during testing.

Figure 16.

Testing the furrow diking system equipped with the optimized straight rotor blades. (a) Testing the equipment performance on difficult soils. (b) Evaluation of the equipment wear during testing.

Figure 17.

Testing the furrow diking system equipped with the inclined rotor blades. (a) Testing the equipment performance on difficult soils. (b) Evaluation of the equipment wear during testing.

Figure 18.

Testing the furrow diking system equipped with the curved rotor blades. (a) Testing the equipment performance on difficult soils. (b) Evaluation of the equipment wear during testing.

3.2.2. Determining Fuel Consumption and Energy Indicators

The economics of integrating furrow diking technology into conventional agricultural practices is evaluated by measuring real fuel consumption and energy characteristics.

The fuel consumption device Flowtronic 217 was adopted to determine the amount of additional diesel used in the operation of the furrow diking equipment. The analysis indicates that the fuel consumption of the agricultural tractor operating without load was between 14.20–14.70 L/ha, while the fuel consumption when utilizing the compartmenting equipment varied between 15.5–16.2 L/ha. When furrow diking equipment is used, the analysis shows an additional 9–10% increase in fuel consumption.

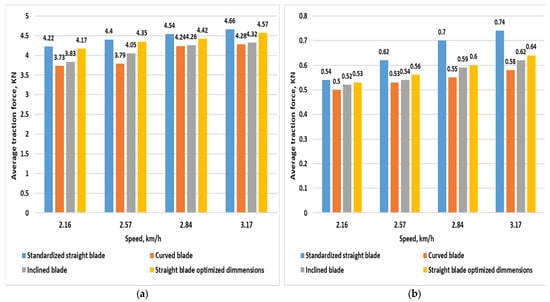

The evaluation of the stresses encountered by the equipment during the working process is performed by measuring the deformations of the component elements. Deformation of a material under the action of various applied forces is called specific deformation and is calculated as the ratio of the variation in length of the material, subjected to forces, to the original length. The values obtained for the average traction force, respectively the force on the working organ, for the four blade shapes, namely: 1—standardized straight blade, 2—curved blade, 3—inclined blade, 4—straight blade at optimized dimensions, recorded for four speeds are depicted in Figure 1. The speed values were calculated for a testing length of 30 m, resulting in the following values for time: t1 = 50 s, t2 = 42 s, t3 = 38 s, and t4 = 34 s. Figure 19a presents the variation of the traction force, in accordance with the working speed, while Figure 19b depicts the force on the working organ as a function of speed.

Figure 19.

Evaluation of the forces exerted during the working of the furrow diking system: (a) Variation of the average traction force as a function of speed, for four speeds and the four blade shapes. (b) Variation of the average force on the working organ as a function of speed, for four speeds and the four blade shapes.

Figure 19a shows that the force on the working organ increases with the working speed, but in a negligible rate. This increase has higher values for the standardized blade shape, while the lower values are recorded for the curved shape due to the easier sliding of the soil to the blade surface, compared with the straight and inclined options. Figure 19b shows that the force required to operate the furrow diking equipment is approximately 10–15% of the total traction force needed to perform the hoe work, which justifies the low consumption of additional fuel, required to perform this task. Taking into account the cost of the equipment and the additional energy consumption to carry out this work, compared with the surplus of harvest obtained, the use of this equipment is justified. All of the evaluated blade options passed the minimal deformation standards defined for these agricultural working organs. Therefore, their reliability will be relatively high.

4. Discussion

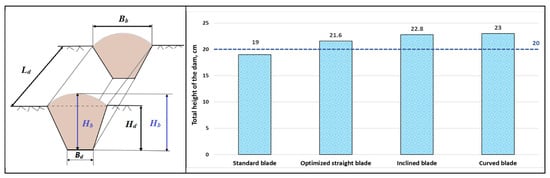

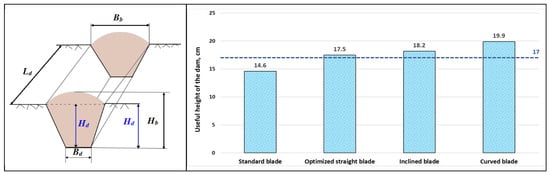

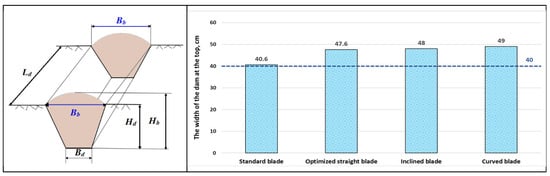

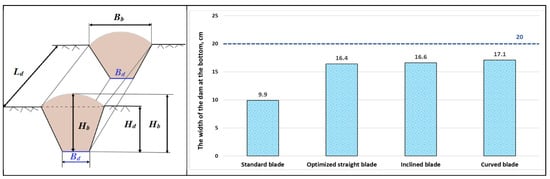

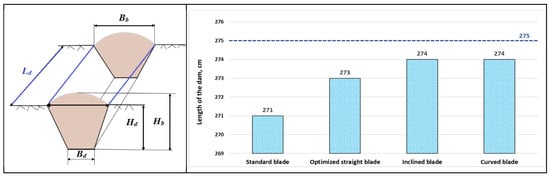

In the process of opening and partitioning water furrows, a study of the operation conditions is achieved through the use of a working body with an active surface of the mouldboard type, a butting plough, and a rotor at an increased speed regime. Figure 20, Figure 21, Figure 22 and Figure 23 comparatively analyze the performance indicators, consisting of the main micro-basin dimensions for the four types of rotor blades. The evaluation is performed with respect to the theoretical values determined using the optimization calculations, as shown in the graphs depicted below with a dotted line.

Figure 20.

Comparative evaluation of the qualitative indicator Hb (total height of the dam) for the four constructive rotor blades.

Figure 21.

Comparative evaluation of the qualitative indicator Hd (useful height of the dam) for the four constructive rotor blades.

Figure 22.

Comparative evaluation of the qualitative indicator Bb (width height of the dam at the top) for the four constructive rotor blades.

Figure 23.

Comparative evaluation of the qualitative indicator Bd (width of the dam at the bottom), for the four constructive rotor blades.

Figure 20 presents an evaluation of the qualitative indicator Hb (total height of the dam). The values had been selected to allow for the accumulation of an additional amount of soil between the compartments. This supplemental amount of soil ensures the stability of the micro-dam in the case of heavy rainfall or wind, which could result in the collapse of the construction. Although this indicator is the least important, its size increases the stability of micro-dams. In most cases, after the first rainfall Hb reaches its highest level, the height of Hd indicator (useful height of the dam) reaches its peak. As a consequence, Hb indicator readings were taken before the rain. To retain the predefined value of the water volume, all of the three upgrading options must meet the performance criteria.

The useful height of the dam (Hd) represents the stable height of the micro-basin compartment, which must remain steady during and after the accumulation of water (Figure 21). As a result, measurements for this indicator were taken after the first rain. All of the optimized blades showed an efficiency above the value established by the improvement calculation. The best result was obtained by the curved blade due to its concave shape, which can accumulate a larger amount of soil. The enhanced properties of the inclined and curved shapes are due to the greater conducting action as the rotor spins.

Qualitative indicator Bb (width of the dam at the top) represents the upper width of the micro-pool (Figure 22). The indicator is accomplished using all of the blade shapes, including the standardized rotor. It is easier to accomplish since the excess of soil will never remain at the top, but will fall inside the micro-dam.

Figure 23 depicts indicator Bd (width of the dam at the bottom), a very difficult indicator to accomplish, since the earth tends to slide down. Furthermore, after each rainfall, new quantities of soil accumulate inside the micro-dam, filling the useful space.

Measurements after the first rain showed that this indicator is below the theoretically calculated values. The curved blade has the best performance again, due to the larger volume of soil displaced from the furrow.

The dam length indicator actually determines the volume of water that can be hosted by the micro-pool. The equipment showed acceptable values for the inclined and curved blades, although the values were 1 cm below those established as optimal (Figure 24).

Figure 24.

Comparative evaluation of the qualitative indicator Ld (length of the basins) for the four constructive rotor blades.

The shape of the curved blade gave the rotor an important advantage in operation, particularly due to the larger amount of soil it manages. Soil boulders were better carried by the concave blade and transported above the dam, unlike the right blade that only scrapes the bottom of the micro-basin. In the case of indicator Bd (width of the dam at the bottom), no consistent values were obtained in accordance with the optimization calculation for any of the blades, since the ground was relatively dry at the surface at the time of testing. Therefore, the base of the micro-basin tends to clog with the ground due to soil-slipping. This limitation could be remedied by operating the soil in higher moisture conditions. However, it should be noted that during the summer difficult soils often tend to lose surface moisture.

A disadvantage identified in furrow compartmentation technology that uses the rotor as an active component is the inability to customize the length of the dam in accordance with the special local needs. Length of the dam and length between of the basin are two parameters that are correlated with each other and are highly important, particularly in areas where high water flows may damage the micro-basin construction. The length of the basin is conditioned by the soil loading capacity on the blade, while the length of the basin is conditioned by the rotor construction. A possible solution could be the replacement of the rotor with electronically operated equipment. However, this increases the maintenance and complexity of the machine, which usually displeases farmers.

Large-scale use of furrow diking equipment should take into account the variation of the slope angle of the terrain. Tests have shown that when establishing extensive plantations, the angle of the slope varies greatly. Therefore, an automated equipment for measuring the slope of the terrain must be included to correlate the slope with the length of the micro-dam. The problem occurs less in the case of watering exclusively through rainfall. However, this can cause puddles in the case of watering with irrigation systems.

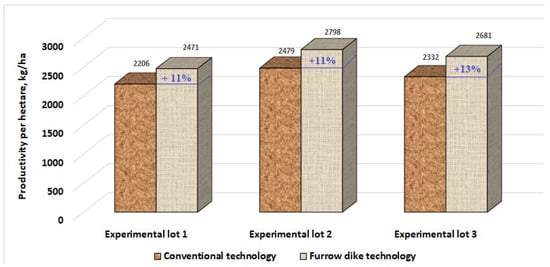

4.1. Efficiency in the Usage of the Furrow Compartmenting Equipment (Furrow Diking System)

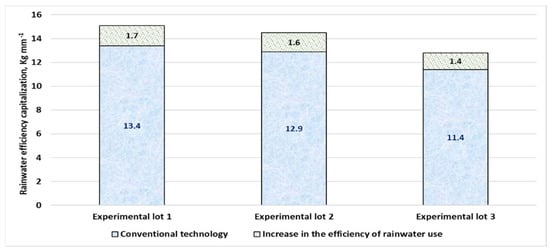

The efficiency in the use of furrow compartmenting equipment is provided by the harvest surplus obtained, under identical cultural conditions. The sunflower crop was harvested at the beginning of the ripening phase when the seed average moisture dropped below 15%. The production was reported at a standardized humidity of 12%, in the weighing process. To evaluate the efficiency of the precipitation capitalization, the grain production was reported on the precipitations registered during the vegetation period (April-August) and expressed in kg/ha seeds, in accordance with the precipitation amount. The results are shown in Figure 25.

Figure 25.

Evaluation of furrow diking technology compared with conventional technology by comparing seed productivity per hectare.

Productivity on the three analyzed soils showed an improvement in production when using 11–13% of the furrow diking technology. The differences were driven by different weather conditions, given that the assessment considered only rainwater intake.

Although productivity growth when using compartmentalization technology is significant, it may still not persuade farmers to consider large-scale adoption. A key element for efficiency increase is the suitability for adopting an irrigation system, which would make the furrow compartmentalization even more useful.

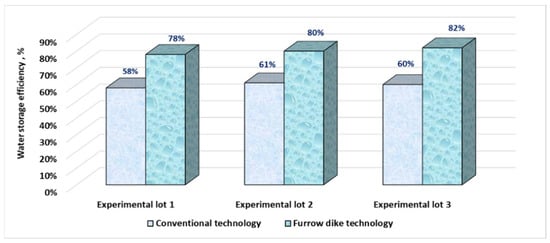

4.2. Evaluation of the Water Usage and Storage Efficiency from Rainfall

Water storage efficiency has been evaluated on how effective the system delivers rainfall from the conveyance system to the crop for the type of land analyzed, in accordance with the specific climatic conditions. The first analysis associated water storage efficiency with the productivity of sunflower crops. The assessed experimental lots were all sown with the same sunflower hybrid and received identical treatments. Therefore, the furrow diking system was the only element that changed. Considering the level of precipitation during the plant development, the production surplus for the three locations due to the implementation of the furrow diking technology is presented in Figure 26.

Figure 26.

Evaluation of the increase in the efficiency of rainwater usage with the use of furrow diking calculated depending on the production associated with the amount of precipitation.

Efficiency improvement in the use of rainwater, as a result of applying the furrow diking technology was calibrated by comparing the production yields to the total amount of water received from precipitation per square meter, during plant development. The reduction of water leakage on the land slope is the major factor producing the positive effect, since all of the other factors have been maintained in the same way. Based on the specific conditions of each lot, the efficiency of rainwater storage was analyzed, as shown in Figure 27.

Figure 27.

Evaluation of furrow diking technology compared with conventional technology by comparing seed productivity per hectare.

Although water storage efficiency was considerably higher in furrow diking technology, seed productivity did not increase at the same rate due to the fact that the experiment focused only on rain storage, which is dependent on local climatic conditions. As a result, it is evident that combining an irrigation system with furrow diking technology will significantly increase the output. However, for the best results, the irrigation method must take into account the type of soil and the inclination of the slope.

Other studies that have compared the two technologies, found that micro-basin tillage reduced runoff by 66.7% and sediment yield by 71.43%, compared with conventional tillage [5]. On some sites with unique characteristics, such as hard terrain and steep slopes, runoff from conventional tillage was three times higher than from micro-basin management [11].

The present paper focused on the advancement of rotor blades, rather than the assessment of all the elements that determine crop productivity. However, it should be noted that in addition to the slope and the soil type, several other factors can affect the relative humidity of the soil, depending on the depth, rainfall efficiency capitalization, and water storage efficiency. The results commonly found in the literature evaluate the cases of various plantations that benefit from furrow watering. However, this research focuses on sunflower crop grown on less fertile sloped soil, presenting a significant risk of soil-washing, sliding, and runoff. None of these negative phenomena occurred on any of the analyzed plots during the investigation, although no study was conducted on the intensity of the severe events.

The performance increases recorded in this research study promise to allow a successful association of furrow diking technology with the new strategies established for regenerating degraded soils, as a result of the limited crop interventions and the minimization of chemicals used on agricultural soils.

The length of the dam will be considered for examination in future research. The investigated locations rarely experience significant torrential rains. However, in this scenario, the rotor technology is limited since it does not allow for the modification of the soil dam between the micro-basins to strengthen its resistance.

5. Conclusions

In this study, the primary objective was aimed at designing and testing novel constructive rotors associated with furrow diking technology to enhance the functioning and structure of water storage micro-basins. Herein, the experimental rotor models developed and evaluated demonstrated excellent working indices, outperforming the standardized rotor. Due to the increased volume of managed soil and lower soil losses, the curved rotor blade proved most effective in constructive design, in accordance with the investigated quality parameters.

Working under complex terrain conditions, the furrow compartment equipment demonstrated simplicity in use, durability, and easy integration into present agricultural processes, with reasonable additional fuel expenses. The results may encourage farmers to adopt the technology for crops less specific to furrow construction, such as non-irrigated sunflower plantations.

The furrow diking of sunflower crops planted on a sloping site demonstrated good results for the climatic and pedological conditions in southern Romania, with maximum enhanced seed yields of 13%, compared with non-compartmentalized crops.

Although the proposed technology has helped in reducing storm flows, enhancing water storage, reducing soil erosion, and increasing agricultural yields in the year of 2020, we believe that the project should be extended for at least three additional years for several other types of soil to properly confirm the field results.

In conclusion, furrow diking systems are more successful when the terrain provides certain evident challenges, such as high level of inclination or desertification tendency. For this specific instance, the technology has shown cost-effectiveness and easy implementation, while the new shapes of the rotor blades greatly improved the furrow compartmentation system.

Author Contributions

Conceptualization, F.N., M.R.O. and S.-S.B.; methodology, F.N.; software, M.R.O.; validation, F.N., M.R.O. and S.-S.B.; investigation, F.N. and M.R.O.; resources, S.-S.B.; writing—original draft preparation, F.N. and M.R.O.; writing—review and editing, F.N., M.R.O. and S.-S.B.; visualization, F.N. and M.R.O.; supervision, F.N., M.R.O. and S.-S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This paper was financed by the support of the Executive Agency for Higher Education, Research, Development and Innovation Funding, Exploratory Research Program, PN-III-P4-ID-PCE-2016-0860, contr. 174/08.08.2017, “Research on the development of some mathematical models to evaluate the impact of soil contamination on fruits and vegetables—CONTAMOD” and contr. 16PFE/2018. The APC was funded by University Politehnica of Bucharest, Romania, within the PubArt Program.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nenciu, F.; Stanciulescu, I.; Vlad, H.; Gabur, A.; Turcu, O.L.; Apostol, T.; Vladut, V.N.; Cocarta, D.M.; Stan, C. Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology. Sustainability 2022, 14, 2835. [Google Scholar] [CrossRef]

- Nielsen, D.C.; Vigil, M.F. Legume green fallow effect on soil water content at wheat planting and heat yield. Agron. J. 2005, 97, 684–689. [Google Scholar] [CrossRef]

- Nuti, R.C.; Lamb, M.C.; Sorensen, R.B.; Truman, C.C. Agronomic and economic response to furrow diking tillage in irrigated and non-irrigated cotton. Agric. Water Manag. 2009, 96, 1077–1083. [Google Scholar] [CrossRef]

- Harris, B.L.; Krishna, J.H. Furrow diking to conserve moisture. J. Soil Water Conserv. 1989, 44, 271–273. [Google Scholar]

- Liu, Y.; Xin, Y.; Xie, Y.; Wang, W. Effects of slope and rainfall intensity on runoff and soil erosion from furrow diking under simulated rainfall. Catena 2019, 177, 92–100. [Google Scholar] [CrossRef]

- Cardei, P.; Nenciu, F.; Ungureanu, N.; Pruteanu, M.A.; Vlăduț, V.; Cujbescu, D.; Găgeanu, I.; Cristea, O.D. Using Statistical Modeling for Assessing Lettuce Crops Contaminated with Zn, Correlating Plants Growth Characteristics with the Soil Contamination Levels. Appl. Sci. 2021, 11, 8261. [Google Scholar] [CrossRef]

- Baumhardt, R.L.; Blanco-Canqui, H. Soil Conservation practices. In Encyclopedia of Agriculture and Food Systems; Van Alfen, N., Ed.; Elsevier: San Diego, CA, USA, 2014; Volume 5, pp. 153–165. [Google Scholar]

- Bryant, C.J.; Krutz, L.J.; Nuti, R.C.; Truman, C.C.; Locke, M.A.; Falconer, L.; Atwill, R.L.; Wood, C.W.; Spencer, G.D. Furrow Diking as a Mid-Southern USA Irrigation Strategy: Soybean Grain Yield, Irrigation Water Use Efficiency, and Net Returns above Furrow Diking Costs. Crop Manag. 2019, 5, 1–5. [Google Scholar] [CrossRef]

- Twomlow, S.J.; Bruneau, P.M.C. The influence of tillage on semi-arid soilwater regimes in Zimbabwe. Geoderma 2000, 95, 33–51. [Google Scholar] [CrossRef]

- Ciobotaru, I.E.; Nenciu, F.; Vaireanu, D.I. The Electrochemical Generation of Ozone using an Autonomous Photovoltaic System. Rev. Chim. 2013, 64, 1339–1342. [Google Scholar]

- Truman, C.C.; Nuti, R.C. Improved water capture and erosion reduction through furrow diking. Agric. Water Manag. 2009, 96, 1071–1077. [Google Scholar] [CrossRef]

- Asrstad, J.S.; Miller, D.E. Soil management to reduce runoff under center-pivot sprinkler systems. J. Soil Water Conserv. 1973, 1973. 28, 171–173. [Google Scholar]

- Gerard, C.J.; Sexton, P.D.; Conover, D.M. Effect of furrow diking, subsoiling and slope position on crop yields. Agron. J. 1984, 76, 945–950. [Google Scholar] [CrossRef]

- Nenciu, F.; Vladut, V. Studies on the perspectives of replacing the classic energy plants with Jerusalem artichoke and Sweet Sorghum, analyzing the impact on the conservation of ecosystems. IOP Conf. Ser. Earth Environ. Sci. 2020, 635, 012002. [Google Scholar] [CrossRef]

- Wallace, J.S. Increasing agricultural water use efficiency to meet future food production. Agric. Ecosyst. Environ. 2000, 82, 105–119. [Google Scholar] [CrossRef]

- Hatfield, J.L.; Dold, C. Water-Use Efficiency: Advances and Challenges in a Changing Climate. Front. Plant Sci. 2019, 10, 103. [Google Scholar] [CrossRef]

- Sharma, B.; Molden, D.; Cook, S. Water Use Efficiency in Agriculture: Measurement, Current Situation and Trends, Managing Water and Fertilizer for Sustainable Agricultural Intensification, 39–64. Available online: https://publications.iwmi.org/pdf/H046807.pdf (accessed on 20 March 2022).

- Jones, O.R.; Stewart, B.A. Research study. Basin tillage. Soil Till. Res. 1990, 18, 249–265. [Google Scholar] [CrossRef]

- Jones, O.R.; Clark, R.N. Effects of Furrow Dikes on Water Conservation and Dryland Crop Yields. Soil Water Manag. Conserv. 1987, 51, 1307–1314. [Google Scholar] [CrossRef]

- Baumhardt, R.L. The Dust Bowl Era. In Encyclopedia of Water Science; Stewart, B.A., Howell, T.A., Eds.; Marcel-Dekker: New York, NY, USA, 2003; pp. 187–191. [Google Scholar]

- Balkcom, K.S.; Schomberg, H.H.; Reeves, D.W.; Clark, A.; Baumhardt, R.L.; Collins, H.P.; Delgado, J.A.; Kaspar, T.C.; Mitchell, J.; Duiker, S. Managing cover crops in conservation tillage systems. In Managing Cover Crops Profitably, 3rd ed.; Clark, A., Ed.; Handbook Series Book 9; Sustainable Agriculture Network: Beltsville, MD, USA, 2007; pp. 44–61. [Google Scholar]

- Mircea, C.; Nenciu, F.; Vlǎduț, V.; Voicu, G.; Cujbescu, D.; Gageanu, I.; Voicea, I. Increasing the performance of cylindrical separators for cereal cleaning, by using an inner helical coil. INMATEH Agric. Eng. 2020, 62, 249–258. [Google Scholar] [CrossRef]

- Foote, W.; Nuti, R.; Edmisten, K.; Jordan, D.; Wells, R.; Fisher, L. Crop Responses to Furrow Diking in North Carolina. Crop Manag. 2014, 47, 36–40. [Google Scholar] [CrossRef]

- Irmak, S.; Odhiambo, L.O.; Kranz, W.L.; Eisenhauer, D.E. Irrigation Efficiency and Uniformity, and Crop Water Use Efficiency. Biol. Syst. Eng. Pap. Publ. 2011, 451, 1–8. [Google Scholar]

- Howell, T.A.; Schneider, A.D.; Dusek, D.A. Effects of Furrow Diking on Corn Response to Limited and Full Sprinkler Irrigation. Soil Sci. Soc. Am. J. 2002, 66, 222–227. [Google Scholar] [CrossRef]

- Nenciu, F.; Paraschiv, M.; Kuncser, R.; Stan, C.; Cocarta, D.; Vladut, V.N. High-Grade Chemicals and Biofuels Produced from Marginal Lands Using an Integrated Approach of Alcoholic Fermentation and Pyrolysis of Sweet Sorghum Biomass Residues. Sustainability 2022, 14, 402. [Google Scholar] [CrossRef]

- Bana, R.S.; Bamboriya, S.D.; Padaria, R.N.; Dhakar, R.K.; Khaswan, S.L.; Choudhary, R.L.; Bamboriya, J.S. Planting Period Effects on Wheat Productivity and Water Footprints: Insights through Adaptive Trials and APSIM Simulations. Agronomy 2022, 12, 226. [Google Scholar] [CrossRef]

- Cojocaru, C.; Cocârţă, D.M.; Istrate, I.A.; Creţescu, I. Graphical Methodology of Global Pollution Index for the Environmental Impact Assessment Using Two Environmental Components. Sustainability 2017, 9, 593. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).