Featured Application

The use of construction and demolition waste (CDW) in the development of building materials has been done constantly. The CDW from Passo Fundo region of Rio Grande do Sul/Brazil can be used in development of foamed concrete fully replacing the natural sand.

Abstract

The main objective of this study was to evaluate the use of construction and demolition waste (CDW) from the Passo Fundo region of Rio Grande do Sul (RS), Brazil, in the development of aerated foamed concrete. This waste had not yet been characterized or even reused. CDW was processed (sieved only), characterized, and used as an aggregate, completely substituting natural sand. The influence of CDW granulometry and the amount of foam upon compressive strength, wet and dry bulk density, water absorption, and the air voids of concrete blocks were determined. Results showed that CDW has regular characteristics for the development of aerated foamed concrete. Compressive strength and density decreased as the amount of foam increased, while water absorption and air voids also increased. Also, CDW that was classified as coarse showed higher compressive strength. On average, CDW medium-sized particles had a higher air void content, while water absorption showed little variation with respect to granulometry. CDW residue from the region of study can be used as aggregate for the development of aerated foamed concrete. However, it must characterized before being used to guarantee the quality of the final product.

1. Introduction

Construction and demolition waste (CDW) has been used significantly since World War II due of the great amount of debris and the need to satisfy the great demand for construction materials [1,2]. The use of CDW as aggregate for the development of concrete has been an alternative to reduce environmental and economic impacts through the preservation of natural resources, because the global demand for construction quality aggregates is expected to be more than 51 billion metric tons by 2019 [3]. Research related to obtaining aggregates through debris recycling is currently emphasized. In European Union countries, approximately 50% of the total generated volume of CDW is reused, and 70% of total CDW should be recycled by 2020 [4]. Also, in these countries, residues from construction and demolition comprise the most significant part of all potentially recyclable residues, and in some cases, such as the Netherlands and Denmark, the reuse of the produced CDW can be up to 80% [5]. In the United States, approximately 136 million tons of waste were generated by construction and demolition activities, of which only about 28% were recycled [6]. However, recently in China, only less than 10% of CDW was recycled, while the majority of the waste remained to be simply landfilled or just dumped [7].

CDW from Brazil represents more than 40% of solid urban residues [8]. In many medium (population from 100,000 to 500,000 inhabitants) and large size (population higher than 500,000 inhabitants) Brazilian cities, CDW residues are produced by activities such as renovation and demolition (60%), and new buildings (20%) and house (20%) construction [9]. In Passo Fundo, the CDW produced comes from renovation and demolition (42.5%), the cleaning of urban lots (16.7%), the construction of buildings (11.1%) and houses (18.6%), and from soil excavation (11.1%) [10]. The irregular and clandestine dumping of these residues is a problem that generates significant environmental impacts such as degrading roads and public places, the uncontrolled generation of residues, the silting up of waterways, unpleasant odors, burning, noise, and the depletion of natural resources, among others [11]. Aside from the environmental impacts, discarding these residues occupies spaces that could be used for housing, since the Passo Fundo region has a significant deficit of land for such purpose [12].

On the other hand, this material presents positive reuse potential, whenever it is properly separated and transformed into new feedstock [13]. In Brazil, CDW is mainly composed of bricks, ceramics, ceramic blocks, concrete and mortar, wood and wood boards, plaster, and metallic materials, among other materials [14,15].

The Brazilian legislation classifies CDWs into four classes: A, B, C, and D. Class A contains the reusable or recyclable residues produced by construction, demolition, renovation, paving repairs, and other infrastructure works, as well as from the construction and/or demolition of precast concrete objects such as ceramic (bricks, blocks, tiles, floor boards, etc.); mortar and concrete; and even soil derived from earthwork. Class B contains residues such as plastics, paper, cardboard, metals, glass, and wood, among others. Residues for which there are still no developed reuse technologies or applications are included in Class C; for example, residues derived from products that use plaster in their composition. Class D includes hazardous residues derived from fabrication processes such as paint, solvents, oils, etc., or those contaminated or harmful to health arising from demolition, renovations, and repair in radiological clinics and industrial facilities; it also includes roofing tiles, and other objects and materials containing asbestos or products harmful to human health [15]. In Brazil, CDW constituents are included predominantly in Class A—around 91% of mass—and Class B, (9%). The CDW constituents in Classes C and D have not been quantified [14]. In Passo Fundo, according to Bernardes et al. [10], 94.5% of CDW constituents are included in Class A, 3.1% in Class B, 2.4% in Class C, while Class D did not contain significant amounts.

According to Cardoso et al. [16], four main kinds of construction and demolition wastes have reuse potential as recycled aggregate such as concrete, mortar, ceramic materials, and road residues. The use of recycled aggregates in concrete and mortar can be undermined by limits imposed by CDW composition; for example, recycled materials usually have higher water absorption, lower specific mass, and less mechanical resistance when compared with natural aggregates [17]. On the other hand, Jones et al. [18] state that using coarse recycled aggregates could be a successful substitute for natural aggregates in the production of concrete; however, these materials can have problems related to high water absorption and particle distribution. Also, fine recycled aggregates present poorer mechanical properties than coarse recycled aggregates due to the greater angularity of the coarse fraction [19] and the difficulty of separating the contaminants (wood, tiles, styrofoam, glass, and others) [20] contained in the fine recycled aggregates. For example, the addition of wood chips significantly reduced the splitting tensile strength [20]. However, the use of recycled aggregates is more appropriate in cases where there is no need for high structural performance, low water absorption, and exposure to aggressive environments [21,22].

A construction material that does not require structural function is lightweight concrete, which is defined as hardened concrete with a specific mass between 800–2000 kg/m3 [23]. Aerated concretes are a variation within lightweight concretes that have a specific mass between 320–1920 kg/m3 and a compressive strength above 1.5 MPa [24]. Lightweight concretes can be obtained by the use of lightweight aggregates in the mixture or by the incorporation/production of air in the form of bubbles distributed into the mortar [25,26]. The lightweight concretes known as autoclaved aerated concrete (AAC) are those that are produced with bubbles of air inside the mortar via a chemical reaction process activated by curing in an autoclave [27]. Another variation of cellular concrete is known as foamed cellular concrete (FCC), where bubbles of air are incorporated into the mortar by the addition of preformed foam [28].

Using CDW for the production of foamed cellular concrete has been pointed out as one of the possible uses for such residue [29]. However, the chemical composition and physical properties of residues can vary drastically according to the geographic region and the construction processes of the industry where they are generated. Thus, the main aim of this work was to characterize the CDW from the Passo Fundo region of Rio Grande do Sul (RS), Brazil, and to evaluate its use for the production of foamed cellular concrete blocks. This study consisted in determining the influence of CDW granulometry (CDWG) and foam amount (FA) upon foamed cellular concrete properties.

2. Materials and Methods

2.1. Materials

A Portland cement of high initial compressive strength (CP V-ARI) (InterCement Brasil, Candiota, RS, Brazil) was used with the following properties: Blaine of 410 m2/kg compression strength after 28 days of 50 MPa; and specific mass of 3000 kg/m3.

The CDW used in the experiments was obtained from a construction and demolition sorting facility located in Passo Fundo, RS, Brazil. The CDW was processed only by milling and sieving. Three different CDW granulometries were used in the production of foamed concrete blocks: coarse (aggregates retained between sieves of 4.75 mm and 1.18 mm), medium (aggregates retained between sieves of 1.18 and 0.6 mm), and fine (aggregates that were not retained in the 0.6 mm sieve)

The foaming agent used in foam production was water and amide 90 (Alpha Química LTDA, Porto Alegre, RS, Brazil) in a proportion of 30:1. The amide 90, known as coconut oil diethanolamine condensate , is a mixture of the diethanolamides of the fatty acids that constitute coconut oil. This proportion was established in former studies [30]. A mechanical stirrer was used to produce foam with a density of 75 kg/m3.

2.2. Characterization of the CDW

Three granulometry fractions, coarse (4.75–1.18 mm), medium (1.18–0.6 mm) and fine (<0.6 mm) of the CDW were characterized by multiple assays in order to determine their granulometric composition. The Brazilian standard NBR NM 248 [31] considers the mean retained percentage and the mean accumulated retained percentage in each sieve. Chapman’s assay, as described by Brazilian standard NBR 9776 [32], determines specific mass. Brazilian standard NBR 6467 [33] describes an assay that determines the swelling of CDW, which is described as the variation of apparent volume caused by the absorption of free water by the aggregate grains altering their mass. X-ray fluorescence (XRF) identifies the chemical elements present in CDW composition. Loss on ignition was also measured, which is related to the amount of volatile organics and the dehydration of the cement contained in the CDW. Visual analysis of macrographic images was also conducted in order to verify the constituents of CDW such as bricks, concrete, wood, and glass, among others. X-ray fluorescence was performed using a PANalytical-MiniPal 4 equipment (PANalytical B.V., Almelo, The Netherlands).

The proposed methodology for CDW aggregate swelling determination is based on the successive addition of water in order to obtain a homogeneous mixture between the aggregate sample and a moisture content of 0.5% and 12%, by determining the unitary mass at each moisture content. The ratio between wet and dry volumes for the same unitary mass is expressed by Equation (1).

where, Vh is the aggregate’s volume at h% moisture, Vs is the aggregate’s volume after being oven dried, δh is the aggregate’s unitary mass after being oven dried, and h is the aggregate’s moisture (%).

2.3. Experimental Design

In this study, two parameters were used as control factors: foam amount (FA) and CDW granulometry (CDWG). Four levels of FA and three levels of CDWG were used, while all other parameters were held constant. The water/cement (W/C) ratio was maintained constant by varying the amount of water, and it was considered that 98% of the foam is water [30]. Five output variables (responses) were analyzed: compressive strength (CS), wet bulk density (WBD), dry bulk density (DBD), air void (AV) and water absorption (WA). Foam levels were defined in former experiments that determined the minimum values of foam for mortar production.

An experimental design matrix with 12 concrete traits was implemented. Six samples of each trait were prepared: three were used for compressive strength (CS) assays, and the remaining three were used in the other assays. A total of 72 specimens were produced. The experimental design was based on a full factorial statistical method with the respective values shown in Table 1.

Table 1.

Experimental matrix with all mixtures used.

An analysis of variance (ANOVA) was used to determine the influence of factors upon output variables. Factors were considered to be significant for p-values equal to or lower than 0.05 (critical value adopted), which indicates a confidence level equal or superior to 95% with respect to what is being stated. The percentage contribution of each factor was also determined.

2.4. Characterization of Foamed Concrete Cylindrical Blocks

Experimental tests for the determination of CS, WA, AV, WBD, and DBD were used in the characterization of foamed concrete blocks. Also, the amount and mean pore size were determined through macrographs of the specimens. The software used during image processing was ImageJ.

Axial compression strength tests were performed using an EMIC PC 100C (EMIC-PC100C, Instron, Norwood, MA, USA) hydraulic press following Brazilian standard NBR 5739 [34].

Values of WA (%) by immersion, WBD (kg/m3), DBD (kg/m3), and AV (%) were obtained after testing as described by ASTM C948-81 [35] and NBR 9778 [36] standards, which are expressed in the following equations:

where: Wsat is the mass of the saturated specimen, Ws is the mass of the oven dried specimen, and Wi is the mass of the specimen saturated and immersed in water.

To analyze pore sizes, two specimens of each sample were prepared: one specimen for the longitudinal section, and another for the transverse section. The specimens were prepared with the dimensions of 20 × 20 × 20 mm, and were, in sequence, embedded with an epoxy resin and sanded with following sequence of sand paper: #100, #220, #320, #400, #600, and #1200. In order to increase the contrast between the pores and the matrix, samples were cleaned to remove possible residues and then treated by applying two coats of permanent marker. Once the marker was dry, sodium bicarbonate (a white powder with a minimum particle size of 5 µm) was added on the samples to cover the pores, and left on the concrete surface for contrast by image analysis, that is, a dark concrete matrix and white pores. Macrographic images were taken with a camera. This analysis technique is described in British standard BS EM 480-11 [37] and by other authors [38,39].

3. Results

3.1. Characterization of CDW

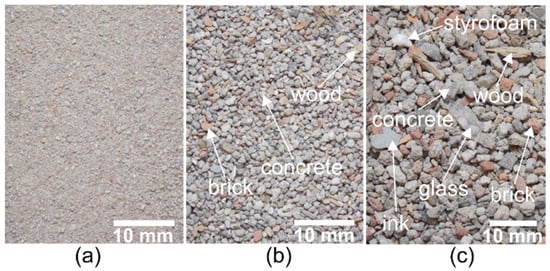

CDW residue was characterized for granulometry, specific mass, swelling, and by X-ray fluorescence, loss on ignition, and image visual analysis. Figure 1a–c show the CDW fine, medium, and coarse granulometry, respectively. The presence of different materials such as wood, Styrofoam, glass, concrete, brick, and paint among others can be observed. These materials are characteristic of CDW residues and, according to some authors, can influence concrete properties. The amount of wood can increase WA and decrease CS [40]. The addition of Styrofoam to the concrete can reduce its density, and consequently decrease CS as well as improve its thermal conductivity [41,42]. The addition of glass residues to the concrete can induce an alkali–silica expansive reaction that occurs between the alkali in the cement and the silica in the glass, causing serious problems of cracking that compromise concrete durability. However, glass particle sizes smaller than 100 µm do not react with silica, so concrete durability is assured [43].

Figure 1.

Construction and demolition waste (CDW) granulometry (a) fine; (b) medium; and (c) coarse.

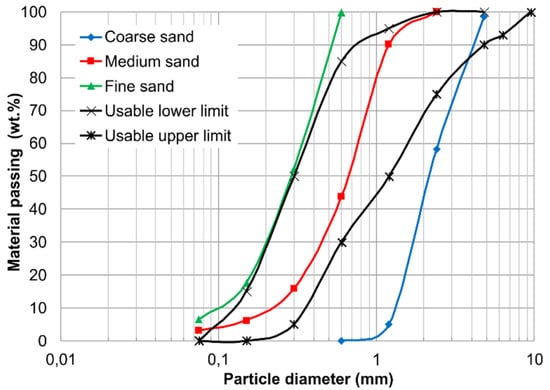

The graph in Figure 2 shows the distribution of accumulated undersized CDW aggregates as a function of average particle diameter. It can be observed that approximately 95% of the CDW classified as coarse has aggregates with a diameter between 4.75 and 1.2 mm, 4.5% are between 1.2 and 0.6 mm, and 0.5% are smaller than 0.6 mm. With respect to CDW classified as medium, approximately 10% of the aggregates have a diameter between 4.75 and 1.2 mm, 46% are between 1.2 and 0.6 mm, and 44% are smaller than 0.6 mm. As for the CDW classified as fine, approximately 99% of its aggregates have a diameter smaller than 0.6 mm, and 1% between 1.2 and 0.6 mm. The fineness modulus for coarse, medium, and fine CDW granulometry were found to be respectively 3.4, 2.44, and 2.24; and maximum diameters were 4.75 mm, 1.18 mm, and 0.6 mm. The fineness modulus values obtained for CDW granulometries are in accordance with the limits established by Brazilian standard NBR 7211 [44].

Figure 2.

Cumulative underflow distribution of different CDW granulometries and normal upper and lower limits for concrete production.

Figure 2 also shows the upper and lower limits of fine aggregate distribution for concrete production following the NBR 7211 [44] standard method. According to these limits, it can be seen that the medium granulometry curve is contained within the usual ranges, the fine CDW distribution is found to be practically at the lower limit, and the coarse distribution is found above the upper limit of natural fine aggregates used in concrete production.

The specific mass was determined via Chapman’s test. For coarse CDW granulometry, the specific mass was found to be 2450 kg/m3 and 1 cm3 of floated material; for medium granulometry, the specific mass was found to be 2430 kg/m3 and 4 cm3 of floated material; and fine granulometry showed a specific mass of 2420 kg/m3 and 1 cm3 of floated material. The results showed little specific mass differences between different CDW granulometries. These results are in agreement with former studies run by Angulo (2005).

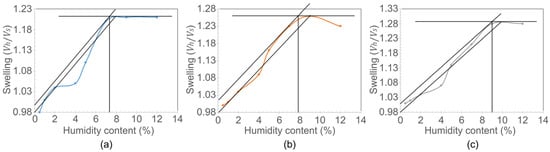

Considering that fine grained aggregates have high water retention capacity, it is important to consider swelling due to WA during concrete production for particle size distribution whenever added in terms of volume. According to NBR 6467 [33] Brazilian standard, the swelling can vary from 20% to 40%. For this, the swelling coefficient (ratio between wet and dry volumes) and critical moisture for different CDW granulometry was determined. Figure 3 shows swelling as a function of moisture content; the critical moisture values for coarse, medium, and fine granulometry fractions were 7.3%, 7.8%, and 9%, respectively. These results indicate that the amount of water absorbed by CDW residue caused an increase in volume. Also, fine granulometry CDW residue needs a greater amount of water to obtain the same swelling volume as medium and coarse granulometries. However, such addition of water can led to mortar expansion which, when exposed to the sun, will lead to water loss through elevated drying by shrinkage and cracking [45].

Figure 3.

Swelling coefficient as a function of moisture content for CDW classified as (a) coarse; (b) medium; and (c) fine.

Curves found for CDW residue swelling present a similar behavior to those found by Fonseca [45], where there was a small decrease in volume at 10% moisture (Fonseca found 16%). This behavior was probably due to a lubrication effect between the fine particles of the aggregate and a water film for this given water addition [45]. Swelling values for coarse, medium, and fine aggregates were 22%, 25%, and 28%, respectively (Fonseca [45] found 48%). The aggregate swelling test indicates that the recycled aggregate has a higher critical moisture for the same swelling coefficient.

The results listed in Table 2 show the X-ray fluorescence for different CDW residues granulometries obtained from quantitative analysis and accomplished via molten sample technique with calibration curves from rock standards. Values are shown as a percentage of sample weight; Nd means “not detected” by the method. Loss on ignition (volatile presence) was evaluated through gravimetric techniques and is indicated as LOI.

Table 2.

X-ray fluorescence (XRF) chemical analysis for CDW.

The analysis of XRF for CDW residue shows that the higher concentrations are related to SiO2, 73.05% to 78.38%, which has an origin associated with natural aggregates of concrete and mortar, and CaO, 6.53% to 8.43%, which is associated with binders. XRF results also indicate Mg and Ca, which can be present as carbonates. If Mg and Ca are in oxide shape, the presence of CaO and MgO in the concrete can be dangerous, since they can induce pathologies over time (expansions). Al2O3 is also present in concentrations varying from 3.39% to 4.83% from the presence of red ceramics and soil and, secondly, due to the presence of feldspar and cement in the CDW residue. A mean SO4 concentration of 0.94% is possibly due to the presence of plaster in the residue [46]. This percentage is below the amount of plaster found in residues from this region analyzed in former studies (around 2.4%) [10]. The amount of K2O found in the residue can induce an alkali–silica reaction in the concrete.

The variation in CDW granulometry influences the amount of SiO2; that is, the CDW with fine granulometry has a greater amount of SiO2 than medium CDW and is, in turn, greater than coarse CDW.

The loss on ignition (LOI) varied from 6.96% to 7.71%, and was essentially related to the loss of volatiles by the release of combined water and carbon dioxide from hydrated calcium silicates and hydrated lime and carbonates. It was also related to water released from phyllosilicates present in soil, ceramics burnt bellow 500 °C, and other minor minerals present in coarse natural aggregates (gravel obtained from rocks such as granite) [46,47]. Another observation is that increases in CaO (%) ultimately related to the amount of CaCO3 will increase LOI values, since CaCO3 yields CaO + CO2. Results found in this study were similar to those obtained by Angulo et al. [47] and Silva [48] in different regions in Brazil.

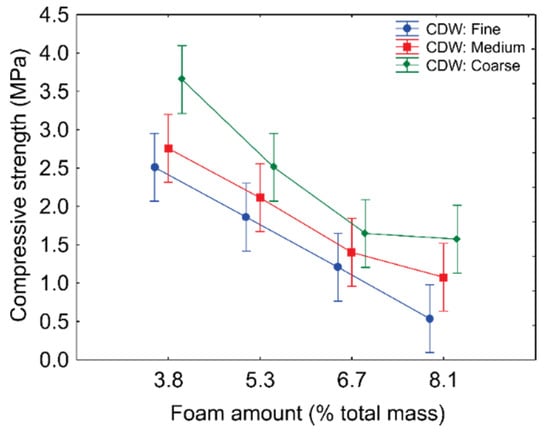

3.2. Compressive Strength—CS

A CS ANOVA with 95% confidence can be seen in Table 3. This shows that CDW granulometry has a significant influence upon CS by a contribution of 15%. Studies performed by Haach et al. [49] also found a small influence of granulometry on CS; however, natural sand was used as aggregate. FS also significantly influenced CS by a contribution of 71%. For the interaction between factors, FA and CDW granulometry did not influence each other; herein, no interaction is considered between them.

Table 3.

Compressive strength (CS) An analysis of variance (ANOVA).

Figure 4 shows CS with respect to FA for the different granulometries. It can be seen that increasing FA reduces CS due to the incorporation of air into the mortar, which reduces its density. The specimens with coarse CDW showed higher values of CS than those with medium CDW, and those higher than fine CDW. This phenomenon can be explained; the fine-grained residue absorbs more water than coarse. The WA allows the coalescence of foam bubbles inside the mortar, and consequently, an increase in the size of the bubbles and air content, which lessens density and CS. Results are in agreement with former studies by Nambiar and Ramamurthy [50] and Haach et al. [49].

Figure 4.

CS as a function of foam amount (FA) for different CDW granulometries.

The average values for CS are above the minimum values established by the Brazilian standard NBR 13438 [51] for autoclaved cellular concrete (values of at least 1.2–1.5 MPa at densities between 400–600 kg/m3). The specimen produced with 8.1% of FA related to total mass and fine CDW was an exception, with an average CS value of 0.6 MPa.

3.3. Dry (DBD) and Wet (WBD) Bulk Density

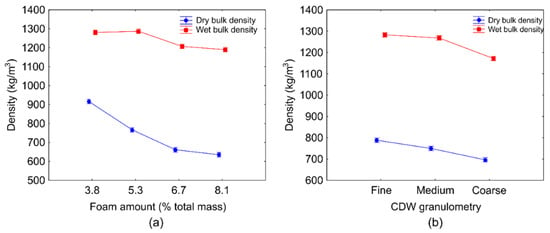

The ANOVA (95% significance) for DBD and WBD in water are shown in Table 4 and Table 5, respectively. FA and CDWG factors had significant influences on DBD and WBD. There is also an interaction between factors; thus, one factor can influence the other for both densities.

Table 4.

Dry bulk density (DBD) ANOVA.

Table 5.

Wet bulk density (WBD) ANOVA.

The behavior of DBD and WBD as a function of FA and CDWG can be seen in Figure 5a,b. Figure 5a shows that increasing FA in the mortar causes a nonlinear DBD decrease. The WBD was shown to be almost constant for FA variations from 3.8% to 5.5% and from 6.7% to 8.1%. However, there was a decrease in WBD with an FA increase from 5.3% to 6.7%. Figure 5b shows that both densities (dry and saturated) decrease with an increase in CDWG. With a smaller addition of foam, the bubbles of air incorporated gather by dehydration, creating larger bubbles. These density variations occur given an increase in water content (FA increase) that makes bubbles collapse by a reduction of the hydro-lipophilic film, which makes them less resistant to the strength of the medium [52,53]. It is also due to the union of air bubbles incorporated into the mortar by dehydration; that is, it is a consequence of having CDW granulometry variation.

Figure 5.

Densities (DBD and WBD) as a function of FA (a) and CDW granulometry (CDWG) (b).

A significant difference between DBD and WBD values can also be observed. This difference is associated with elevated values of WA, which are discussed below.

3.4. Water Absorption (WA)

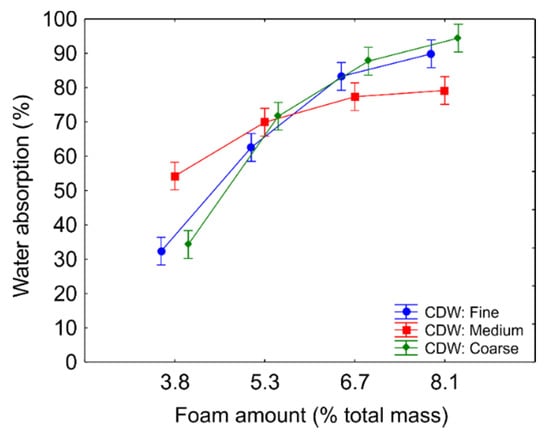

The ANOVA for WA, as seen in Table 6, shows that CDWG and FA, as well as the interaction between them, showed significant influences (95% significance) upon WA in produced concrete blocks. The factor that contributed the most to WA behavior was FA, with an 87% value.

Table 6.

Water absorption (WA) ANOVA.

WA as a function of FA and different CDW granulometries is shown in Figure 6; increases in FA associated to increases in WA were observed. This phenomenon occurs given an increase of total AV and an increase in the connectivity between pores (higher capillarity) [23]. Curve intersections indicate that there was an interaction between FA and CDWG (factors); that is, there was different behavior in terms of WA at different levels of CDWG and FA. In this context, medium size CDW had less variation of WA than the other granulometries with an increase of FA. Nambiar and Ramamurthy [54] also found an increase in WA as a function of FA when boiler ash was used as a substitute for natural sand. However, they found different results for natural sand (water absorption decreased with an increase of foam). High WA values were found for concrete blocks made with CDW residue, where WA varied from about 30% to 90%. The variation in WA values possibly occurred due to the different capillarities found in concrete blocks.

Figure 6.

Water absorption as a function of FA for different CDW granulometries.

3.5. Air Void (AV) Investigation

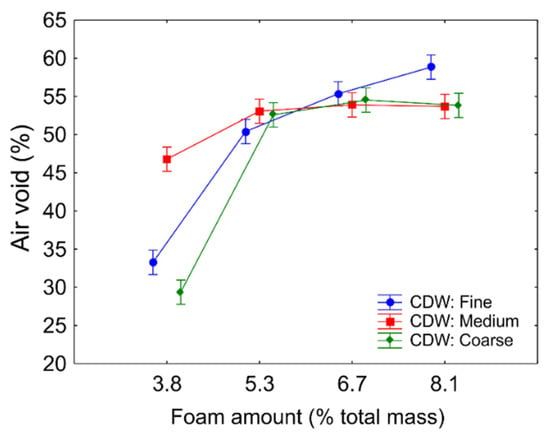

Based on Table 7, which shows a quantitative ANOVA for pores, it is possible to ensure that CDWG and FA (factors) have a significant influence (95% confidence) on the amount of pores in concrete blocks. There was also an interaction between both factors in pore formation, 17% contribution. Again, FA added to the mortar was found to be the most significant factor contributing to pore formation (78%).

Table 7.

ANOVA for air void (AV).

Results for AV as a function of FA for different CDW granulometries are presented in Figure 7. Specimens constructed with coarse CDW had smaller AV variations, on average. Specimens constructed with fine CDW also showed increases in FA paired with AV increases. As for specimens made with medium and coarse CDW granulometries, an increase of AV for increases in FA from 3.8% to 5.3% was shown. However, AV remained almost constant for FA from 5.3% to 8.1%. It is understood that these variations might be caused by changes in CDW granulometry that interfered significantly with pore formation. The intersection of curves in Figure 7 represents the interaction between factors on AV.

Figure 7.

AV as a function of FA for different CDW granulometries.

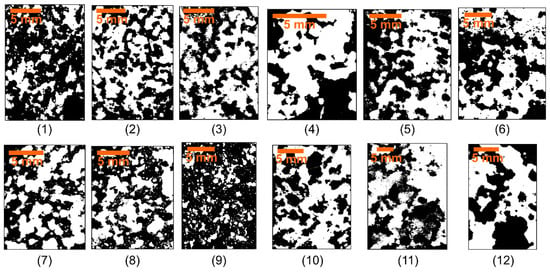

Figure 8 presents typical binary images of transversal sections of the 12 specimens in sequence, following the order of Table 2. Average porosity values were: (1) 31%; (2) 51%; (3) 55%; (4) 59%; (5) 48%; (6) 54%; (7) 53%; (8) 47%; (9) 24%; (10) 56%; (11) 54%; and (12) 53%.

Figure 8.

Typical binary images for different mixes.

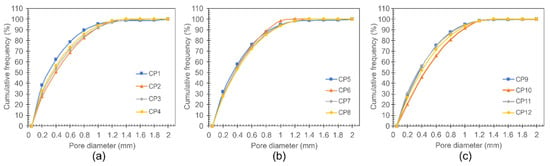

Figure 9 shows cumulative frequency as a function of average pore diameters for different amounts of foam. Figure 9a–c refer to fine, medium, and coarse CDW granulometries, respectively. Results indicate that pore sizes, which are considered to be perfect circles, showed a variation from 20 µm to 1200 µm. Based on D10, D50, and D90 (which are used to represent the mean and ranges of particle sizes), it can be stated that there was a slight increase in the diameter of pores when there was an increase in FA from 3.8% to 5.3% (D10—62 µm to 95 µm; D50—325 µm to 395 µm; D90—838 µm to 910 µm), while pore diameter remained almost constant with FA increases from 5.3% to 8.1%. Medium pore sizes were found to be: D10—80 µm; D50—372 µm; D90—903 µm.

Figure 9.

Cumulative frequency (%) as a function of average pore diameter for different amounts of foam. Granulometry: (a) fine; (b) medium and (c) coarse CDW.

Another aspect with respect to pore sizes that can be noticed is an increase in the average D10 and D50 sizes for increases in DWG granulometry (fine: D10—52 µm, D50—347 µm; medium: D10—80 µm, D50—355 µm; coarse: D10—98 µm and D50—379 µm). For D90 changes that are not linear, medium CDW pore diameters had the smallest sizes of all fractions (D90—865 µm), which remained almost the same for fine (D90—899 µm) and coarse (D90—897 µm) fractions. Findings for D50 and D90 are in agreement with Nambiar and Ramamurthy [39] for foam volumes of 40% and 50%.

4. Conclusions

In the present work, foamed concrete blocks were developed with the addition of construction and demolition waste (CDW) as a substitute aggregate of natural sand. Based on the results and discussion, the following conclusions are made:

- CDW can be used as an aggregate in the manufacture of foamed concrete blocks, reducing the liabilities of construction civil companies and reducing environmental impacts due to the irregular disposal of this waste. Also, with the use of this residue, it is possible to reduce the consumption of natural sand, which is a finite aggregate and its extraction causes environmental damages, mainly in riverbeds and lakes.

- The results of the CDW characterization show that the granulometry and the chemical composition were suitable for the development of foamed concrete. It is relevant to note that CDW was used only with the sifting process. According to the Brazilian standard NBR 7211, the CDW with medium distribution granulometry is the most appropriate for the development of cellular concrete blocks. The chemical elements, densities, fineness modulus, and swelling found in the CDW from Passo Fundo, RS region resemble the CDW of other Brazil regions.

- For the concrete blocks developed, foam amount and CDW granulometry had significant influences on compressive strength, dry and wet density, water absorption, and air voids. Foam amount was the independent variable with the highest influence on dependent variables. However, in order to improve the properties of foamed concrete blocks, other proportions of foams may be studied, and also the addition of additives in the concrete may be made with greater compressive strength. In this way, the concrete blocks can be competitive with concrete blocks already marketed.

Acknowledgments

Two Authors (Rodrigo and Richard) would like to thank Fundação Meridional for financial support grant.

Author Contributions

Patrícia Favaretto performed the tests, analyzed the results and wrote the paper. Gelsa Edith Navarro Hidalgo and Carlos Hoffmann Sampaio assisted in the characterization of CDW and analysis of the results. Rodrigo de Almeida Silva and Richard Thomas Lermen planned the study, assisted in the analysis of the results and with writing the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bravo, M.; Santos Silva, A.; de Brito, J.; Evangelista, L. Microstructure of Concrete with Aggregates from Construction and Demolition Waste Recycling Plants. Microsc. Microanal. 2016, 22, 149–167. [Google Scholar] [CrossRef] [PubMed]

- Pacheco-Torgal, F.; Tam, V.W.Y.; Labrincha, J.A.; Ding, Y.; de Brito, J. Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing Limited: West Conshohocken, CA, USA, 2013; p. 663. [Google Scholar]

- Kumar, R. Influence of recycled coarse aggregate derived from construction and demolition waste (CDW) on abrasion resistance of pavement concrete. Constr. Build. Mater. 2017, 142, 248–255. [Google Scholar] [CrossRef]

- European Commission. EU Construction & Demolition Waste Management Protocol. 2016. Available online: http://ec.europa.eu/growth/content/eu-construction-and-demolition-waste-protocol-0_en (accessed on 10 october 2017).

- Böhmer, S.; Moser, G.; Neubauer, C.; Peltoniemi, M.; Schachermayer, E.; Tesar, M.; Walter, B.; Winter, B. Aggregates Case Study; Final Report; Umweltbundesamt: Vienna, Austria, 2008; Available online: http://www.sarmaproject.eu/uploads/media/JRC_Aggregates_FinalRep_UBA_080331.pdf (accessed on 23 July 2017).

- Li, T.; Xiao, J.; Zhu, C.; Zhong, Z. Experimental study on mechanical behaviors of concrete with large-size recycled coarse aggregate. Constr. Build. Mater. 2016, 120, 321–328. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J.; Duan, H.; Ouyang, L.; Huang, W.; Zuo, J. An innovative approach to managing demolition waste via GIS (geographic information system): A case study in Shenzhen city, China. J. Clean. Prod. 2016, 112, 494–503. [Google Scholar] [CrossRef]

- ABRELPE. Panorama dos Resíduos Sólidos no Brasil 2015; Associação Brasileira de Empresas de Limpeza Pública e Resíduos Especiais (ABRELPE): São Paulo, Brasil, 2015; Available online: http://www.abrelpe.org.br/panorama_edicoes.cfm (accessed on 10 July 2017).

- Miranda, L.F.R.; Angulo, S.C.; Careli, É.D. A reciclagem de resíduos de construção e demolição no Brasil: 1986–2008. Ambient. Construído 2009, 9, 57–71. [Google Scholar]

- Bernardes, A.; Thomé, A.; Prietto, P.D.M.; de Abreu, Á.G. Quantificação e classificação dos resíduos da construção e demolição coletados no município de Passo Fundo, RS. Ambient. Construído 2008, 8, 65–76. [Google Scholar]

- Freitas, I.M. Os Resíduos de Construção Civil no Município de Araraquara/Sp; Centro Universitário de Araraquara—UNIARA: Araraquara, São Paulo, Brasil, 2009. [Google Scholar]

- PMPF. Prefeitura Busca Interessados Para Iniciar Programa Habitacional. Secretaria de Comunicação Social, Prefeitura Municipal de Passo Fundo (PMPF): Passo Fundo, Brazil, 2014. Available online: http://www.pmpf.rs.gov.br/interna.php?t=19&c=11&i=8035 (accessed on 20 August 2017).

- Ulsen, C.; Kahn, H.; Hawlitschek, G.; Masini, E.A.; Angulo, S.C.; John, V.M. Production of recycled sand from construction and demolition waste. Constr. Build. Mater. 2013, 40, 1168–1173. [Google Scholar] [CrossRef]

- Angulo, S.C.; Teixeira, C.E.; de Castro, A.L.; Nogueira, T.P. Resíduos de construção e demolição: Avaliação de métodos de quantificação. Engenharia Sanitaria e Ambiental 2011, 16, 299–306. [Google Scholar] [CrossRef]

- CONAMA. Resolução nº 307, de 05 de Julho de 2002: Estabelece Diretrizes, Critérios e Procedimentos Para a Gestão dos Resíduos da Construção Civil; Conselho Nacional do Meio Ambiente (CONAMA), Ministério do Meio Ambiente: Brasília, Brazil, 2002. Available online: http://www.mma.gov.br/estruturas/a3p/_arquivos/36_09102008030504.pdf (accessed on 20 August 2017).

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef] [PubMed]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Jones, R.; Zheng, L.; Yerramala, A.; Rao, K.S. Use of recycled and secondary aggregates in foamed concretes. Mag. Concr. Res. 2012, 64, 513–525. [Google Scholar] [CrossRef]

- Saiz Martínez, P.; González Cortina, M.; Fernández Martínez, F.; Rodríguez Sánchez, A. Comparative study of three types of fine recycled aggregates from construction and demolition waste (CDW), and their use in masonry mortar fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef]

- Poon, C.-S.; Chan, D. Effects of contaminants on the properties of concrete paving blocks prepared with recycled concrete aggregates. Constr. Build. Mater. 2007, 21, 164–175. [Google Scholar] [CrossRef]

- Jones, M.; McCarthy, A.; Dhir, R. Recycled and Secondary Aggregates in Foamed Concrete. Project Code: DTI/WRAP Agregates Research Programme STBF 13/13C; The Waste & Resources Action Programme. 2005. Available online: https://slideblast.com/recycled-and-secondary-aggregates-in-foamed-concrete-wrap_594ca6fa1723dd7b7ba6de0b.html (accessed on 12 August 2017).

- Levy, S.; Helène, P. Durability of concrete mixed with fine recycled aggregates. Exacta 2007, 5, 25–34. [Google Scholar] [CrossRef]

- Gomes, P.C.C.; de Alencar, T.F.F.; Silva, N.V.d.; de Moraes, K.A.M.; Angulo, S.C. Obtenção de concreto leve utilizando agregados reciclados. Ambient. Construído 2015, 15, 31–46. [Google Scholar] [CrossRef]

- Lamond, J.F.; Pielert, J.H. Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM: Montgomery, PA, USA, 2006. [Google Scholar]

- Hernández-Zaragoza, J.B.; López-Lara, T.; Horta-Rangel, J.; López-Cajún, C.; Rojas-González, E.; García-Rodríguez, F.; Adue, J. Cellular concrete bricks with recycled expanded polystyrene aggregate. Adv. Mater. Sci. Eng. 2013, 2013, 160162. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Kunhanandan Nambiar, E.K.; Indu Siva Ranjani, G. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Qu, X.; Zhao, X. Previous and present investigations on the components, microstructure and main properties of autoclaved aerated concrete—A review. Constr. Build. Mater. 2017, 135, 505–516. [Google Scholar] [CrossRef]

- Richard, A.O.; Ramli, M. Experimental production of sustainable lightweight foamed concrete. Br. J. Appl. Sci. Technol. 2013, 3, 994. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Pedro, R.; Tubino, R.; Anversa, J.; De Col, D.; Lermen, R.; Silva, R. Production of Aerated Foamed Concrete with Industrial Waste from the Gems and Jewels Sector of Rio Grande do Sul-Brazil. Appl. Sci. 2017, 7, 985. [Google Scholar] [CrossRef]

- ABNT. NBR NM 248—Agregados—Determinação da Omposição Granulométrica; Associação Brasileira De Normas Técnicas: São Paulo, Brasil, 2003. [Google Scholar]

- ABNT. NBR 9776—Agregados—Determinação da Massa Específica de Agregados Miúdos por Meio do Frasco Chapman; Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 1987. [Google Scholar]

- ABNT. NBR 6467—Agregados—Determinação do Inchamento de Agregado Miúdo—Método de Ensaio; Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 2006. [Google Scholar]

- ABNT. NBR 5739—Concreto—Ensaio de Compressão de Corpos-de-Prova Cilindricos; Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 2007. [Google Scholar]

- ASTM. C 948-81. Standard—Dry And Wet Bulk Density, Water Absorption and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ABNT. NBR 9778—Argamassa e Concreto Endurecidos—Determinação da Absorção de Água por Imersão—Índice de Vazios e Massa Específica; Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 1987. [Google Scholar]

- British Standards Institution. BS 480-11. Admixtures for Concrete, Mortar and Grout-Test Methods-Part 11: Determination of Air Void Characteristics in Hardened Concrete; British Standards Institution: London, UK, 2005. [Google Scholar]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On void structure and strength of foamed concrete made without/with additives. Constr. Build. Mater. 2015, 85, 157–164. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Air-void characterisation of foam concrete. Cem. Concr. Compos. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- Yang, Z.; Huddleston, J.; Brown, H. Effects of Wood Ash on Properties of Concrete and Flowable Fill. J. Mater. Sci. Chem. Eng. 2016, 4, 101–114. [Google Scholar] [CrossRef]

- Babu, D.S.; Ganesh Babu, K.; Tiong-Huan, W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Laukaitis, A.; Žurauskas, R.; Keriene, J. The effect of foam polystyrene granules on cement composite properties. Cem. Concr. Compos. 2005, 27, 41–47. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Gnappi, G.; Moriconi, G.; Montenero, A. Reuse of ground waste glass as aggregate for mortars. Waste Manag. 2005, 25, 197–201. [Google Scholar] [CrossRef] [PubMed]

- ABNT. NBR 7211—Agregados para Concreto—Especificação; Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 2005. [Google Scholar]

- De Fonseca, F.B. Desempenho Estrutural de Paredes de Alvenaria de Blocos de Concreto de Agregados Reciclados de Rejeitos de Construção e Demolição; Universidade de São Paulo—USP: São Carlos, Brasil, 2002. [Google Scholar]

- Ulsen, C.; Kahn, H.; Angulo, S.C.; John, V.M. Composição química de agregados mistos de resíduos de construção e demolição do Estado de São Paulo. REM: Revista Escola Minas 2010, 63, 339–346. [Google Scholar] [CrossRef]

- Angulo, S.C.; Ulsen, C.; John, V.M.; Kahn, H.; Cincotto, M.A. Chemical-mineralogical characterization of C&D waste recycled aggregates from Sao Paulo, Brazil. Waste Manag. 2009, 29, 721–730. [Google Scholar] [PubMed]

- Silva, M.B.d.L.e. Novos Materiais à Base de Resíduos de Construção e Demolição (Rcd) e Resíduos de Produção de cal (Rpc) para uso na Construção Civil; Universidade Federal do Paraná: Curitiba, Brazil, 2014. [Google Scholar]

- Haach, V.G.; Vasconcelos, G.; Lourenço, P.B. Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars. Constr. Build. Mater. 2011, 25, 2980–2987. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Models relating mixture composition to the density and strength of foam concrete using response surface methodology. Cem. Concr. Compos. 2006, 28, 752–760. [Google Scholar] [CrossRef]

- ABNT. NBR 13438—Blocos de Concreto Celular Autoclavado—Requisitos; Associação Brasileira de Normas Técnica: São Paulo, Brasil, 2013. [Google Scholar]

- Krämer, C.; Schauerte, M.; Kowald, T.L.; Trettin, R.H. Three-phase-foams for foam concrete application. Mater. Charact. 2015, 102, 173–179. [Google Scholar] [CrossRef]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. Failure mechanism of foamed concrete made with/without additives and lightweight aggregate. J. Adv. Concr. Technol. 2016, 14, 511–520. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Sorption characteristics of foam concrete. Cem. Concr. Res. 2007, 37, 1341–1347. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).