Abstract

In the present study, Autodesk Fusion 360 software (which includes the A360 environment) is used to train engineering students for the demands of the industry 4.0. Fusion 360 is a tool that unifies product lifecycle management (PLM) applications and 3D-modeling software (PDLM—product design and life management). The main objective of the research is to deepen the students’ perception of the use of a PDLM application and its dependence on three categorical variables: PLM previous knowledge, individual practices and collaborative engineering perception. Therefore, a collaborative graphic simulation of an engineering project is proposed in the engineering graphics subject at the University of La Laguna with 65 engineering undergraduate students. A scale to measure the perception of the use of PDLM is designed, applied and validated. Subsequently, descriptive analyses, contingency graphical analyses and non-parametric analysis of variance are performed. The results indicate a high overall reception of this type of experience and that it helps them understand how professionals work in collaborative environments. It is concluded that it is possible to respond to the demand of the industry needs in future engineers through training programs of collaborative 3D modeling environments.

1. Introduction

At the end of the 20th century, companies indicated that engineers were very individualistic. This profile did not meet the new needs of the industry, such as task management between several work teams or design and manufacturing time. For this, communication between all project members was a major requirement [1]. This lack inevitably relates to the fact that in engineering education the lecture method was the main teaching approach [2]. Today, human collaboration and interoperability of software systems are essential requirements in industry 4.0 [3].

In the industry, product lifecycle management (PLM) applications have been used for decades to reduce design time and to manage collaborative work of the product engineering teams [4]. So, 3D modeling software companies for engineering such as Pro-Engineer, Autodesk or Solidworks offer collaborative work platforms (Autodesk Vault, PTC PLM Cloud or 3D Experience) that are mainly aimed at large companies and combine PLM tasks and 3D modeling, that we will abbreviate as PDLM (product design and life management). Nevertheless, the cost and use complexity of these collaborative platforms makes their implementation in educational engineering environments very difficult.

Meanwhile, collaborative pedagogies and project-based learning methods are becoming increasingly popular. Their combination with cloud-based software creates a simulation of the professional context. So, this approach fosters coordination and communication between team members while solving challenges. For this, several cloud technologies have been tested in education to improve collaborative learning (Google Docs, Skype, Dropbox, Facebook, Prezi, Skype, etc.) [5]. Collaborative writing tasks in distance engineering education have also been tested with web-based tool experiences and have obtained high student acceptability [6], deeper learning and high motivation [7]. Moreover, they promote a self-motivational environment and help students to comprehend the engineering profession [8]. Likewise, e-journals allow sharing laboratory resources among colleagues with certain limitations due to technical compatibility problems [9]. However, they focus on communication and writing [10]. They are not entirely appropriate for particular engineering activities such as design and 3D modeling.

In Spain, engineering graphics professors have begun to assume the shift towards multi-method active teaching [11] and the inclusion of ICT (Information and Communication Technologies) methodologies [12,13]. Furthermore, project-based learning stands as one of the most appropriate methods for the development of professional competencies of the engineer [14].

In this context, a collaborative experience has been carried out with civil engineering students at the University of La Laguna in the academic year 2018–2019. The novelty of this study relies on the use of categories to deepen the student perception of usability of a PDLM software through a categorical analysis of variance, which is essential to know how to design training experiences for industry 4.0. Autodesk Fusion 360 software is used to develop the graphic simulation of an engineering project. This cloud-based software incorporates PLM tools and a 3D modeling synchronous environment. This paper focuses on the explanation of the educational experience and the student’s perception of the resolution of an engineering project under the approach of collaborative design as training for industry 4.0.

At the University of La Laguna, engineering graphics professors teach under a project-based learning approach. In groups, students design an engineering product made of five components, which they model in 3D solids. Then, they develop 2D drawings and produce dynamic animations and create some realistic infographics. In 2013, Autodesk Inventor and Dropbox were combined to achieve collaboration in the 3D modeling process [15,16]. This system was a simulation of a PDLM application in terms of functionality, which allowed several students to work simultaneously in the creation of the project graphic documentation. However, this system had the following limitation: students could not use simultaneously the same design file. A similar experience took place at the School of Engineering Arts et Metiers ParisTech by combining Catia V5 and Dropbox [17].

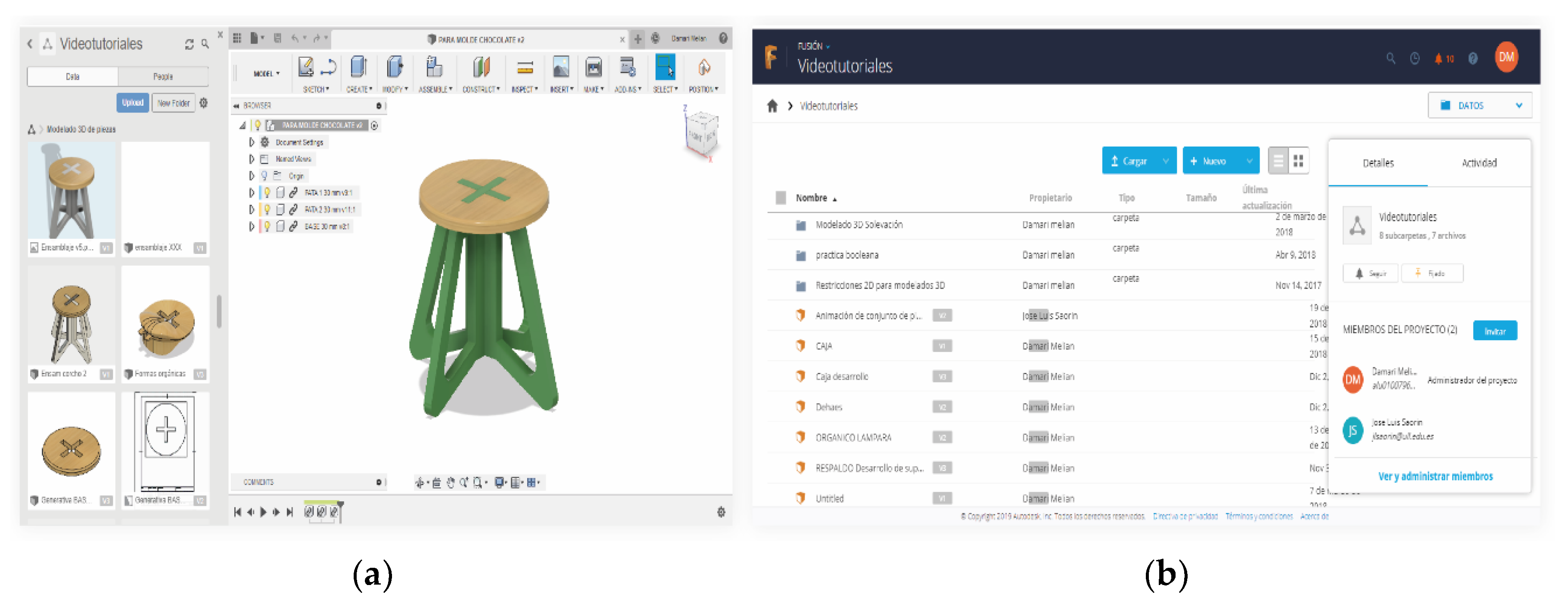

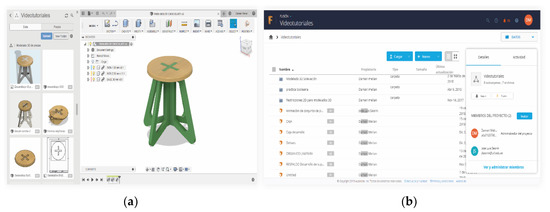

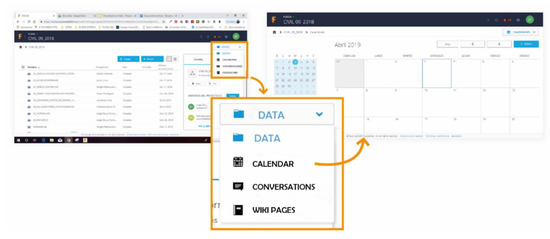

The recent arrival of Autodesk Fusion 360 solves some of the tasks reserved for the PLM programs that the engineering companies use. Fusion 360 combines 3D modeling with the advantages of cloud computing tools (Figure 1) through cloud-stored files in the Autodesk cloud (called A360). It naturally allows collaborative 3D modeling, which is appropriate for educational environments and fab labs [18].

Figure 1.

(a) A 3D modeling environment and (b) file web environment (A360).

In 2017 Vila, Ugarte, Ríos and Abellán [19] proposed the use of PLM systems to encourage collaboration among engineering students. They compared Fusion 360 and 3D Experience in terms of data management, decision support, personal data management, project management and communication. They concluded that both environments allowed proper collaborative 3D-model management. Moreover, while 3D Experience allows better project planning and its data management is highly complex, Fusion 360 presented more limitations in the other categories. Nevertheless, Fusion 360 seemed to be easier to be implemented in educational environments in terms of economic cost (free for educational purposes and for start-ups generating less than $100,000/year in total revenue or wholly non-commercial hobbyist users [20]) and ease of learning.

Likewise, in the Youngstown State University, Brozina and Sharma used Fusion 360 in their first year of engineering design course [21]. They conducted a collaborative workshop using Cloud Computing to allow the exchange of notes and views using browsers, mobile devices and the software itself. They concluded that students better understand the collaboration process using a collaborative 3D modeling environment.

Rassovytska and Striuk analyzed the suitability of cloud tools for the professional activity of mechanical engineers [22]. The objective of this work was to identify mobile and cloud services for professional activity in mechanical engineering and how to implement them in higher education. More than 30 services in the cloud and mobile applications were evaluated. The analysis found that the use of the services in the Autodesk cloud and its integration with Google Cloud is appropriate for teaching and professional use in mechanical engineering. They applied a questionnaire to professionals and professors to figure out which competencies engineers should enhance. CAD software was pointed out as the most important, followed in the seventh position by collaboration. They analyzed On-Shape, a 3D CAD cloud-based application that works on the web browser, which has been developed from scratch to solve the current problems of engineers, taking into account aspects such as collaboration in 3D environments. They analyzed functionality, availability, access, integration and collaboration; Fusion 360 obtained the highest value.

At the University of Illinois, the professors decided to move from non-collaborative CAD software (Inventor, Rhinoceros and Alias) towards Autodesk Fusion 360 for the creation of digital prototyping in multidisciplinary teams [23]. Most students indicated that they used the Fusion 360 cloud options and also that the use of this application reduced the need for face-to-face meetings. Moreover, they indicated that they usually worked simultaneously in several design stages which improved their productivity.

Furthermore, at the University of Tianjin (China), the different environments offered by Fusion 360 were analyzed and it was concluded that this application is an ideal tool for collaborative design in engineering, since it integrates modeling, rendering, manufacturing analysis and data management [24].

Besides, some synchronous collaboration tools may not be successful in face-to-face teaching. Students seem to prefer direct interaction and when they need an alternative, they choose their asynchronous communication solutions such as SMS [9]. Furthermore, one of the educational challenges in the inclusion of PLM software is that students must know how to divide the work among the different stakeholders [16].

2. Materials and Methods

The research design corresponds to a quantitative quasi-experimental approach. A collaborative graphic simulation of an engineering project was proposed in the engineering graphics subject of the civil engineering degree at the University of La Laguna in the academic year 2018–2019. After the elaboration and presentation of each team’s results, a questionnaire was designed and applied to measure student’s perception of the resolution of an engineering project under the approach of integral collaborative design as training for industry 4.0. Groups were asked to agree on their answers, but each member delivered their own questionnaire sheet. This criterion was based on the need to receive a group perception of the collaborative practice, meanwhile we took into consideration whether the number of students in each group varied. Then, Cronbach’s alpha and descriptive analysis were conducted (mean, median and standard deviation). Consequently, line graphs were generated to observe whether Usability of Product Design and Life Management platform (UPDLM) scale values varied concerning three grouping variables. Finally, non-parametric analyses were applied to check whether the previous differences were statistically meaningful.

2.1. Sample

The sample consisted of 65 civil engineering undergraduate students from the University of La Laguna. A proportion of 30% the students knew PLM applications for collaborative work in CAD environments. However, 95% of the them had not worked in a collaborative 3D modeling experience. They considered that group work in engineering environments is very important for their professional activity and 97% reflected that working with cloud-based data is fundamental for an engineer.

2.2. Software

Autodesk Fusion 360 was the selected parametric design software due to its collaborative cloud-based environment. Moreover, A360 (the Autodesk cloud) was used for data management.

2.3. Measurement Instrument

The usability of product design and life management platform (UPDLM) scale (Table 1) was designed to measure the perception of the participants about the use of the Fusion 360 software for the accomplishment of collaborative work. UPDLM scale is a 1–5 Likert scale style, in other words, students were indicated to score each item from 1 (low importance) to 5 (high importance).

Table 1.

Usability of product design and life management platform (UPDLM) scale.

This questionnaire is composed of 14 questions divided into three categories: collaboration and design features (Factor 1 or F1), PLM features (Factor 2 or F2) and collaborative engineering (Factor 3 or F3). The design of the measurement instrument was based on the theoretical ground that has been referenced in the introduction section by combining collaborative-based learning and PLM theories with the needs of the industry 4.0.

In addition, students rated three grouping variables from 1 to 5: PLM knowledge, individual practices utility and collaborative engineering perception.

2.4. Procedure

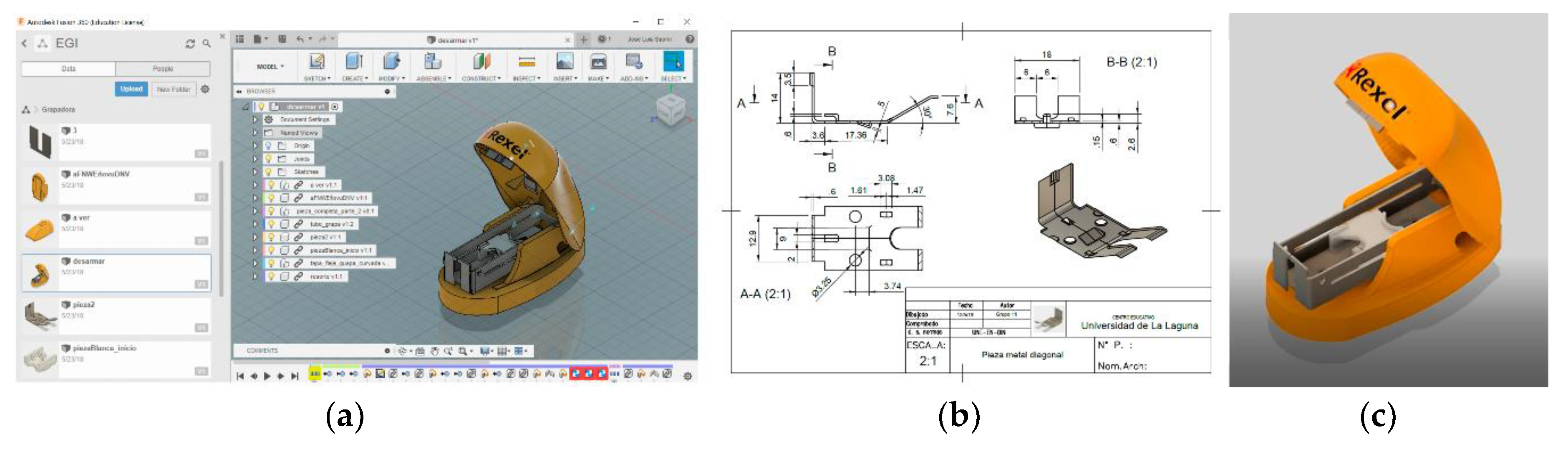

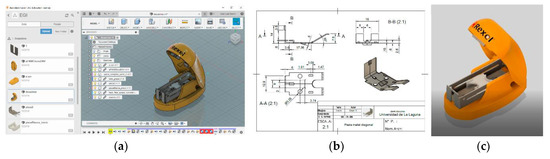

The educational experience was to perform the graphic simulation of an engineering project. The graphic documentation includes the 3D models of each component of the object, their assembly, the 2D engineering drawings, an animation of the assembly–disassembly process, the creation of infographics and a video-presentation (Figure 2). Finally, each group made a presentation to report their work.

Figure 2.

Example views of group 3: (a) Fusion 360 environment; (b) 2D-drawings; (c) infographic.

For this, each group assigned different roles to the participants: project manager, 3D modeler, 2D drawings assistant, infographic assistant, video editing manager and supervisor of additional materials (models, augmented reality, etc.). The objective of roles assignment was to distribute the responsibilities of the project. However, all the members participated in all the tasks. After, each student group had to propose an object to work with, which must fulfil the following characteristics. The object must be composed of at least five different components. The pieces must be simple to model, but students must use at least three different modeling operations (extrusion, revolution, sweep or loft). The pieces must also need editing operations. This activity was distributed in ten sessions (2 h each), in addition to the time they needed outside the classroom:

- Session 1: Students must form groups of five members and install Fusion 360.

- Session 2: Groups must assign roles and distribute tasks to each member. Moreover, they have to create a project in A360 and share it among the team members, so that everyone has access to the files of the modeling process. Besides, comment, calendar and data management are explained by the professor.

- Session 3: The object must be proposed to the professor who must accept its viability (some examples are watches, PlayStation controls are Wi-Fi routers). Then, students begin the sketch phase and 3D modeling with Fusion 360.

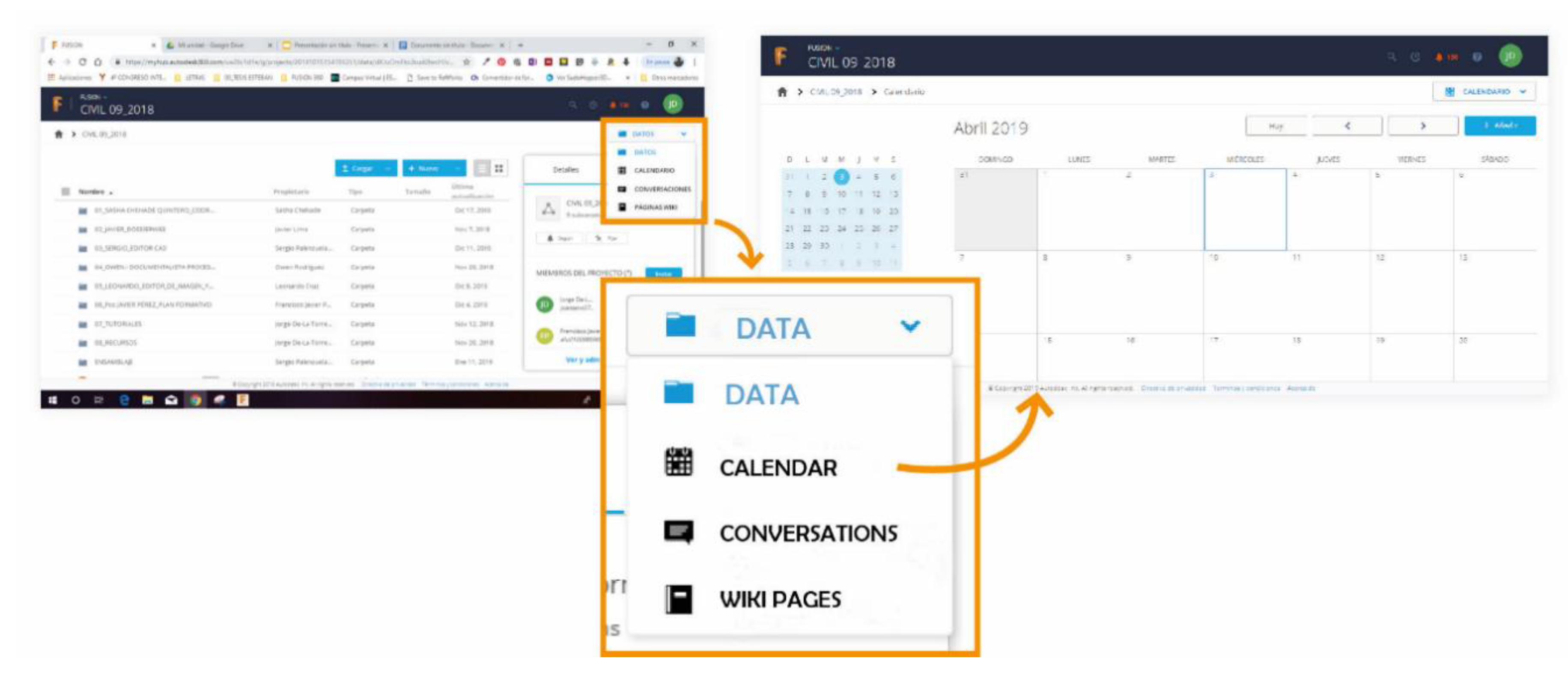

- Sessions 4–9: The group simultaneously generates all the graphic documentation, so that one of the members can be modeling a piece, while other is doing the 2D drawing of the same piece and a third is doing the assembly of the set. Moreover, project management in terms of model and file changes in A360 is taught (Figure 3). At this stage, groups are encouraged to access the A360 utilities and each student is asked to make at least one comment with the members of their group.

Figure 3. A360 interface with data management options, calendar and conversations.

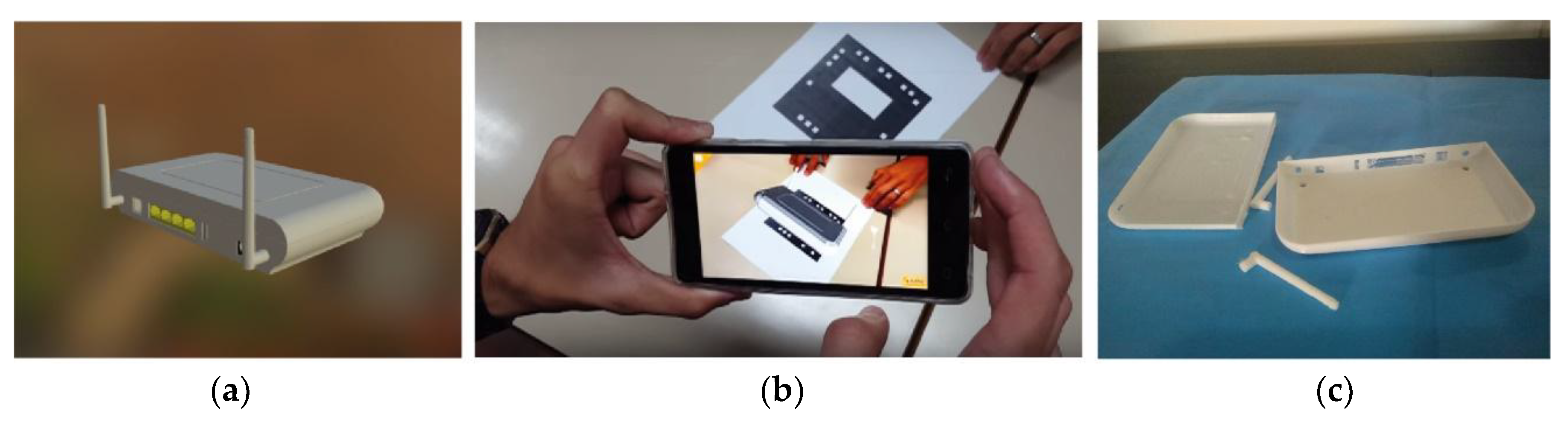

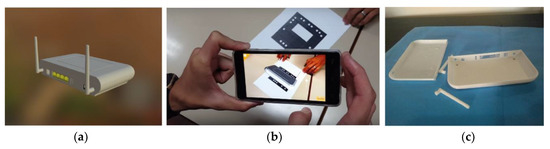

Figure 3. A360 interface with data management options, calendar and conversations. - Session 10: At the end of this experience, each group makes a presentation of the work done. Some groups present additional materials such as 3D printed models, online 3D repositories and models in augmented or virtual reality (Figure 4). After that, each group fills the UPDLM scale.

Figure 4. (a) 3D models in Sketchfab; (b) Augmented reality; (c) 3D printed model.

Figure 4. (a) 3D models in Sketchfab; (b) Augmented reality; (c) 3D printed model.

3. Results

Cronbach’s alpha statistic was calculated to assess the reliability of the scale and a high value was obtained (α = 0.838). Likewise, the reliability of F1 (α = 0.829), F2 (α = 0.782) and F3 (α = 0.714) have been calculated. Consequently, descriptive analyses of the mean, median and standard deviation were carried out (Table 2).

Table 2.

Mean and standard deviation results.

Regarding F1 (collaboration and design features), the students scored all the items close to two values: 3.60 (coordination, collaboration and communication features) and 4.50 (geometry and design usability and its viability to reduce face-to-face meetings). In terms of PLM features, students scored values close to 2.00 for all the PLM tools. However, they assigned a 3.46 to the effectiveness of the roles to collaborate. Finally, students highly scored the third factor (collaborative engineering); they scored values close to 3.8 (for the 3D public viewer and the app as a PDLM) and 4.5 (for utility for understanding a collaborative engineering environment and the need to add permissions).

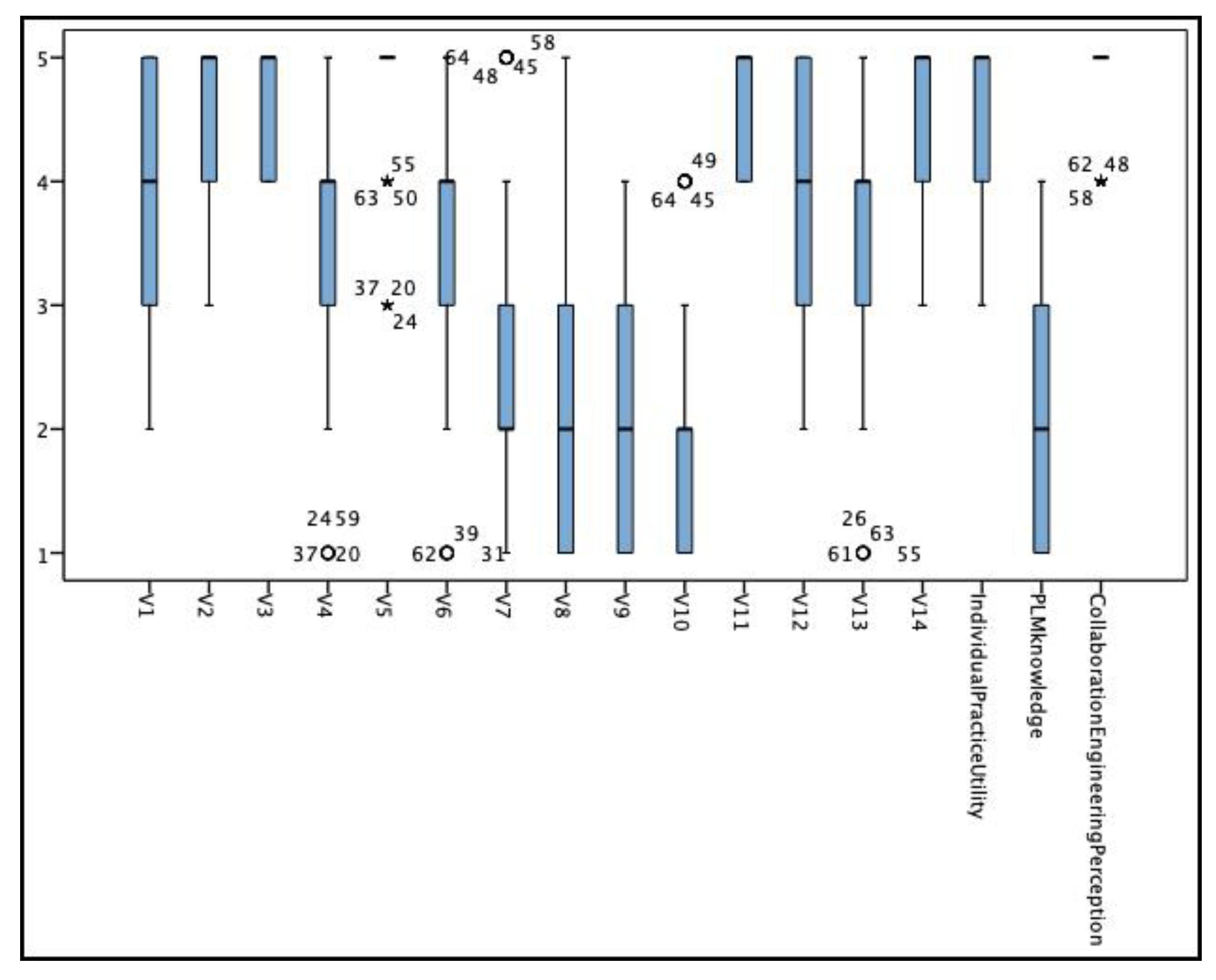

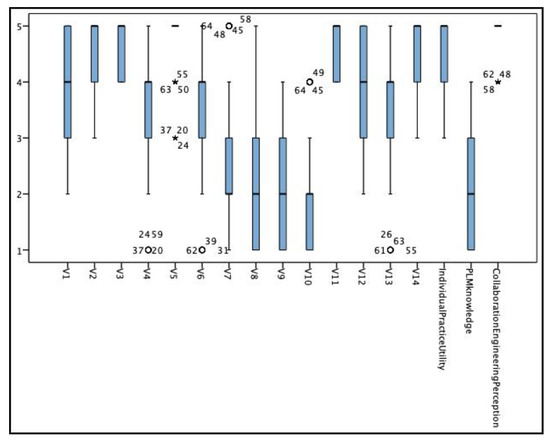

Moreover, Figure 5 represents the distribution of UPDLM and grouping variables. The range of values varies among one and five points. Students scored F1 and F3 variables with high values (mostly from 3 to 5 points) and F2 with low values (mostly from 1 to 3 points). In a few cases, groups provided data points that deviate significantly from the mean values in a rather consistent manner (See the Table S1 in Supplementary Materials). For example, students normally rated the variable 8 with a low value (1, 2 or 3). However, two groups perceived this variable with a value of 5. Both groups that rated V8 with 5 points, also gave a high value (4 points) to the grouping variable of PLM previous knowledge. Meanwhile, the students that rated V8 with a low value indicated their PLM previous knowledge with a similar value.

Figure 5.

Box plot of UPDLM and grouping variables.

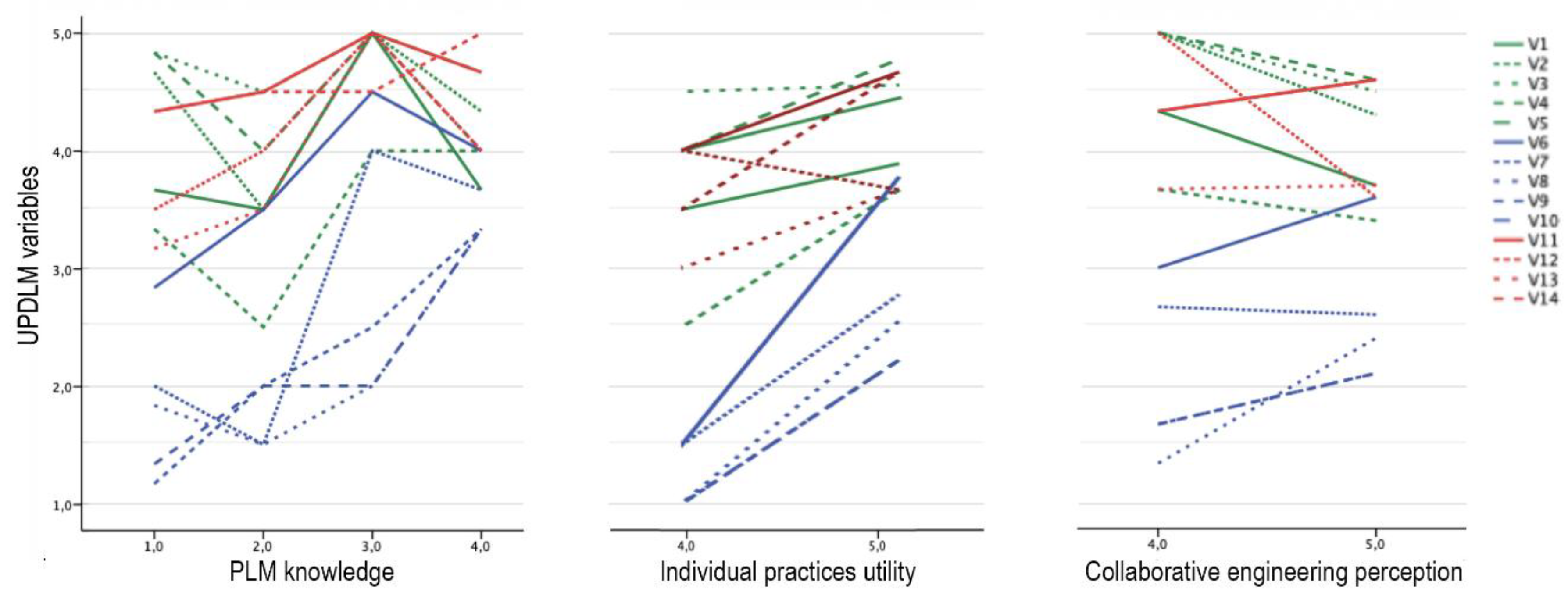

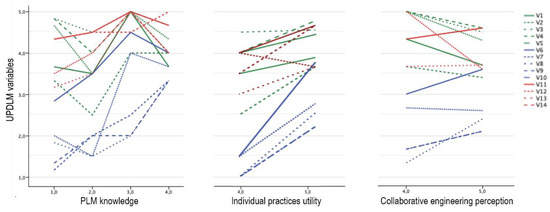

Subsequently, UPDLM mean values were represented in line graphs (see Figure 6) according to the score that the students attributed to the grouping variables: individual practices utility, PLM knowledge, and collaborative engineering perception. A color code has been used to easily differentiate the membership factor (F1 = green, F2 = blue and F3 = red).

Figure 6.

UPDLM scale line graphs. Grouping variables: product lifecycle management (PLM) knowledge, individual practices utility and collaborative engineering perception.

On the one hand, the grouping variable PLM knowledge exhibits the following trends. The variables belonging to F1 oscillate their scores by an average of 1.2 points, F2 variables by 2.04 points and F3 variables by 1.10 points. Also, there is an inverse trend from the 3-point valuation of the grouping variable for most variables (except for three variables of F2 and one of the F1). On the other hand, in the individual practices utility group, the results indicate a direct relationship in all the variables except one (V12). In this case, the scores range from 0.50, 1.46 and 0.57 average points for F1, F2 and F3, respectively. Finally, in the collaborative engineering perception grouping, the results of the scale show an inverse relationship for all the F1 variable and for two variables of the F3. In F2, V7 remains and the others increase by an average of 0.7 points.

Afterwards, the Kolmogorov–Smirnov test was applied to assess the normality of the variables PLM knowledge, individual practices utility and collaborative engineering perception. None of them followed a normal distribution (p < 0.001), so non-parametric analyses were applied.

Finally, the non-parametric variance analysis test for the PLM knowledge cluster shows significant differences in all variables (Table 3). The individual practices utility group shows significant differences concerning all the variables of F2 and F3 and for V2 (face-to-face meetings), V3 (simultaneous 3D modeling) and V5 (ease of geometry drawing) of F1. The collaborative engineering perception group shows significant differences in four of the five variables belonging to F1, as well as in the V8 (A360 Calendar is useful for coordination) and V12 (A360 public 3D viewer is useful).

Table 3.

Kruskal–Wallis test.

4. Discussion and Conclusions

In most Spanish universities, engineering education includes learning to model in 3D but does not include the possibility of working collaboratively in 3D modeling. In fact, professors have recently begun to include ICT teaching methods [12,13]. This research aims to address the new reality of industry 4.0 through a training experience of engineering graphics students in a cloud-based collaborative 3D modeling platform. For this, we proposed an engineering training through Fusion 360 and A360 environment, which merge the functionalities of a traditional PLM and simultaneous 3D modeling, and which we have named as PDLM: product design and life management. The didactic proposal consisted of the collaborative graphic simulation of an engineering project.

Students highly valued the implementation of a PDLM concerning the factors of collaboration and design features as well as collaborative engineering. Specifically, students considered that simultaneous 3D modeling is indispensable and that its application reduces the need for face-to-face meetings to serve the current connected industry, which supports previous research [23]. Likewise, this training helped students to understand how specialists work in collaborative engineering environments, obtaining similar results to other authors [21].

Furthermore, the variables of the PLM features factor obtained much lower results, except for the role-assignment as a teamwork facilitator, which agrees with the literature as a challenge to overcome since students need to know how to divide work in PLM environments [17]. These low results in PLM features are consistent with previous research that indicates that students prefer to use their asynchronous communication solutions such as SMS [9].

Moreover, these results match with the graphic contingency analysis outcomes. They indicated that the better the PLM knowledge and individual practices are valued by students, the better students will embrace PDLM software. Besides, the analysis of variance by categories of dependent variables brings new information to the literature. The results evidenced that the student perception of the implementation of a PDLM statistically varies concerning their value towards the individual practices and their previous knowledge of PLM software. So, both factors are essential in the implementation and training in these engineering environments, which are a must for industry 4.0. However, students’ preconception of collaborative engineering work hardly shows significant variations, and when they occur, the mean variations are not high.

To conclude, this research has applied training for future engineers adapted to the needs of industry 4.0 through a cloud-based collaborative 3D modeling platform. This has demonstrated a good reception with statistically significant changes with dependence on PLM knowledge and individual practices. Likewise, the analysis of relationships carried out shows that different pieces of training can serve to further improve some perceptions of the students and consequently their future application in professional practice.

Additionally, it is necessary to emphasize the importance of this type of study in engineering. Literature and companies have evidenced a relationship between the profiles of engineers and their training in the university. Therefore, other authors are encouraged to address the needs of industry 4.0 from the university, not only through proposals but also through applied research that generates knowledge on how to address their training.

Finally, and despite the difficulties of implementing PLM programs in education (due to their cost and difficulty), the results of this research provide some suggestions for making possible PDLM training in the first year of engineering studies by using Autodesk Fusion360. Learning must be continuous and addressed as early as possible. At first, individual practices should focus on learning the basic tools of the chosen environment (both modeling and management), PLM knowledge and applicability. Later, the teacher will be vital to monitor and detect weaknesses in time. Likewise, it is essential to organize groups and roles to balance responsibilities and simulate from the beginning of the training the experience of a collaborative project.

Supplementary Materials

The following are available online at https://www.mdpi.com/2076-3417/9/21/4559/s1, Table S1: UPDLM ULL database.

Author Contributions

Conceptualization, J.L.S.; methodology, software investigation and resources, J.d.l.T.-C. and D.M.D.; formal analysis, V.L.-C.; original draft preparation of the manuscripts J.d.l.T.-C. and J.L.S.; writing—review and editing V.L.-C. and D.M.D.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Koehn, E.E. Assessment of communications and collaborative learning in civil engineering education. J. Prof. Issues Eng. Educ. Pract. 2001, 127, 160–165. [Google Scholar] [CrossRef]

- McCuen, R.H. Constructivist learning model for ethics education. J. Prof. Issues Eng. Educ. Pract. 1995, 120, 273–278. [Google Scholar] [CrossRef]

- Rajala, S.A. Beyond 2020: Preparing engineers for the future. Proc. IEEE 2012, 100, 1376–1383. [Google Scholar] [CrossRef]

- Garetti, M.; Terzi, S.; Bertacci, N.; Brianza, M. Organisational change and knowledge management in PLM implementation. Int. J. Prod. Lifecycle Manag. 2005, 1, 43–51. [Google Scholar] [CrossRef]

- Jung, Y.W.; Lim, Y.K.; Kim, M.S. Possibilities and limitations of online document tools for design collaboration: The case of Google Docs. In Proceedings of the 2017 ACM Conference on Computer Supported Cooperative Work and Social Computing, Portland, OR, USA, 25 February–1 March 2017; pp. 1096–1108. [Google Scholar]

- Hadjileontiadou, S.J.; Sakonidis, H.N.; Balafoutas, G.J. Lin2k: A novel web-based collaborative tool-application to engineering education. J. Eng. Educ. 2003, 92, 313–324. [Google Scholar] [CrossRef]

- Moreno, L.; Gonzalez, C.; Castilla, I.; Gonzalez, E.; Sigut, J. Applying a constructivist and collaborative methodological approach in engineering education. Comput. Educ. 2007, 49, 891–915. [Google Scholar] [CrossRef]

- do Carmo, B.B.T.; Pontes, R.L.J. Collaborative learning concept implementation through web. 2.0 tools: The case of industrial engineering fundamentals’ discipline. Int. J. Eng. Educ. 2013, 29, 205–214. [Google Scholar]

- Gillet, D.; Ngoc, A.V.N.; Rekik, Y. Collaborative web-based experimentation in flexible engineering education. IEEE Trans. Educ. 2005, 48, 696–704. [Google Scholar] [CrossRef]

- Al-Samarraie, H.; Saeed, N.A. Systematic review of cloud computing tools for collaborative learning: Opportunities and challenges to the blended-learning environment. Comput. Educ. 2018, 124, 77–91. [Google Scholar] [CrossRef]

- López-Pena, V.; López-Chao, V.A.; López-Chao, A. Analysis of teaching methods in graphic design in the Galician University System (GUS) in Spain. Anthropologist 2016, 25, 214–219. [Google Scholar] [CrossRef]

- López-Chao, V.; López-Pena, V.; Ramiro-Aparicio, D. Beyond graphic expression: A diagnosis about the use of ICT teaching methods in engineering and architecture degrees. In Proceedings of the 12th international technology, education and development conference (INTED), Valencia, Spain, 5–7 March 2016; pp. 9290–9295. [Google Scholar]

- Ramiro-Aparicio, D.; López-Pena, V.; López-Chao, V. Comparative study of the acquisition of ICT competence in graphic expression between the UDC and the US. In Proceedings of the 10th International Conference of Education, Research and Innovation, Seville, Spain, 16–18 November 2017; pp. 5150–5154. [Google Scholar]

- Arri, Z.A.; Mujika, M.G.; Albisua, M.J.B.; Mendez, E.S. El desarrollo de habilidades profesionales en los estudios de ingeniería en la Universidad del País Vasco: ¿Aprendizaje basado en problemas o en proyectos? DYNA 2019, 94, 22–25. [Google Scholar] [CrossRef]

- Saorin, J.L.; de La Torre, J.; Martín, N.; Carbonell, C. Education working group management using digital tablets. Procedia Soc. Behav. Sci. 2013, 93, 1569–1573. [Google Scholar] [CrossRef][Green Version]

- Segonds, F.; Maranzana, N.; Veron, P.; Aoussat, A. Collaborative reverse engineering design experiment using PLM solutions. Int. J. Eng. Educ. 2011, 27, 1037–1045. [Google Scholar]

- Maranzana, N.; Segonds, F.; Buisine, S. Collaborative design tools in engineering education: Insight to choose the appropriate PLM software. Int. J. Mech. Eng. Educ. 2018. [Google Scholar] [CrossRef]

- Saorín, J.L.; Lopez-Chao, V.; de la Torre-Cantero, J.; Díaz-Alemán, M.D. Computer aided design to produce high-detail models through low cost digital fabrication for the conservation of aerospace heritage. Appl. Sci. 2019, 9, 2338. [Google Scholar] [CrossRef]

- Vila, C.; Ugarte, D.; Ríos, J.; Abellán, J.V. Project-based collaborative engineering learning to develop Industry 4.0 skills within a PLM framework. Procedia Manuf. 2017, 13, 1269–1276. [Google Scholar] [CrossRef]

- Autodesk Fusion 360: Fusion 360 for Hobbyist and Makers. Available online: https://www.autodesk.com/campaigns/fusion-360-for-hobbyists (accessed on 2 September 2019).

- Brozina, C.; Sharma, A. Workshop: Implementing cloud collaboration using fusion 360 into a first-year engineering design course. In Proceedings of the FYEE Conference, Daytona Beach, FL, USA, 6–8 August 2017. [Google Scholar]

- Rassovytska, M.; Striuk, A. Mechanical engineers training in using cloud and mobile services in professional activity. CEUR Workshop Proc. 2017, 1844, 348–359. [Google Scholar]

- Leake, J.M.; Weightman, D.; Batmunkh, B. Digital prototyping by multidisciplinary teams. In Proceedings of the ASEE Annual Conference Exposition, Columbus, OH, USA, 25–28 June 2017. [Google Scholar]

- Song, P.P.; Qi, Y.M.; Cai, D.C. Research and application of autodesk fusion360 in industrial design. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012037. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).