Abstract

With the depletion of shallow coal resources, deep extra-thick coal seam mining has become vital for energy security, yet fully mechanized top-coal caving (FMTC) goaf-side roadways face severe challenges of excessive advanced deformation and intense strata behavior. To address this gap, this study took the 4301 tailgate of a coal mine in Shaanxi province as the engineering background, integrating field investigation, theoretical analysis, FLAC3D numerical simulation, and industrial tests. Guided by the key stratum theory, we systematically analyzed the influence of overlying key strata fracture on strata pressure. The results show three key strata: near-field secondary key strata (KS1, KS2) with “vertical O-X” fracturing and far-field main key stratum (MKS) with “horizontal O-X” fracturing. The radial extrusion force from MKS rotational blocks is the core cause of 200 m range advanced deformation. A collaborative control scheme of near-field key strata directional fracturing roof-cutting pressure relief and high-strength bolt-cable support was proposed. Industrial verification indicates roadway deformation was significantly reduced, with roof subsidence, floor heave, and rib convergence controlled within safe engineering limits. This study fills the gap of insufficient research on far-field key strata’s impact, providing a reliable technical solution for similar extra-thick coal seam FMTC goaf-side roadway surrounding rock control.

1. Introduction

China possesses substantial coal reserves, with thick and ultra-thick coal seams constituting approximately 45% of the total national resources, thereby serving as a cornerstone for the nation’s energy security [1,2]. With the gradual depletion of shallow-depth deposits, the strategic development of deep coal resources has become imperative [3,4,5]. However, the application of conventional ground pressure theories and surrounding rock control strategies in FMTC roadways within ultra-thick seams under specific geological conditions poses significant challenges [6,7,8]. The inadequacy of these existing approaches results in a considerable reduction in the surrounding rock’s load-bearing capacity, manifesting as frequent rib spalling, highly concentrated abutment pressures in advance roadway sections, and deformations exceeding control thresholds. These issues collectively hinder safe and efficient mining operations [9,10,11].

In recent years, regarding the issues of strata movement laws, intense strata behavior manifestation, and its control in extra-thick coal seam mining, numerous scholars have conducted research from diverse perspectives and achieved a series of progressive findings [12,13,14,15]. Li et al. [16] established a novel “separation + interface” simulation method, demonstrating through physical experiments that separation beneath high-level hard strata impedes overburden load transfer to the goaf, inducing coal seam stress concentration that triggers severe roadway deformation and prop failure. Yang et al. [17] demonstrate that stope width directly governs trapezoidal spatial structure height, driving a transition in strata fracture patterns from horizontal to vertical O-X configurations, with elastic thin plate theory validating key stratum stability and revealing suspended dimension relationships that proved effective in field applications. Guo et al. [18] developed a Winkler-based Timoshenko beam model incorporating coal-rock elastoplasticity, demonstrating that hard thick roof hydraulic fracturing effectively controls impact loads by reducing PBSD and shortening rupture distances. Guo et al. [19] demonstrate that graded rock-breaking technology controls roof pressure by releasing bending strain energy through stratified fragmentation, effectively weakening hard strata and enhancing ground control capacity. Li et al. [20] established a mining bearing capacity model for hard roof cantilever structures based on elastic foundation beam theory, revealing the evolution of bearing capacity and energy accumulation-dissipation mechanisms in high-hardness roofs, with field trials confirming that integrated control technology effectively mitigates strong ground pressure during extraction. Unver et al. [21] used FLAC3D to model top-coal caving at the Omerler Mine in Turkey, identifying a 1.5–2.0 m well-fractured zone above shields and a 3.0–3.5 m poorly fractured layer that obstructs caving, and proposed targeted pre-fracture blasting to achieve uniform fragmentation, reduce dilution, and improve extraction efficiency. Lin et al. [22] conducted a preliminary numerical study using FLAC3D to assess ground response and interaction effects in the future underground mining of double extra-thick coal seams at Mae Moh mine in Thailand, considering challenges such as deep cover, complex geology, and large final slopes. Ji et al. [23] proposed a superposition-based beam model incorporating a partially yielded coal seam and non-uniform overburden to simplify the analysis of roof strata stability and failure patterns in longwall mining. These research findings have, to some extent, elucidated the impact mechanisms of strong ground pressure on working faces in ultra-thick coal seams and proposed corresponding control measures. However, studies considering the influence of fracture movements in far-field key strata on ground pressure manifestations remain relatively limited.

In this study, a combined research approach integrating field investigation, laboratory tests, theoretical analysis, and numerical simulation was adopted. Based on the key stratum theory for strata control [24,25], the mechanism of large deformation in the surrounding rock of the advanced section of goaf-side roadways in extra-thick coal seams was systematically investigated. Additionally, the fracture characteristics of overlying rock in FMTC mining of extra-thick coal seams were identified. Combined with theoretical mechanical models and numerical simulation results, stable control measures for goaf-side roadways were scientifically proposed. The results of industrial tests demonstrate that the control effect is remarkably significant.

2. Engineering Background

2.1. Geological Overview of the Mining Face

The coal mine is located in the southern part of the Huangling Mining Area in Yan’an City, Shaanxi Province. The mine field covers a registered area of approximately 49 km2, with dimensions of about 10.5 km in the east–west direction and 6.4 km in the north–south direction. The currently active 4301 panel is located on the western flank of the 43rd mining district. This panel is oriented in a southwest–northeast direction and is geographically constrained by unmined areas to the north, the goaf of the adjacent 4300 panel to the south, the boundary of the 4-2 coal seam to the west, and the protective coal pillar of the main entries in the 43rd district to the east.

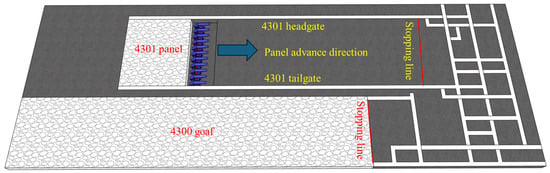

The 4301 panel is designed to extract the No. 4-2 coal seam. This seam has an average burial depth of 800 m and a mean thickness of 8.50 m, classifying it as an ultra-thick coal seam. The minable panel dimensions include a strike length of 2940 m and a dip length of 300 m. The seam inclination ranges from 2° to 6°, with an average of approximately 3°. Structurally, the coal seam exhibits a banded texture and layered formation, characterized by medium hardness, brittle behavior, and well-developed joint systems. It contains 1 to 3 partings, with individual thicknesses ranging from 0.20 m to 0.60 m (locally reaching 1.6 m), averaging 0.60 m. The layout of the 4301 panel is presented in Figure 1.

Figure 1.

Layout of the 4301 panel.

2.2. Characteristics of Strata Behavior in the 4301 Panel

The 4301 panel mines the No. 4-2 coal seam at a depth of 800 m using the FMTC method. As the panel advances over long distances with high mining intensity, ground pressure manifestations in the stope have become increasingly severe. The goaf-side 4301 tailgate experiences intense ground pressure, resulting in significant surrounding rock deformation characterized by substantial roof subsidence, severe floor heave, and extensive rib spalling. The peak rib convergence reaches 950 mm, with frequent support failures including tensile fractures of rock bolts and rupture of anchor cables. Although the panel is equipped with ZY18000 shield supports rated at 18,000 kN working resistance, they remain inadequate to withstand the strong ground pressure impacts. During mining operations, rapid yielding of support legs and frequent opening of safety valves have been repeatedly observed, posing serious threats to the continuous and safe extraction of the longwall panel.

Field strata pressure monitoring data reveal that the intense strata behavior in the 4301 panel exhibits an obvious periodic pattern. Statistical analysis shows that the advance distance intervals between successive intense strata behavior events are 169 m, 154 m, 176 m, and 180 m, respectively. Combined with the strata pressure observation records of similar panels in this mining field from 2018 to 2025, a total of 86 cases of such intense strata behavior have been documented. Data statistics indicate that the interval distances between adjacent intense strata behavior occurrences are concentrated in the range of 160–180 m, and most of these intervals exhibit the characteristic of being integer multiples of values within this range. Before the panel advanced to 169 m, the strata behavior was mild with low weighting intensity, and the average working resistance of the hydraulic supports remained below 12,000 kN. However, when the advance distance reached 340 m, a sudden intense strata behavior event occurred: the maximum bearing capacity of the supports surged to 21,000 kN instantaneously, exceeding the rated resistance by 16.7%. This abnormal pressure impact resulted in varying degrees of damage to 12 hydraulic supports.

3. Stope Spatial Strata Structure of the 4301 Panel

3.1. Determination of Key Stratum Positions and Fracture Modes in Overlying Strata

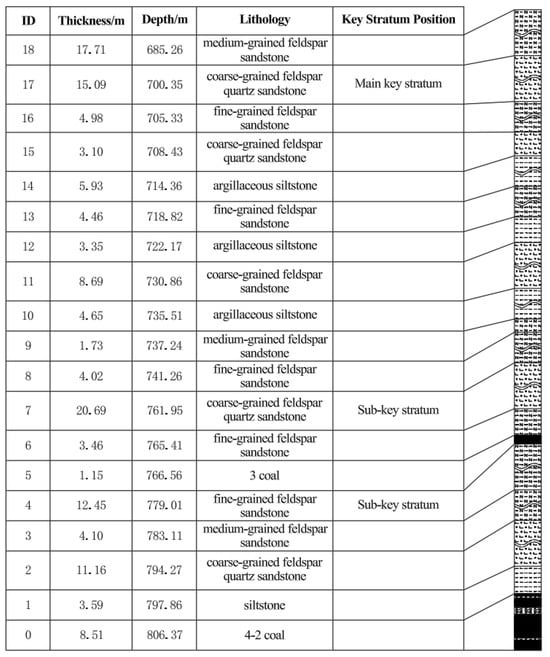

The intensity and distribution pattern of stope strata behavior are essentially determined by the structural fracture characteristics and movement state of the key strata in the overlying rock mass. Different fracture characteristics of the primary and secondary controlling key strata directly lead to distinct stope strata pressure response features [26,27]. Therefore, it is necessary to conduct a specific analysis from the perspective of identifying the primary and secondary controlling rock strata for intense strata behavior, combined with the surface borehole columnar section of the 4301 panel in the 4-2 coal seam of the coal mine. Based on the Key Stratum Theory proposed by Academician Qian Minggao [28], a systematic identification of the key stratum positions in the overlying rock mass of this working face was carried out. This provides a fundamental basis for the subsequent analysis of the influence of rock stratum fracture on strata pressure. The conditions of the overlying rock mass and the identification results of interlayer key strata in the 4301 panel are illustrated in Figure 2.

Figure 2.

Identification of key strata in the overburden of 4301 panel.

Under the conditions of FMTC in ultra-thick coal seams, the spatial dimensions of the goaf area increase significantly, leading to progressive fracture of the roof strata from bottom to top in a plate-like structural form. Influenced by the fracture angle of the rock layers and differences in lithology between strata, the vertical distance from various stratigraphic levels to the coal seam varies, resulting in corresponding changes in the exposed dimensions along both the dip and strike directions of the working face [29,30]. Consequently, the plate-type fracture characteristics of individual rock layers exhibit distinct variations [31]. Following the criterion for determining key stratum fracture characteristics [32], the following formulas are employed to calculate the dip exposure length (), panel width (), and weighting interval () of each key stratum overlying the 4301 panel, enabling quantitative analysis of the fracture patterns in key strata [33]:

In the equation: is the weighting interval, m; is the exposed area of the key stratum, m2; is the dip exposure length of the key stratum, m; is the working face width, m; is the critical breaking span of the key stratum, m; is the vertical distance between the key stratum and the coal seam, m.

Substituting the specific geological parameters of the 4301 panel into the aforementioned formulas yields the core parameters of each key stratum, with the results presented in Table 1.

Table 1.

Exposed length, ultimate span, and weighting interval of key strata in the overburden of 4301 panel.

Based on the classification of key stratum fracture characteristics and combined with the above calculation results [34], it is concluded that for the sub-key strata KS1 and KS2 in the overlying rock mass of the 4301 panel, their dip exposure length () meet the conditions and respectively, and their weighting intervals () satisfy and correspondingly. These sub-key strata (KS1 and KS2) exhibit “vertical O-X” fracture characteristics and belong to near-field key strata, i.e., secondary controlling key strata. For the main key stratum (MKS), its dip exposure length () meets , and the weighting interval () satisfies . This stratum undergoes “horizontal O-X” fracture and is identified as a far-field key stratum, i.e., the primary controlling key stratum. The corresponding relationship between the fracture types of each key stratum and their near-field/far-field attributes is presented in Table 2.

Table 2.

Fracture types of key strata in the overburden of 4301 panel.

In conclusion, the sub-key strata KS1 and KS2 are identified as secondary controlling key strata, which correspond to near-field key strata; the main key stratum (MKS) is defined as the primary controlling key stratum, and it belongs to the far-field key stratum.

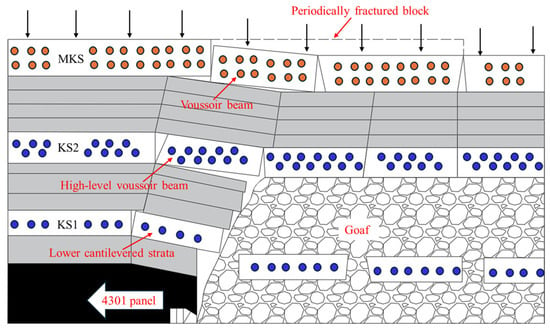

3.2. Structural Morphology of Key Stratum Fracture

Based on the aforementioned findings that the sub-key strata undergo “vertical O-X” fracturing while the main key stratum experiences “horizontal O-X” fracturing, the structural configuration of the overlying key strata post-fracture is determined by the spatial constraints following the collapse of the immediate roof. If the caved space accommodates the maximum rotation required for forming articulated structures after key stratum fracture, a voussoir beam structure develops; otherwise, a cantilever beam structure forms. At the No. 4-2 ultra-thick coal seam of the mine, where the cumulative mining height using the FMTC method reaches 11 m, the large extraction thickness significantly influences the structural behavior. Key strata that would form a “voussoir beam” under smaller mining heights may exceed their rotational capacity for stable articulation under these conditions, consequently developing into “cantilever beam” structures. Only key strata at sufficiently elevated positions can form stable “voussoir beam” structures under such high-extraction conditions.

The specific discrimination is conducted based on Formula (4) for analysis [28].

In the equation: is the mining height of panel, m; is the height of collapsed strata beneath key stratum, m; is the bulking factor of caved zone rock; is the thickness of key stratum, m; is the critical breaking span of key stratum, m; is the load acting on key stratum and its overlying strata, MPa; is the compressive strength of key stratum fractured blocks, MPa.

Based on Formula (4), the fracture-induced structural configurations of the overlying key strata at the 4301 panel were evaluated. The results indicate that the sub-key stratum KS1 forms a “cantilever beam” structure after fracture, while both the sub-key stratum KS2 and the main key stratum (MKS) develop “voussoir beam” structures post-fracture. A schematic model illustrating the fracture patterns and structural configurations of the overburden key strata is presented in Figure 3.

Figure 3.

Schematic diagram of the structural configuration of the overburden key stratum after fracture in 4301 panel.

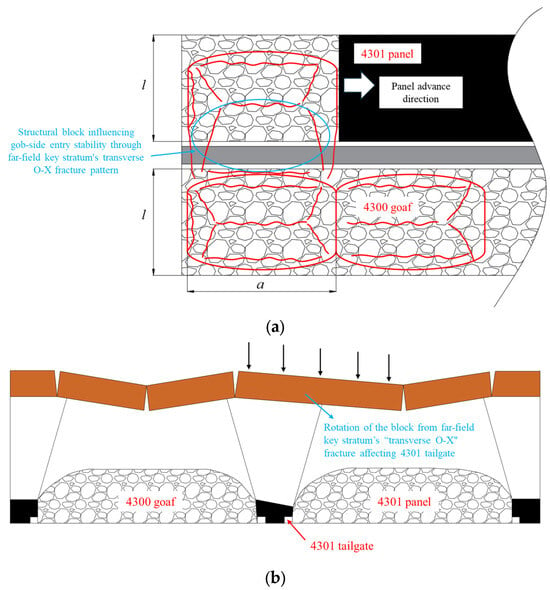

3.3. Effect of Key Stratum Fracture Modes on Goaf-Side Roadways

The disturbance effects of different key stratum fracture modes on the goaf-side roadway exhibit significant differentiation, governed by the spatial configuration between the 4301 panel and the adjacent 4300 goaf. The near-field sub-key strata, KS1 and KS2, are characterized by “vertical O-X” fracturing, with their fracture lines extending perpendicular to the roadway axis. The resulting composite “cantilever beam and voussoir beam” structure imposes axial loads on the roadway in the direction of face advance. These axial loads can be partially compensated for by conventional support systems, and their overall impact on roadway stability remains within a controllable range.

The “horizontal O-X” fracture of the far-field main key stratum (MKS) constitutes the dominant mechanism inducing large deformations in the goaf-side roadway. As illustrated in Figure 4a, the fracture lines of MKS develop parallel to the axis of the 4301 tailgate. The resulting fractured blocks form a large-scale voussoir beam structure that undergoes rotational movement under the overburden load of ultra-thick strata. Critically, this rotation occurs perpendicular to the roadway axis (Figure 4b), thereby imposing radially concentrated compressive forces on the roadway cross-section. Furthermore, the overlying strata above the adjacent 4300 goaf have completed their stable fracturing process, and the resulting residual stress field intensifies the rotational tendency of the MKS blocks. This mechanical interaction leads to persistent radial compression acting on the roof, floor, and both ribs of the roadway, ultimately triggering excessive roof subsidence, floor heave, and rib convergence beyond allowable limits—eventually causing complete failure of the support system.

Figure 4.

Schematic diagram of the governing key stratum’s role in the transverse O-X fracture at 4301 tailgate: (a) plan view; (b) sectional view.

The analysis reveals that the hazardous nature of the “horizontal O-X” fracture primarily stems from the resulting voussoir beam structure, whose axis of rotation aligns parallel to the roadway axis. This configuration directs the substantial pressure generated by block rotation directly onto the roadway ribs, creating high susceptibility to global instability. Evidently, given the fixed spatial position of the roadway, the most effective approach to control this failure mode involves fundamentally altering the fracture behavior of the far-field key stratum itself. Based on this premise, the subsequent section will employ numerical simulation to demonstrate that implementing roof cutting in near-field key strata can modify stress transfer and redistribution pathways. This intervention forces the far-field key stratum to either undergo favorable transformation in its fracture pattern or experience significant reduction in its fracture span, thereby ultimately mitigating its adverse impact on the goaf-side roadway.

3.4. Analysis of Strata Pressure Observation Results in the 4301 Panel

3.4.1. Analysis of Weighting Occurrence in the 4301 Panel

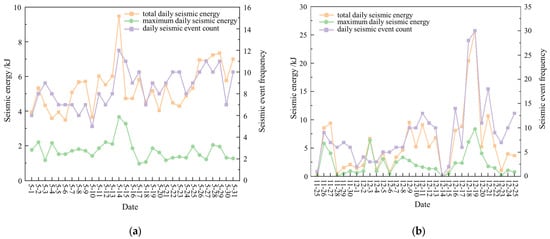

Microseismic data from the 4301 panel during May 2025 were collected and processed, as shown in Figure 5a. On 14 May 2025, when the face had advanced to 499 m, a periodic strong ground pressure event was recorded. Comparative analysis with microseismic data from the adjacent 4304 panel in the same mining district during December 2022 (Figure 5b) reveals that the 4304 panel also experienced a periodic strong ground pressure event on 18–19 December 2022, at a comparable advance distance of 512 m.

Figure 5.

Microseismic monitoring data plot: (a) 4301 panel; (b) 4304 panel.

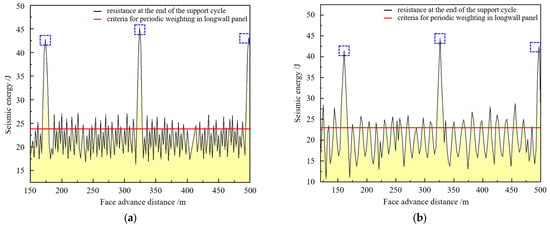

Monitoring data from hydraulic supports at both the panel center and the tailgate end of the 4301 panel were selected to plot the resistance curves at the end of support cycles during face advance to 600 m, as shown in Figure 6.

Figure 6.

The curve of the hydraulic support average cycle end resistance: (a) shield supports at the panel center; (b) tailgate end supports of the 4301 panel.

Under the combined influence of far-field and near-field key strata, distinct major and minor periodic weighting events were observed at the 4301 panel. The minor weighting intervals ranged from 21 to 30 m, averaging 26.4 m, while major weighting intervals averaged 160–180 m, with intensities 1.7–2.1 times greater than minor events. The four recorded strong ground pressure events at the 4301 panel occurred at advance distances of 169 m, 323 m, 499 m, and 679 m, while those at the adjacent 4304 panel were recorded at 173 m, 332 m, 512 m, and 673 m. The consistent 160–180 m spacing of these events across both panels indicates they originate not from the fracture of near-field key strata, but are fundamentally associated with the breakage of higher-positioned far-field key strata.

Field measurements corroborate the theoretical calculations regarding strong ground pressure events induced by the fracture of the main key stratum (MKS), confirming that during the extraction of the No. 4-2 ultra-thick coal seam using the fully mechanized top-coal caving method, periodic strong ground pressure occurs at advance intervals of 160–180 m due to the “horizontal O-X” fracture of the far-field MKS. This pattern demonstrates consistent applicability within the No. 4-2 mining district, thereby providing field validation for the preceding theoretical analysis.

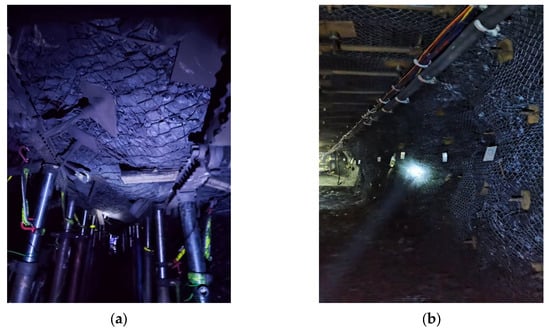

3.4.2. Analysis of Roadway Surrounding Rock Observation Results

Monitoring of surrounding rock deformation in the gateways of the 4301 panel revealed distinctly different behaviors during panel extraction. The 4301 headgate, flanked by solid coal on both sides, exhibited negligible deformation. In contrast, the 4301 tailgate began to experience severe deformation and failure after the face advanced beyond 169 m. Specifically, floor heave initiated 150–200 m ahead of the working face, rib spalling and significant roof-to-floor convergence occurred within 100 m ahead, and intense damage concentrated within 50 m of the face. Particularly in the mechanically supported section at the face end, substantial surrounding rock convergence severely impeded production operations, as documented in Figure 7.

Figure 7.

Failure conditions in the area ahead of 4301 tailgate: (a) roof deformation; (b) rib deformation.

Field monitoring data of the surrounding rock in the 4301 tailgate are presented in Figure 8.

Figure 8.

Surrounding sock deformation data plot for the advanced section of the 4301 tailgate: (a) roof–floor; (b) ribs.

The field strata pressure observation results indicate that no significant deformation or failure occurred in the 4301 headgate. In contrast, severe floor heave and surrounding rock deformation and failure took place within the range of 200 m ahead of the panel in the mining gateway adjacent to the goaf, namely the 4301 tailgate, with remarkable differences observed in both deformation degree and influence scope. From the perspective of the action mechanism of key strata, although the periodic fracture of low-horizon key strata can induce advanced abutment pressure on the roadway, the influence zone of this pressure is generally small due to the constraints of its fracture scale and energy transmission range. This cannot explain the advanced deformation phenomenon occurring within the 200 m range of the roadway adjacent to the goaf. Thus, it can be determined that the disaster-causing root cause of the abnormal roadway deformation is not the low-horizon key strata, but should be attributed to the key stratum structure at higher horizons.

Further analysis integrating previous theoretical findings confirms that the abnormal strong ground pressure manifestations in the 4301 tailgate correspond precisely with the disaster-causing process of the trapezoidal plate structure formed by the “horizontal O-X” fracture of the far-field main key stratum. When this trapezoidal plate undergoes rotation, it imposes a sustained lateral compressive force on the underlying goaf-side roadway. The superposition of this force and the load from the overlying strata, if exceeding the bearing capacity of the coal mass on both sides of the roadway, directly triggers severe deformation damage, including floor heave and rib convergence. This mechanism constitutes the fundamental reason why the destruction intensity in the goaf-side roadway significantly exceeds that in other gateway locations.

4. Comprehensive Control Technology for the 4301 Tailgate

4.1. Advanced Roof Cutting and Pressure Relief Technology for the 4301 Tailgate

Theoretical analysis and field measurements presented in previous sections demonstrate a clear hierarchical structure of key strata in the overburden of the 4301 panel, comprising both primary and subordinate control strata. The near-field subordinate key strata KS1 and KS2 undergo “vertical O-X” fracturing, forming “cantilever beam” and “voussoir beam” structures, respectively. In contrast, the far-field main key stratum (MKS) experiences “horizontal O-X” fracturing, developing a stable voussoir beam structure. The radial compressive forces generated by the rotation of the fractured MKS blocks are identified as the fundamental mechanism responsible for the large deformations and instability in the surrounding rock of the goaf-side roadway. Furthermore, the overlying strata above the adjacent 4300 goaf have reached a state of caving equilibrium. Their fracture patterns and associated stress distribution exacerbate the ground pressure manifestations in the 4301 tailgate. Conventional support methods prove inadequate in fundamentally interrupting the load transfer from the far-field key stratum to the roadway.

To address this issue, it is necessary to proceed from the technical logic of “source control-process regulation-forced modification” and proactively intervene in the fracture behavior of near-field key strata to alter the overlying rock stress transmission path and the fracture mode of far-field key strata. Specifically, advanced directional fracturing roof cutting is implemented on the low-level near-field key strata to force them to deviate from their original “vertical O-X” fracture pattern and collapse in advance. On one hand, this eliminates the load transmission channel formed by the secondary controlling key strata themselves; on the other hand, the sufficient collapse of low-level rock strata fills the goaf, restricting the exposed space of the far-field primary controlling key stratum (MKS). This prevents the MKS from forming large-scale “horizontal O-X” fractures or decomposes it into small-scale fractured blocks to reduce the rotational squeezing force.

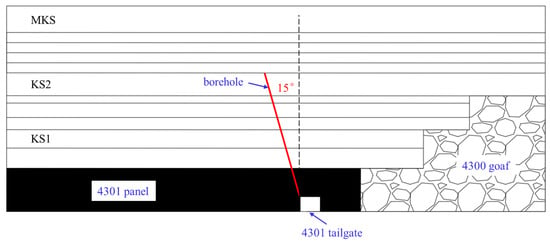

Based on this, combined with the geological conditions of the 4301 panel, the cross-sectional dimensions of the 4301 tailgate, the roof cutting engineering volume, and the rock mechanical parameters, a targeted roof-cutting pressure-relief technical scheme for the 4301 tailgate was developed. Specifically, in the 4301 tailgate, 50 m or more ahead of the 4301 panel and perpendicular to the coal rib, directional long-borehole hydraulic fracturing technology was adopted. Boreholes were drilled obliquely upward at a 15° elevation angle toward the 4301 panel, with a borehole spacing of 50 m and a roof cutting height of 58 m, as shown in Figure 9.

Figure 9.

Schematic diagram of the presplitting borehole layout.

4.2. Numerical Simulation Analysis of Roof-Cutting Pressure Relief

4.2.1. Establishment of Numerical Model

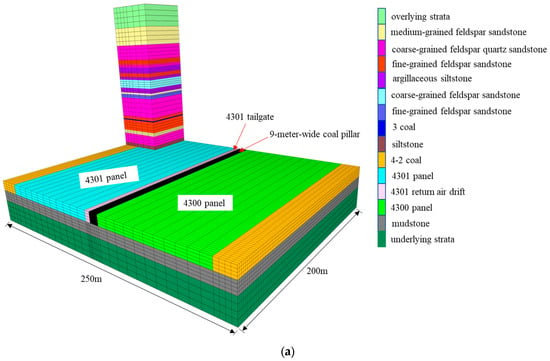

To analyze the fracture types of each key stratum in the overlying rock strata of the 4301 panel, a numerical model was established based on the actual geological conditions and roadway layout of the 4301 panel. A numerical calculation model was constructed using FLAC3D, as shown in Figure 10, with dimensions of 250 m (length) × 200 m (width) × 190 m (height). The 4301 tailgate was arranged with dimensions of 5.0 m × 3.5 m, containing a total of 2,230,400 elements and 2,454,010 nodes. The displacement of the model’s bottom surface and the four side surfaces (front, rear, left, and right) was fixed. A vertical stress of 16.25 MPa was applied to the top of the model, with a lateral pressure coefficient of 1.0.

Figure 10.

Numerical simulation model: (a) overall view; (b) cross-section.

Based on the mechanical parameters of roof and floor rock strata provided by the mine, the mechanical parameters adopted for each rock stratum in the numerical model are determined, as shown in Table 3. To restore the mechanical properties of rock stratum materials as accurately as possible, the Mohr-Coulomb model was used to simulate the rock strata.

Table 3.

Physical and Mechanical Parameters of Rock Strata for FLAC3D Numerical Simulation.

4.2.2. Numerical Simulation Analysis Before and After Roof Cutting

To investigate the evolution of surrounding rock stability before and after pressure relief, numerical models with and without roof cutting were established [35]. By examining the distribution patterns of displacement and vertical stress evolution in the surrounding rock, this study further elucidates the mechanistic role of roof cutting in maintaining roadway stability.

To simulate the field-implemented directional fracturing for roof-cutting pressure relief, this study employed the embedded joint model approach within the FLAC3D numerical model. According to the on-site roof-cutting design scheme, the influenced zone of roof cutting was defined along the axis of the 4301 tailgate, extending 50 m ahead of the working face advance direction. The roof-cutting height was set to 58 m, corresponding to the thickness range of the near-field secondary key strata (KS1 and KS2). Borehole layout parameters—spacing of 50 m and inclination angle of 15°—were geometrically projected in the model to delineate the element zones containing embedded joints.

The simulation procedure for roof-cutting pressure relief was conducted as follows:

- Initial Equilibrium: The complete geological model was established and brought to initial geostatic equilibrium.

- Simulation without Roof Cutting: The working face was excavated stepwise according to the actual mining advance distance. Surrounding rock stresses and displacements were recorded as baseline references.

- Simulation with Roof Cutting: Prior to excavation, mechanical parameters were assigned to specified stratum units within the roof-cutting zone. Excavation was then performed for the joint elements after parameter assignment. The working face was subsequently re-excavated, and the mechanical responses before and after roof cutting were compared for analysis.

This simulation primarily focuses on the mechanical effects of active pressure relief and does not incorporate a refined model for the interaction between support structures and surrounding rock.

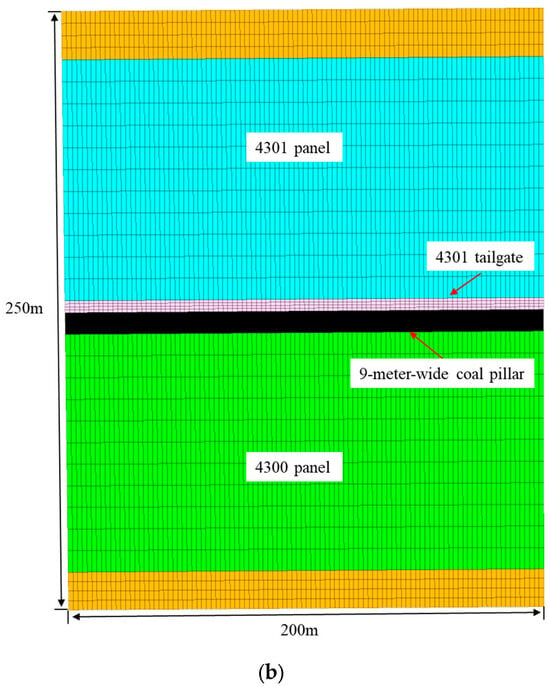

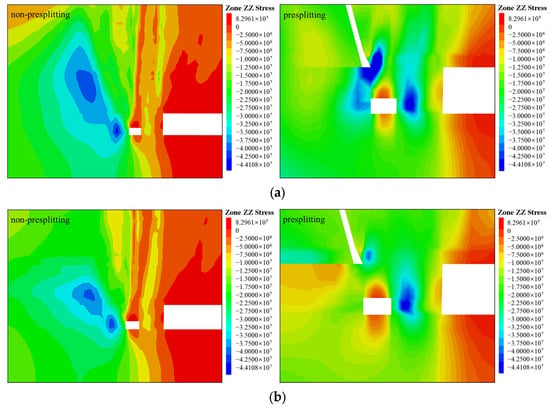

(1) Characteristics of Vertical Stress Distribution

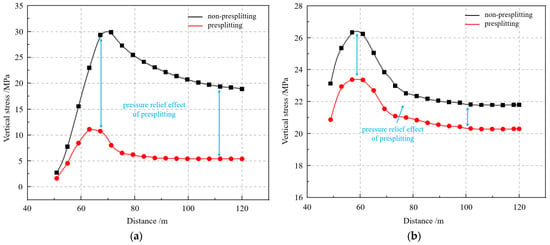

To reveal the mechanical mechanism of roof-cutting pressure relief in controlling roadway deformation, a comparative analysis was conducted on the vertical stress distribution law of the 4301 tailgate before and after pressure relief. After the working face was excavated by 50 m and the model reached equilibrium, the vertical stress distribution patterns at 50 m and 150 m in the advance section of the 4301 tailgate under the two simulation schemes are shown in Figure 11 and Figure 12.

Figure 11.

Distribution law of vertical stress in the advanced section of the 4301 tailgate before and after presplitting: (a) advance 50 m; (b) advance 150 m.

Figure 12.

Vertical stress curves with and without presplitting: (a) solid coal rib; (b) coal pillar rib.

Combined with the numerical simulation results and the actual geological conditions of the 4301 panel, this study on the vertical stress distribution characteristics around the goaf-side tailgate before and after roof cutting shows the following: Before roof cutting, the vertical stress in the areas 50 m and 150 m ahead of the roadway exhibited the characteristics of “high concentration and narrow-range distribution”. The peak vertical stress of the solid coal rib reached 3.08 × 107 Pa, and that of the coal pillar rib reached 2.68 × 107 Pa, with a high stress concentration coefficient. Moreover, the high-stress zone was transmitted along the straight path from the far-field primary controlling key stratum to the roadway, and the range 200 m ahead of the roadway was affected by high stress, which was consistent with the on-site phenomenon of large deformation in the advance section of the roadway. After roof cutting, the directional fracture of the near-field secondary controlling key stratum destroyed the original stress transmission channel. The peak vertical stress in the areas 50 m and 150 m ahead of the roadway decreased significantly: the peak vertical stress of the solid coal rib dropped to 1.13 × 107 Pa, and that of the coal pillar rib reached 2.32 × 107 Pa. The high-stress zone changed from a “narrow-peak type” to a “broad-gentle type”, the stress influence range was reduced, and the stress state of the coal mass returned to the safe bearing range. After roof cutting, the vertical stress of the solid coal rib decreased by 63.3%, and that of the coal pillar rib decreased by 13.3%.

This result confirms that implementing roof cutting on the near-field key stratum can effectively cut off the load transmission path from the far-field key stratum to the roadway, realize the release and redistribution of vertical stress, and provide mechanical support for the stability control of the surrounding rock of the goaf-side roadway.

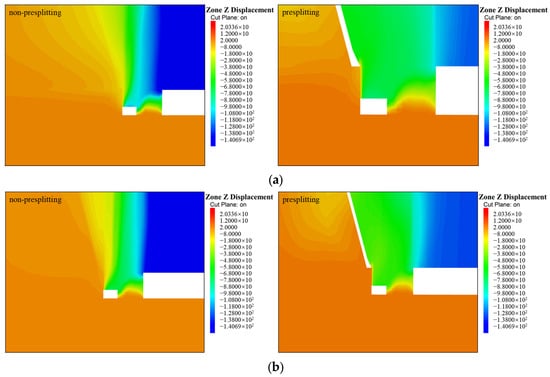

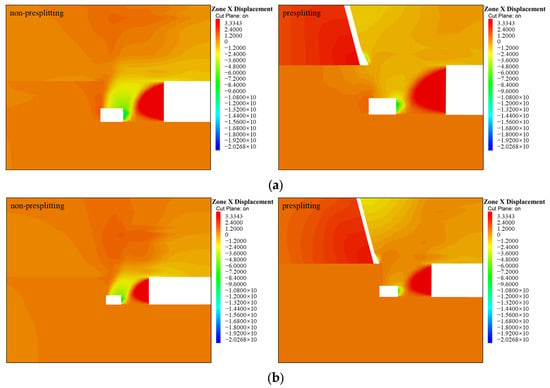

(2) Displacement Analysis

A comparative analysis of the vertical and horizontal displacement patterns in the 4301 tailgate was conducted before and after pressure relief. The vertical and horizontal displacements at 50 m and 150 m within the advanced section of the 4301 tailgate under both simulation schemes are presented in Figure 13, Figure 14 and Figure 15.

Figure 13.

Vertical displacement contours in the advanced section of the 4301 tailgate before and after presplitting (unit/mm): (a) advance 50 m; (b) advance 150 m.

Figure 14.

Horizontal displacement contours in the advanced section of the 4301 tailgate before and after presplitting (unit/mm): (a) advance 50 m; (b) advance 150 m.

Figure 15.

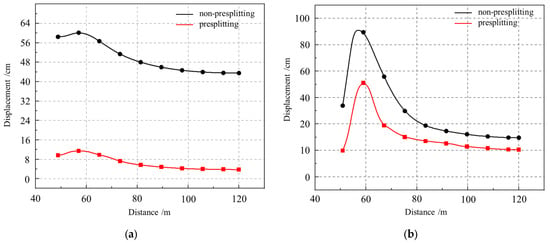

Surrounding rock deformation curves of the gateway with and without presplitting: (a) roof subsidence; (b) rib-to-rib convergence.

Analysis of the numerical simulation results regarding the vertical and horizontal displacement characteristics of the 4301 tailgate before and after roof cutting further verifies the control effectiveness of this pressure relief technology on surrounding rock stability. Prior to roof cutting, the advanced section of the airway exhibited a “concentrated large deformation” pattern: the peak vertical roof displacement reached 616.69 mm, and the maximum rib convergence measured 930.27 mm. Deformation was predominantly localized at the roof, floor, and the goaf-side rib, consistent with field observations and indicative of the continuous damaging effect caused by radial compressive forces resulting from the “horizontal O-X” fracture of the far-field key stratum. Following roof cutting, the displacement distribution transitioned to a “uniform small deformation” mode. The peak vertical roof displacement decreased to 130.45 mm, representing a 78.8% reduction, while the peak horizontal displacement was reduced to 500.36 mm, a 46.1% decrease. The zone of significant deformation ahead of the face was shortened from 200 m to 80 m, with deformations becoming more uniformly distributed between the roof, floor, and ribs. These results confirm that roof cutting effectively mitigates the compressive action of the far-field key stratum on the roadway by disrupting the stress transfer pathway through the near-field key strata.

4.3. Support Scheme for the 4301 Tailgate

The roof cutting and pressure relief technique establishes a mechanical foundation for roadway stability by disrupting the load transfer path from far-field key strata. However, relying solely on this approach is insufficient to fully counteract the residual stresses and localized deformation risks in the surrounding rock. Optimizing support parameters to design a new high-strength passive support system is essential for controlling radial forces and achieving substantial reductions in horizontal convergence. The synergistic interaction between this system and active pressure relief technology constitutes the core mechanism for stabilizing surrounding rock, as reliance on either technique alone cannot achieve comparable control effectiveness. The new high-strength passive support system not only supplies radial support force but also, through its high system stiffness and pre-tensioning, establishes a continuous, reinforced compressive bearing arch within the surrounding rock mass. This bearing arch effectively absorbs and redistributes residual horizontal compressive stresses persisting after roof cutting, significantly restraining the shear-dilation deformation in the pressure-relieved zone and limiting further expansion of the plastic zone. By providing sustained lateral confinement, it transforms the “active deformation” of the coal rib into “passive resistance” within the support system.

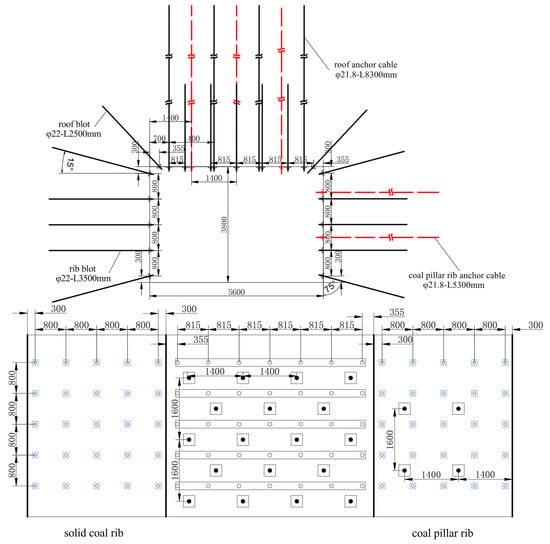

To enhance the load-bearing capacity of the surrounding rock and achieve synergistic stability control through “active pressure relief and passive support,” a combined bolt-cable support scheme is proposed, specifically designed for the geological conditions of the 4301 tailgate.

(1) Roof bolt support: Threaded steel bolts with a diameter of Φ22 mm and length of 2500 mm are adopted, with a spacing and row distance of 815 mm × 850 mm, and 7 bolts per row. They are equipped with 150 mm × 150 mm × 8 mm iron bearing plates. T140-L5100/7 steel strips with a length of 5100 mm and a spacing of 850 mm are used. 8# diamond-shaped wire mesh with dimensions of 1000 mm × 6000 mm is installed on the roadway roof.

(2) Roof cable support: Steel strand cables with a diameter of Φ21.8 mm and length of 8300 mm are arranged in a staggered pattern with a spacing and row distance of 1400 mm × 850 mm. They are equipped with 300 mm × 300 mm × 16 mm iron bearing plates, and the ends are fixed with locksets.

(3) Mining face rib bolt support: Threaded steel bolts with a diameter of Φ22 mm and length of 3500 mm are used, with a spacing and row distance of 800 mm × 850 mm. They are equipped with 200 mm × 200 mm × 10 mm iron bearing plates. 8# diamond-shaped wire mesh with dimensions of 1000 mm × 3600 mm is hung on the rib.

(4) Coal pillar rib bolt support: Threaded steel bolts with a diameter of Φ22 mm and length of 3500 mm are adopted, with a spacing and row distance of 800 mm × 850 mm. They are equipped with 200 mm × 200 mm × 10 mm iron bearing plates. 8# diamond-shaped wire mesh with dimensions of 1000 mm × 3600 mm is hung on the rib.

(5) Coal pillar rib cable support: Hollow grouting cables with a specification of Φ21.8-L5300 mm are adopted, with a spacing and row distance of 1400 mm × 1600 mm, and arranged at a distance of 1400 mm from the roadway floor. They are equipped with 300 mm × 300 mm × 16 mm iron bearing plates, and the ends are fixed with locksets. The specific support parameters are shown in Figure 16.

Figure 16.

Control parameters of roadway surrounding rock.

4.4. Field Implementation Results

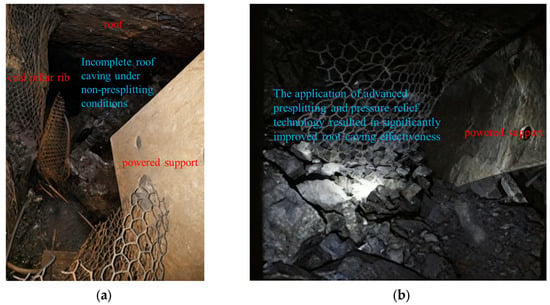

After the industrial test, the advanced roof-cutting pressure relief technology for the 4301 tailgate successfully cut off the load transmission path of the “horizontal O-X” fracture in the far-field primary controlling key stratum by directional fracturing of the low-level near-field key stratum. During the period of intense strata pressure, the maximum working resistance of the ZY18000-type supports decreased from 21,000 kN to 14,500 kN; the single maximum microseismic energy during intense strata pressure periods dropped from 4.2 × 103 J to 2.5 × 103 J, with a total energy release reduction of 37.6%. This completely eliminated support crushing accidents, and the periodic impact intensity and energy release scale of intense strata pressure were significantly reduced, transforming the strata pressure behavior from “violent and uncontrolled” to “stable and controllable”. The on-site roof caving conditions of the 4301 tailgate before and after roof cutting are shown in Figure 17.

Figure 17.

Field observations of roof caving conditions at the face area before and after presplitting: (a) non-presplitting; (b) presplitting.

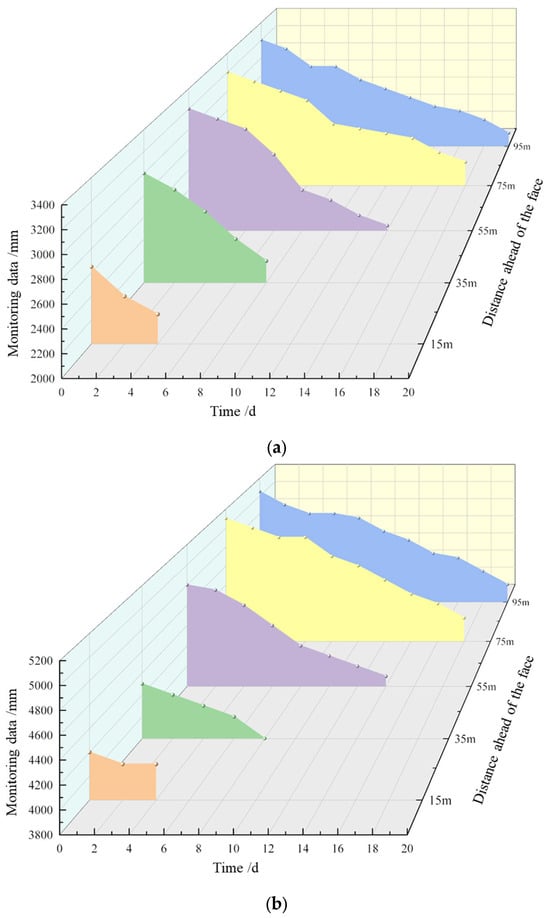

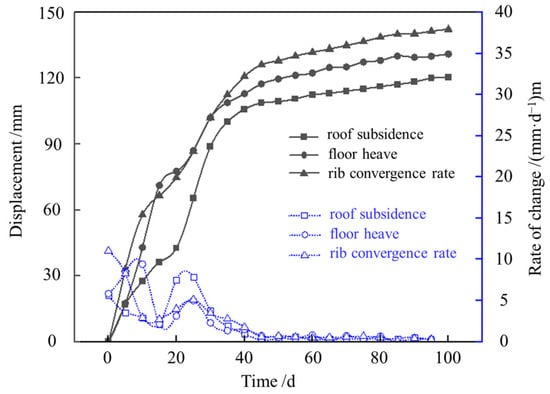

The implementation of roof cutting and pressure relief achieved comprehensive control of roadway deformation. Working synergistically with the bolt-cable support system to manage surrounding rock movement, the maximum roof subsidence was reduced from 530 mm to below 120 mm—a 77.3% decrease—while the maximum rib convergence decreased from 950 mm to below 150 mm, representing an 84.2% reduction. Furthermore, the advance influence range of significant deformation was shortened from over 200 m to 80 m. This effectively resolved the critical issue of extensive, advanced large deformations in the goaf-side roadway, ensuring that the roadway cross-section maintained the required spatial dimensions for continuous panel extraction. These results validate the engineering effectiveness of this technology for stabilizing surrounding rock in gateways developed for ultra-thick coal seam mining using the fully mechanized top coal caving method.

The exceptional control performance achieved in the field results from the combined action of “roof cutting and pressure relief” and “high-strength synergistic support,” generating a synergistic effect where the whole is greater than the sum of its parts (1 + 1 > 2).The convergence-time curve for the 4301 tailgate, based on field monitoring data, is presented in Figure 18.

Figure 18.

Field-measured surrounding rock deformation versus time curve for the 4301 tailgate.

5. Conclusions

Through a series of research efforts, including on-site investigation, numerical simulation, and theoretical analysis, this study draws the following conclusions:

(1) Based on the identification framework for primary and secondary controlling rock strata of intense strata pressure, combined with the key stratum theory, it is determined that there are three key strata in the overlying rock of the 4301 panel: the near-field secondary controlling key strata (KS1 and KS2) and the far-field primary controlling key stratum (MKS). The analysis shows that the near-field secondary controlling key strata (KS1 and KS2) undergo “vertical O-X” fractures, forming a “cantilever beam + masonry beam” structure; and the far-field primary controlling key stratum (MKS) undergoes “horizontal O-X” fractures, forming a “masonry beam” structure. Among them, the weighting interval of the far-field primary controlling key stratum (MKS) is >160 m, and the radial squeezing force generated by the rotation of its fractured blocks is the core cause of large-scale roadway deformation in the advance section (over 200 m) of the 4301 tailgate.

(2) Aiming at the load transmission of the far-field key stratum, a scheme of directional fracturing for the low-level near-field key stratum is proposed. The numerical simulation analysis and on-site application show remarkable effects: the peak vertical stress of the roadway is significantly reduced, and the high-stress zone presents a “broad-gentle” distribution; the deformation of the roof and floor is reduced by more than 83.3%, the rib convergence is reduced by 78.9%, and the advance deformation influence range is shortened to 80 m; during intense strata pressure, the maximum working resistance of the supports decreases from 21,000 kN to 14,500 kN, the maximum microseismic energy is reduced by 37.6%, support crushing accidents are completely eliminated, and the support integrity rate increases from 72% to 98%.

(3) A set of surrounding rock control technology systems suitable for goaf-side roadways in extra-thick coal seams of a coal mine in Shaanxi province is constructed, and a collaborative technology system of “source cutting of load transmission-process enhancement of surrounding rock bearing capacity” is established. This system ensures that roadway deformation remains stably within the safety threshold for a long time. After on-site application, the 4301 tailgate meets the requirements of continuous mining, and the support cost is reduced. This study can provide an engineering paradigm for strata pressure control of goaf-side roadways in fully mechanized top-coal caving working faces of the same type of extra-thick coal seams.

Author Contributions

S.Y.: writing—original draft, methodology. Y.W.: writing—review and editing, visualization. J.B.: supervision. X.L.: data curation. Q.Q.: software. All authors have read and agreed to the published version of the manuscript.

Funding

The research described in this paper was financially supported by the Jiangsu Province International Collaboration Program-Key National Industrial Technology Research and Development Cooperation Project (BZ2024024); and the National Natural Science Foundation of China (No. 52574126 and U21A20107).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Wang, H.; Tian, C.; Liu, Y.; Li, Y.; Lu, M.; Jiao, J.; Bai, J.; Qiao, Z. Overburden structure fracture evolution and ground pressure behavior under oblique residual coal pillars in thick seam mining. Sci. Rep. 2025, 15, 30932. [Google Scholar] [CrossRef] [PubMed]

- Shan, R.; Wu, H.; Sun, P.; Huang, G.; Bai, H.; Li, Y.; Zhao, X. Analysis of the mechanism and effects of advanced pipes support in roadways. Sci. Rep. 2025, 15, 15230. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Cao, C.; Li, G.; Guo, B. Anchorage performance of a new rebar bolt under different surrounding rock strength and borehole depth. Sci. Rep. 2024, 14, 9581. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Cheng, S.; Lv, J.; Wu, Z.; Huang, A. Numerical analysis of impact resistance mechanical properties of energy-absorbing columns under static and dynamic loads. Sci. Rep. 2024, 14, 25347. [Google Scholar] [CrossRef]

- Chen, D.; Wang, X.; Zhang, F.; Bai, J.; Zhao, X.; Li, M.; Yu, Y.; Wang, X.; Sun, S. Study on the Mechanism of Progressive Instability of Special-Shaped Coal Pillar and the Stability Control of Roadway Under the Influence of Mining. Rock Mech. Rock Eng. 2024, 57, 6461–6483. [Google Scholar] [CrossRef]

- Sun, D.; Ding, H.; Sun, Y.; Yi, X. Borehole transient electromagnetic response calculation and experimental study in coal mine tunnels. Meas. Sci. Technol. 2024, 35, 045112. [Google Scholar] [CrossRef]

- Kang, X.; Xie, X.; Zeng, K.; Li, A. Numerical simulation and physical modeling of staged control support for roadway stability in water rich weakly cemented sandstone. Sci. Rep. 2025, 15, 11635. [Google Scholar] [CrossRef]

- Zhou, K.; Dou, L.; Kan, J.; Yang, K.; Li, J.; Ma, X. Coal burst mechanism in large-scale panel under extra-thick key strata. Geomat. Nat. Hazards Risk 2024, 15, 2347420. [Google Scholar] [CrossRef]

- Zhang, N.; Cao, A.; Zhao, W.; Hao, Q.; Lv, G.; Wu, B. Layout Pattern of Small Panel and Large Coal Pillar for Rockburst Prevention and Water Control under Extra-Thick Water-Bearing Key Strata. Appl. Sci. 2024, 14, 2195. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Du, F.; Li, G. Study on fracture characteristics of high key stratum and development law of water and gas transport channels in Datong mining area. Energy Sci. Eng. 2023, 11, 48–61. [Google Scholar] [CrossRef]

- Zhang, D.; Bai, J.; Tian, Z.; Zhang, Z.; Guo, Y.; Wang, R.; Xu, Y.; Fu, H.; Yan, S.; Deng, M.; et al. Stability mechanism and control of the pumpable supports in longwall recovery room. Int. J. Min. Sci. Technol. 2024, 34, 957–974. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, Q.; He, Y.; Wang, Q.; Wei, Y. A study on the mechanism and control technology of strong mine pressure in parallel coal pillar and hard roof mining. Front. Earth Sci. 2024, 12, 1407084. [Google Scholar] [CrossRef]

- Lu, Y.; Yan, S.; Zhou, K.; Zhang, C.; Zhou, Y. Structural quantification of multi-thick hard roof and strong ground pressure control in large mining height stope: A case study. Geomech. Geophys. Geo-Energy Geo-Resour. 2025, 11, 56. [Google Scholar] [CrossRef]

- Godyń, K. Structurally altered hard coal in the areas of tectonic disturbances—An initial attempt at classification. Arch. Min. Sci. 2016, 61, 677–694. [Google Scholar] [CrossRef]

- Bednarek, Ł.; Małkowski, P.; Niedbalski, Z.; Mucha, K. Steel arch and rock bolt support in terms of the Gateroad stability maintaining behind the longwall face. Appl. Sci. 2024, 14, 3594. [Google Scholar] [CrossRef]

- Li, Z.; Qi, C.; Gao, R.; Yu, B.; Zhu, Y.; Zhang, H.; Zhang, J. Simulation Study and Engineering Application of Weakening Mine Pressure Behavior in Stope through Ground Fracturing Thick and Hard Rock Strata. Appl. Sci. 2024, 14, 415. [Google Scholar] [CrossRef]

- Yang, Z.; Zheng, Z.; El Naggar, M.H.; Liu, C. Study on the fracture characteristics of overlying rock strata under different mining face widths. Sci. Rep. 2025, 15, 11298. [Google Scholar] [CrossRef]

- Guo, F.; Peng, M.; Meng, X.; Tai, Y.; Yu, B. Control Mechanism of Earthquake Disasters Induced by Hard–Thick Roofs’ Breakage via Ground Hydraulic Fracturing Technology. Processes 2025, 13, 919. [Google Scholar] [CrossRef]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.; Zhang, W. Ground fracturing of multi-strata for strong ground pressure control in extra-thick coal seams with hard roofs: Numerical simulation and case study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar] [CrossRef]

- Li, Y.; Tai, Y.; Yu, B.; Kuang, T.; Gao, R.; Liu, J. Evolution and control technology of energy aggregation and dissipation of a high hard roof during breakage and destabilization. Int. J. Fract. 2024, 245, 1–23. [Google Scholar] [CrossRef]

- Unver, B.; Yasitli, N.E. Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int. J. Coal Geol. 2006, 66, 227–252. [Google Scholar] [CrossRef]

- Lin, N.; Sasaoka, T.; Shimada, H.; Hamanaka, A.; Matsuia, K. Numerical analysis of interaction effects in double extra-thick coal seams mining. Procedia Earth Planet. Sci. 2013, 6, 343–349. [Google Scholar] [CrossRef]

- Ji, S.; He, H.; Karlovšek, J. Application of superposition method to study the mechanical behaviour of overlying strata in longwall mining. Int. J. Rock Mech. Min. Sci. 2021, 146, 104874. [Google Scholar] [CrossRef]

- Guo, G.; Yang, Y. The study of key stratum location and characteristics on the mining of extremely thick coal seam under goaf. Adv. Civ. Eng. 2021, 2021, 8833822. [Google Scholar] [CrossRef]

- Chen, Y.; Gong, F.; Zhao, M. The study on the movement law of overlying strata in fully mechanized caving face under alluvium with huge thickness in deep mine. IOP Conf. Ser. Earth Environ. Sci. 2017, 59, 012039. [Google Scholar] [CrossRef]

- Yang, K.; Chi, X.; Liu, W.; Dou, L.; Wei, Z. Strong ground pressure mechanism and control at the longwall top coal caving with a single key stratum in goaf. Shock. Vib. 2020, 2020, 8835101. [Google Scholar] [CrossRef]

- Chen, L.; Kong, D.; Li, L.; Liu, Q.; Zhang, P.; Zhang, L.; Yujun, Z. Analysis of the impact of key strata failure on overlying strata and surface transport patterns. Eng. Fail. Anal. 2024, 163, 108532. [Google Scholar] [CrossRef]

- Qian, M.; Miao, X.; Xu, J.; Mao, X. Key Strata Theory in Strata Control; China University of Mining and Technology Press: Xuzhou, China, 2003; pp. 11–12. [Google Scholar]

- Zheng, R.; Hao, B.; Shi, C.; Li, T. Study on the Ground Pressure Manifestation Patterns of Roof Cutting and Pressure Relief. Appl. Sci. 2025, 15, 6049. [Google Scholar] [CrossRef]

- Pan, C.; Xia, B.; Zuo, Y.; Yu, B.; Ou, C. MMechanism and control technology of strong ground pressure behaviour induced by high-position hard roofs in extra-thick coal seam mining. Int. J. Min. Sci. Technol. 2022, 32, 499–511. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, B.; Xia, N.; Zhou, L.; Gong, T. Material point method for simulating strong mining pressure manifestation in multiple hard roof panels controlled by hydraulic fracturing. Front. Earth Sci. 2025, 13, 1528088. [Google Scholar] [CrossRef]

- Qian, M.; Shi, P.; Xu, J. Mine Pressure and Strata Control; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Lyu, G.; Cao, A.; Xue, C.; Wang, S.; Hao, Q.; Bai, X.; Peng, Y.; Zhang, N. Rock burst mechanisms induced by dynamic and static loading under composite key strata: A case study. Sci. Rep. 2025, 15, 16935. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, X.; Qiu, Q.; Tian, Y.; Ren, W.; Xu, J.; Wang, X. Failure and development height of overlying rock of a water flowing fracture in goaf under a karst aquifer. Sci. Rep. 2025, 15, 2473. [Google Scholar] [CrossRef]

- Ismail, A.; Azadbakht, S. A comprehensive review of numerical simulation methods for hydraulic fracturing. Int. J. Numer. Anal. Methods Geomech. 2024, 48, 1433–1459. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.