Featured Application

This paper studies the influence of different energy conversion equipment on the energy distribution and structure of iron and steel enterprises.

Abstract

In steel enterprises, the design of energy systems mainly depends on experience and lacks systematic optimization methods. Therefore, it is of great significance to propose an overall optimization design method for the energy system of steel enterprises. In this paper, a linear model is proposed to select the energy conversion equipment types and distribute energy sources with the aim of maximizing the economic benefits of an energy system. In the model, the choice of energy conversion technology and the distribution of energy source are considered comprehensively. For the S steel plant, the case analysis results show that under the condition of keeping the original energy conversion equipment unchanged and optimizing the distribution of energy source, the economic benefits of the energy system can be increased by 15.77 CNY/t steel, and under the conditions of optimizing the distribution schemes of the energy conversion equipment types and energy sources, the economic benefits of the energy system can be increased by 180.26 CNY/t steel. In addition, the effects of different energy conversion equipment configurations, different energy sources prices and different pollution cost standards on the steel plant energy economic benefits were analyzed.

1. Introduction

The steel industry is a resource- and energy-intensive industry, and is also a high-pollution, high-energy, and high-emission industry. In 2015, the energy consumption of the steel industry accounted for 26.1% of the total industrial energy consumption, which accounted for 14.9% of the total energy consumption in China [1]. The integrated steel enterprises include main steel production systems, energy systems, and auxiliary systems. The main steel production systems include sintering, pellet production, blast furnace (BF), coke oven, converting, refining, continuous casting, hot rolling, cold rolling, and so on. The energy systems include power and steam production systems, chemical product manufacturing systems, and technical gas production systems. The auxiliary systems include transportation equipment and warehousing processes. As large material energy input and output systems, steel companies include complex energy distribution networks that use multiple energy sources. Among them, 34% of the primary energy (cleaned coal and anthracite coal) is transformed to byproduct gases during the iron and steel production process [2,3]. As the Chinese steel industry pays increasing attention to environmental protection [4], people are paying increasing attention to the recycling, conversion, and utilization of secondary energy. In the iron and steel production process, there is often a surplus or shortage of secondary energy, which will lead to an increase in operating costs and environmental pollution costs. Therefore, optimizing the utilization of secondary energy and improving the conversion efficiency of secondary energy are of great significance to the steel industry [5]. Therefore, the design and optimization of energy systems in steel enterprises are receiving increasing attention.

The secondary energy utilization of iron and steel enterprises has been widely studied by researchers [6,7,8]. Previous studies have focused on the production or consumption prediction and optimal scheduling of byproduct gases, steam, and electricity. In terms of energy forecasting, Lei et al. [9] forecasted the surplus gas in the iron and steel industry to make full use of gas resources and stabilize the pipe network pressure. Zhang Qi et al. [10] made comprehensive use of the grey model and back-propagation (BP) neural network to establish a prediction model of the blast furnace gas (BFG) system. In addition, several researchers, based on the ARIMA model, neural network, and least-squares support vector machine (LSSVM), have established composite prediction models to predict the production and consumption levels of energy source in steel enterprises [11,12,13,14]. In terms of energy scheduling, Kim et al. [15] proposed an optimal distribution model of the gas supply and demand by considering constraints such as boiler fuel fluctuations, boiler efficiencies, and gasholder capacities. Kong et al. [16] used a dynamic mixed-integer linear programming (MILP) model to optimize the multi-cycling of byproduct gas. Zhao et al. [17,18,19] used MILP to establish an optimal distribution model for surplus gas and considered the influences of peak and valley electricity prices on the optimization results, thereby making the model closer to reality. Based on analysis of the supplies and demands of gas, steam, and electricity in the production cycle, Zhang Qi et al. [20,21,22] established a multi-cycle optimal distribution model of the surplus gas, steam, and electric power. The model considered the impacts of polluting gases on the environment.

The above research aims to predict and optimize the distribution of one or several secondary energy sources (gas, steam, electricity, etc.) under the premise of determining the production processes and energy conversion devices. There are few types of energy sources involved in the above studies, and there is no comprehensive consideration of the interactions and the different uses of multiple energy sources.

The distribution of energy source is also different if steel plants are equipped with different energy conversion devices [23]. For example, the introduction of desalination plants will change the distribution of steam in steel plants [24]. In their research on the configurations of energy conversion equipment in iron and steel enterprises, Li et al., [25] combined the analyses of the Angang Iron and Steel Group’s gas balance and gas power generation configurations and analyzed the process flows, overall benefits, technical advantages, and disadvantages of the high temperature and high-pressure power generation and combined cycle power plant (CCPP). Wang et al. [26] proposed a technical route for the utilization of BFG and evaluated the environmental economy of methanol made from BFG. Joseck et al. [27] studied the energy and emission effects of coke oven gas (COG) hydrogen production and compared these effects with those of other hydrogen production options. Although the above studies have proposed the impact of the choice of energy conversion method on the production efficiency, the evaluation of only a single energy conversion technology lacks the systematic consideration of the configurations of different energy conversion technologies (devices).

At present, in the design process of steel enterprises, the design steps of the energy systems are as follows: First, energy consumption analysis and evaluation of the production capacity of each process of the steel plant are conducted [28]; then, selection of the energy conversion technology (equipment) occurs according to experience [29]; and finally, the balance of the energy supply and demand is evaluated. The power determination and energy source distribution scheme determination of the energy conversion equipment are performed. The existing design methods do not comprehensively consider the interaction between energy conversion equipment types and the interaction between multiple energy sources. The design of an energy system has, in general, not been optimized.

In view of the drawbacks of the previous research work, this study proposes a linear programming model for the optimization design of the energy systems in steel plants. The model involves more than 20 energy sources and 27 equipment types/processes in iron and steel enterprises. At the same time, the model emphasizes the impacts of energy conversion devices on the energy distribution and the interaction between different energy sources and provides guidance for the optimization design of the energy systems in steel enterprises from the perspective of system optimization.

2. Problem Analysis

Portions of the BFG, COG, and Linz–Donawitz process gas (LDG) produced by a steel enterprise are used inside the steel system to meet the production demands of iron and steel, and the remaining byproduct gas is supplied to energy systems. The production of the iron and steel system is relatively stable, in which the amount and consumption of byproduct gas remain unchanged, and thus the amount of byproduct gas supplied to the energy systems does not change.

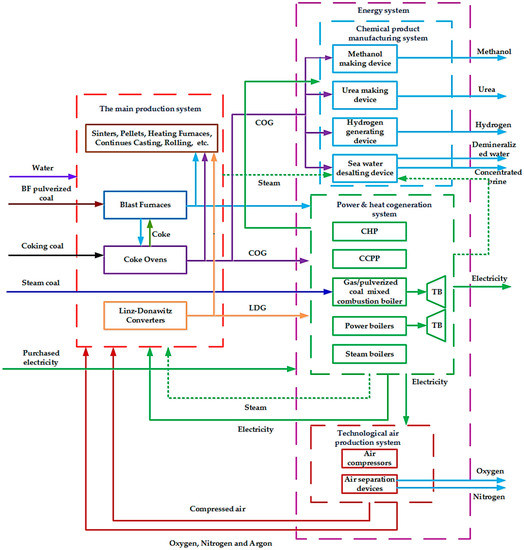

In energy systems, chemical product production systems can choose from the following processes: hydrogen production, methanol production, urea production, and seawater desalination. The corresponding products include hydrogen, methanol, urea, saltwater, and concentrated saltwater, and these products can be sold [30,31]. Power and steam production systems and optional equipment types, including CCPPs [32], combined heat and power (CHP) systems [33], gas/pulverized coal-fired generator sets [34], electric boilers, and steam boilers, use byproduct gas and steam coal to produce electricity and steam. At the same time, electricity and steam support the steel production process and part of the steam supply desalination. Technical gas systems include air compressors and air separation units that primarily consume power and produce technical gases, including compressed air, argon, nitrogen, and oxygen. The technical gas supply outside the steel production system, which consists of the remaining liquid nitrogen and liquid oxygen, are sold. The energy systems of integrated steel enterprises are shown in Figure 1. In Figure 1, the energy system of the iron and steel enterprise contains almost all possible energy conversion equipment types. In fact, certain energy conversion equipment types are selected by an iron and steel enterprise.

Figure 1.

Schematic flow of an iron and steel enterprise energy system.

As shown in the above figure, the energy source distribution is different if the energy system has different process configurations. Due to the existence of energy substitution, the distributions of different energy sources affect each other. For example, a power boiler can simultaneously use BFG, LDG, and COG, and the three types of gases can be substituted for each other within a certain range. In a gas/pulverized coal-fired generator unit, gas and pulverized coal can also be substituted for each other within a certain range [35]. It is necessary to optimize the configuration of energy conversion equipment in the energy system and the coupled optimal distribution of various energy sources. This consideration means that we should choose the right energy conversion equipment and determine the types and quantities of energy sources to be distributed, thereby realizing the design optimization of the energy system of an iron and steel enterprise. At present, the design of an energy system is mainly based on experience and lacks evaluation of the overall structure of the energy system and energy conversion efficiency. In this paper, the overall optimization design of an energy system will be carried out to achieve the rational distribution and utilization of energy source.

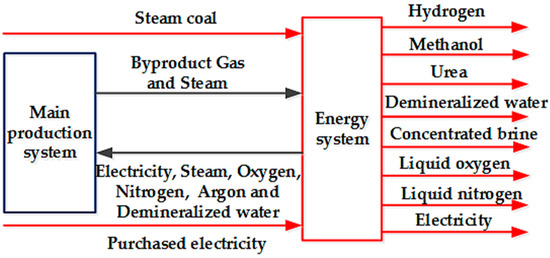

To ensure power demand and reduce cost, most integrated iron and steel corporations have built on-site power plants (OSPP) to cover 50–80% of the power demand, and the remaining demand is supplied by the main grid [36], which should be purchased. Both the purchased electricity and the self-produced electricity maintain the power balance of iron and steel enterprises. The goal of energy system design optimization is to optimize the equipment configuration of the energy system and energy source distribution to meet the energy source requirements of the steel production system and to maximize the economic benefits of the energy system. That is, maximum the economic benefits of the energy system is equal to the value of the maximum energy system products for sale minus the purchase cost of the input energy source. Since the input energy source, such as coking coal, pulverized coal injection into a BF, and water input, are determined by the production scale of the steel production system, the output scale is unchanged, and the input levels of the three media are constant, and optimization is not considered. Therefore, the above formula is transformed into: Maximum economic benefits of the energy system is equal to the value of the maximum energy system products for sale minus the purchase cost of the steam coal, and then minus the purchase cost of electricity, and the specific optimizable input and output energy source are shown in Figure 2.

Figure 2.

Input–output diagram of the energy source for an iron and steel enterprise.

3. Mathematical Model

3.1. Application Scope of the Model

The mathematical model for the optimal distribution of multiple energy sources was established for a typical iron and steel manufacturing process with a large BF-large LD-continuous casting machine (CCM)-hot rolling mill (HRM) system. The model involves 27 production processes and related devices, including the main production, energy conversion, and auxiliary processes, and over 20 energy sources, including coal gas, steam, and technical gas. The optimization model was used to determine the optimal energy distribution considering mutual conversions, device constraints, and supply–demand balances among the various energy sources to gain the optimized distribution plans. The main feature of this model is its ability to optimize the distributions of all secondary energy sources and of the main primary energy sources, rather than being limited to one or a few kinds of secondary energy sources.

Our model is suitable for steel plants with different process configurations and can help guide the factory to select among energy conversion devices. The model is applicable not only to iron and steel production processes, but also to other process manufacturing plants through appropriate modifications.

3.2. Model Assumptions

A number of complicated factors influence the energy-consuming devices during the various production processes involved in iron and steel manufacturing. In addition, various energy sources coexist and interact with each other in the process. To simplify the problem, the following assumptions have been made:

- (1)

- The external inputs of coking coal, pulverized coal injection into the BF, and water meet the needs of the iron and steel-making system, and the output scale of the iron and steel-making system is fixed; the input levels of the three media are unchanged.

- (2)

- Steam coal is provided to the pulverized coal/gas mixed combustion boiler power generators, and the consumption (input) of steam coal is variable.

- (3)

- Electricity can be purchased from the public grid or sold to the public grid.

- (4)

- The byproduct gas and steam balance the supply and demand within the enterprise; that is, the input and output are both 0.

- (5)

- The energy source can be mutually converted and utilized to meet the process requirements. In the case of a hot rolling heating furnace, LDG can replace part of the COG given the developments in regenerative heating technology.

- (6)

- If the energy conversion process/device generates multiple products, the output levels of the main products and the yields of the byproducts will be in a certain proportion.

3.3. Objective Function

The optimal design model of the energy system is aimed at making rational use of the energy sources and improving the energy utilization efficiency, thereby increasing the economic benefits of the energy system. Therefore, the objective is to maximize the economic benefits of the energy system. The economic benefits of the energy system are equal to the value of the takeout products of the energy system minus the cost of purchasing energy sources minus the cost of pollution in the energy conversion process. The objective function of the model is established as follows:

where n represents the number of output and input energy source types of the energy system, represents the market price of the output or input of energy source i, and is the output or input amount. If is smaller than zero, energy i needs to be input (purchased); if energy source i equals zero, energy source i has reached a supply–demand balance inside the iron and steel enterprise; if is greater than zero, energy source i can be output, namely, the outward supply, where represents the environmental cost of the emission of polluting gas pi and represents the amount of emission of polluting gas pi.

3.4. Constraint Conditions

3.4.1. Energy Supply and Demand Balance Constraints

Iron and steel plants are characterized by large, complex structures that can be divided into three subsystems, namely, the main production system, the energy system, and the auxiliary system. The energy balance for an iron and steel enterprise is based on the energy balance principle, and can be expressed by Equation (2):

where is the recycled amount of energy source i in working procedure j, refers to the usage amount of energy source i in working procedure j, is the emitted amount of energy source i, and m, k, and l indicate the number of production processes/devices involved in the main production system, the energy system, and the auxiliary system, respectively.

3.4.2. Energy Source Constraints

In the case of energy sources such as coal, gas, and steam, the sum of the amounts of energy consumed and emitted by the various users in the energy system should not exceed the generated amount of energy, which can be compactly stated as follows:

As for the other energy sources, the sum of the energy consumption, the maximum sales volume, and the emitted amount should not be greater than the generated amount of energy:

where denotes the maximum sales volume of energy source i.

3.4.3. Operational Constraints of the Energy-Consuming Device

The operational constraints of the energy-consuming device are mainly due to its process heating requirements. In other words, it is necessary for a specific kind of coal gas to meet the temperature requirements of the heating device. The heating temperature is directly determined by the calorific value of the gas. If the calorific value is too low, the heating temperature requirements cannot be satisfied; if the calorific value is too high, it will adversely affect the heating. Thus, the calorific value of the gas is only allowed to fluctuate within a certain range. This constraint can be expressed as follows:

where denotes the calorific value of the mixed gas used in working procedure j; , , and represent the calorific values of BOG, LDG, and COG, respectively; and and represent the minimum and the maximum calorific values of the gas required by working procedure j, respectively.

3.4.4. Balance Constraints of the Material Transformation

During the iron and steel manufacturing process, conversion between different energy sources can occur. For example, the byproduct gas in the boiler can be converted into steam. In the conversion process, the steam production is equal to the product of gas consumption multiplied by the energy conversion efficiency. The balance of energy conversion can be stated as follows:

where indicates the efficiency of energy conversion from source l to source i in working procedure j.

3.4.5. Energy Balance Constraints

Energy balance constraints can generally be divided into two types. Based on the first law of thermodynamics, the first type refers to the amount of unchanged energy during the conversion process, which mainly corresponds to the energy balance among the gas, steam, and electricity during the mutual conversion processes. The other type requires a constant total energy amount during the replacement of energy sources to guarantee a constant production capacity, which mainly corresponds to the replacement of the energy source in the heating furnace.

(1) Gas-electricity conversion energy balance

(2) Gas-steam conversion energy balance

(3) Steam-electricity conversion energy balance

(4) Energy balance caused by the mutual replacement of energy source in the heating furnace.

The heating furnace contains regenerative heating technology. It is possible to use BOG instead of COG to establish the equilibrium constraint stated in Equation (11), where represents the power generation efficiency or the thermal efficiency of the steam production device; subscripts s1, s2, and s3 indicate high-pressure steam, medium-pressure steam, and low-pressure steam, respectively; represents the calorific value of electricity; , , and refer to the enthalpy values of the three types of steams; and , , and indicate the initial energy consumption levels of BOG, LDG, and COG in working procedure j, respectively, when the production rate of the iron and steel manufacturing process is constant.

3.4.6. CCPP Constraints on the BFG Consumption

The CCPP fuel is mainly low calorific value BFG in an iron and steel enterprise. As a CCPP has a high requirement for the stability of the gas supply, the plant will be shut down when the gas supply is smaller than its minimum requirement. To avoid an insufficient supply of BFG caused by abnormal conditions, such as BF repair, the surplus BFG cannot be completely consumed by the CCPP, and other power generation devices should be equipped. Therefore, the range of BFG consumed by the CCPP should be set as follows:

where represents the amount of BFG consumed by the CCPP and and represent the minimum consumption levels of BFG by the CCPP and the maximum consumption level of BFG by the CCPP, respectively.

3.4.7. Other Constraints

(1) Non-negativity constraints

(2) Initial value constraints

4. Case Analysis

4.1. Basic Information about the Iron and Steel Plant

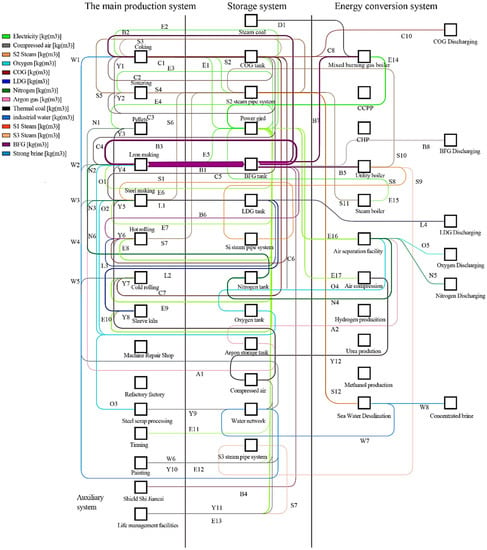

The optimization model established in this study is mainly applicable to the typical manufacturing process of a large-scale iron and steel plant, featuring a large BF-large LD-CCM-HRM system. As a large-scale modernized iron and steel enterprise, the Chinese S plant was chosen as a case to validate our model. The diagram reflects the energy system of the S steel plant, as shown in Figure 3. Table 1 summarizes the market prices of the energy source. Table 2 provides the surplus or demand amounts of the energy source in the main production system. The surplus energy source can be used for energy conversion in the energy system. The demand amounts of the energy source must be supplied by the energy system or imported from outside the iron and steel enterprise. The data were collected from year-averaged values of the S steel plant.

Figure 3.

Network diagram of the actual energy system in the S steel plant.

Table 1.

Market prices of the energy source.

Table 2.

The surplus or demand amounts of the energy source.

4.2. Analysis of the Optimization Results

To maintain the steel production capacity of the S steel plant, the production and consumption levels of the secondary energy sources in the main production system must remain unchanged. The heating furnace is considered an energy conversion device, where part of the consumed gas can be replaced by another gas.

The model can be used to optimize the distribution of energy source in the energy conversion process according to two different schemes. The first scheme keeps the original process configuration without changing the energy conversion equipment, thus only modifying the energy source distribution. The second scheme adds new energy conversion equipment, changes both the original process and the distribution of the energy source, and forms a new process. The energy conversion equipment introduced in the latter scheme includes the CCPP, the CHP system, and the production of hydrogen, urea, and methanol. Table 3 shows the power distribution schemes of the S steel plant before and after model optimization. After optimizing the energy source distribution under the condition of the original energy conversion equipment, the steam boiler with a low power generation rate (power generation efficiency of 26%) no longer generates electricity. At the same time, the amount of electricity generated by the pulverized coal/gas mixed combustion boiler is also reduced. The analysis shows that the power generation efficiency of the pulverized coal/gas mixed combustion boiler is low, and the consumption level of steam coal is reduced after considering the pollution. Thus, the power generation of the pulverized coal/gas mixed combustion boiler is reduced. After the introduction of new power generation equipment (CCPP and CHP) and energy conversion technology (urea production, methanol production, and hydrogen production), the BFG, LDG, and COG are fully utilized, and the utilization rates of the energy source are improved. The CCPP realizes the maximum power generation, and the remaining BFG and LDG are distributed to the CHP system and pulverized coal/gas mixed combustion boiler for power generation. Due to the addition of new energy conversion technology, more electric energy needs to be consumed. Therefore, it is necessary to purchase steam coal and electricity to maintain the balance between the supply and demand of electricity.

Table 3.

Comparison between the model optimization results and practical conditions of electric power production.

Table 4 shows the gas distribution plans of the S steel plant before and after optimization. After optimization on the basis of the original equipment, the BFG, LDG, and COG are fully utilized. The amount of emission is reduced to zero. When new energy conversion technologies are added, the COG is used to produce urea, and the BFG and LDG are fully used for power generation. Overall, through optimization of the model, the utilization rates of energy source can be improved, and zero emission of gas can be realized.

Table 4.

Comparison between the model optimization results and practical conditions of byproduct gas distribution.

As shown in Table 5, prior to optimization of the energy source, the economic benefits of the energy system products for sale in the S plant are −28.16 CNY/t steel, indicating that the S plant needs to spend 24.16 CNY for the outsourcing of energy for each ton of steel the plant produces and 4 CNY to pay for the environmental costs. In the first kind of optimized scheme, under the current equipment and technological conditions, after optimization, the economic benefits of the energy system are −12.39 CNY/t steel; namely, the costs of the energy systems (including pollution costs) are 12.39 CNY/t steel. Compared with the actual situation of the S plant, the economic benefits of the energy system increased by 15.77 CNY/t steel. This result is significantly higher than that before the optimization, indicating that, in the case of a stable production, the model provides the optimal distribution plans of the different energy sources with significant economic advantages in a practical case.

Table 5.

Comparison between the model optimization results and practical conditions of the economic benefits of the energy system.

In the second kind of scheme, the model is used to optimize the secondary energy conversion device configurations of the S steel plant. As shown in Table 4, the energy sources are optimally distributed after the process modification. Meanwhile, the BOG, LDG, and COG can be utilized more efficiently, and their emissions are reduced by 53.41, 5.66, and 7.95 m3/t steel, respectively. The economic benefits of the energy system of the S plant are 152.10 CNY/t steel. Compared with the actual situation of the S plant, the economic benefits of the energy system increased by 180.26 CNY/t steel. This result is significantly superior to that before the optimization. Compared with the S plant process before the optimization, the new techniques introduced in the optimized process include the CCPP and urea production. This result also indicates that the CCPP performs better than the CHP system in electric power production and that the COG will be utilized more efficiently to produce urea but not hydrogen or methanol. When urea, hydrogen, and methanol are under the price conditions shown in Table 1, considering the energy conversion rates and economic benefits of the energy system and other factors, the selection of COG to produce urea is more conducive to the optimization of the entire energy system.

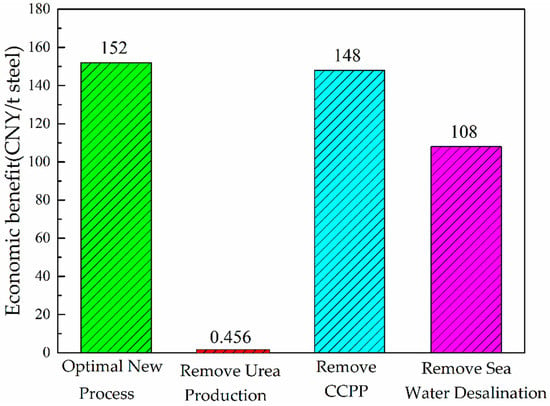

4.3. Economic Benefits of Energy System Analysis of Different Secondary Energy Conversion Devices

The secondary energy sources of the iron and steel production process can be converted and exploited in a number of ways. A sensible choice for the energy utilization device may significantly improve the energy conversion efficiency and enhance the economic benefits. The configuration of the energy conversion process mainly contains the CCPP, urea production, and sea water desalination in the optimal new process. Figure 4 shows the optimization results obtained after removing only one secondary energy source conversion device from the optimal new process of the S plant.

Figure 4.

The best economic benefits of the energy system after removal of different secondary energy source conversion devices.

For the S plant, after removing the urea production plant, CCPP, and desalination plant, the best economic benefits of the energy system are 0.456, 148, and 108 CNY/t steel, respectively. The results changed greatly when removing the urea production and sea water desalination plants, which shows that the urea production and the sea water desalination processes have the greatest impacts on the energy system. We find that these two processes are the main working procedures that consume COG and steam, and their energy utilizations are relatively high, so the influences of their energy structures are greater than those of the other processes. This model can be tuned to fit different steel manufacturing processes to calculate the economic benefits of an energy system with different secondary energy conversions and utilization devices.

4.4. Effects of Different Energy Sources Prices on the Economic Benefits of the Energy System

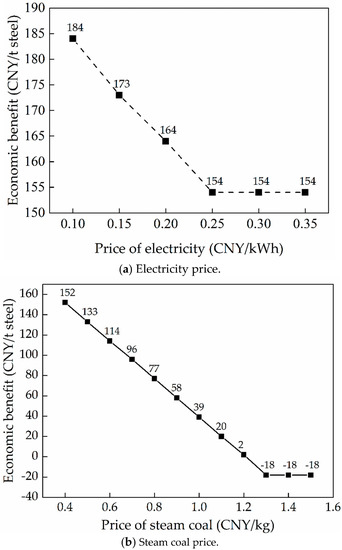

The main energy source purchased by iron and steel enterprises are electric power and steam coal, and these two prices have been changing in the market. Therefore, it is necessary to discuss the impacts of price changes on the energy structure. Through the model, we can draw the trend of the economic benefits of the energy system with the prices of steam coal and purchased electricity, as shown in Figure 5a,b.

Figure 5.

The effects of the steam coal price and electricity price on the economic benefit of the energy system.

It can be seen from Figure 5a that the economic benefits of the energy system decreased with the increase in the price of the purchased electricity; when the price of the purchased electricity was 0.25 CNY/kWh or higher, the economic benefits of the energy system remained unchanged. The reason is that the power generation cost is 0.25 CNY/kWh and when the purchase price is higher than the cost, the steel plant can fully utilize power plants and no longer needs to purchase electricity. It can be concluded that the steel plant should flexibly adjust the energy structure within a certain range according to the market price of the energy source for purchase or sale to obtain the maximum economic benefits of the energy system.

As shown in Figure 5b, the economic benefits of the energy system of the S steel plant decreases with increasing steam coal price. When the price of steam coal increases from 0.4 to 1.3 CNY/kg, the economic benefits of the energy system decrease from 152 to −18 CNY. When the price reaches 1.3 CNY, the economic benefits of the energy system tend to be fixed. When the price of steam coal is low, a large amount of steam coal is used to generate electricity to maintain the balance of electricity. When the price of steam coal is too high, the latter will increase the power generation levels by other energy sources or increase the purchased electricity amount to maintain the balance of electricity, and even completely eliminate the purchase of steam coal.

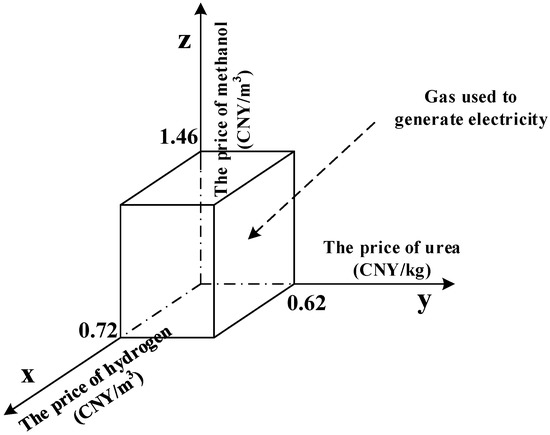

In the model, the COG can be used to produce hydrogen, urea, and methanol and can also be used as fuel to generate electricity. Therefore, it is necessary to discuss the influences of the prices of hydrogen, urea, and methanol on the utilization of COG.

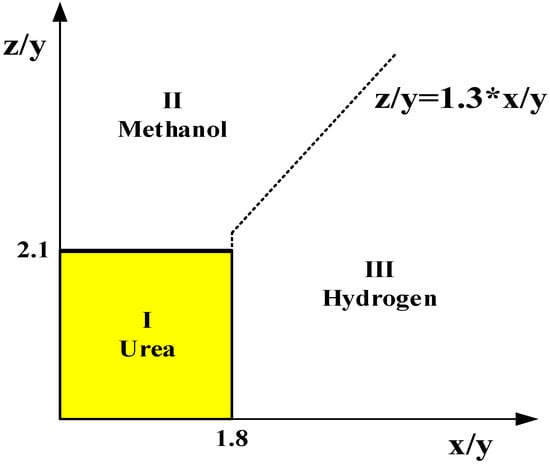

As seen from Figure 6, when the three resource prices of hydrogen, urea and methanol fall within the area of the cube body (x < 0.72 and y < 0.62 and z < 1.46), COG should be used as fuel for electricity generation. Otherwise, COG should be used as a chemical product raw material. It can also be seen from Figure 6 that when the respective prices of hydrogen, urea, and methanol are 0.72 CNY/m3, 0.62 CNY/kg, and 1.46 CNY/m3, the COG should be used to generate electricity if the price of purchased electricity is more than 0.5 CNY/kWh, whereas it should be used to produce chemical products if the price of purchased electricity is less than 0.5 CNY/kWh. Figure 7 shows the different chemical products produced by COG in different conditions, where zones I, II, and III represent urea, methanol, and hydrogen, respectively, x/y represents the ratio of the hydrogen price to the urea price, and z/y represents the ratio of the methanol price to the urea price.

Figure 6.

The choice between generating electricity and chemical utilization of coke oven gas (COG).

Figure 7.

The choice of different utilization way of COG.

4.5. The Effects of Different Emission Charge Standards

Both the surplus gas power generation and purchased steam coal power generation will produce polluting gases, and different standards of pollution emission costs will affect the distribution of gas and the utilization of steam coal. Two typical possible emission charge standards in China are discussed in this paper. EC1, based on China’s current pollution damage fee collection standard, has been in effect since 2003. This standard is based on partial compensation of the statistical monetary losses from environmental pollution and destruction of environmental resources; EC2 is based on the pollutant abatement costs of mature technologies [37]. Table 6 shows the different environmental charge standards.

Table 6.

Different standards of environmental pollution costs.

Table 7 shows the steam coal consumption levels, pollution costs, and total benefits of the new process with non-polluting costs or two different pollution cost standards. Compared with EC1, when using the EC1 standard, the pollution costs will increase sharply from 6.49 to 87.12 CNY/t steel, while the amount of purchased steam coal will be significantly reduced from 192.07 to 151.38 kg/t. It can be concluded that enterprises should adopt a flexible energy outsourcing strategy based on specific environmental policies. Comparing EC1 and EC2, the cost of pollution accounted for a large part of the total costs under EC2, and the amount of coal purchased at this time was greatly reduced.

Table 7.

Steam coal purchased, pollution costs, and economic benefits of the new process.

5. Conclusions

The system optimization design of an energy system is an important issue in the design phase of an iron and steel enterprise. However, there are few studies on the problem. In response to this issue, this paper proposed a linear programming model for the optimal distribution of all energy sources and the selection of the energy conversion device in an iron and steel enterprise, and the following conclusions can be drawn.

- (1)

- The model can optimize the distribution of all energy sources instead of a single one or a few. Two factors are considered in this model, which were ignored in previous studies. The first factor is the configuration of the secondary energy conversion devices; the second factor includes the interchange and interaction effects among the different energy sources.

- (2)

- The model was applied to a practical case study (the S plant) to maximize its energy system economic value. Compared with the actual production situation, the economic value was greatly enhanced after the optimization, thereby proving the validity of the model.

- (3)

- The effects of different devices for the conversion of secondary energy sources on the energy source distribution and the economic benefits of the S plant were also analyzed with the model. For the S plant, after adding the CCPP, CHP system, and urea production facility, the best economic benefits of the energy system were increased by 180.26 CNY/t steel.

- (4)

- The influences of different electricity and steam coal prices and different standards of environmental pollution costs on the optimization results were analyzed. The sensitivities of the model to the prices of chemical products and the prices of secondary energy sources were also analyzed.

Author Contributions

Data curation, Z.H.; Formal analysis, Z.H.; Funding acquisition, D.H.; Methodology, K.F.; Project administration, D.H.; Resources, P.L. and Y.J.; Software, P.L. and Y.J.; Writing—original draft, Z.H.; Writing—review & editing, D.H. and K.F.

Funding

The authors are grateful for the financial support provided by the General Programme of the National Natural Science Foundation of China (Grant No. 51574032).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Abbreviation | |

| BF | blast furnace |

| BFG | blast furnace gas |

| LDG | Linz–Donawitz process gas |

| CCM | continuous casting machine |

| CDQ | coke dry quenching |

| COG | coke oven gas |

| HRM | hot rolling mill |

| CRM | cold rolling mill |

| LF | ladle furnace |

| TRT | blast furnace top gas recovery turbine unit |

| CCPP | combined cycle power plant |

| CHP | combined heat and power |

| Parameters | |

| Ci | market price of energy source i |

| environmental cost of the emission of polluting gas pi | |

| calorific value of electricity | |

| calorific value of high-pressure steam | |

| calorific value of medium-pressure steam | |

| calorific value of low-pressure steam | |

| maximum sales volume of energy source i | |

| calorific value of the mixed gas used in working procedure j | |

| calorific value of blast furnace gas | |

| calorific value of Linz–Donawitz process gas | |

| calorific value of coke oven gas | |

| minimum calorific value of the gas required by working procedure j | |

| maximum calorific values of the gas required by working procedure j | |

| efficiency of energy source l to be converted into energy source i in working procedure j | |

| power generation efficiency in the power generation process, which represents the thermal efficiency in the steam production process | |

| initial energy consumption of blast furnace gas in working procedure j initial energy consumption of the Linz–Donawitz process gas in working procedure j | |

| initial energy consumption of coke oven gas in working procedure j | |

| minimum consumption of blast furnace gas by the CCPP | |

| maximum consumption of blast furnace gas by the CCPP | |

| Variables | |

| recycled amount of energy source i in working procedure j | |

| usage amount of energy source i in working procedure j | |

| emitted amount of energy source i Ui output or input amount of energy source i | |

| emission amount of polluting gas pi | |

| amount of blast furnace gas consumed by the CCPP | |

| Subscripts | |

| i | index for the energy source |

| j | index for the processes/equipment types |

| pi | index for the polluting gases |

| m | number of production processes/equipment types in the main production system |

| k | number of procedures/equipment types in the energy system |

| l | number of procedures/equipment types in the energy system |

| s1 | high-pressure steam |

| s2 | medium-pressure steam |

| s3 | low-pressure steam |

References

- National Bureau of Statistics of China. Consumption of Total Energy and Its Main Varieties by Sector. Available online: http://data.stats.gov.cn/english/easyquery.htm?cn=C01 (accessed on 9 June 2016).

- Babich, A.; Senk, D. Coal use in iron and steel metallurgy. In Coal Handbook Towards Cleaner Production Coal Utilisation; Woodhead Publishing Limited: Cambridge, UK, 2013; Volume 9, pp. 267–311. [Google Scholar]

- Kong, H.N.; Qi, E.; He, S.G.; Li, G. MILP Model for Plant-Wide Optimal By-Product Gas Scheduling in Iron and Steel Industry. J. Iron Steel Res. (Int.) 2010, 7, 34–37. [Google Scholar] [CrossRef]

- Li, H.; Bao, W.; Xiu, C.; Zhang, Y.; Xu, H. Energy conservation and circular economy in China’s process industries. Energy 2010, 11, 4273–4281. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Yang, J.; Cai, J.J.; Sun, W.Q.; Huang, J. Optimal allocation of surplus gas and suitable capacity for bu_er users in steel plant. Appl. Therm. Eng. 2016, 115, 586–596. [Google Scholar] [CrossRef]

- Ma, S.H.; Wen, Z.G.; Chen, J.N.; Wen, Z.C. Mode of circular economy in China’s iron and steel industry: A case study in Wu’an city. J. Clean. Prod. 2014, 1, 505–512. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, J.J.; Du, T. Optimum utilisation of gas system in incorporated business enterprise of iron and steel. Energy Metall. Ind. 2005, 5, 9–11. [Google Scholar]

- Li, L.; Li, H.J. Forecasting and optimal probabilistic scheduling of surplus gas systems in iron and steel industry. J. Cent. South Univ. 2015, 4, 1437–1447. [Google Scholar] [CrossRef]

- Zhang, Q.; Gu, Y.L.; Ti, W.; Cai, J.J. Supply and Demand Forecasting of Blast Furnace Gas Based on Artificial Neural Network in Iron and Steel Works. Adv. Mater. Res. 2012, 443, 183–188. [Google Scholar] [CrossRef]

- Liu, H.J.; Wang, J.J.; Wang, H.; Meng, H. Application of Elman Neural Network with HP Filter in the Trend Supply of Self-Provided Power Plant Forecasting in the Iron and Steel Industry. Adv. Mater. Res. 2013, 712, 3211–3214. [Google Scholar] [CrossRef]

- Porzio, G.F.; Fornai, B.; Amato, A.; Matarese, N.; Vannucci, M.; Chiappelli, L.; Colla, V. Reducing the energy consumption and CO2 emissions of energy intensive industries through decision support systems—An example of application to the steel industry. Appl. Energy 2013, 112, 818–833. [Google Scholar] [CrossRef]

- Han, Z.Y.; Liu, Y.; Zhao, J.; Wang, W. Real time prediction for Linz–Donawitz process gas tank levels based on multi-output least square support vector regressor. Control Eng. Pract. 2012, 12, 1400–1409. [Google Scholar] [CrossRef]

- Sheng, C.Y.; Zhao, J.; Liu, Y.; Wang, W. Prediction for noisy nonlinear time series by echo state network based on dual estimation. Neurocomputing 2012, 82, 186–195. [Google Scholar] [CrossRef]

- Kim, J.H.; Yi, H.S.; Han, C. Novel MILP Model for Plantwide Multiperiod Optimization of Byproduct Gas Supply System in the Iron- and Steel-Making Process. Chem. Eng. Res. Des. 2003, 8, 1015–1025. [Google Scholar] [CrossRef]

- Kong, H.N.; Qi, E.; Li, H.; Li, G.; Zhang, X. An MILP model for optimization of byproduct gases in the integrated iron and steel plant. Appl. Energy 2010, 7, 2156–2163. [Google Scholar] [CrossRef]

- Zhao, X.C.; Bai, H.; Shi, Q.; Lu, X.; Zhang, Z.H. Optimal scheduling of a byproduct gas system in a steel plant considering time-of-use electricity pricing. Appl. Energy 2017, 195, 100–113. [Google Scholar] [CrossRef]

- Zhao, X.C.; Bai, H.; Lu, X.; Shi, Q.; Han, J.H. A MILP model concerning the optimisation of penalty factors for the short-term distribution of byproduct gases produced in the iron and steel production process. Appl. Energy 2015, 2, 142–158. [Google Scholar] [CrossRef]

- Shi, Q.; Zhao, X.C.; Bai, H.; Xing, W.L.; Zhang, Z.H. Short-term distribution model of byproduct gases in iron and steel enterprise. Iron Steel 2016, 8, 81–89. [Google Scholar]

- Zhang, Q.; Shen, Y.; Wang, Y. Optimal Distribution of Gases in integrated Iron and Steel Works. Appl. Mech. Mater. 2014, 492, 586–589. [Google Scholar] [CrossRef]

- Zhang, Q.; Ti, W.; Cai, J.J.; Du, T.; Wang, A. Multi-Period Optimal Distribution Model of Energy Medium and Its Application. J. Iron Steel Res. Int. 2011, 8, 37–41. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, J.; Gao, J. Gas-steam-power system coupling optimization and application in iron and steel enterprises. J. Chem. Eng. 2018, 7, 3149–3158. [Google Scholar]

- Larsson, M.; Wang, C.; Dahl, J. Development of a method for analyzing energy, environmental and economic efficiency for an integrated steel plant. Appl. Therm. Eng. 2006, 13, 1353–1361. [Google Scholar] [CrossRef]

- Gadhamshetty, V.; Gude, V.G.; Nirmalakhandan, N. Thermal energy storage system for energy conservation and water desalination in power plants. Energy 2014, 4, 938–949. [Google Scholar] [CrossRef]

- Li, J. Discussion on type selection of gas power generation in iron and steel enterprises. Henan Metall. 2014, 4, 23–24. [Google Scholar]

- Wang, H.; Wang, J.; Gao, W. Study on gas utilization for resource in iron and steel factory. Baosteel Tech. Res. 2010, s1, 133. [Google Scholar]

- Joseck, F.; Wang, M.; Wu, Y. Potential energy and greenhouse gas emission effects of hydrogen production from coke oven gas in U.S. steel mills. Int. J. Hydrogen Energy 2008, 4, 1445–1454. [Google Scholar] [CrossRef]

- He, D.F.; Liang, C.; Ai, L.X. Energy utilization evaluation oriented to energy flow network in the iron and steel enterprises. Energy Metall. Ind. 2016, 1, 3–7. [Google Scholar]

- Chen, L.G.; Meng, F.K.; Sun, F.R.; Yang, B. Analysis on energy-saving potential of recycle waste hest of iron and steel industry based on thermoelectric power generation technology. Res. Iron Steel 2013, 6, 40–44. [Google Scholar]

- Razzaq, R.; Li, C.S.; Zhang, S.J. Coke oven gas: Availability, properties, purification, and utilization in China. Fuel 2013, 2, 287–299. [Google Scholar] [CrossRef]

- Yang, Z.B.; Zhang, Y.Y.; Wang, X.G.; Zhang, Y.W. Steam Reforming of Coke Oven Gas for Hydrogen Production over a NiO/MgO Solid Solution Catalyst. Energy Fuels 2011, 2, 785–788. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, L.; Li, H.Q.; Fujita, T.; Ohnishi, S.; Tang, Q. Analysis of low-carbon industrial symbiosis technology for carbon mitigation in a Chinese iron/steel industrial park: A case study with carbon flow analysis. Energy Policy 2013, 61, 1400–1411. [Google Scholar] [CrossRef]

- Balli, O.; Aras, H.; Hepbasli, A. Exergetic performance evaluation of a combined heat and power (CHP) system in Turkey. Int. J. Energy Res. 2007, 9, 849–866. [Google Scholar] [CrossRef]

- Feron, P. The potential for improvement of the energy performance of pulverized coal fired power stations with post-combustion capture of carbon dioxide. Int. J. Greenh. Gas Control 2009, 1, 1067–1074. [Google Scholar] [CrossRef]

- Costa, M.; Silva, P.; Azevedo, J. Measurements of gas species, temperature, and char burnout in a low-no x pulverized-coal-fired utility boiler. Combust. Sci. Technol. 2003, 2, 271–289. [Google Scholar] [CrossRef]

- Yang, J.Y.; Chai, S.X.; Yang, C. Economic benefit between autonomous power and purchasing power from state grid in iron and steel enterprises. J. Northeast. Univ. 2015, 7, 980–984. [Google Scholar]

- Luo, X.L.; Zhang, B.J.; Chen, Y.; Mo, S.P. Operational planning optimization of multiple interconnected steam power plants considering environmental costs. Energy 2012, 1, 549–561. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).