Abstract

Aircraft maintenance is a complex, multifaceted process that greatly benefits from IT systems designed to improve supervision, record keeping, and task management. This study focuses on the role of a dedicated mobile application, integrated into the broader IT Aircraft Maintenance Support System, which supports maintenance operations for the M-346 BIELIK training aircraft. Aircraft maintenance is a highly intricate and multifaceted process that significantly benefits from advanced IT systems designed to enhance supervision, streamline record keeping, and optimize task management. This study explores the pivotal role of a dedicated mobile application integrated into the broader IT Aircraft Maintenance Support System, specifically tailored to support the maintenance operations of the M-346 BIELIK training aircraft. By focusing on the analysis of Intelligent Transportation Systems (ITSs), the research highlights how the application contributes to maintenance reliability and operational efficiency, with sustainability considerations in mind. The ITS-based approach assesses maintenance scheduling, tracking, and resource optimization, thereby enhancing the reliability of aircraft operations while reducing unnecessary resource consumption. This alignment with sustainable practices not only improves reliability characteristics and exploitation rates but also positively impacts the efficiency and effectiveness of aviation training. By accurately estimating the time requirements of specific maintenance tasks during periodic inspections, the application aids in identifying and addressing organizational bottlenecks, ultimately supporting both operational sustainability and improved task reliability across maintenance activities.

1. Introduction

IT systems are increasingly being integrated into various aspects of life, revolutionizing how processes are managed, and their role in the operation and maintenance of aircraft is no exception. These systems provide numerous advantages, such as convenient data storage, streamlined bureaucracy, reduced paper usage, and enhanced decision-making capabilities []. Such benefits have driven their widespread adoption across industries, with aviation being a notable example. The aviation sector has seen a growing trend in developing IT support systems tailored to meet the unique operational needs of modern aircraft. Practically every new aircraft is now equipped with a dedicated operational support system capable of collecting extensive data [,]. However, a detailed analysis of IT systems used in the Polish Air Force (PLAF), including those developed domestically and those supplied by foreign manufacturers, reveals that the vast potential of these systems often remains untapped [,,]. The systems generate a wealth of information that, with proper utilization, could significantly improve operational efficiency.

This study aims to demonstrate the critical role IT systems can play beyond their traditional use in managing and overseeing aircraft operations. By leveraging these systems to identify inefficiencies and propose targeted improvements, maintenance operations can be significantly optimized. Statistical methods for reliability analysis, well-documented in the existing literature, serve as a foundation for this research [,]. However, practical examples of their application in aviation are surprisingly limited. While these methods are primarily designed to evaluate the reliability of technical components, this study explores their broader applicability in enhancing maintainability. By addressing organizational inefficiencies, statistical techniques can help refine operational workflows and improve overall performance.

This study focuses on the M-346 BIELIK aircraft, a relatively new addition to the Polish Air Force’s fleet. Despite its modern design, the aircraft’s maintenance program remains underdeveloped. Manufacturer-provided documentation lacks critical details, such as specific task durations and recommended execution sequences. This lack of clarity poses significant challenges for effective planning and scheduling, leading to organizational delays and extended maintenance times. By conducting a detailed analysis of these challenges, the research aims to identify characteristics of maintenance task durations that could streamline operations, enhance efficiency, and reduce unnecessary delays [,,].

1.1. Review of Existing Research

The integration of IT technologies into aircraft maintenance processes has become a cornerstone of modern aviation operations. These technologies are crucial for enhancing task management, improving record keeping, and boosting overall operational efficiency. Despite the widespread adoption of IT-based support systems in aviation, there are notable gaps in research regarding their practical application in optimizing resource utilization and enhancing reliability. This shortfall is particularly evident in the framework of Intelligent Transportation Systems (ITSs), which aim to integrate advanced technologies into transportation systems for improved efficiency and sustainability. Military aviation, with its unique operational demands, presents specific challenges that require customized approaches to maintenance planning and execution [,,].

Research on aviation maintenance support systems has primarily focused on improving maintenance techniques [,], increasing fleet availability [], reducing the incidence of technical failures [], and enhancing scheduling efficiency [,]. Digital systems for real-time monitoring, as highlighted in numerous studies, demonstrated significant potential for streamlining maintenance planning and execution [,]. These systems excel at collecting and organizing vast amounts of operational data. However, their effectiveness in providing actionable insights for reliability improvements and efficiency gains remains underexplored. The current literature rarely addresses how these systems could reduce maintenance delays or optimize workflows based on observed task durations, leaving a critical gap in practical applications. This oversight underscores the need for research that bridges theoretical knowledge with real-world implementation.

1.2. Unsolved Problems

Military aviation maintenance faces a distinct set of challenges that set it apart from civilian maintenance operations. One prominent issue is the lack of precise guidelines from manufacturers for the durations and sequences of maintenance tasks [,,]. This ambiguity often results in inefficient scheduling and organizational delays, which affect technical readiness and overall operational efficiency. Research suggests that these issues are not isolated to specific aircraft models but are widespread across various military aviation platforms. The distinctive operational demands of military aviation often deviate from the assumptions made by manufacturers, further complicating maintenance workflows []. Addressing these challenges requires innovative and tailored solutions that align with the specific requirements of military operations.

Recent studies emphasize the potential of mobile technologies in maintenance contexts. Mobile applications specifically designed for maintenance management, like those of [,], provide a valuable solution for documenting task durations directly at the worksite, offering a new level of accuracy for reliability assessments. By enabling real-time recording and analysis of maintenance activities, mobile applications contribute to a more detailed understanding of task efficiency and can highlight inefficiencies or deviations in standard procedures. This approach supports the broader ITS objectives of optimizing resources and reducing operational downtimes, aligning with sustainability goals in aviation.

In line with global sustainability trends, studies such as [,,] emphasize the importance of developing maintenance systems that enhance efficiency and minimize environmental impact. Sustainable maintenance in aviation depends on reducing resource waste and energy consumption by optimizing the planning and execution of maintenance tasks. The integration of ITS principles with digital tools can facilitate more eco-friendly operations by minimizing unnecessary downtimes, optimizing resource allocation, and extending the lifespan of critical components.

1.3. Goal, Subject, and Scope of This Study

The overarching goal of this research is to develop and validate an IT-supported maintenance solution that addresses the identified challenges in military aviation maintenance. The focus is on the M-346 BIELIK aircraft operated by the Polish Air Force. The study explores how IT technologies can enhance maintenance efficiency, optimize task scheduling, and improve reliability analysis. Specifically, the research aims to identify characteristics of maintenance task durations, develop a mobile application for real-time data collection and analysis, and evaluate the potential of this solution in reducing organizational inefficiencies.

The research scope includes a detailed examination of existing maintenance practices, the development of a mobile application tailored to the needs of the M-346 BIELIK, and the integration of statistical methods to analyze task durations. By addressing these objectives, this study aims to provide practical insights and tools that enhance aviation maintenance processes. Additionally, the research aligns with global sustainability goals by promoting resource-efficient practices and minimizing environmental impacts. Through the innovative use of IT systems and advanced statistical techniques, this study aspires to set a new standard for maintenance operations in military aviation, providing a framework that could be adapted to other sectors of aviation as well.

2. The Importance of Supervising and Modeling the Maintenance Process

Dependability refers to the ability to provide trustworthy services within a time period. According to international standards [,,], it can be characterized as a set of properties describing the availability of the object and influencing it:

- Reliability;

- Maintainability;

- Providing support.

The term dependability is used only for a non-numeric general description.

Focusing on maintainability, it can be concluded that it is the ability of the object to maintain or restore, under given operating conditions, a state in which it can perform the required functions, assuming that the service is carried out under established conditions with the observance of established procedures and means [,].

Another definition describes maintainability as a property of a technical object, which is measured by the Maintainability function. The Maintainability function represents the probability of restoring the object to a working condition within a given time frame.

where the following variables are defined as follows:

- DMT—the duration of the maintenance task;

- m(τ)—is a function of the probability density of the duration of the maintenance task.

Maintainability programming consists of a set of activities aimed at endowing a technical object and its environment with features that facilitate maintenance to the greatest extent possible. We distinguish actions on the technical object itself and actions on elements of the object’s surroundings []. These activities are carried out during the following:

- Designing a technical facility;

- Designing the technique and organization of servicing an object with a shaped susceptibility to servicing.

The implementation of the second type of activities (in the vicinity of the facility) is essential, as their absence could hinder the effective use of the maintainability features built into the object during the design phase. Throughout the entire life cycle of a technical object, maintenance techniques and their organizational structure should be continuously improved [,,,].

3. Analysis of the Research Object Maintenance Process

The research conducted in this article focuses on the analysis of the maintainability of training jet aircraft. This paper focuses on foundational operational research of the M-346 aircraft. The M-346 aircraft is one of the most modern aircraft used in the Polish military aviation fleet, having been in service with the Polish Air Force since 2017. It is a twin-engine jet aircraft for flight training. In practical flight training, it is important to maintain high technical readiness in aircraft [,]. The success of the training sequence directly depends on the availability of the aircraft. Therefore, the effectiveness of the maintenance system is crucial.

The aircraft is maintained based on the use of two exploitation strategies. Condition-based maintenance is the dominant one. The condition of most aggregates must be checked periodically. Moreover, the operation of the remaining components follows the operation strategy with planned preventive works, based on their service life. This approach forces the aircraft user to carry out maintenance activities in a strictly defined time, in accordance with the adopted Maintenance Programme [,,,].

3.1. Airworthiness of Research Object

The starting point of the analysis is the airworthiness of the M-346 aircraft. Airworthiness refers to the condition in which the aircraft is capable of performing its intended tasks safely and effectively. The airworthiness of considered A/C is registered in dedicated IT System called Samanta [,]. Generally, airworthiness can be characterized by the following formula:

where

- C—A/C on the records [pcs.];

- D—airworthy A/C [pcs.];

- X—A/C not counted for airworthiness [pcs.];

- F—airworthiness [%].

The exact airworthiness percentage of the analyzed aircraft are sensitive data belonging to the organization in which it is used. This information should not be publicly disclosed. As a consequence, the following relationship was used to present the airworthiness tests conducted:

where

- max(F)—the highest recorded percentage airworthiness of the M-346 aircraft in 2018-2020.

On the basis of data from IT System Samanta, an airworthiness analysis of the aircraft was carried out M-346 in the years of 2018–2020, the results of which are presented in the table below (Table 1).

Table 1.

Airworthiness percentage of the M-346 aircraft in 2018–2020 in the Polish Air Force.

From the above data, it was concluded that higher airworthiness in the first year of operation is mainly due to the fact that new aircraft did not require as many periodic maintenance processes. In 2019, most of the higher-level periodic maintenance (conducted every two years) was performed, which significantly reduced the total airworthiness.

3.2. Analysis of the Duration of Periodic Maintenance of the M-346 Aircraft

An analysis of archive data was conducted, with a focus on examining the detailed work cards for each periodic service. Based on the information gathered, a list of periodic services performed at the Polish Air Force (PLAF) and their respective durations was compiled.

Between 2017 and 2020, a total of 35 periodic Calendar Post-Flight Inspection (CPFI) services were conducted at the PLAF. Each service was analyzed to identify factors that could influence the total service duration.

In some cases, the CPFI service coincided with a higher-level Post-Inspection (PI) service, resulting in both services being carried out in parallel. The execution of technical tasks included in the CPFI service was dependent on the progress of the PI service []. This often led to an extension of the overall maintenance duration. A total of eight CPFI services were carried out alongside PI services.

Another factor contributing to extended service durations was the unavailability of spare parts or logistic delays in their delivery. The CPFI service itself does not involve any replacements or repairs but focuses primarily on a thorough verification of the aircraft’s systems. However, if defects are identified during the inspection, defective components must be replaced. The duration of five CPFI services was extended due to delays in the availability of spare parts.

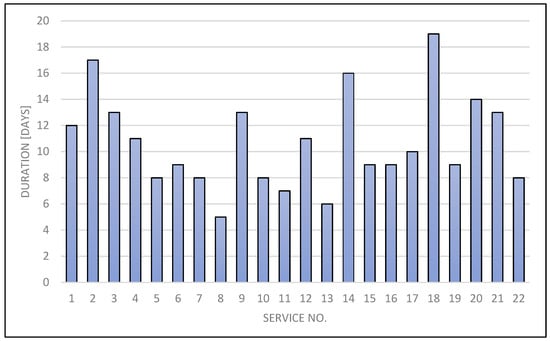

Taking into account the CPFI services performed independently and without logistic delays, we can distinguish 22 services. In the surveyed population of 22 services, the duration of the service (days) can be characterized by the basic statistical parameters listed in the table below (Table 2).

Table 2.

Duration of M-346 CPFI services performed in 2018–2020 in Polish Air Force—statistical parameters.

The presented parameters indicate a significant variation in service durations, as shown in the graph (Figure 1). Such a phenomenon may indicate major organizational problems, problems with planning and scheduling work.

Figure 1.

Chart—summary of the duration of CPFI servicing.

It is also important to note that the analyses conducted do not encompass other projects performed by technical personnel, which arise from the nature of military service. These include daily musters, shooting training, physical education classes, adherence to regulations, and other routine activities.

3.3. Conclusions from the Analysis

After analyzing the average airworthiness of the M-346 aircraft, it was concluded that the performance of long-term periodic maintenance has a significant impact on reducing the total airworthiness of military aircraft.

The technical documentation provided by the manufacturer of the M-346 aircraft does not specify the sequence of tasks to be performed during a given periodic maintenance. The user also has no information about the expected time of the completion of a specific task or its labor consumption. Therefore, it is not possible to precisely plan the course of the service based on the available technical documentation.

Operational documentation used during the operation of the aircraft the M-346, developed by the A/C manufacturer, as well as the documentation developed by the user, do not allow recording the labor consumption of individual tasks during periodic maintenance. Therefore, data on the labor intensity of individual tasks are not collected.

The current state of affairs does not allow the user to prepare a reliable schedule based on historical estimates. Furthermore, an analysis of the history of periodic maintenance performed in the PLAF reveals significant discrepancies in the total duration of individual maintenance tasks. Despite the relatively extensive experience in conducting semi-annual maintenance (CPFI), the times required to complete each maintenance cycle vary considerably.

Based on the analysis, it was determined that there is a need to develop a dedicated tool—an IT system for acquiring data on the duration of individual tasks included in the considered service.

4. Data Acquisition Tool—IT System Design

In order to collect the data from the maintenance process, a mobile application was built. The program records the times of performing each maintenance task included in the considered inspection. Based on the collected data, the duration of individual maintenance tasks was estimated. In practice, this was achieved by determining the probability distributions for individual maintenance tasks and then determining the parameters describing them.

Collecting the execution times of individual technical tasks represents a very narrow application of a mobile device, yet the developed application offers much broader functionality. The remaining functionalities will only be briefly mentioned to signal the general benefits of using mobile applications because, for the purposes of this article, their detailed description seems to be unjustified.

4.1. The Idea of an IT System for Monitoring the Service Process

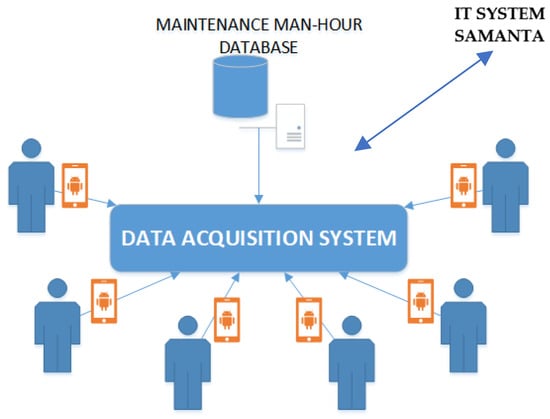

The basis of the IT system for assessing serviceability is the operational data acquisition subsystem, the main component of which is mobile devices. System users and service technicians will use an application that collects relevant data and sends them to the database server (Figure 2).

Figure 2.

Scheme of the IT system for maintenance man-hour data acquisition.

The mobile application designed as part of this thesis will be used to acquire data on the duration of individual technical tasks. The collected data will make it possible to generate probability distributions of the duration of individual technical tasks.

The idea of the entire system is much broader, and this work only focuses on its selected fragment, i.e., a mobile application for data acquisition on service durations. Below are the assumptions for the entire serviceability assessment system:

- Replacing paper registration documentation of aircraft with their digital version;

- Using a mobile device to record the activities performed during services;

- Collecting information enabling the performance of optimization analyses;

- Using the IT systems currently in use, extending them with the above-mentioned functionalities, e.g., the IT system Samanta.

The Samanta system, developed by the Air Force Institute of Technology, has been in use within the Polish Armed Forces since the late 1990s. Over this period, the system has undergone continuous improvements. Samanta is a modular IT solution designed to support aircraft operations, enabling both real-time and periodic analysis of reliability, flight safety, operational status, and resource management. It collects, processes, and transmits data related to aircraft, components, airport equipment, part shortages, and personnel training [].

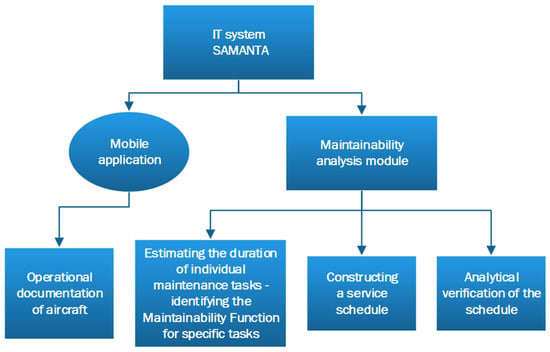

The diagram (Figure 3) below presents the concepts behind extending the Samanta IT system with additional functionalities. The extended Samanta IT system introduces advanced functionalities to enhance aircraft maintenance management. Key additions include the following:

Figure 3.

The concept of expanding the IT system Samanta.

- A mobile application that replaces traditional AMCs, allowing the real-time recording of maintenance tasks and their durations, improving data accuracy, and reducing manual errors.

- Maintainability Analysis Module: This module processes task data to estimate maintainability functions, optimize service schedules, and verify their reliability through advanced analytical tools.

- Enhanced Integration: The system links maintenance data with operational documentation, ensuring synchronized and updated records.

The baseline Samanta system focuses on broad operational data analysis and resource management. In contrast, the proposed extended system emphasizes the following:

- Task-level data recording and real-time documentation;

- Predictive maintainability analysis for optimizing schedules;

- Mobile integration for efficient field operations.

4.2. Maintainability Analysis Module

The Maintainability Analysis Module is a key component of the extended Samanta system, designed to improve the efficiency and reliability of maintenance operations. It leverages analytical methods to assess the maintainability of individual tasks, optimize maintenance schedules, and minimize downtime. By integrating predictive algorithms and real-time task tracking, the module enhances decision-making processes, ensuring optimal resource allocation and improved system availability. The following sections outline the mathematical model and schedule strategies employed to achieve these objectives.

4.2.1. Data Acquisition Model

Each maintenance task Ti is associated with a duration Di. The system records n samples of these durations {Di1,Di2,…,Din} for analysis.

- Probability Distribution of Task Durations: For each task Ti, the duration Di is modeled as a random variable. The probability distribution function (PDF) fDi(d) is estimated from the collected data:where Kh is a kernel function (e.g., Gaussian) with bandwidth h, used for nonparametric density estimation.

- Cumulative Distribution Function (CDF): The CDF FDi(d) is defined as follows:

- Expected Duration E[Di]: The expected task duration is

4.2.2. Task Scheduling Optimization

The system optimizes the scheduling of maintenance tasks by minimizing downtime T, defined as the total time required to complete all tasks {T1,T2,…,Tm}.

- Objective Function:where σ(Ti) represents the sequence or priority of task Ti.

- Constraints: Tasks dependent on preceding tasks:

Availability of resources (technicians, tools, etc.).

4.2.3. Reliability Assessment

The reliability of the maintenance process is modeled as a function of task completion times and their variability.

- Maintainability Function :where t is the time threshold for task completion.

- Variance of Task Duration: Variance helps in identifying bottlenecks.

4.3. Functional Characteristics of the Mobile Application

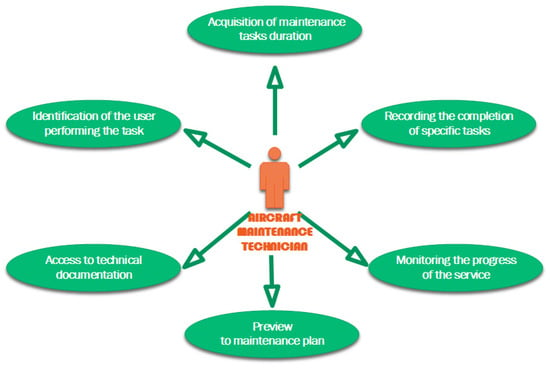

The mobile application is dedicated to aircraft maintenance technicians. Its main task is to collect data from the service process regarding the time of implementation of individual maintenance tasks. The full functionality of the application has been presented using a UML use case diagram (Figure 4).

Figure 4.

UML use case diagram—application functionality.

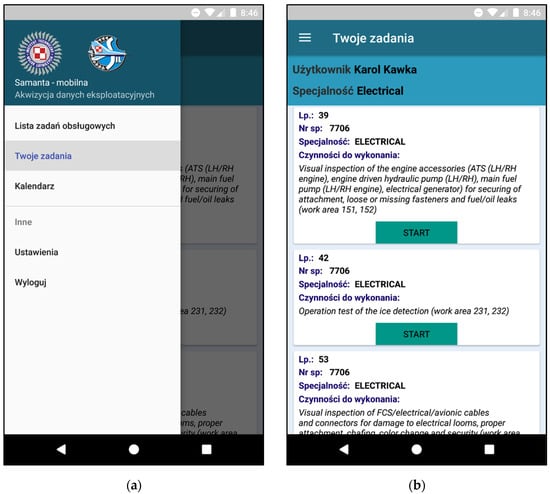

The functionalities described above are organized into three tabs within the application, accessible through a menu typical of the Android system (Figure 5a). This menu is activated by either swiping from the left side of the screen or tapping the icon located in the upper left corner of the action bar. This design provides a user-friendly way to manage the application without interfering with the currently active view.

Figure 5.

An image of the mobile device screen showing: (a) application menu; (b) “Your Tasks” tab.

The most important application feature in the case of data acquisition is the tab “Your task/Twoje zadania”. The tab “Your task” is launched by default right after starting the application, which contains the most important information from the user’s point of view, their identification data, and tasks assigned to their specialty (Figure 5b). The user, after pressing the “Start” button, starts the implementation of the maintenance task and, after its completion, presses the “Stop” button. After pressing the “Stop” button, a question message appears on the device screen for the confirmation of the correctness of the data.

Once confirmed, the application calculates the duration of the technical task and transmits this information, along with the ID of the user performing this task, to a server database.

The designed application was successfully verified in a test environment, operating inside its own separate wireless network. Data from the course of CPFI maintenance were collected via the application, which will be used to study the maintainability of the M-346 aircraft. Thus, the usefulness of the application was confirmed.

5. Assessment of the Usefulness of the Collected Data

The mobile application collected data on the duration of individual maintenance tasks included in the considered inspection. For each of the 101 technical maintenance tasks, approximately 20 measurements of task execution time were made.

From the perspective of a maintenance planning engineer, information about the time of the completion of a specific task is very important []. Accurate duration data enable the creation of more effective schedules, ultimately leading to reduced downtime due to technical servicing. The more accurately the available information describes the analyzed phenomenon, the greater the potential for achieving improved outcomes, such as reduced downtime caused by technical servicing.

The data collected by the application could be used to estimate the probability distribution that describes the time of performing the individual maintenance task. The developed algorithm for identifying the probability distribution and the identification process for an exemplary technical task are presented below. Such considerations were carried out for all maintenance tasks of the considered inspection, and the characteristics describing their duration were determined.

5.1. Examination of Probability Distributions of Maintenance Tasks

The identification of the density function of the distribution of a random variable is one of the main issues in the application of statistical methods. Traditional identification methods rely on assuming a predetermined type of distribution of a random variable and then specifying the parameters that define that distribution.

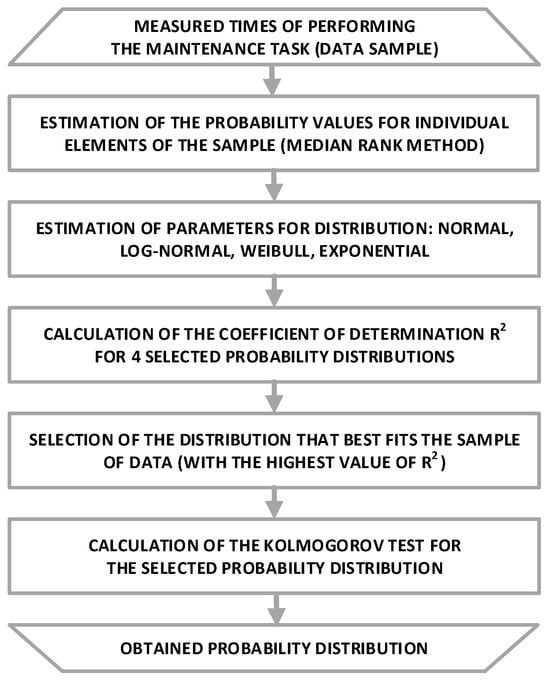

The proprietary probability distribution identification algorithm is presented below (Figure 6).

Figure 6.

An algorithm for identifying the distribution of a maintenance task.

The probability values for individual elements in the sample were estimated using the Median Rank method. The calculation involves solving a binomial distribution equation [,]. This method calculates the probability of the ii-th event in a sample of nn items at a 50% confidence level according to the following equation (the calculation of the equation presented above requires the use of numerical methods):

The estimation of distribution parameters was carried out based on the least squares method. The method of least squares fits a straight line to a set of data points so as to minimize the sum of the squares of the points’ deviations from the straight line. For the Y-axis linear regression (RRY) method, the sum of the squares of the vertical deviations is minimized; in the case of the RRX method, the sum of the squares of the horizontal deviations is minimized [,]. The choice between the RRY and RRX method depends on the direction of expected deviations. Since in the analysis of the duration of technical tasks, the precisely known values are the measured durations on the X-axis and the Y-axis Rank Regression method that will be used in further analysis. Suppose a set of data pairs was determined, plotted, and all values of x were known exactly. The straight line best describing the considered data is defined by the equation . The values of and are estimated as follows:

In order to estimate the parameters of the distributions for the tested maintenance tasks, formulas for the coordinates and parameters for the four considered probability distributions were determined and summarized in Table 3.

Table 3.

Determined parameters of considered probability distributions.

where

- —probability value estimated using the Median Rank method;

- —are the parameters of the scale, shape, and position of the probability distribution, respectively;

- —the distribution function of the standard normal distribution, N(0, 1);

- —the inverse distribution function of the standard normal distribution, N(0, 1).

The coefficient of determination R2 informs us about what part of the variability (variance) of the explained variable in the sample coincides with the correlations with the variables included in the model []. It is, therefore, a measure of the extent to which the model fits the sample. The coefficient of determination takes values in the range (0, 1); the higher the value, the better the model fits the sample of data. Its values are most often expressed as a percentage. It can be calculated using the following formula:

The probability distribution that best fits the sample of data is verified using the Kolmogorov–Smirnov match test. This test is used to verify the consistency of empirical distribution with the theoretical distribution of the continuous type []. An unquestionable advantage of the test is the possibility of using it when examining the distributions of very small populations of samples (). The Kolmogorov test is based on a comparison of the empirical distribution function (cumulants) with the theoretical distribution function , according to the following equation:

At the significance level α = 0.05, we will conduct a statistical test in which

H0.

The distribution represents the data as follows:

H1.

The distribution does not represent the data as follows:

From the tables for the Kolmogorov distribution, the critical value for the given significance level α and the size of the tested sample n could be read. If , then at the significance level α, there are no grounds to reject the null hypothesis , while if , then we reject the null hypothesis in favor of the alternative hypothesis .

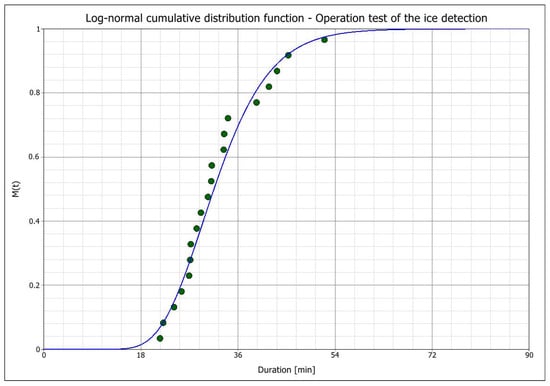

5.2. Identification of the Probability Distribution of an Exemplary Technical Task

Exemplary calculations for a single maintenance task are presented below. For this purpose, 20 measurements of the duration of the maintenance procedure were used: the operation test of the ice detection system.

The data from Table 4 were arranged in a non-decreasing sequence , and the distribution coordinates for the four considered distributions were calculated using the equations presented in Table 3. The results obtained are presented in Table 5.

Table 4.

Measured duration of performing sample maintenance task.

Table 5.

Calculation of coordinates for four considered probability distributions.

After substituting the data from Table 5 into Equation (7), the following results were obtained:

Summarizing the obtained results, the log-normal distribution was selected as the distribution best suited to the sample of data. Based on Equations (5) and (6) and formulas for log-normal distribution parameters from Table 3, the resulting function (Figure 7) was obtained with the following parameters:

Figure 7.

Maintainability function—duration of performing “Operation test of the ice detection”.

- Scale parameter μ = 3.45;

- Shape parameter σ = 0.256.

To confirm that the selected distribution fits the collected data, the Kolmogorov test of consistency was calculated at the significance level [,]. The calculated value of (i.e., the largest deviation between the theoretical and empirical distribution function) is smaller than the value of the tabulated critical value (). Thus, there is no reason to reject the hypothesis that the data distribution is log-normal.

6. Discussion

This study highlights the broader potential of modern IT solutions in streamlining maintenance processes. By focusing on the practical application of data analysis, the research demonstrates how the precise measurement and modeling of service durations can enhance the predictability and efficiency of maintenance schedules. This approach addresses organizational challenges and provides a foundation for continuous improvement in operational performance.

This study successfully met its main goals, but there is room for improvement. The algorithm used to find the best-fitting probability distribution, based on the coefficient of determination R2, provides a solid foundation. However, it does not fully capture the nuances of distributional differences, particularly in tails or extreme values. Adding other metrics or methods could give a clearer understanding of the data. Including the Kolmogorov test is a helpful step in making the analysis more thorough.

The test environment, while ideal for validating the concept, offers a simplified representation of real-world conditions. Future efforts could focus on integrating the application into existing maintenance systems and testing its performance under more complex operational settings, such as varying network conditions or larger datasets. These steps would further enhance the applicability and scalability of the proposed solution.

It is also worth noting that this study focused on a single type of periodic service for the M-346 aircraft, which provided a well-defined and manageable scope. Expanding the application to other types of maintenance tasks, with varying complexity and requirements, would provide valuable insights and help to generalize the findings across a broader range of scenarios.

Lastly, while the application has proven its technical effectiveness, its success in real-world implementation will depend on its acceptance by maintenance personnel. Ensuring the tool is intuitive, user-friendly, and seamlessly integrates into existing workflows will be crucial for its long-term adoption and impact.

7. Conclusions

This article shows that a lot of data collected by aircraft maintenance support IT systems can be used in a very interesting way. By building a simple mobile application for recording services, you can collect data to analyze the times of their implementation, which will allow you to reduce organizational problems by creating a credible and reliable schedule.

The designed application was successfully verified in a test environment, operating inside its own separate wireless network. Data from the execution of the considered periodic service were collected via the application. This information will be used to study the maintainability of the M-346 aircraft. Thus, the usefulness of the application was confirmed.

The proposed methodology for planning periodic maintenance inspections, based on the determined probability characteristics of individual task execution, is expected to be implemented in Polish military aviation. The method can be implemented as one of the modules of the IT system supporting the operation of aircraft, e.g., “Samanta”. The introduction of the developed method in the aircraft operation would result in faster and more effective performance of periodic maintenance, increasing the level of technical readiness of training aircraft at the same time.

Further work in this field focuses on creating mechanisms for the automatic scheduling of maintenance services and real-time response to any disruptions in the operation process. Unexpected failures, issues of the availability of spare parts, and staff shortages are another challenge in modeling the serviceability of aircraft.

In summary, this research presents a forward-looking and practical approach to leveraging IT tools for improving aircraft maintenance processes. While the results are highly promising, continued development and testing in broader operational contexts will further enhance the value and versatility of the proposed solution. These efforts can pave the way for more reliable scheduling and improved maintainability, benefiting both operators and maintenance teams alike.

Author Contributions

Conceptualization: A.Ż.; methodology: M.Z.; software: K.K.; validation: B.G.; writing—original draft preparation: K.K.; writing—review and editing: B.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tsakalerou, M.; Nurmaganbetov, D.; Beltenov, N. Aircraft Maintenance 4.0 in an era of disruptions. Procedia Comput. Sci. 2022, 200, 121–131. [Google Scholar] [CrossRef]

- Brzozowski, B.; Kawka, K.; Kaźmierczak, K.; Rochala, Z.; Wojtowicz, K. Supporting the Process of Aircraft Maintenance with Mobile Devices. Trans. Aerosp. Res. 2017, 2017, 7–18. [Google Scholar] [CrossRef]

- Zieja, M.; Kawka, K.; Wojtowicz, K.; Wetoszka, A.; Pietrzak, T. Portable biometric module software for military aviation support system. Aviat. Secur. Issues 2023, 4, 235–252. [Google Scholar] [CrossRef]

- Glinka, S.; Bajer, J.; Wierzbicki, D.; Karwowska, K.; Kedzierski, M. The Use of Deep Learning Methods for Object Height Estimation in High Resolution Satellite Images. Sensors 2023, 23, 8162. [Google Scholar] [CrossRef]

- Dangut, M.D.; Jennions, I.K.; King, S.; Skaf, Z. Application of deep reinforcement learning for extremely rare failure prediction in aircraft maintenance. Mech. Syst. Signal Process. 2022, 171, 108873. [Google Scholar] [CrossRef]

- Pigłas, M.; Radoń, T.; Szymański, M.; Krutkow, A.; Przystawska, A. Information system support for military aircraft operations SI SAMANTA as a tool to support logistic resource management. J. KONBiN 2020, 50, 269–286. [Google Scholar] [CrossRef]

- Smith, D.J. Reliability, Maintainability and Risk, 9th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Korba, P.; Šváb, P.; Vereš, M.; Lukáč, J. Optimizing Aviation Maintenance through Algorithmic Approach of Real-Life Data. Appl. Sci. 2023, 13, 3824. [Google Scholar] [CrossRef]

- Izdebski, M.; Jacyna-Gołda, I.; Gołębiowski, P.; Gołda, P.; Pyza, D.; Żak, J. Decision problems in designing database architecture for the assessment of logistics services, Scientific Journal of Silesian University of Technology. Ser. Transp. 2020, 108, 53–71. [Google Scholar] [CrossRef]

- Juncen, V.G. Effectiveness of Aircraft Ground Operation Course in Enriching the Aircraft Maintenance Program. IRE J. 2023, 7, 563–579. [Google Scholar]

- Yang, L.; Zhou, S.; Ma, X.; Chen, Y.; Jia, H.; Dai, W. Group machinery intelligent maintenance: Adaptive health prediction and global dynamic maintenance decision-making. Reliab. Eng. Syst. Saf. 2024, 252, 110426. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Xiahou, T.; Huang, H. A heuristic maintenance scheduling framework for a military aircraft fleet under limited maintenance capacities. Reliab. Eng. Syst. Saf. 2023, 235, 109239. [Google Scholar] [CrossRef]

- Pastrana, C.; Ricardo, R. Improving Efficiency in Military Aircraft Maintenance Operations in Terms of Jobs Completion Time. PRCR J. 2022. Available online: https://prcrepository.org/xmlui/handle/20.500.12475/2177 (accessed on 12 October 2024).

- Melo, S.P.; Barke, A.; Cerdas, F.; Thies, C.; Mennenga, M.; Spengler, T.S.; Herrmann, C. Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools. Sustainability 2020, 12, 5663. [Google Scholar] [CrossRef]

- Bisanti, G.M.; Mainetti, L.; Montanaro, T.; Patrono, L.; Sergi, I. Digital twins for aircraft maintenance and operation: A systematic literature review and an IoT-enabled modular architecture. Internet Things 2023, 24, 100991. [Google Scholar] [CrossRef]

- Wu, W.; Vu, V. Application of Virtual Reality Method in Aircraft Maintenance Service—Taking Dornier 228 as an Example. Appl. Sci. 2022, 12, 7283. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, X.; Wei, F.; Yang, L.; Qiu, Q. Dynamic Scheduling of Intelligent Group Maintenance Planning under Usage Availability Constraint. Mathematics 2022, 10, 2730. [Google Scholar] [CrossRef]

- Perehuda, O.; Rodionov, A.; Fedorchuk, D.; Zhuravskyi, S.; Konvisar, M.; Volynets, T.; Datsyk, V.; Zakalad, M.; Tsybulia, S.; Trysnyuk, T. Devising a method for integrated dataset formation and selecting a model for recognizing the technical condition of unmanned aerial vehicle. East.-Eur. J. Enterp. Technol. 2024, 5, 42–51. [Google Scholar] [CrossRef]

- Okoro, O.C.; Zaliskyi, M.; Dmytriiev, S.; Solomentsev, O.; Sribna, O. Optimization of Maintenance Task Interval of Aircraft Systems. Int. J. Comput. Netw. Inf. Secur. 2022, 14, 77–89. [Google Scholar] [CrossRef]

- Yazdi, M. Maintenance Strategies and Optimization Techniques. In Advances in Computational Mathematics for Industrial System Reliability and Maintainability; Springer Series in Reliability Engineering; Springer: Berlin/Heidelberg, Germany, 2024; pp. 43–58. [Google Scholar] [CrossRef]

- Andrade, P.; Silva, C.; Ribeiro, B.; Santos, B.F. Aircraft Maintenance Check Scheduling Using Reinforcement Learning. Aerospace 2021, 8, 113. [Google Scholar] [CrossRef]

- De Pater, I.; Reijins, A.; Mitici, M. Alarm-based predictive maintenance scheduling for aircraft engines with imperfect Remaining Useful Life prognostics. Reliab. Eng. Syst. Saf. 2022, 221, 108341. [Google Scholar] [CrossRef]

- Blond, K.; Himschoot, A.; Klein, E.; Conley, S.; Clark, A. Adapting Commercial Best Practices to U.S. Air Force Maintenance Scheduling. Aerospace 2023, 10, 61. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; Zhao, X.; Xiang, J. Predictive Maintenance Scheduling for Aircraft Engines Based on Remaining Useful Life Prediction. IEEE Internet Things J. 2024, 11, 23020–23031. [Google Scholar] [CrossRef]

- Fu, S.; Avdelidis, N.P. Prognostic and Health Management of Critical Aircraft Systems and Components: An Overview. Sensors 2023, 23, 8124. [Google Scholar] [CrossRef]

- Pop, G.I.; Titu, A.M.; Pop, A.B. Enhancing Aerospace Industry Efficiency and Sustainability: Process Integration and Quality Management in the Context of Industry 4.0. Sustainability 2023, 15, 16206. [Google Scholar] [CrossRef]

- Zuluaga, A.E.M.; De Mantenimiento, E.E.G.; Marcos, C.S. Development of a Mobile Application for Maintenance Management. In Proceedings of the 2023 VI Congreso Internacional en Inteligencia Ambiental, Ingeniería de Software y Salud Electrónica y Móvil (AmITIC), Cali, Colombia, 25–27 October 2023; pp. 1–8. [Google Scholar] [CrossRef]

- OTAC Reliability Monitoring Programs. OTAC 39-14. 2021. Available online: https://www.airsafety.aero/getmedia/6d844aa3-8a14-4199-824c-15aa4cbfda61/20210126_ALPR08_OTAC_39-14_Reliability_Monitoring_Programmes_Issue1.pdf?ext=.pdf (accessed on 12 October 2024).

- Alomar, I.; Yatskiv (Jackiva), I. Digitalization in aircraft maintenance processes. Vilnius Tech J. 2023, 27, 86–94. [Google Scholar] [CrossRef]

- Kechagias, E.P.; Gayialis, S.P.; Konstantakopoulos, G.D.; Papadopoulos, G.A. An Application of a Multi-Criteria Approach for the Development of a Process Reference Model for Supply Chain Operations. Sustainability 2020, 12, 5791. [Google Scholar] [CrossRef]

- IEC 60050-192; International Electrotechnical Vocabulary. Chapter 192: Dependability and Quality of Service. International Electrotechnical Commission: Geneva, Switzerland, 2015.

- STANREC 4174, ADMP-02 Guidance for Dependability Management; Guidance for Dependability In-Service; Edition A Version 1; NATO: Brussels, Belgium, 2014.

- Eddarhri, M.; Adib, J.; Hain, M.; Marzak, A. Towards predictive maintenance: The case of the aeronautical industry. Procedia Comput. Sci. 2022, 203, 769–774. [Google Scholar] [CrossRef]

- Patton, J.D. Preventive Maintenance, 3rd ed.; International Society of Automation: Pittsburgh, PA, USA, 2016. [Google Scholar]

- Zhang, Y.; Li, C.; Su, X.; Cui, R.; Wan, B. A baseline-reactive scheduling method for carrier-based aircraft maintenance tasks. Complex Intell. Syst. 2023, 9, 367–397. [Google Scholar] [CrossRef]

- Okeagu, F.N.; Mgbemena, C.E. A systematic review of digital twin systems for improved predictive maintenance of equipment in smart factories. Int. J. Ind. Prod. Eng. 2022, 1, 1–20. [Google Scholar]

- Zieja, M.; Ważny, M.; Stępień, S. Distribution determination of time of exceeding permissible condition as used to determine lifetimes of selected aeronautical devices/systems. Eksploat. Niezawodn. 2016, 18, 57–64. [Google Scholar] [CrossRef]

- Miśkiewicz, R.; Wolniak, R. Practical Application of the Industry 4.0 Concept in a Steel Company. Sustainability 2020, 12, 5776. [Google Scholar] [CrossRef]

- Kawka, K.; Wojtowicz, K.; Zieja, M. Examination and evaluation of training jet aircraft maintainability. In Proceedings of the 2020 IEEE International Workshop on Metrology for Aerospace, Pisa, Italy, 22–24 June 2020; IEEE: Piscataway, NJ, USA. [Google Scholar] [CrossRef]

- Wibowo, U.; Kurniawan, I.E.; Prayitno, H. Implementation of Safety Risk Management in Aircraft Airffame Maintenance. Sinergi Int. J. Logist. 2023, 1, 85–95. [Google Scholar] [CrossRef]

- Jodejko-Pietruczuk, A.; Werbińska-Wojciechowska, S. Availability model of technical objects-block inspection policy implementation. In Proceedings of the Safety and Reliability: Methodology and Applications Conference, Wrocław, Poland, 14–18 September 2014. [Google Scholar] [CrossRef]

- Marugán, A.P.; García Márquez, F.P.; Pinar Pérez, J.M. Optimal maintenance management of offshore wind farms. Energies 2016, 9, 46. [Google Scholar] [CrossRef]

- Stanton, I.; Munir, K.; Ikram, A.; El-Bakry, M. Predictive maintenance analytics and implementation for aircraft: Challenges and opportunities. INCOSE Syst. Eng. 2022, 26, 216–237. [Google Scholar] [CrossRef]

- Inspections Requirements Handbook, PI 1T-M346(PLAF)-6; Leonardo Spa Aircraft Division: Venegono Superiore, Italy, 2017.

- Jacyna, M.; Izdebski, M.; Szczepański, E.; Gołda, P. The task assignment of vehicles for a production company. Symmetry 2018, 10, 551. [Google Scholar] [CrossRef]

- Rabanal, A.; Ulazia, A.; Ibarra-Berastegi, G.; Sáenz, J.; Elosegui, U. A benchmarking multi-criteria method for the identification of defective anemometers in wind farms. Energies 2019, 12, 28. [Google Scholar] [CrossRef]

- Paiva, R.G.N.; Cavalcante, C.A.V.; Do, P. Applying association rules in the maintenance and reliability of physical systems: A review. Comput. Ind. Eng. 2024, 194, 110332. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Shardt, Y.A.W.; Cui, J.; Tong, C. A KPI-based probabilistic soft sensor development approach that maximizes the coefficient of determination. Sensors 2018, 18, 3058. [Google Scholar] [CrossRef]

- Oszczypała, M.; Konwerski, J.; Ziółkowski, J.; Małachowski, J. Reliability analysis and redundancy optimization of k-out-of-n systems with random variable k using continuous time Markov chain and Monte Carlo simulation. Reliab. Eng. Syst. Saf. 2024, 242, 109780. [Google Scholar] [CrossRef]

- Ziółkowski, J.; Oszczypała, M.; Lęgas, A.; Konwerski, J.; Małachowski, J. A method for calculating the technical readiness of aviation refuelling vehicles. Eksploat. Niezawodn. 2024, 26, 187888. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).