A Review on Air and Liquid Cooling Strategies for Lithium-Ion Batteries

Abstract

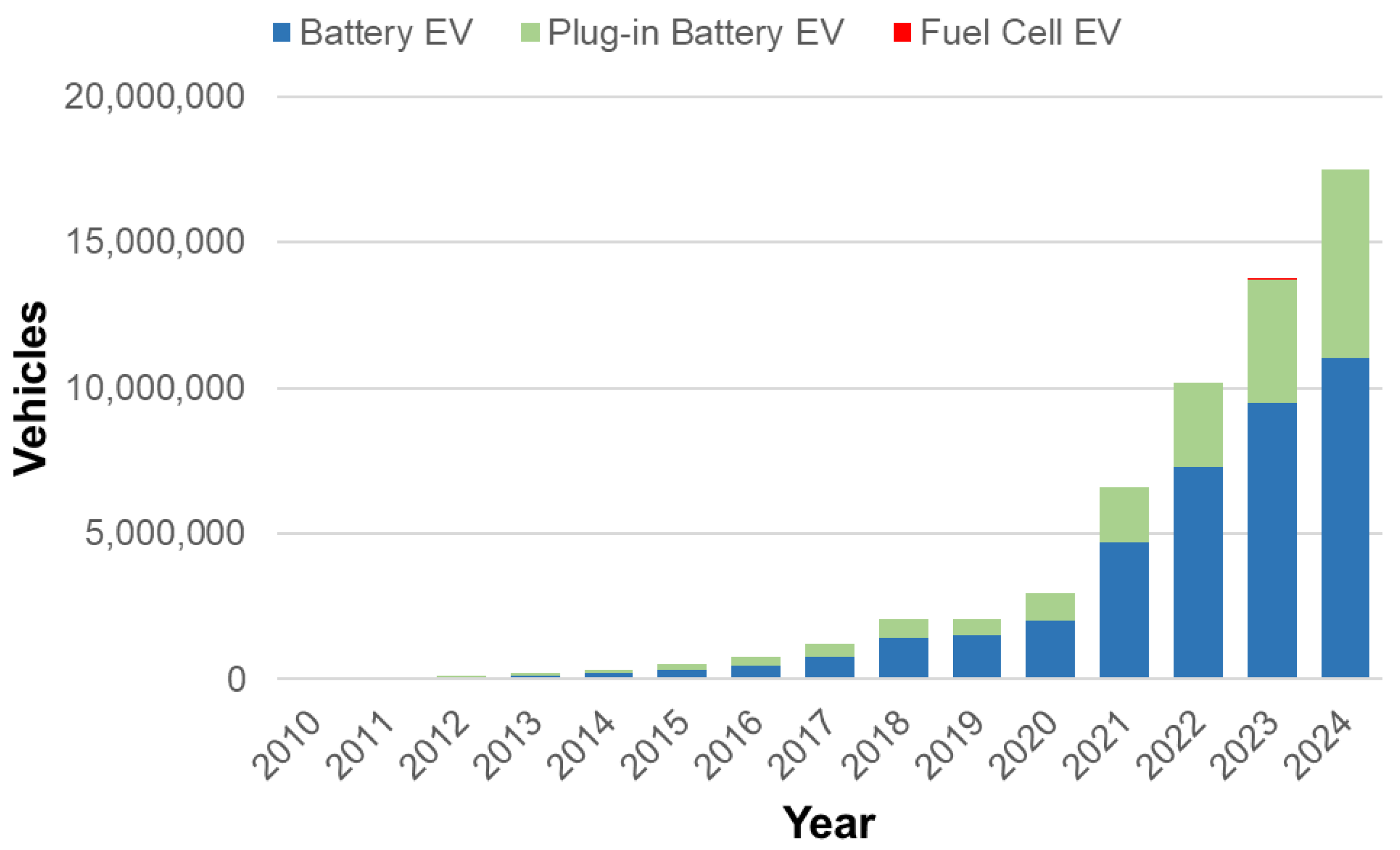

1. Introduction

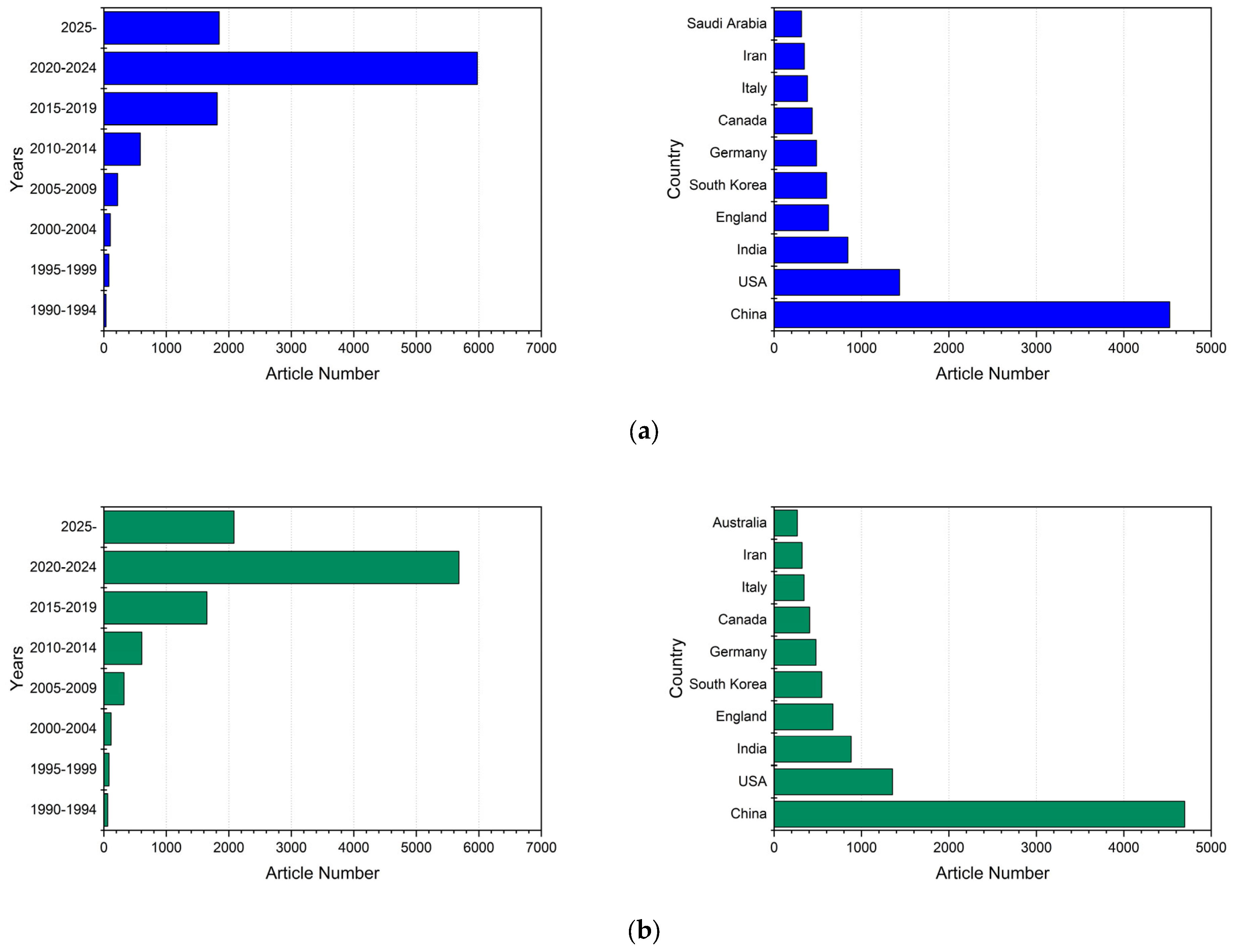

2. The Motivation of Present Work

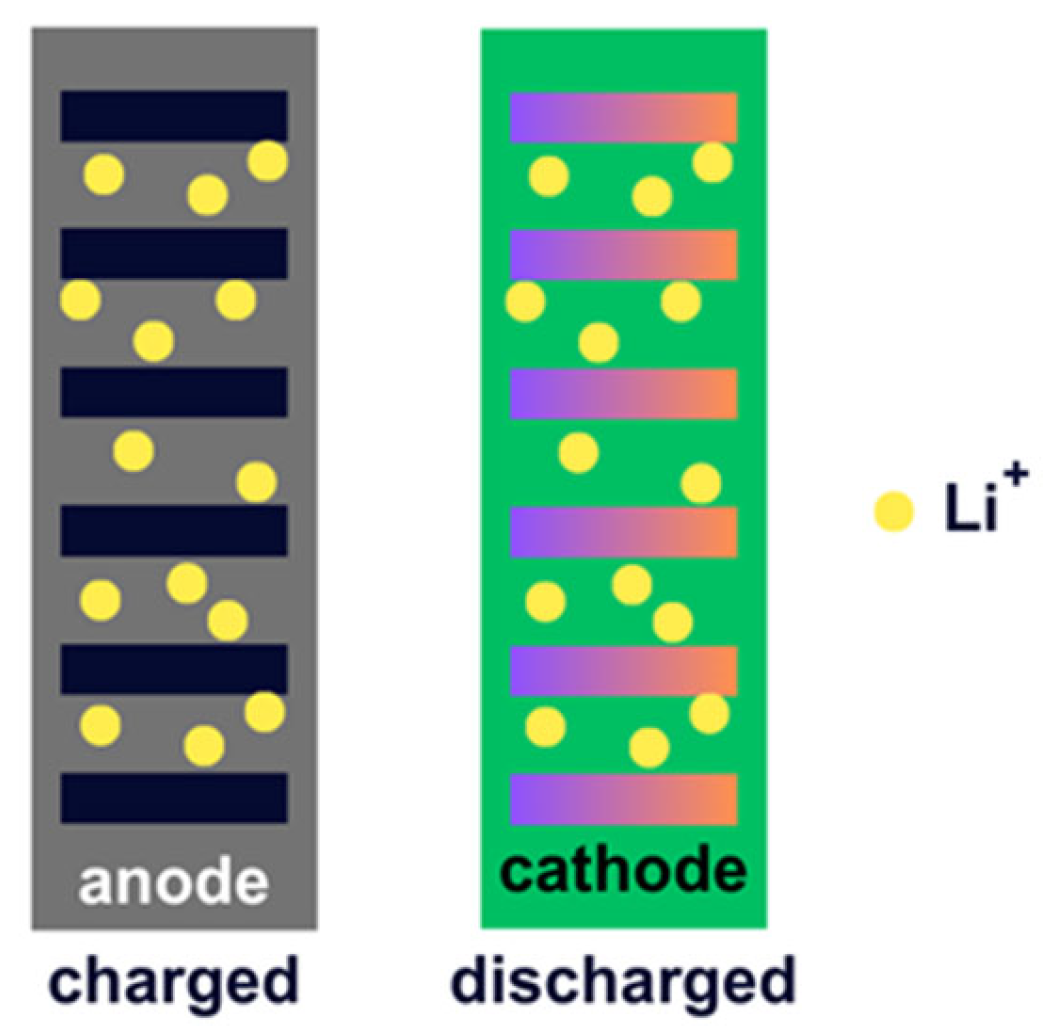

3. Fundamentals of LiBs

4. Classification of BTMSs

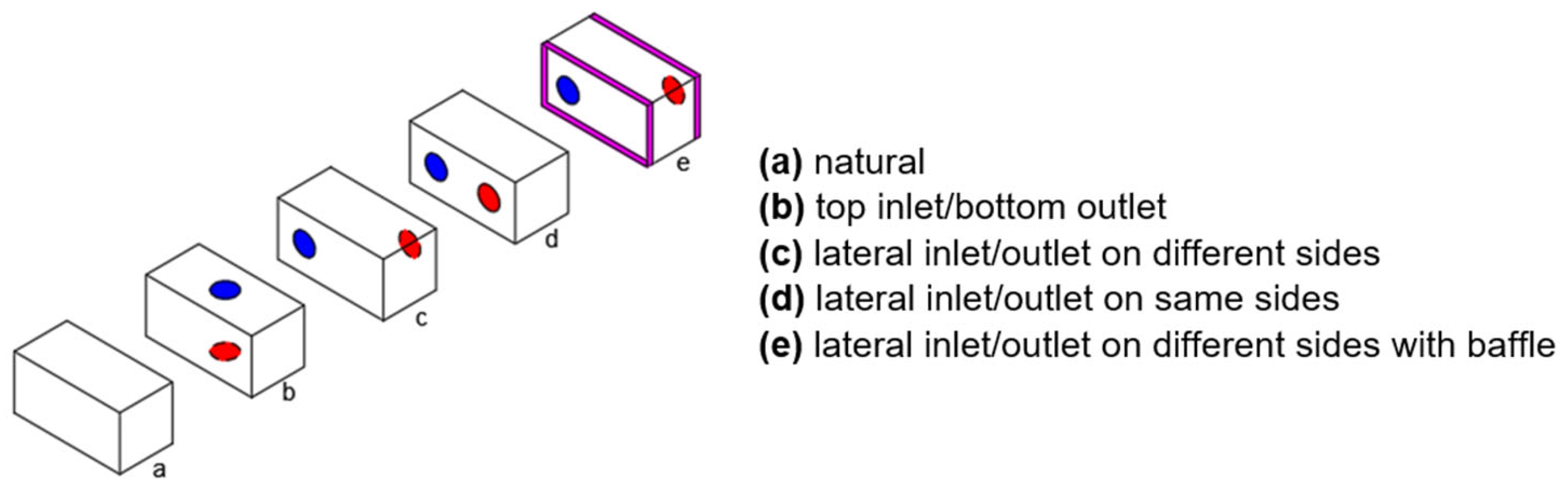

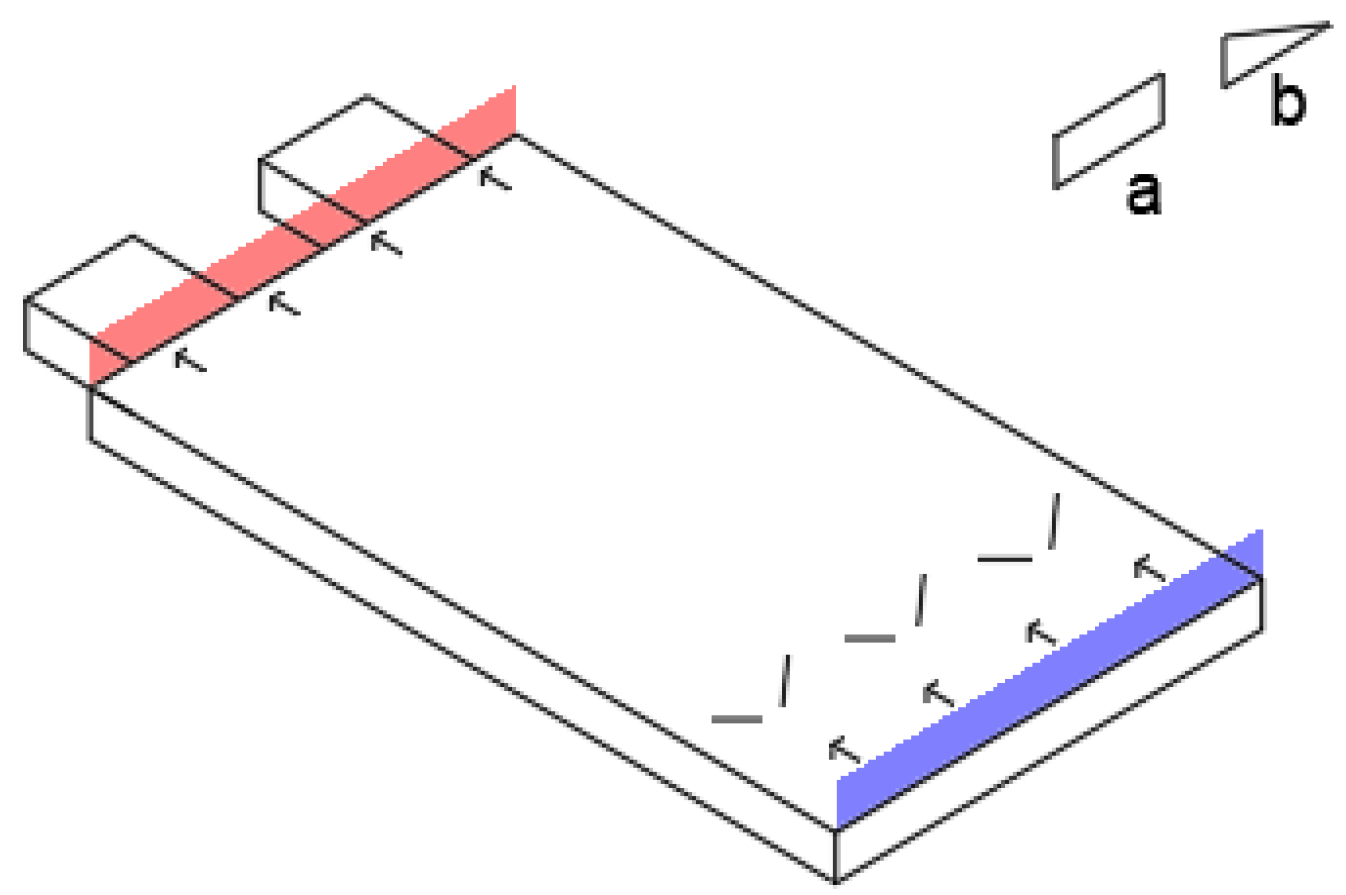

5. Air Cooled BTMS

6. Liquid-Cooled BTMS

7. Discussion and Conclusions

7.1. Air-Cooled BTMSs

7.2. Liquid-Cooled BTMSs

8. Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EV | Electric vehicle |

| BTMS | Battery thermal management system |

| DEC | Direct evaporative cooling |

| FAC | Forced air cooling |

| GCD | Gradient channel design |

| HTFs | Heat transfer fluids |

| ICE | Internal combustion engines |

| LCP-DD | Liquid cooling plates with drop-shaped deflectors |

| LCP-MSs | Liquid cooling plates with mesh structures |

| LCP-SC | Liquid cooling plates with mesh structures |

| LiB | Lithium-ion batteries |

| NSGA-II | Non-dominated sorting genetic algorithm-II |

| PCM | Phase change material |

| VG | Vortex generators |

| ULCD | Uniform large channel design |

References

- Tüccar, G.; Tosun, E.; Özgür, T.; Aydın, K. Diesel Engine Emissions and Performance from Blends of Citrus Sinensis Biodiesel and Diesel Fuel. Fuel 2014, 132, 7–11. [Google Scholar] [CrossRef]

- Jaguemont, J.; Van Mierlo, J. A Comprehensive Review of Future Thermal Management Systems for Battery-Electrified Vehicles. J. Energy Storage 2020, 31, 101551. [Google Scholar] [CrossRef]

- Kumar, R.R.; Alok, K. Adoption of Electric Vehicle: A Literature Review and Prospects for Sustainability. J. Clean. Prod. 2020, 253, 119911. [Google Scholar] [CrossRef]

- Rao, Z.; Qian, Z.; Kuang, Y.; Li, Y. Thermal Performance of Liquid Cooling Based Thermal Management System for Cylindrical Lithium-Ion Battery Module with Variable Contact Surface. Appl. Therm. Eng. 2017, 123, 1514–1522. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Q.; Wang, T. Effects of Air Cooling Structure on Cooling Performance Enhancement of Prismatic Lithium-ion Battery Packs Based on Coupled Electrochemical-thermal Model. Energy Sci. Eng. 2021, 9, 1450–1464. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A Review of Energy Sources and Energy Management System in Electric Vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global EV Data Explorer—Data Tools—IEA. Available online: https://www.iea.org/data-and-statistics/data-tools/global-ev-data-explorer (accessed on 21 June 2025).

- Lu, M.; Zhang, X.; Ji, J.; Xu, X.; Zhang, Y. Research Progress on Power Battery Cooling Technology for Electric Vehicles. J. Energy Storage 2020, 27, 101155. [Google Scholar] [CrossRef]

- Sharma, D.K.; Prabhakar, A. A Review on Air Cooled and Air Centric Hybrid Thermal Management Techniques for Li-Ion Battery Packs in Electric Vehicles. J. Energy Storage 2021, 41, 102885. [Google Scholar] [CrossRef]

- ELJarray, O.; Dai, H.; Chen, Z.; Raja, S.V.; Li, B.; Cao, S.; Sun, S.; Zhang, G. Ensuring Battery Safety in Electric Vehicles: Challenges, Developments, and Future Perspectives. Small 2025, e2503406. [Google Scholar] [CrossRef]

- Ghiji, M.; Novozhilov, V.; Moinuddin, K.; Joseph, P.; Burch, I.; Suendermann, B.; Gamble, G. A Review of Lithium-Ion Battery Fire Suppression. Energies 2020, 13, 5117. [Google Scholar] [CrossRef]

- Behi, H.; Gandoman, F.H.; Karimi, D.; Hosen, M.S.; Behi, M.; Jaguemont, J.; Van Mierlo, J.; Berecibar, M. Thermal Management of the Li-Ion Batteries to Improve the Performance of the Electric Vehicles Applications. In Modern Automotive Electrical Systems; Wiley: Hoboken, NJ, USA, 2022; pp. 149–191. [Google Scholar]

- Akinlabi, A.A.H.; Solyali, D. Configuration, Design, and Optimization of Air-Cooled Battery Thermal Management System for Electric Vehicles: A Review. Renew. Sustain. Energy Rev. 2020, 125, 109815. [Google Scholar] [CrossRef]

- Basu, S.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Sohn, D.K.; Yeo, T. Coupled Electrochemical Thermal Modelling of a Novel Li-Ion Battery Pack Thermal Management System. Appl. Energy 2016, 181, 1–13. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A.O.; Chong, W.T.; Kuan, S.H.; Yew, M.C. Computational Fluid Dynamic and Thermal Analysis of Lithium-Ion Battery Pack with Air Cooling. Appl. Energy 2016, 177, 783–792. [Google Scholar] [CrossRef]

- Zhao, C.; Cao, W.; Dong, T.; Jiang, F. Thermal Behavior Study of Discharging/Charging Cylindrical Lithium-Ion Battery Module Cooled by Channeled Liquid Flow. Int. J. Heat Mass Transf. 2018, 120, 751–762. [Google Scholar] [CrossRef]

- Liu, Y.; Ouyang, C.; Jiang, Q.; Liang, B. Design and Parametric Optimization of Thermal Management of Lithium-Ion Battery Module with Reciprocating Air-Flow. J. Cent. South Univ. 2015, 22, 3970–3976. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Trends in Batteries—Global EV Outlook 2023—Analysis—IEA. Available online: https://www.iea.org/reports/global-ev-outlook-2023/trends-in-batteries (accessed on 21 June 2025).

- Park, S.; Jung, D. Battery Cell Arrangement and Heat Transfer Fluid Effects on the Parasitic Power Consumption and the Cell Temperature Distribution in a Hybrid Electric Vehicle. J. Power Sources 2013, 227, 191–198. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S. A Review of Power Battery Thermal Energy Management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A Critical Review of Thermal Management Models and Solutions of Lithium-Ion Batteries for the Development of Pure Electric Vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- Xia, G.; Cao, L.; Bi, G. A Review on Battery Thermal Management in Electric Vehicle Application. J. Power Sources 2017, 367, 90–105. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A Critical Review of Battery Thermal Performance and Liquid Based Battery Thermal Management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Wu, S.; Xiong, R.; Li, H.; Nian, V.; Ma, S. The State of the Art on Preheating Lithium-Ion Batteries in Cold Weather. J. Energy Storage 2020, 27, 101059. [Google Scholar] [CrossRef]

- Patel, J.R.; Rathod, M.K. Recent Developments in the Passive and Hybrid Thermal Management Techniques of Lithium-Ion Batteries. J. Power Sources 2020, 480, 228820. [Google Scholar] [CrossRef]

- Buidin, T.I.C.; Mariasiu, F. Battery Thermal Management Systems: Current Status and Design Approach of Cooling Technologies. Energies 2021, 14, 4879. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Maghrabie, H.M.; Abo-Khalil, A.G.; Adhari, O.H.K.; Sayed, E.T.; Radwan, A.; Rezk, H.; Jouhara, H.; Olabi, A.G. Thermal Management Systems Based on Heat Pipes for Batteries in EVs/HEVs. J. Energy Storage 2022, 51, 104384. [Google Scholar] [CrossRef]

- Olabi, A.G.; Maghrabie, H.M.; Adhari, O.H.K.; Sayed, E.T.; Yousef, B.A.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery Thermal Management Systems: Recent Progress and Challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Kumar Thakur, A.; Sathyamurthy, R.; Velraj, R.; Saidur, R.; Pandey, A.K.; Ma, Z.; Singh, P.; Hazra, S.K.; Wafa Sharshir, S.; Prabakaran, R.; et al. A State-of-the Art Review on Advancing Battery Thermal Management Systems for Fast-Charging. Appl. Therm. Eng. 2023, 226, 120303. [Google Scholar] [CrossRef]

- Torabi, F.; Ahmadi, P. Front Matter. In Simulation of Battery Systems; Elsevier: Amsterdam, The Netherlands, 2020; pp. i–iii. ISBN 9780128162125. [Google Scholar]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in Battery Thermal Management Systems for Electric Vehicles: A Technical Review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Lin, X. Recent Developments of Thermal Management Strategies for Lithium-Ion Batteries: A State-of-The-Art Review. Energy Technol. 2022, 10, 2101135. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Li, H.B.; Qu, Z.G.; Zhang, J.F. Recent Progress in Lithium-Ion Battery Thermal Management for a Wide Range of Temperature and Abuse Conditions. Int. J. Hydrog. Energy 2022, 47, 9428–9459. [Google Scholar] [CrossRef]

- Afaynou, I.; Faraji, H.; Choukairy, K.; Djebali, R.; Rezk, H. Comprehensive Analysis and Thermo-Economic Optimization of a Hybrid Phase Change Material-Based Heat Sink for Electronics Cooling. Heat. Transf. 2025, 54, 3754–3774. [Google Scholar] [CrossRef]

- Shahjalal, M.; Shams, T.; Islam, M.E.; Alam, W.; Modak, M.; Hossain, S.B.; Ramadesigan, V.; Ahmed, M.R.; Ahmed, H.; Iqbal, A. A Review of Thermal Management for Li-Ion Batteries: Prospects, Challenges, and Issues. J. Energy Storage 2021, 39, 102518. [Google Scholar] [CrossRef]

- E, J.; Yue, M.; Chen, J.; Zhu, H.; Deng, Y.; Zhu, Y.; Zhang, F.; Wen, M.; Zhang, B.; Kang, S. Effects of the Different Air Cooling Strategies on Cooling Performance of a Lithium-Ion Battery Module with Baffle. Appl. Therm. Eng. 2018, 144, 231–241. [Google Scholar] [CrossRef]

- Park, H. A Design of Air Flow Configuration for Cooling Lithium Ion Battery in Hybrid Electric Vehicles. J. Power Sources 2013, 239, 30–36. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Jiang, J.-M.; Chung, Y.-H.; Chen, W.-C.; Shu, C.-M. Forced-Air Cooling System for Large-Scale Lithium-Ion Battery Modules during Charge and Discharge Processes. J. Therm. Anal. Calorim. 2019, 135, 2891–2901. [Google Scholar] [CrossRef]

- Chen, K.; Wu, W.; Yuan, F.; Chen, L.; Wang, S. Cooling Efficiency Improvement of Air-Cooled Battery Thermal Management System through Designing the Flow Pattern. Energy 2019, 167, 781–790. [Google Scholar] [CrossRef]

- Widyantara, R.D.; Naufal, M.A.; Sambegoro, P.L.; Nurprasetio, I.P.; Triawan, F.; Djamari, D.W.; Nandiyanto, A.B.D.; Budiman, B.A.; Aziz, M. Low-Cost Air-Cooling System Optimization on Battery Pack of Electric Vehicle. Energies 2021, 14, 7954. [Google Scholar] [CrossRef]

- Shen, X.; Cai, T.; He, C.; Yang, Y.; Chen, M. Thermal Analysis of Modified Z-Shaped Air-Cooled Battery Thermal Management System for Electric Vehicles. J. Energy Storage 2023, 58, 106356. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, J.; Gu, J.; Zhai, L.; Ma, F. Experimental Study of a Direct Evaporative Cooling Approach for Li-ion Battery Thermal Management. Int. J. Energy Res. 2020, 44, 6660–6673. [Google Scholar] [CrossRef]

- Zhang, S.-B.; He, X.; Long, N.-C.; Shen, Y.-J.; Gao, Q. Improving the Air-Cooling Performance for Lithium-Ion Battery Packs by Changing the Air Flow Pattern. Appl. Therm. Eng. 2023, 221, 119825. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H.; Li, C. Performance Improvement of a Novel Trapezoid Air-Cooling Battery Thermal Management System for Electric Vehicles. Sustainability 2022, 14, 4975. [Google Scholar] [CrossRef]

- Kirad, K.; Chaudhari, M. Design of Cell Spacing in Lithium-Ion Battery Module for Improvement in Cooling Performance of the Battery Thermal Management System. J. Power Sources 2021, 481, 229016. [Google Scholar] [CrossRef]

- E, J.; Zeng, Y.; Jin, Y.; Zhang, B.; Huang, Z.; Wei, K.; Chen, J.; Zhu, H.; Deng, Y. Heat Dissipation Investigation of the Power Lithium-Ion Battery Module Based on Orthogonal Experiment Design and Fuzzy Grey Relation Analysis. Energy 2020, 211, 118596. [Google Scholar] [CrossRef]

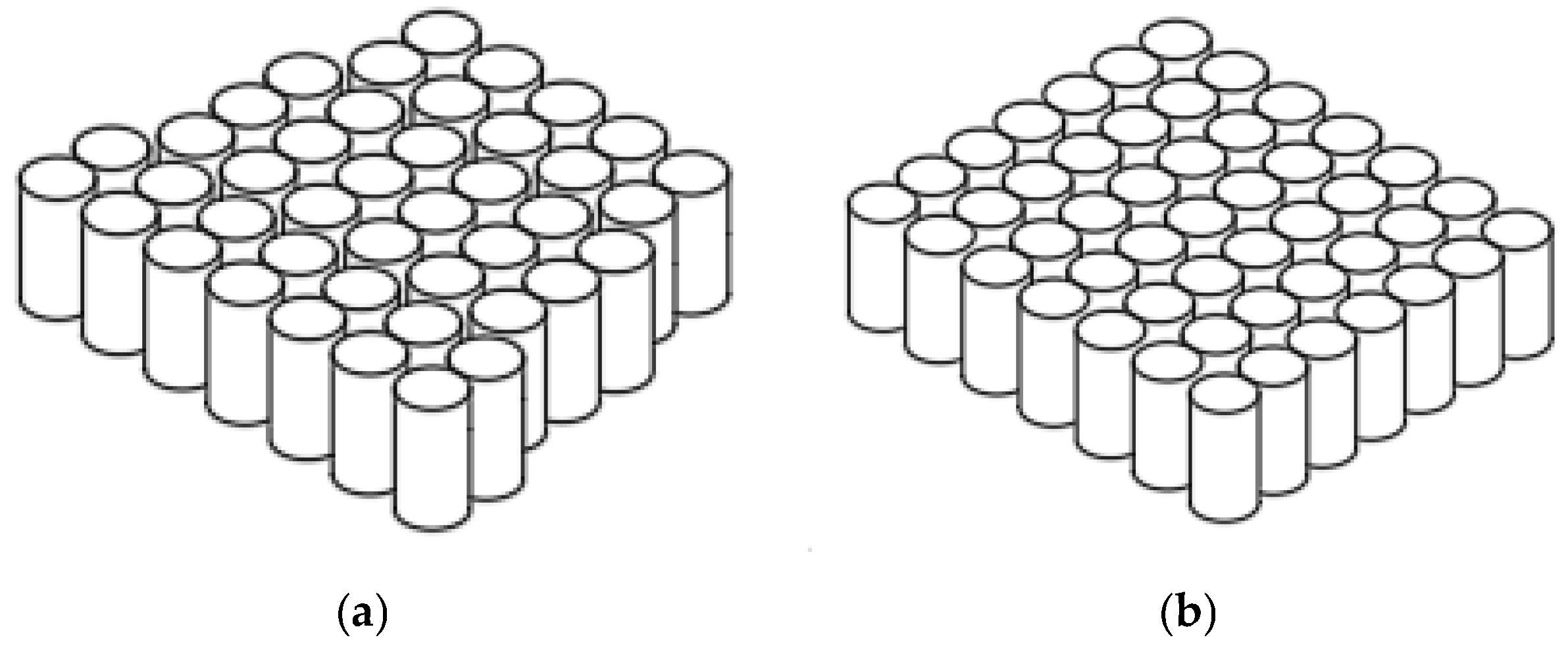

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal Investigation of Lithium-Ion Battery Module with Different Cell Arrangement Structures and Forced Air-Cooling Strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Peng, X.; Cui, X.; Liao, X.; Garg, A. A Thermal Investigation and Optimization of an Air-Cooled Lithium-Ion Battery Pack. Energies 2020, 13, 2956. [Google Scholar] [CrossRef]

- Du, J.; Tao, H.; Chen, Y.; Yuan, X.; Lian, C.; Liu, H. Thermal Management of Air-Cooling Lithium-Ion Battery Pack. Chin. Phys. Lett. 2021, 38, 118201. [Google Scholar] [CrossRef]

- Fan, Y.; Bao, Y.; Ling, C.; Chu, Y.; Tan, X.; Yang, S. Experimental Study on the Thermal Management Performance of Air Cooling for High Energy Density Cylindrical Lithium-Ion Batteries. Appl. Therm. Eng. 2019, 155, 96–109. [Google Scholar] [CrossRef]

- Lu, Z.; Yu, X.; Wei, L.; Qiu, Y.; Zhang, L.; Meng, X.; Jin, L. Parametric Study of Forced Air Cooling Strategy for Lithium-Ion Battery Pack with Staggered Arrangement. Appl. Therm. Eng. 2018, 136, 28–40. [Google Scholar] [CrossRef]

- Xie, J.; Ge, Z.; Zang, M.; Wang, S. Structural Optimization of Lithium-Ion Battery Pack with Forced Air Cooling System. Appl. Therm. Eng. 2017, 126, 583–593. [Google Scholar] [CrossRef]

- Zhang, F.; Lin, A.; Wang, P.; Liu, P. Optimization Design of a Parallel Air-Cooled Battery Thermal Management System with Spoilers. Appl. Therm. Eng. 2021, 182, 116062. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, F.; Xu, L.; Kong, J.; Yang, Q. Thermal Performance of Cylindrical Lithium-Ion Battery Thermal Management System Based on Air Distribution Pipe. Int. J. Heat Mass Transf. 2019, 131, 984–998. [Google Scholar] [CrossRef]

- Xie, J.; Xie, Y.; Yuan, C. Numerical Study of Heat Transfer Enhancement Using Vortex Generator for Thermal Management of Lithium Ion Battery. Int. J. Heat Mass Transf. 2019, 129, 1184–1193. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Kalogiannis, T.; Jaguemont, J.; Jin, L.; Behi, H.; Karimi, D.; Beheshti, H.; Van Mierlo, J.; Berecibar, M. A Comparative Study between Air Cooling and Liquid Cooling Thermal Management Systems for a High-Energy Lithium-Ion Battery Module. Appl. Therm. Eng. 2021, 198, 117503. [Google Scholar] [CrossRef]

- Anisha; Kumar, A. Identification and Mitigation of Shortcomings in Direct and Indirect Liquid Cooling-Based Battery Thermal Management System. Energies 2023, 16, 3857. [Google Scholar] [CrossRef]

- Teng, H.; Yeow, K. Design of Direct and Indirect Liquid Cooling Systems for High- Capacity, High-Power Lithium-Ion Battery Packs. SAE Int. J. Altern. Powertrains 2012, 1, 525–536. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Li, Y. Thermal Performance of Mini-Channel Liquid Cooled Cylinder Based Battery Thermal Management for Cylindrical Lithium-Ion Power Battery. Energy Convers. Manag. 2015, 103, 157–165. [Google Scholar] [CrossRef]

- Du, X.; Qian, Z.; Chen, Z.; Rao, Z. Experimental Investigation on Mini-Channel Cooling-Based Thermal Management for Li-Ion Battery Module under Different Cooling Schemes. Int. J. Energy Res. 2018, 42, 2781–2788. [Google Scholar] [CrossRef]

- Gao, R.; Fan, Z.; Liu, S. A Gradient Channel-Based Novel Design of Liquid-Cooled Battery Thermal Management System for Thermal Uniformity Improvement. J. Energy Storage 2022, 48, 104014. [Google Scholar] [CrossRef]

- Li, P.; Zhao, J.; Zhou, S.; Duan, J.; Li, X.; Zhang, H.; Yuan, J. Design and Optimization of a Liquid Cooling Thermal Management System with Flow Distributors and Spiral Channel Cooling Plates for Lithium-Ion Batteries. Energies 2023, 16, 2196. [Google Scholar] [CrossRef]

- Liu, F.; Chen, Y.; Qin, W.; Li, J. Optimal Design of Liquid Cooling Structure with Bionic Leaf Vein Branch Channel for Power Battery. Appl. Therm. Eng. 2023, 218, 119283. [Google Scholar] [CrossRef]

- Zhang, T.; Gao, Q.; Wang, G.; Gu, Y.; Wang, Y.; Bao, W.; Zhang, D. Investigation on the Promotion of Temperature Uniformity for the Designed Battery Pack with Liquid Flow in Cooling Process. Appl. Therm. Eng. 2017, 116, 655–662. [Google Scholar] [CrossRef]

- Xu, K.; Zhang, H.; Zhu, J.; Qiu, G. Thermal Management for Battery Module with Liquid-Cooled Shell Structure under High Charge/Discharge Rates and Thermal Runaway Conditions. Batteries 2023, 9, 204. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, G.; Meng, L.; Li, X.; Situ, W.; Lv, Y.; Rao, M. Liquid Cooling Based on Thermal Silica Plate for Battery Thermal Management System. Int. J. Energy Res. 2017, 41, 2468–2479. [Google Scholar] [CrossRef]

- Xu, J.; Chen, Z.; Qin, J.; Minqiang, P. A Lightweight and Low-Cost Liquid-Cooled Thermal Management Solution for High Energy Density Prismatic Lithium-Ion Battery Packs. Appl. Therm. Eng. 2022, 203, 117871. [Google Scholar] [CrossRef]

- Zhao, D.; An, C.; Lei, Z. Liquid Cooling Plate with Drop-Shaped Deflectors Based on Coanda Effect—For Li-Ion Battery Thermal Management. J. Energy Storage 2023, 70, 108014. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Z.; Hu, L.; Bai, M.; Gao, L.; Li, Y.; Liu, X.; Li, Y.; Song, Y. Experimental Studies of Liquid Immersion Cooling for 18650 Lithium-Ion Battery under Different Discharging Conditions. Case Stud. Therm. Eng. 2022, 34, 102034. [Google Scholar] [CrossRef]

- Tousi, M.; Sarchami, A.; Kiani, M.; Najafi, M.; Houshfar, E. Numerical Study of Novel Liquid-Cooled Thermal Management System for Cylindrical Li-Ion Battery Packs under High Discharge Rate Based on AgO Nanofluid and Copper Sheath. J. Energy Storage 2021, 41, 102910. [Google Scholar] [CrossRef]

- Yetik, O.; Karakoc, T.H. A Study on lithium-ion Battery Thermal Management System with Al2O3 Nanofluids. Int. J. Energy Res. 2022, 46, 10930–10941. [Google Scholar] [CrossRef]

- Yetik, O.; Karakoc, T.H. Thermal and Electrical Analysis of Batteries in Electric Aircraft Using Nanofluids. J. Energy Storage 2022, 52, 104853. [Google Scholar] [CrossRef]

- Xie, L.; Huang, Y.; Lai, H. Coupled Prediction Model of Liquid-Cooling Based Thermal Management System for Cylindrical Lithium-Ion Module. Appl. Therm. Eng. 2020, 178, 115599. [Google Scholar] [CrossRef]

| Year | The Focus of the Review Article | Ref. |

|---|---|---|

| 2011 | Overview of progress in battery development focusing on mathematical models of battery thermal behavior | [20] |

| 2016 | Identify challenges and critical gaps between current BTM strategies, research, and implementation used by automotive suppliers | [21] |

| 2017 | Thermal management challenges and solutions at both the cell and module levels, including local heat generation, thermal resistance, cooling configurations, and direct liquid cooling strategies | [22] |

| 2019 | The impact of temperature on battery performance, including both direct and indirect contact methods for liquid-based BTMSs | [23] |

| 2020 | The existing preheating methods and technologies of preheating methods for LiBs | [24] |

| 2020 | Passive BTMS using phase change material (PCM) and a heat pipe | [25] |

| 2021 | The feasibility, cost efficiency, or integrability of various BTM methods and strategies for cylindrical, prismatic, and pouch LiBs | [26] |

| 2022 | Applications of heat pipes in BTMSs for EV applications in different operating conditions such as fast charging, rapid discharge, and hard-working | [27] |

| 2022 | Advancements in BTMS technologies, highlighting their role in ensuring battery safety and performance, reviewing various cooling methods | [28] |

| 2023 | Recent advances in the suitability of hybrid BTMSs using PCM-liquid cooling for fast-charging, and identifying the ongoing challenge of the thermal runaway in LiBs during fast charging | [29] |

| Anode | Cathode | Overall | |

|---|---|---|---|

| Discharge reactions | |||

| Charge reactions |

| Method | Battery Type/Capacity | Parameters /Variables | Discharge rate | Flow Rate | Tambient | Tmax Taverage * | ΔT | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Numerical and experimental | Lithium-ion, prismatic, 6 cells, 3.2 V, 12.3 Ah (cell) | Inlet and outlet relative position, the height of battery pack, cell distribution, and cell spacing | 3 C | 0.0014 m3/s | 298.15 K | - | - | Aligned inlets and outlets on the same side enhanced thermal performance compared to crossed and diagonal inlets and outlets on different sides. The best thermal efficiency for longitudinal inlets and outlets on the same side was observed with increased spacing between them. Raising the inlet height and lowering the outlet height enhances cooling and achieves a more uniform temperature distribution in laterally aligned inlets and outlets. | [5] |

| Numerical | Lithium-ion, 18,650, 60 cells, 10S6P 37 V, 15.6 Ah (module) | Inlet and outlet positions of airflow | 1 C | 2 m/s | 25 °C | 38.9 °C | 7.3 °C | The best thermal performance was achieved by the configuration of a lateral inlet/outlet on different sides with the utilization of a baffle (e), since the baffle stopped most of the air passing between the battery and the case, which led to uniform airflow near the inlet section. | [36] |

| Numerical | Lithium-ion, prismatic, 72 cells 270 V, 1400 Wh (module) | Tapered manifold, pressure relief ventilation | - | 0.045 m3/s | - | 58.2 °C | 18.2 °C | The ventilation hole used in Type V is provided to hold the battery system temperature at controlled levels by contributing energy use. Type V has also led to obtaining lower and more uniform pressure distribution in the manifolds. | [37] |

| Experimental | Lithium-ion, 18,650, 30 cells, 6S5P 21.6 V, 14.5 Ah (module) | Discharge rate, cooling channel type | 1 C–2 C | 8 m/s | - | 37.9 °C @ 1C 45.2 °C @ 1.5C 55 °C @ 2C | 3.4 °C @ 1C 8.1 °C @ 1.5C 17.6 °C @ 2C | The ΔT values of the battery in case 2 were higher than case 1 at the 1C discharge rate. Nevertheless, increased discharge rates have also led to obtained increased ΔT. Tmax and ΔTmax values in the cells were obtained as 69.8 °C and 17.7 °C when no cooling system was used. Approximately 970.3 J and 856.9 J heat removals were achieved for case 1 and case 2, respectively, when the FAC system was used under the 1C discharge rate. The cooling efficiency obtained was 73% for case 1 and 62.3% for case 2. | [38] |

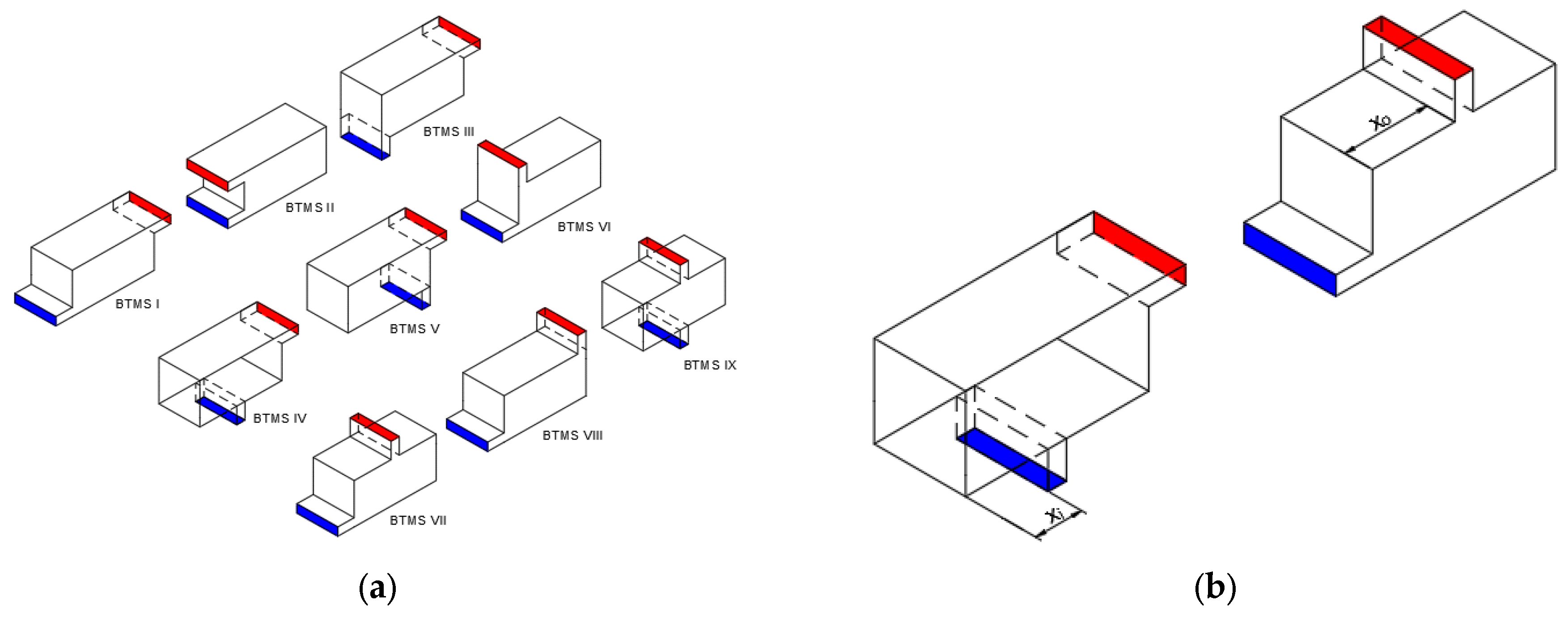

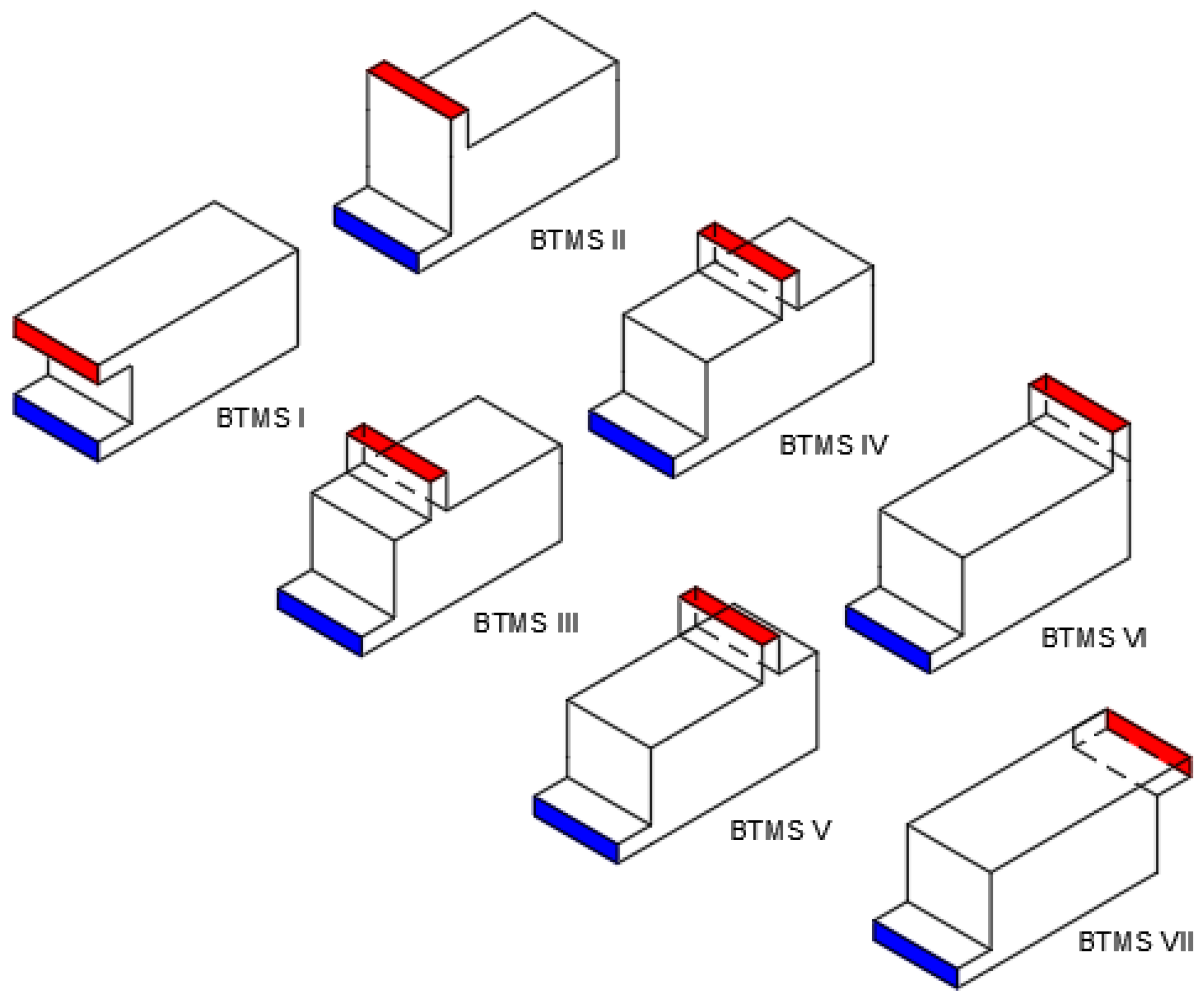

| Numerical and experimental | Lithium-ion, prismatic, for heat generation models: 12 Ah LiFePO4 (experimental) Aluminum blocks (numerical) | Inlet–outlet configurations | 5 C | 0.015 m3/s | 298.15 K | - | - | Higher cooling efficiency was obtained with BTMS IX (both inlet and outlet at middle). BTMS IX has decreased Tmax by 4.3 K and ΔT by 6 K compared to BTMS I. Optimization of inlet and outlet locations was realized by changing variables xi and xo. The optimized position of the outlet in BTMS VII (BTMS VII-opt) gave the best cooling performance among others. | [39] |

| Numerical | Lithium-ion, 18,650, 240 cells, 20S12P, 3.7 V, 2.6 Ah (cell) | The number of cooling fans | 1 C | 20–30 °C | 33.1 °C * | 14.9 °C | Implementing an optimized cooling approach for an air-cooled BTMS with a three-inlet arrangement and 25 °C air inlet temperature is recommended. | [40] | |

| Numerical | Lithium-ion 70 Ah (cell) | Z-shaped airflow channel with a non-vertical structure | - | 4 m/s | 20 °C | 34.14 °C | 1.97 °C | The ideal angle between the inlet/outlet and the flow channel is fixed at 19°, and the width of the flow passage is adjusted to 2 mm, with an airflow rate of 4 m/s at the inlet of the channel. | [41] |

| Experimental | Lithium-ion, 18,650, 9 cells, 9S 3.6 V, 3.35 Ah (cell) | Integration of DEC system for BTMS | 3 A, 5 A | 3.75 m3/min | - | 33.6 °C | 6.9 °C | The thermal performance is strongly linked to the surrounding air’s relative humidity (RH), and a low RH is favored for achieving more effective cooling. | [42] |

| Numerical | Lithium-ion, 21,700, 36 cells | Positioning the air outlets | 2 C | 0.5–5 m/s | 23.85 °C | ~37 °C | 6.2 °C | BTMS III achieved superior thermal efficiency compared to the conventional Z-flow-type BTMS. Specifically, the Taverage and Tmax of BTMS III were reduced by approximately 3 °C. | [43] |

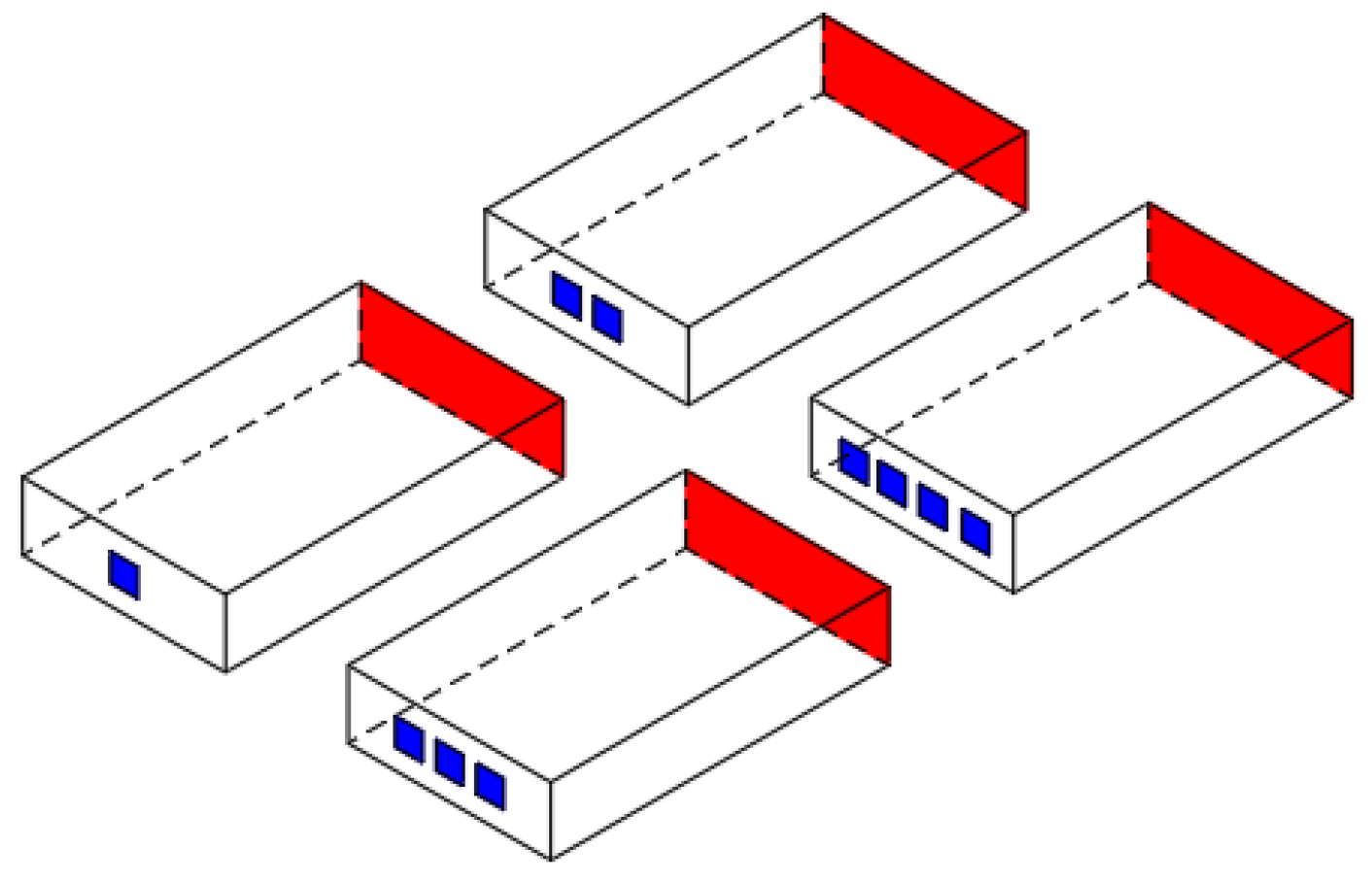

| Numerical | Lithium-ion, 21,700, 42 cells | Battery pack layout | 0.5 C–2 C | 20–100 L/s | 20 °C | 32.95 °C | 3.10 °C | The trapezoid design showed better cooling performance than the rectangular design, with a reduced Tmax of 0.9 °C and a ΔTmax reduction of 1.17 °C at a 60 L/s inlet airflow rate. | [44] |

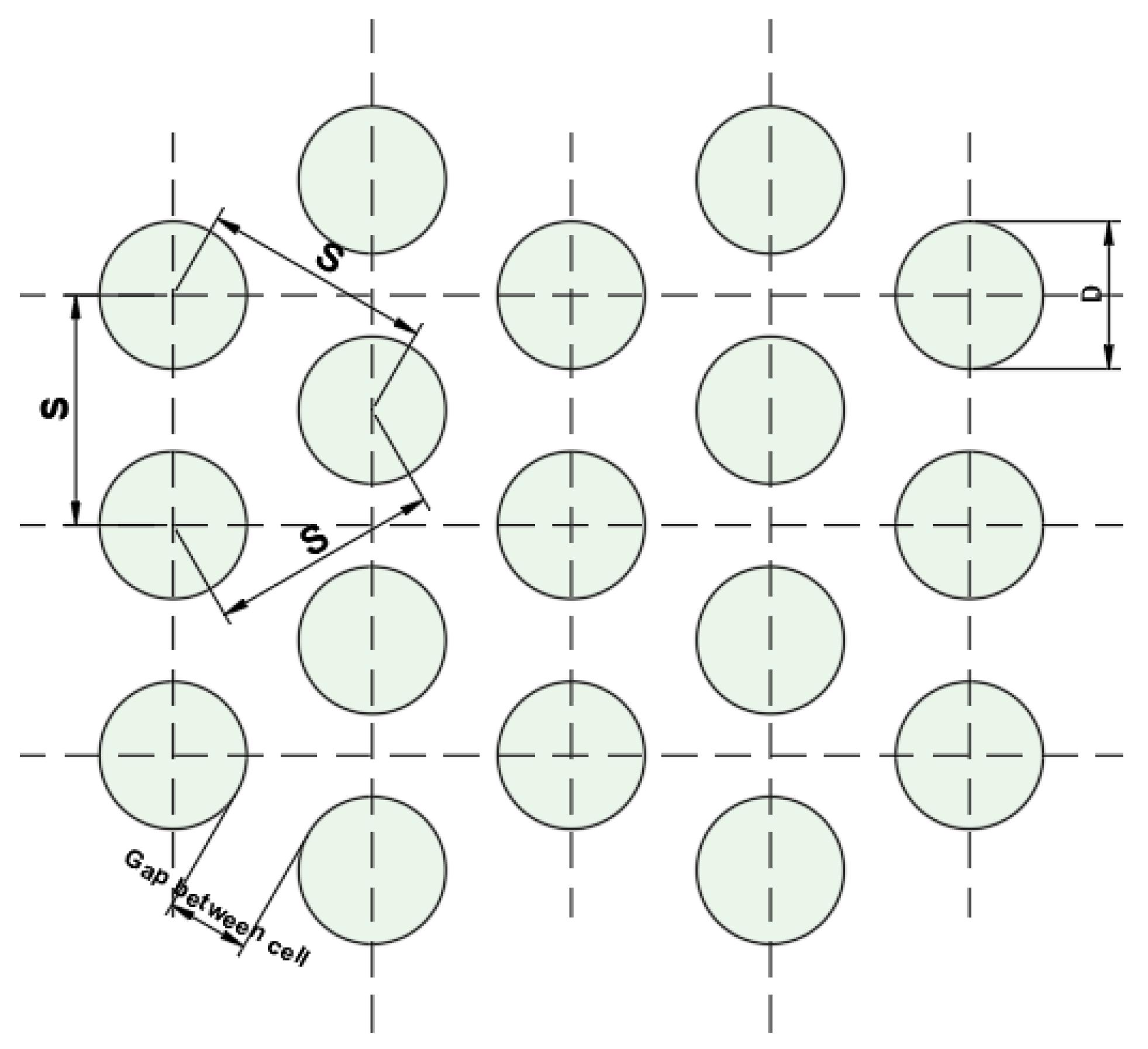

| Numerical | Lithium-ion, 18,650, 30 cells, 6S5P, 3.6 V, 2.9 Ah (cell) | Cell spacing, flow velocity, and discharge rate | 1 C–5 C | 2–10 m/s | 25 °C | - | - | The evaluation parameters for the system cooling efficiency were α (battery packing efficiency), β (battery module efficiency factor), Tmax, ΔT, and ΔP (pressure drop). The highest value of β was observed for 8 m/s air velocity with St = 38 mm and Sl = 23 mm. Sl substantially affected the Tmax and ΔT. Flow velocity triggered to obtain reduced levels of Tmax and ΔT. An increase in velocity causes an increase in ΔP, which in turn leads to a loss in β. For various discharge rates, β increased while ΔP and flow velocity were held constant. | [45] |

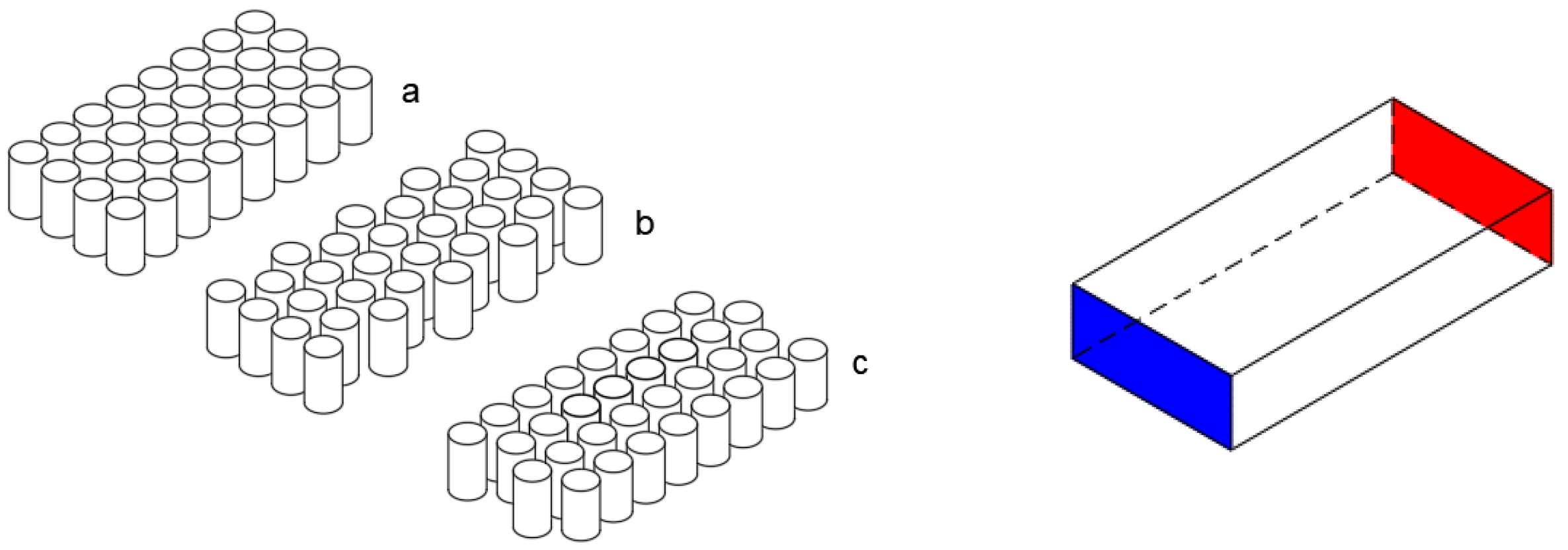

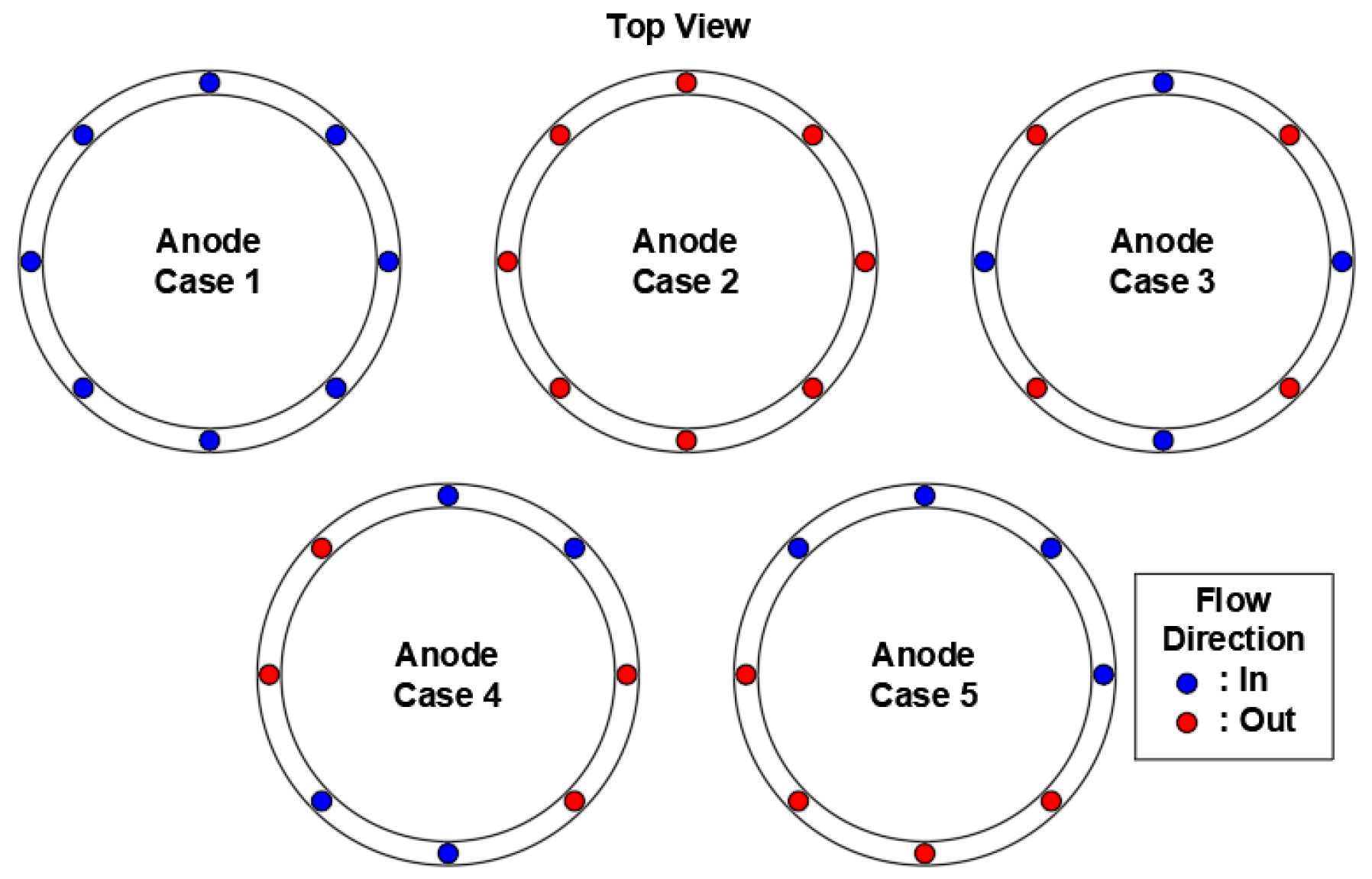

| Numerical and experimental | Lithium-ion, 18,650, 16 cells, 3.6 V, 2.4 Ah (cell) | Cell arrangements, ventilation schemes | 2 C, 3 C | 1 m/s | 298.15 K | 304.97 K * | - | According to the results, 4 × 4, straight configuration (c) under top-in, bottom-out flow mode (b) exhibited the optimum cooling condition. | [46] |

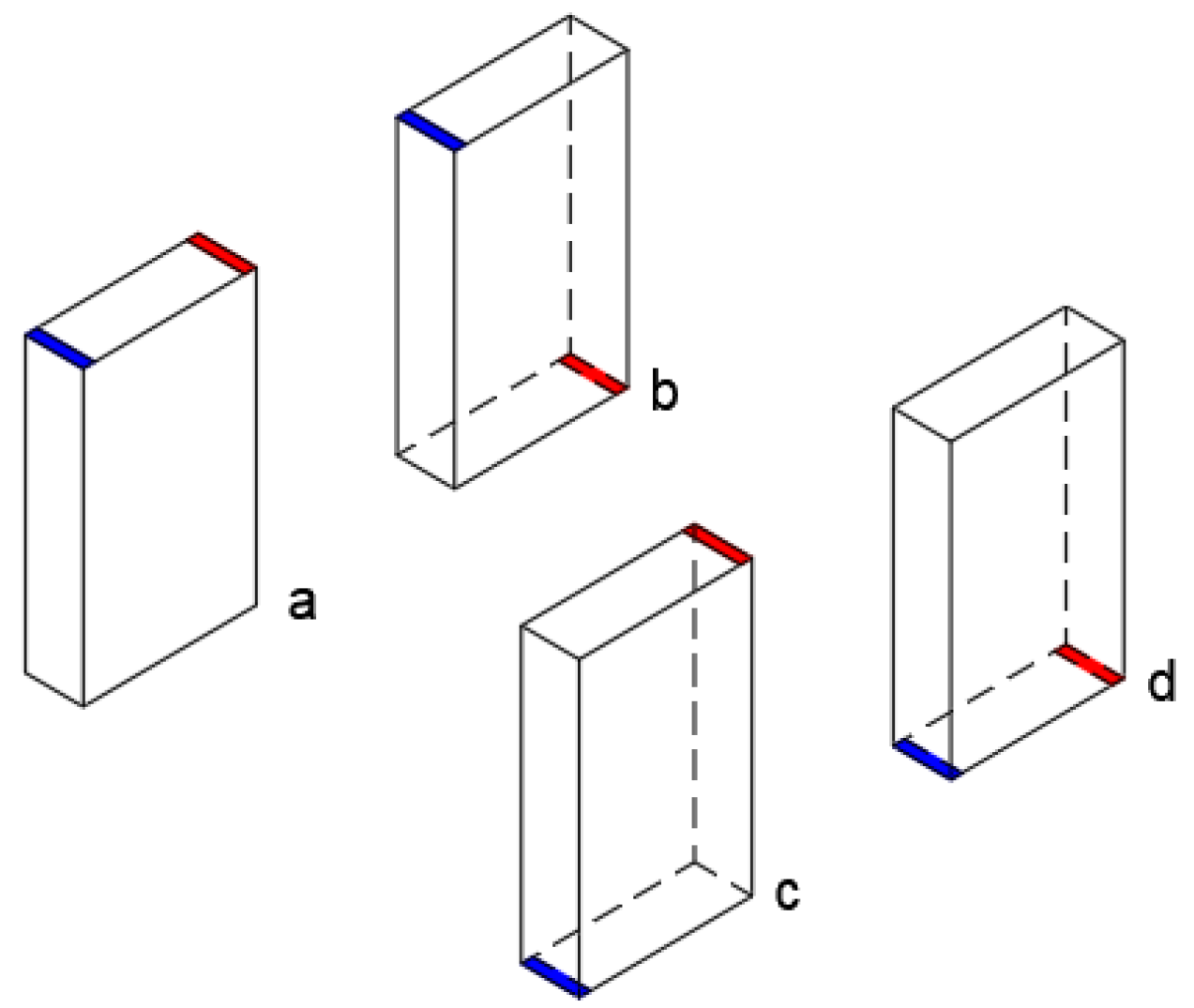

| Numerical and experimental | Lithium-ion, 18,650, 3.7 V, 1.5 Ah (cell) | Cell arrangements, flow configurations, and inter-cell spacing | 3 C | 1 m/s | 25 °C | 33.6 °C 32.8 °C * | 2.95 °C | A 5 × 5 rectangular arrangement (c) exhibited the best performance from the perspective of cost and efficient cooling when the airflow input was located at the top of case (b). On the other hand, if space utilization is one of the major issues besides effective cooling, hexagonal structure (d) can be selected. The optimum inter-cell distance was 1 mm for c arrangement when the airflow speed was 1 m/s. | [47] |

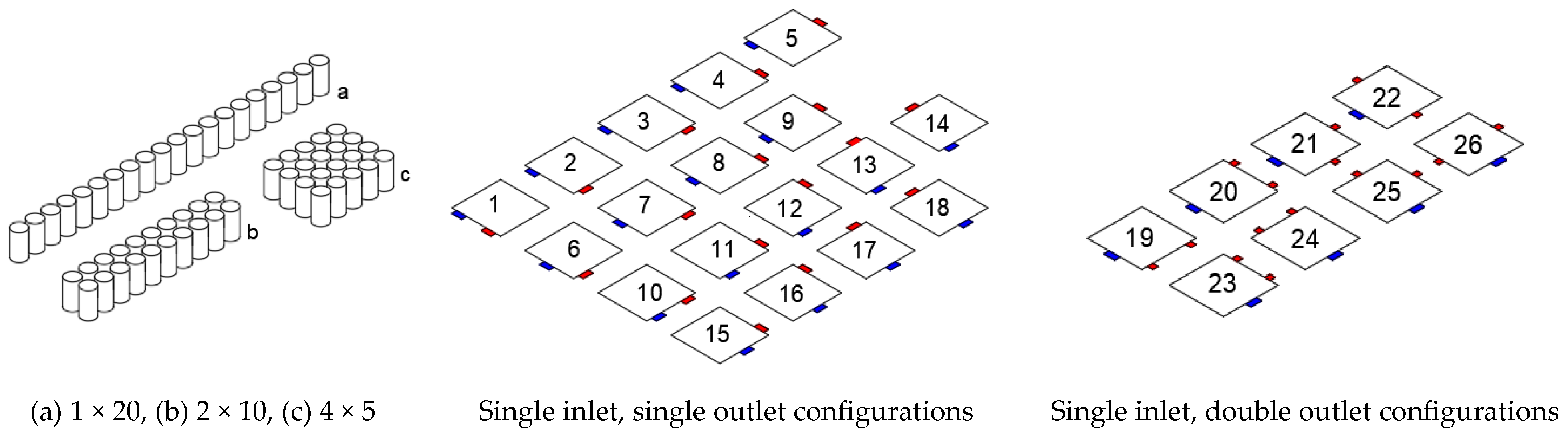

| Numerical and experimental | Lithium-ion, 18,650, 20 cells, 3.6–4.2 V, 2.6 Ah (cell) | Cell arrangement, inlet–outlet configurations | 8 A | 1 m/s | - | 301.65 K | 22.1 K | A 4 × 5 configuration gave the best results in both directions (transverse and longitudinal) compared to others. Since the longer path of airflow enhanced cooling performance, arrangements 13 and 24 were the best designs for single inlet, single outlet and single inlet, double outlet, respectively. | [48] |

| Numerical | Lithium-ion, 18,650, 25 cells | Cell arrangement, inlet–outlet configurations | 5 C (charging) | 1.458 m3/s | 25 °C | ~320 K | - | Square configuration (a) exhibited the optimum cooling performance. Based on flow configuration, the top inlet and bottom outlet (c) case resulted in the best cooling performance, which can be explained by the rejection of more heat per unit of time since the short flow path. | [49] |

| Experimental | Lithium-ion, 18,650, 32 cells, 8S4P, 3.635 V, 3.5 Ah (cell) | Cell arrangement, inlet velocity, discharge rate, and inlet air temperature | 0.5 C–2 C | 0.6–4 m/s | 20, 30 °C | - | - | The aligned type exhibited the most effective cooling performance and uniform temperature distribution. Cross-pack demonstrated poorer cooling characteristics. Increments in discharge rates for the same velocity have triggered a rise in temperatures. Cooling occurred more effectively when the air inlet velocity increased. | [50] |

| Numerical | Lithium-ion, 18,650, 14 cells, 1S14P, 2.2 Ah (cell) | Size of cooling channel, air supply strategy | 0.5 C | 0.0001 kg/s | 293.15 K | 302.6 K | - | The enlargement of the cooling channel size lowered the Tmax value. The optimal cooling channel size was 1 mm for the battery by considering Tmax, α, and β. The most effective cooling mode was obtained at configuration a (inlet and outlet on top). Ten rows of batteries along the flow direction are recommended for staggered configuration, enabling high power density with the effectiveness of cooling. | [51] |

| Numerical and experimental | Lithium-ion, prismatic, 10 cells | Air inlet/outlet angles, airflow channel width | 20 A | 3 m/s | 25 °C | - | - | The 2.5° air inlet and outlet angle with equally spaced flow channel design resulted in lower Tmax and ΔT values. | [52] |

| Numerical | Lithium-ion, prismatic, 8 cells | Adding spoilers at different heights and inclination angles | - | 4 m/s | 26 °C | - | - | Incorporating spoilers in the optimized scenario yielded notable improvements over the baseline model. Specifically, it led to a remarkable decrease of 1.86 K in the Tmax and a significant reduction of 2.51 K in the ΔTmax. | [53] |

| Numerical and experimental | Lithium-ion, 18,650, 2 Ah (cell) | Air distribution pipe with different diameters of the orifice, the number of rows of the orifice | 3 C–5 C | 48 L/min | 298.15 K | 305.7 K | 2.8 K | With 100 Pa inlet pressure, 1.5 mm diameter of orifice, five rows, and 3 C discharge rate, the Tmax of the battery module drops from 325.9 K to 305.7 K, depending on the situation without air cooling. | [54] |

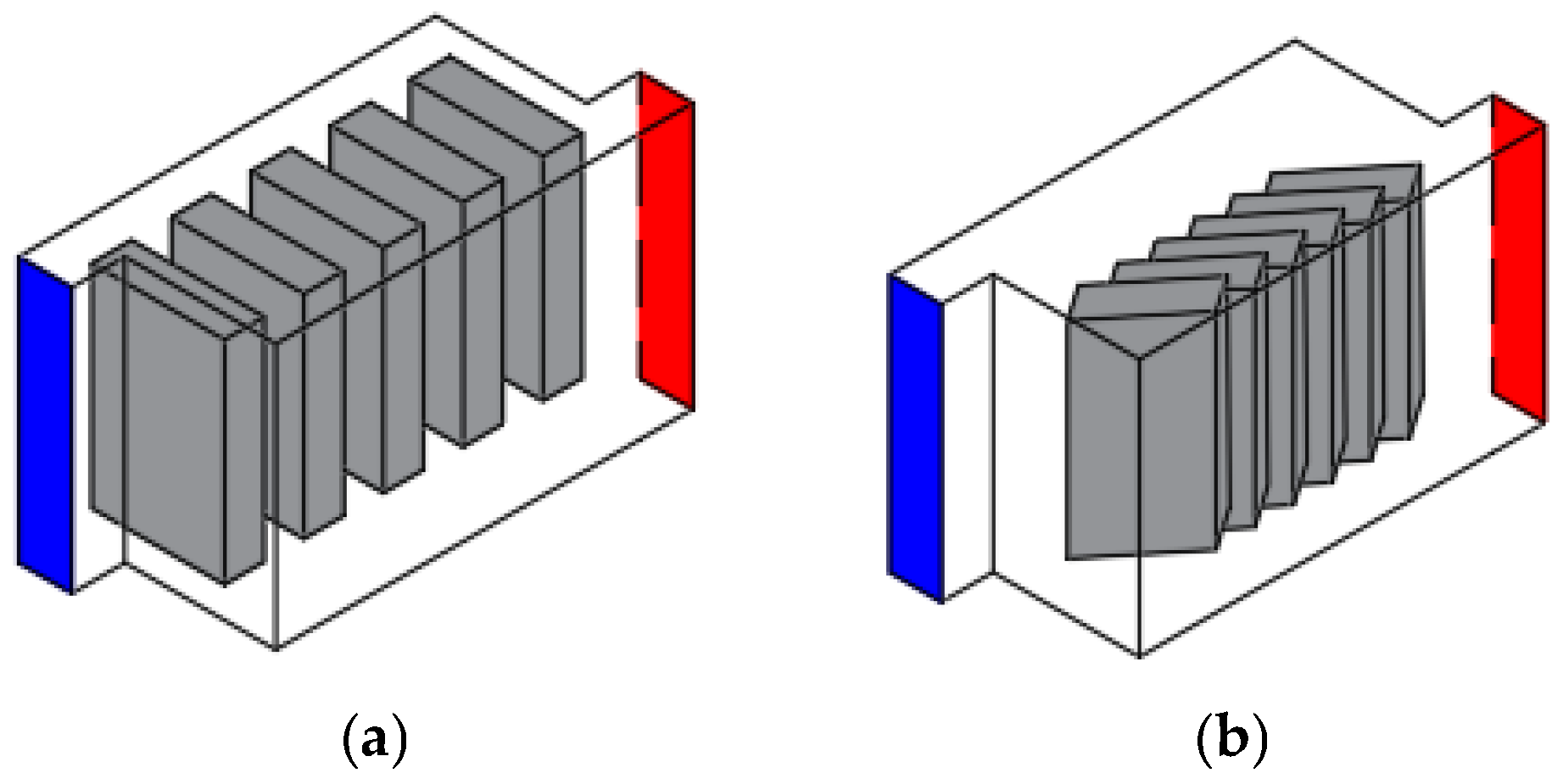

| Numerical | Lithium-ion, pouch, 14.6 Ah (cell) | Novel structure (two types of vortex generators: delta winglet and rectangular rib) | 0.5 C–5 C | 4 m/s | 25 °C | - | - | In the baseline scenario where no VGs are present, a discharge rate of 5 C can lead to a 10% reduction in Tmax and a 38% increase in the local Nusselt number. | [55] |

| Method | Battery Type/Capacity | Parameters/Variables - Liquid | Discharge Rate | Flow Rate | Tambient Tliquid * | Tmax Taverage # | ΔT | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Numerical | Lithium-ion, 26,650 3.3 V, 3 Ah (cell) 6 cells | Cooling block length, inlet velocity - Water | 3C | 0.05–0.3 m/s | 22.5 °C 25 °C * | <32 °C | <5 °C | The temperature distribution is influenced by the interaction between the temperature gradient and the contact area. Lower inlet velocities and increased slope tend to improve distribution, with contact area positively affecting it. However, at higher inlet velocities, an extreme slope can disrupt this balance, leading to a negative impact. | [4] |

| Numerical | Lithium-ion, 3.3 V, 2.3 Ah (cell) | Gap between the cells, cell arrangement - Mineral oil | Heat generation Q = 7 W/cell | 0.5–5 kg/s | 25 °C | 60 °C | <3° C | For liquid-type BTMSs, designing a narrow battery module with minimal spacing between battery cells is more practical. | [19] |

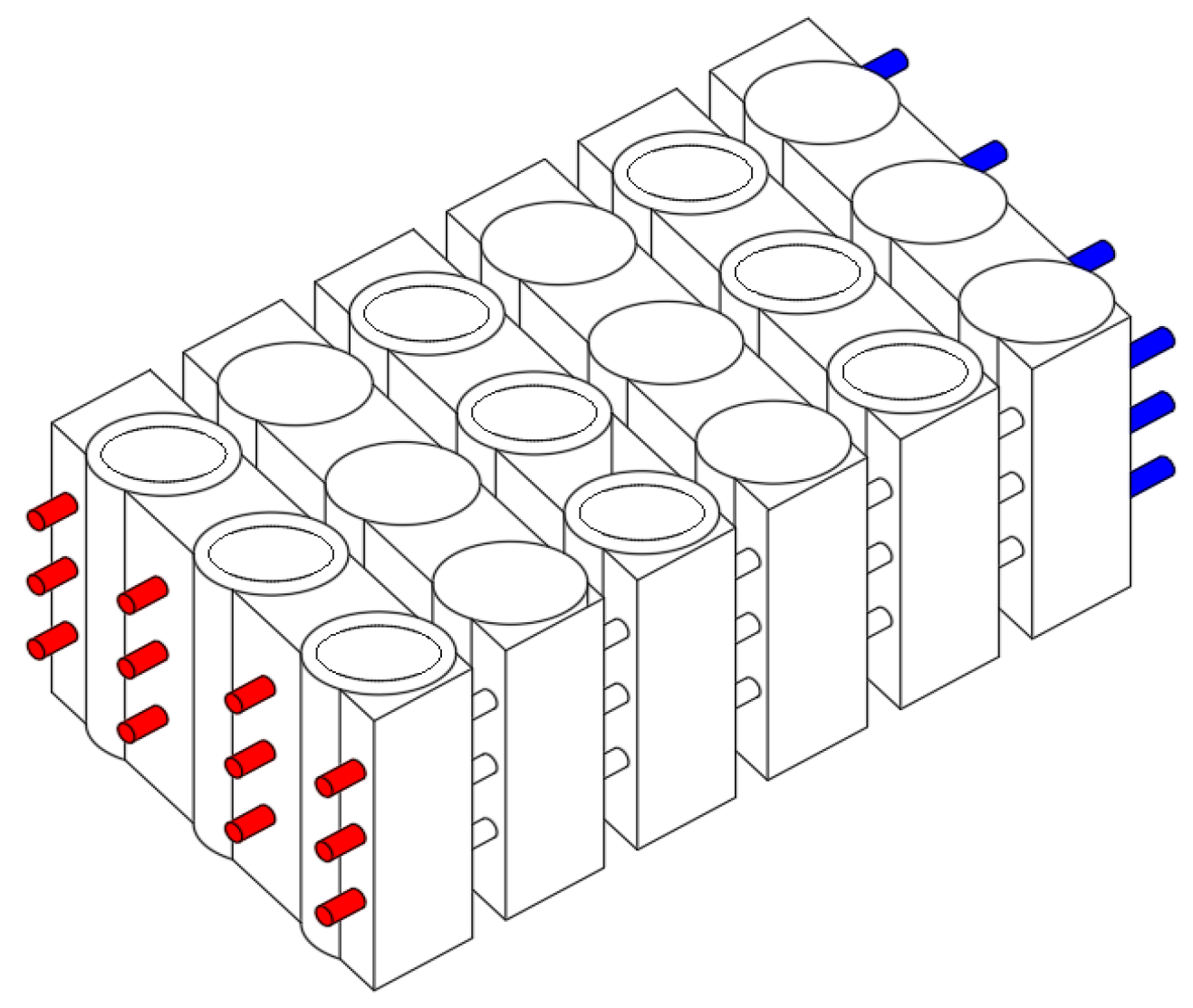

| Numerical | Lithium-ion, 42,110, 40 cells | Entrance size, flow direction, mass flow rate, and channel quantity - Water | 5 C | 5 × 10−6 - 1 × 10−3 kg/s | 25 °C 25 °C * | <40 °C | <12 °C | It is necessary to have a minimum of four passages and an inlet mass flow rate of 1 × 10−3 kg/s to maintain the Tmax below 40 °C. | [59] |

| Experimental | Lithium-ion, 26,650, 18 cells, 6S3P, 22.2 V, 15 Ah (module) | Cooling scheme - Water | 1 C, 1.5 C | 100 mL/min | 25 °C * | ~31.8 °C # @ 1C, ~36.6 °C # @ 1.5 C | ~4.2 °C @ 1C, ~5.6 °C @ 1.5 C | Through the mini-channel design, the temperature values of the battery module have remained below 40 °C for all three cases. | [60] |

| Numerical and experimental | Lithium-ion, 18,650 3.7 V, 2.6 Ah (cell) | Channel design, inlet flow rate - Water | 2 C | 180–900 mL/min | 298 K | <40 °C | <3 °C | The optimal gradient channel design (GCD) for enhancing thermal uniformity was achieved with a two-segment configuration, featuring segment lengths of 60 mm/120 mm. When operated at an inlet flow rate of 360 mL/min, this optimal GCD exhibited a ΔT reduction of 79.2% compared to the Uniform Large Channel Design and a 60.2% reduction compared to the Uniform Small Channel Design. | [61] |

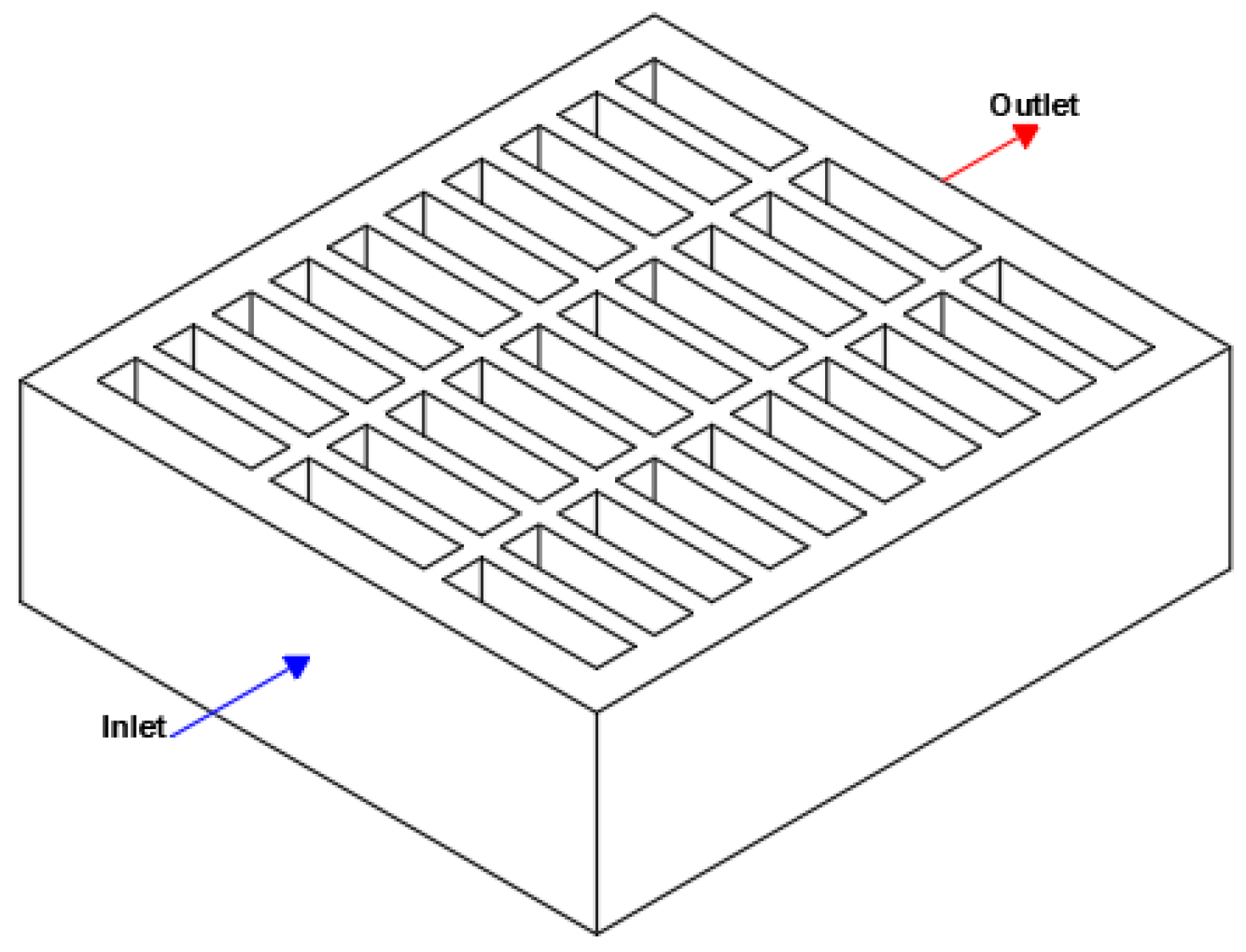

| Numerical and experimental | Lithium-ion, pouch, 7 cells, 3.7 V, 21 Ah (cell) | Channel layout, channel size, flow distributor type, mass flow rate, and structure of the cooling plate - Water | 2 C | 0.4–3.2 g/s | 30–33 °C * | 34.65 °C | 3.95 °C | In the context of various Worldwide Harmonized Light Vehicle Test Cycles (WLTCs), the proposed liquid cooling BTMS has demonstrated its ability to efficiently maintain the Tmax and ΔTmax within the EV battery pack at levels below 25.51 °C and 0.21 °C, correspondingly. | [62] |

| Numerical and experimental | Lithium-ion, pouch, 3.7 V, 20 Ah (cell) | Inlet flow rate, channel configuration - 50% glycol–water | 3 C | 0.05–0.2 m/s | 27 °C 25 °C * | 30.31 °C | 2.78 °C | An effective liquid cooling system design was achieved through the utilization of methods such as the orthogonal test range method and the non-dominated sorting genetic algorithm II. Even under a 3C discharge, the Tmax was maintained below 33.34 °C. | [63] |

| Experimental | Lithium-ion, pouch, 20 cells | Cooling strategy, flow rate - Water | 2 C | 3–6 L/min | 20, 40 °C 20–40 °C * | <40 °C | 2.9 °C | The temperature variance between the liquid and the battery pack can affect cell temperature uniformity. In addition, cascade cooling leads to reduced ΔT within the battery. | [64] |

| Numerical and experimental | Lithium-ion, 18,650, 20 cells, 4S5P 4.2 V, 2.5 Ah (cell) | Coolant flow speed, coolant temperature, and busbar connection - Water | 1 C–3 C | 0.2–1 m/s | 25 °C 25 °C * | 26.85 °C @ 1C 30.42 °C @ 2C 35.81 °C @ 3C | ~5 °C | A velocity range of approximately 0.3 to 0.5 m/s is adequate to satisfy the temperature criteria for the battery module during standard operating conditions. In addition to battery temperature, the connection of the busbars also influences the system’s temperature profile. | [65] |

| Numerical and experimental | Lithium-ion, prismatic, 20 Ah (cell) | Number of cooling channels, flow rate, and flow direction - Water | 3 C, 5 C | 0.1–0.4 m/s | 30 °C | 39.1 °C @ 3C <42 °C @ 5C | - | Considering cost, energy consumption, and cooling performance, the most reasonable results were achieved with the design with five channels and 0.25 m/s liquid velocity. Also, flow direction has no significant effect on cooling performance. | [66] |

| Experimental | Lithium-ion, 2S1P, 3.7 V, 100 Ah (cell) | Flowrate, inlet temperature, and cooling plate arrangement - Water | 1 C, 2 C | 6–30 L/h | 15–25 °C * | 25.04 °C @ 1C 32.5 °C @ 2C | 2.83 °C @ 1C 6.4 °C @ 2C | Among the four liquid cooling systems (LCSs), Z-LCS has the most uniform temperature distribution. F1-LCS and F2-LCS are the top performers in terms of cooling efficiency. However, F2-LCS stands out as the best choice overall because it has the highest cooling efficiency, uses less power, and performs better in transferring heat. | [67] |

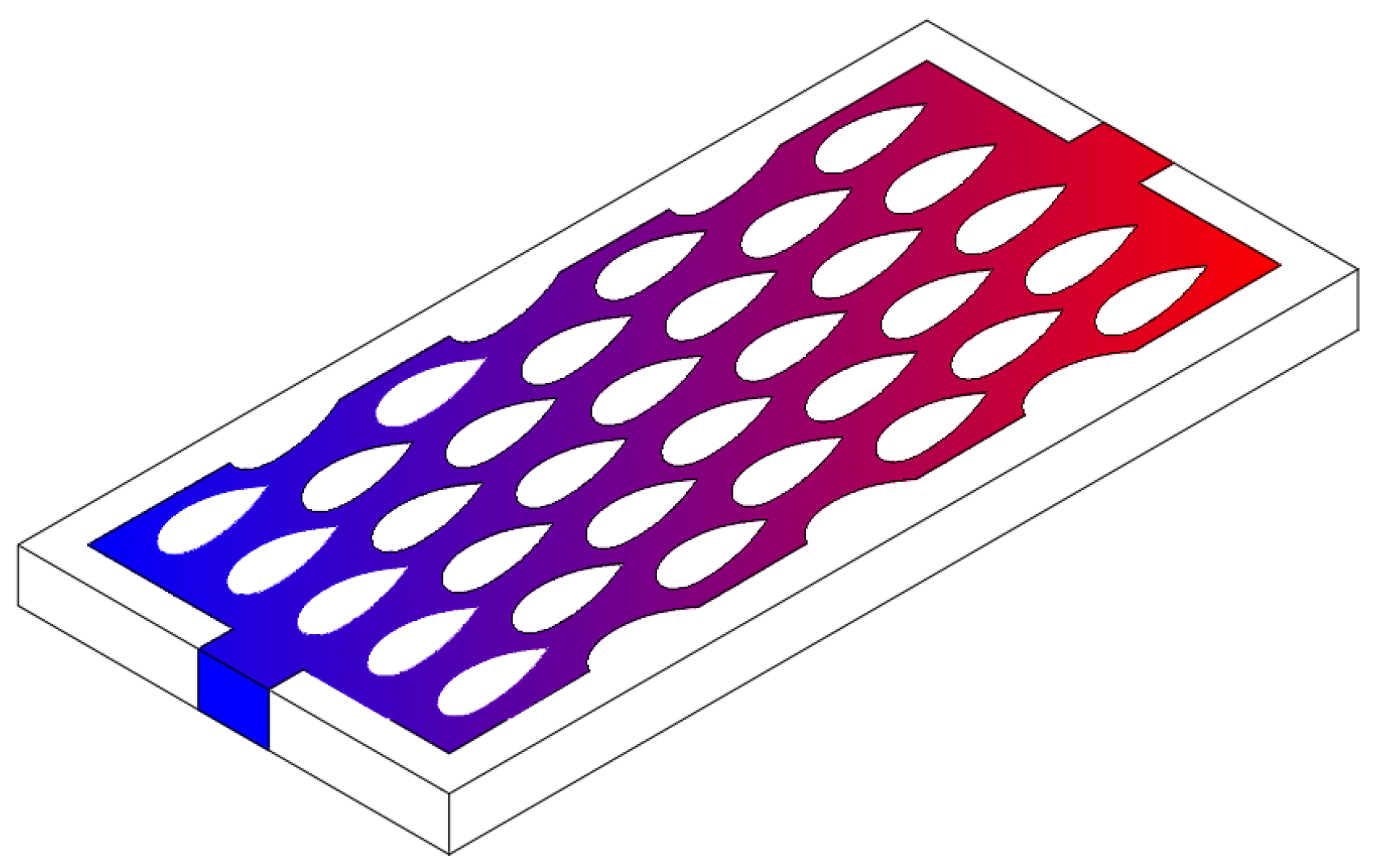

| Numerical | Lithium-ion, prismatic, LiFePO4, 10 cells 8 Ah (cell) | Deflector shape, deflector number, structural parameter, and deflector layout inlet velocity - Water | 5 C | 0.01–0.5 m/s | 298.15 K | 301.3 K | 3.1 K | Liquid cooling plates with mesh structures (LCP-MSs), especially the drop-shaped deflector, outperform the others, reducing ΔP by 72.5% and 76.3% compared to the alternative LCP-MSs. | [68] |

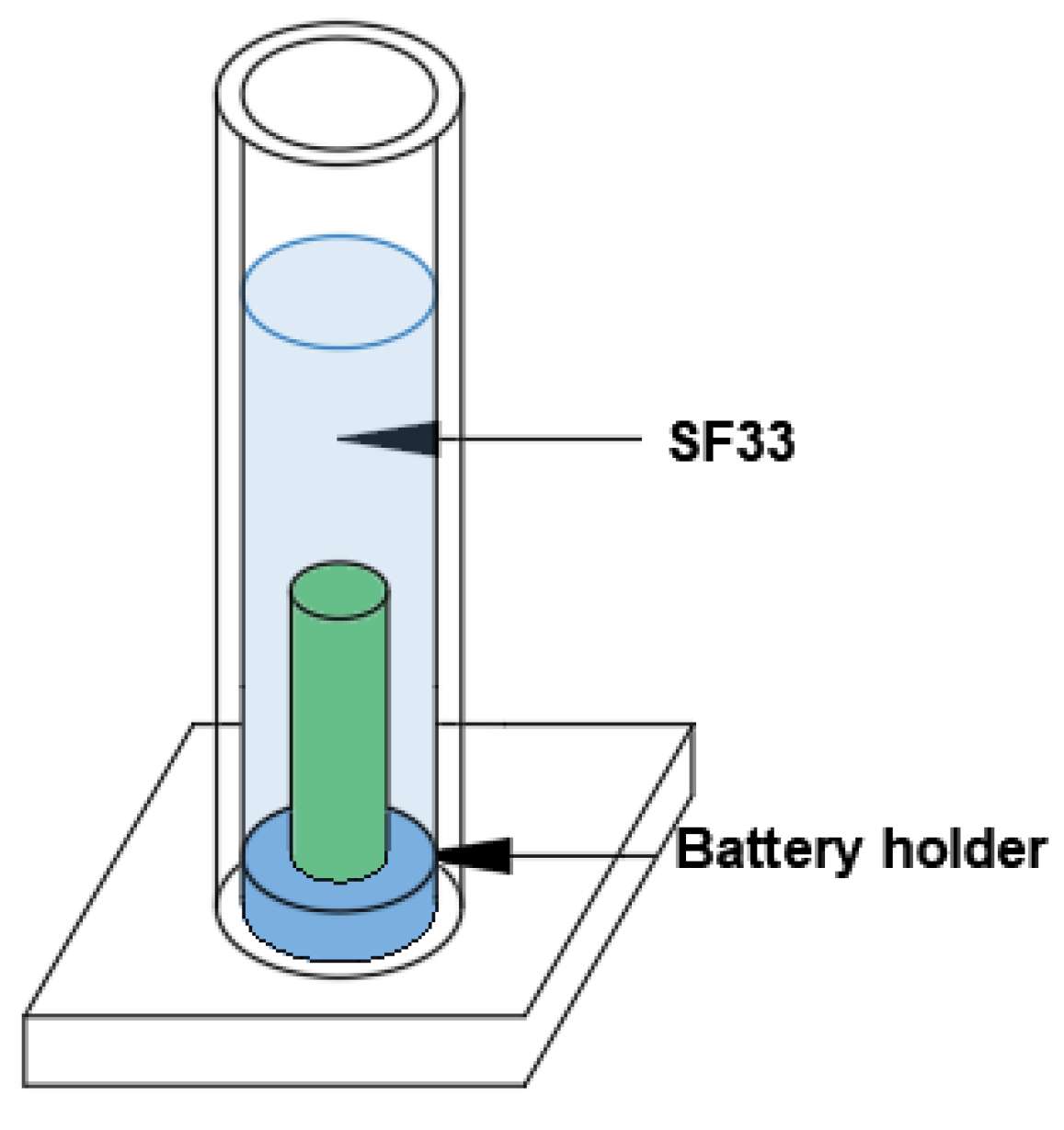

| Experimental | Lithium-ion, 18,650, 1 cell, 3.65 V, 3 Ah (cell) | Immersion - SF33 | 2 C, 4 C | - | 30 °C | 33, 34 °C | 4.97 °C | SF33 (fluorinated liquid) immersion cooling outperforms FAC in heat removal for both continuous and dynamic discharging. | [69] |

| Numerical | Lithium-ion, 18,650, 12 cells, 21,700, 7 cells | Nanofluid volume fraction, coolant flow rate, and hydraulic diameter - Water + AgO | 3 C–7 C | 0.2–0.28 m/s | 298 K | <305.59 K | <1.07 K | The use of the 21,700 battery instead of the 18,650 has not only positively affected the cooling performance but also resulted in an 11% weight savings. | [70] |

| Numerical | Lithium-ion, prismatic, 15S1P, 20 Ah (cell) | Nanoparticle concentration, inlet velocity - Water + Al2O3 | 1 C–5 C | 0.01–0.04 m/s | 295, 300 K | <313 K @ 5C | <1 K @ 2C | When the discharge rate stays at or below 3, the battery module maintains a safe operating temperature. Higher fluid velocity and lower ambient (fluid) temperature are highly effective in keeping batteries at their safe operating temperature. | [71] |

| Numerical | Lithium-ion, prismatic, 10S3P, 30 Ah (cell) | Nanoparticle concentration, inlet velocity, and refrigerant type - Water, Engine Oil + Fe2O3 | 1 C–5 C | 0.02, 0.04 m/s | 300 K | <313 K | ~3 °C @ 4C | As the C value increases, the proportion of nanoparticles in the refrigerant becomes more significant, leading to notable changes. In contrast, when the C value is low, variations in the proportion of nanoparticles have minimal impact on the temperature. | [72] |

| Numerical | Lithium-ion, 18,650, 27 cells, 2.2 Ah (cell) | Baffle height and position - Water | 5 C | 0.2 m/s | 298.15 K 298.15 K * | <304 K | <5 K | Considering the production strategy and the cost, it can be evaluated to make a modification by adding baffles to the microchannel to enhance cooling. | [73] |

| BTMS Type | Air | Liquid |

|---|---|---|

| Typical Tmax reduction potential | ●●●○○ | ●●●●○ |

| Typical ΔT level | ●●●○○ | ●●●●○ |

| Cooling efficiency | ●●●○○ | ●●●●○ |

| Cost | ●●○○○ | ●●●○○ |

| Complexity | ●●○○○ | ●●●○○ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tosun, E.; Ilinčić, P.; Keyinci, S.; Yakaryilmaz, A.C.; Ozcanli, M. A Review on Air and Liquid Cooling Strategies for Lithium-Ion Batteries. Appl. Sci. 2025, 15, 12617. https://doi.org/10.3390/app152312617

Tosun E, Ilinčić P, Keyinci S, Yakaryilmaz AC, Ozcanli M. A Review on Air and Liquid Cooling Strategies for Lithium-Ion Batteries. Applied Sciences. 2025; 15(23):12617. https://doi.org/10.3390/app152312617

Chicago/Turabian StyleTosun, Erdi, Petar Ilinčić, Sinan Keyinci, Ali Cem Yakaryilmaz, and Mustafa Ozcanli. 2025. "A Review on Air and Liquid Cooling Strategies for Lithium-Ion Batteries" Applied Sciences 15, no. 23: 12617. https://doi.org/10.3390/app152312617

APA StyleTosun, E., Ilinčić, P., Keyinci, S., Yakaryilmaz, A. C., & Ozcanli, M. (2025). A Review on Air and Liquid Cooling Strategies for Lithium-Ion Batteries. Applied Sciences, 15(23), 12617. https://doi.org/10.3390/app152312617