Abstract

In modern tunnel construction, complex environments with high geothermal gradients and abundant groundwater are frequently encountered. To investigate the damage and failure mechanisms of sandstone under the combined effects of temperature and water, uniaxial compression tests were conducted on sandstone at different temperatures (25 °C, 55 °C, 85 °C, and 95 °C) and soaking durations (0.5 h, 1 h, and 3 h). The acoustic emission (AE) signals and energy evolution during the damage and failure processes were analyzed, revealing the damage characteristics and failure mechanisms of sandstone. The results indicate the following: (1) As the temperature increases, under the 3 h condition, the water content of sandstone is highest at 55 °C, reaching 3.01%, and the thermal expansion effect of sandstone is not obvious. Under the conditions of 85 °C and 95 °C, the thermal expansion effect leads to a decrease in the water content, enhances the water absorption softening effect, increases the plastic deformation capacity of sandstone, and weakens its brittle failure capacity. (2) When soaked for 0.5 h and 1 h, the maximum acoustic emission ring count and maximum acoustic emission energy of sandstone increase initially, then decrease, and subsequently increase again as the temperature rises, while the cumulative acoustic emission ring count gradually increases with temperature. Under the 3 h soaking condition, the maximum ring count, maximum energy, and cumulative ring count of sandstone at all temperatures show a consistent increasing trend with temperature. (3) The increase in soaking time reduced the damage variable of sandstone, with the largest reduction of 54.17% under the 3 h condition. At different temperatures, the damage variable of sandstone was smallest at 55 °C, only 0.33. (4) Sandstone primarily experiences tensile failure under different temperatures and soaking times. The extension of soaking time promotes the development of shear cracks, while the increase in temperature can effectively promote the expansion of tensile cracks. The research results provide certain theoretical references for the damage and failure of surrounding rock in modern tunnel construction.

1. Introduction

With the rapid development of global transportation, the geological challenges faced in tunnel construction are becoming increasingly severe. In high geothermal and water-rich environments, the surrounding rock of tunnels is frequently exposed to the combined effects of high temperature and water, resulting in significant rock corrosion and fatigue deterioration. This results in deformation, instability, and potential collapse, causing engineering disasters. Consequently, it is essential to investigate the damage evolution and failure mechanisms of rock under the combined effects of high temperature and water is particularly important for the safety and stability of tunnel construction.

Currently, numerous scholars have conducted extensive research on the damage mechanisms and failure characteristics of rocks under the effects of temperature, water, or their combined effect. Sirdesai et al. [] conducted uniaxial compression tests on sandstone at temperatures ranging from 200 °C to 1000 °C and found that the expansion of mineral grains and anisotropy lead to changes in the physical and mechanical properties of the sandstone. Pradeep et al. [] studied the mechanical and mineralogical changes in granite with different grain sizes under the effect of temperature, revealing that grain expansion was the cause of the mechanical property changes, with coarse-grained granite being more significantly affected. Pan et al. [] examined the effects of different cooling media on the mechanical properties of granite and limestone at temperatures ranging from 25 °C to 800 °C, discovering that air cooling had a minimal impact on the mechanical properties, while all cooling media caused a degradation in the compressive strength of the rocks. Cai et al. [] performed Brazilian splitting tests on high-temperature granite (150–600 °C) under two cooling methods, natural cooling and liquid nitrogen cooling, and they found that liquid nitrogen cooling effectively promoted the development of internal cracks in high-temperature granite and reduced its mechanical properties. Cui et al. [] analyzed the damage evolution of granite under thermal cycling at 400 °C, observing that as the number of heating–cooling cycles increased, the weight loss rate and volume expansion rate of the granite increased exponentially, while the evolution of internal micro-cracks was described using acoustic emission parameters. These studies show that various high-temperature conditions and cooling methods significantly influence the mechanical properties of rocks, leading to a reduction in strength, crack propagation, and degradation of internal structures. In studies on the effects of water on rocks, Hu et al. [] investigated the impact of different water contents on the damage characteristics of red sandstone, finding that higher water content led to greater damage, and derived a damage constitutive model for sandstone at different water contents using Lemaitre’s model. Azhar et al. [], using sandstone from the Lanzhou water supply project crossing highly clayey sandstone, conducted uniaxial compression tests under different soaking times and combined XRD and SEM techniques, concluding that water absorption and softening were the reasons for the reduced durability of the sandstone. Wasantha et al. [] used ARAMIS to study the damage evolution of sandstone under dry and saturated conditions, discovering that the quartz content significantly influenced the water-weakening effect, and higher clay content resulted in more significant damage. Alomari et al. [] conducted uniaxial and triaxial compression tests on sandstone from Wyoming, USA, and developed a predictive model for compressive strength based on water content and grain size, finding that as water content and grain size increased, the compressive strength of the sandstone decreased. Zhao et al. [] studied the post-peak mechanical behavior of sandstone under water-pressure coupling, observing that peak strength and residual strength decreased as water pressure increased, and established a predictive model for the post-peak strength of sandstone under different water pressures. Roy et al. [] investigated the effects of water content on the mechanical properties and fracture behavior of three different types of shale, finding that higher water content led to lower strength and greater susceptibility to fracture. These studies demonstrate that higher water content and larger grain sizes both contribute to a reduction in rock strength and an exacerbation of its damage, while an increase in water pressure further decreases both peak strength and residual strength. Regarding the combined effects of temperature and water on rocks, Ping Qi et al. [] conducted temperature–water coupling experiments on sandstone with varying internal ring diameters, discussing the influence of temperature and water on sandstone damage and degradation. However, they did not consider the effects of different temperatures, and the experimental conditions differed from real construction environments. Yan Minghui et al. [] subjected granite to thermal–liquid coupling treatments and used uniaxial compression tests to examine the physical and mechanical damage caused by thermal–liquid–mechanical coupling. Yang et al. [] conducted water–rock interaction tests on heat-treated granite under high temperatures and pressures, observing that thermal expansion initially increased permeability, which later decreased. Wang Chun et al. [], focusing on deep geothermal energy exploitation, used Hopkinson bar tests to conduct dynamic tests under thermal–water–mechanical conditions, establishing a damage model based on deformation characteristics and revealing the dynamic damage failure patterns of rocks. Zheng et al. [] analyzed the effects of temperature–water coupling on coal samples, finding that as the temperature increased, the coal’s energy storage capacity initially decreased and then increased. These studies demonstrate that the combined effect of temperature and water intensifies rock damage, affects its energy storage capacity, and causes changes in permeability due to thermal expansion.

It is evident that a wide range of scholars have conducted relevant research concerning the evolution of rock damage, destruction patterns, and theoretical analyses under the combined effects of temperature and water, achieving fruitful results. However, in current international and domestic transportation tunnel construction, the high ground temperatures encountered are generally below 100 °C. The Seikan Tunnel, which crosses the seabed, faces a construction environment with high temperatures (up to 55 °C), high pressure, and high water content. Similarly, the Gotthard Base Tunnel also encounters high temperatures (up to 46 °C) and humid conditions during its construction. In the construction of the Sang Zhuling Tunnel, temperatures can reach 89 °C, while the temperatures in the tunnels of the Andes Mountains approach 100 °C. However, there are few reports on the damage evolution and destruction patterns of sandstone with different water contents below 100 °C. This study conducts uniaxial compression tests on sandstones with different soaking times (varying water contents) and temperatures (below 100 °C) to investigate the alterations in sandstone mechanical properties influenced by temperature and water, analyze the damage and destruction characteristics of the sandstones, and establish a damage equation based on dissipated energy, thereby facilitating the examination of damage and destruction patterns of sandstone under the interactions of temperature and water.

2. Experimental Methods

2.1. Sample Preparation

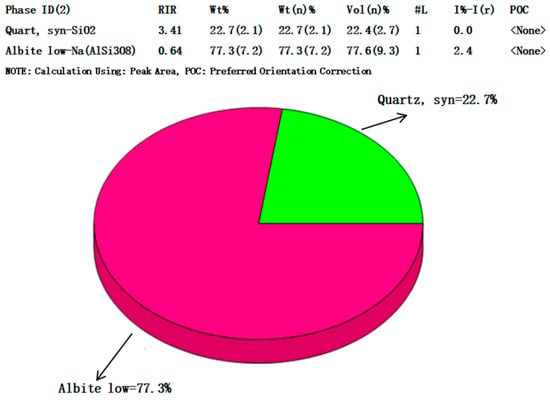

The test material was selected from the sandstone inside a high-temperature, water-rich tunnel in Southern Tibet. The surface of the sandstone showed no obvious cracks. According to diffraction composition analysis, the main components of the sandstone are quartz (22.7%) and feldspar (77.3%), as shown in Figure 1. The sampling and preparation process strictly followed the “Rock Physical and Mechanical Property Test Specification” (DZ/T0276.18-2015 []). The sandstone was processed into cylindrical specimens with a diameter of 50 mm and a height of 100 mm. The flatness error of both ends of the specimen was ±0.02 mm, and the deviation of the end faces from perpendicularity to the axis was less than 0.001 radians, as shown in Figure 2.

Figure 1.

Mineral composition of red sandstone.

Figure 2.

Some sandstone samples.

2.2. Experimental Plan

The “Technical Specification for Highway Tunnel Construction” (JTG 3370.1-2018 []) in China defines tunnels with temperatures exceeding 28 °C as high-temperature tunnels. To compare with normal temperature (25 °C), four temperatures—25 °C, 55 °C, 85 °C, and 95 °C—were set for this study. According to references [,,,], sandstone reaches saturation after 3 h of soaking, and temperature increase enhances the interaction between water and the mineral structure, strengthening the water absorption effect of the rock. Therefore, three soaking durations were set: unsaturated (0.5 h, 1 h) and saturated (3 h). First, an electric constant temperature box was used to heat the sandstone at a rate of 4 °C/min to 105 °C, where it was held for 24 h to remove the original moisture inside the specimen. Then, the temperature was lowered at a rate of 0.5 °C/min to reduce thermal shock and ensure that only the thermal gradient would affect thermal cracking. Next, the sandstone was subjected to a water bath at different temperatures and times using a warm water tank. After heating the sandstone specimens to the target temperature and time, they were removed and immediately insulated using polyethylene film and a homemade asbestos insulation shell. (The polyethylene film used is a common commercial polyethylene film. The asbestos insulation shell is made through a specific processing procedure, where nano-sized silica aerogel particles are fully integrated into ceramic fiberglass cotton. The customized aerogel felt is bonded to the polyethylene shell using adhesive). Finally, the combined effects of temperature, water, and time on the damage and failure of sandstone were investigated using uniaxial compression and acoustic emission systems. The specific experimental scheme is shown in Table 1. For example, H-25-0.5 represents a sandstone specimen at 25 °C with a soaking time of 0.5 h. The calculation formula for the water content of the sandstone specimen is:

In the formula: represents the moisture content, is the mass of the sandstone after immersion, and is the mass of the dry sandstone before immersion, and the unit is g.

Table 1.

Experimental Plan and Moisture Content of Sandstone at Different Immersion Times and Temperatures.

Table 1.

Experimental Plan and Moisture Content of Sandstone at Different Immersion Times and Temperatures.

| Numbering | Temperature/°C | Soaking Time/h | Water Content | Numbering | Temperature/°C | Soaking Time/h | Water Content |

|---|---|---|---|---|---|---|---|

| H-25-0.5 | 25 | 0.5 | 1.04 | H-85-0.5 | 85 | 0.5 | 1.02 |

| H-25-1 | 25 | 1 | 1.62 | H-85-1 | 85 | 1 | 1.56 |

| H-25-3 | 25 | 3 | 2.02 | H-85-3 | 85 | 3 | 2.91 |

| H-55-0.5 | 55 | 0.5 | 1.37 | H-95-0.5 | 95 | 0.5 | 1.21 |

| H-55-1 | 55 | 1 | 1.71 | H-95-1 | 95 | 1 | 1.43 |

| H-55-3 | 55 | 3 | 3.01 | H-95-3 | 95 | 3 | 2.68 |

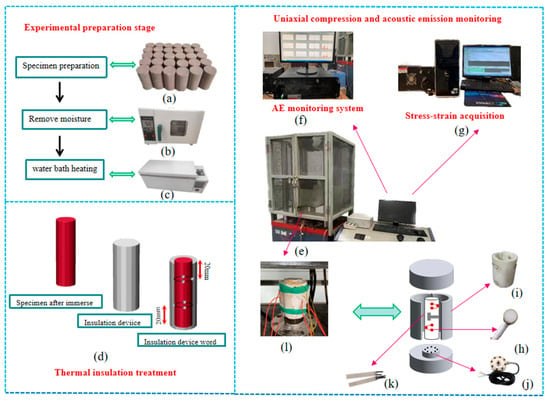

2.3. Experimental Equipment and Procedure

The experimental process is divided into three stages: the preparation stage, the sandstone soaking stage, and the uniaxial loading stage. (1) Preparation stage: the sandstone is processed into cylindrical specimens with dimensions of ø50 mm × 100 mm, as shown in Figure 3a. After processing, the red sandstone is placed into a drying oven, heated at a rate of 4 °C/min to 105 °C, and dried for 24 h (Shaoxing Shangcheng Instrument manufacturing Co., Ltd., Shaoxing, China), as shown in Figure 3b. Then, the specimens are cooled to room temperature at a rate of 0.5 °C/min. (2) Sandstone soaking stage: the mass of the red sandstone after drying, denoted as m0, is measured. The specimens are then placed into a constant temperature water tank set to the target temperatures (25 °C, 55 °C, 85 °C, and 95 °C). At each target temperature, the sandstone specimens are soaked for 0.5 h, 2 h, and 3 h, (Shaoxing Supo Instrument Co., Ltd., Shaoxing, China), as shown in Figure 3c, and the mass of the red sandstone after soaking, denoted as m1, is measured. (3) Uniaxial loading stage: the sandstone specimens, after soaking, are immediately placed into a homemade insulation device, as shown in Figure 3i. Uniaxial compression is performed using a WAW-1000B electro-hydraulic servo universal testing machine (Jinan Liangong Testing Technology Co., Ltd., Jinan, China), as shown in Figure 3e, with a loading rate of 0.2 mm/min. Real-time monitoring is conducted using an AE win Express8 acoustic emission system (Physical Acoustics Corporation of America (PAC), Beijing, China), as shown in Figure 3f, and strain data are collected using the DH3820 strain acquisition system Donghua Testing Technology Co., Ltd., Jingjiang, China), as shown in Figure 3g. The Nano 30 sensors (Physical Acoustics Corporation of America (PAC), Beijing, China), shown in Figure 3d, are arranged in two layers, with three sensors in each layer, positioned in a 90° staggered pattern. The distance between the probes and the top and bottom faces is 20 mm. The acoustic emission bandwidth ranges from 125 kHz to 750 kHz, and the preamplifier models are 2/4/6, with amplification factors of 20, 40, and 60, respectively, with the test set to 40 to ensure measurement accuracy. Calibration is performed before the experiment by using the lead-breaking operation to ensure that the collected signals are stable, clear, and free from noise. The specific experimental procedure is shown in Figure 3.

Figure 3.

Test flow chart. (a) Sandstone specimen. (b) Electric heating constant temperature drying oven. (c) Warm water tank. (d) Nano 30 sensor arrangement. (e) WAW-1000B electro-hydraulic servo universal testing machine. (f) AE win Express8 acoustic emission system. (g) Donghua DH3820 stress–strain acquisition system. (h) Nano sensor. (i) Insulation device. (j) Radial stress sensor. (k) Strain gauge. (l) Sandstone in the experiment.

3. Analysis of Sandstone Damage Characteristics Under Different Immersion Times and Temperatures

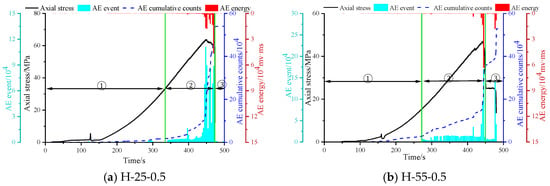

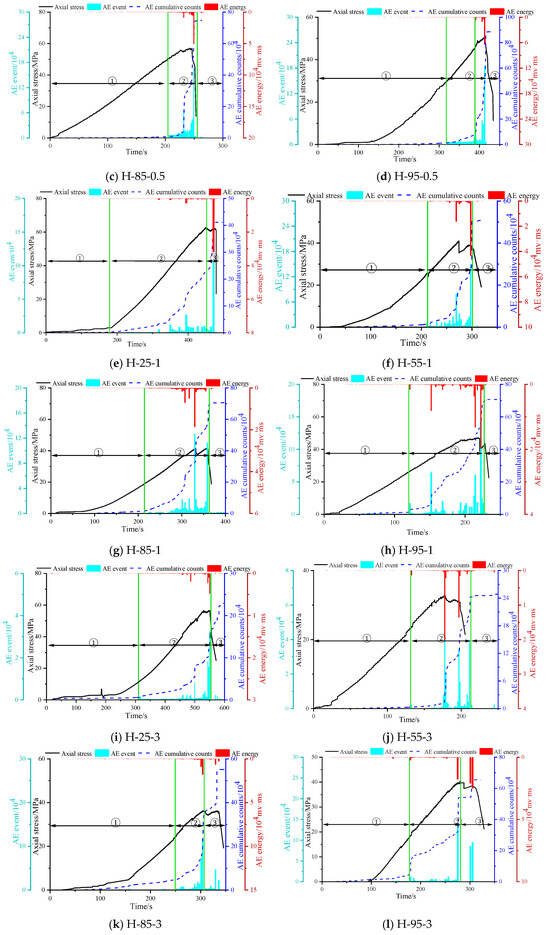

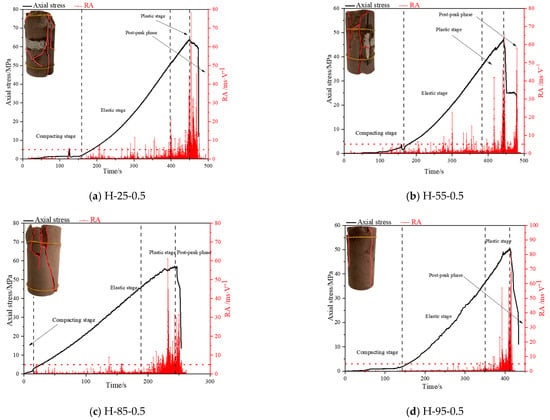

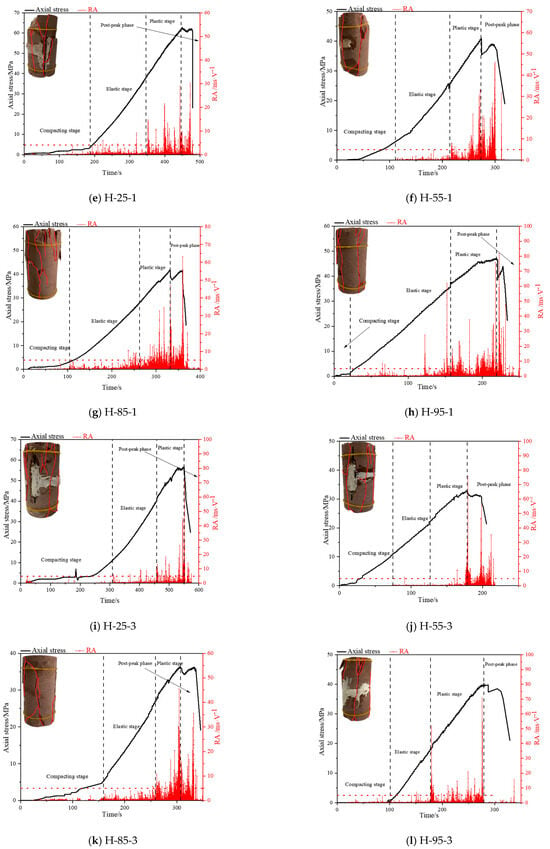

During the fracture and failure process of sandstone, the development and propagation of internal cracks are often accompanied by the generation and transfer of energy. Acoustic emission (AE) can be used to monitor the internal damage of rocks [,]. The AE counts and cumulative counts reflect the extent of crack development and cumulative damage during rock rupture, while the AE energy indicates the amount of energy released during the failure of the sandstone. The acoustic emission signals obtained from the uniaxial compression tests of sandstone under different temperatures and soaking durations are illustrated in Figure 4.

Figure 4.

Acoustic emission ringing and energy of sandstone with different temperatures and immersion times.

As illustrated in Figure 4, the acoustic emission signals of sandstone under different temperatures and soaking times exhibit similar patterns of change. The acoustic emission ringing and energy variations with time go through three distinct phases: ① the quiet period, ② the rapid increase period, and ③ the decay period. The cumulative ringing count of the acoustic emission increases gradually with loading time and reaches its maximum value after the peak stage. In the quiet period, due to the gradual compression of the primary pores and cracks within the sandstone, the acoustic emission signals (ringing counts, energy) of the sandstone are relatively low at all temperatures. In the rapid increase period, as the internal damage of the sandstone continues to intensify under axial force, cracks begin to develop and propagate. The acoustic emission signals (ringing count and energy) gradually increase, and near the peak stress, the acoustic emission activity suddenly surges, with the acoustic emission signals (ringing count and energy) reaching their maximum. In the decay period, as the stress–strain curve declines, macroscopic through-cracks develop both internally and on the surface of the rock, leading to complete failure of the rock. At this point, the acoustic emission signals (ringing count and energy) tend to stabilize and eventually disappear, while the cumulative acoustic emission ringing count reaches its maximum.

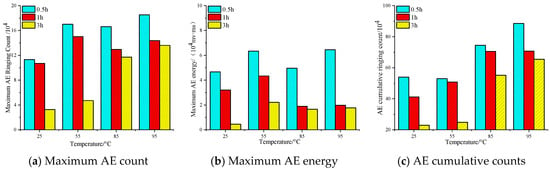

To present the influence of different temperatures and soaking times on the acoustic emission (AE) damage characteristics of sandstone in a more intuitive and clear manner, we conducted a more detailed quantitative analysis of the maximum AE ring count, energy, and cumulative AE ring count of sandstone under various temperatures and soaking times. The results of this analysis are shown in Figure 5.

Figure 5.

Acoustic emission damage characteristics of sandstone under different temperature and soaking time.

As shown in Figure 5, at the same temperature, as the soaking time increases, the maximum AE ring count, maximum AE energy, and cumulative AE ring count of sandstone gradually decrease. When soaked for 3 h, the acoustic emission signals (ring count, energy) and cumulative ring count of sandstone at all temperature conditions reach their minimum values. At the same soaking time, as the temperature rises, for soaking durations of 0.5 h and 1 h, the maximum AE ring count and maximum AE energy of sandstone exhibit a trend of first increasing, then decreasing, and finally increasing again, while the cumulative AE ring count shows a gradual upward trend. For soaking durations of 3 h at different temperatures, the maximum AE ring count, maximum energy, and cumulative AE ring count of sandstone all gradually increase with rising temperature.

With the increase in soaking time, the water content of sandstone gradually rises. High water content enhances the plastic deformation capacity of sandstone and reduces its brittleness failure degree, leading to a significant decrease in the acoustic emission signal values. This is the reason why the maximum AE ring count, maximum AE energy, and cumulative AE ring count of sandstone are all at their minimum after soaking for 3 h. At the same soaking time but different temperatures, the water content of sandstone is highest at 55 °C, resulting in weakened brittleness and enhanced plasticity of the sandstone, with a larger energy accumulation before the peak. Therefore, when the rock fails near the peak stress, it produces higher acoustic emission signals. When the temperature further increases (above 55 °C), on the one hand, the thermal expansion effect of the rock begins to appear, and on the other hand, the temperature continues to promote an increase in the water content of sandstone. The water content of the rock first decreases and then increases, causing the maximum ring count and maximum energy to also exhibit a trend of first decreasing and then increasing. After soaking for 3 h, high temperatures promote the further development of the thermal expansion effect in sandstone, causing more original microcracks to close, thereby significantly increasing the ring count and energy of the acoustic emission signals [].

4. Damage Characterization of Sandstone Under Different Soaking Times and Temperatures

The process of uniaxial compression-induced rock failure is associated with energy input, accumulation, dissipation, and release []. Phenomena such as brittle failure or plastic deformation in rocks represent macroscopic manifestations of the rapid or gradual release of energy. Therefore, from an energy perspective, the influence of temperature and water content (characterized by soaking time) on rock damage and failure can be analyzed more effectively. In the experiment, assuming that the energy input is entirely utilized for internal work or storage, a portion of the energy will be stored as elastic potential energy or dissipated as internal cracks develop. According to the first law of thermodynamics (the law of energy conservation), energy remains constant during its transformation and transfer [].

where is the total energy input into the rock during uniaxial compression, is the elastic energy, is the dissipated energy, and the units of each of the above quantities are MJ/m3, where

where is the initial modulus of elasticity, and is the value of stress and strain at any point on the stress–strain curve. Based on the above analysis, it is evident that the energies involved in the uniaxial compression process are influenced by the stress, strain, and elastic modulus of the rock. Next, we will analyze the evolution of energy in sandstone under different soaking times and temperatures.

4.1. Energy Evolution Patterns of Sandstones with Different Immersion Times and Temperatures

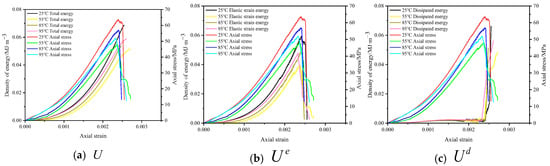

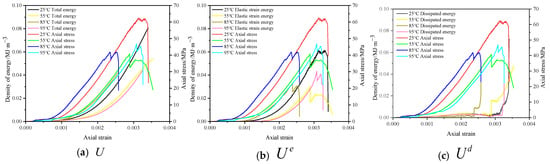

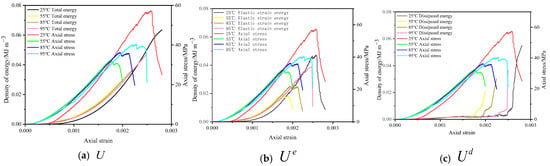

The variations in total strain energy, elastic potential energy, and dissipated energy under different soaking times and temperatures are illustrated in Figure 6, Figure 7 and Figure 8, respectively.

Figure 6.

Evolution of energy in sandstone under different temperatures after 0.5 h of water immersion.

Figure 7.

Evolution of energy in sandstone under different temperatures after 1 h of water immersion.

Figure 8.

Evolution of energy in sandstone under different temperatures after 3 h of water immersion.

As illustrated in Figure 6, Figure 7 and Figure 8, under different soaking times and temperatures, the energy evolution behavior of sandstone follows a similar pattern. Both total energy and elastic potential energy increase parabolically before the peak stress, while dissipated energy tends to develop linearly and slowly before the peak stress. This indicates that prior to the peak stress, the energy input into the rock is primarily stored in the form of elastic potential energy, with minimal increase in dissipated energy. After reaching the peak stress, the total energy continues to increase, but at a significantly reduced rate, while the elastic potential energy decreases rapidly. Dissipated energy gradually increases before reaching the peak stress, with a small rate of change, but after reaching the peak stress, dissipated energy increases sharply.

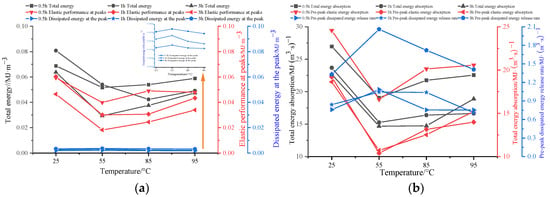

In order to more intuitively illustrate the influence of different temperatures and soaking times on the energy variation in sandstone, the total energy, elastic potential energy at peak stress, dissipated energy at peak stress, energy absorption rate, elastic potential energy absorption rate at peak stress, and dissipated energy release rate at peak stress are summarized in Figure 9.

Figure 9.

Plot of energy and rate of change in sandstone for different temperatures and immersion times. (a) Plot of energy changes in sandstone at different temperatures and immersion times; (b) plot of the rate of change in energy in sandstone at different temperatures and immersion times.

According to Figure 9, under the same soaking time, as the temperature increases, the variation patterns of total energy, peak elastic energy, total energy absorption rate, and elastic energy absorption rate are similar, all showing a trend of first decreasing and then increasing, with the lowest values occurring at 55 °C. This phenomenon occurs because at 55 °C, the sandstone reaches its maximum water content, which diminishes its energy absorption capacity of the sandstone, resulting in the lowest total energy absorption. As soaking time increases, the plastic deformation ability of the sandstone improves, enabling it to continue absorbing energy in the post-peak stage. At 3 h of soaking, the softening effect within the sandstone increases due to temperature, and the force further promotes the exfoliation of mineral particles and the development of microcracks, this processes the degree of rock failure and increasing the damage, thereby reducing the sandstone’s energy absorption capacity, with the lowest values of total energy absorption. The variation patterns of peak elastic energy, total energy absorption rate, and elastic energy absorption rate follow a similar trend. In contrast, the variation patterns of dissipated energy and dissipated energy release rate exhibit an opposite trend compared to the aforementioned patterns, showing an initial increase followed by a decrease. Under different soaking conditions, the peak dissipated energy and dissipated energy release rate are maximal at 55 °C. Additionally, as the soaking time increases, both the peak dissipated energy and dissipated energy release rate also rise. This phenomenon occurs because dissipated energy is directly related to crack development, which requires a substantial amount of energy. The results indicate that increased water content effectively facilitates the development of internal microcracks in sandstone, consistent with the trends observed in the acoustic emission signals of sandstone in Section 3.

4.2. Sandstone Damage Characterization

Under external forces, damage occurs within the rock, and the development and propagation of cracks consume a significant amount of energy. Therefore, the degree of energy dissipation can be used to quantitatively reflect the damage state of the rock. Dang et al. [] defined the damage variable of rock using normalized dissipated energy.

where is the cumulative dissipated energy at any stress state, is the cumulative dissipated energy for rock, and the units of each of the above quantities are MJ·m−3. D = 1 means that the rock is completely destroyed, and D = 0 means that the rock is intact and undamaged.

However, the sandstone retains its load-bearing capacity in the post-peak stage. To reflect the existence of the rock’s residual strength, a correction factor is introduced. By modifying the relationship between dissipated energy and the damage variable, the damage variable D does not completely reach 1 in the post-peak stage, thereby providing a more precise representation of the damage evolution characteristics of sandstone. Consequently, modifications are made to Equation (6) []

where is the peak strength, is the residual value stress; the unit of each of the above quantities are MPa. The , , of sandstone at different temperatures and immersion times are shown in Table 2.

Table 2.

, of sandstone at different temperatures and immersion times.

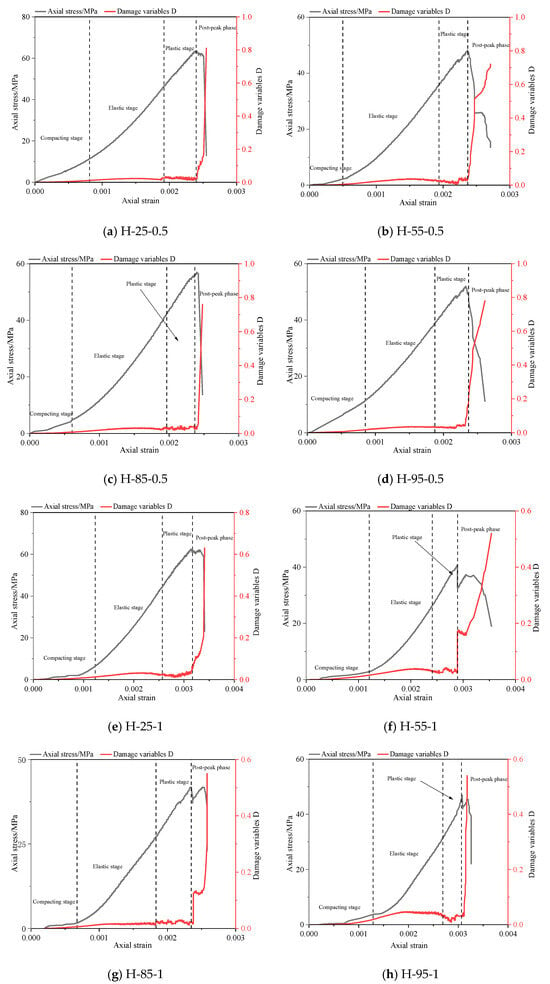

By substituting the values from Table 2 into Equation (6), the damage evolution of sandstone under varying temperatures and immersion times can be determined, as illustrated in Figure 10.

Figure 10.

Damage evolution law of sandstone under different temperature and soaking time.

From Figure 10, it is evident that the damage variable accurately represents the stress–strain behavior of the sandstone. During the compaction stage, under external force, the initial cracks inside the rock close, and the dissipated energy shows little change, with the damage variable remaining nearly almost constant. In the elastic stage, a significant portion of the energy input into the rock is stored as elastic energy, while a small fraction is allocated for crack development. During this stage, the damage variable increases slightly, but the increase is minimal. In the plastic stage, the rock begins to undergo plastic deformation, and the initiation and development of new cracks require significant energy, leading to a gradual increase in the damage variable with fluctuating changes, which indicates that the damage to the rock is intensifying. In the post-peak stage, when the stress exceeds the peak strength of the rock, the internal cracks continue to develop, resulting in macroscopic damage, with through cracks forming, a large release of elastic energy, and a sharp increase in dissipated energy. The damage variable shows a sudden increase but does not reach 1, indicating that the rock has not been completely destroyed after the peak and still retains some bearing capacity.

From Figure 10, it can be observed that under 0.5 h soaking, the maximum damage variable values at each temperature are 0.81, 0.72, 0.76, and 0.78, respectively. Under 1 h soaking, the maximum damage variable values at each temperature are 0.63, 0.52, 0.55, and 0.54, respectively. Under 3 h soaking, the maximum damage variable values at each temperature are 0.56, 0.33, 0.47, and 0.48. These data indicate that as the soaking time increases, the maximum damage variable value decreases gradually at the same temperature. This phenomenon occurs because under 0.5 h soaking, the sandstone has a lower water content and undergoes brittle failure, resulting in a larger damage variable. As the soaking time increases, the water content of the sandstone increases, and its ductility improves, resulting in a decrease in the maximum damage value. At the same soaking time, as the temperature increases, the maximum damage variable value initially decreases and then increases, with the smallest maximum damage variable value occurring at 55 °C. This is attributed to the fact that at 55 °C, the sandstone possesses the highest water content, resulting in the minimum damage variable value at this temperature.

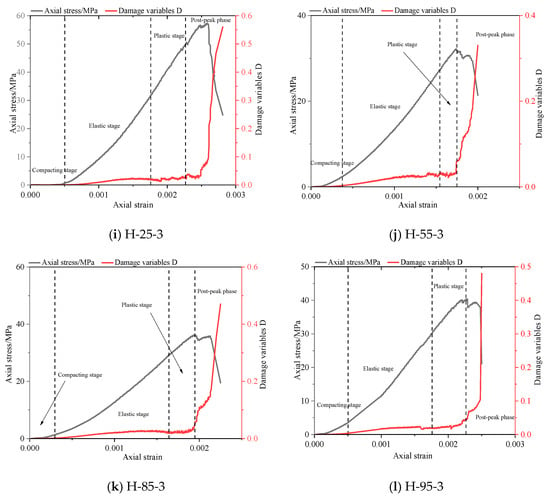

5. Analysis of Sandstone Failure Characteristics Under Different Soaking Times and Temperatures

In the previous sections, the damage evolution process of sandstone under different soaking times and temperature conditions has been analyzed. To further investigate the failure characteristics and the final failure type of sandstone, based on the acoustic emission (AE) RA evolution characteristics, the failure modes of sandstone specimens under different soaking times and temperature conditions are examined. The ratio of the rise time to amplitude, denoted as RA, can be used to characterize the development of cracks and failure in rocks. High RA values indicate tensile failure in sandstone, while low RA values correspond to shear failure []. In this study, a threshold of 5 ms·V−1 is defined for high and low RA values []. The time–stress–RA values and the failure types of specimens under different temperatures are illustrated in Figure 11.

Figure 11.

Characteristics of RA distribution in sandstone under different temperatures and immersion times and specimen damage maps.

From Figure 11, it can be observed that the RA value distribution characteristics of sandstone under different soaking times and temperatures are similar. During the compaction stage, under external force, a small amount of acoustic emission signals is generated due to the closure of internal pores and friction between particles, resulting in very low RA values, all below 5 ms·V−1. As the axial compressive stress increases, during the elastic stage, the number of RA values begins to increase, indicating the initiation of microcracks start to initiate within the rock, which leads to some tensile cracks, though high RA values remain relatively few. During the plastic stage, internal cracks in the sandstone begin to develop and propagate continuously, resulting in an increase in the number of RA values and the emergence of high RA values. This indicates that microcracks within the rock gradually cluster together, leading to an increasing number of tensile cracks, which ultimately results in the formation of a main crack. In the post-peak stage, the number of RA values decreases as the rock fractures. Under different temperatures, the sandstone generates the maximum RA signal near the peak stress, as shown in Table 3. This indicates that, under soaking conditions, a significant number of tensile cracks are generated near the peak stress at all temperatures, accompanied by a certain number of shear cracks. The primary mode of failure in sandstone is tensile failure, with a combination of tensile and shear failure. This conclusion is also supported by the photographic results of the experiments conducted under various soaking times and temperatures.

Table 3.

Maximum RA Values of Sandstone under Different Temperatures and Soaking Times.

6. Discussion

This study employs the WAW-1000B electro-hydraulic servo universal testing machine loading system to carry out uniaxial compression tests on sandstone samples subjected to different temperatures (25 °C, 55 °C, 85 °C, 95 °C) and soaking durations (0.5 h, 1 h, 3 h). Additionally, an acoustic emission system is used to study the damage and failure characteristics of sandstone under the combined influence of temperature and water. The findings indicate that at 85 °C and 95 °C, the thermal expansion effect of sandstone is more evident, leading to a decrease in the rock’s permeability and water absorption capacity. In contrast, at 25 °C and 55 °C, the thermal expansion effect of sandstone is relatively less pronounced, which promotes water infiltration and results in a higher moisture content [,,,,]. High moisture content exacerbates the dissolution [,], softening [,,], and stress corrosion effects [,] of sandstone mineral particles, causing a decline in their mechanical properties. As the soaking duration increases, sandstone samples soaked for 3 h exhibit the highest moisture content, which intensifies their softening and damage. This results in maximum damage to the sandstone, making the mineral particles within the rock more susceptible to external forces and facilitating the initiation and propagation of cracks.

The research results indicate that the damage to rocks in high-temperature and water-saturated environments is not solely the result of increased temperature or prolonged immersion time, but rather the result of the interaction between the two factors. This finding further reveals the damage and failure mechanisms of sandstone under the combined effects of high temperature and water, particularly the comprehensive impact of different temperatures on the thermal expansion and moisture migration of sandstone. The experiments found that 55 °C is the threshold for sandstone damage, indicating that there is a turning point in the thermal expansion effect of sandstone across different temperature ranges. This means that an increase in temperature does not always uniformly affect moisture migration; instead, there are both enhancing and inhibiting effects. This finding provides a new perspective for studying the damage mechanisms of rocks in high-temperature environments and offers theoretical support for establishing more accurate rock damage models. From an engineering perspective, the research results are significant for tunnel construction in high-temperature, water-rich environments. In practical construction, special attention should be paid to the stability of surrounding rock in such temperature ranges. Measures such as optimizing drainage systems, enhancing the impermeability of surrounding rock, and implementing effective reinforcement measures can be employed to mitigate the damage to sandstone caused by high moisture content, thereby reducing the likelihood of accidents.

7. Conclusions

Through uniaxial compression tests conducted on sandstone under different temperatures and soaking times (with varying moisture content), the damage characteristics and failure mechanisms of sandstone were investigated. The following conclusions were drawn.

(1) Different temperatures and soaking durations have an impact on the thermal expansion effect of sandstone. Specifically, under a soaking duration of 3 h, sandstone at 55 °C exhibits the highest moisture content, yet its thermal expansion effect is relatively insignificant. In contrast, at 85 °C and 95 °C, the moisture content decreases, resulting in an enhanced water absorption and softening effect.

(2) Under the influence of different soaking durations and temperatures, the acoustic emission of sandstone undergoes a period of calm, a surge, and a decay. At different temperatures, for soaking durations of 0.5 h and 1 h, the maximum ringing, energy, and cumulative ringing count of acoustic emission from sandstone show a trend of first increasing, then decreasing, and finally increasing again. However, for a soaking duration of 3 h, the maximum ringing, energy, and cumulative ringing count of acoustic emission gradually increase as the temperature rises.

(3) Under varying soaking durations and temperature conditions, sandstone exhibits the lowest total energy, elastic energy, total energy absorption rate, and elastic energy absorption rate at 55 °C. Conversely, it shows the highest pre-peak dissipated energy and dissipated energy release rate at this temperature. Among different temperatures, the damage variable of sandstone is the largest at 55 °C.

(4) The RA parameter of acoustic emission indicates that sandstone mainly undergoes tensile failure. An increase in temperature can effectively promote the development of tensile cracks, while an increase in soaking duration can facilitate the development of shear cracks, but tensile failure remains the dominant failure mode.

Author Contributions

Data curation: L.W., J.Q. and C.Y.; formal analysis: S.H. and Y.H.; supervision: X.B.; writing—original draft: X.B. and B.T.; writing—review and editing: X.B. and B.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the Basic Scientific Research Business Fee Project of Universities directly under the Inner Mongolia Autonomous Region (Grant No. 2024XKJX009); Natural Science Foundation of Inner Mongolia of China (Grant No. 2024LHMS05044); and Central Support for Local Universities Reform and Development Project—Discipline Construction—Civil Engineering Quality Improvement and Cultivation Discipline Construction Project (Grant No. 0404052401).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

All participants in this study received informed consent.

Data Availability Statement

The datasets generated and/or analyzed during the current study are not publicly available due to privacy restrictions but are available from the corresponding author on reasonable request.

Acknowledgments

The authors of the article sincerely appreciate and thank all the people who made it possible to implement this project.

Conflicts of Interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

References

- Gautam, P.K.; Singh, S.P.; Agarwal, A.; Singh, T.N. Thermomechanical characterization of two Jalore granites with different grain sizes for India’s HLW disposal. Bull. Eng. Geol. Environ. 2022, 81, 457. [Google Scholar] [CrossRef]

- Sirdesai, N.; Gupta, T.; Singh, T.; Ranjith, P. Studying the acoustic emission response of an Indian monumental sandstone under varying temperatures and strains. Constr. Build. Mater. 2018, 168, 346–361. [Google Scholar] [CrossRef]

- Pan, P.Z.; Shao, C.Y. Experimental studies on the physical and mechanical properties of heated rock by air, water and high-viscosity fluid cooling. Geomech. Energy Environ. 2022, 31, 100315. [Google Scholar] [CrossRef]

- Cai, C.; Wang, B.; Zou, Z.; Feng, Y.; Tao, Z. Experimental Study on the Damage and Failure Characteristics of High-Temperature Granite after Liquid-Nitrogen Cooling. Processes 2023, 11, 1818. [Google Scholar] [CrossRef]

- Cui, Y.; Xue, L.; Zhai, M.; Xu, C.; Bu, F.; Wan, L. Experimental investigation on the influence on mechanical properties and acoustic emission characteristics of granite after heating and water-cooling cycles. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 88. [Google Scholar] [CrossRef]

- Hu, X.; Hong, B.; Meng, Y. Statistical damage model of red sandstone with effect of water ratio considered. J. China Univ. Min. Technol. -Chin. Ed. 2007, 36, 609. [Google Scholar]

- Azhar, M.U.; Zhou, H.; Yang, F.; Younis, A.; Lu, X.; Fang, H.; Geng, Y. Water-induced softening behavior of clay-rich sandstone in Lanzhou Water Supply Project, China. J. Rock Mech. Geotech. Eng. 2020, 12, 557–570. [Google Scholar] [CrossRef]

- Wasantha, P.; Ranjith, P.; Permata, G.; Bing, D. Damage evolution and deformation behaviour of dry and saturated sandstones: Insights gleaned from optical measurements. Measurement 2018, 130, 8–17. [Google Scholar] [CrossRef]

- Alomari, E.M.; Ng, K.W.; Khatri, L.; Wulff, S.S. Effect of Physical Properties on Mechanical Behaviors of Sandstone under Uniaxial and Triaxial Compressions. Materials 2023, 16, 4867. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Liu, J.; Zhang, C.; Zhang, H.; Liao, J.; Zhu, S.; Zhang, L. Mechanical behavior of sandstone during post-peak cyclic loading and unloading under hydromechanical coupling. Int. J. Min. Sci. Technol. 2023, 33, 927–947. [Google Scholar] [CrossRef]

- Roy, D.G.; Singh, T.N.; Kodikara, J.; Das, R. Effect of water saturation on the fracture and mechanical properties of sedimentary rocks. Rock Mech. Rock Eng. 2017, 50, 2585–2600. [Google Scholar] [CrossRef]

- Ping, Q.; Gao, Q.; Wang, C. Mechanical test study on thermo-water coupled dynamic splitting of annular sandstone specimens with different inner diameters. J. Vib. Shock. 2023, 42, 43–51+152. [Google Scholar] [CrossRef]

- Yan, M.H. Physical and Mechanical Properties of Thermal-Liquid-Stress Coupled Granite. Master’s Thesis, Hebei University, Baoding, China, 2020. [Google Scholar] [CrossRef]

- Yang, F.; Wang, G.; Hu, D.; Zhou, H.; Tan, X. Influence of water-rock interaction on permeability and heat conductivity of granite under high temperature and pressure conditions. Geothermics 2022, 100, 102347. [Google Scholar] [CrossRef]

- Wang, C.; Hu, M.G.; Wang, C. Dynamic damage characteristics and structural model of concentric perforated granite subjected to thermal-hydro-mechanical coupling. Rock Soil Mech. 2023, 44, 741–756. [Google Scholar]

- Zheng, C.; Yao, Q.; Li, X.; Hudson-Edwards, K.; Shan, C.; Shang, X.; Li, Y. Experimental investigation of mechanical characteristics of coal samples at different drying temperatures. Dry. Technol. 2022, 40, 3483–3495. [Google Scholar] [CrossRef]

- DZ/T0276.18-2015; Regulation for Testing the Physical and Mechanical Properties of Rock. Part 18: Test for Determing the Uniaxial Compressive Strength of Rock. Available online: https://www.chinesestandard.net/PDF/English.aspx/DZT0276.18-2015 (accessed on 18 December 2024).

- JTG 3370.1-2018; Specifications for Design of Highway Tunnels Section 1 Civil Engineering. Available online: https://www.codeofchina.com/standard/JTG3370.1-2018.html (accessed on 18 December 2024).

- Fang, J.; Yao, Q.L.; Wang, W.N.; Tang, C.J.; Wang, G. Experimental study on damage characteristics of siltstone under water action. J. China Coal Soc. 2018, 43, 412–419. [Google Scholar] [CrossRef]

- Yu, C.; Tang, S.; Tang, C.; Duan, D.; Zhang, Y.; Liang, Z.; Ma, K.; Ma, T. The effect of water on the creep behavior of red sandstone. Eng. Geol. 2019, 253, 64–74. [Google Scholar] [CrossRef]

- Xu, Y.; Xiao, J.; Li, X.; Xia, K.; Peng, J. Experimental study on the permeability evolution of argillaceous sandstone under elevated temperatures. Eng. Geol. 2023, 313, 106974. [Google Scholar] [CrossRef]

- Wang, F.; Cao, P.; Cao, R.-H.; Xiong, X.-G.; Hao, J. The influence of temperature and time on water-rock interactions based on the morphology of rock joint surfaces. Bull. Eng. Geol. Environ. 2019, 78, 3385–3394. [Google Scholar] [CrossRef]

- Shkuratnik, V.L.; Kravchenko, O.S.; Filimonov, Y.L. Acoustic emission of rock salt at different uniaxial strain rates and under temperature. J. Appl. Mech. Tech. Phys. 2020, 61, 479–485. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Pan, Z.L.; Zhang, F.M.; Pan, X.L.; Zhang, F.M.; Luo, Y. Experimental study on triaxial mechanics and permeability characteristics of sandstone on the roof of the closed Sanhejian Coal Mine. J. Min. Saf. Eng. 2024, 41, 1267–1278. [Google Scholar] [CrossRef]

- Hao, J.W.; Li, Q.W.; Qiao, L.; Deng, N.F. Study on pore fractal characteristics and rock constitutive model of sandstoneafter high temperature. J. Huazhong Univ. Sci. Technol. (Nat. Sci.Ed.) 2024, 52, 142–148. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, F. Experimental investigation on the energy evolution of dry and water-saturated red sandstones. Int. J. Min. Sci. Technol. 2015, 25, 383–388. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Shi, Z.; Chen, J. Energy evolution and failure characteristics of red sandstone under discontinuous multilevel fatigue loading. Int. J. Fatigue 2022, 160, 106830. [Google Scholar] [CrossRef]

- Yaqian, D.A.; Yamin, W.U.; Tuanjie, W.A.; Xiuli, C.U.; Dingqian, A.N. Energy and Damage Evolution Characteristics of Rock Materialsunder Different Water Contents. Chin. J. High Press. Phys. 2023, 37, 62–71. [Google Scholar] [CrossRef]

- Liu, D.; Guo, Y.; Li, J.; Ling, K.; Ge, J. Experimental study on damage and failure energy evolution of brittle rocks under uniaxial compression. J. Eng. Geol. 2023, 31, 843–853. [Google Scholar] [CrossRef]

- Wang, J.; Liang, P.; Zhang, Y.B.; Yao, X.L.; Yu, G.Y.; Guo, B. Research on classification of rock tensile-shear fracture based on acousticemission R4-4F values and kneedle algorithm. Chin. J. Rock Mech. Eng. 2024, 43, 3267–3279. [Google Scholar]

- Wu, X.H.; Li, P.; Guo, Q.F.; Cai, M.F.; Ren, F.H.; Zhang, J. Research progress on the evolution of physical and mechanical properties of thermally damaged rock. Chin. J. Eng. 2022, 44, 827–839. [Google Scholar] [CrossRef]

- Luo, J.; Xiong, J.; Zhu, M.; Liu, X.; Zheng, C.; Wu, Y.; Zhou, Y. Experimental study on the influence of temperature on rock physical properties:taking sandstone of Xujiahe formation and shale of Longmaxi formation in Sichuan basin as examples. Prog. Geophys. 2023, 38, 2080–2093. [Google Scholar] [CrossRef]

- Liu, X.J.; Gao, H.; Liang, L.X. Study of temperature and confining pressure effects on porosity and permeability in low permeability sandstone. Chin. J. Rock Mech. Eng. 2011, 30, 3771–3778. [Google Scholar]

- Amro, M.M.; Benzagouta, M.S. Effect of pressure and temperature on petrophysical characteristics in the case of carbonate reservoirs. Oil Gas Eur. Mag. 2009, 35, 74–78. [Google Scholar] [CrossRef]

- Hu, Y.X.; Ye, Z.Y.; Li, S. Shear mechanical properties of rough-walled joints of red sandstone under real-time temperature. J. China Coal Soc. 2024, 1–12. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, S.; Xiao, H. Tribological properties of sliding quartz sand particle and shale rock contact under water and guar gum aqueous solution in hydraulic fracturing. Tribol. Int. 2019, 129, 416–426. [Google Scholar] [CrossRef]

- Chen, Y. Permeability evolution of sandstone under multi-field coupling. J. Cent. South Univ. (Sci.Technol.) 2017, 48, 2449–2457. [Google Scholar]

- Liu, Z.; He, X.; Fan, J.; Zhou, C. Study on the softening mechanism and control of red-bed soft rock under seawater conditions. J. Mar. Sci. Eng. 2019, 7, 235. [Google Scholar] [CrossRef]

- Ding, W.; Tan, S.; Zhu, R.; Jiang, H.; Zhang, Q. Study on the damage process and numerical simulation of tunnel excavation in water-rich soft rock. Appl. Sci. 2021, 11, 8906. [Google Scholar] [CrossRef]

- Sun, X.; Shi, F.; Luan, Z.; Yang, L.; Ding, J.; He, L.; Zhang, Y. Constitutive model and microscopic mechanism for sandstone strength softening damage. Rock Mech. Rock Eng. 2023, 56, 797–813. [Google Scholar] [CrossRef]

- Li, H.; Zhong, Z.; Eshiet, K.I.-I.; Sheng, Y.; Liu, X.; Yang, D. Experimental investigation of the permeability and mechanical behaviours of chemically corroded limestone under different unloading conditions. Rock Mech. Rock Eng. 2020, 53, 1587–1603. [Google Scholar] [CrossRef]

- Peng, T.; Ren, D.; He, F.; Li, B.; Wu, F.; Zhou, H. Study on fatigue characteristics of red sandstone under extremely high stress in the hydro-chemical environment. Front. Earth Sci. 2024, 12, 1453080. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).