Characteristics of Overlying Rock Breakage and Fissure Evolution in the Mining of Extra-Thick Coal Seams in Anticline Structural Area

Abstract

1. Introduction

2. Engineering Background

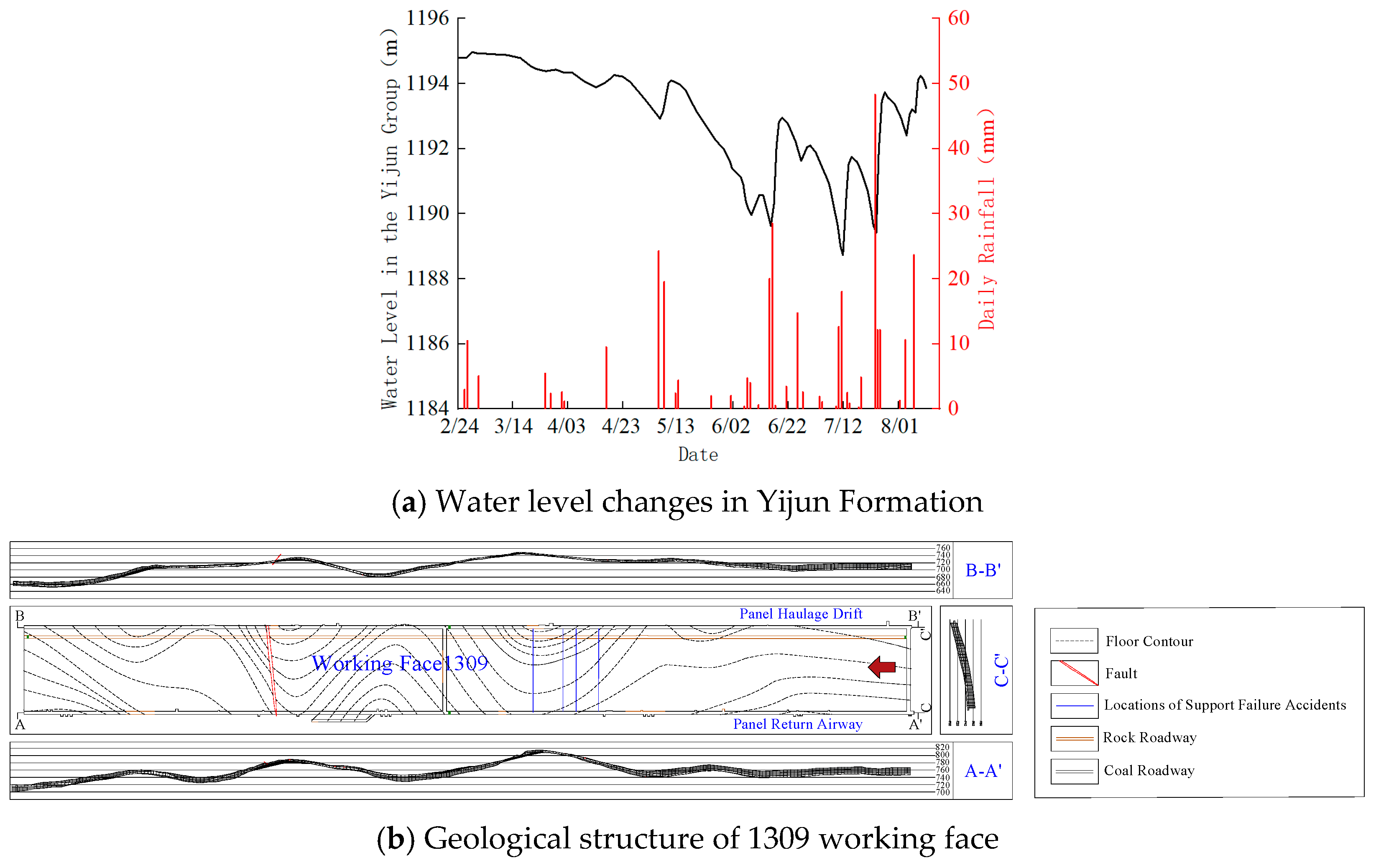

2.1. Mining Conditions and Support Crushing Incidents

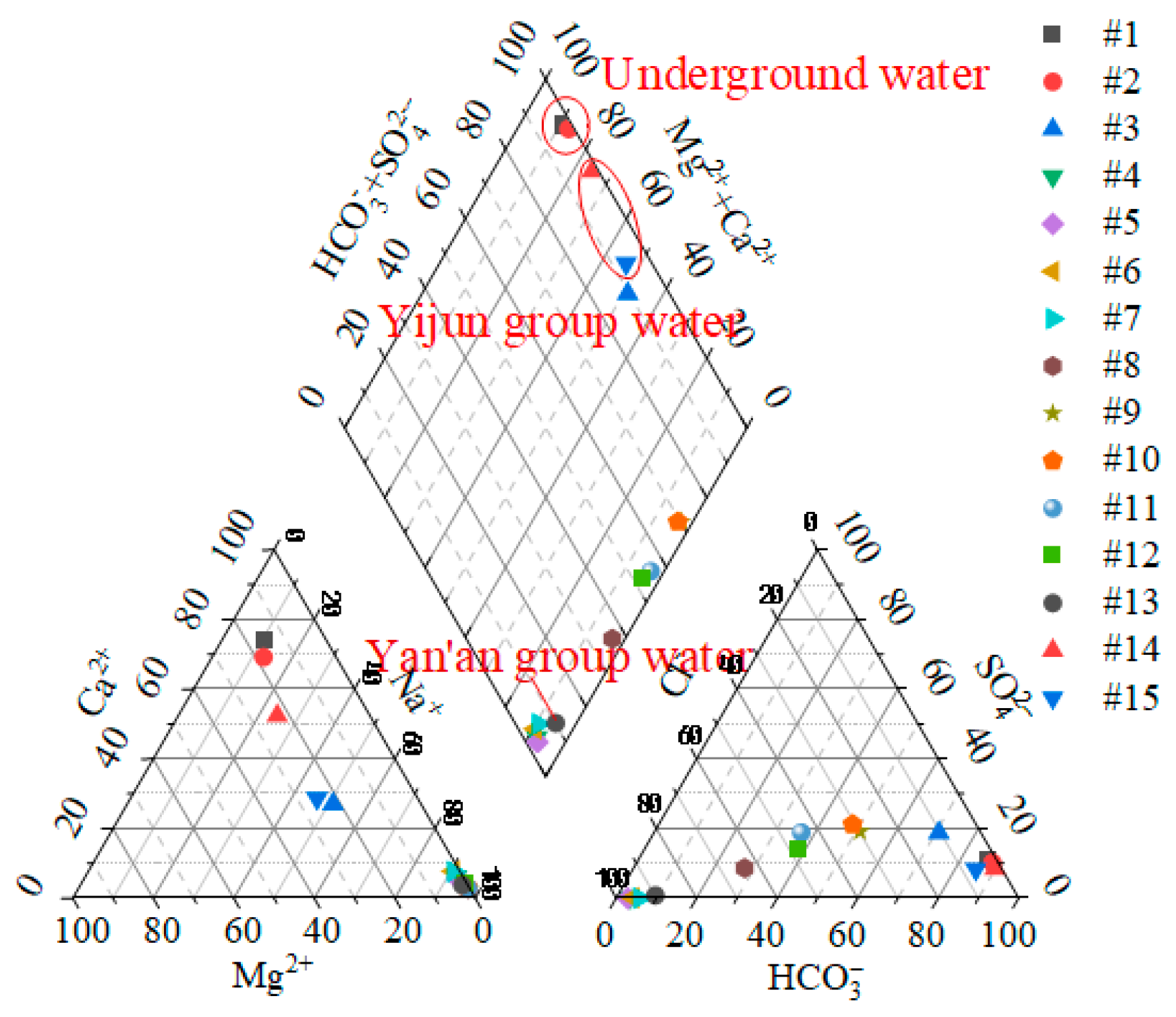

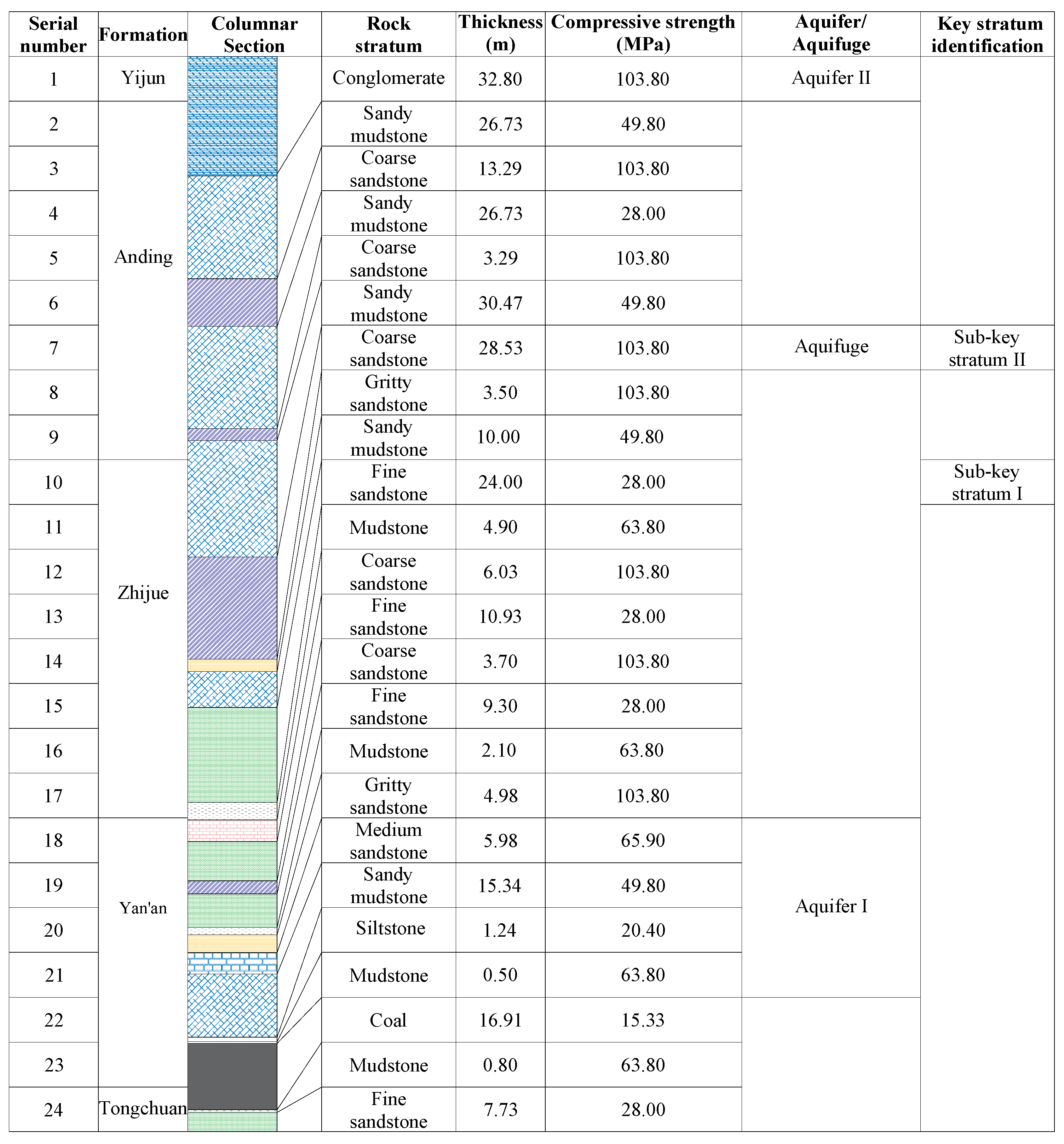

2.2. Identification of Key Aquifers and Impermeable Layer in Overlying Strata

3. Destabilization Law of Overburden Rock Breakage in Mining of Extra-Thick Coal Seams in Dorsal Tectonic Zone

3.1. Experimental Program

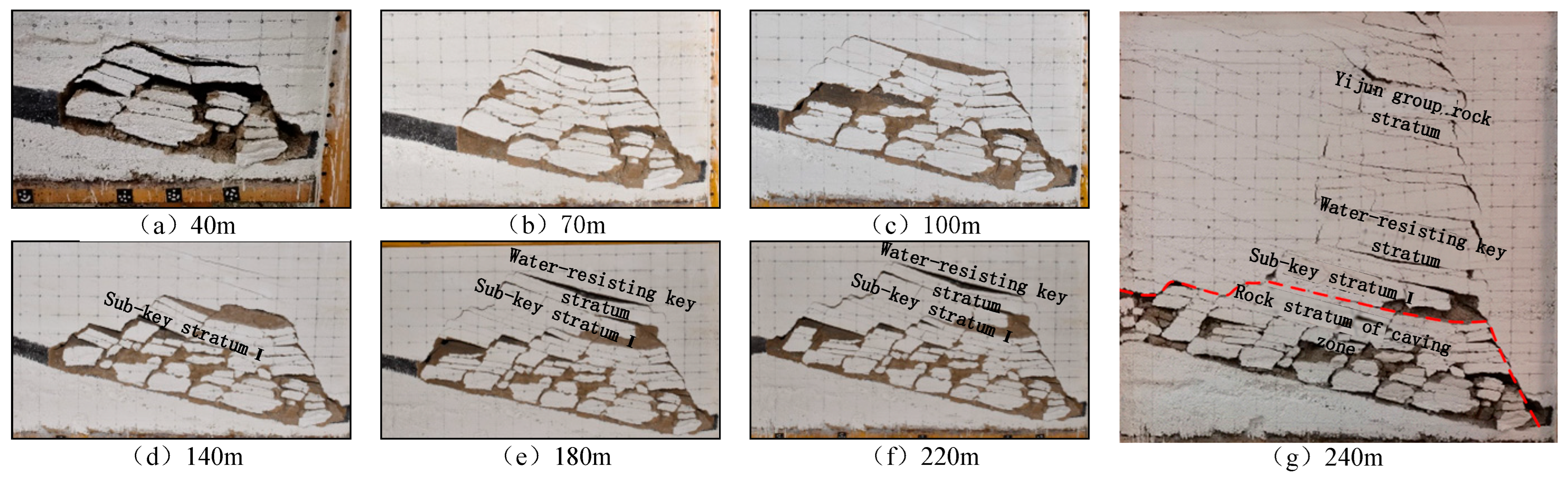

3.2. Experimental Results and Analysis

Characterization of Water-Conducting Fissure Zone Development

4. Discrete Element Simulation of Extra-Thick Coal Seam Mining in Anticlinal Structural Zones

4.1. Model Establishment

4.2. Calibration of Microscopic Parameters

5. Analysis of Numerical Simulation Results for Extra-Thick Coal Seam Mining in Anticlinal Zones

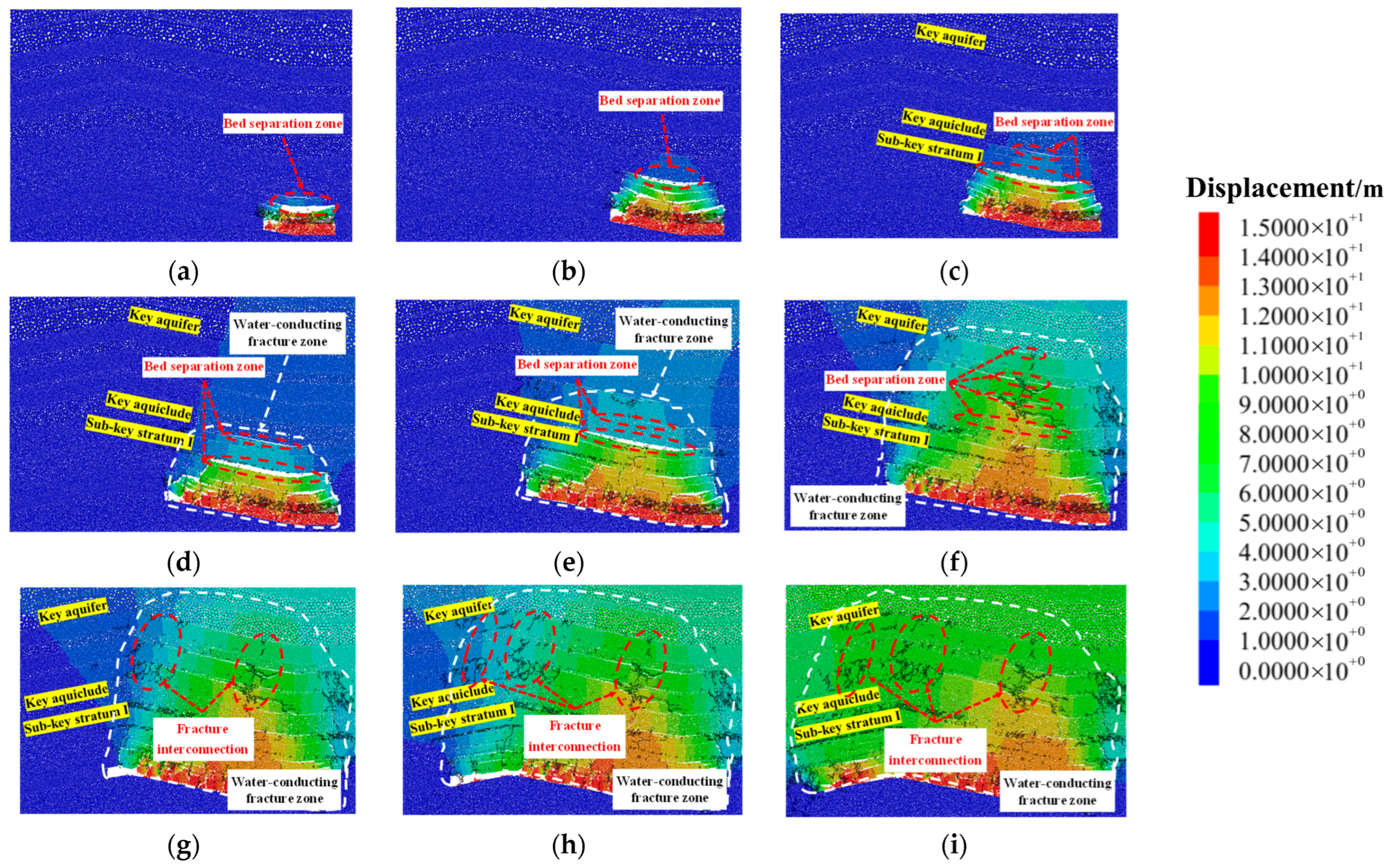

5.1. Fracturing Characteristics of Overlying Strata and Development Features of Water-Conducting Fracture Zones

5.2. Distribution Characteristics of Fracture Angle

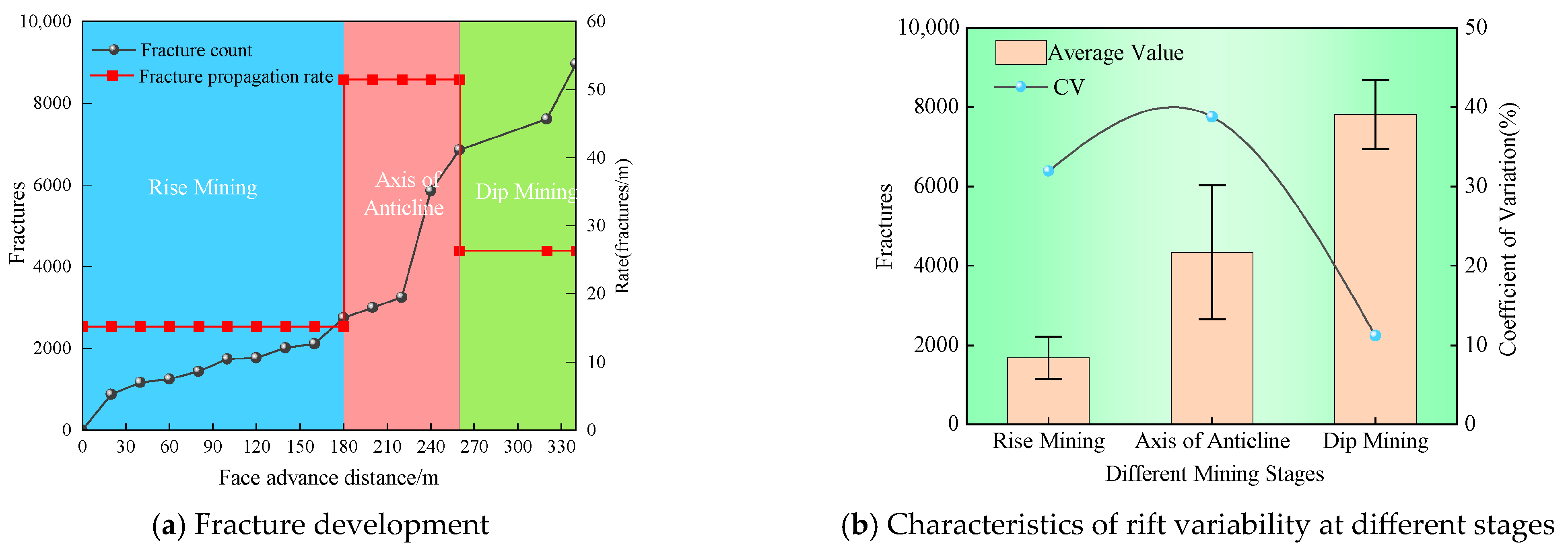

5.3. Development and Distribution Characteristics of Overburden Fractures

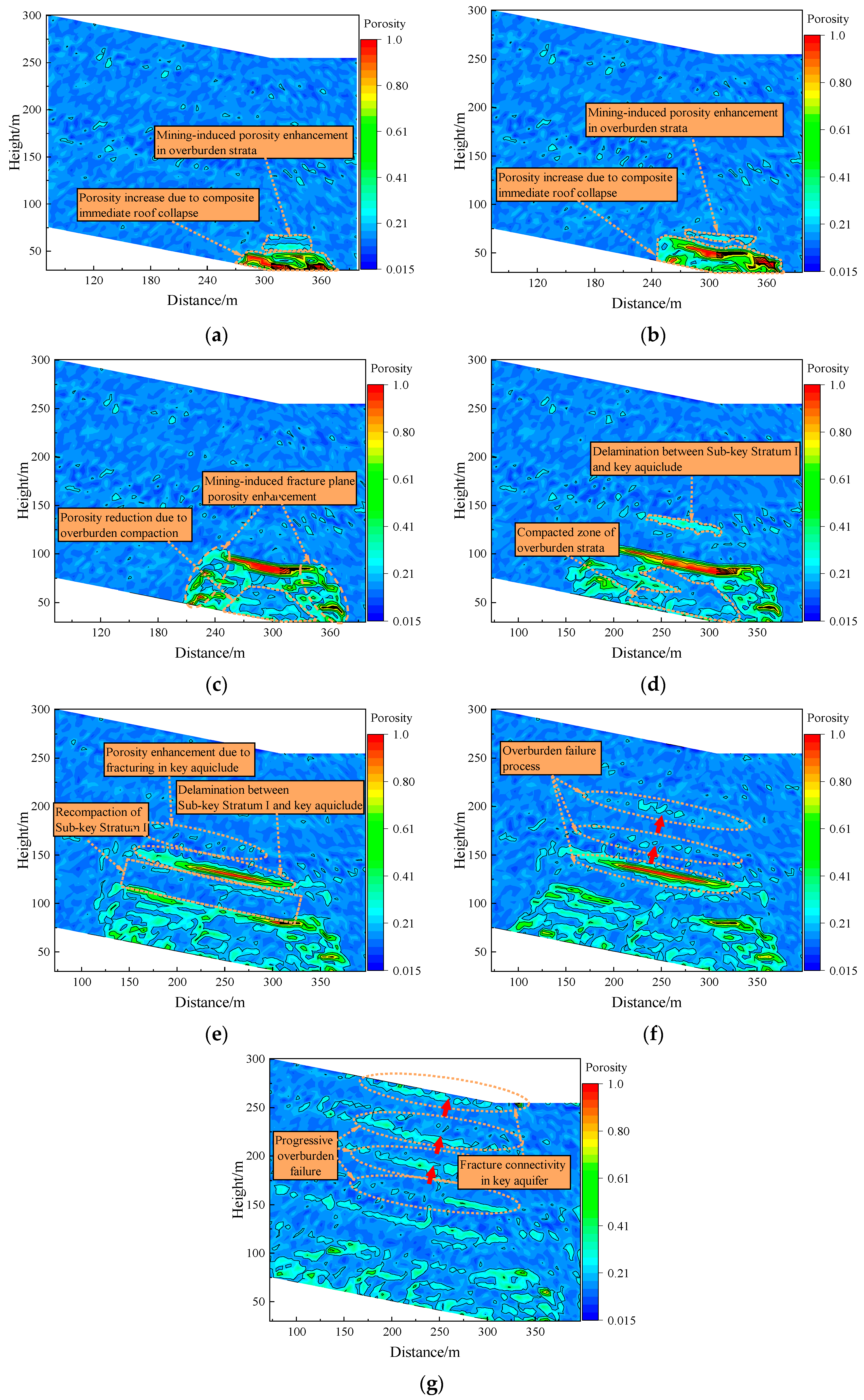

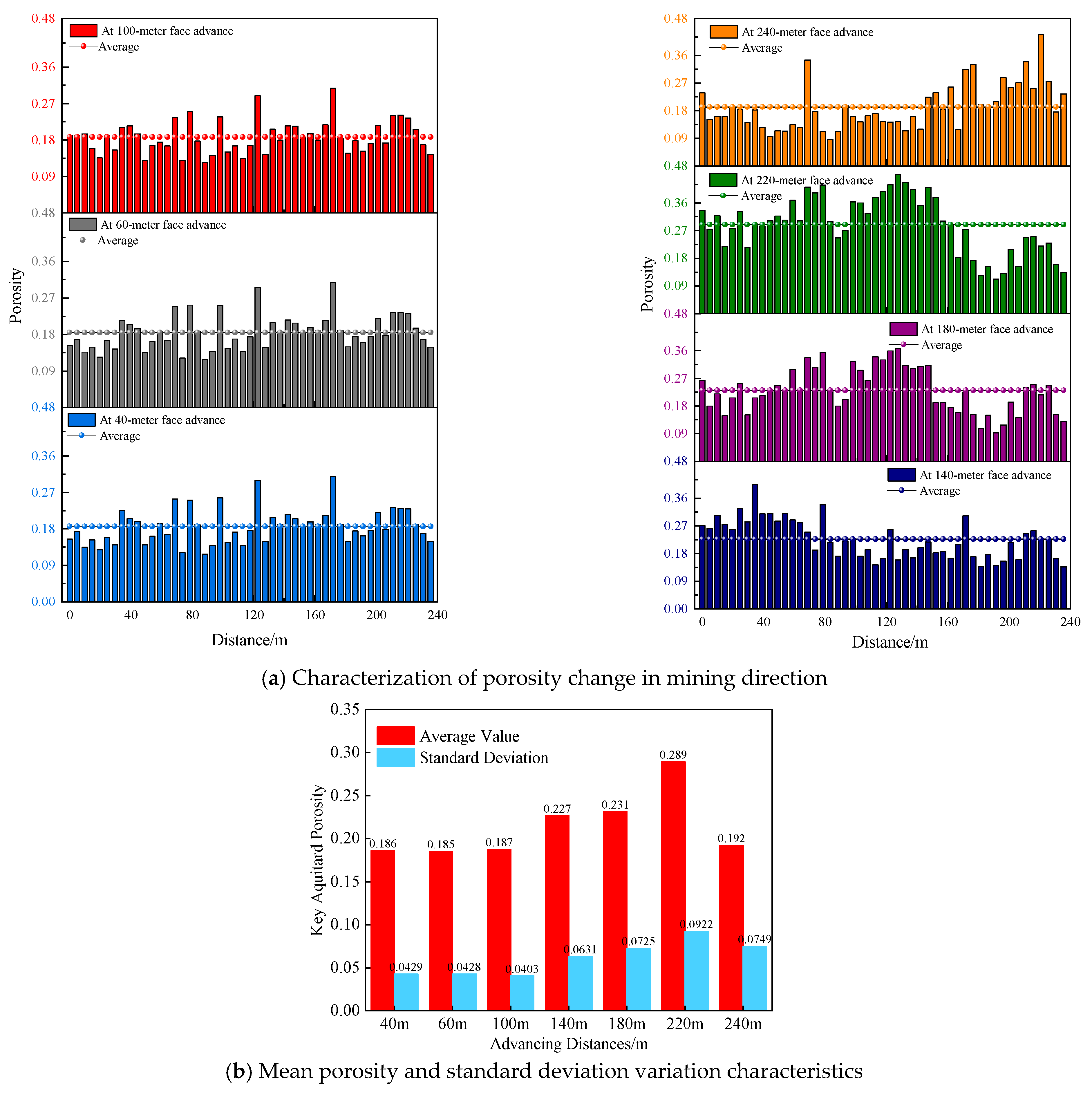

5.4. Evolution Characteristics of Porosity in Key Aquiclude

6. Discussions

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lyu, X.; Yang, K.; Fang, J. Utilization of resources in abandoned coal mines for carbon neutrality. Sci. Total Environ. 2022, 822, 153646. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zhao, M.; Wang, Y.; Vigne, S.A.; Benkraiem, R. Technological innovation and its influence on energy risk management: Unpacking China’s energy consumption structure optimisation amidst climate change. Energy Econ. 2024, 131, 107321. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, S.; Zhang, D.; Zhang, C.; Chen, M.; Li, Q. An Index of Aquiclude Destabilization for Mining-Induced Roof Water Inrush Forecasting: A Case Study. Water 2019, 11, 2170. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Du, F.; Cao, Z.; Li, G. Study of Roof Water Inrush Control Technology and Water Resources Utilization During Coal Mining in a Karst Area. Mine Water Environ. 2023, 42, 546–559. [Google Scholar] [CrossRef]

- Shi, L.; Qu, X.; Qiu, M.; Han, J.; Zhang, W. Water-inrush mechanism from the head-on working face roof in a Jurassic coal seam in the Ordos Basin. PLoS ONE 2024, 19, e0298399. [Google Scholar] [CrossRef]

- Sun, X.; Liu, K.; Jin, T.; Wang, K.; Lin, S.; Pang, J.; Xie, J. Dynamic mechanical response and failure characteristics of coal and rock under saltwater immersion conditions. Sci. Rep. 2024, 14, 11869. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Wang, X.; Lan, H.; Ren, W.; Tian, Y.; Xu, J.; Tian, S. Study of the development patterns of water-conducting fracture zones under karst aquifers and the mechanism of water inrush. Sci. Rep. 2024, 14, 20790. [Google Scholar] [CrossRef]

- Shi, X.; Lyu, G. Mechanism of Bed Separation Water Inrush during the Mining of Extra-Thick Coal Seam under Super-Thick Sandstone Aquifer. Sustainability 2023, 15, 10599. [Google Scholar] [CrossRef]

- Li, H.; Chen, Q.; Shu, Z.; Li, L.; Zhang, Y. On prevention and mechanism of bed separation water inrush for thick coal seams: A case study in China. Environ. Earth Sci. 2018, 77, 759. [Google Scholar] [CrossRef]

- Sui, W.; Liu, J.; Gao, B.; Liang, Y. A review on disaster mechanism of quicksand with a high potential energy due to mining and its prevention and control. J. China Coal Soc. 2019, 44, 2419–2426. [Google Scholar]

- Xiao, L.; Li, F.; Niu, C.; Dai, G.; Qiao, Q. Evaluation of Water Inrush Hazard in Coal Seam Roof Based on the AHP-CRITIC Composite Weighted Method. Energies 2023, 16, 114. [Google Scholar] [CrossRef]

- Cheng, W.; Yin, H.; Xie, D.; Dong, F.; Li, Y.; Zhu, T.; Wang, J. Prediction of dominant roof water inrush windows and analysis of control target area based on set pair variable weight-Forward correlation cloud model. J. Clean. Prod. 2024, 483, 144253. [Google Scholar] [CrossRef]

- Zeng, Y.; Wu, Q.; Du, X.; Liu, S.; Zan, J.; Dou, G.; Wu, Z. Further research on “water-richness index method” for evaluation of aquifer water abundance. J. China Coal Soc. 2020, 45, 2423–2431. [Google Scholar]

- Zhang, J.; Yang, T. Study of a roof water inrush prediction model in shallow seam mining based on an analytic hierarchy process using a grey relational analysis method. Arab. J. Geosci. 2018, 11, 153. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, T.; Wang, B.; Zhao, Q.; Liu, D.; Ren, Y. Prediction analysis of roof water-inrush in shallow coal seam with surface valley runoff. J. Min. Saf. Eng. 2017, 34, 868–875. [Google Scholar]

- Enke, H.O.; Yan, Y.; Wen, Q.; Che, X.; Miao, Y.; Li, H.; Lu, B. Study on prediction of water inrush hazard in roof of roadway driving. Coal Sci. Technol. 2022, 50, 110–120. [Google Scholar]

- Qiao, W.; Wang, Z.; Li, W.; Lü, Y. Formation mechanism, disaster-causing mechanism and prevention technology of roof bed separation water disaster in coal mines. Journal of China Coal Society 2021, 46, 507–522. [Google Scholar]

- Wang, Z.; Tang, S.; Li, M.; Wu, S.; Sun, W.; Li, J.; Shui, Y. Development and application of overburden structure composed of caving arch and towering roof beam in deep longwall panel with thin bedrock. J. China Coal Soc. 2023, 48, 563–575. [Google Scholar]

- Wu, M.; Hu, N.; Ye, Y.; Wang, X. Multi-hazard risk characterization and collaborative control oriented to space in non-coal underground mines. Sci. Rep. 2022, 12, 16452. [Google Scholar] [CrossRef]

- Liu, C.; Liu, H.; Chen, Y.; Yang, P.; Wang, C.; Yang, J. Failure laws of overburden and mechanisms of water inrush and support crushing in extra-thick coal seam mining within anticline structural. J. Min. Saf. Eng. 2025, 42, 239–251. [Google Scholar]

- Liu, H.; Liu, C.; Yang, P.; Wang, C.; Yang, J. Structural stability of overlying rock and mechanism of water inrush and support rushing in extra-thick coal seam mining within syncline structural area. J. China Coal Soc. 2024, 49, 3745–3758. [Google Scholar]

- Wang, X.; Han, H.; Fu, X.; Yang, Y. Linkage type between water level in confined aquifer and over burden movement and its application. J. Min. Saf. Eng. 2020, 37, 247–253. [Google Scholar]

- Wang, X.; Xu, J.; Zhu, W.; Hao, H. Overburden structure influence to support crushing and water inrush during mining under unconsolidated confined aquifer. J. Min. Saf. Eng. 2014, 31, 838–844. [Google Scholar]

- Zhou, X.; Ouyang, Z.; Zhou, R.; Ji, Z.; Yi, H.; Tang, Z.; Chang, B.; Yang, C.; Sun, B. An Approach to Dynamic Disaster Prevention in Strong Rock Burst Coal Seam under Multi-Aquifers: A Case Study of Tingnan Coal Mine. Energies 2021, 14, 7287. [Google Scholar] [CrossRef]

- Wang, B.; Feng, G.; Jiang, F.; Ma, J.; Wang, C.; Li, Z.; Wu, W. Investigation into Occurrence Mechanism of Rock Burst Induced by Water Drainage in Deep Mines. Sustainability 2023, 15, 8891. [Google Scholar] [CrossRef]

- Vu, T.T.; Do, S.A. Determination of the rock mass displacement zone by numerical modeling method when exploiting the longwall at the Nui Beo Coal Mine, Vietnam. Min. Miner. Depos. 2023, 17, 59–66. [Google Scholar] [CrossRef]

- Matayev, A.; Uakhitova, B.; Kaumetova, D.; Imangazin, M.; Sarkulova, Z.; Issengaliyeva, G.; Orazbekova, R. Substantiation and selection of parameters for supporting mine workings at deep levels. Min. Miner. Depos. 2024, 18, 125–138. [Google Scholar] [CrossRef]

- Ye, Z.; Hou, E.; Duan, Z. Micrometer-scale pores and fractures in coals and the effects of tectonic deformation on permeability based on fractal theory. AlP Adv. 2020, 10, 025118. [Google Scholar] [CrossRef]

- Velychkovych, A.; Mykhailiuk, V.; Andrusyak, A. Numerical model for studying the properties of a new friction damper developed based on the shell with a helical cut. Appl. Mech. 2025, 6, 1. [Google Scholar] [CrossRef]

- Shatskyi, I.; Velychkovych, A. Analytical model of structural damping in friction module of shell shock absorber connected to spring. Shock. Vib. 2023, 2023, 4140583. [Google Scholar] [CrossRef]

- Landar, S.; Velychkovych, A.; Ropyak, L.; Andrusyak, A. A method for applying the use of a smart 4 controller for the assessment of drill string bottom-part vibrations and shock loads. Vibration 2024, 7, 802–828. [Google Scholar] [CrossRef]

- Xu, J.; Qian, M. Method to distinguish key strata in overburden. J. China Univ. Min. Technol. 2000, 05, 21–25. [Google Scholar]

- Tao, Z.; Zhu, C.; He, M.; Karakus, M. A physical modeling-based study on the control mechanisms of Negative Poisson’s ratio anchor cable on the stratified toppling deformation of anti-inclined slopes. Int. J. Rock Mech. Min. Sci. 2021, 138, 104632. [Google Scholar] [CrossRef]

- Peng, L.; Hu, X.; Su, G.; Qin, Z.; Lu, H.; He, B. Cracking characteristics of the surrounding rocks of a hydraulic tunnel under high geothermal conditions: A model test. Rock Mech. Rock Eng. 2021, 54, 1369–1390. [Google Scholar] [CrossRef]

- Tu, S. Experimental Methods and Real-World Measurement Techniques for Rock Control; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Hou, E.; Cong, T.; Xie, X.; Wei, J. Ground surface fracture development characteristics of shallow double coal seam staggered mining based on particle flow. J. Min. Strat. Control. Eng. 2020, 2, 20–28. [Google Scholar]

- Liu, G.; Wang, Z.; Cui, Y.; Ma, Q.; Yan, L.; Han, Y. Mechanism of rock burst in deep coal tunnel surroundings due to three-way stress difference gradient. J. China Coal Soc. 2023, 48, 2106–2122. [Google Scholar]

- Zhou, N.; Zhang, J.; Xu, J.; Yan, Y.; Ma, H. Research on prediction of the height of water-conducting fracture zone in Huanglong Jurassic Coalfield. Coal Sci. Technol. 2023, 51, 231–241. [Google Scholar]

- Zhou, N.; Zhang, J.; Xu, J.; Zhang, Y.; Li, Z. Rock control mechanism of gangue grouting and interval backfilling in post-mining space under aquifer in China’s western mining area. Chin. J. Rock Mech. Eng. 2025, 44, 1736–1751. [Google Scholar]

- Meng, Q.; Zhang, X.; Ge, Z.; Han, X.; An, G. Time-dependent analysis of bolt-grouting support structures in deep roadways. Chin. J. Rock Mech. Eng. 2025, 44, 1420–1437. [Google Scholar] [CrossRef]

- Song, Z.; Konietzky, H.; Herbst, M. Three-dimensional particle model based numerical simulation on multi-level compressive cyclic loading of concrete. Constr. Build. Mater. 2019, 225, 661–677. [Google Scholar] [CrossRef]

| Serial Number | Structural Types | Throw (m) | Working Face Inclination (°) |

|---|---|---|---|

| 1 | Anticline | 17.55 | 7.51 |

| 2 | Synclines | 17.42 | −6.74 |

| 3 | Anticline | 55.73 | 10.93 |

| 4 | Synclines | 66.63 | −10.86 |

| 5 | Anticline | 41.85 | 8.12 |

| 6 | Synclines | 48.12 | −11.77 |

| 7 | Anticline | 20.09 | 7.56 |

| 8 | Synclines | 41.29 | −7.41 |

| Serial Number | Water Samples | Na+ | Mg2+ | Ca2+ | Cl− | SO42− | HCO3− | Mineralization (mg·L−1) |

|---|---|---|---|---|---|---|---|---|

| 1 | The river water of Xiao’anchuan | 12.95 | 18.15 | 88.70 | 8.32 | 41.04 | 317.75 | 489.68 |

| 2 | The water of ground ditch | 12.57 | 17.61 | 67.84 | 4.20 | 30.11 | 263.59 | 404.35 |

| 3 | No. 7 discharge hole | 38.35 | 16.13 | 24.95 | 20.72 | 38.42 | 177.01 | 320.44 |

| 4 | TS5-2 hole | 2411.61 | 41.45 | 161.58 | 4161.25 | 12.40 | 134.45 | 6934.36 |

| 5 | TS8-1 hole | 2662.90 | 41.92 | 156.34 | 4600.74 | 1.15 | 135.90 | 7610.28 |

| 6 | The open-off cut roof watering of 1309 | 2825.14 | 49.84 | 240.82 | 5042.13 | 6.68 | 214.92 | 8406.90 |

| 7 | The belt lane head of 1309 | 2967.62 | 53.04 | 248.07 | 5288.17 | 1.03 | 324.27 | 8904.21 |

| 8 | The 103rd drain for water of 1309 | 677.82 | 3.08 | 19.10 | 805.93 | 109.23 | 349.19 | 1985.08 |

| 9 | The rear chute lower outlet of 1309 | 276.21 | 0.86 | 7.22 | 167.79 | 107.60 | 287.77 | 871.14 |

| 10 | The 49th frame of the spray water of 1309 | 266.93 | 1.00 | 9.05 | 158.22 | 109.58 | 248.59 | 836.44 |

| 11 | The upper exit of 1309 | 483.14 | 1.89 | 14.88 | 436.47 | 184.93 | 358.86 | 1485.38 |

| 12 | The lower exit of 1309 | 489.48 | 2.91 | 20.91 | 488.45 | 140.60 | 388.85 | 1549.03 |

| 13 | Yan’an group water | 1322.27 | 19.27 | 52.19 | 2050.00 | 17.49 | 213.17 | 3674.39 |

| 14 | Yijun group water—1 | 59.09 | 31.84 | 36.52 | 24.98 | 32.17 | 329.19 | 513.79 |

| 15 | Yijun group water—2 | 32.20 | 30.02 | 68.54 | 384.65 | 36.63 | 6.76 | 558.80 |

| Rock Stratum | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio | Compressive Strength (MPa) | Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| Conglomerate | 2800 | 15.61 | 0.23 | 103.80 | 36.31 | 13.23 | 4.14 |

| Sandy mudstone | 2700 | 9.32 | 0.25 | 49.80 | 30.81 | 7.26 | 2.91 |

| Coarse sandstone | 2800 | 15.61 | 0.23 | 103.80 | 36.31 | 13.23 | 4.14 |

| Gritty sandstone | 2800 | 15.61 | 0.23 | 103.80 | 36.31 | 13.23 | 4.14 |

| Fine sandstone | 2450 | 7.84 | 0.15 | 28.00 | 27.73 | 7.49 | 1.43 |

| Medium sandstone | 2600 | 11.41 | 0.23 | 65.90 | 32.89 | 10.72 | 2.12 |

| Composite immediate roof | 2700 | 9.32 | 0.25 | 49.80 | 30.81 | 7.26 | 2.91 |

| Coal | 1400 | 10.24 | 0.27 | 15.33 | 41.87 | 4.28 | 0.96 |

| Floor | 2450 | 7.84 | 0.15 | 28.00 | 27.73 | 7.49 | 1.43 |

| Symbols | Meaning | Symbols | Meaning |

|---|---|---|---|

| E | the elastic modulus, GPa | the parallel bond normal strength, MPa | |

| Ec | the parallel bond modulus, GPa | the parallel bond shear strength, MPa | |

| the stiffness ratio | the tensile strength, MPa | ||

| 1.652 | −0.965 | ||

| −0.395 | 2.292 | ||

| μ | Poisson’s ratio | 1.327 | |

| 0.209 | −0.174 | ||

| 0.111 | 0.463 | ||

| the compressive strength, MPa | 0.289 |

| Rock Stratum | Stiffness Ratio | Elastic Modulus (GPa) | PB Stiffness Ratio | PB Modulus (GPa) | PB Normal Strength (MPa) | PB Shear Strength (MPa) |

|---|---|---|---|---|---|---|

| Conglomerate | 1.77 | 10.92 | 1.77 | 10.92 | 1 | 0.75 |

| Sandy mudstone | 1.95 | 6.71 | 1.95 | 6.71 | 1 | 0.75 |

| Coarse sandstone | 1.77 | 10.92 | 1.77 | 10.92 | 1 | 0.75 |

| Gritty sandstone | 1.77 | 10.92 | 1.77 | 10.92 | 1 | 0.75 |

| Fine sandstone | 1.21 | 4.96 | 1.21 | 4.96 | 1 | 0.75 |

| Medium sandstone | 1.77 | 10.92 | 1.77 | 10.92 | 1 | 0.75 |

| Composite immediate roof | 1.95 | 6.71 | 1.95 | 6.71 | 1 | 0.75 |

| Coal | 2.14 | 7.59 | 2.14 | 7.59 | 1 | 0.75 |

| Floor | 1.21 | 4.96 | 1.21 | 4.96 | 1 | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liu, S.; Yu, X.; Gu, H.; Liu, H.; Liu, C. Characteristics of Overlying Rock Breakage and Fissure Evolution in the Mining of Extra-Thick Coal Seams in Anticline Structural Area. Appl. Sci. 2025, 15, 8812. https://doi.org/10.3390/app15168812

Wang J, Liu S, Yu X, Gu H, Liu H, Liu C. Characteristics of Overlying Rock Breakage and Fissure Evolution in the Mining of Extra-Thick Coal Seams in Anticline Structural Area. Applied Sciences. 2025; 15(16):8812. https://doi.org/10.3390/app15168812

Chicago/Turabian StyleWang, Jun, Shibao Liu, Xin Yu, Haoyuan Gu, Huaidong Liu, and Changyou Liu. 2025. "Characteristics of Overlying Rock Breakage and Fissure Evolution in the Mining of Extra-Thick Coal Seams in Anticline Structural Area" Applied Sciences 15, no. 16: 8812. https://doi.org/10.3390/app15168812

APA StyleWang, J., Liu, S., Yu, X., Gu, H., Liu, H., & Liu, C. (2025). Characteristics of Overlying Rock Breakage and Fissure Evolution in the Mining of Extra-Thick Coal Seams in Anticline Structural Area. Applied Sciences, 15(16), 8812. https://doi.org/10.3390/app15168812