Featured Application

The described spraying method concerns the application of foamed insulating geopolymers to building partitions. Potential applications may also include other applications in construction (plasters, smoothing, etc.).

Abstract

Foamed geopolymer materials are increasingly studied due to their inherent fire resistance. To date, these materials have primarily been produced by casting into moulds, with foaming occurring during mixing or within the moulds, shortly before setting. For practical applications, however, it is advantageous to apply these materials directly onto surfaces with complex geometries. Although several techniques for geopolymer spraying have been described in the literature, many exhibit limitations that restrict their practical implementation. This study presents a novel spraying technology developed on a dedicated process line, enabling in situ dosing of the foaming agent immediately before application. The system integrates infrared heating to ensure controlled curing of the geopolymer. This paper outlines the design of the process line and its core functionalities while presenting selected results of material tests conducted on the obtained geopolymer coatings. Tests performed on approximately 200 m2 of surface confirmed the functionality of the process. The thermal conductivity of the sprayed foams was about 0.07 W/m-K. The inclusion of a phase-change material (PCM) in the geopolymers further enhanced their ability to store and regulate thermal energy. The adhesion strength results, consistently exceeding 1 MPa across various substrates (steel, geopolymer, gypsum board), confirmed the practical suitability of the proposed solution. This was also demonstrated by the homogeneous foamed structure obtained.

1. Introduction

Geopolymers are inorganic polymers based on aluminosilicates and alkaline activators derived from these aluminosilicates. They are also referred to as polysilicates, polysilans, and alkaline-activated aluminosilicate binders (AAAS) [1,2,3,4]. Geopolymers result from the well-known and widely described mineral polycondensation reaction known as geosynthesis [5,6,7]. They consist of copolymeric chains of silicon and aluminium oxides, stabilised by metal cations such as sodium, potassium, lithium, or calcium, along with bound water. The most commonly used activators are sodium hydroxide and aqueous sodium silicate solution (potassium water glass), due to their availability and cost-effectiveness. The properties of geopolymers are primarily determined by the precursor composition and key structural parameters, including the Si/Al ratio, reaction temperature, and humidity [8,9]. Consequently, differences in precursor composition can lead to differences in mechanical properties, even with similar mix designs. Recent studies demonstrate that employing machine learning can be beneficial in optimising mix designs and identifying influential factors affecting the performance of geopolymers, as shown by Zeng et al. [10]. Their study utilised machine learning models to predict compressive and flexural strength based on parameters such as the Si/Al ratio and water-to-binder ratio. This study highlighted the significant predictive potential of these models, indicating that they can effectively assist in the geopolymer design process for solid materials, and likely for foamed materials as well. The workability and setting time of geopolymers can be controlled using various additives and curing conditions. Geopolymers cure within a few hours at ambient temperature, while curing at higher temperatures accelerates their production and enhances their properties [11,12,13].

Geopolymers have garnered significant interest due to their unique properties and the ongoing pursuit of developing sustainable construction materials. Rising energy costs and the high environmental impact of Portland-cement-based concretes are leading to an intensified search for alternatives, with geopolymers being one of them [14,15,16,17,18]. Appropriately designed geopolymers are considered to be lower-emission materials than concrete and exhibit higher compressive strength and chemical resistance, as well as exceptional fire and temperature resistance (up to 1000 °C). Other notable properties include low shrinkage during curing, faster setting, high wear resistance, enhanced acid resistance, and good adhesion to different materials [19,20,21]. These characteristics make geopolymers promising materials for the future of the construction industry.

Special attention is given to foamed geopolymers due to their fine thermal insulation properties and fire resistance at temperatures exceeding 1000 °C [22,23,24,25,26]. Traditional insulation materials include expanded or extruded polystyrene (EPS and XPS, respectively), mineral wool, and glass wool. In recent years, the popularity of polyurethane (PUR) and polyisocyanurate (PIR) foams has increased, particularly those applied by spraying onto various surfaces. Despite their effectiveness as thermal insulators, all of these materials have numerous drawbacks, including flammability, water absorption, low mechanical strength, and environmental or human toxicity [27,28,29,30]. Undoubtedly, further efforts are needed to identify alternative materials to those currently in use. In this context, a promising approach involves geopolymers modified with phase-change materials (PCMs). In our previous studies, we explained the mechanism of synergistic heat management in such systems [31,32,33,34]. The PCM, in the form of silicate microcapsules, can be uniformly distributed within the porous geopolymer matrix, forming an integrated baffle that is capable of effectively regulating heat flow. Upon thermal exposure (e.g., due to solar radiation on an exterior wall), the PCM partially absorbs thermal energy and stores it through a phase-change process (melting). This delays the temperature increase within the partition, contributing to enhanced thermal comfort inside the building. Subsequently, after the cessation of the heat source, the PCM recrystallises (solidifies), releasing the stored energy. Due to the insulating nature of the foamed geopolymer matrix, the released energy is predominantly retained within the structure and dissipated locally rather than being transferred to the interior. This mitigates the secondary reheating of the indoor environment and minimises the reverse heat flow effect. Such a synergistic mechanism between the PCM and the geopolymer matrix enables the material to store thermal energy effectively and insulate against it. This combination is unattainable when PCMs or conventional thermal insulation materials are used independently. Consequently, this mechanism leads to temperature stabilisation indoors, reducing the amplitude of daily temperature fluctuations and diminishing the demand for mechanical cooling during warmer periods. As a result, partitions constructed using the described material significantly enhance buildings’ energy efficiency and improve the occupants’ thermal comfort.

In practical applications of geopolymer composites incorporating PCMs, long-term stability and cost-effectiveness remain key issues. In traditional PCMs, environmental factors such as temperature fluctuations, humidity, and chemical exposure can lead to structural degradation and reduced material performance over time [35]. However, PCM–geopolymer composites present a promising alternative, thanks to the unique protective properties of the geopolymer matrix. Geopolymers are characterised by high resistance to corrosive environments, which effectively protects the phase-change materials that they house from degradation. This paper highlights the use of PCMs encapsulated with silicates that show robust resistance to alkaline environments typical of geopolymers. As a result, the PCM does not degrade even under prolonged exposure. Studies have confirmed the high multi-cycle stability of such materials [35], which significantly enhances their practical utility. Based on the findings of previous studies, it is expected that the geopolymer matrix will provide a protective function for the PCM, shielding it from external factors and, thus, improving the overall durability and cost-effectiveness of the system in engineering and construction applications.

In this study, greater emphasis was placed on the impact of the manufacturing process on the functionality of the geopolymer/PCM foamed coating, rather than on material factors or variations in composition and structure. Therefore, potential methods for producing such coatings require more comprehensive discussion. For years, the technology of foaming geopolymer mixtures has been researched, developed, and described in the scientific literature. However, several technological challenges remain, including the low stability of foamed structures before curing. This often results in a lack of reproducibility and foam collapse, leading to higher material density and degraded insulation properties. Various stabilisers are used to address these issues, and foamed geopolymers are usually produced by casting into moulds, allowing for better control over the foaming process [31,32,33,34,35,36]. However, the most significant benefits of foamed geopolymers can be achieved by applying them directly to existing structures. Several authors have described such techniques, but no simple, inexpensive, and effective method has yet been developed to apply foamed geopolymer layers with stable porous structures that can be cured directly on the object to be thermally insulated. Various methods, such as manual application using rollers or brushes, centrifugal application, air spraying, and robotic systems, have been discussed in patent applications and scientific publications [23,37,38,39,40]. Deshmukh et al. studied fly-ash-based geopolymer coatings applied by brushing onto cleaned mild steel plates [41]. Zhang et al. described a manual spatula application method [42]. Geopolymer coatings applied by dipping or brushing result in relatively thick layers, which may limit their application in cases requiring thin coatings. Bhardwaj et al. presented a centrifugal application method [43]. The centrifugal coating method allows for producing well-ordered, thin geopolymer coatings (13–20 µm thick). However, in the literature, spray application is the most frequently described method for producing geopolymer coatings, particularly on vertical substrates, and is often considered to be the preferred technique. The key advantages of the spray method include low cost, attractive efficiency, the ability to control the thickness of the applied layer, and the possibility of adjusting the application pressure. The resulting coatings are uniform, exhibit good stability, and demonstrate strong adhesion to the substrate. It is essential to ensure that the coating suspension possesses adequate fluidity for practical spray application [44,45].

Several solutions concerning equipment designed specifically for applying geopolymer materials have also been reported. In McAlorum et al.’s work, a robot-assisted spray-coating process was implemented for geopolymers. By optimising the composition of the mixture, the robot’s operating paths, and the parameters of the spraying device, the researchers demonstrated a reliable and automated method for applying coatings onto surfaces of approximately 250 mm2 under laboratory conditions. The hardened geopolymer exhibited a compressive strength of 20 MPa and a bond strength with the concrete substrate of 0.5 MPa [46]. Several noteworthy solutions have also been submitted for patent protection or registered as utility models, particularly concerning devices used for the production of insulating and fire-resistant geopolymer materials. For instance, utility model CN218010702U describes equipment for spraying fire-resistant geopolymer materials onto structural surfaces. The equipment includes, among other components, a stand and an auxiliary mixing device [47]. Similarly, utility model CN217998810U describes a device for spraying fire-resistant geopolymer material, comprising a base, spraying machine, control panel, connecting pipe, spraying pipe, agitator, feed hopper, filtering screen, pendulum mechanism, and a clamping and fixing structure [48].

All solutions described thus far in the scientific literature and patent filings are not free from drawbacks and imperfections, which can lead to significant problems in their industrial application. One of the most common issues is the uneven foaming process. It often results in the collapse of the porous structure during spraying, particularly when the application parameters and mixture composition are not correctly selected. Another problem is the formation of so-called “sinks”, i.e., local depressions in areas of the material lacking a porous structure. This is most often caused by excessive liquidity of the mixture or inadequate curing control. Another undesirable phenomenon is “sagging” of the foam, caused by the rapid escape of gas bubbles before the material sets, leading to distortion of the foam structure and a decrease in insulation properties. Controlling the thickness of the applied layer also remains a significant challenge, especially in manual applications, where uniform material distribution is difficult to achieve without advanced equipment and operator experience. A different concern is the need for elevated temperatures during the curing of the geopolymer coating. During prefabrication, geopolymeric elements can be heat-cured in furnaces. However, delivering heat during the application of geopolymers on construction sites, or directly to pre-constructed building elements, poses significant challenges [49,50,51]. The solution proposed in this paper effectively eliminates the above problems by adjusting the composite composition, controlling the application conditions, and using reliable curing methods. As a result, it is possible to obtain a homogeneous, durable coating with predictable performance properties.

As part of a three-year research effort within the project titled “Development of technology for the additive production of environmentally friendly and safe insulating and heat storage capable materials based on alkaline activation of anthropogenic raw materials” (funded by the National Centre for Research and Development, grant no. LIDER/16/0061/L-11/19/NCBR/2020), the authors of this study have developed a prototype installation for the spray application of foamed geopolymers, featuring simultaneous infrared-assisted curing of the coating. This article presents the newly developed setup, its functionality, and the results of tests conducted on foamed geopolymer/PCM coatings produced using this setup. The system enables in situ curing of the geopolymer directly on the sprayed substrate, with the foaming process occurring after the geopolymer mass has been applied. This approach prevents degradation of the porous, aerated structure that typically occurs when the material is forced through spray nozzles. The entire spraying line is mobile, as both the spraying and curing systems are integrated into a movable platform. This solution is unique and has been submitted for patent protection. The tests conducted confirmed the effectiveness of the developed system. Moreover, the present study brings new insights into the integration of PCMs into the structure of foamed geopolymer coatings. It examines the potential of these coatings to function as homogeneous insulation-accumulation layers applied directly onto various building substrates. The general thermal properties of geopolymers and PCMs are known [31]. However, understanding how they interact under dynamic conditions (heating and cooling cycles) and how the matrix material’s porosity affects PCMs’ effectiveness requires further analysis.

2. Materials, Methods, and Developed Technological Setup

The research on developing the innovative technological line was conducted for a geopolymer mixture based on fly ash originating from the Skawina Power Plant. Table 1 shows the oxide chemical composition of the fly ash, while Table 2 presents the particle size analysis results. The chemical analysis (Table 1) indicated that the main mineral components were silicon dioxide (SiO2) and aluminium oxide (Al2O3), with contents of 59.41% and 30.15%, respectively. The calculated molar ratio of SiO2/Al2O3 was approximately 1.97, which falls within the optimal range (1.5–2.5) conducive to efficient geopolymerisation. The presence of additional oxides, such as Fe2O3 (3.48%), CaO (2.21%), K2O (2.11%), TiO2 (0.74%), and SO3 (0.56%), can further affect the rheology, reaction kinetics, and physicochemical properties of the material, including durability and resistance to environmental factors.

Table 1.

Fly ash oxide analysis.

Table 2.

Fly ash-particle size analysis.

Particle size analysis (Table 2) showed that the material had a relatively fine grain size, as evidenced by characteristic values of D10 = 2.44 µm, D50 = 12.86 µm, and D90 = 32.23 µm, with an average particle size of 16.23 µm and a very low standard deviation (0.03 µm). Such parameters testify to a homogeneous distribution of grains, which translates into a large specific surface area and promotes high reactivity of the raw material in alkaline environments. The appropriate chemical composition and grain size of fly ash indicate its high suitability as a component for manufacturing durable and homogeneous geopolymer materials.

The geopolymer mixture contained 10 wt.% of phase-change material (PCM), a commercial product called GR42 from Rubitherm. The additive was introduced to further enhance the thermal properties of the coatings. Hydrogen peroxide (H2O2) with a concentration of 36% was used as the foaming agent and was continuously dosed during the spray application of the geopolymer, ensuring that its proportion in the geopolymer mixture ranged between 2 and 4 wt.%. The geopolymers were produced using an alkaline solution composed of sodium hydroxide (10M) and a sodium silicate solution (water glass R-145). Foamed geopolymer was sprayed onto plasterboard panels mounted on walls. Thus, removing these panels after spraying enabled further testing of the resulting coatings.

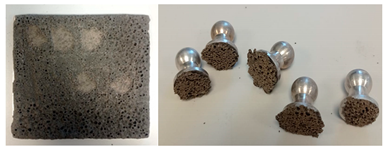

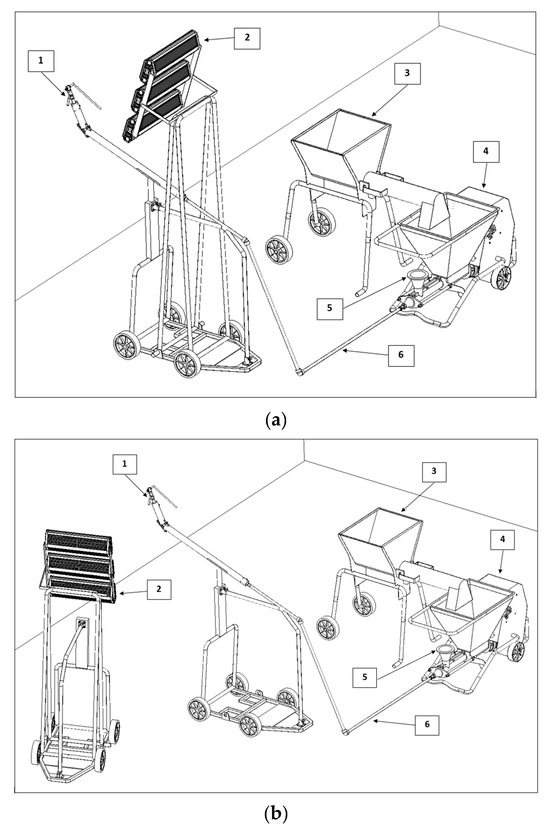

The trials described in this paper primarily focused on the liquid geopolymer spraying process, using a specially designed technological line. The following description details the construction and operation of the devices and elements that are part of this system. The technological line developed for the production of foamed geopolymer coatings by spraying directly onto construction surfaces consisted of a mixing and spraying unit (optionally including a flow mixer, from which the geopolymer mass was fed to the unit), a manipulator equipped with a spray nozzle (to which a hose supplying liquid geopolymer was attached), and an infrared heater. The spraying manipulator, the hose delivering the mixture, and the spray nozzle were mounted on a movable arm, enabling the nozzle to move without the need for manual force or operator load. The manipulator allowed for effortless direction of the spray nozzle and hose, facilitating easy adjustment of the spray direction onto ceilings, walls, or floors. Both the manipulator and the infrared heater were mounted on a standard mobile platform. The manipulator and infrared heater were equipped with control systems and a synchronised system for rotating both devices around a vertical axis. The schematic of the developed geopolymer spraying solution is shown in Figure 1.

Figure 1.

Diagram of the innovative technological line for the application and curing of foamed geopolymers, presented in two variants: infrared heater not integrated with the mobile platform and manipulator (a); infrared heater and manipulator integrated on a shared mobile platform (b). The names of the parts are as follows: 1—spray gun, 2—infrared illuminator, 3—flow mixer designed for continuous operation with plastering units and mixing of re-prepared mortars, 4—mixing and spraying unit for plaster mortars, 5—frothing agent insertion spigot, 6—cable connecting the unit to the spray gun.

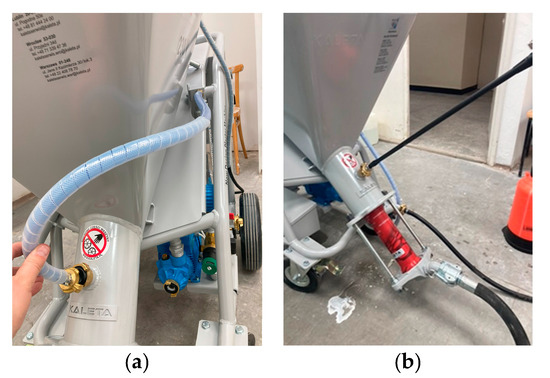

The construction of the entire spraying line utilised a standard plastering unit that was significantly modified to remove the water circulation system, allowing the unit to operate without a water supply. Instead, a foaming agent was introduced just before the geopolymer mass entered the rotor (compressing part). As a result, the geopolymer mass only came into contact with the foaming agent (hydrogen peroxide) for approximately 2–3 s before being applied to the surface, causing the mass to begin foaming only after it was sprayed onto the wall.

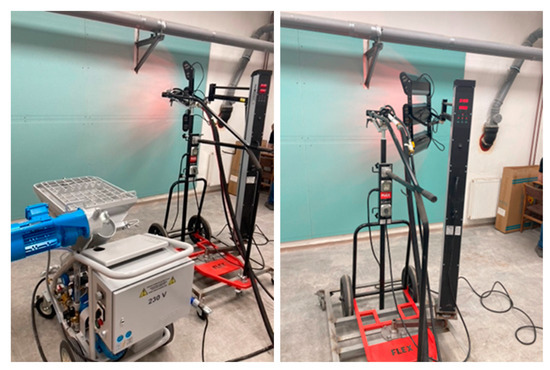

The described setup involved high-pressure units that incorporated a stator and rotor, with the foaming agent, in the form of liquid hydrogen peroxide, being introduced directly into the geopolymer mass before the stator and rotor module. From an application standpoint, this solution was highly advantageous, as it led to the formation of porous structures as the material exited the unit, with foaming occurring in the open space either during or immediately after application onto the surface. This made the foaming process more efficient than in other technologies, such as cup spraying (spray guns), hydrodynamic methods, and the use of concrete mixers with pumps. Additionally, the automation of the spraying process through the use of an adjustable arm/manipulator, as well as the thermal curing process using infrared heaters, eliminated some of the main barriers and challenges associated with the application of foamed geopolymer materials. The developed arm, with an extendable boom (manipulator), facilitated the application of geopolymer layers without the need to support the hose, making it easier to apply the material on floors, walls, and ceilings. This was an innovative approach, as it had never been used for such applications before. Figure 2 shows the prototype installation developed.

Figure 2.

A technological line for applying layers of foamed geopolymers, comprising a mobile platform outfitted with a manipulator that holds a spray nozzle connected to a material supply hose, alongside an infrared heater, as well as a modified mixing unit designed for compressing the geopolymer mass with direct dosing of the foaming agent.

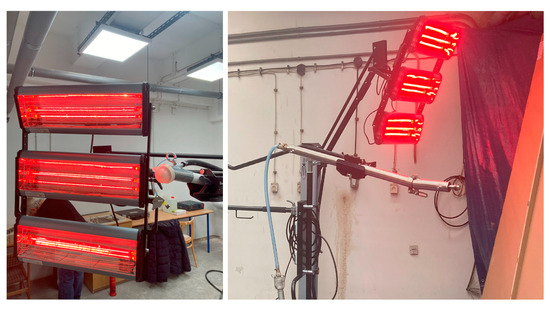

As is well known, geopolymer materials require the application of thermal energy to achieve the desired mechanical parameters. This is particularly important in the case of geopolymer foams, whose structure is unstable. Furthermore, when these materials are applied to vertical surfaces, there is a significant risk of material sagging and the formation of so-called “puddles”. In such cases, providing heating to these freshly applied coatings is crucial. In the developed solution, infrared heaters with adjustable radiation intensity and the ability to regulate their position and angle of incidence were utilised on a mobile platform. A visualisation of this solution is shown in Figure 3.

Figure 3.

An infrared heater integrated with a mobile platform and manipulator, intended for thermal curing of sprayed foamed geopolymer layers.

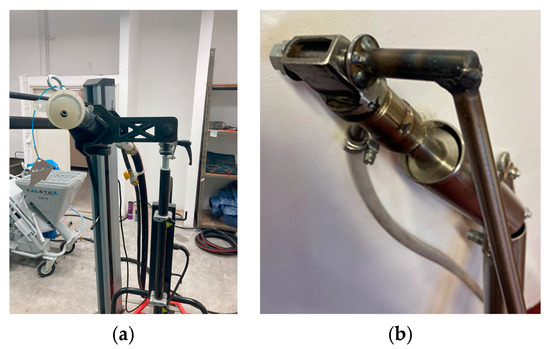

Figure 4 presents two solutions related to the spray nozzles/lances used. The developed device allowed for the use of standard nozzles dedicated to spray units (a) as well as a modified nozzle (in-house design), which enabled the control and adjustment of the amount of sprayed material and changes in the material flow by employing a nozzle with a rectangular cross-section (b). The designed nozzle allowed for the smooth regulation of the opening, enabling a controlled reduction in the material flow.

Figure 4.

Spray gun with an attached delivery hose—mounted on the manipulator’s arm and mobile spraying station (a); flat spray nozzle with adjustable flow—proprietary design (b).

Figure 4 and Figure 5 also illustrates how the existing systems were modified by replacing water delivery with a foaming agent dosing system positioned just before the mixing compression section. The liquid geopolymer mixture was in contact with the foaming agent for approximately 2–3 s, so the foaming process did not occur in the spray unit and the feeding hose but, rather, on the surface coated with the geopolymer layer.

Figure 5.

In the standard solution, water is supplied to the sprayed material through a special pipe (a); in the alternative solution, the water circuit is disabled, and at the water supply connection point, a blowing agent is supplied instead (b).

Our invention contributes to overcoming many issues associated with spraying foamed geopolymers using standard methods. It ensures greater accessibility to the use of new materials, such as geopolymer/PCM system composites. This solution, which involves the use of a mobile spraying station, can be applied with spray units utilising compressed air, as well as with screw feeders for concrete.

3. Results and Discussion

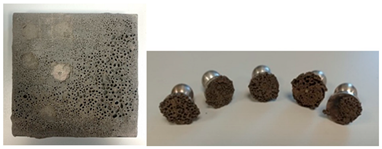

The pilot-scale line designed and constructed for the spray application of foamed geopolymers was utilised to perform multi-variant tests under real conditions. These tests confirmed the effective functioning of the developed technological system. The validation of the proposed solution encompassed the coverage of more than 200 m2 of various surfaces with geopolymer/PCM foam, along with assessments of coating adhesion and microstructure, visual inspection, and thermal conductivity measurements. Selected results validating our novel spray system are presented below. The tests were primarily conducted on gypsum board substrates, which were easy to remove and suitable for further testing. To prevent the wet, uncured coating from flowing down the vertical surfaces of the substrate being sprayed, tests were conducted to select an appropriate formulation of the geopolymer/PCM.

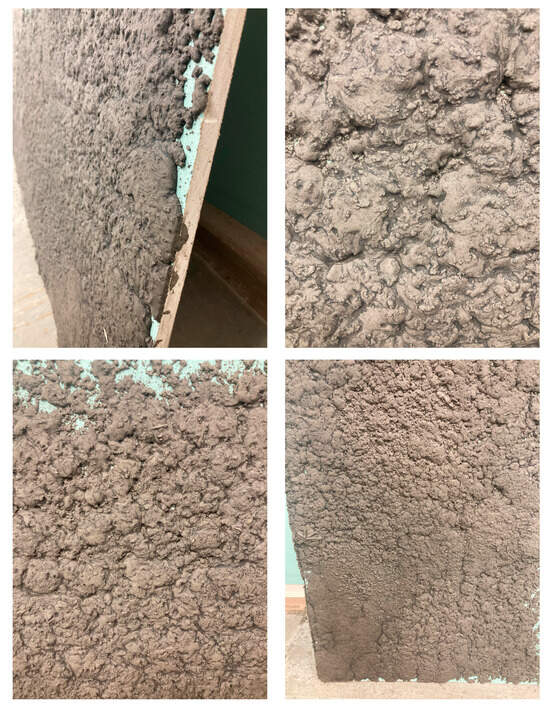

Figure 6 presents an example of gypsum boards covered with a material that is too thin in consistency. Due to the excessive amount of liquid solution, it was impossible to maintain the foamed geopolymer’s structure under such conditions, even after heating with infrared radiation. The photographs show the streaks and flow of the geopolymers, along with the absence of a visible foaming effect. The initial spray trials, conducted as part of the preliminary studies, involved varying the liquid-to-solid ratio. The most satisfactory results were achieved for a solid-to-liquid ratio of 0.24:1. This ratio was adopted for further research and was determined based on measurements of the mixture’s consistency on a spreading table. The resulting spillage of the geopolymer mixture averaged 195 mm, corresponding to consistency class S3 in concrete classification according to PN-EN 206. This consistency provided good workability, uniform foaming, and adequate adhesion to various substrates (steel, concrete, cardboard–gypsum). Simultaneously, it was stable enough to limit issues such as liquid phase segregation and excessive foam subsidence.

Figure 6.

Effect of applying sprayed foamed geopolymer with an improper consistency of the used geopolymer mixture.

The curing process was carried out using infrared (IR) heaters. It was crucial to maintain a constant surface temperature of 80 °C. The temperature was controlled continuously using a non-contact optical pyrometer. This system made it possible to precisely adjust the power of the radiant heaters to the sample’s instantaneous surface temperature, eliminating the risk of local overheating or underheating. With such control, it was possible to maintain the temperature within 80 ± 2 °C throughout the curing process. A constant temperature was crucial not only for ensuring a homogeneous foamed structure but also for the proper course of the geopolymerisation process. Under certain temperature conditions, the cured material achieved the optimal level of crosslinking and binding of alkaline activators to the solid phase.

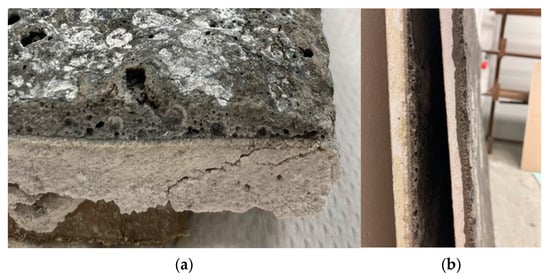

The technological parameters used—appropriate solid–liquid ratio, controlled viscosity, optimal consistency, and precise temperature control—made obtaining high-quality porous geopolymer structures possible. Figure 7 illustrates a single layer of the spray-applied geopolymer material foamed and cured on the substrate. Figure 8 presents a cross-section of a gypsum board with a layer of geopolymer foam applied, along with a side view of the board with the coating.

Figure 7.

Examples of a single layer of geopolymer material applied by spraying, which underwent foaming and curing on the substrate.

Figure 8.

Close-up view of a cut-out section of the gypsum board with the applied geopolymer foam layer (a), and a side view of the boards with the applied coating (b). Layer thickness approx. 1.5 cm.

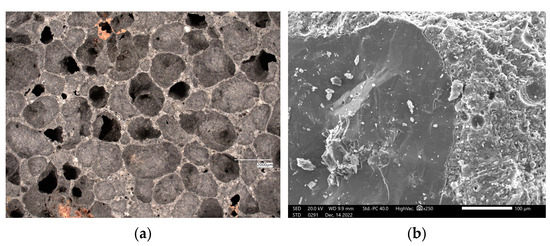

The microstructure shown in Figure 9 provides valuable information on the efficiency of the geopolymer foaming process and the homogeneity of the resulting porous structure. It can be assessed that the pore size distribution is relatively uniform throughout the entire volume of the analysed material, with predominant pore diameters ranging from 500 to 2000 µm. Although some deviations from ideal uniformity are natural and expected for materials of this type, the absence of clear clusters of excessively large or small pores confirms effective control over the foaming process. It should be emphasised that the pore size distribution itself was not the key objective of this study, since these parameters can easily be modified, if necessary, by appropriate selection of the blowing agent or adjustment of its concentration. The more important aspect was to confirm whether the process of foaming proceeded uniformly and efficiently, directly translating into the material’s final thermal and mechanical properties. In the analysed sample, massive, unfoamed material fragments or excessively thick pore walls, which could indicate an incomplete or uncontrolled gas release reaction, were not observed.

Figure 9.

Microstructure of the foamed geopolymer layer: optical microscopy (a); scanning electron microscopy (SEM) (b).

The tested geopolymer/PCM coating exhibited a typical open and well-developed pore system, which clearly demonstrated the efficiency of foaming and the appropriate choice of the technological parameters of the process, such as mixing time, temperature, and the activity of the blowing agent. A homogeneous microstructure contributes to stable performance and high quality of the final product.

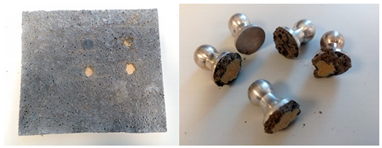

In the conducted tests, a crucial aspect of evaluating the performance of the foamed geopolymer/PCM coating was its adhesion to various types of substrates. Table 3 presents the results of adhesion tests for the foamed geopolymer/PCM coating applied by spraying onto steel, geopolymer, and gypsum plasterboard. The tests were performed using the PosiTest® AT (DeFelsko Corporation, Ogdensburg, NY, USA). automatic pull-off adhesion tester, with five measurements taken per substrate; the values shown in the table represent the average. Visual inspection after the tests showed that the adhesion was sufficiently strong for steel and geopolymer substrates, with fracture occurring within the foamed geopolymer layer. No coating detachment from the cardboard surface was observed for the gypsum board substrate, but the cardboard layer was torn from the gypsum core of the board. The adhesion strength between the coating and the cardboard exceeded the bond strength between the cardboard and the gypsum core. The high level of adhesion testifies to the strong interaction between the geopolymer/PCM and the cellulose surface of the cardboard, which may result from both the chemical properties (reactivity of the basic functional groups) and the microporous structure that allows for penetration and mechanical anchoring in the substrate. This phenomenon was confirmed not only by the experimental observation of damage but also by the determined peel strength values, which exceeded the internal adhesion limit of the gypsum board. The literature [52] indicates that the typical bond strength of cardboard with gypsum is approximately 0.2–0.3 MPa. In all cases, the pull-off strength exceeded 1 MPa, demonstrating good adhesion of the foamed coating to the substrate. These results are particularly significant because they surpass the standard adhesion values achieved for conventional coatings used in construction, such as plaster or protective coatings, which often reach values below 1 MPa [53]. This indicates that the tested coating not only adheres effectively to various substrates but may also potentially withstand deformation, mechanical stress, and cyclic weather fluctuations during service. Furthermore, the strong adhesion of the functional layer enhances the overall integrity of the material system, reducing the risk of delamination, cracking, or spalling. Thus, using the described material as an insulating, protective, or thermal storage layer is well justified from both technological and functional perspectives.

Table 3.

Results of the pull-off strength test of foamed geopolymer layers applied to different substrates.

The research and development of the spraying method aimed to identify a simple application technique enabling the use of foamed insulating geopolymers containing PCMs. Therefore, the measurements of specific heat and thermal conductivity were crucial in confirming the results’ effectiveness. In order to assess the thermal conductivity of the insulation layers produced by the spraying method, a series of samples were prepared by spraying the geopolymer into moulds with dimensions of 20 × 20 × 3 cm3. The samples were fabricated using the developed spraying system and subjected to infrared heating for 30 min. The distance between the IR emitter and the sample surface was maintained at 45 cm, which ensured a surface temperature of approximately 80 °C. Measurements of thermal conductivity (λ) and specific heat capacity (Cp) were carried out using the HFM 446 heat flow meter (Netzsch, Hanau, Germany), under standards including ASTM C1784 [54], ASTM C518 [55], ISO 8301 [56], and EN 12664 [57]. Temperature regulation and control were verified using the Peltier system. The measurement accuracy was ±1–2%, repeatability was ±0.25%, and reproducibility was ±0.5%. The thermal properties were determined using the hot-and-cold plate method. The thermal conductivity was measured in the temperature range typical for standard insulation materials (e.g., expanded polystyrene), i.e., 0–20 °C. The specific heat capacity was determined in the temperature range of 27.5–32.5 °C.

Figure 10 shows an example of a fabricated sample and its initial placement in the testing device. The average thermal conductivity of the produced samples (based on three measurements for each of the three samples) was 0.0776 W/m·K, while the specific heat capacity reached 1.398 J/g·K. The density of the tested samples, as determined using the measuring device, averaged 356.95 kg/m3. Samples without the addition of the PCM exhibited approximately 15% lower average specific heat values (mean value: 1.214 J/g·K). The increase in thermal storage capacity resulted from the incorporation of 10 wt.% of PCM GR42. Geopolymer compositions containing the PCM ensured good thermal insulation, non-flammability, and high heat storage capacity, making them attractive solutions for the construction industry. Although foamed geopolymers generally exhibit slightly lower thermal insulation properties than traditional insulation materials, their thermal conductivity coefficient, averaging around 0.07 W/m·K, is considered reliable and has been confirmed by multiple independent studies [58,59,60,61]. The earlier literature occasionally reported much lower values, such as 0.037 W/m·K [61], but those results have not been consistently replicated and are not considered representative for practical applications.

Figure 10.

Foamed geopolymer produced by spray application prior to thermal conductivity testing.

A number of potential performance and technological advantages were identified based on process observation and analysis of operating parameters. Compared to manual methods of applying foams or geopolymers, the spraying technique allowed for uniform coverage of large areas in a short time. The estimated spraying rate using the designed system was about 0.4–0.5 m2/min for a layer thickness of approximately 20 mm, while limiting material losses to less than 7%. Another aspect contributing to the cost-effectiveness of the proposed solution is the ability to apply it directly to various types of substrates (steel, concrete, cardboard–gypsum) without priming, which reduces the preparation time and material costs. In addition, the technology is scalable and can be adapted to automated application systems in prefabrication conditions, significantly increasing its industrial potential. Further quantitative studies are planned, including a detailed analysis of operating costs, material and energy consumption, and long-term efficiency compared to available PUR foam spray technologies and traditional insulation boards.

The solution presented in this article is a starting point for further research and development to optimise the structure and functionality of foamed geopolymer/PCM composites. Additional experiments are planned to improve both the methods of introducing PCMs into the geopolymer matrix and the selection of the most effective forms of encapsulation of PCMs that will guarantee their long-term stability, resistance to alkaline conditions, and minimal thermal losses during phase transition cycles. Previous literature reports confirm that PCMs can be effectively integrated with geopolymers, achieving heat accumulation and control benefits without significant loss of material mechanical performance [31,32,33,34]. However, much depends on the proper selection of the type of PCM, the type of microcapsule envelope, the manner in which it is dispersed in the structure, and the chemical and physical interactions with the geopolymer matrix. Therefore, further optimisation of the material formulation is needed to ensure a balance between thermal efficiency, mechanical durability, and resistance to multiple heating and cooling cycles. Machine learning can serve as a valuable tool in this context. An additional research direction will also be to analyse the effects of the type and amount of the blowing agent on the distribution of the PCM and its impact on heat conduction and accumulation. Employing advanced microstructural imaging and numerical modelling techniques to predict the thermal behaviour of a partition constructed with the described material under real-world service conditions will also be considered. The overall objective of such studies would be to develop highly functional and durable hybrid materials intended for use in energy-efficient and passive construction, with the aim of significantly enhancing thermal comfort and reducing energy consumption.

4. Conclusions

Among the key advantages of foamed geopolymers are their high thermal resistance and non-flammability, resistance to chemically aggressive environments, fine mechanical properties, and durability against biological factors, including rodent activity. Their thermal insulation performance can be further improved by the incorporation of PCMs. This study presents a novel technology enabling the effective application of such materials to various substrates, ensuring uniform coverage and minimising material losses. The described system operates by spraying a hydrated geopolymer mixture and foaming it after exiting the spray unit, either directly onto building surfaces or into moulds, with a foaming agent added at the final stage of material delivery. A single sprayed layer created with this system enables the formation of a foamed geopolymer coating up to 2 cm thick. The proposed solution is innovative in the field of spray process automation, thanks to the use of a controllable arm/manipulator, as well as the implementation of a thermal curing process using infrared (IR) radiators. The geopolymer/PCM foamed coatings produced using this method were subjected to testing, and the results can be summarised as follows:

- The high adhesion strength of the geopolymer/PCM foam, consistently exceeding 1 N/mm2 across various substrates, underscores its potential as a durable protective coating for construction applications. Cohesive failure was observed in the foam layer for steel and geopolymer substrates, whereas failure occurred within the gypsum board itself at the gypsum–cardboard interface. Direct application to steel, concrete, and gypsum board without priming gave satisfactory results.

- Microstructural analysis confirmed a relatively uniform pore size distribution, indicating effective control over the foaming process. No significant clustering of excessively large or small pores was observed, demonstrating consistent foaming.

- The thermal conductivity of the foamed geopolymer/PCM composites averaged 0.0776 W/m·K. The addition of the PCM increased the specific heat capacity by approximately 15%, reaching 1.398 J/g·K, thereby enhancing the material’s thermal storage capacity.

- The proper solid-to-liquid ratio for the geopolymer/PCM mixture was determined to be 0.24:1. This formulation enabled sufficient adhesion, foam stability, and uniform layer formation.

The solution developed and presented in this paper provided several benefits, including the following:

- A “Delayed foaming” effect, occurring only at the stage of spraying onto the substrate, which prevents premature volume expansion in the mixing system and supply lines. This significantly reduces the risk of system clogging and material loss due to uncontrolled foaming inside the device. Furthermore, it enables more precise control over the porous structure directly at the application site.

- Uniform pore distribution can be achieved, since foaming occurs immediately after application. This ensures even expansion of the material while maintaining high flowability and adhesion of the sprayed geopolymer. As a result, microcracks and surface irregularities are filled more effectively.

- Improved material stream control results in better surface coverage and more uniform coating thickness. Enhanced spraying accuracy contributes to increased material efficiency, minimising waste and improving the final aesthetic and uniformity of the applied layer.

- Infrared-assisted curing accelerates the hardening of the applied material and enhances the stability of the porous structure by preventing slump or collapse. The system’s capability for pulsed heating allows for better control over the reaction kinetics, enabling targeted activation of the setting only after spraying. Rapid surface curing minimises the risk of sagging or deformation and, under favourable conditions, permits the faster application of successive layers, thereby shortening the overall application time.

- Reduced physical strain on the operator, as there is no need to lift and manoeuvre a heavy hose filled with material, results in lower fatigue, enhanced precision, and increased safety, especially during prolonged work sessions or applications at height or over large surface areas.

- The manipulator system enables the operator to focus on application precision, while the infrared heaters dynamically regulate the curing conditions in real time. Together, they create a modern, mobile spraying solution, ideal for rapid geopolymer application in construction, industrial insulation, and even post-industrial sites (e.g., revitalisation or protective coatings).

- The system also shows potential for integration with semi-automated or fully robotic solutions, especially in scenarios involving prefabrication or high-volume production runs.

- The process enhances efficiency and reduces material losses. It involves a spraying rate of 0.4–0.5 m2/min for a 20 mm layer and keeps material losses below 7%, which is significantly lower than the typical 15–20% associated with manual methods.

This is a novel technological approach, as no comparable comprehensive solution has been previously described in the literature. Validation tests confirmed the effectiveness and practical utility of the entire system for the efficient and successful application of foamed geopolymer/PCM composites on construction substrates. Further studies are planned to optimise PCM encapsulation methods and investigate their long-term thermal stability, mechanical durability, and the effects of multiple heating and cooling cycles.

5. Patents

The technological solution presented in this article—a spray system dedicated to foamed geopolymers—has been submitted for patent protection at the Patent Office of the Republic of Poland under application number P.447177, titled: “Method for producing foamed geopolymer layers by spraying and a technological line for implementing this method”.

Author Contributions

Conceptualisation, A.P. and M.Ł.; methodology, A.P. and J.P.; validation, A.P., M.Ł. and P.R.; formal analysis, A.P., M.Ł. and P.R.; investigation, A.P. and J.P.; resources, A.P. and M.Ł.; data curation, A.P. and M.Ł.; writing—original draft preparation, A.P., P.R. and M.Ł.; writing—review and editing, A.P., P.R. and M.Ł.; visualisation, A.P. and M.Ł.; supervision, M.Ł.; funding acquisition, M.Ł. All authors have read and agreed to the published version of the manuscript.

Funding

All research was funded by the National Centre for Research and Development under a grant: Development of technology for the additive production of environmentally friendly and safe insulating and heat storage capable materials based on alkaline activation of anthropogenic raw materials (LIDER/16/0061/L-11/19/NCBR/2020).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Feng, L.; Yi, S.; Zhao, S.; Zhong, Q.; Ren, F.; Liu, C.; Zhang, Y.; Wang, W.; Xie, N.; Li, Z.; et al. Recycling of Aluminosilicate-Based Solid Wastes through Alkali-Activation: Preparation, Characterization, and Challenges. Buildings 2024, 14, 226. [Google Scholar] [CrossRef]

- Wu, Y.; Jia, Z.; Qi, X.; Wang, W.; Guo, S. Alkali-activated materials without commercial activators: A review. J. Mater. Sci. 2024, 59, 3780–3808. [Google Scholar] [CrossRef]

- Dacić, A.; Kopecskó, K.; Fenyvesi, O.; Merta, I. The Obstacles to a Broader Application of Alkali-Activated Binders as a Sustainable Alternative—A Review. Materials 2023, 16, 3121. [Google Scholar] [CrossRef] [PubMed]

- Nasir, M.; Mahmood, A.H.; Bahraq, A.A. History, recent progress, and future challenges of alkali-activated binders—An overview. Constr. Build. Mater. 2024, 426, 136141. [Google Scholar] [CrossRef]

- Sithole, N.T.; Mashifana, T. Geosynthesis of building and construction materials through alkaline activation of granulated blast furnace slag. Constr. Build. Mater. 2020, 264, 120712. [Google Scholar] [CrossRef]

- Ouffa, N.; Benzaazoua, M.; Belem, T.; Trauchessec, R.; Lecomte, A. Alkaline dissolution potential of aluminosilicate minerals for the geosynthesis of mine paste backfill. Mater. Today Commun. 2020, 24, 101221. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Razak, R.A.; Vizureanu, P.; Sandu, A.V.; Matasaru, P.-D. A State-of-the-Art Review on Innovative Geopolymer Composites Designed for Water and Wastewater Treatment. Materials 2021, 14, 7456. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mohapatra, S.; Gaur, A.; Dwivedi, G.; Soni, A. Study of various properties of geopolymer concrete—A review. Mater. Today Proc. 2020, 46, 5687–5695. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; Van Deventer, J.S. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf. A Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Zeng, Y.; Chen, Y.; Liu, Y.; Wu, T.; Zhao, Y.; Jin, D.; Xu, F. Prediction of compressive and flexural strength of coal gangue-based geopolymer using machine learning method. Mater. Today Commun. 2025, 44, 112076. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, A.; Bao, X.; Ni, T.; Ling, J. A review on geopolymer in potential coating application: Materials, preparation and basic properties. J. Build. Eng. 2020, 32, 101734. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, H.; Xu, M.; Cui, X. Preparation, characterization and application of geopolymer-based tubular inorganic membrane. Appl. Clay Sci. 2021, 203, 106001. [Google Scholar] [CrossRef]

- Kaplan, G.; Shi, J.; Öz, A.; Bayrak, B.; Dheyaaldin, M.H.; Aydın, A.C. Preparation and characterization of a novel prepacked aggregate geopolymer: A feasibility study. Powder Technol. 2023, 421, 118423. [Google Scholar] [CrossRef]

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900. [Google Scholar] [CrossRef]

- Zhao, J.; Tong, L.; Li, B.; Chen, T.; Wang, C.; Yang, G.; Zheng, Y. Eco-friendly geopolymer materials: A review of performance improvement, potential application and sustainability assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar] [CrossRef]

- Alahmari, T.S.; Abdalla, T.A.; Rihan, M.A.M. Review of Recent Developments Regarding the Durability Performance of Eco-Friendly Geopolymer Concrete. Buildings 2023, 13, 3033. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Almakayeel, N.; Yunus Khan, T. Development and optimization of an eco-friendly geopolymer brick production process for sustainable masonry construction. Case Stud. Constr. Mater. 2023, 18, e02133. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Ahmed, H.U.; Mosavi, A. Survey of Mechanical Properties of Geopolymer Concrete: A Comprehensive Review and Data Analysis. Materials 2021, 14, 4690. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, X.; Hao, H. Dynamic tensile properties of geopolymer concrete and fibre reinforced geopolymer concrete. Constr. Build. Mater. 2023, 393, 132159. [Google Scholar] [CrossRef]

- Łach, M. Geopolymer Foams—Will They Ever Become a Viable Alternative to Popular Insulation Materials?—A Critical Opinion. Materials 2021, 14, 3568. [Google Scholar] [CrossRef] [PubMed]

- Abdellatief, M.; Elrahman, M.A.; Alanazi, H.; Abadel, A.A.; Tahwia, A. A state-of-the-art review on geopolymer foam concrete with solid waste materials: Components, characteristics, and microstructure. Innov. Infrastruct. Solut. 2023, 8, 230. [Google Scholar] [CrossRef]

- Dhasindrakrishna, K.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, current thinking and challenges in geopolymer foam concrete technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- Le, V.S.; Szczypinski, M.M.; Hájková, P.; Kovacic, V.; Bakalova, T.; Volesky, L.; Hiep, L.C.; Louda, P. Mechanical properties of geopolymer foam at high temperature. Sci. Eng. Compos. Mater. 2020, 27, 129–138. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Hu, Y.; Li, Y.; Hu, P.; Zhao, Y. Physical and high temperature properties of basalt fiber-reinforced geopolymer foam with hollow microspheres. Constr. Build. Mater. 2024, 411, 134698. [Google Scholar] [CrossRef]

- Schiavoni, S.; D′Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Lynn, M. Insulation. In Edition Material, 1st ed.; RIBA Publishing: London, UK, 2024; pp. 1–16. [Google Scholar]

- Vatin, N.I.; Pestryakov, I.I.; Sultanov, S.T.; Ogidan, O.T.; Yarunicheva, Y.A.; Kiryushina, A.P. Water Vapour by Diffusion of PIR and Mineral Wool Thermal Insulation Materials. In Advances and Trends in Engineering Sciences and Technologies III, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019; pp. 1–7. [Google Scholar]

- Dickson, T.; Pavía, S. Energy performance, environmental impact and cost of a range of insulation materials. Renew. Sustain. Energy Rev. 2021, 140, 110752. [Google Scholar] [CrossRef]

- Przybek, A.; Łach, M. Insulating Innovative Geopolymer Foams with Natural Fibers and Phase-Change Materials—A Review of Solutions and Research Results. Materials 2024, 17, 4503. [Google Scholar] [CrossRef]

- Marczyk, J.; Przybek, A.; Setlak, K.; Bazan, P.; Łach, M. Energy-Efficient Insulating Geopolymer Foams with the Addition of Phase Change Materials. ACS Omega 2025, 10, 2488–2500. [Google Scholar] [CrossRef]

- Przybek, A.; Łach, M.; Bogucki, R.; Ciemnicka, J.; Prałat, K.; Koper, A.; Korniejenko, K.; Masłoń, A. Energy-Efficient Geopolymer Composites Containing Phase-Change Materials-Comparison of Different Contents and Types. Materials 2024, 17, 4712. [Google Scholar] [CrossRef] [PubMed]

- Bąk, A.; Pławecka, K.; Bazan, P.; Łach, M. Influence of the addition of phase change materials on thermal insulation properties of foamed geopolymer structures based on fly ash. Energy 2023, 278, 127624. [Google Scholar] [CrossRef]

- Haily, E.; Ousaleh, H.A.; Zari, N.; Faik, A.; Bouhfid, R.; Qaiss, A. Use of a form-stable phase change material to improve thermal properties of phosphate sludge-based geopolymer mortar. Constr. Build. Mater. 2023, 386, 131570. [Google Scholar] [CrossRef]

- Bazan, P.; Figiela, B.; Kozub, B.; Łach, M.; Mróz, K.; Melnychuk, M.; Korniejenko, K. Geopolymer Foam with Low Thermal Conductivity Based on Industrial Waste. Materials 2024, 17, 6143. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarski, K.; Pławecka, K.; Kozub, B.; Bazan, P.; Łach, M. Preliminary Investigation of Geopolymer Foams as Coating Materials. Appl. Sci. 2022, 12, 11205. [Google Scholar] [CrossRef]

- Gu, G.; Xu, F.; Huang, X.; Ruan, S.; Peng, C.; Lin, J. Foamed geopolymer: The relationship between rheological properties of geopolymer paste and pore-formation mechanism. J. Clean. Prod. 2020, 277, 123238. [Google Scholar] [CrossRef]

- Palmero, P.; Formia, A.; Antonaci, P.; Brini, S.; Tulliani, J. Geopolymer technology for application-oriented dense and lightened materials. Elaboration and characterization. Ceram. Int. 2015, 41, 12967–12979. [Google Scholar] [CrossRef]

- Boros, A.; Korim, T. Development of Geopolymer Foams for Multifunctional Applications. Crystals 2022, 12, 386. [Google Scholar] [CrossRef]

- Deshmukh, K.; Parsai, R.; Anshul, A.; Singh, A.; Bharadwaj, P.; Gupta, R.; Mishra, D.; Sitaram Amritphale, S. Studies on fly ash based geopolymeric material for coating on mild steel by paint brush technique. Int. J. Adhes. Adhes. 2017, 75, 139–144. [Google Scholar] [CrossRef]

- Zhang, Z.; Yao, X.; Wang, H. Potential application of geopolymers as protection coatings for marine concrete III. Field experiment. Appl. Clay Sci. 2012, 67–68, 57–60. [Google Scholar] [CrossRef]

- Bhardwaj, P.; Gupta, R.; Deshmukh, K.; Mishra, D. Optimization studies and characterization of advanced geopolymer coatings for the fabrication of mild steel substrate by spin coating technique. Indian J. Chem. Technol. 2021, 28. Available online: http://op.niscair.res.in/index.php/IJCT/article/view/31721 (accessed on 11 April 2025).

- Ferreira, M.; Moreira, A.P.; Neto, P. A low-cost laser scanning solution for flexible robotic cells: Spray coating. Int. J. Adv. Manuf. Technol. 2012, 58, 1031–1041. [Google Scholar] [CrossRef][Green Version]

- Lu, B.; Zhu, W.; Weng, Y.; Liu, Z.; Yang, E.; Leong, K.F.; Tan, M.J.; Wong, T.N.; Qian, S. Study of MgO-activated slag as a cementless material for sustainable spray-based 3D printing. J. Clean. Prod. 2020, 258, 120671. [Google Scholar] [CrossRef]

- McAlorum, J.; Perry, M.; Vlachakis, C.; Biondi, L.; Lavoie, B. Robotic spray coating of self-sensing metakaolin geopolymer for concrete monitoring. Autom. Constr. 2020, 121, 103415. [Google Scholar] [CrossRef]

- Pang, Q.F.; Zhao, J.Z.; Li, Y.; Yang, S.Q. A Spraying Equipment for Construction of Geopolymer Fireproof Material. Patent CN218010702U, 13 December 2022.

- Pang, Q.F.; Zhao, J.Z.; Li, Y.; Yang, S.Q. A Geopolymer Fireproof Material Spraying Equipment. Patent CN217998810U, 9 December 2022.

- Aiman, M.S.; Othman, I.; Waqar, A.; Sor, N.H.; Isleem, H.F.; Najm, H.M.; Benjeddou, O.; Sabri, M.M.S. Geopolymers: Enhancing Environmental Safety and Sustainability in Construction. Civ. Eng. J. 2024, 10, 3122–3136. [Google Scholar] [CrossRef]

- Aliyar Zanjani, M.H. Exploring Knowledge Gap in Geopolymer Concrete Adoption in the Dutch construction Industry. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2024. Available online: https://purl.utwente.nl/essays/102744 (accessed on 11 April 2025).

- Kriven, W.M.; Leonelli, C.; Provis, J.L.; Boccaccini, A.R.; Attwell, C.; Ducman, V.S.; Ferone, C.; Rossignol, S.; Luukkonen, T.; Emiliano, J.V.; et al. Why geopolymers and alkali-activated materials are key components of a sustainable world: A perspective contribution. J. Am. Ceram. Soc. 2024, 107, 5159–5177. [Google Scholar] [CrossRef]

- Erbs, A.; Nagalli, A.; de Carvalho, K.Q.; Mazer, W.; de Moraes Erbs, M.; Paz, D.H.F.; Lafayette, K.P.V. Development of plasterboard sheets exclusively from waste. J. Build. Eng. 2021, 44, 102524. [Google Scholar] [CrossRef]

- Szymanowski, J. Evaluation of the Adhesion between Overlays and Substrates in Concrete Floors: Literature Survey, Recent Non-Destructive and Semi-Destructive Testing Methods, and Research Gaps. Buildings 2019, 9, 203. [Google Scholar] [CrossRef]

- ASTM C1784; Standard Test Method for Using a Heat Flow Meter Apparatus for Measuring Thermal Storage Properties of Phase Change Materials and Products. International American Society for Testing of Materials: West Conshohocken, PA, USA, 2020.

- ASTM C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. International American Society for Testing of Materials: West Conshohocken, PA, USA, 2021.

- ISO 8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Standards Organization: London, UK, 1991.

- EN 12664; Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Dry and Moist Products of Medium and Low Thermal Resistance. European Committee for Standardisation: Brussels, Belgium, 2001.

- Agustini, N.K.A.; Triwiyono, A.; Sulistyo, D.; Suyitno, S. Mechanical Properties and Thermal Conductivity of Fly Ash-Based Geopolymer Foams with Polypropylene Fibers. Appl. Sci. 2021, 11, 4886. [Google Scholar] [CrossRef]

- Kočí, V.; Černý, R. Directly Foamed Geopolymers: A Review of Recent Studies. Cem. Concr. Compos. 2022, 130, 104530. [Google Scholar] [CrossRef]

- Sitarz, M.; Zdeb, T.; Mróz, K.; Hager, I.; Setlak, K. Foaming and Physico-Mechanical Properties of Geopolymer Pastes Manufactured from Post-Metallurgical Recycled Slag. Materials 2024, 17, 1449. [Google Scholar] [CrossRef]

- Liefke, E. Industrial Applications of Foamed Inorganic Polymers. In Proceedings of the Geopolymere ‘99 Proceedings, International Geopolymere Conference, Saint-Quentin, France, 30 June–2 July 1999; pp. 189–200. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).