Linear Methods for Predictive Maintenance: The Case of NASA C-MAPSS Datasets

Abstract

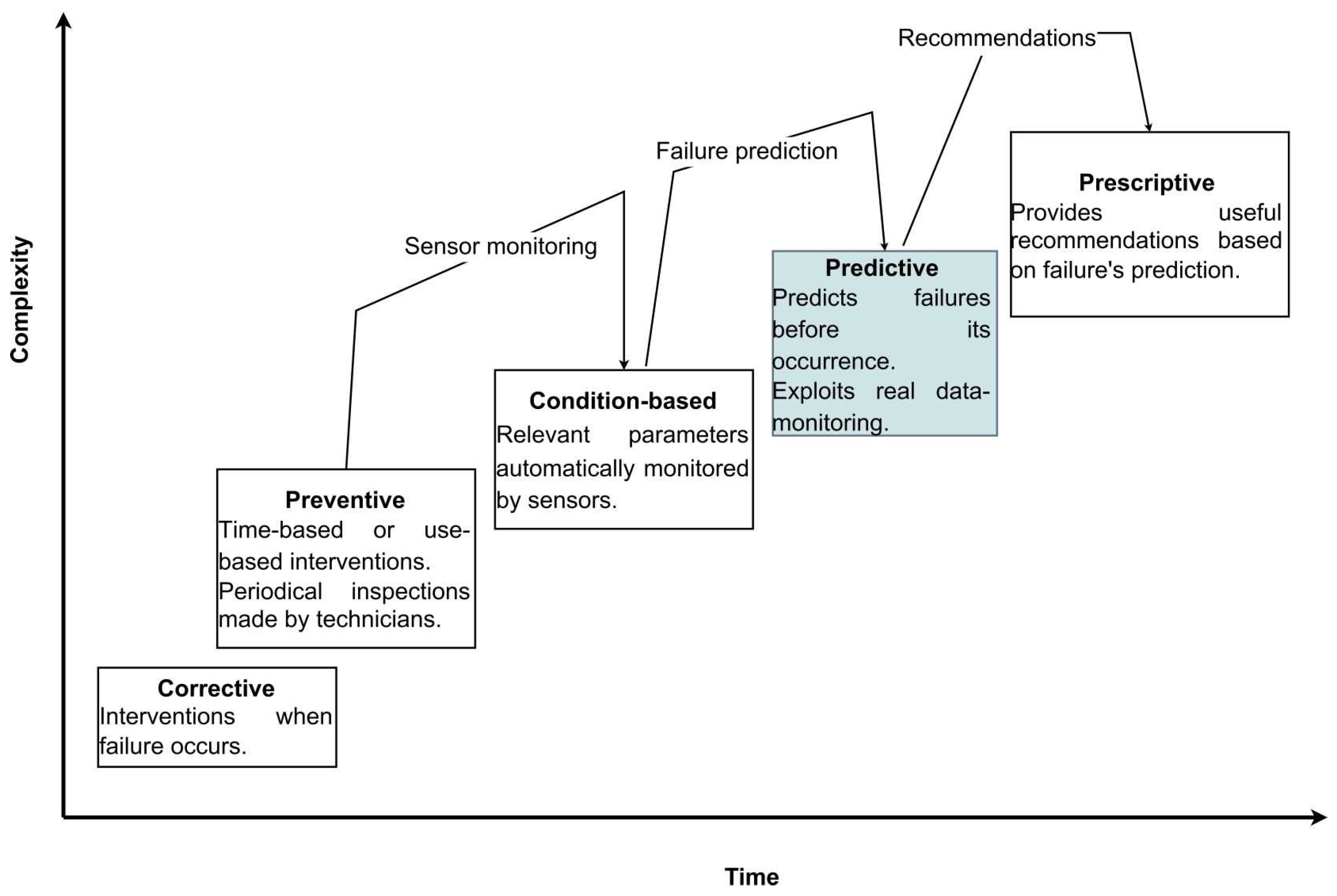

1. Introduction

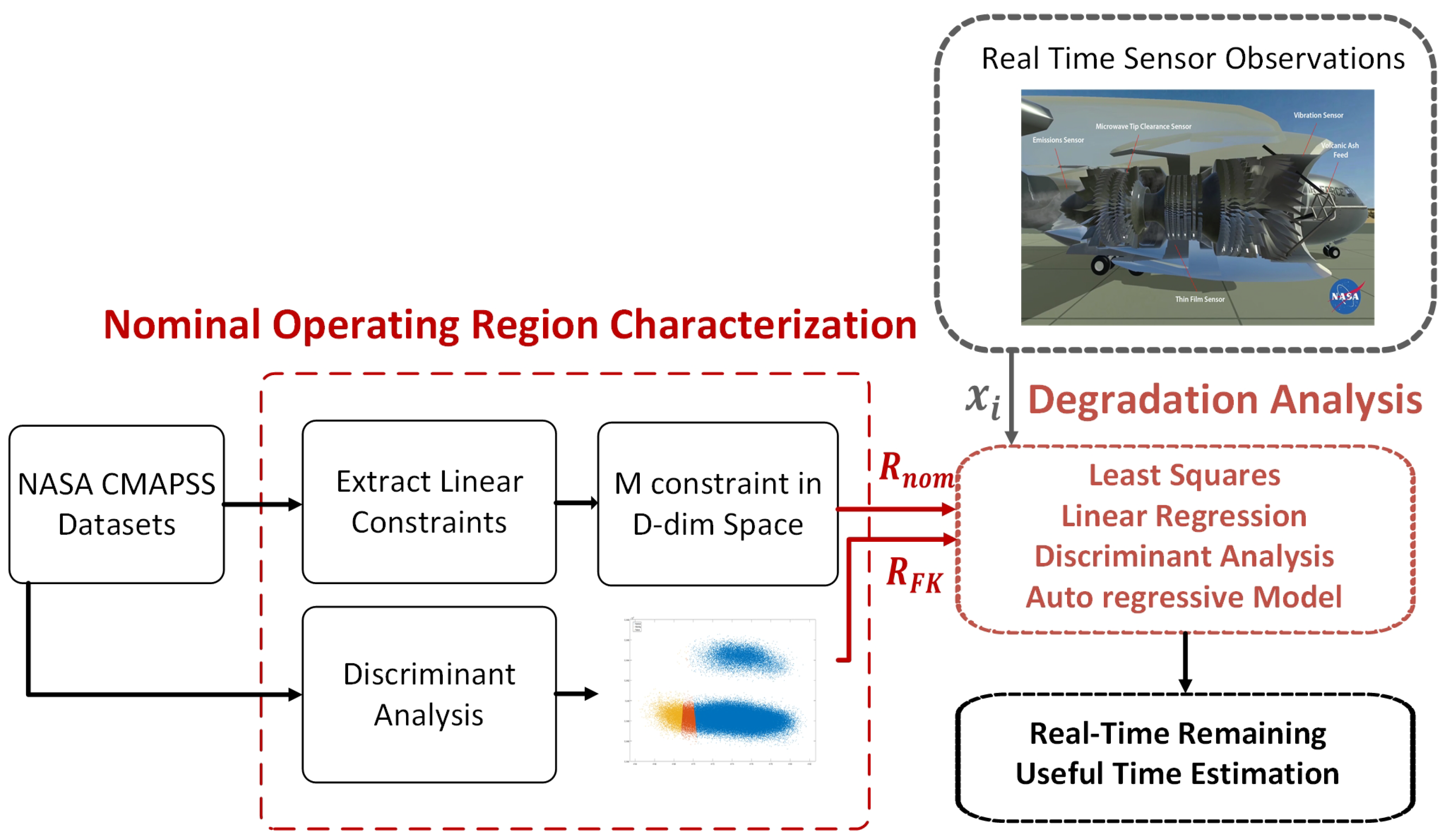

- The proposed linear framework segments the measurement space through hyperplane boundaries, effectively capturing operational regimes and degradation patterns. While demonstrated on the NASA C-MAPSS dataset, the unified measurement space approach can naturally accommodate heterogeneous sensor modalities without requiring separate preprocessing pipelines or complex fusion architectures, making it suitable for multi-model predictive maintenance applications.

- The system uniquely combines classification and regression objectives within a single linear framework. Equipment states are classified into nominal, warning, and failure zones based on their position relative to learned hyperplane boundaries, while the signed distance to these boundaries provides continuous RUL estimation. This dual functionality ensures consistency between discrete maintenance decisions and continuous degradation monitoring.

- The linear architecture offers computational efficiency and interpretability advantages over complex multi-task alternatives. The learned hyperplane coefficients directly reveal feature importance, enabling maintenance engineers to understand which sensor measurements most strongly indicate degradation. This transparency facilitates model validation and knowledge transfer across similar equipment types.

- The proposed system is particularly effective for run-to-failure data, providing a flexible framework for prognostics even with limited failure instances. By tracking system trajectories through the measurement space, the method enables early anomaly detection and degradation assessment. The computationally lightweight nature of the linear approach makes it suitable for real-time implementation in industrial environments where multiple assets require simultaneous monitoring.

2. Materials and Methods

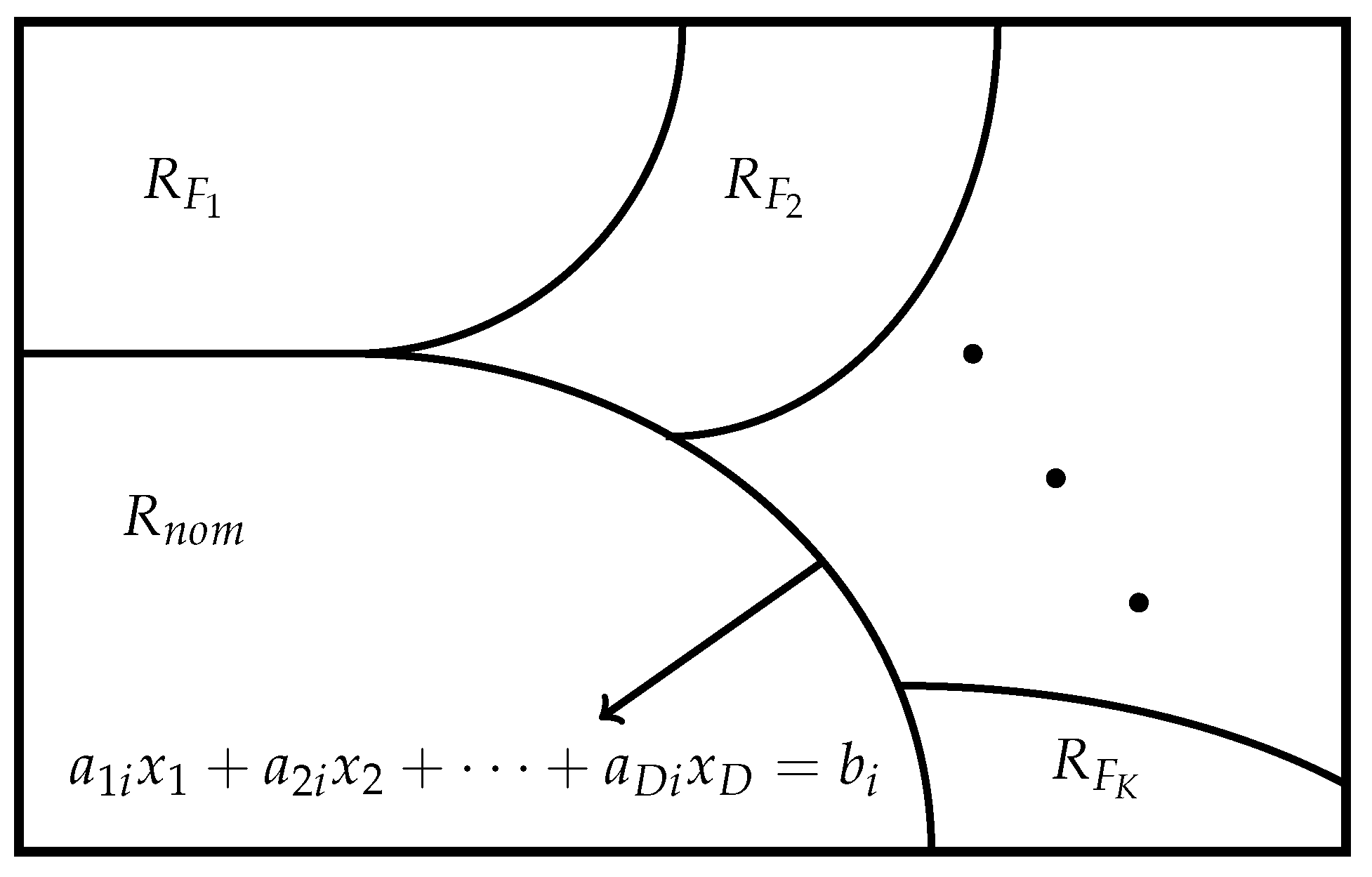

2.1. Theoretical Definition of the Problem

- Nominal region : Represents healthy operational states;

- Warning region : Indicates degradation onset;

- Failure region : Requires immediate maintenance action.

2.2. Linear Classification for Health State Determination

2.3. Remaining Useful Life Estimation

2.3.1. Distance-Based Features

- : System is in nominal region (negative distance to warning boundary);

- and : System is in warning region;

- : System has reached failure region.

2.3.2. Degradation Trend Modeling

2.3.3. RUL Prediction

3. Simulations and Results

3.1. Dataset Description

3.2. Data Preprocessing and Labeling

- Nominal state: 20 < RUL ≤ 30 cycles;

- Warning state: 10 < RUL ≤ 20 cycles;

- Failure state: RUL ≤ 10 cycles.

- Feature selection: Sensors with constant readings across all units are removed as they provide no discriminative information.

- Smoothing: A moving average filter with window size 5 is applied to reduce measurement noise while preserving degradation trends.

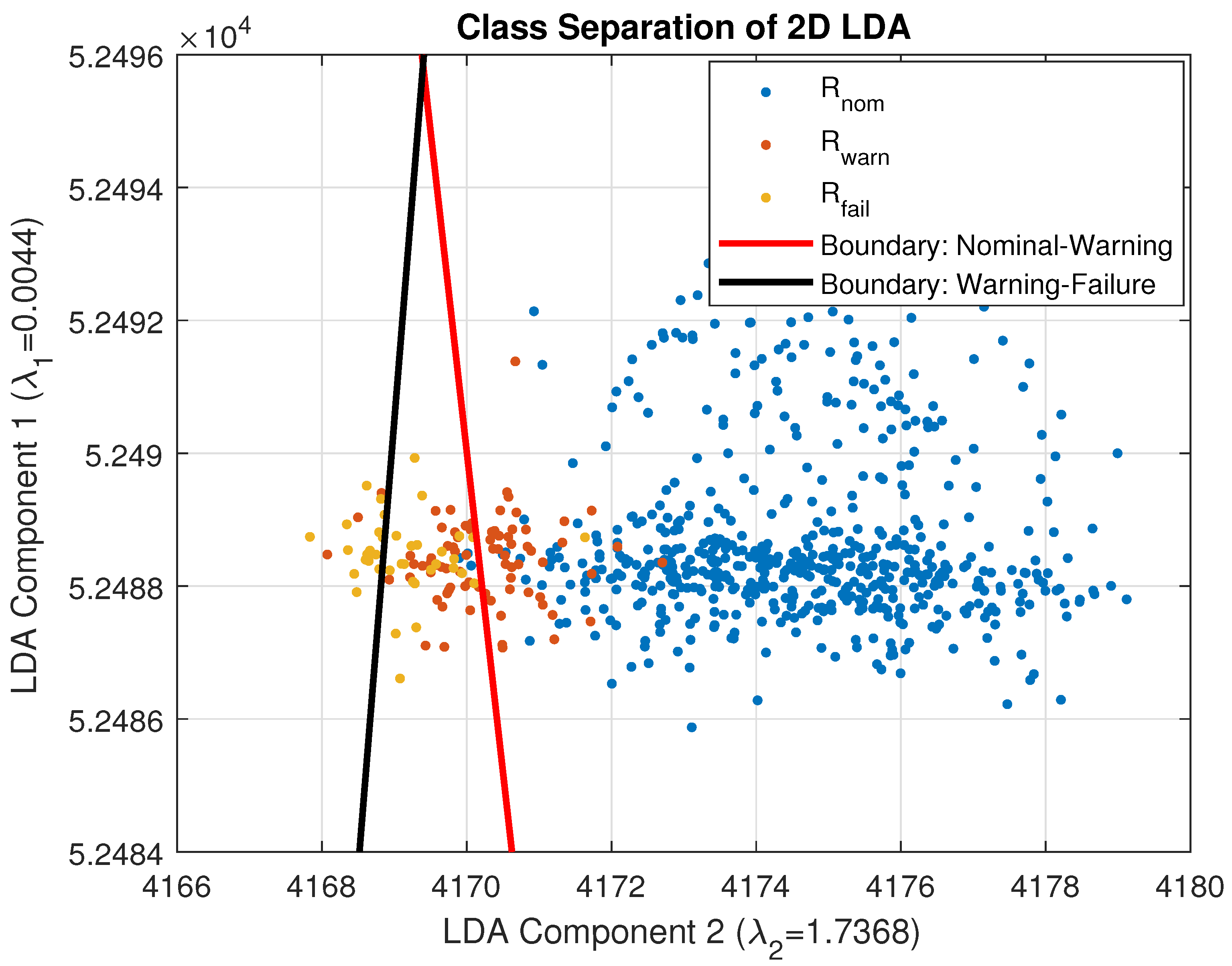

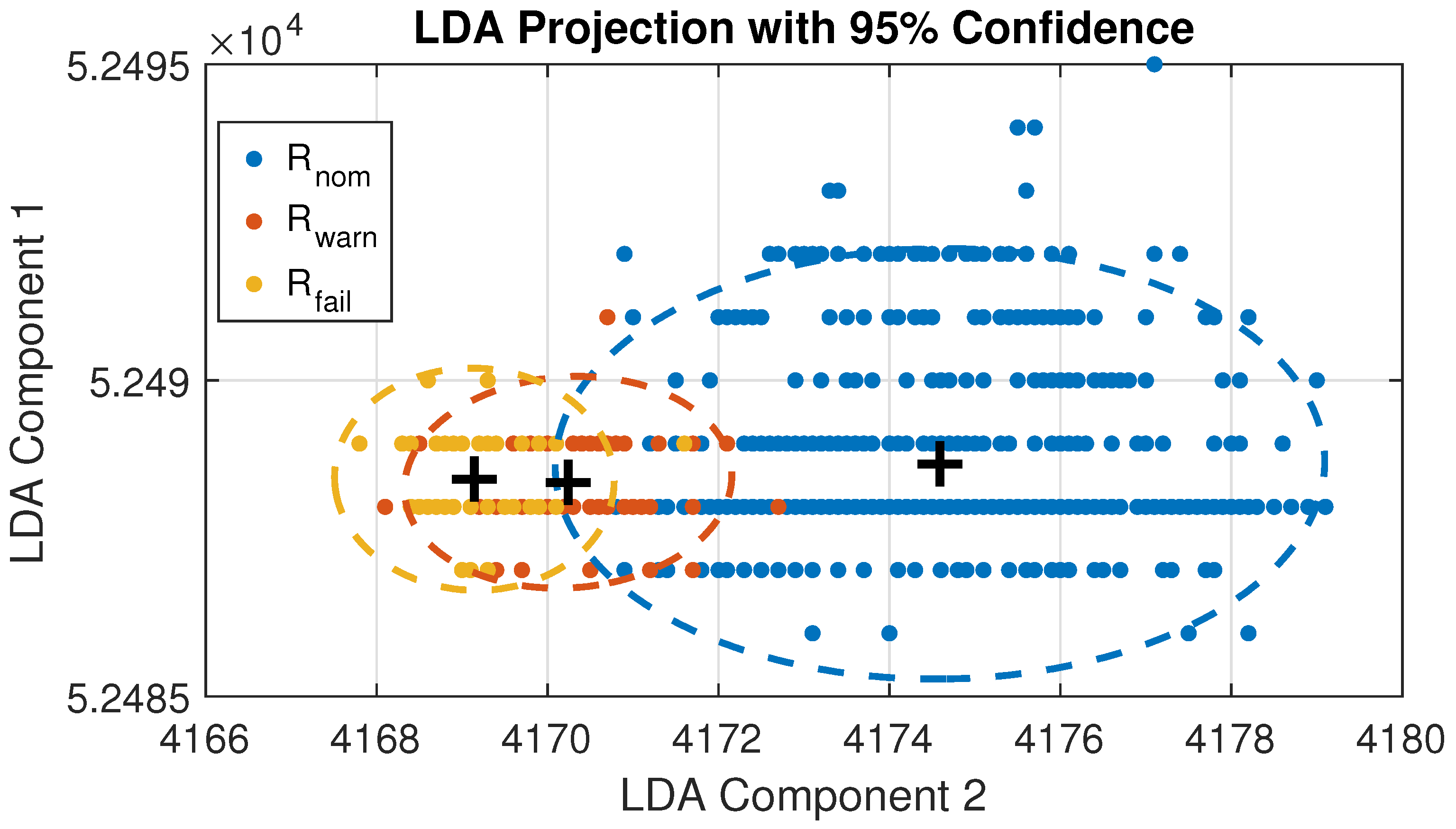

3.3. Impact of LDA Assumption Violations on Classification Performance

3.4. Experimental Setup

3.5. Performance Evaluation

3.5.1. RUL Prediction Metrics

3.5.2. Classification Performance Metrics

3.5.3. Related Work

3.6. Experimental Results

3.6.1. Training Process

- Nominal region (): 20 < RUL ≤ 30 cycles;

- Warning region (): 10 < RUL ≤ 20 cycles;

- Failure region (): RUL ≤ 10 cycles.

3.6.2. Degradation Modeling

- For each test unit, distances and are computed at each time step.

- A sliding window of size cycles captures recent degradation trends.

- Both linear regression and AR models are fitted to predict future distances.

- RUL is estimated as the time until the predicted distance crosses zero.

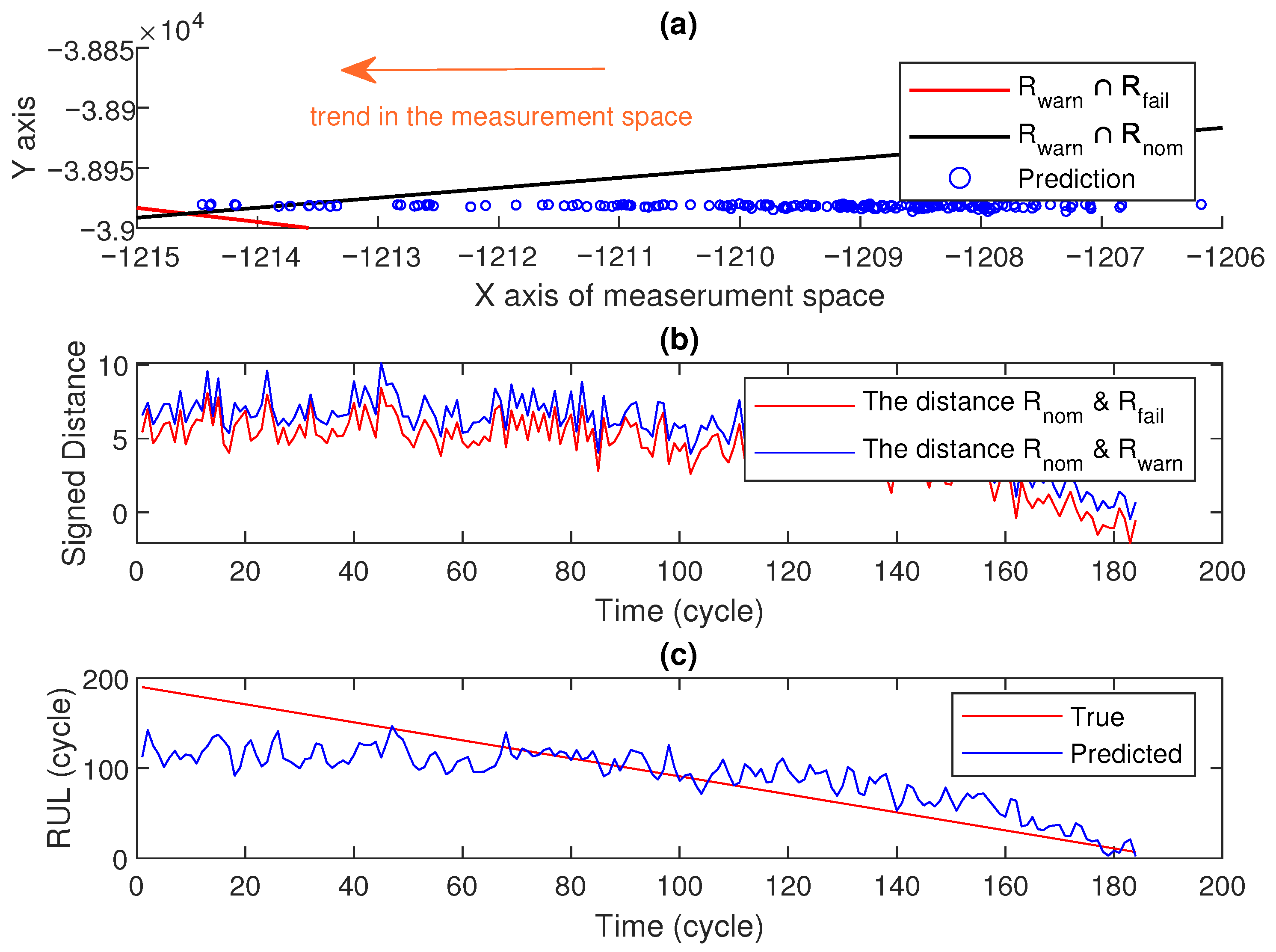

3.6.3. Case Study A: FD002 Engine 7

- The engine follows a clear left-to-right trajectory in the measurement space, indicating consistent degradation.

- Distance to the failure boundary decreases monotonically after cycle 200.

- Final RUL prediction: 2.48 cycles (actual: 6 cycles), yielding a score of 0.31.

- The warning region is entered at cycle 176, providing 14 cycles of advance warning.

- Figure 6a shows the trajectory of measurements in the measurement space.

- Figure 6b displays their distances to the warning and failure boundaries.

- Figure 6c presents the predicted RUL estimates and true RUL values.

3.6.4. Case Study B: FD001 Engine 1

- Initial measurements place the unit firmly in the nominal region.

- A limited degradation trend is observable in the available data.

- Final RUL prediction: 120.6 cycles (actual: 113 cycles).

- Despite data scarcity, the prediction error of 6.4 cycles represents a PHM08 score of only 1.38.

- Figure 7a shows the trajectory of measurements in the measurement space.

- Figure 7b displays their distances to the warning and failure boundaries.

- Figure 7c presents the predicted RUL estimates and true RUL values.

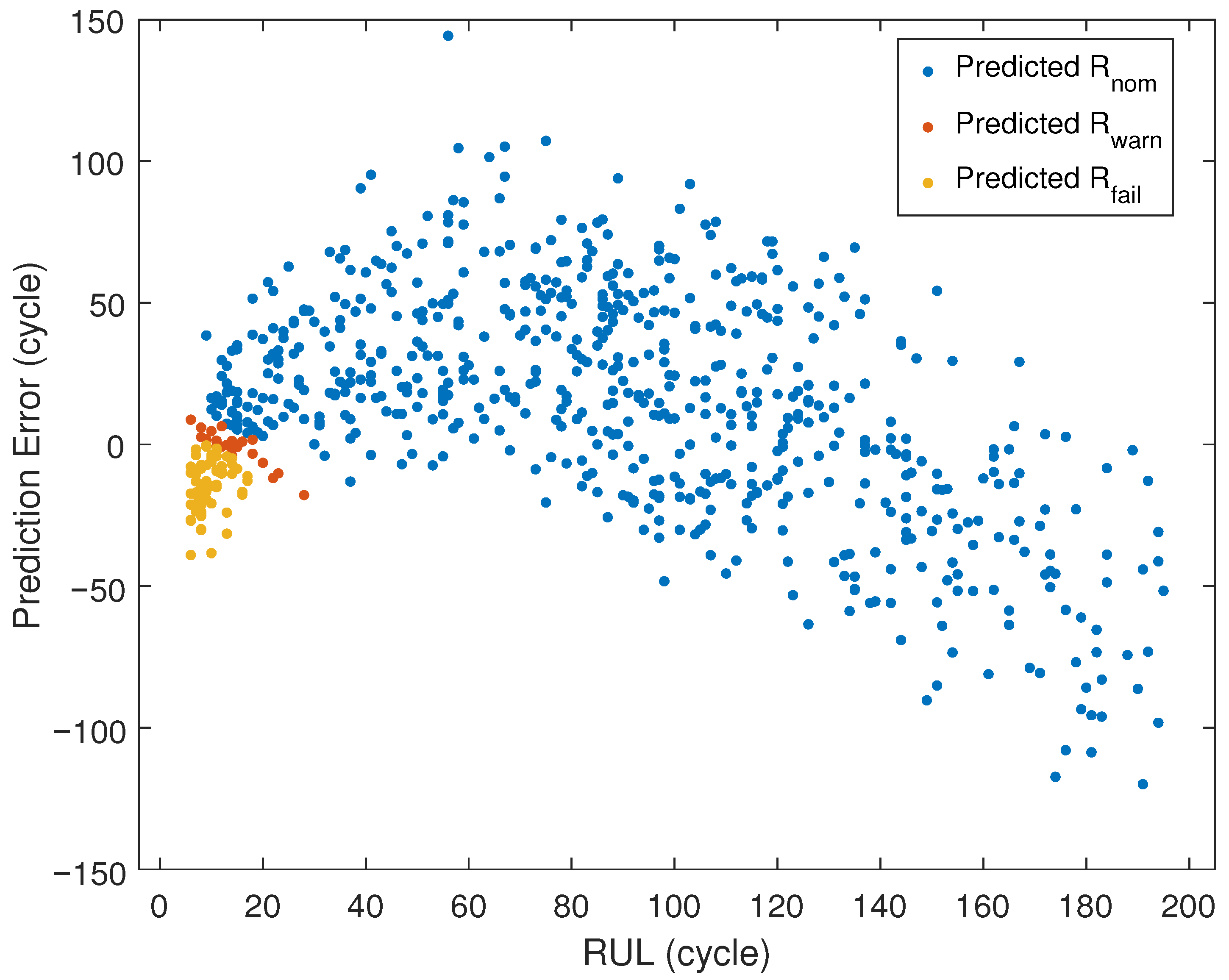

3.6.5. Overall Performance

4. Conclusions

- A novel integration of LDA for health state classification with distance-based regression for RUL estimation, where the same hyperplane boundaries serve both objectives.

- A hybrid prediction approach combining linear regression and autoregressive modeling to capture both long-term degradation trends and short-term dynamics.

- Demonstration that linear methods can achieve competitive performance on the challenging C-MAPSS dataset while maintaining interpretability and computational efficiency.

- Interpretability: Maintenance engineers can directly understand how sensor measurements influence predictions through the learned hyperplane coefficients.

- Computational efficiency: Real-time processing capability for monitoring multiple assets simultaneously.

- Extensibility: Natural accommodation of heterogeneous sensor modalities without complex fusion architectures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| RUL | Remaining Useful Life |

| LDA | Linear Discriminant Analysis |

| AR | Autoregressive |

| RMSE | Root Mean Square Error |

| C-MAPSS | Commercial Modular Aero-Propulsion System Simulation |

| XJTU-SY | Xi’an Jiaotong University—Suzhou |

| AIC | Akaike Information Criterion |

| SVR | Support Vector Regression |

| RVR | Relevance Vector Regression |

| MLPs | Multilayer Perceptrons |

References

- Borgi, T.; Hidri, A.; Neef, B.; Naceur, M.S. Data analytics for predictive maintenance of industrial robots. In Proceedings of the 2017 International Conference on Advanced Systems and Electric Technologies (IC_ASET), Hammamet, Tunisia, 14–17 January 2017; pp. 412–417. [Google Scholar]

- Biswal, S.; Sabareesh, G.R. Design and development of a wind turbine test rig for condition monitoring studies. In Proceedings of the 2015 International Conference on Industrial Instrumentation and Control (ICIC), Pune, India, 28–30 May 2015; pp. 891–896. [Google Scholar]

- Peres, R.S.; Rocha, A.D.; Leitao, P.; Barata, J. IDARTS–towards intelligent data analysis and real-time supervision for industry 4.0. Comput. Ind. 2018, 101, 138–146. [Google Scholar] [CrossRef]

- Sezer, E.; Romero, D.; Guedea, F.; Macchi, M.; Emmanouilidis, C. An industry 4.0-enabled low cost predictive maintenance approach for smes. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- Nunes, P.; Santos, J.; Rocha, E. Challenges in predictive maintenance–A review. Cirp J. Manuf. Sci. Technol. 2023, 40, 53–67. [Google Scholar] [CrossRef]

- Hao, Q.; Xue, Y.; Shen, W.; Jones, B.; Zhu, J. A decision support system for integrating corrective maintenance, preventive maintenance, and condition-based maintenance. In Construction Research Congress 2010: Innovation for Reshaping Construction Practice; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2010; pp. 470–479. [Google Scholar]

- Mobley, R.K. An Introduction to Predictive Maintenance; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Lee, J.; Kao, H.A.; Yang, S. Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Jimenez, J.J.M.; Schwartz, S.; Vingerhoeds, R.; Grabot, B.; Salaün, M. Towards multi-model approaches to predictive maintenance: A systematic literature survey on diagnostics and prognostics. J. Manuf. Syst. 2020, 56, 539–557. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Guo, L.; Li, N.; Yan, T.; Lin, J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 2018, 104, 799–834. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, N.; Shen, C. A new multi-task learning framework for remaining useful life prediction. IEEE Trans. Ind. Inform. 2019, 15, 2023–2032. [Google Scholar]

- Wang, B.; Lei, Y.; Li, N.; Yan, T. Deep separable convolutional network for remaining useful life prediction of machinery. Mech. Syst. Signal Process. 2020, 134, 106330. [Google Scholar] [CrossRef]

- Zhou, L. Multi-task model of adaptive multi-scale feature fusion and adaptive mixture-of-experts for equipment remaining useful life prediction and fault diagnosis. Expert Syst. Appl. 2025, 272, 126807. [Google Scholar] [CrossRef]

- Li, R.; Zhan, H.; Yu, J.; Wang, R.; Han, K. A lightweight transformer and depthwise separable convolution model for remaining useful life prediction of turbofan engines. Meas. Sci. Technol. 2024, 35, 025020. [Google Scholar] [CrossRef]

- Guo, P.; Liu, Q.; Yu, S.; Xiong, J.; Tan, X.; Guo, C. A transformer with layer-cross decoding for remaining useful life prediction. J. Supercomput. 2023, 79, 11558–11584. [Google Scholar] [CrossRef]

- Nunes, P.; Rocha, E.; Santos, J. Adaptive Framework for Maintenance Scheduling Based on Dynamic Preventive Intervals and Remaining Useful Life Estimation. Future Internet 2024, 16, 214. [Google Scholar] [CrossRef]

- Wu, F.; Tang, J.; Jiang, Z.; Sun, Y.; Chen, Z.; Guo, B. The Remaining Useful Life Prediction Method of a Hydraulic Pump under Unknown Degradation Model with Limited Data. Sensors 2023, 23, 5931. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.-J.; Tsai, M.-L.; Chen, C.-L.; Lin, P.T.; Lee, H.-Y. Investigation of Machine Learning Methods for Predictive Maintenance of the Ultra-High-Pressure Reactor in a Polyethylene-Vinyl Acetate Production Process. Electronics 2023, 12, 580. [Google Scholar] [CrossRef]

- Xie, S.; Xue, F.; Zhang, W.; Zhu, J. Data-Driven Predictive Maintenance Policy Based on Dynamic Probability Distribution Prediction of Remaining Useful Life. Machines 2023, 11, 923. [Google Scholar] [CrossRef]

- Zhou, S.; Yao, Y.; Liu, A.; Wang, F.; Chen, L.; Xiong, R. Multiform Informed Machine Learning Based on Piecewise and Weibull for Engine Remaining Useful Life Prediction. Sensors 2023, 23, 5669. [Google Scholar] [CrossRef]

- Riccio, C.; Menanno, M.; Zennaro, I.; Savino, M.M. A New Methodological Framework for Optimizing Predictive Maintenance Using Machine Learning Combined with Product Quality Parameters. Machines 2024, 12, 443. [Google Scholar] [CrossRef]

- Aminzadeh, A.; Sattarpanah Karganroudi, S.; Majidi, S.; Dabompre, C.; Azaiez, K.; Mitride, C.; Sénéchal, E. A Machine Learning Implementation to Predictive Maintenance and Monitoring of Industrial Compressors. Sensors 2025, 25, 1006. [Google Scholar] [CrossRef]

- Cen, Z.; Hu, S.; Hou, Y.; Chen, Z.; Ke, Y. Remaining useful life prediction of machinery based on improved Sample Convolution and Interaction Network. Eng. Appl. Artif. Intell. 2024, 135, 108813. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Wang, H.; Liu, J. A method for predicting remaining useful life using enhanced Savitzky–Golay filter and improved deep learning framework. Sci. Rep. 2024, 14, 24123. [Google Scholar] [CrossRef]

- Ren, J.; Wang, L.; Zhang, Q.; Chen, M. A novel equipment remaining useful life prediction approach considering dynamic maintenance threshold. Qual. Reliab. Eng. Int. 2024, 40, 1623–1640. [Google Scholar] [CrossRef]

- Hamza, R.T. Remaining Useful Life Prediction with Uncertainty Quantification Using Evidential Deep Learning. J. Artif. Intell. Soft Comput. Res. 2025, 15, 43–58. [Google Scholar] [CrossRef]

- Qi, D.; Zhu, Z.; Yao, F.; Song, W.; Kudreyko, A.; Cattani, P.; Villecco, F. Predicting the remaining useful life of turbofan engines using fractional Lévy stable motion with long-range dependence. Reliab. Eng. Syst. Saf. 2024, 8, 55. [Google Scholar] [CrossRef]

- Liu, L.; Song, X.; Zhou, Z. Aircraft engine remaining useful life estimation via a double attention-based data-driven architecture. Reliab. Eng. Syst. Saf. 2022, 221, 108330. [Google Scholar] [CrossRef]

- Costa, N.; Sánchez, L. Variational encoding approach for interpretable assessment of remaining useful life estimation. Reliab. Eng. Syst. Saf. 2022, 222, 108353. [Google Scholar] [CrossRef]

- Lillelund, C.M.; Pannullo, F.; Jakobsen, M.O.; Morante, M.; Pedersen, C.F. A probabilistic estimation of remaining useful life from censored time-to-event data. arXiv 2024, arXiv:2405.01614. [Google Scholar]

- Chen, L.; Wang, H.; Meng, L.; Xu, Z.; Xue, L.; Ren, M. An End-to-End Adaptive Method for Remaining Useful Life Prediction of Rolling Bearings Using Time–Frequency Image Features. Mach. Learn. Knowl. Extr. 2024, 6, 2892–2912. [Google Scholar] [CrossRef]

- Saxena, A.; Goebel, K. PHM08 Challenge Data Set. In NASA Ames Prognostics Data Repository; NASA Ames Research Center: Moffett Field, CA, USA, 2008. Available online: http://ti.arc.nasa.gov/project/prognostic-data-repository (accessed on 10 December 2024).

- Maulana, F.; Starr, A.; Ompusunggu, A.P. Explainable Data-Driven Method Combined with Bayesian Filtering for Remaining Useful Lifetime Prediction of Aircraft Engines Using NASA CMAPSS Datasets. Machines 2023, 11, 163. [Google Scholar] [CrossRef]

- Drucker, H.; Burges, C.J.; Kaufman, L.; Smola, A.; Vapnik, V. Support vector regression machines. Adv. Neural Inf. Process. Syst. 1996, 9, 155–161. [Google Scholar]

- Smola, A.J.; Schölkopf, B. A tutorial on support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef]

- Vapnik, V. Statistical Learning Theory; Wiley-Interscience: Hoboken, NJ, USA, 1998. [Google Scholar]

- Tipping, M.E. Sparse Bayesian learning and the relevance vector machine. J. Mach. Learn. Res. 2001, 1, 211–244. [Google Scholar]

- Tipping, M.E. The relevance vector machine. In Advances in Neural Information Processing Systems; ACM: New York, NY, USA, 2000; pp. 652–658. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Ramasso, E.; Saxena, A. Performance benchmarking and analysis of prognostic methods for CMAPSS datasets. Int. J. Progn. Health Manag. 2014, 5, 1–15. [Google Scholar] [CrossRef]

- Zheng, S.; Ristovski, K.; Farahat, A.; Gupta, C. Long short-term memory network for remaining useful life estimation. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; pp. 88–95. [Google Scholar]

| Dataset ID | Training Units | Test Units | Fault Mode(s) | Training Samples | Test Samples |

|---|---|---|---|---|---|

| FD001 | 100 | 100 | HPC | 20,631 | 13,096 |

| FD002 | 260 | 259 | HPC | 53,759 | 33,991 |

| FD003 | 100 | 100 | HPC, Fan | 24,720 | 16,596 |

| FD004 | 249 | 248 | HPC, Fan | 61,249 | 41,214 |

| Confusion Matrix | |||

| Predicted | 1 | 2 | 3 |

| True | |||

| 1 | 578 | 6 | 4 |

| 2 | 12 | 20 | 48 |

| 3 | 1 | 0 | 38 |

| Classification Performance | |||

| Dataset | F1-micro | F1-macro | |

| FD001 | 0.920 | 0.678 | |

| FD002 | 0.892 | 0.691 | |

| FD003 | 0.920 | 0.610 | |

| FD004 | 0.891 | 0.640 | |

| Combined | 0.900 | 0.649 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yıldırım, U.; Afşer, H. Linear Methods for Predictive Maintenance: The Case of NASA C-MAPSS Datasets. Appl. Sci. 2025, 15, 9945. https://doi.org/10.3390/app15189945

Yıldırım U, Afşer H. Linear Methods for Predictive Maintenance: The Case of NASA C-MAPSS Datasets. Applied Sciences. 2025; 15(18):9945. https://doi.org/10.3390/app15189945

Chicago/Turabian StyleYıldırım, Uğur, and Hüseyin Afşer. 2025. "Linear Methods for Predictive Maintenance: The Case of NASA C-MAPSS Datasets" Applied Sciences 15, no. 18: 9945. https://doi.org/10.3390/app15189945

APA StyleYıldırım, U., & Afşer, H. (2025). Linear Methods for Predictive Maintenance: The Case of NASA C-MAPSS Datasets. Applied Sciences, 15(18), 9945. https://doi.org/10.3390/app15189945